ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3221 of 6020

Fuel System – V6 Page 6C – 19

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

1 Remove the fuel pump relay, refer to 8A Electrical Body and Chassis.

2 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

Never drain or store fuel into an open

container, due to the possibility of fire or

explosion.

3 Siphon the fuel tank, using commercially-available equipment.

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

7 Place a drain tray under the fuel filter area.

Fuel can spill from the disconnected filter.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3222 of 6020

Fuel System – V6 Page 6C – 20

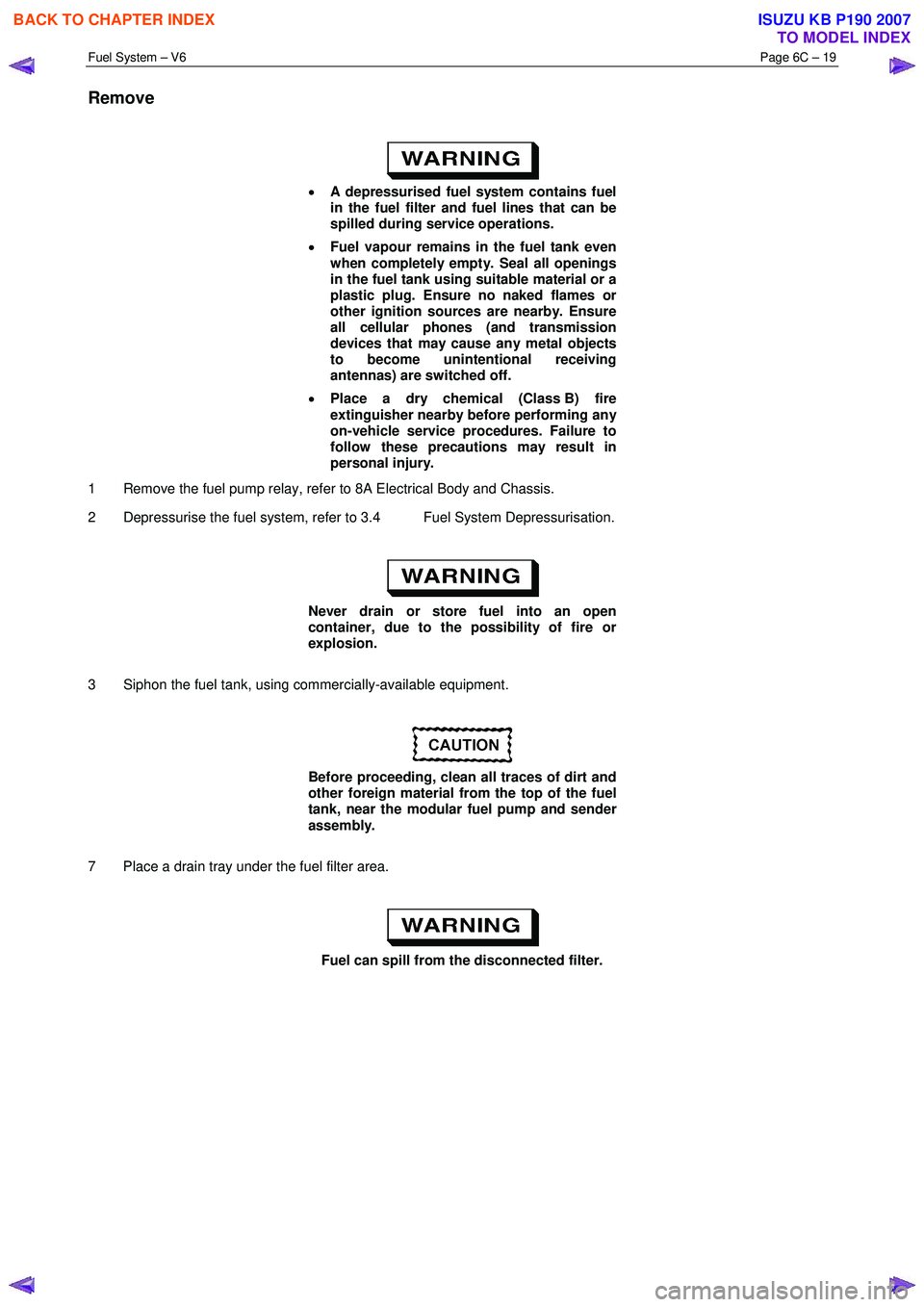

8 From behind the fuel filler door (1), unscrew the fuel

filler cap (4) and cover the end of the fuel filler neck

with a suitable material to prevent foreign objects from

entering the fuel tank.

9 Remove the screw (2) securing the fuel filler neck (3) to the fuel filler pocket.

10 Remove the front half of the right-hand rear wheelhouse liner, refer to 10 Cab.

Fuel filler neck attaching screw

torque specification ..............................................5.0 Nm

Figure 6C – 18

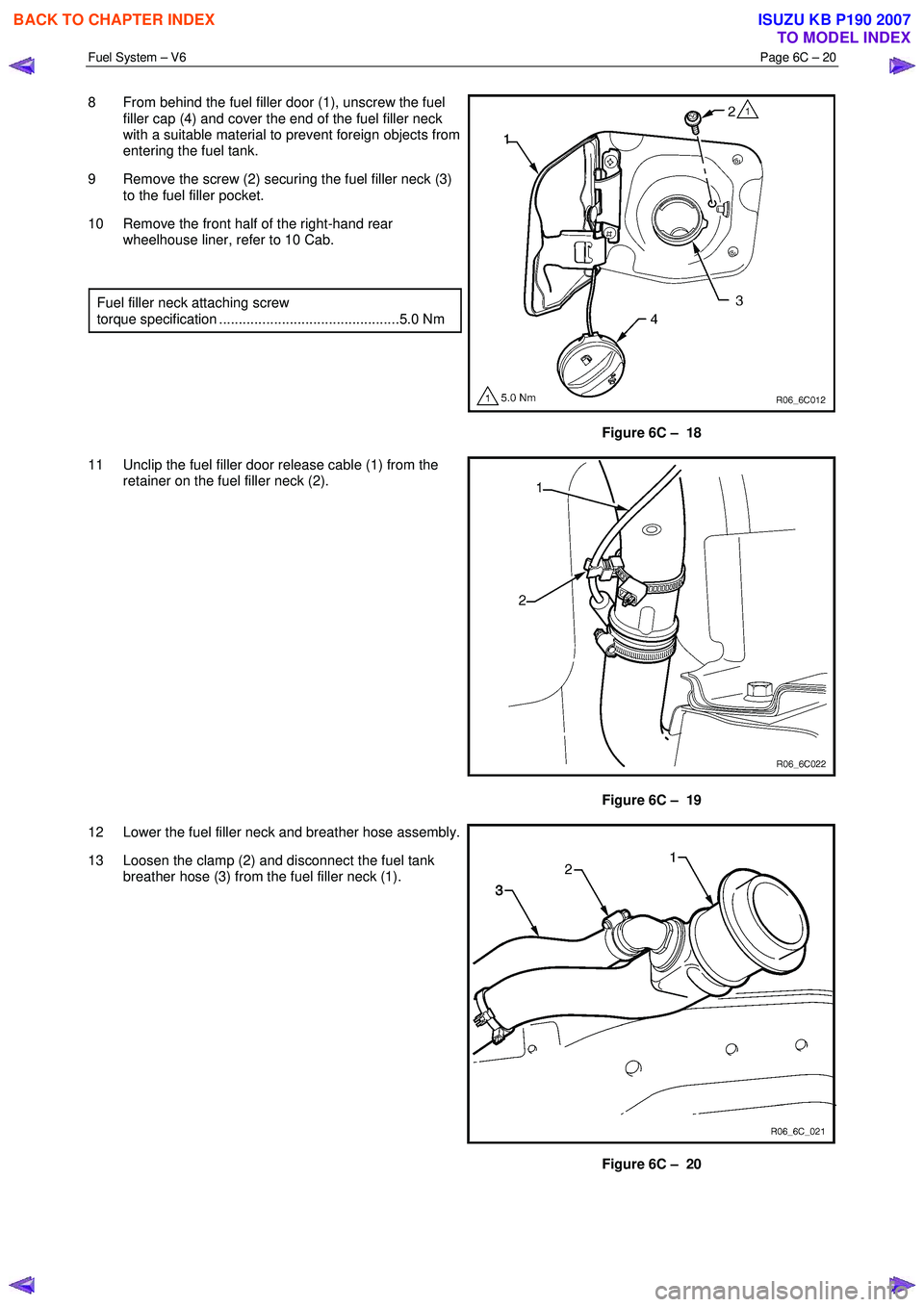

11 Unclip the fuel filler door release cable (1) from the retainer on the fuel filler neck (2).

Figure 6C – 19

12 Lower the fuel filler neck and breather hose assembly.

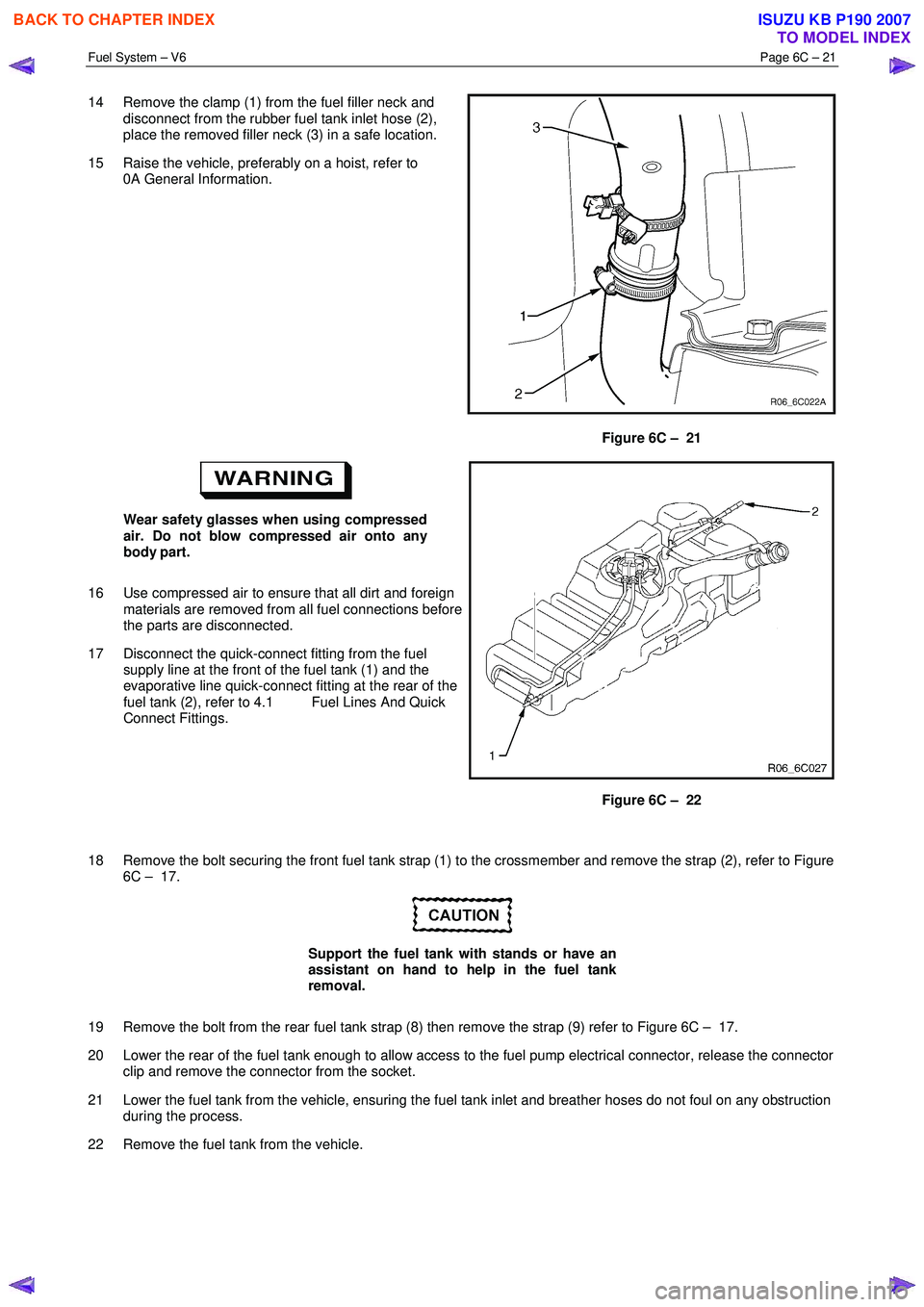

13 Loosen the clamp (2) and disconnect the fuel tank breather hose (3) from the fuel filler neck (1).

Figure 6C – 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3223 of 6020

Fuel System – V6 Page 6C – 21

14 Remove the clamp (1) from the fuel filler neck and

disconnect from the rubber fuel tank inlet hose (2),

place the removed filler neck (3) in a safe location.

15 Raise the vehicle, preferably on a hoist, refer to 0A General Information.

Figure 6C – 21

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

16 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before

the parts are disconnected.

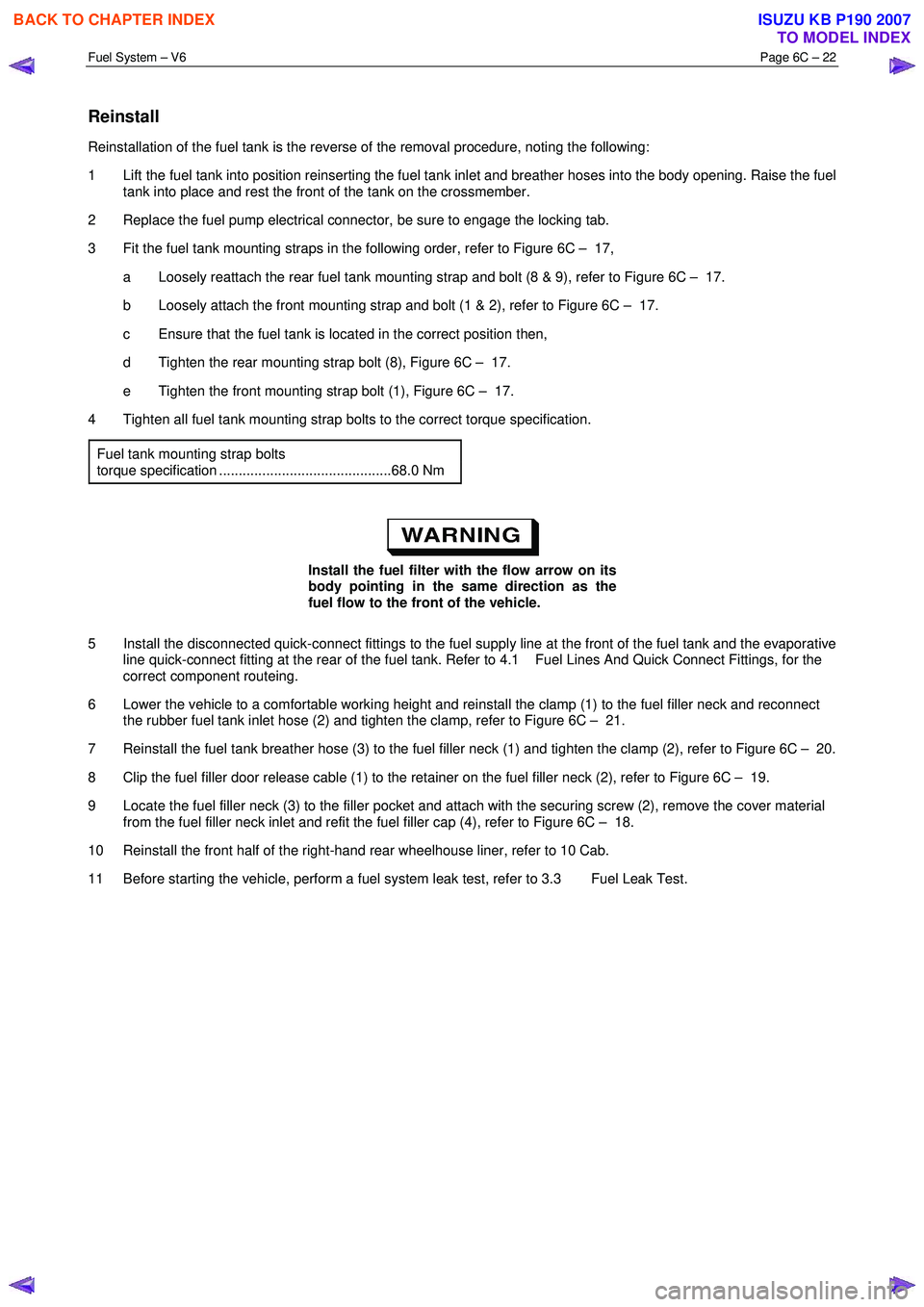

17 Disconnect the quick-connect fitting from the fuel supply line at the front of the fuel tank (1) and the

evaporative line quick-connect fitting at the rear of the

fuel tank (2), refer to 4.1 Fuel Lines And Quick

Connect Fittings.

Figure 6C – 22

18 Remove the bolt securing the front fuel tank strap (1) to the crossmember and remove the strap (2), refer to Figure 6C – 17.

Support the fuel tank with stands or have an

assistant on hand to help in the fuel tank

removal.

19 Remove the bolt from the rear fuel tank strap (8) then remove the strap (9) refer to Figure 6C – 17.

20 Lower the rear of the fuel tank enough to allow access to the fuel pump electrical connector, release the connector clip and remove the connector from the socket.

21 Lower the fuel tank from the vehicle, ensuring the fuel tank inlet and breather hoses do not foul on any obstruction during the process.

22 Remove the fuel tank from the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3224 of 6020

Fuel System – V6 Page 6C – 22

Reinstall

Reinstallation of the fuel tank is the reverse of the removal procedure, noting the following:

1 Lift the fuel tank into position reinserting the fuel tank inlet and breather hoses into the body opening. Raise the fuel tank into place and rest the front of the tank on the crossmember.

2 Replace the fuel pump electrical connector, be sure to engage the locking tab.

3 Fit the fuel tank mounting straps in the following order, refer to Figure 6C – 17, a Loosely reattach the rear fuel tank mounting strap and bolt (8 & 9), refer to Figure 6C – 17.

b Loosely attach the front mounting strap and bolt (1 & 2), refer to Figure 6C – 17.

c Ensure that the fuel tank is located in the correct position then,

d Tighten the rear mounting strap bolt (8), Figure 6C – 17.

e Tighten the front mounting strap bolt (1), Figure 6C – 17.

4 Tighten all fuel tank mounting strap bolts to the correct torque specification.

Fuel tank mounting strap bolts

torque specification ............................................68.0 Nm

Install the fuel filter with the flow arrow on its

body pointing in the same direction as the

fuel flow to the front of the vehicle.

5 Install the disconnected quick-connect fittings to the fuel supply line at the front of the fuel tank and the evaporative line quick-connect fitting at the rear of the fuel tank. Refer to 4.1 Fuel Lines And Quick Connect Fittings, for the

correct component routeing.

6 Lower the vehicle to a comfortable working height and reinstall the clamp (1) to the fuel filler neck and reconnect the rubber fuel tank inlet hose (2) and tighten the clamp, refer to Figure 6C – 21.

7 Reinstall the fuel tank breather hose (3) to the fuel filler neck (1) and tighten the clamp (2), refer to Figure 6C – 20.

8 Clip the fuel filler door release cable (1) to the retainer on the fuel filler neck (2), refer to Figure 6C – 19.

9 Locate the fuel filler neck (3) to the filler pocket and attach with the securing screw (2), remove the cover material from the fuel filler neck inlet and refit the fuel filler cap (4), refer to Figure 6C – 18.

10 Reinstall the front half of the right-hand rear wheelhouse liner, refer to 10 Cab.

11 Before starting the vehicle, perform a fuel system leak test, refer to 3.3 Fuel Leak Test.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3225 of 6020

Fuel System – V6 Page 6C – 23

4.5 Modular Fuel Pump and Sender

Assembly

NOTE

If the modular fuel pump and sender assembly

develops a fault it must be replaced as a

complete unit. The only serviced parts are the

retainer locking ring and the O-ring seal.

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

• Wear safety glasses when using

compressed air. Do not blow compressed

air directly onto any body part.

1 Remove the fuel pump relay, refer to 8A Engine Body and Chassis.

2 Remove the fuel tank assembly from the vehicle, refer to 4.4 Fuel Tank.

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

3 Use compressed air to ensure all dirt and foreign materials are removed from all fuel connections before disconnecting the parts.

Fuel can spill from the disconnected modular

fuel pump and sender assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3226 of 6020

Fuel System – V6 Page 6C – 24

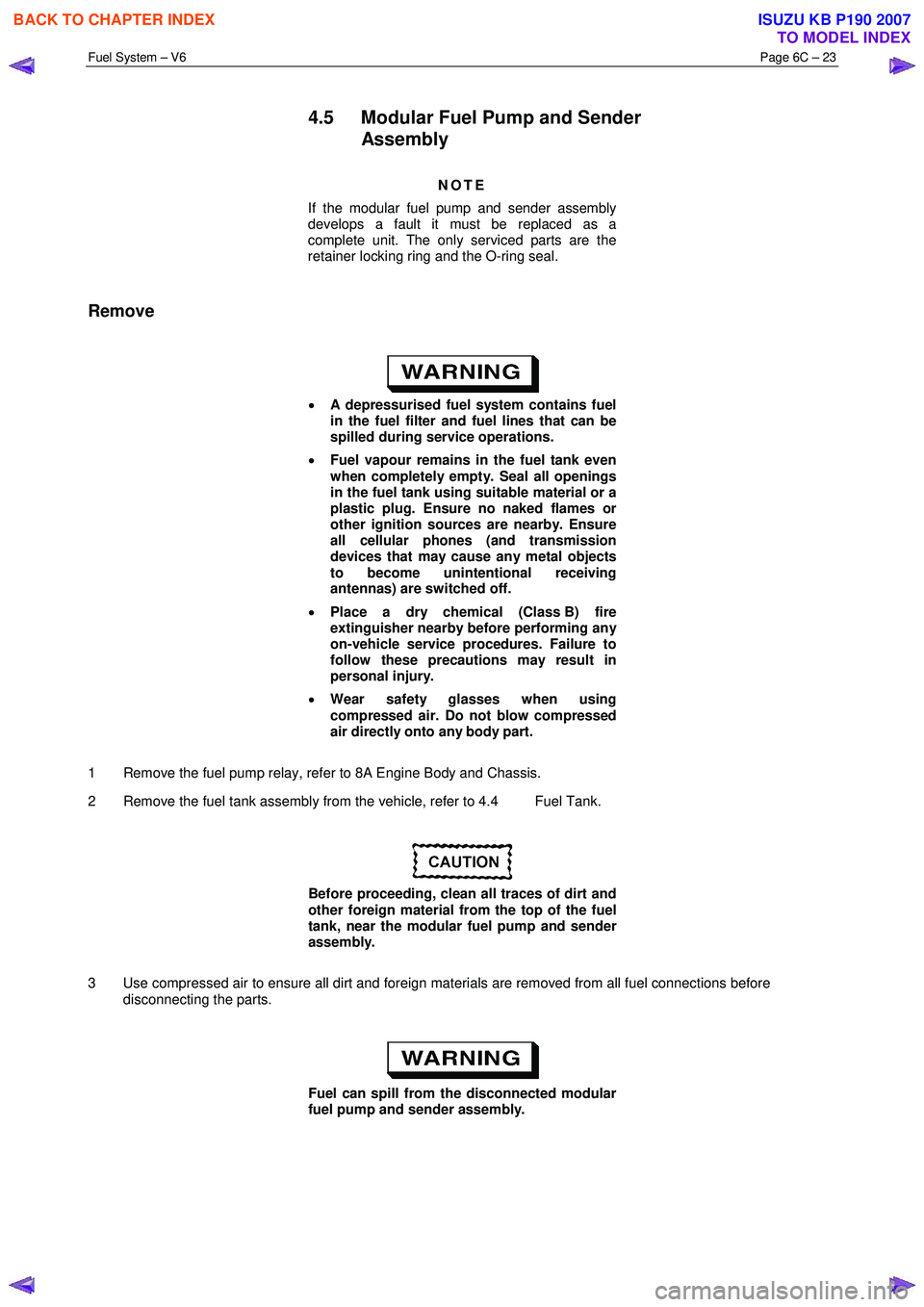

4 Tag the fuel feed line connecting the fuel feed port (1)

on the modular fuel pump and sender assembly cover.

5 Tag the fuel return port (2) on the modular fuel pump and sender assembly cover.

6 Tag the evaporative line on the modular fuel pump and sender assembly cover (3).

Figure 6C – 23

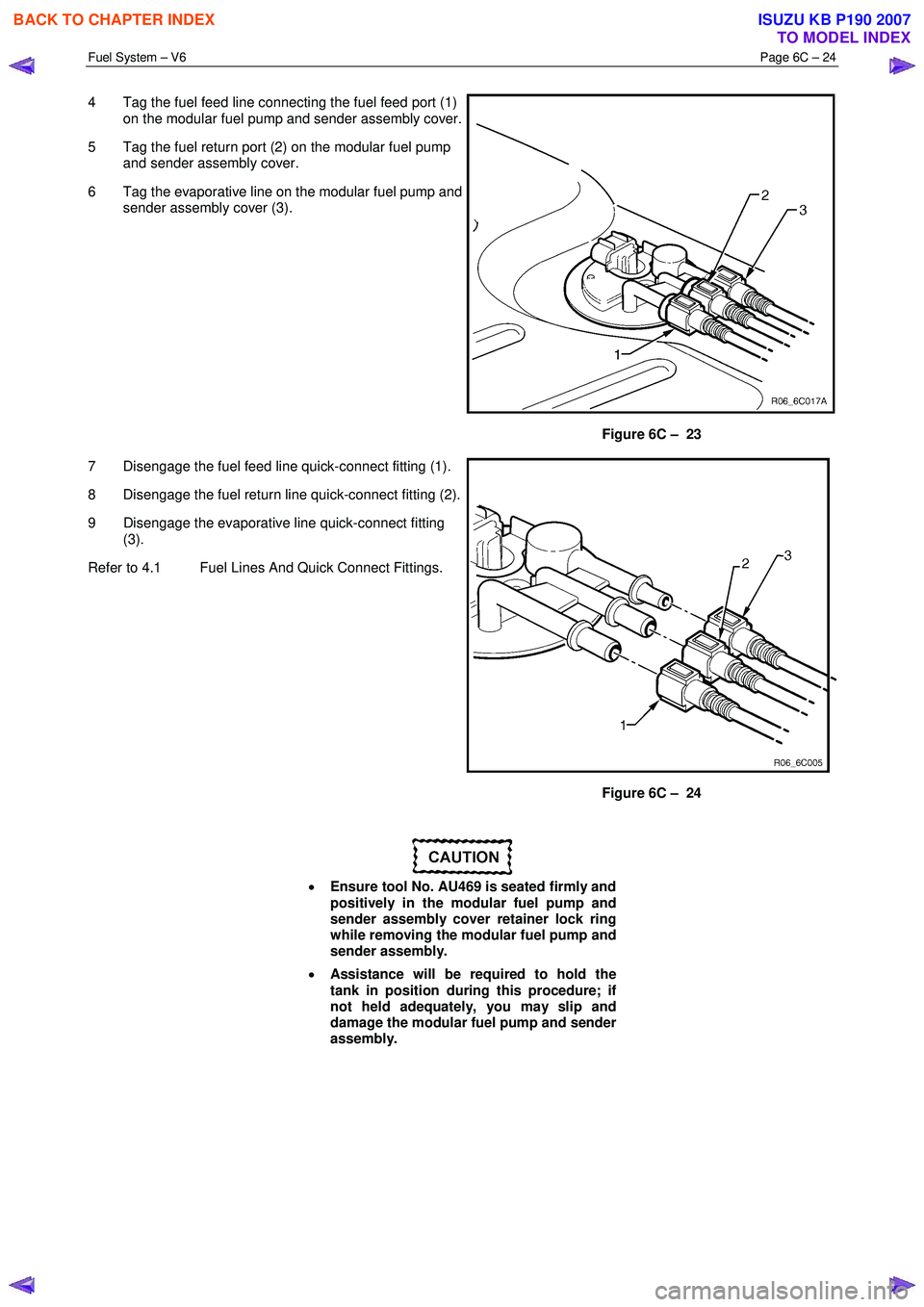

7 Disengage the fuel feed line quick-connect fitting (1).

8 Disengage the fuel return line quick-connect fitting (2).

9 Disengage the evaporative line quick-connect fitting (3).

Refer to 4.1 Fuel Lines And Quick Connect Fittings.

Figure 6C – 24

• Ensure tool No. AU469 is seated firmly and

positively in the modular fuel pump and

sender assembly cover retainer lock ring

while removing the modular fuel pump and

sender assembly.

• Assistance will be required to hold the

tank in position during this procedure; if

not held adequately, you may slip and

damage the modular fuel pump and sender

assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3227 of 6020

Fuel System – V6 Page 6C – 25

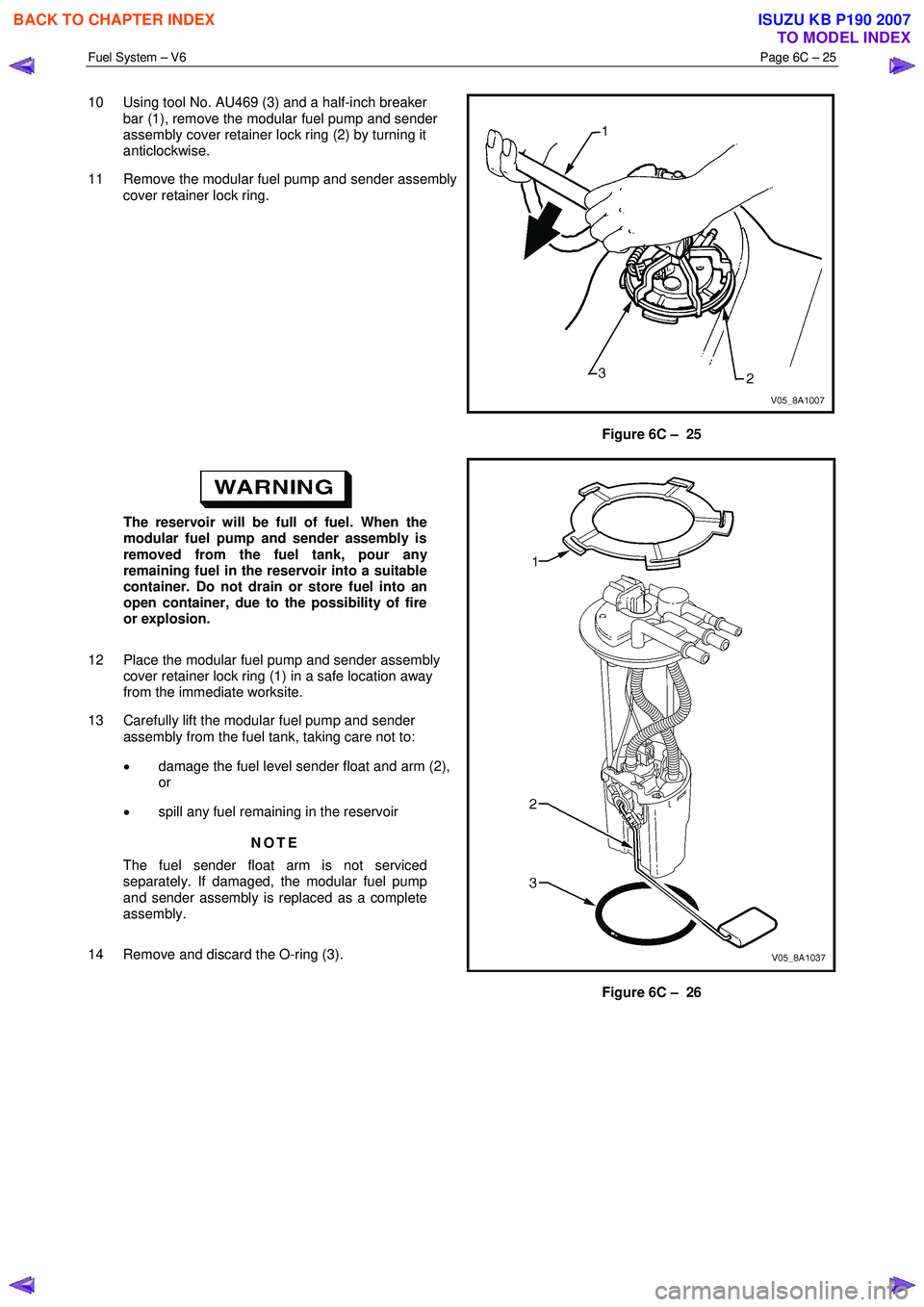

10 Using tool No. AU469 (3) and a half-inch breaker

bar (1), remove the modular fuel pump and sender

assembly cover retainer lock ring (2) by turning it

anticlockwise.

11 Remove the modular fuel pump and sender assembly cover retainer lock ring.

Figure 6C – 25

The reservoir will be full of fuel. When the

modular fuel pump and sender assembly is

removed from the fuel tank, pour any

remaining fuel in the reservoir into a suitable

container. Do not drain or store fuel into an

open container, due to the possibility of fire

or explosion.

12 Place the modular fuel pump and sender assembly cover retainer lock ring (1) in a safe location away

from the immediate worksite.

13 Carefully lift the modular fuel pump and sender assembly from the fuel tank, taking care not to:

• damage the fuel level sender float and arm (2),

or

• spill any fuel remaining in the reservoir

NOTE

The fuel sender float arm is not serviced

separately. If damaged, the modular fuel pump

and sender assembly is replaced as a complete

assembly.

14 Remove and discard the O-ring (3).

Figure 6C – 26

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3228 of 6020

Fuel System – V6 Page 6C – 26

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

15 Place a suitable material over the opening in the fuel tank to prevent any foreign matter from entering the fuel system.

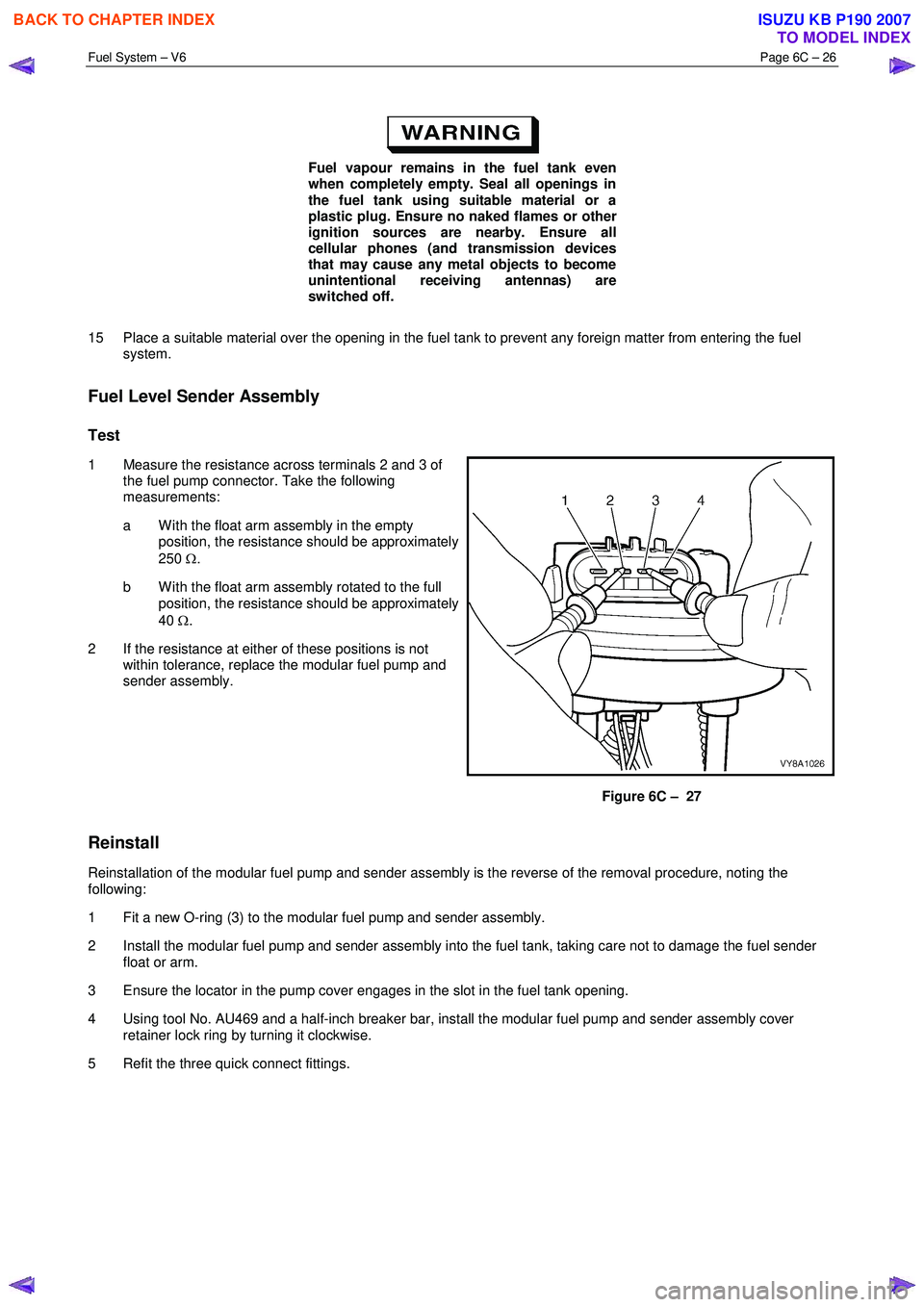

Fuel Level Sender Assembly

Test

1 Measure the resistance across terminals 2 and 3 of the fuel pump connector. Take the following

measurements:

a W ith the float arm assembly in the empty position, the resistance should be approximately

250 Ω.

b W ith the float arm assembly rotated to the full position, the resistance should be approximately

40 Ω.

2 If the resistance at either of these positions is not within tolerance, replace the modular fuel pump and

sender assembly.

Figure 6C – 27

Reinstall

Reinstallation of the modular fuel pump and sender assembly is the reverse of the removal procedure, noting the

following:

1 Fit a new O-ring (3) to the modular fuel pump and sender assembly.

2 Install the modular fuel pump and sender assembly into the fuel tank, taking care not to damage the fuel sender float or arm.

3 Ensure the locator in the pump cover engages in the slot in the fuel tank opening.

4 Using tool No. AU469 and a half-inch breaker bar, install the modular fuel pump and sender assembly cover retainer lock ring by turning it clockwise.

5 Refit the three quick connect fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3229 of 6020

Fuel System – V6 Page 6C – 27

4.6 Evaporative Emission Control Canister

Remove

1 Raise the vehicle on a hoist to give access to the evaporative emission control canister, located above the spare

wheel , refer to 0A General Information.

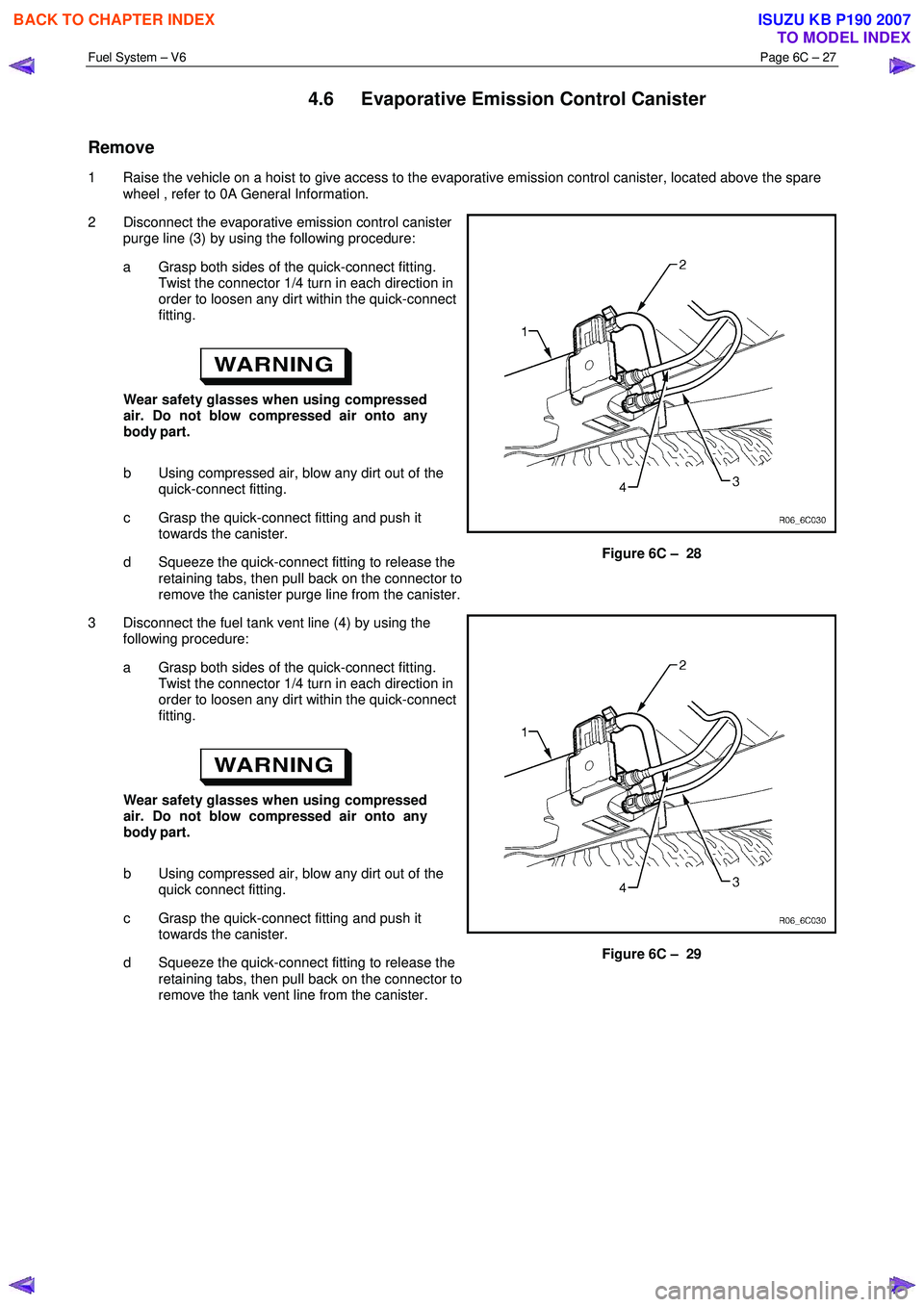

2 Disconnect the evaporative emission control canister purge line (3) by using the following procedure:

a Grasp both sides of the quick-connect fitting. Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b Using compressed air, blow any dirt out of the quick-connect fitting.

c Grasp the quick-connect fitting and push it towards the canister.

d Squeeze the quick-connect fitting to release the retaining tabs, then pull back on the connector to

remove the canister purge line from the canister.

Figure 6C – 28

3 Disconnect the fuel tank vent line (4) by using the following procedure:

a Grasp both sides of the quick-connect fitting. Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b Using compressed air, blow any dirt out of the quick connect fitting.

c Grasp the quick-connect fitting and push it towards the canister.

d Squeeze the quick-connect fitting to release the retaining tabs, then pull back on the connector to

remove the tank vent line from the canister.

Figure 6C – 29

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3230 of 6020

Fuel System – V6 Page 6C – 28

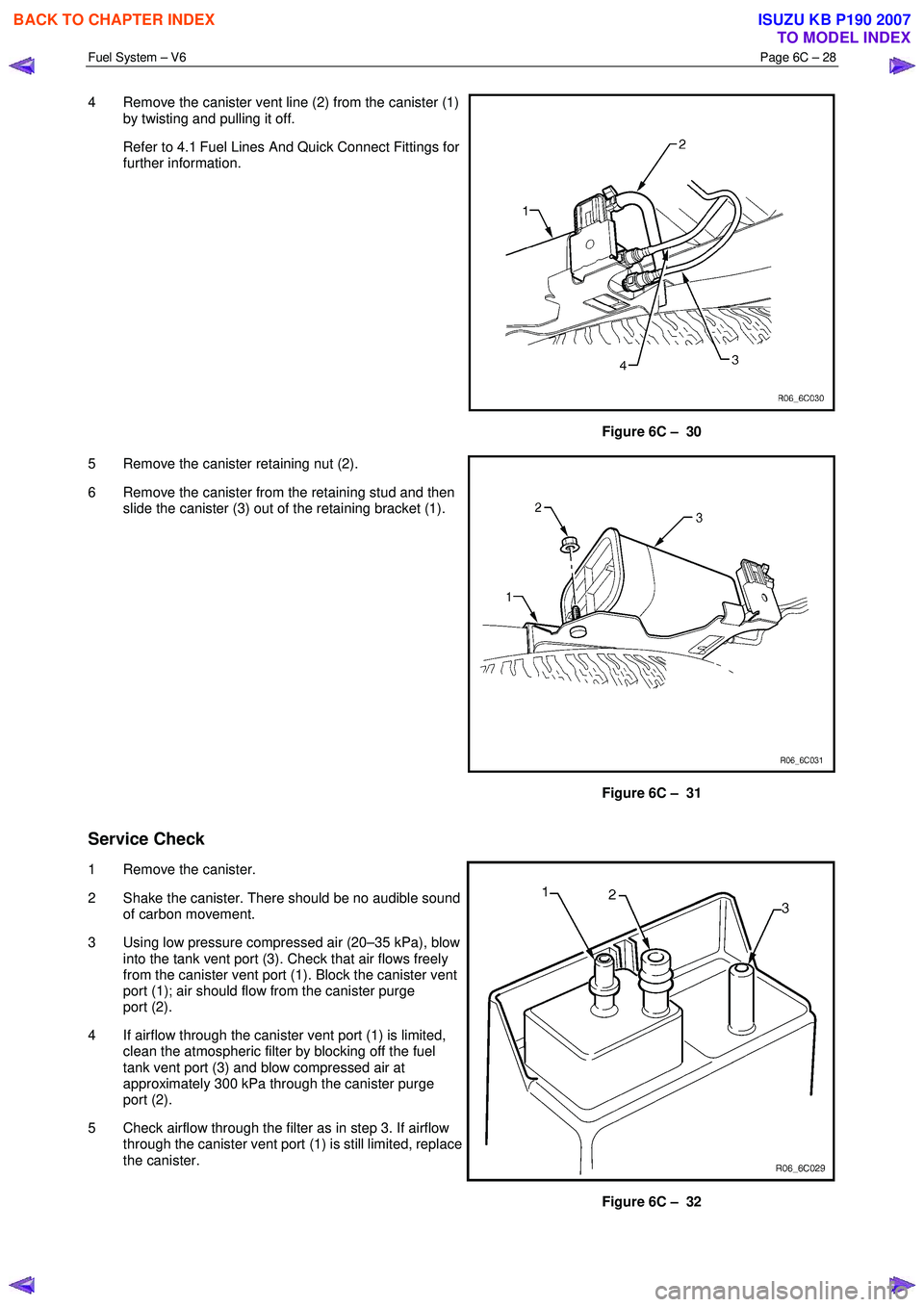

4 Remove the canister vent line (2) from the canister (1)

by twisting and pulling it off.

Refer to 4.1 Fuel Lines And Quick Connect Fittings for further information.

Figure 6C – 30

5 Remove the canister retaining nut (2).

6 Remove the canister from the retaining stud and then slide the canister (3) out of the retaining bracket (1).

Figure 6C – 31

Service Check

1 Remove the canister.

2 Shake the canister. There should be no audible sound of carbon movement.

3 Using low pressure compressed air (20–35 kPa), blow into the tank vent port (3). Check that air flows freely

from the canister vent port (1). Block the canister vent

port (1); air should flow from the canister purge

port (2).

4 If airflow through the canister vent port (1) is limited, clean the atmospheric filter by blocking off the fuel

tank vent port (3) and blow compressed air at

approximately 300 kPa through the canister purge

port (2).

5 Check airflow through the filter as in step 3. If airflow through the canister vent port (1) is still limited, replace

the canister.

Figure 6C – 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007