ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4301 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-17

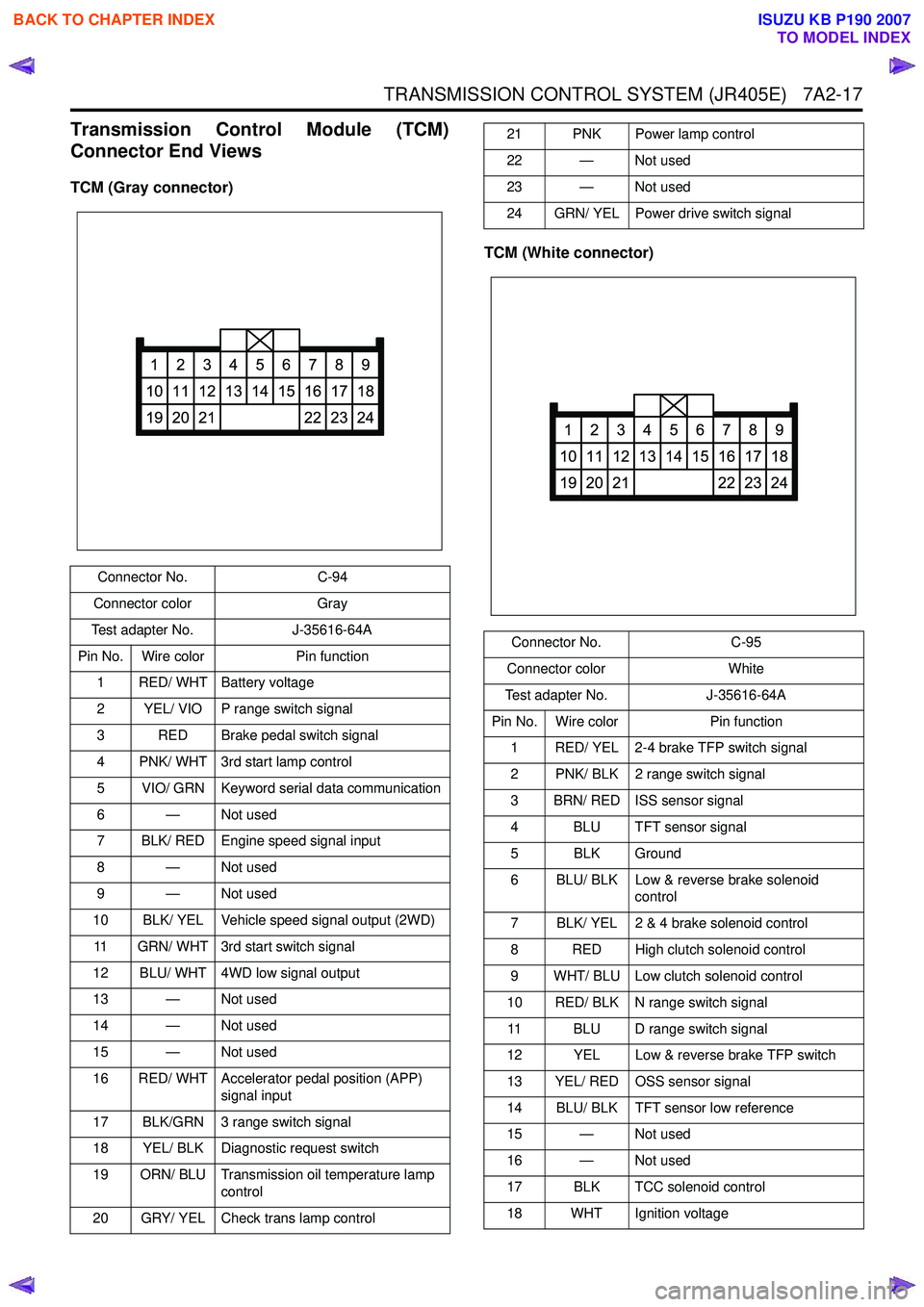

Transmission Control Module (TCM)

Connector End Views

TCM (Gray connector)

TCM (White connector)

Connector No.C-94

Connector color Gray

Test adapter No. J-35616-64A

Pin No. Wire color Pin function

1 RED/ WHT Battery voltage

2 YEL/ VIO P range switch signal

3 RED Brake pedal switch signal

4 PNK/ WHT 3rd start lamp control

5 VIO/ GRN Keyword serial data communication

6 — Not used

7 BLK/ RED Engine speed signal input

8 — Not used

9 — Not used

10 BLK/ YEL Vehicle speed signal output (2WD)

11 GRN/ WHT 3rd start switch signal

12 BLU/ WHT 4WD low signal output

13 — Not used

14 — Not used

15 — Not used

16 RED/ WHT Accelerator pedal position (APP) signal input

17 BLK/GRN 3 range switch signal

18 YEL/ BLK Diagnostic request switch

19 ORN/ BLU Transmission oil temperature lamp control

20 GRY/ YEL Check trans lamp control

1

10

19

2

11

20

3

12

21

4

13

5

14

6

15

7

16

22

8

17

23

9

18

24

21 PNK Power lamp control

22 — Not used

23 — Not used

24 GRN/ YEL Power drive switch signal

Connector No. C-95

Connector color White

Test adapter No. J-35616-64A

Pin No. Wire color Pin function

1 RED/ YEL 2-4 brake TFP switch signal

2 PNK/ BLK 2 range switch signal

3 BRN/ RED ISS sensor signal

4 BLU TFT sensor signal

5 BLK Ground

6 BLU/ BLK Low & reverse brake solenoid control

7 BLK/ YEL 2 & 4 brake solenoid control

8 RED High clutch solenoid control

9 WHT/ BLU Low clutch solenoid control

10 RED/ BLK N range switch signal 11 BLU D range switch signal

12 YEL Low & reverse brake TFP switch

13 YEL/ RED OSS sensor signal

14 BLU/ BLK TFT sensor low reference

15 — Not used

16 — Not used

17 BLK TCC solenoid control

18 WHT Ignition voltage

1

10

19

2

11

20

3

12

21

4

13

5

14

6

15

7

16

22

8

17

23

9

18

24

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4302 of 6020

7A2-18 TRANSMISSION CONTROL SYSTEM (JR405E)

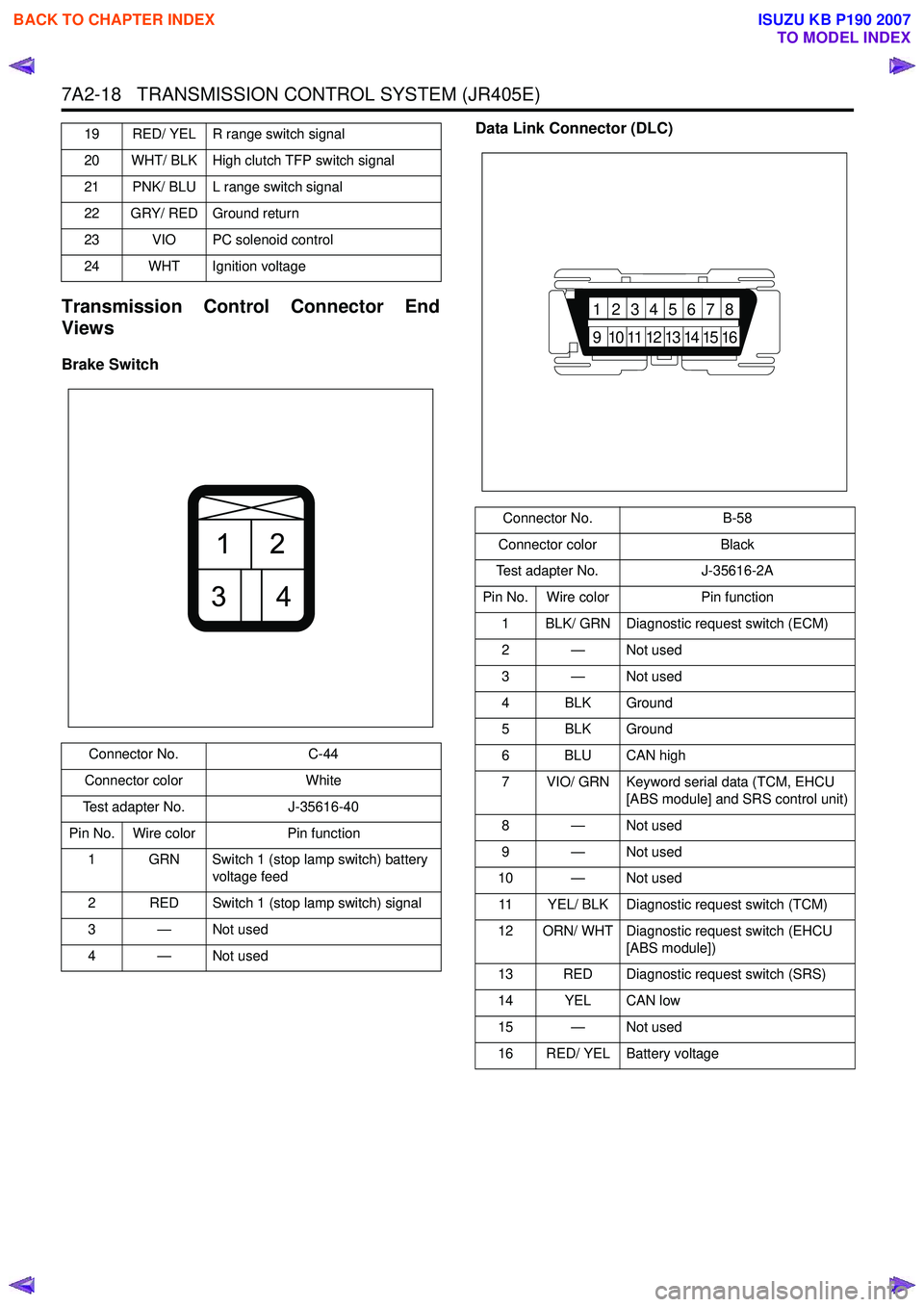

Transmission Control Connector End

Views

Brake Switch Data Link Connector (DLC)

19 RED/ YEL R range switch signal

20 WHT/ BLK High clutch TFP switch signal

21 PNK/ BLU L range switch signal

22 GRY/ RED Ground return

23 VIO PC solenoid control

24 WHT Ignition voltage

Connector No. C-44

Connector color White

Test adapter No. J-35616-40

Pin No. Wire color Pin function

1 GRN Switch 1 (stop lamp switch) battery voltage feed

2 RED Switch 1 (stop lamp switch) signal

3—Not used

4—Not used

21

34

Connector No. B-58

Connector color Black

Test adapter No. J-35616-2A

Pin No. Wire color Pin function

1 BLK/ GRN Diagnostic request switch (ECM)

2 — Not used

3 — Not used

4 BLK Ground

5 BLK Ground

6 BLU CAN high

7 VIO/ GRN Keyword serial data (TCM, EHCU [ABS module] and SRS control unit)

8 — Not used

9 — Not used

10 — Not used

11 YEL/ BLK Diagnostic request switch (TCM)

12 ORN/ WHT Diagnostic request switch (EHCU [ABS module])

13 RED Diagnostic request switch (SRS)

14 YEL CAN low

15 — Not used

16 RED/ YEL Battery voltage

87654321

16151413121110

9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4303 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-19

Input Shaft Speed (ISS) Sensor

Output Shaft Speed (OSS) Sensor Power Drive/ 3rd Start Switch

Connector No.

E-31

Connector color Gray

Test adapter No. J-35616-

Pin No. Wire color Pin function 1 BRN/ RED Sensor signal

2 WHT Sensor ignition voltage feed

3 BLK Sensor low reference

Connector No. E-30

Connector color Gray

Test adapter No. J-35616-

Pin No. Wire color Pin function

1 YEL/ RED Sensor signal

12

3

123

2 WHT Sensor ignition voltage feed

3 BLK Sensor low reference

Connector No. B-50

Connector color White

Test adapter No. J-35616-33

Pin No. Wire color Pin function

1 GRN/ RED Illumination lamp voltage feed

2 RED/ GRN (TF) or

BLK (UC) Illumination lamp ground

3 GRN/ YEL Power drive switch signal

4 — Not used

5 GRN/ WHT 3rd start switch signal

6 BLK Switch ground

1

345

2

6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4304 of 6020

7A2-20 TRANSMISSION CONTROL SYSTEM (JR405E)

Transmission In-line Harness ConnectorTransmission Range (TR) Switch

Connector No.E-54

Connector color Black

Test adapter No. J-35616-64A

Pin No. Wire color Pin function

1 WHT/ BLK High clutch TFP switch signal

2 BLU TFT sensor signal

3 WHT/ BLU Low clutch solenoid control (PWM)

4 BLK TCC solenoid control (PWM)

5 BLU/ BLK Low & reverse brake solenoid control (PWM)

6 VIO PC solenoid control

7 RED/ YEL 2-4 brake TFP switch signal

8 BLU/ BLK TFT sensor low reference

9 BLK/ YEL 2-4 brake solenoid control (PWM)

10 RED High clutch solenoid control (PWM)

11 GRY/ RED Ground return

12 YEL Low & reverse brake TFP switch signal

RTW77ASH004001

123456

789101112

Connector No. E-51

Connector color Black

Test adapter No. J-35616-64A (pin 1 - 6) J35616-33 (pin 7 - 10)

Pin No. Wire color Pin function

1 BLK/GRN 3 range switch signal

2 YEL/ VIO P range switch signal

3 WHT Ignition voltage feed

4 RED/ YEL R range switch signal

5 BLU D range switch signal

6 PNK/ BLU L range switch signal

7 BLK/ WHT P or N range start switch signal

8 RED/ BLK N range switch signal

9 PNK/ BLK 2 range switch signal

10 BLK P or N range start switch ground

RTW77ASH004101

123456

78910

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4305 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-21

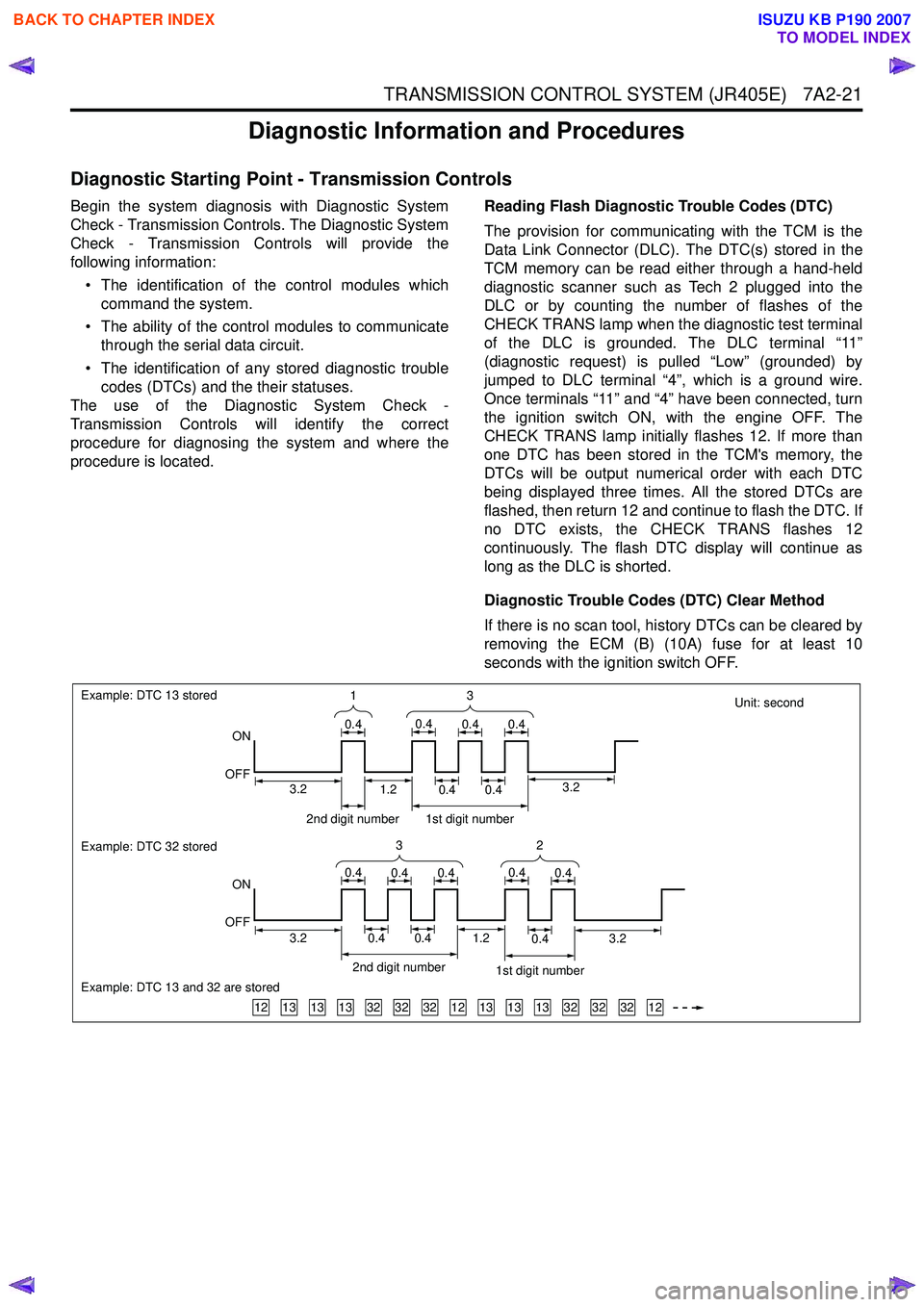

Diagnostic Information and Procedures

Diagnostic Starting Point - Transmission Controls

Begin the system diagnosis with Diagnostic System

Check - Transmission Controls. The Diagnostic System

Check - Transmission Controls will provide the

following information:

• The identification of the control modules which command the system.

• The ability of the control modules to communicate through the serial data circuit.

• The identification of any stored diagnostic trouble codes (DTCs) and the their statuses.

The use of the Diagnostic System Check -

Transmission Controls will identify the correct

procedure for diagnosing the system and where the

procedure is located. Reading Flash Diagnostic Trouble Codes (DTC)

The provision for communicating with the TCM is the

Data Link Connector (DLC). The DTC(s) stored in the

TCM memory can be read either through a hand-held

diagnostic scanner such as Tech 2 plugged into the

DLC or by counting the number of flashes of the

CHECK TRANS lamp when the diagnostic test terminal

of the DLC is grounded. The DLC terminal “11”

(diagnostic request) is pulled “Low” (grounded) by

jumped to DLC terminal “4”, which is a ground wire.

Once terminals “11” and “4” have been connected, turn

the ignition switch ON, with the engine OFF. The

CHECK TRANS lamp initially flashes 12. If more than

one DTC has been stored in the TCM's memory, the

DTCs will be output numerical order with each DTC

being displayed three times. All the stored DTCs are

flashed, then return 12 and continue to flash the DTC. If

no DTC exists, the CHECK TRANS flashes 12

continuously. The flash DTC display will continue as

long as the DLC is shorted.

Diagnostic Trouble Codes (DTC) Clear Method

If there is no scan tool, history DTCs can be cleared by

removing the ECM (B) (10A) fuse for at least 10

seconds with the ignition switch OFF.

Unit: second

131313323232121313133232321212

Example: DTC 13 stored

ON

OFF

Example: DTC 32 stored

Example: DTC 13 and 32 are stored

ON

OFF 3

1

0.40.40.40.4

32

0.40.40.40.40.4

2nd digit number1st digit number

3.23.20.40.40.41.2

2nd digit number 1st digit number

0.40.41.23.23.2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4306 of 6020

7A2-22 TRANSMISSION CONTROL SYSTEM (JR405E)

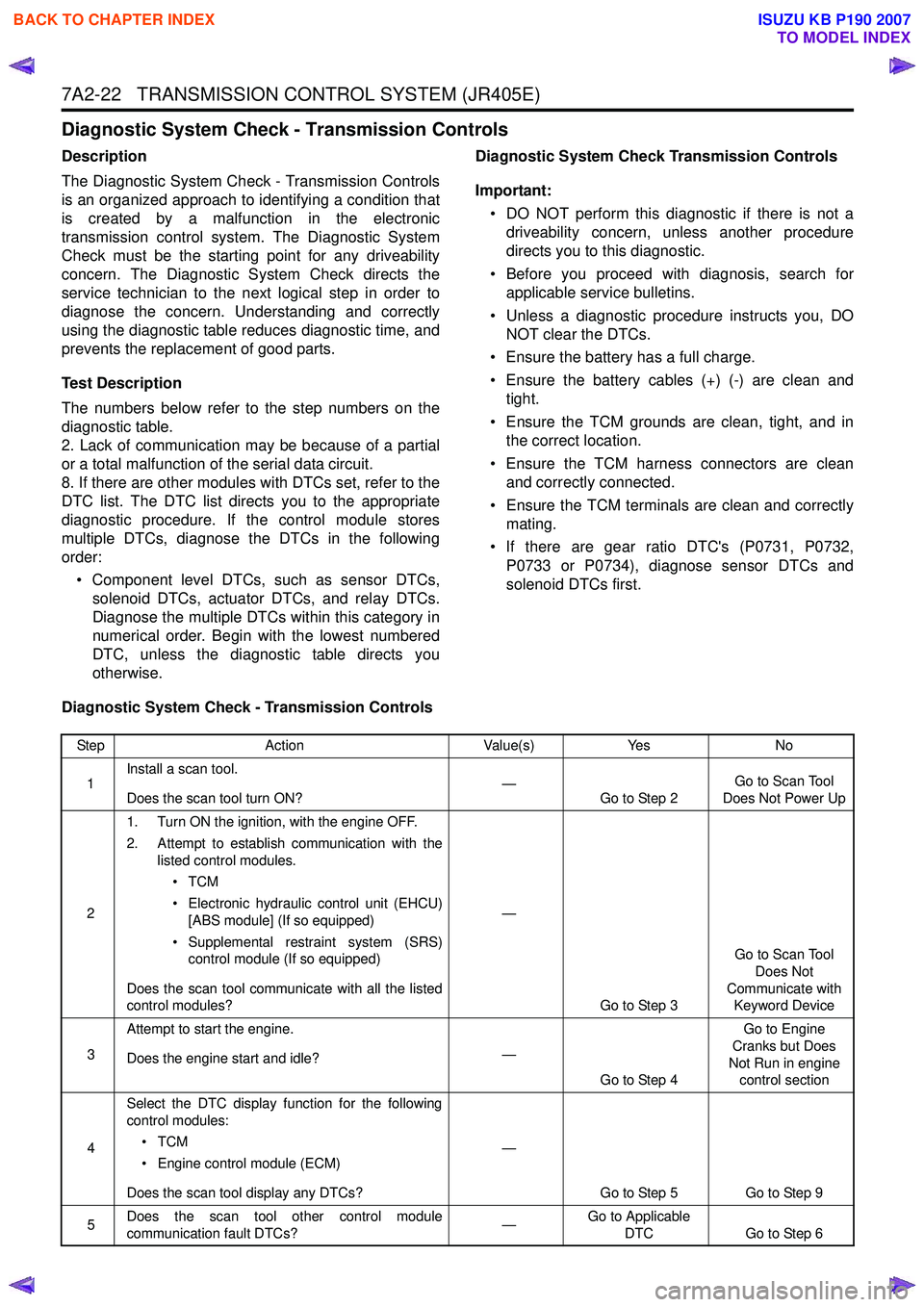

Diagnostic System Check - Transmission Controls

Description

The Diagnostic System Check - Transmission Controls

is an organized approach to identifying a condition that

is created by a malfunction in the electronic

transmission control system. The Diagnostic System

Check must be the starting point for any driveability

concern. The Diagnostic System Check directs the

service technician to the next logical step in order to

diagnose the concern. Understanding and correctly

using the diagnostic table reduces diagnostic time, and

prevents the replacement of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

8. If there are other modules with DTCs set, refer to the

DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

• Component level DTCs, such as sensor DTCs, solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise. Diagnostic System Check Transmission Controls

Important: • DO NOT perform this diagnostic if there is not a driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the TCM grounds are clean, tight, and in the correct location.

• Ensure the TCM harness connectors are clean and correctly connected.

• Ensure the TCM terminals are clean and correctly mating.

• If there are gear ratio DTC's (P0731, P0732, P0733 or P0734), diagnose sensor DTCs and

solenoid DTCs first.

Diagnostic System Check - Transmission Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•TCM

• Electronic hydraulic control unit (EHCU) [ABS module] (If so equipped)

• Supplemental restraint system (SRS) control module (If so equipped)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with Keyword Device

3 Attempt to start the engine.

Does the engine start and idle? —

Go to Step 4 Go to Engine

Cranks but Does

Not Run in engine control section

4 Select the DTC display function for the following

control modules:

•TCM

• Engine control module (ECM)

Does the scan tool display any DTCs? —

Go to Step 5 Go to Step 9

5 Does the scan tool other control module

communication fault DTCs? —Go to Applicable

DTC Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4307 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-23

6Does the scan tool display TCM DTC P0602?

—Go to Applicable

DTC Go to Step 7

7 Does the scan tool display TCM DTC P0560?

—Go to Applicable

DTC Go to Step 8

8 Is there any other code in any controller that has

not been diagnosed? —

Go to Applicable

DTC Go to Step 9

9 Is the customer's concern with the engine system?

—Go to Diagnostic

System Check -

Engine Controls Go to Step 10

10 Drive vehicle and verify if any engine or

transmission related driveability concern exist.

Does an engine or transmission driveability

concern exist? —Go to Symptoms -

Engine Controls in

engine control section or

Symptoms

Transmission Controls System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4308 of 6020

7A2-24 TRANSMISSION CONTROL SYSTEM (JR405E)

Scan Tool Data List

The Transmission Scan Tool Data List contains all

transmission related parameters that are available on

the scan tool. Use the Transmission Scan Tool Data

List only after the following is determined:

• The Transmission Controls - Diagnostic System Check is completed. • On-board diagnostics are functioning properly.

Scan tool values from a properly running engine may

be used for comparison with the transmission you are

diagnosing. The Transmission Scan Tool Data List

represents values that would be seen on a normal

running engine. Only the parameters listed below are

referenced in this service manual for use in diagnosis.

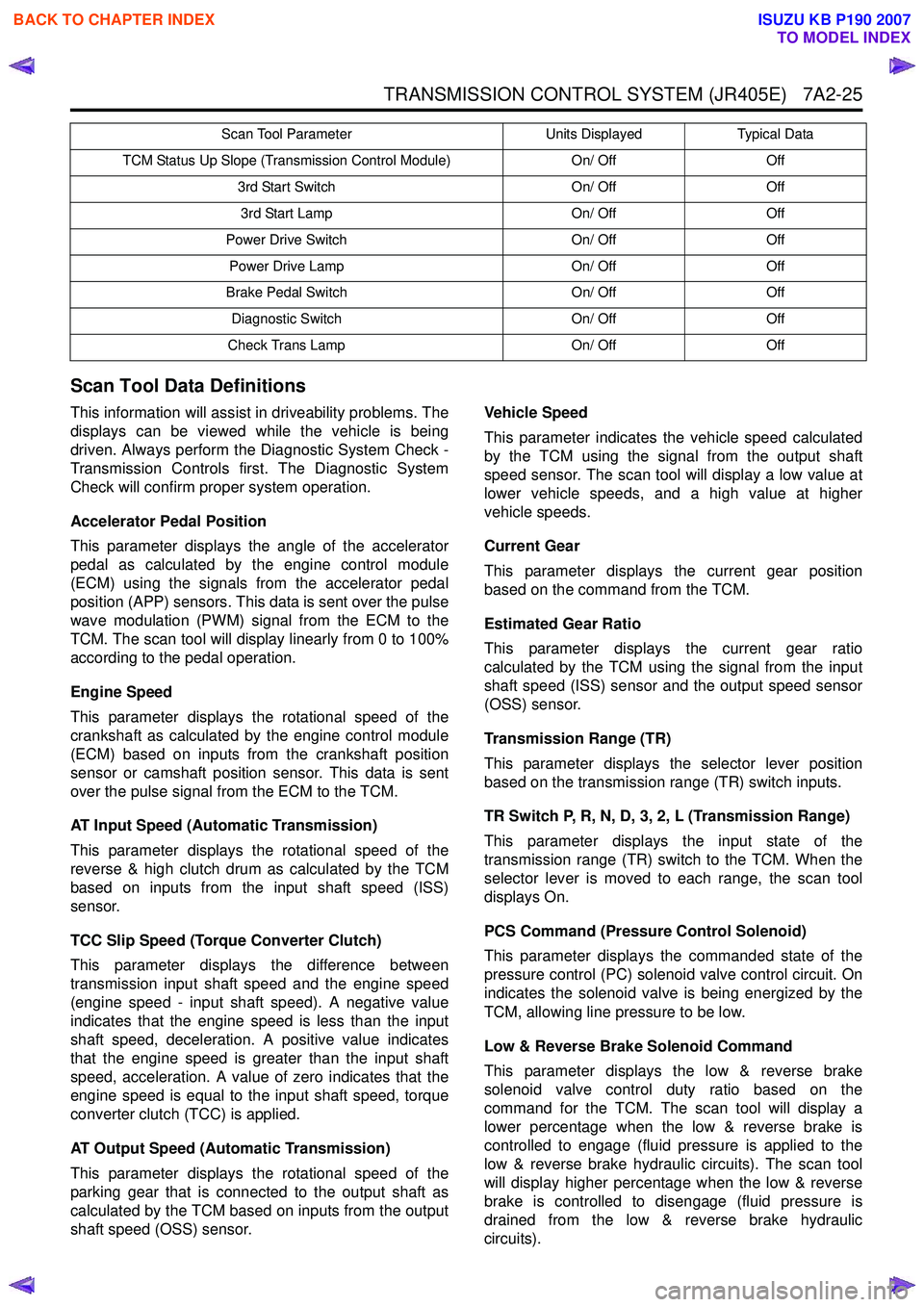

Scan Tool Parameter Units DisplayedTypical Data

Operating Conditions: Engine idle/ Engine coolant temperature is between 75 to 85 °C (167 to 185 °F)/ Accelerator pedal is not

pressed/ Park range/ Transfer case is 2H position/ Accessories OFF

Accelerator Pedal Position %0%

Engine Speed RPMNearly 700 RPM

AT Input Speed (Automatic Transmission) RPM600 to 700 RPM

TCC Slip Speed (Torque Converter Clutch) RPMLess than 100 RPM

AT Output Speed (Automatic Transmission) RPM0 RPM

Vehicle Speed km/h/ MPH0 km/h / MPH

Current Gear 1st/ 2nd/ 2nd L-Up/ 3rd/ 3rd

L-Up/ 4th/ 4th L-Up 1st

Estimated Gear Ratio : 132.77:1

Transmission Range (TR) Park/ Neutral/ Reverse/

Drive/ Drive 3/ Drive 2/ Drive 1 Park

TR Switch P (Transmission Range) On/ OffOn

TR Switch R (Transmission Range) On/ OffOff

TR Switch N (Transmission Range) On/ OffOff

TR Switch D (Transmission Range) On/ OffOff

TR Switch 3 (Transmission Range) On/ OffOff

TR Switch 2 (Transmission Range) On/ OffOff

TR Switch L (Transmission Range) On/ OffOff

PCS Command (Pressure Control Solenoid) On/ OffOn

Low & Reverse Brake Solenoid Command %100%

Low & Reverse Brake Pressure Switch On/ OffOff

2-4 Brake Solenoid Command %100%

2-4 Brake Pressure Switch On/ OffOff

High Clutch Solenoid Command %100%

High Clutch Pressure Switch On/ OffOff

Low Clutch Solenoid Command %0%

TCC Solenoid (Torque Converter Clutch) %5%

Transmission Fluid Temperature °C/ °F V arie s

Transmission Oil Temperature Lamp On/ OffOff

TCM Status Temp. (Temperature Transmission Control Module) Low/ HighLow

4 Wheel Drive Low On/ OffOff

TCM Status Transfer (Transmission Control Module) Low/ HighHigh

TCM Status Down Slope (Transmission Control Module) On/ OffOff

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4309 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-25

Scan Tool Data Definitions

This information will assist in driveability problems. The

displays can be viewed while the vehicle is being

driven. Always perform the Diagnostic System Check -

Transmission Controls first. The Diagnostic System

Check will confirm proper system operation.

Accelerator Pedal Position

This parameter displays the angle of the accelerator

pedal as calculated by the engine control module

(ECM) using the signals from the accelerator pedal

position (APP) sensors. This data is sent over the pulse

wave modulation (PWM) signal from the ECM to the

TCM. The scan tool will display linearly from 0 to 100%

according to the pedal operation.

Engine Speed

This parameter displays the rotational speed of the

crankshaft as calculated by the engine control module

(ECM) based on inputs from the crankshaft position

sensor or camshaft position sensor. This data is sent

over the pulse signal from the ECM to the TCM.

AT Input Speed (Automatic Transmission)

This parameter displays the rotational speed of the

reverse & high clutch drum as calculated by the TCM

based on inputs from the input shaft speed (ISS)

sensor.

TCC Slip Speed (Torque Converter Clutch)

This parameter displays the difference between

transmission input shaft speed and the engine speed

(engine speed - input shaft speed). A negative value

indicates that the engine speed is less than the input

shaft speed, deceleration. A positive value indicates

that the engine speed is greater than the input shaft

speed, acceleration. A value of zero indicates that the

engine speed is equal to the input shaft speed, torque

converter clutch (TCC) is applied.

AT Output Speed (Automatic Transmission)

This parameter displays the rotational speed of the

parking gear that is connected to the output shaft as

calculated by the TCM based on inputs from the output

shaft speed (OSS) sensor. Vehicle Speed

This parameter indicates the vehicle speed calculated

by the TCM using the signal from the output shaft

speed sensor. The scan tool will display a low value at

lower vehicle speeds, and a high value at higher

vehicle speeds.

Current Gear

This parameter displays the current gear position

based on the command from the TCM.

Estimated Gear Ratio

This parameter displays the current gear ratio

calculated by the TCM using the signal from the input

shaft speed (ISS) sensor and the output speed sensor

(OSS) sensor.

Transmission Range (TR)

This parameter displays the selector lever position

based on the transmission range (TR) switch inputs.

TR Switch P, R, N, D, 3, 2, L (Transmission Range)

This parameter displays the input state of the

transmission range (TR) switch to the TCM. When the

selector lever is moved to each range, the scan tool

displays On.

PCS Command (Pressure Control Solenoid)

This parameter displays the commanded state of the

pressure control (PC) solenoid valve control circuit. On

indicates the solenoid valve is being energized by the

TCM, allowing line pressure to be low.

Low & Reverse Brake Solenoid Command

This parameter displays the low & reverse brake

solenoid valve control duty ratio based on the

command for the TCM. The scan tool will display a

lower percentage when the low & reverse brake is

controlled to engage (fluid pressure is applied to the

low & reverse brake hydraulic circuits). The scan tool

will display higher percentage when the low & reverse

brake is controlled to disengage (fluid pressure is

drained from the low & reverse brake hydraulic

circuits).

TCM Status Up Slope (Transmission Control Module) On/ OffOff

3rd Start Switch On/ OffOff

3rd Start Lamp On/ OffOff

Power Drive Switch On/ OffOff

Power Drive Lamp On/ OffOff

Brake Pedal Switch On/ OffOff

Diagnostic Switch On/ OffOff

Check Trans Lamp On/ OffOff

Scan Tool Parameter

Units DisplayedTypical Data

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4310 of 6020

7A2-26 TRANSMISSION CONTROL SYSTEM (JR405E)

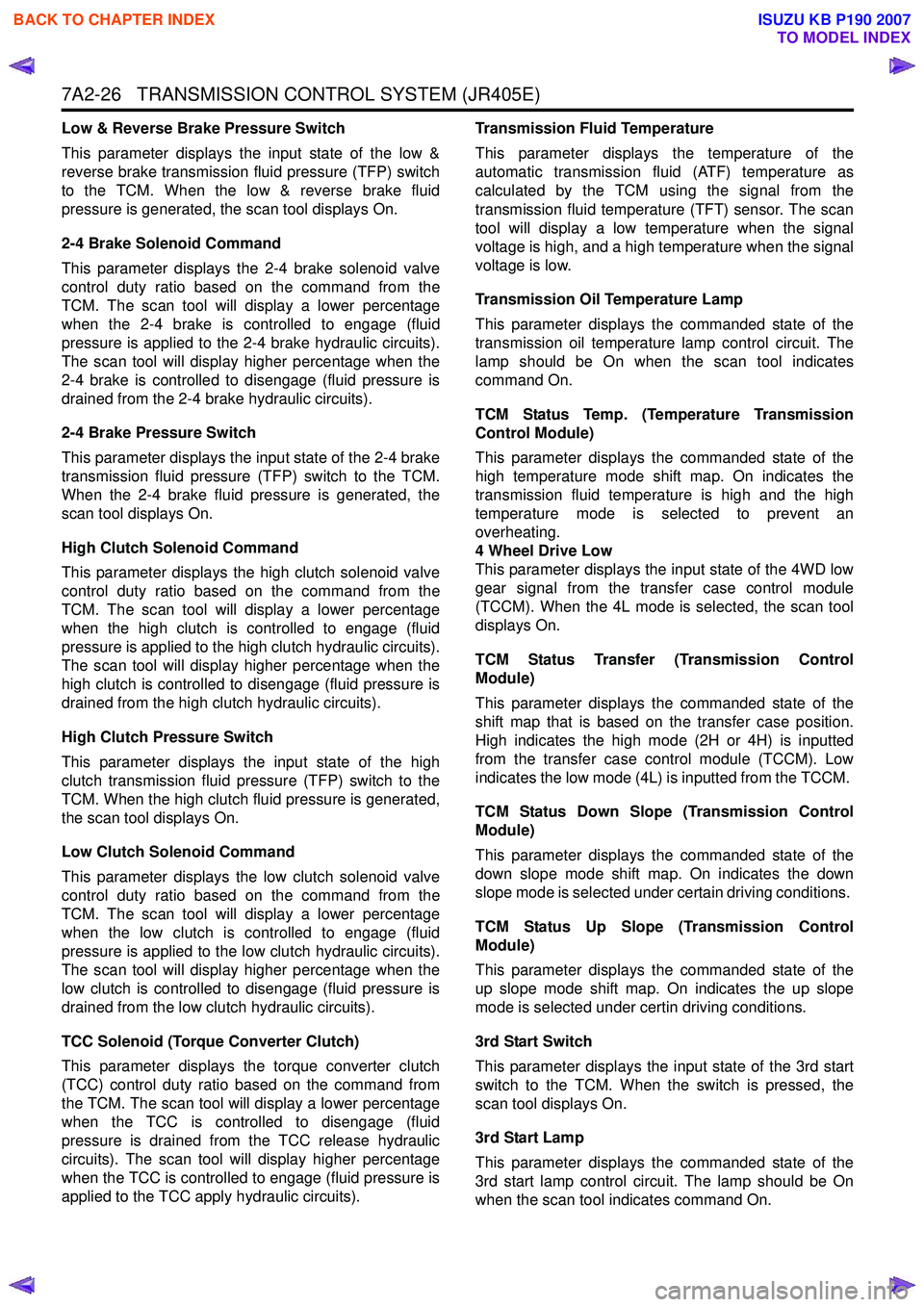

Low & Reverse Brake Pressure Switch

This parameter displays the input state of the low &

reverse brake transmission fluid pressure (TFP) switch

to the TCM. When the low & reverse brake fluid

pressure is generated, the scan tool displays On.

2-4 Brake Solenoid Command

This parameter displays the 2-4 brake solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the 2-4 brake is controlled to engage (fluid

pressure is applied to the 2-4 brake hydraulic circuits).

The scan tool will display higher percentage when the

2-4 brake is controlled to disengage (fluid pressure is

drained from the 2-4 brake hydraulic circuits).

2-4 Brake Pressure Switch

This parameter displays the input state of the 2-4 brake

transmission fluid pressure (TFP) switch to the TCM.

When the 2-4 brake fluid pressure is generated, the

scan tool displays On.

High Clutch Solenoid Command

This parameter displays the high clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the high clutch is controlled to engage (fluid

pressure is applied to the high clutch hydraulic circuits).

The scan tool will display higher percentage when the

high clutch is controlled to disengage (fluid pressure is

drained from the high clutch hydraulic circuits).

High Clutch Pressure Switch

This parameter displays the input state of the high

clutch transmission fluid pressure (TFP) switch to the

TCM. When the high clutch fluid pressure is generated,

the scan tool displays On.

Low Clutch Solenoid Command

This parameter displays the low clutch solenoid valve

control duty ratio based on the command from the

TCM. The scan tool will display a lower percentage

when the low clutch is controlled to engage (fluid

pressure is applied to the low clutch hydraulic circuits).

The scan tool will display higher percentage when the

low clutch is controlled to disengage (fluid pressure is

drained from the low clutch hydraulic circuits).

TCC Solenoid (Torque Converter Clutch)

This parameter displays the torque converter clutch

(TCC) control duty ratio based on the command from

the TCM. The scan tool will display a lower percentage

when the TCC is controlled to disengage (fluid

pressure is drained from the TCC release hydraulic

circuits). The scan tool will display higher percentage

when the TCC is controlled to engage (fluid pressure is

applied to the TCC apply hydraulic circuits). Transmission Fluid Temperature

This parameter displays the temperature of the

automatic transmission fluid (ATF) temperature as

calculated by the TCM using the signal from the

transmission fluid temperature (TFT) sensor. The scan

tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Transmission Oil Temperature Lamp

This parameter displays the commanded state of the

transmission oil temperature lamp control circuit. The

lamp should be On when the scan tool indicates

command On.

TCM Status Temp. (Temperature Transmission

Control Module)

This parameter displays the commanded state of the

high temperature mode shift map. On indicates the

transmission fluid temperature is high and the high

temperature mode is selected to prevent an

overheating.

4 Wheel Drive Low

This parameter displays the input state of the 4WD low

gear signal from the transfer case control module

(TCCM). When the 4L mode is selected, the scan tool

displays On.

TCM Status Transfer (Transmission Control

Module)

This parameter displays the commanded state of the

shift map that is based on the transfer case position.

High indicates the high mode (2H or 4H) is inputted

from the transfer case control module (TCCM). Low

indicates the low mode (4L) is inputted from the TCCM.

TCM Status Down Slope (Transmission Control

Module)

This parameter displays the commanded state of the

down slope mode shift map. On indicates the down

slope mode is selected under certain driving conditions.

TCM Status Up Slope (Transmission Control

Module)

This parameter displays the commanded state of the

up slope mode shift map. On indicates the up slope

mode is selected under certin driving conditions.

3rd Start Switch

This parameter displays the input state of the 3rd start

switch to the TCM. When the switch is pressed, the

scan tool displays On.

3rd Start Lamp

This parameter displays the commanded state of the

3rd start lamp control circuit. The lamp should be On

when the scan tool indicates command On.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007