check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2009 of 6020

ENGINE DIAGNOSIS (C24SE) 6-9

Abnormal Noise Due to Hydraulic Lash Adjuster

Should abnormal noise due to the hydraulic lash

adjuster trouble be heard immediately after the engine

is started, inspect as follows:

Condition Possible cause Correction

Abnormal noise is heard Air contaminated Bleed

HLA is spongy Check ball valve broken Repair

Safety valve in cylinder head

broken Replace

Valve clearance is not zero HLA inside stick

Replace HLA assembly

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with

defective bearing by listening for abnormal noise that

stops when spark plug is shorted out.

Condition Possible cause Correction

Noise from connecting rods or

from connecting rod bearings

(Faulty connecting rods or

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing

noise, which becomes more

evident when engine is

accelerated) Bearing or crankshaft pin worn Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Crankpin out of round Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Connecting rod bent Correct or replace

Connecting rod bearing seized Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the

cylinder with defective parts is shorted out.

Condition Possible cause Correction

Piston and cylinder

(Faulty piston or cylinder usually

makes a combined mechanical

thumping noise which increases

when engine is suddenly

accelerated but diminishes

gradually as the engine warms up) Piston clearance increased due to

cylinder wear Replace piston and cylinder body

Piston seized Replace piston and cylinder body

Piston ring broken Replace piston and cylinder body

Piston defective Replace pistons and others

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2013 of 6020

ENGINE DIAGNOSIS (C24SE) 6-13

Fuel Consumption Excessive

Condition Possible cause Correction

Trouble in fuel system Mixture too rich or too lean due to

trouble in fuel injection system Refer to "Abnormal Combustion"

Fuel cut function does not act Refer to "Abnormal Combustion"

Trouble in ignition system Misfiring or abnormal combustion

due to trouble in ignition system Refer to Hard Start or Abnormal

Combustion Troubleshooting

Guide

Others Engine idle speed too high Reset Idle Air Control Valve

Returning of accelerator control

sluggish Correct

Fuel system leakage Correct or replace

Clutch slipping Correct

Brake drag Correct

Selection of transmission gear

incorrect Caution operator of incorrect gear

selection

Oil Problems

Condition Possible cause Correction

Oil pressure too low Wrong oil in use Replace with correct engine oil

Relief valve sticking Replace

Oil pump not operating properly Correct or replace

Oil pump strainer clogged Clean or replace strainer

Oil pump worn Replace

Oil pressure gauge defective Correct or replace

Crankshaft bearing or connecting

rod bearing worn Replace

Oil contamination

Wrong oil in use Replace with new engine oil

Oil filter clogged Replace oil filter

Cylinder head gasket damage Replace gasket

Burned gases leaking Replace piston and piston rings or

rebore cylinders

Oil not reaching valve system Oil passage in cylinder head or cylinder body clogged Clean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine

oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the specified standard.

c. Refer to the "Maintenance and Lubrication" section of this manual.

2. Check the engine oil level. The level should fall somewhere between the

"ADD" and the "FULL" marks on the oil level

dipstick.

If the oil level does not reach the "ADD" mark on

the oil level dipstick, engine oil must be added.

3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal operating temperature (About 80 °C).

6. Measure the oil pressure.

Oil pressure should be:

150 kPa(21.8 psi) at idle speed.

7. Stop the engine.

8. Remove the oil pressure gauge

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2014 of 6020

6-14 ENGINE DIAGNOSIS (C24SE)

Malfunction Indicator Lamp

The instrument panel "CHECK ENGINE" Malfunction

Indicator lamp (MIL) illuminates by self diagnostic

system when the system checks the starting of

engine, or senses malfunctions.

Condition Possible cause Correction

"CHECK ENGINE" MIL does not

illuminate at the starting of engine Bulb defective Replace

MIL circuit open Correct or replace

Command signal circuit to operate

self diagnostic system shorted Correct or replace

Engine Control Module (ECM)

cable loosely connected,

disconnected or defective Correct or replace

ECM

defective Replace

“CHECK ENGINE” MIL

illuminates, and stays on Deterioration heated oxygen

sensor of internal element Replace

Heated oxygen sensor connector

terminal improper contact

(If applicable) Reconnect properly

Heated oxygen sensor lead wire

shorted (If applicable) Correct

Heated oxygen sensor circuit

open (If applicable) Correct or replace

Deterioration engine coolant

temperature sensor of internal

element Replace

Engine coolant temperature

sensor connector terminal

improper contact Reconnect properly

Engine coolant temperature

sensor lead wire shorted Correct

Engine coolant temperature

sensor circuit open Correct or replace

Throttle position sensor open or

shorted circuits Correct or replace

Deterioration of crankshaft

position sensor Replace

Crankshaft position sensor circuit

open or shorted Correct or replace

Vehicle speed sensor circuit open Correct or replace

Manifold absolute pressure sensor

circuit open or shorted Correct or replace

Intake air temperature sensor

circuit open or shorted Correct or replace

Fuel injector circuit open or shorted Correct or replace

ECM driver transistor defective Replace EPROM or ECM

Malfunctioning of ECM RAM

(Random Access Memory) or

Malfunctioning of ECM PROM

(Programmed Read Only Memory) Replace EPROM or ECM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2015 of 6020

ENGINE MECHANICAL (C24SE) 6A-1

SECTION 6A

ENGINE MECHANICAL

TABLE OF CONTENTS

PAGE

General Description ........................................................................................................ 6A- 4

ENGINE PICTORIAL .................................................................................................... 6A- 6

Main Data and Specification ........................................................................................... 6A-11 CRANKCASE VENTILATION SYSTEM ....................................................................... 6A-16

ENGINE ASSEMBLY & LOOSE PARTS ..................................................................... 6A-17

OPERATIONS ON ENGINE AGGREGATES.................................................................... 6A-18 Engine Damping Blocks(Engine without Transmission) ........................................ 6A-18

Toothed Belt and Timing Check ............................................................................... 6A-21

Toothed Belt Tension, Adjust .................................................................................... 6A-23

Toothed Belt, Replace ................................................................................................ 6A-24

OPERATIONS ON INSTALLED ENGINE ......................................................................... 6A-26 Gasket, Exhaust Manifold, Cylinder Head ................................................................ 6A-26

Gasket, Intake Manifold, Cylinder Head .................................................................... 6A-26

Seal Ring, Camshaft Housing, Timing Side.............................................................. 6A-27

Seal Ring, Thermostat Housing, Cylinder Head....................................................... 6A-27

Seal Ring - Front Camshaft Housing, Replace ......................................................... 6A-28

Toother Belt Rear Cover............................................................................................. 6A-30

Toother Belt Tension Roller ....................................................................................... 6A-31

COMPONENT PARTS ...................................................................................................... 6A-32 Cylinder Head .............................................................................................................. 6A- 32

Hydraulic Valve Lifter ................................................................................................. 6A-33

OPERATIONS ON CYLINDER HEAD AND CAMSHAFT HOUSING ............................... 6A-34 Camshaft ..................................................................................................................... 6 A-34

Camshaft Housing Removal and Installation ........................................................... 6A-35

Cylinder Head .............................................................................................................. 6A- 35

Hydraulic Valve Lifers, Replace................................................................................. 6A-37

Camshaft Housing, Replace ...................................................................................... 6A-37

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2016 of 6020

6A-2 ENGINE MECHANICAL (C24SE)

PAGE

Camshaft Housing, Check for Plance Surface ......................................................... 6A-39

Cylinder Head, Removal and Installation.................................................................. 6A-39

Cylinder Head, Disassemble and Assemble............................................................. 6A-42

Valve, Grind ................................................................................................................. 6 A-44

Valve Guide, Ream .................................................................................................... 6A-44

Valve Seating, Mill ...................................................................................................... 6A-45

Cylinder Head, Overhaul ............................................................................................ 6A-45

Flywheel....................................................................................................................... 6A-46

Starter Ring Gear(Manual Transmission) ................................................................. 6A-47

Seal Ring, Crankshaft................................................................................................. 6A-48

Seal Ring, Crankshaft Rear ........................................................................................ 6A-48

Oil Pan and Bearing Bridge ....................................................................................... 6A-49

OPERATIONS ON CRANK DRIVE ................................................................................... 6A-51 Con-Rod Bearing ........................................................................................................ 6A-51

Piston with Con-Rod................................................................................................... 6A-51

Con-Rod....................................................................................................................... 6A-52

Pistion Rings ............................................................................................................... 6A -53

OPERATIONS ON REMOVED ENGINE........................................................................... 6A-55 Crankshaft ................................................................................................................... 6 A-55

Bearing Free Play Measurement ............................................................................... 6A-57

Plastigage Method ...................................................................................................... 6A-57

Micrometer and gauge method.................................................................................. 6A-58

Bypass Valve ............................................................................................................... 6A- 59

Oil Filter ..................................................................................................................... .. 6A-59

Oil Pump ...................................................................................................................... 6A-59

Oil Pump Safety Valve ................................................................................................ 6A-60

Oil Pump(Overhaul) .................................................................................................... 6A-60

OPERATIONS ON OIL CIRCULATION ............................................................................ 6A-61 Cylinder Head Safety Valve ........................................................................................ 6A-61

OPERATIONS ON COOLING SYSYTEM ......................................................................... 6A-63 Cooling System, Check for Leakes ........................................................................... 6A-63

Cooling System, Fill Up and Bleed ............................................................................ 6A-63

Refill Coolant............................................................................................................... 6 A-64

Ignition Timing, Check ............................................................................................... 6A-64

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2029 of 6020

ENGINE MECHANICAL (C24SE) 6A-15

Engine Specification Matrix for destination

04 HEO FOR TF MODEL:

VEHICLE MODEL TFR/S 2.4L

Major Description

AUSTRALIA, CHILE,

GULF, NEW

ZEALAND, SAUDI ARABIA, SOUTH AFRICA COLOMBIA, COSTA

RICA, EQUADOR, GUATEMALA BOLIVIA, GENERAL

EXPORT, PERU, VENEZUELA

VEHICLE TYPE 4× 2 4x4 4 ×2 4 ×4 4 ×2

VEHICLE IDENT. CODE TX TY TX TY TX

ENGINE TYPE C24SE ← ←

FUEL CONTROL SYSYTEM CLOSE LOOP CLOSED LOOP OPEN LOOP

COMPRESSION RATIO 9.6:1 ← ←

FUEL OCTANE(ROD) 91RON 85RON 80RON

FUEL TYPE UN-LEADED UN-LEADED LEADED

HO2 YES YES YES NO

EVAP CANISTER YES YES YES YES

PURGE CONTROL

SOLENOID YES

YES YES YES

CHECK & RELIEF VALVE YES YES YES YES

ECM YES YES YES YES

EXHAUST SYSTEM

FRONT PIPE

SILENCER

TW C YES YES YES NO

CO ADJUSTMENT NO NO NO YES

Refer to 6A-77 Refer to 6A-77 Refer to 6A-77

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2034 of 6020

6A-20 ENGINE MECHANICAL (C24SE)

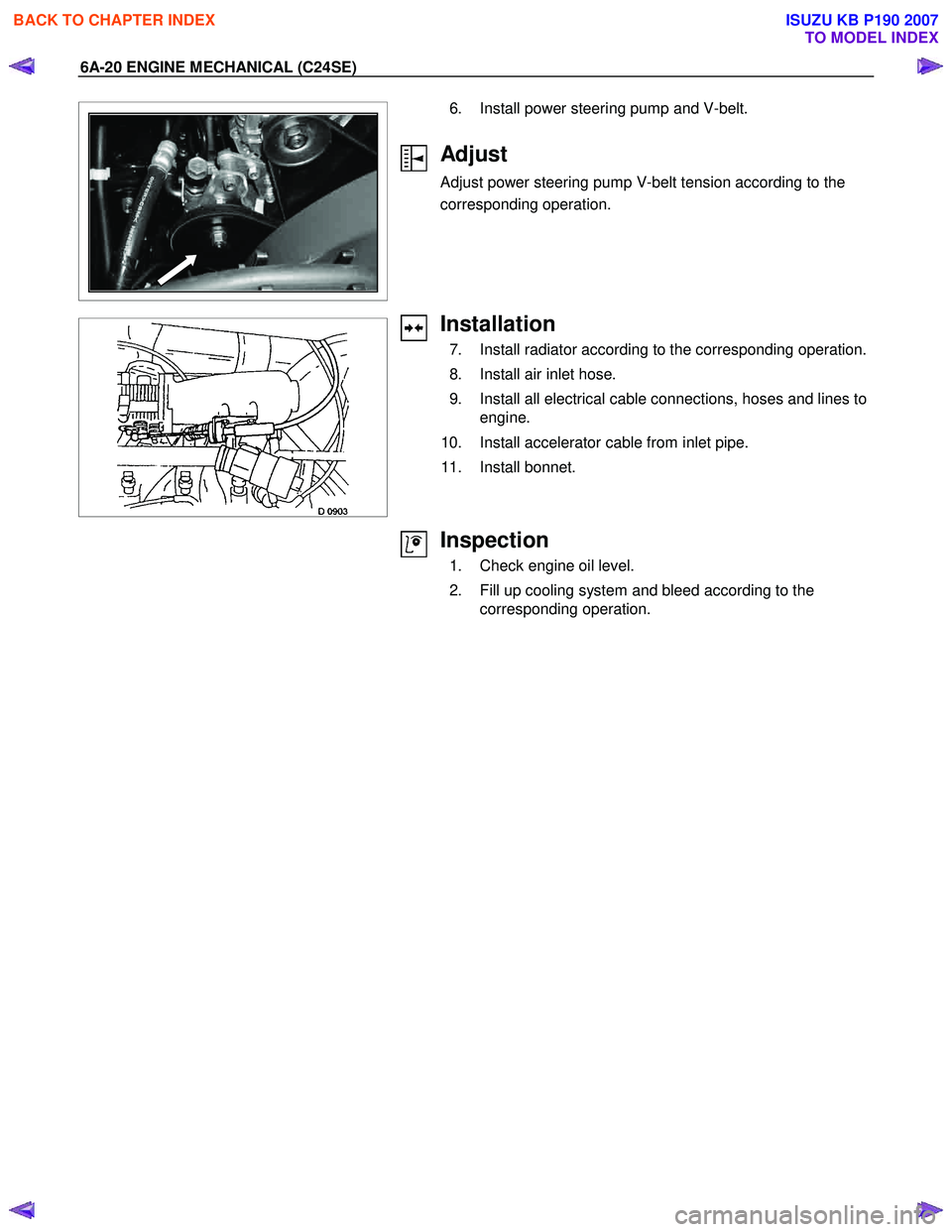

6. Install power steering pump and V-belt.

Adjust

Adjust power steering pump V-belt tension according to the

corresponding operation.

Installation

7. Install radiator according to the corresponding operation.

8. Install air inlet hose.

9. Install all electrical cable connections, hoses and lines to engine.

10. Install accelerator cable from inlet pipe.

11. Install bonnet.

Inspection

1. Check engine oil level.

2. Fill up cooling system and bleed according to the corresponding operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2035 of 6020

ENGINE MECHANICAL (C24SE) 6A-21

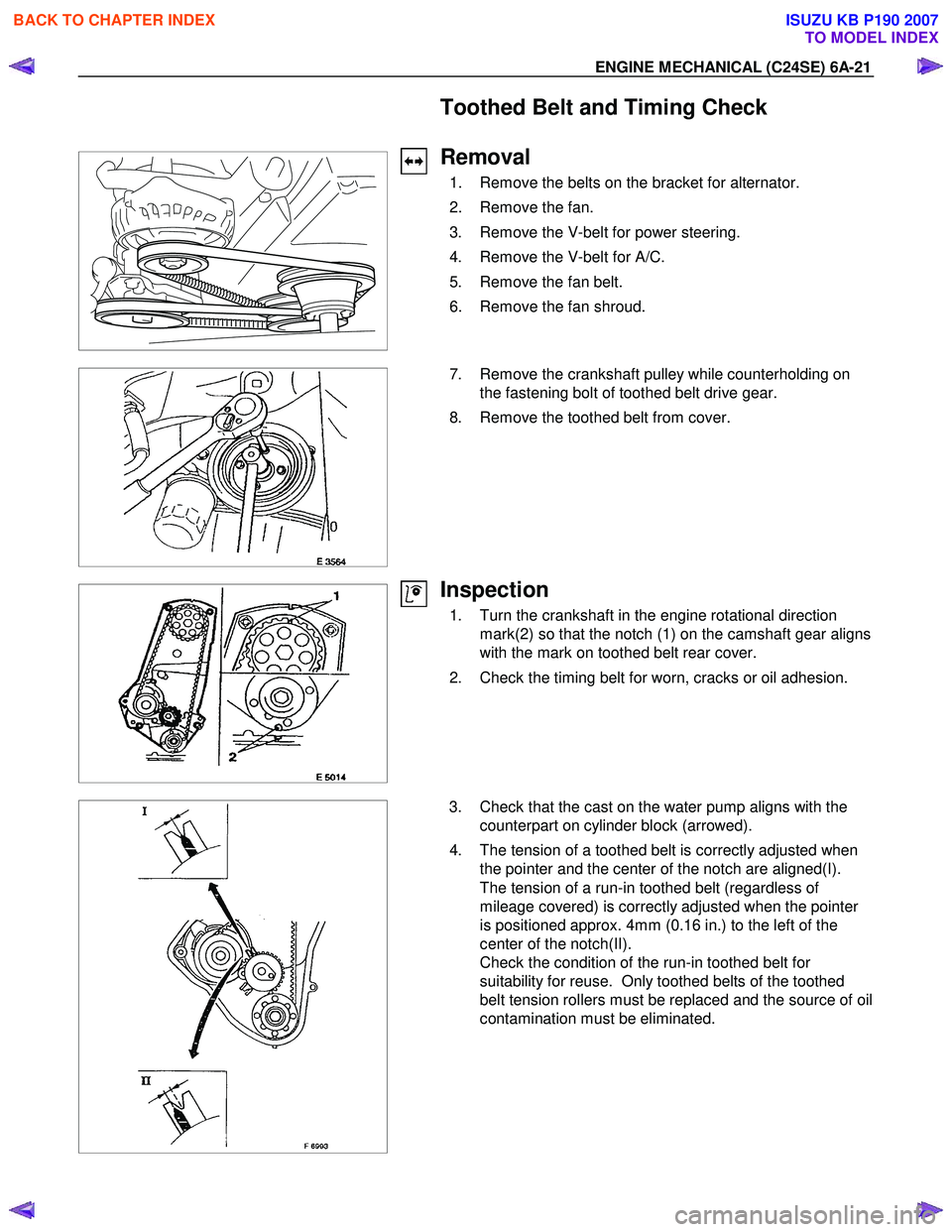

Toothed Belt and Timing Check

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

Inspection

1. Turn the crankshaft in the engine rotational direction mark(2) so that the notch (1) on the camshaft gear aligns

with the mark on toothed belt rear cover.

2. Check the timing belt for worn, cracks or oil adhesion.

3. Check that the cast on the water pump aligns with the counterpart on cylinder block (arrowed).

4. The tension of a toothed belt is correctly adjusted when the pointer and the center of the notch are aligned(I).

The tension of a run-in toothed belt (regardless of

mileage covered) is correctly adjusted when the pointer

is positioned approx. 4mm (0.16 in.) to the left of the

center of the notch(II).

Check the condition of the run-in toothed belt for

suitability for reuse. Only toothed belts of the toothed

belt tension rollers must be replaced and the source of oil

contamination must be eliminated.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2037 of 6020

ENGINE MECHANICAL (C24SE) 6A-23

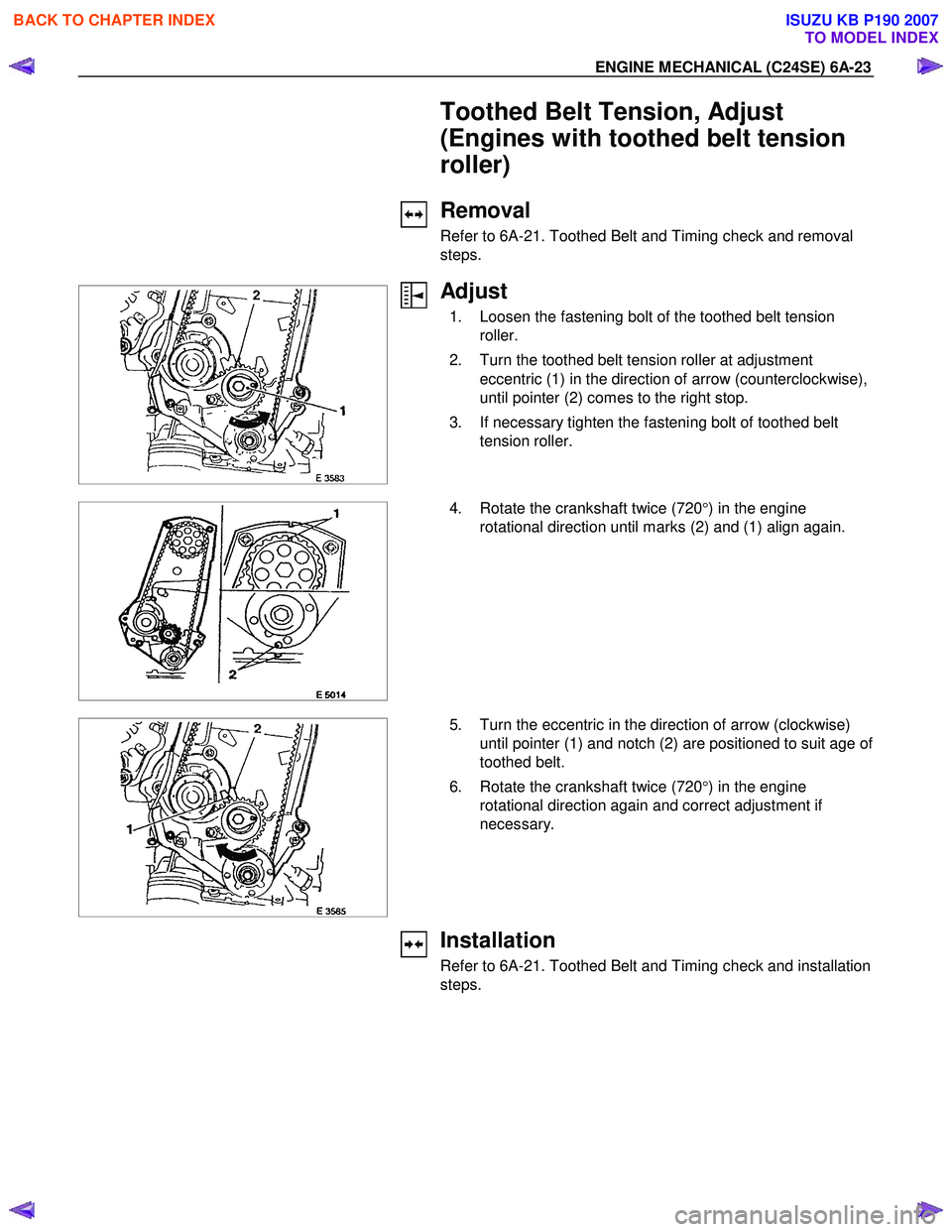

Toothed Belt Tension, Adjust

(Engines with toothed belt tension

roller)

Removal

Refer to 6A-21. Toothed Belt and Timing check and removal

steps.

Adjust

1. Loosen the fastening bolt of the toothed belt tension roller.

2. Turn the toothed belt tension roller at adjustment eccentric (1) in the direction of arrow (counterclockwise),

until pointer (2) comes to the right stop.

3. If necessary tighten the fastening bolt of toothed belt tension roller.

4. Rotate the crankshaft twice (720

°) in the engine

rotational direction until marks (2) and (1) align again.

5. Turn the eccentric in the direction of arrow (clockwise)

until pointer (1) and notch (2) are positioned to suit age of

toothed belt.

6. Rotate the crankshaft twice (720 °) in the engine

rotational direction again and correct adjustment if

necessary.

Installation

Refer to 6A-21. Toothed Belt and Timing check and installation

steps.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2042 of 6020

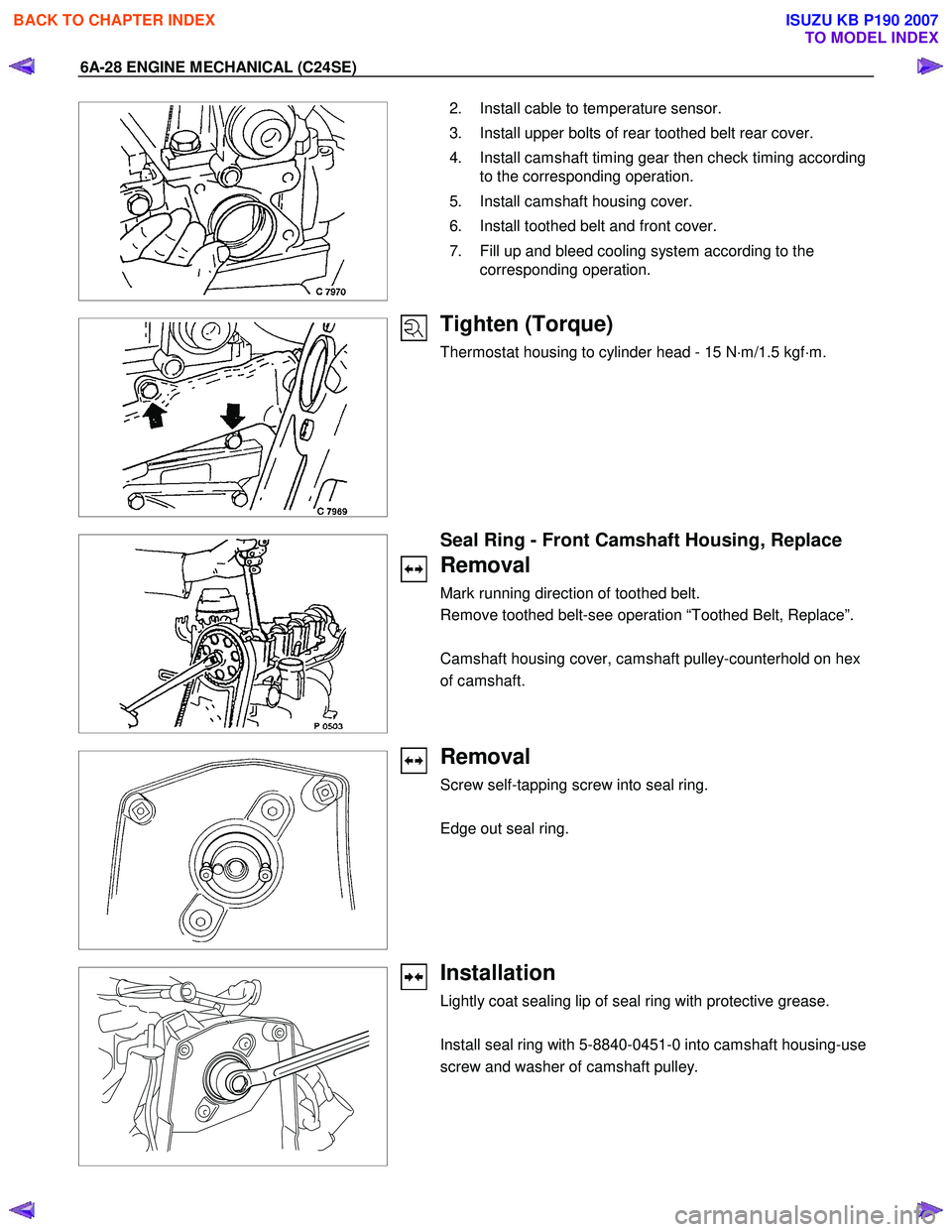

6A-28 ENGINE MECHANICAL (C24SE)

2. Install cable to temperature sensor.

3. Install upper bolts of rear toothed belt rear cover.

4. Install camshaft timing gear then check timing according to the corresponding operation.

5. Install camshaft housing cover.

6. Install toothed belt and front cover.

7. Fill up and bleed cooling system according to the corresponding operation.

Tighten (Torque)

Thermostat housing to cylinder head - 15 N ⋅m/1.5 kgf ⋅m.

Seal Ring - Front Camshaft Housing, Replace

Removal

Mark running direction of toothed belt.

Remove toothed belt-see operation “Toothed Belt, Replace”.

Camshaft housing cover, camshaft pulley-counterhold on hex

of camshaft.

Removal

Screw self-tapping screw into seal ring.

Edge out seal ring.

Installation

Lightly coat sealing lip of seal ring with protective grease.

Install seal ring with 5-8840-0451-0 into camshaft housing-use

screw and washer of camshaft pulley.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007