check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2078 of 6020

6A-64 ENGINE MECHANICAL (C24SE)

Important!

Do not loosen or open the radiator cap when coolant is hot.

Doing so may cause hot water or steam to splash out, resulting

in burn. W hen opening the radiator cap, be sure to confirm the

coolant is cold. Cover a thick cloth over the cap and loosen it

slowly to reduce pressure, then open the cap.

6. Close the radiator cap firmly and run the engine at approx. 2000 rpm. In addition, set the heater temperature

adjuster to the max position to circulate coolant in the

heater conduit system.

7. Confirm that the temperature gauge reads half or more of full scale and that the thermostat is activated.

Then continue idling 5 minutes more and switch off the

engine, and allow it to cool.

8. After the engine cools down, check the coolant level and refill it if necessary. W hen the level is lowered extremely,

check the coolant conduit system and reservoir hose for

leak.

9. Pour coolant into the reservoir to MAX level.

Refill Coolant

Important!

After closing the cooling system, let engine run warm until

thermostat opens (coolant approx. 92 °C/197.6F)

Inspection

Coolant level

Allow engine to cool. If necessary, refill coolant.

Check that cooling system self-bleeds during engine warming-

up phase.

Ignition Timing, Check

No Adjustment

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2088 of 6020

6A-74 ENGINE MECHANICAL (C24SE)

Oxygen Sensor (If applicable)

Removal

1. Remove wiring harness plug.

2. Remove oxygen sensor from the front exhaust pipe.

Tighten (Torque)

Oxygen sensor in exhaust pipe - 30 N ⋅m (3.1 kgf ⋅m)

Throttle Valve Position Sensor

Removal

1. Remove wiring harness connector.

2. Remove throttle valve position sensor.

Installation

1. Install throttle valve position sensor.

2. Install wiring harness connector.

Accelerator Pedal and Cable

Removal

1. Remove pad stopper from pedal stop bolt.

Installation

1. Install pad stopper.

Inspection

Ensure that accelerator pedal is fully in idle position and

accelerator level at engine is in closed position.

Pull outer sleeve of accelerator cable towards pedal and check

that clip on sleeve is in slot nearest to grommet.

Reposition clip if necessary, and check that full throttle and idle

positions are obtained at engine lever.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2089 of 6020

ENGINE MECHANICAL (C24SE) 6A-75

RTW 46JSH000101

Air Cleaner Filter

NOTE:

The air cleaner filter is not damaged with the edge of the air

cleaner housing.

Removal

(2.4L)

1. Remove air cleaner cover and air cleaner element.

2. Remove air intake nose.

3. Remove lower air cleaner.

4. Remove mud guard.

5. Remove front fender cover.

6. Remove outside air intake duct.

Inspection

Check the air cleaner filter for damage or dust clogging.

Replace if it is damaged, or clean if it is clogged.

130RW 002

Cleaning Method

Tap the air cleaner filter gently so as not to damage the paper

filter, or clean the element by blowing with compressed air of

about 490 kPa (71 psi) from the clean side if it is extremely

dirty.

Installation

(2.4L)

1. Install outside air intake duct.

2. Install front fender cover.

3. Install mud guard.

4. Install lower air cleaner.

5. Install air intake hose.

6. Install air cleaner element and air cleaner cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2093 of 6020

ENGINE MECHANICAL (C24SE) 6A-79

Adjustment Values/Checking Values

Valve clearance Inlet Hydraulic valve lash adjustment

Outlet No adjustment necessary

Spark plugs - electrode gap 1.0 ∼ 1.1mm

Compression The difference in compression

between the individual cylinders

in the engine must not exceed

100 kPa (1 bar).

Pressure loss The pressure loss of an engine

in perfect condition per cylinder

is not more than max. 25%

Cylinder Head

Cylinder Head Gasket

Thickness - installed mm 1.2

Valve seat width at cylinder head

inlet mm 1.0 to 1.5

outlet mm 1.7 to 2.2

Valve stem play inlet mm 0.018 to 0.052

outlet mm 0.038 to 0.072

Permissible valve stem to cone runout

inlet mm 0.03

outlet mm 0.33

Overall height of cylinder head

(Sealing surface to sealing surface) mm 95.5 ± 0.25

Installation height

inlet and

outlet valves mm 17.85 to 18.25

dimension "A" Distance Gauge

5-8840-2596-0

Installation height valve guide mm 83.50 to 83.80

Sealing surface peak-to-valley height mm max. 0.025

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2108 of 6020

6B-4 ENGINE COOLING

Antifreeze Solution

• Calculating mixing ratio

Mixing ratio

= Antifreeze solution (Lit/gal.)

Antifreeze solution (Lit/gal.) + W ater (Lit/gal.)

NOTE: Antifreeze solution + W ater = Total cooling system

capacity.

• Total Cooling System Capacity

8Lit

• Mixing ratio

Check the specific gravity of engine coolant in the cooling system temperature ranges from 0 °C to 50 °C using a

suction type hydrometer, then determine the density of the

engine coolant by referring to the table.

NOTE: The LLC is 50% at all environment in order to prevent

the corrosion of cooling system parts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2110 of 6020

6B-6 ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

level should be between the "MIN" and "MAX" lines of reserve

tank when the engine is cold. If low, check for leakage and add

engine coolant up to the "MAX" line. There should not be any

excessive deposit of rust or scales around the radiator cap or

radiator filler hole, and the engine coolant should also be free

from oil.

Replace the engine coolant if excessively dirty.

1. Completely drain the cooling system by opening the drain

plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING BURNED,

DO NOT REMOVE THE CAP WHILE THE ENGINE AND

RADIATOR ARE STILL HOT. SCALDING FLUID AND

STEAM CAN BE BLOWN OUT UNDER PRESSURE.

3. Disconnect all hoses from the engine coolant reserve tank.

Scrub and clean the inside of the reserve tank with soap and water. Flush it well with clean water, then drain it. Install

the reserve tank and hoses.

4. Refill the cooling system with the engine coolant using a solution that is at least 50 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the engine coolant reserve tank to "MAX" line when the engine is cold.

6. Block the drive wheels and firmly apply the parking brake and place the shift lever in the "NEUTRAL" position.

7. Remove the radiator cap. Start the engine and warm it up at 2,500 - 3,000 rpm for about 30 minutes.

8. W hen the air comes out from the radiator filler neck and the engine coolant level has gone down, replenish with the

engine coolant. Repeat this procedure until the engine

coolant level does not go down. Then stop the engine and

install the radiator cap. Let the engine cool down.

9. After the engine has cooled, replenish with engine coolant up to the "MAX" line of the reserve tank.

10. Start the engine. W ith the engine running at 3,000 rpm, make sure there is no running water sound from the heate

r

core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to 10.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2113 of 6020

ENGINE COOLING 6B-9

Thermostat

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat from thermostat housing.

Inspection

Suspend the thermostat in a water-filled container using thin

wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water so

that the entire water is same temperature.

Confirm the temperature when the valve first begins to open.

Valve opening temperature 92 °

°°

°

C (197.6 °

°°

°

F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature 107 °

°°

°

C(224.6 °

°°

°

F)

Make necessary repair and parts replacement if extreme wear

or damage is found during inspection.

Installation

1. Before installing thermostat, coat sealing surface with

silicon grease.

2. Install O-ring.

3. Install thermostat housing and tighten bolts to the specified torque.

Torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kgf ⋅

⋅⋅

⋅

m)

4. Installation rubber hose.

5. Replenish engine coolant (EC).

6. Start engine and check for EC leakage.

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage or any other abnormal condition are found through

inspection.

Visually inspect for damage, leak (silicon grease) or other

abnormal conditions.

1. Inspection (on-vehicle)

1) Turn the fan clutch by hand when in a low temperature condition before starting the engine, and confirm that it

can be turned readily.

2) Start the engine to warm it up until the temperature at the fan clutch portion gets to around 80 °C. Then stop the

engine and confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned by hand.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2116 of 6020

6B-12 ENGINE COOLING

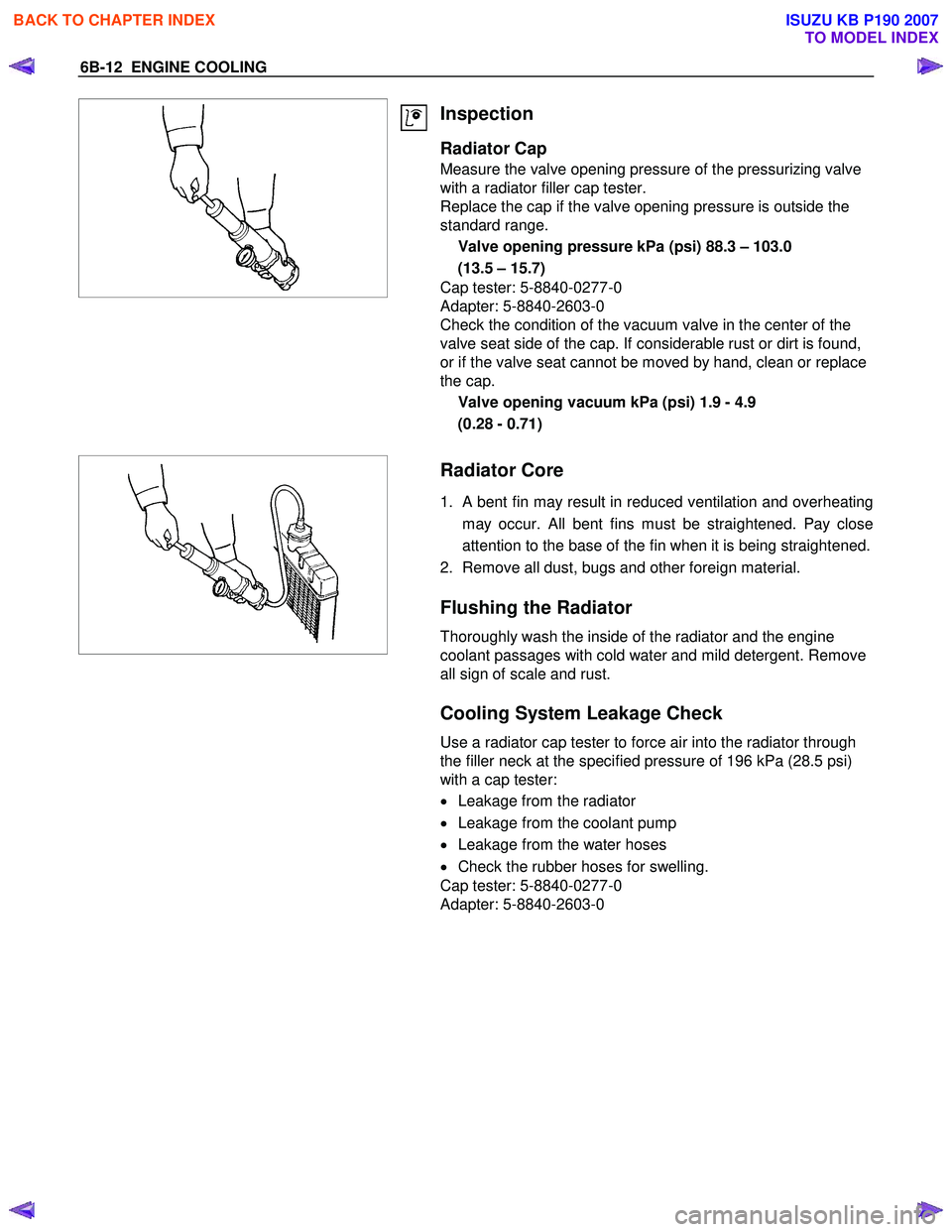

Inspection

Radiator Cap

Measure the valve opening pressure of the pressurizing valve

with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside the

standard range.

Valve opening pressure kPa (psi) 88.3 – 103.0

(13.5 – 15.7)

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

Check the condition of the vacuum valve in the center of the

valve seat side of the cap. If considerable rust or dirt is found,

or if the valve seat cannot be moved by hand, clean or replace

the cap.

Valve opening vacuum kPa (psi) 1.9 - 4.9

(0.28 - 0.71)

Radiator Core

1. A bent fin may result in reduced ventilation and overheating

may occur. All bent fins must be straightened. Pay close

attention to the base of the fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent. Remove

all sign of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator through

the filler neck at the specified pressure of 196 kPa (28.5 psi)

with a cap tester:

• Leakage from the radiator

• Leakage from the coolant pump

• Leakage from the water hoses

• Check the rubber hoses for swelling.

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2121 of 6020

ENGINE FUEL (C24SE) 6C-3

W hen working on the fuel system, there are several things to

keep in mind:

•

Any time the fuel system is being worked on, disconnect the

negative battery cable except for those tests where batter

y

voltage is required.

•

Always keep a dry chemical (Class B) fire extinguisher near

the work area.

• Replace all pipes with the same pipe and fittings that were

removed.

• Clean and inspect "O" rings. Replace if required.

•

Always relieve the line pressure before servicing any fuel

system components.

• Do not attempt repairs on the fuel system until you have

read the instructions and checked the pictures relating to

that repair.

• Adhere to all Notices and Cautions.

All gasoline engines are designed to use only unleaded

gasoline. Unleaded gasoline must be used for proper emission

control system operation.

Its use will also minimize spark plug fouling and extend engine

oil life. Using leaded gasoline can damage the emission control

system and could result in loss of emission warranty coverage.

All cars are equipped with an Evaporative Emission Control

System. The purpose of the system is to minimize the escape

of fuel vapors to the atmosphere.

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or othe

r

corrosion inhibitors) on threaded fasteners or fastene

r

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2123 of 6020

ENGINE FUEL (C24SE) 6C-5

Fuel Filter

Fuel Filter and Associated Parts

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system fo

r

loose connections or leakage. For the fuel system

diagnosis, see Section "Driveability and Emissions".

(2.4L)

1. Disconnect battery ground cable.

2. Disconnect the quick connector from the fuel filter.

3. Pull off fuel filter from the holder to side member side.

4. Remove the fuel filter.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007