JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Trending: oil filter, low beam, refilling coolant system, silencer, inlet manifold, Heater Hose Junction, washer fluid

Page 121 of 2490

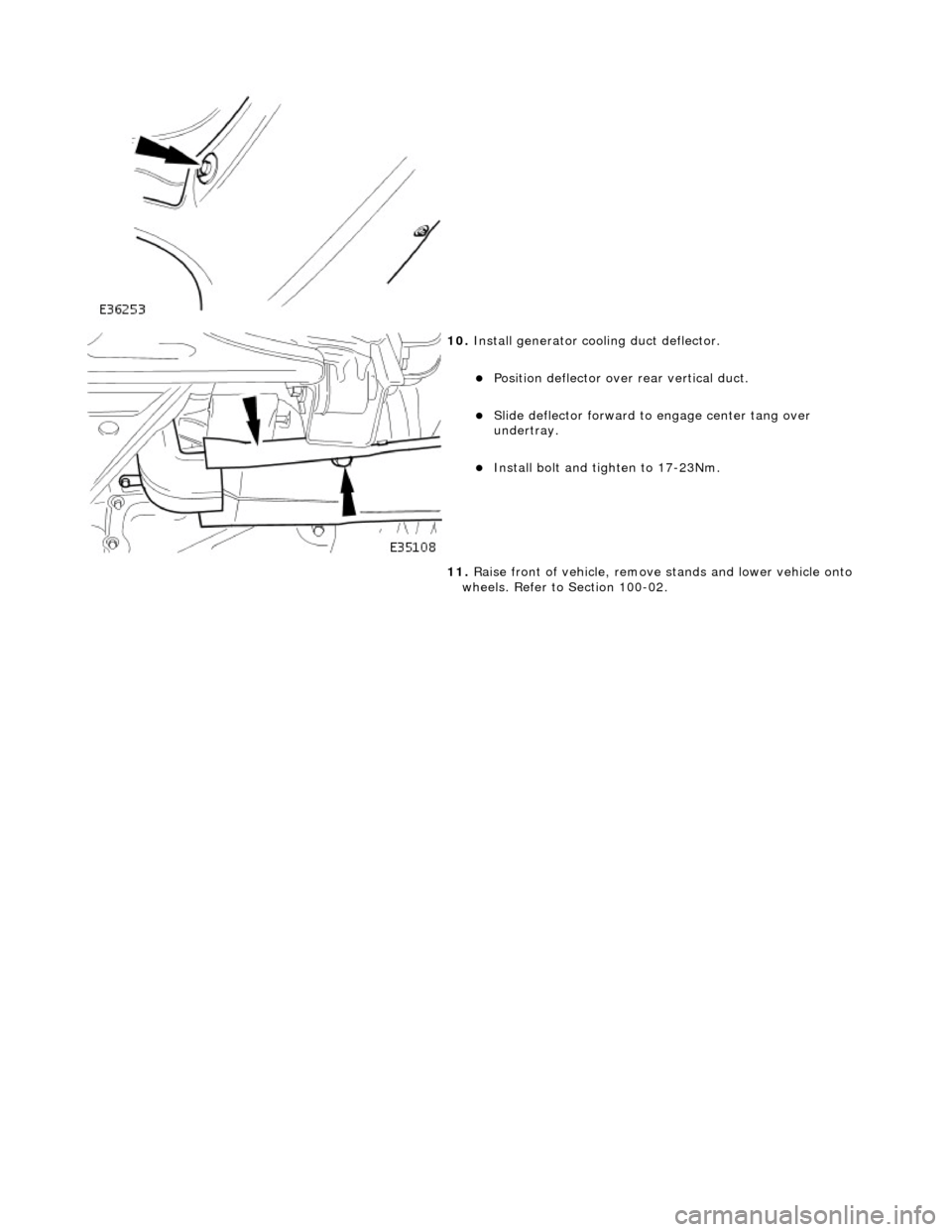

10

.

Install generator cool ing duct deflector.

Po

sition deflector over

rear vertical duct.

Sl

ide deflector forward to

engage center tang over

undertray.

Inst

all bolt and ti

ghten to 17-23Nm.

11. Raise front of vehicle, remove stands and lower vehicle onto

wheels. Refer to Section 100-02.

Page 122 of 2490

Front Suspension - Front Stabilizer B

ar Bushing

Re

mo

val and Installation

Materials

S p

ecification

Cas

t

rol NTR

Remov

a

l

Na

m

e

R

u

bber Suspension Insulator Lube

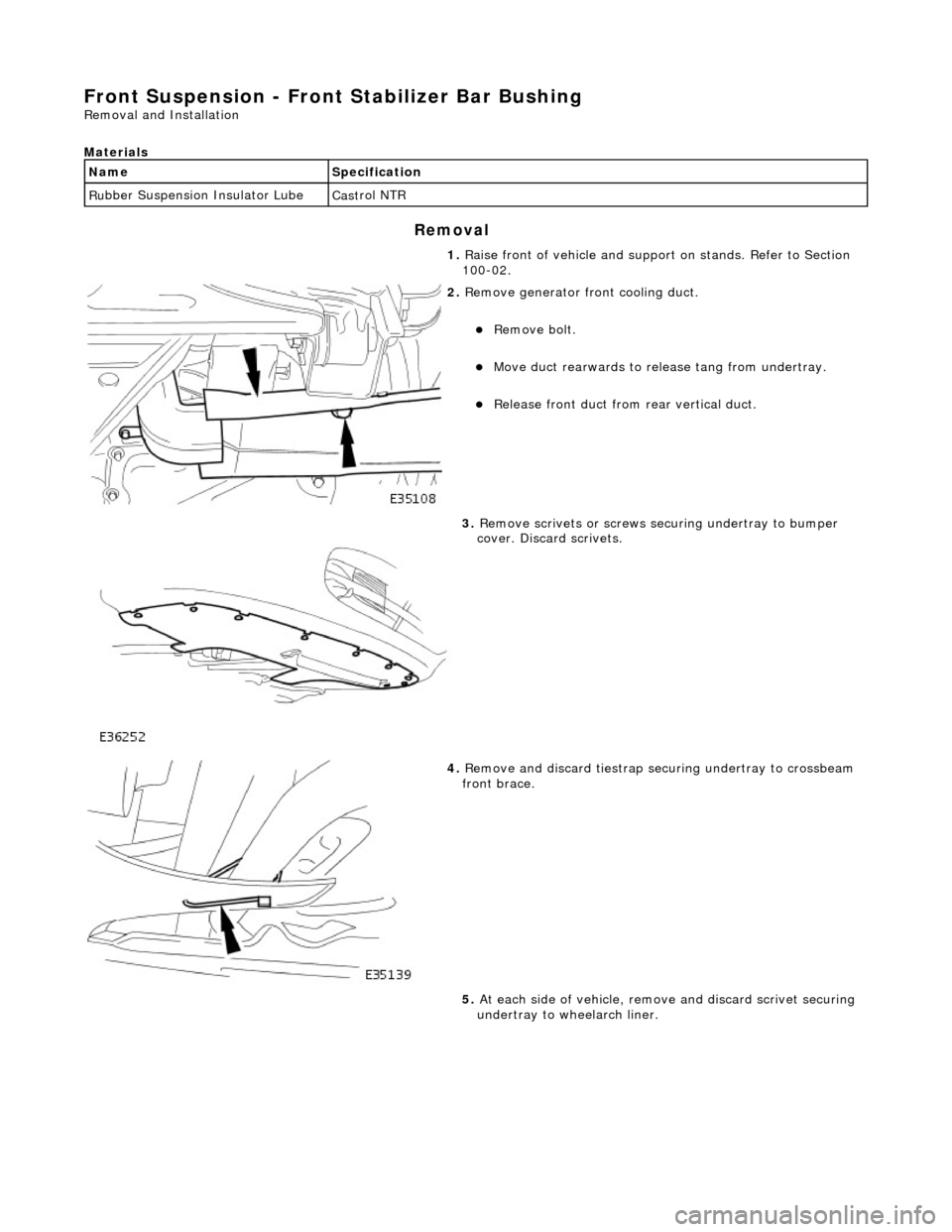

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Re

move generator front cooling duct.

Re

mo

ve bolt.

Move duct rea

r

wards to rele

ase tang from undertray.

Re

lease front duct from rear vertical duct.

3. Re

move scrivets or screws se

curing undertray to bumper

cover. Discard scrivets.

4. Re

move and discard tiestrap securing undertray to crossbeam

front brace.

5. At each side of vehicle, remo ve and discard scrivet securing

undertray to wheelarch liner.

Page 123 of 2490

I

nstallation

6.

R

elease stabilizer bar from link arms.

R

emove nut securing stabilizer bar to link.

R

elease link arm from stabilizer bar.

Repeat operation

at opposite

end of stabilizer bar.

7. N

OTE: On vehicles fitted with an engine oil cooler, it may be

necessary to release the stabilizer bar from each ball joint in turn

to achieve the required cl earance from cooler pipes.

Remove stabilizer bar from crossbeam.

R

emove stabilizer bar securing bolts.

R

emove stabilizer bar mountin

g brackets and remove bar

from crossbeam.

8. Re

move mounting brackets and

rubbers from stabilizer bar.

1. CAUTION: Make sure the Ca strol NTR grease is only

applied to the inner surface of the mounting bushes. Failure to

follow this instruction may affect the retention of the bushes in

the retaining brackets.

Page 124 of 2490

Apply a thi

n film of Castrol NTR

grease to the inner surface of

the bushes.

2. Position mounti n

g rubbers on stabilizer bar.

3. NO

TE: Ensure mounti

ng rubbers seat correctly between

flanges.

Install and fully seat mounti ng brackets on rubbers.

4. Position stabil izer bar assembl

y

on link arms and install but do

not tighten nuts.

5. Ins t

all stabilizer bar mounting bolts.

Install but do not tighten

stabilizer bar LH mounting

bracket bolts.

Instal

l stabilizer bar RH

mounting bracket bolts and

tighten to 30-40Nm.

Tigh ten LH mountin

g bracke

t bolts to 30-40Nm.

6. Secure link arms to stabilizer bar.

Tight

en LH link arm to stabilizer bar nut to 60-80Nm.

Tighte

n RH link arm to stabilizer bar nut to 60-80Nm.

Page 125 of 2490

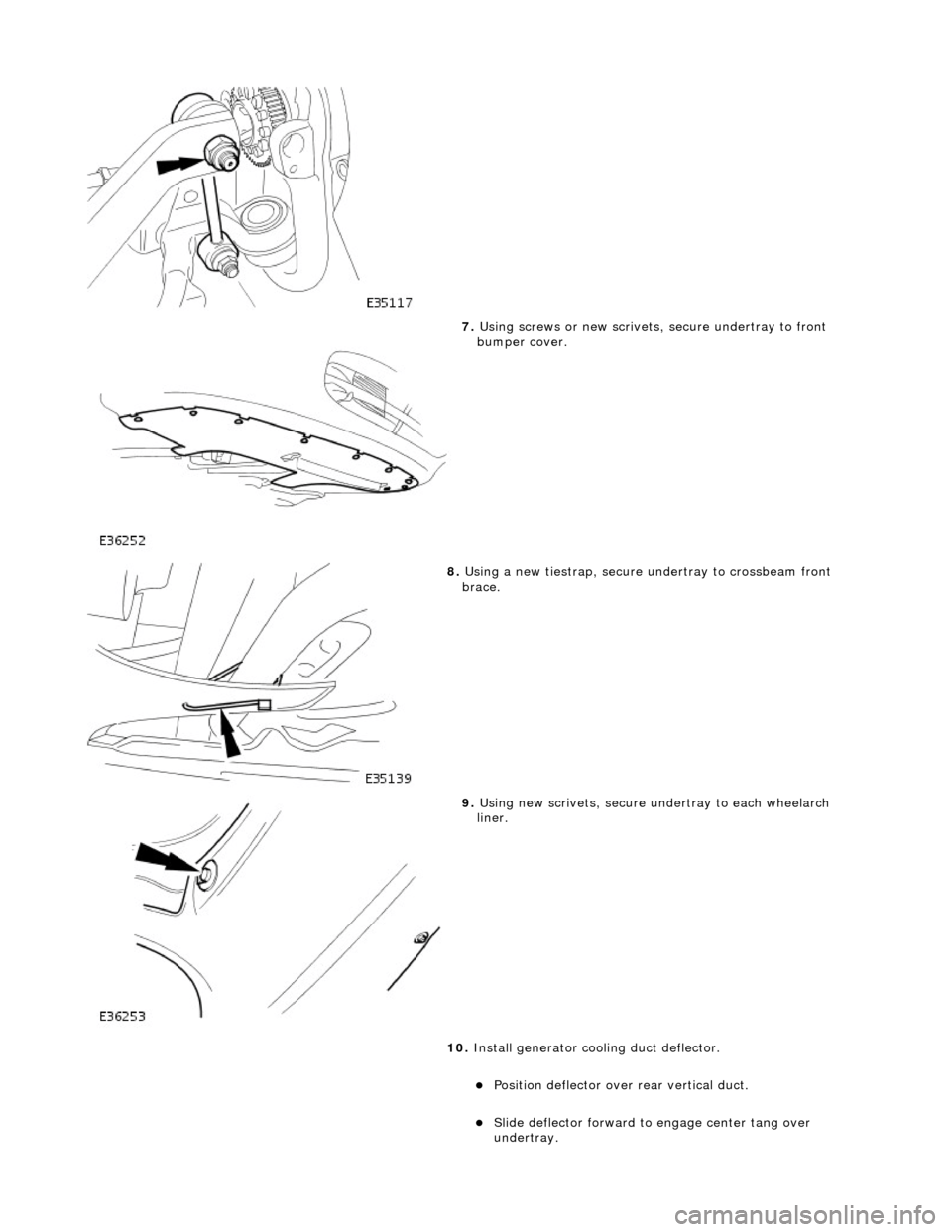

7. Using screws or new scrivets , secure undertray

to front

bumper cover.

8. Usi

ng a new tiestrap, secure undertray to crossbeam front

brace.

9. Usi

ng new scrivets, secure un

dertray to each wheelarch

liner.

10. Install generator cool ing duct deflector.

Po

sition deflector over

rear vertical duct.

Sl

ide deflector forward to

engage center tang over

undertray.

Page 126 of 2490

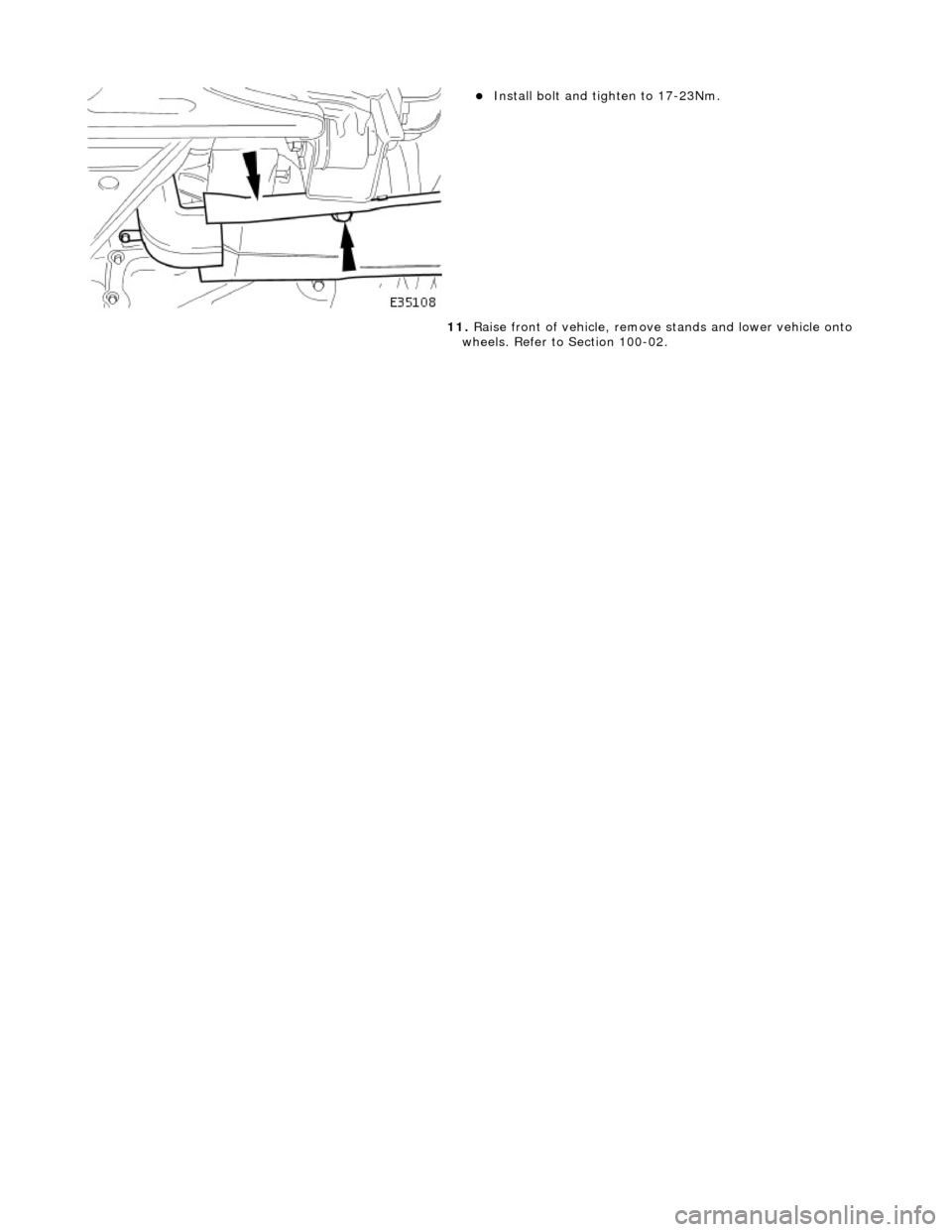

Instal

l bolt and ti

ghten to 17-23Nm.

11. Raise front of vehicle, remove stands and lower vehicle onto

wheels. Refer to Section 100-02.

Page 127 of 2490

Front Suspension - Front Stabiliz

er Bar Link

Re

moval and Installation

Remov

al

Installation

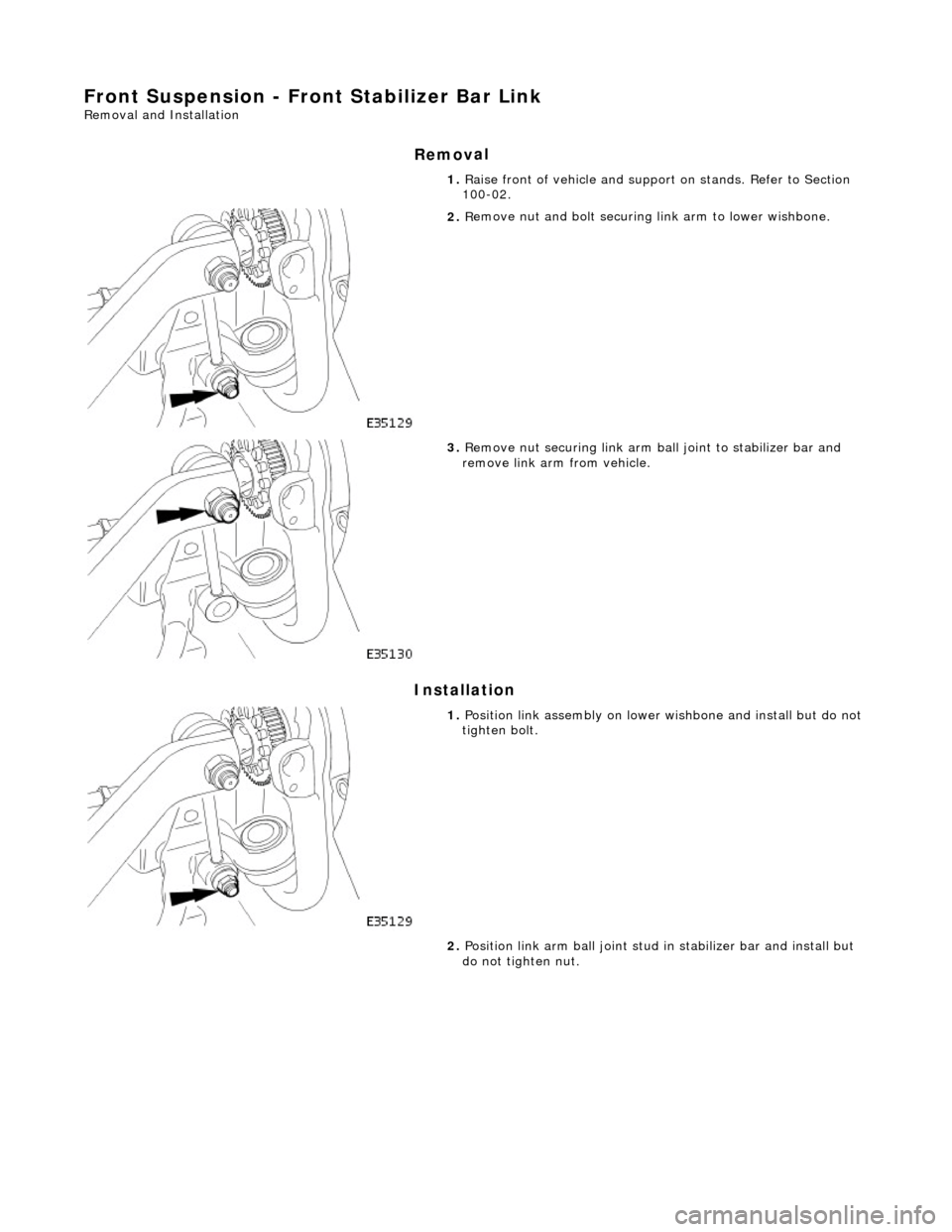

1. R

aise front of vehicle and support on stands. Refer to Section

100-02.

2. R

emove nut and bolt securing

link arm to lower wishbone.

3. R

emove nut securing link arm ba

ll joint to stabilizer bar and

remove link arm from vehicle.

1. Position li

nk assembly on lower

wishbone and install but do not

tighten bolt.

2. Position link arm ball joint stud in stabilizer bar and install but

do not tighten nut.

Page 128 of 2490

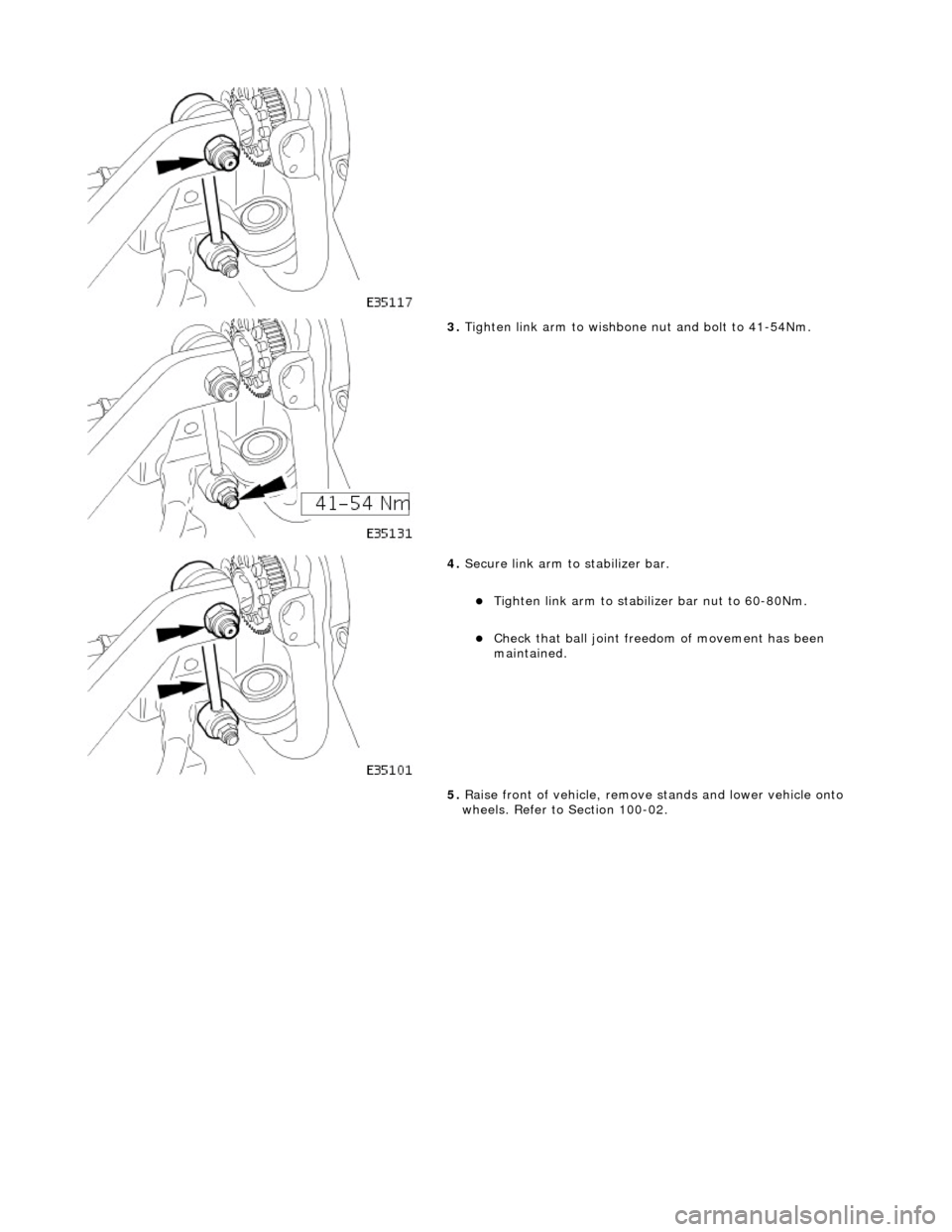

3.

Tighte

n link arm to wishbone

nut and bolt to 41-54Nm.

4. Secure li nk arm to stabil

izer bar.

Tigh

te

n link arm to stabilizer bar nut to 60-80Nm.

Check that ball

joi

nt freed

om of movement has been

maintained.

5. Raise front of vehicle, remove stands and lower vehicle onto

wheels. Refer to Section 100-02.

Page 129 of 2490

Front Suspension - Upper Arm Bushing

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S

pecial Tool(s)

Ball

Joint Taper Separator

204-192 (JD 219)

Front Camber Tie-do

wn Link

204-114 (JD 133)

1. R

aise front of vehicle.

Refer to Section 100-02.

2. P

osition camber tie down spec

ial tool 204-114 on suspension.

Fully s

lacken tool adjuster nut.

Position too

l in road spring and pass upper dowel through

slot in suspen sion turret.

3. Lower front of vehicle.

4. R

otate stem of special tool 204-114 to locate dowel in

suspension turret slot.

5. WARNING: WHEN TIGHTENING TOOL NUT, USE LOWER

DOWEL AS A GUIDE TO ENSURE THAT THE TOOL STEM DOES

NOT ROTATE AND DISTURB POSITION OF DOWEL IN

SUSPENSION TURRET.

Fully tighten nut of special tool to achieve suspension mid-laden

Page 130 of 2490

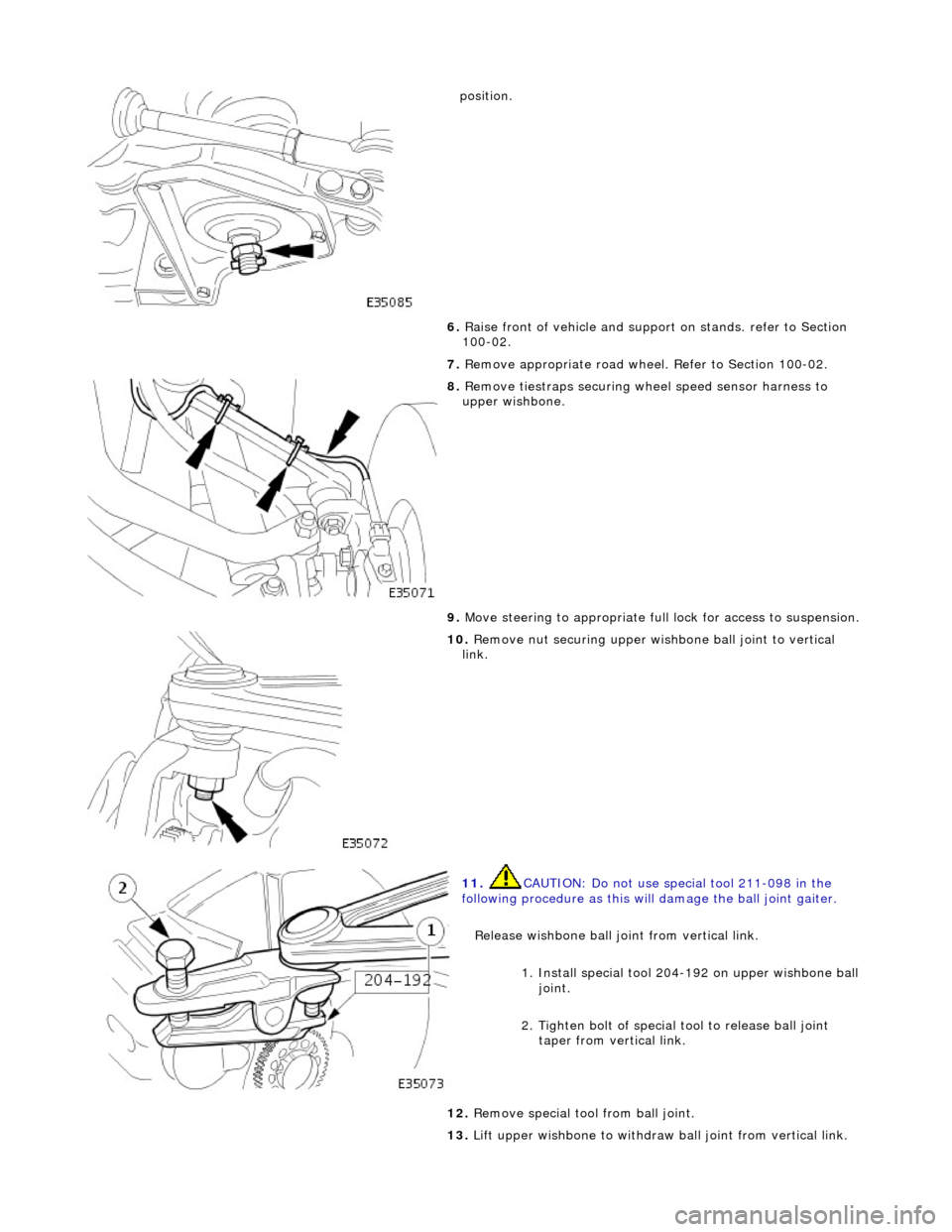

positio

n.

6. Raise front of vehicle and support on stands. refer to Section

100-02.

7. Remove appropriate road wheel. Refer to Section 100-02.

8. Remove t

iestraps securing wheel speed sensor harness to

upper wishbone.

9. Move steering to appropriate full lock for access to suspension.

10. R

emove nut securing upper wish

bone ball joint to vertical

link.

11 . CAUTI

ON: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release wishbone ball joint from vertical link.

1. Install special tool 204-192 on upper wishbone ball joint.

2. Tighten bolt of special tool to release ball joint

taper from vertical link.

12 . Re

move special tool from ball joint.

13. Lift upper wishbone to withdraw ball joint from vertical link.

Trending: P0352, Airbag sensor, fuse diagram, warning light, Door remove, steering, aerial