electrical JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1400 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Diagnostic

Strategy

Diagnosis and Testing

Symptom Chart

Symptom Chart

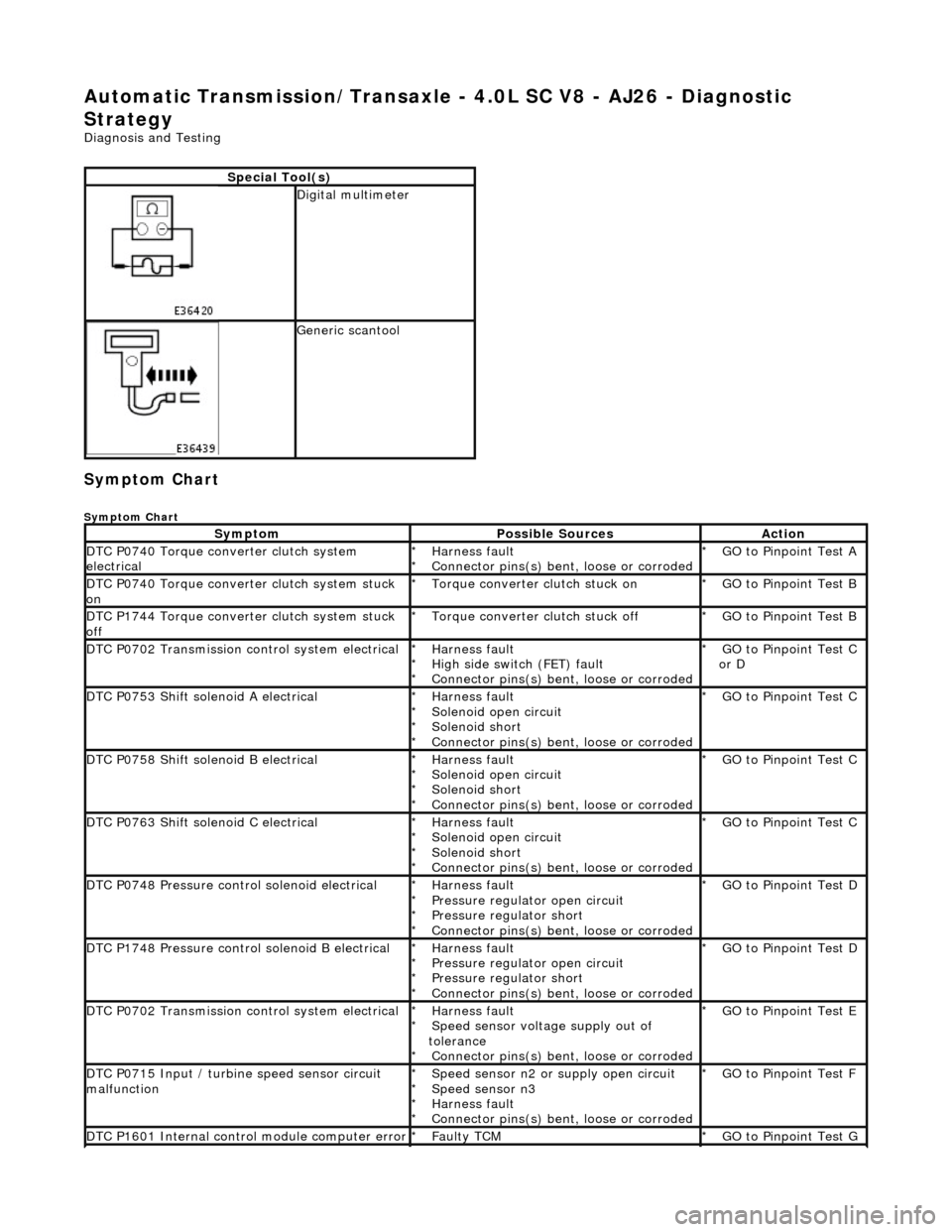

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

DTC P0740 Torque converter clutch system

electricalHarness fault

Connector pins(s) bent , loose or corroded

*

*GO to Pinpoint Test A

*

DTC P0740 Torque converter clutch system stuck

onTorque converter clutch stuck on

*GO to Pinpoint Test B

*

DTC P1744 Torque converter clutch system stuck

offTorque converter clutch stuck off

*GO to Pinpoint Test B

*

DTC P0702 Transmission control system electricalHarness fault

High side switch (FET) fault

Connector pins(s) bent , loose or corroded

*

*

*GO to Pinpoint Test C

or D

*

DTC P0753 Shift solenoid A electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0758 Shift solenoid B electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0763 Shift solenoid C electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0748 Pressure control solenoid electricalHarness fault

Pressure regulator open circuit

Pressure regulator short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test D *

DTC P1748 Pressure control solenoid B electricalHarness fault

Pressure regulator open circuit

Pressure regulator short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test D *

DTC P0702 Transmission control system electricalHarness fault

Speed sensor voltage supply out of

tolerance Connector pins(s) bent , loose or corroded

*

*

*GO to Pinpoint Test E

*

DTC P0715 Input / turbine speed sensor circuit

malfunctionSpeed sensor n2 or supply open circuit

Speed sensor n3

Harness fault

Connector pins(s) bent , loose or corroded

*

*

*

*GO to Pinpoint Test F

*

DTC P1601 Internal control module computer errorFaulty TCM

*GO to Pinpoint Test G *

Page 1438 of 2490

Installation

13. Remove the valve body assembly.

пЃ¬Remove the nine bolts which re tain the valve body to the

transmission case.

1. Installation is the re verse of the removal procedure, noting the

following:

2. Clean all mating faces and relevant parts.

3. Tighten the nine bolts securing the valve body, to the specified

torque figure.

4. Refit the dowel (leaf spring to valve body) and the leaf spring.

Fit and tighten the securing bolt to the specified torque figure.

5. Tighten the centre retaining bolt of the electrical connector to

the specified torque figure.

Page 1445 of 2490

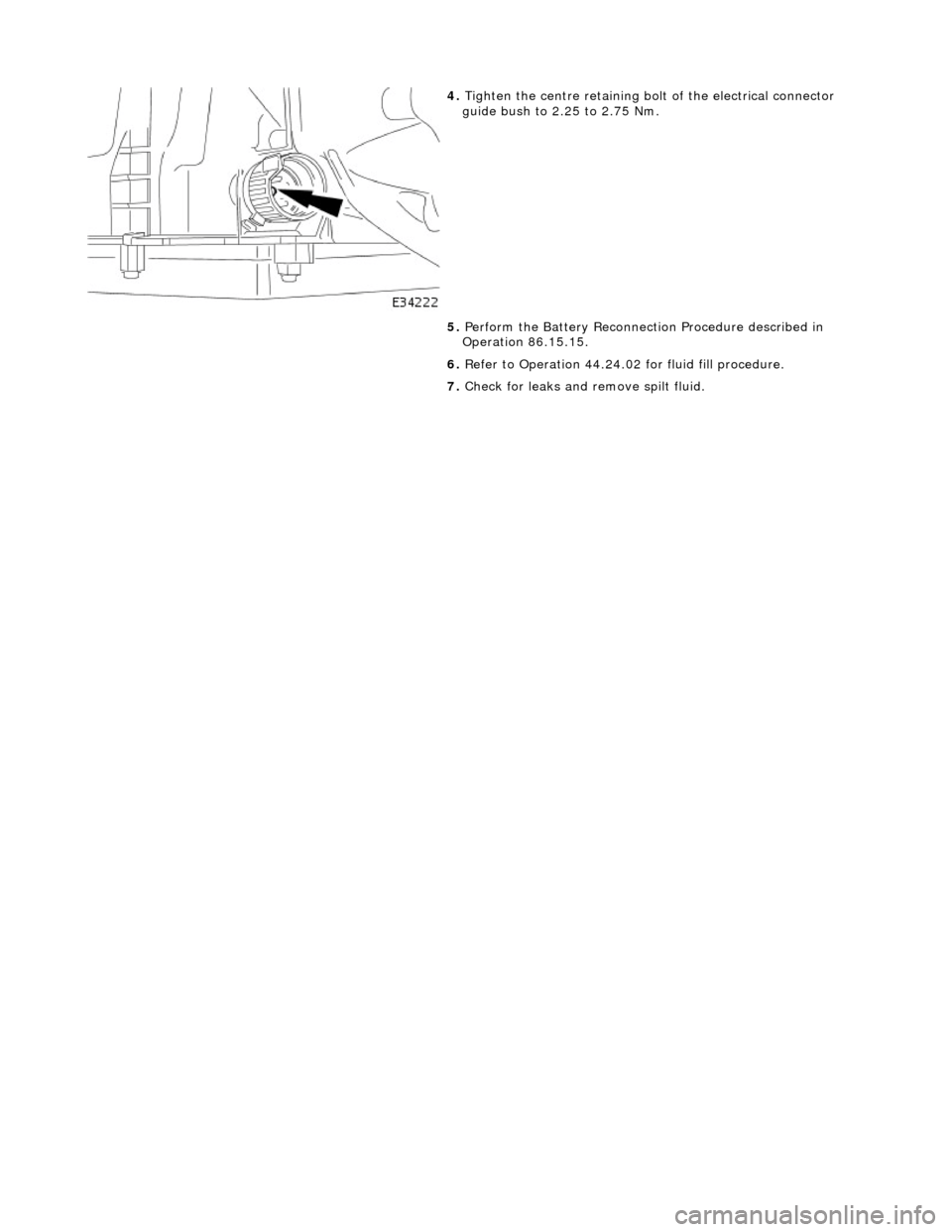

4. Tighten the centre retaining bolt of the electrical connector

guide bush to 2.25 to 2.75 Nm.

5. Perform the Battery Reconnection Procedure described in

Operation 86.15.15.

6. Refer to Operation 44.24.02 for fluid fill procedure.

7. Check for leaks and remove spilt fluid.

Page 1518 of 2490

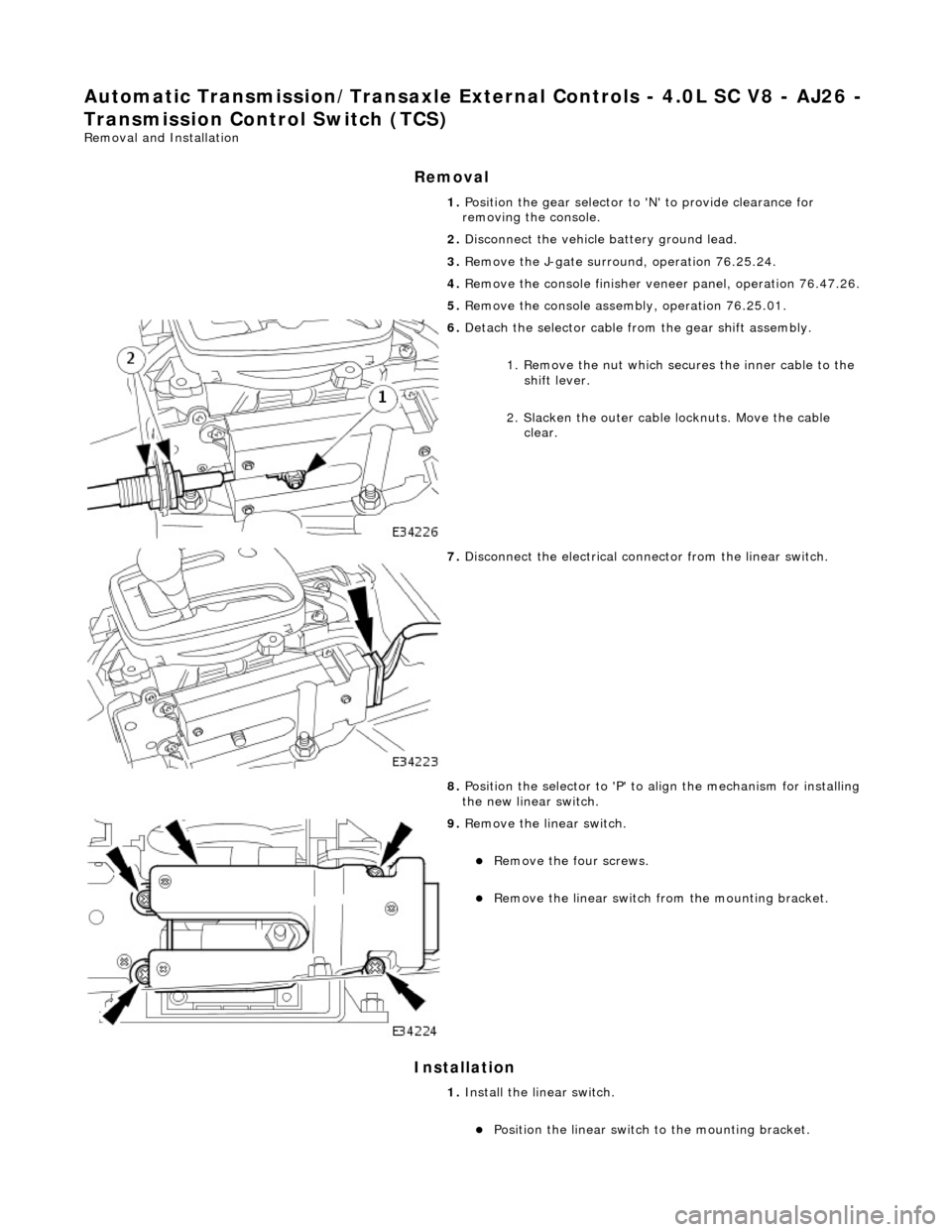

Automatic Transmission/Transaxle External Contro ls - 4.0L SC V8 - AJ26 -

Transmission Control Switch (TCS)

Removal and Installation

Removal

Installation

1. Position the gear selector to 'N' to provide clearance for

removing the console.

2. Disconnect the vehicle battery ground lead.

3. Remove the J-gate surroun d, operation 76.25.24.

4. Remove the console finisher vene er panel, operation 76.47.26.

5. Remove the console assembly, operation 76.25.01.

6. Detach the selector cable from the gear shift assembly.

1. Remove the nut which secures the inner cable to the shift lever.

2. Slacken the outer cable locknuts. Move the cable clear.

7. Disconnect the electrical conne ctor from the linear switch.

8. Position the selector to 'P' to align the mechanism for installing

the new linear switch.

9. Remove the linear switch.

пЃ¬Remove the four screws.

пЃ¬Remove the linear switch fro m the mounting bracket.

1. Install the linear switch.

пЃ¬Position the linear switch to the mounting bracket.

Page 1519 of 2490

пЃ¬Align the drive peg and lower sliding block of the switch to

the mating components of the selector mechanism.

2. Install the four screws, bu t do not fully tighten.

пЃ¬Remove the Ty-Strap from the dual linear switch.

пЃ¬Use the manual release and repo sition the selector to 'N'

for installation of the selector cable.

3. Connect the electrical connector to the linear switch.

4. Assemble the cable to the gear shift assembly.

1. Locate the outer cable and fit the inner cable to the gear selector arm. Tighten to 22-28 Nm.

2. Position the abutment nuts to the approximate position, but do not tighten.

5. NOTE: When setting the selector cable, ensure that the

selector lever on the transmission ca sing is still in the 'N' position.

Adjust the selector cable from inside the vehicle.

1. Confirm that the selector lever is in the 'N' position.

2. Adjust the nuts to lock against the bracket without

Page 1693 of 2490

Filler Cap and P

ipe

The fuel

filler cap with bayonet-type fixi

ng is located beneath a remote-release sp ring-latched lid on the rear saddle panel

on the left-hand-side of the vehicle.

Fuel Pum

p

The fu

el pump(s) is energized by an ECM co

ntrolled relay. Fuel is drawn by this pu mp and supplied to the fuel injectors via

the fuel line, filter and fuel rails.

Servicing of the fuel pump re quires fuel tank removal.

Ev

aporative Loss Flange Assembly

The evaporative-loss flan

ge asse

mbly is mounted centrally on top of the tank. The flange assembly consists of a removeable

steel cap which mounts the evaporative emissions system vapor outlet valves and, if applicable, a pressure sensor. The

external electrical supply to th e fuel pump(s) is also made via a connector on the flange.

The flange assembly is fixed to the tank by a locking ring which is turned usin g special tool JD-174. A seal is fitted between

the flange assembly and the tank. Three di fferent flange assemblies are applicable according to the evaporative emission

system fitted to the vehicle. The fl ange size and fixing are identical fo r the three systems, as described.

Removal of the evaporative flange assembly is necessary to gain access to th e fuel pump(s) and other internal components.

To remove the evaporative fl ange assembly the fuel tank must first be removed.

The evaporative flange variant assemblies are described, together with service information, in Section 303-13.

Fuel R

eturn

Excess fuel

is directed back to

the fuel tank via a return line.

Fuel Pum

p Relay

The

fuel pump relay,

under control of the ECM, switches power to the fuel pump motor.

I

nertia Fuel Shutoff (IFS) Switch

The IF

S switch is located in the right-hand

side footwell behind the footboard carpet . When activated the switch isolates the

ignition system and fuel pump, releases any locked doors and disables unnecessary electrical systems. The system can be

reset by pressing down the flexible cover on the top of the switch.

• NOTE: The doors will not unlock if the IFS switch is tripped when the ignition switch is in position '0'.

Page 1744 of 2490

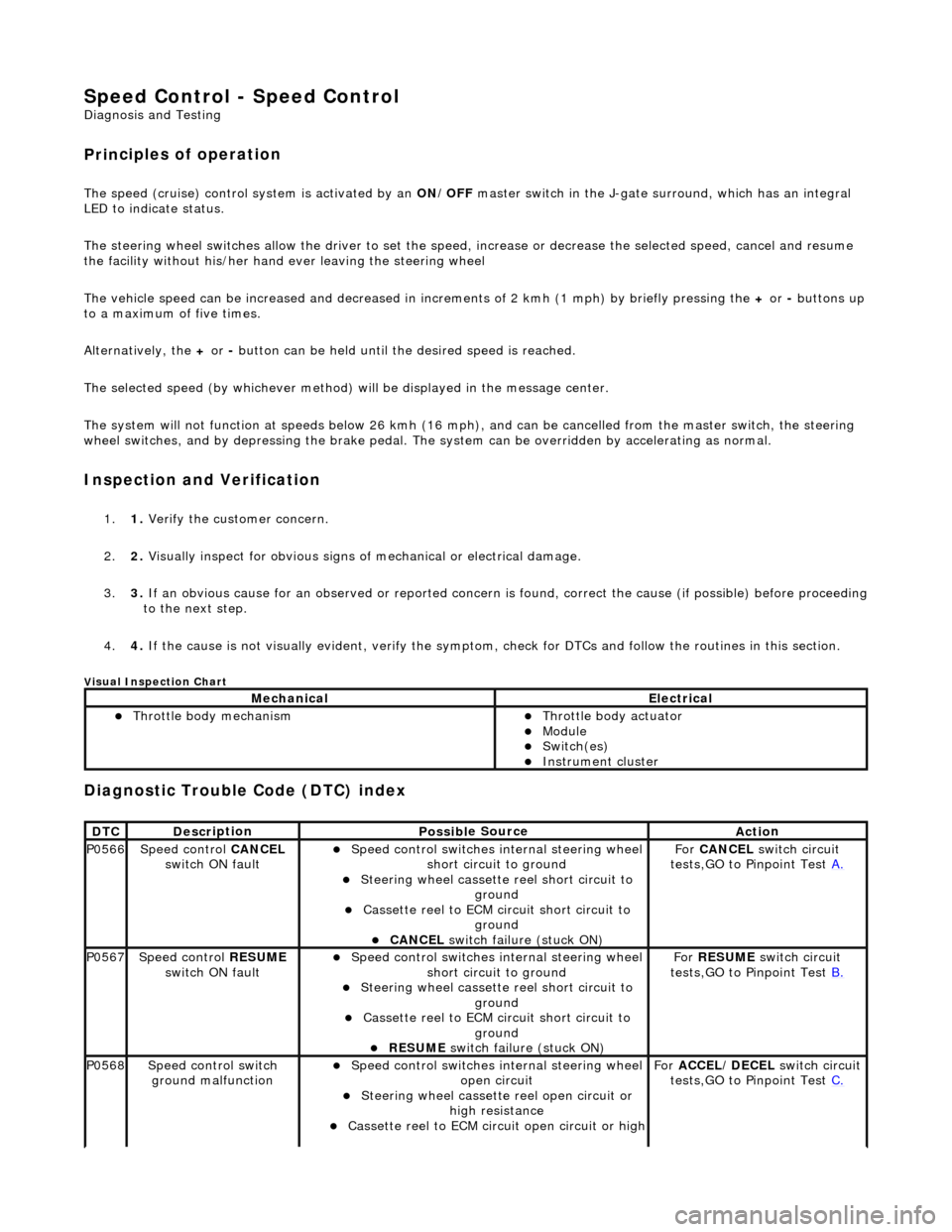

Speed Control - Speed

Control

D

iagn

osis and Testing

Pri

n

ciples of operation

The s

p

eed (cruise) control sy

stem is activated by an ON/OFF master switch in the J-gate surround, which has an integral

LED to indicate status.

The steering wheel switches allow the driver to set the speed, increase or decrease the selected speed, cancel and resume

the facility without his/her hand ever leaving the steering wheel

The vehicle speed can be increased an d decreased in increments of 2 kmh (1 mph) by briefly pressing the + or - buttons up

to a maximum of five times.

Alternatively, the + or - button can be held until th e desired speed is reached.

The selected speed (by whichever method) w ill be displayed in the message center.

The system will not function at speeds below 26 kmh (16 mph), and can be cancelled from the master switch, the steering

wheel switches, and by depressing th e brake pedal. The system can be overridden by accelerating as normal.

In

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical or electrical damage.

3. 3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

4. 4. If the cause is not visually evident, verify the symptom, check for DTCs and follow the routines in this section.

Vi

sual Inspection Chart

Diagnostic Trouble Code (D

TC) index

MechanicalElectrical

пЃ¬Throttle body mechan

ism

пЃ¬Throttle body actuator

пЃ¬Module пЃ¬Switch(es) пЃ¬Instrument cluster

DTC

De

scr

iption

Possib

l

e Source

Acti

o

n

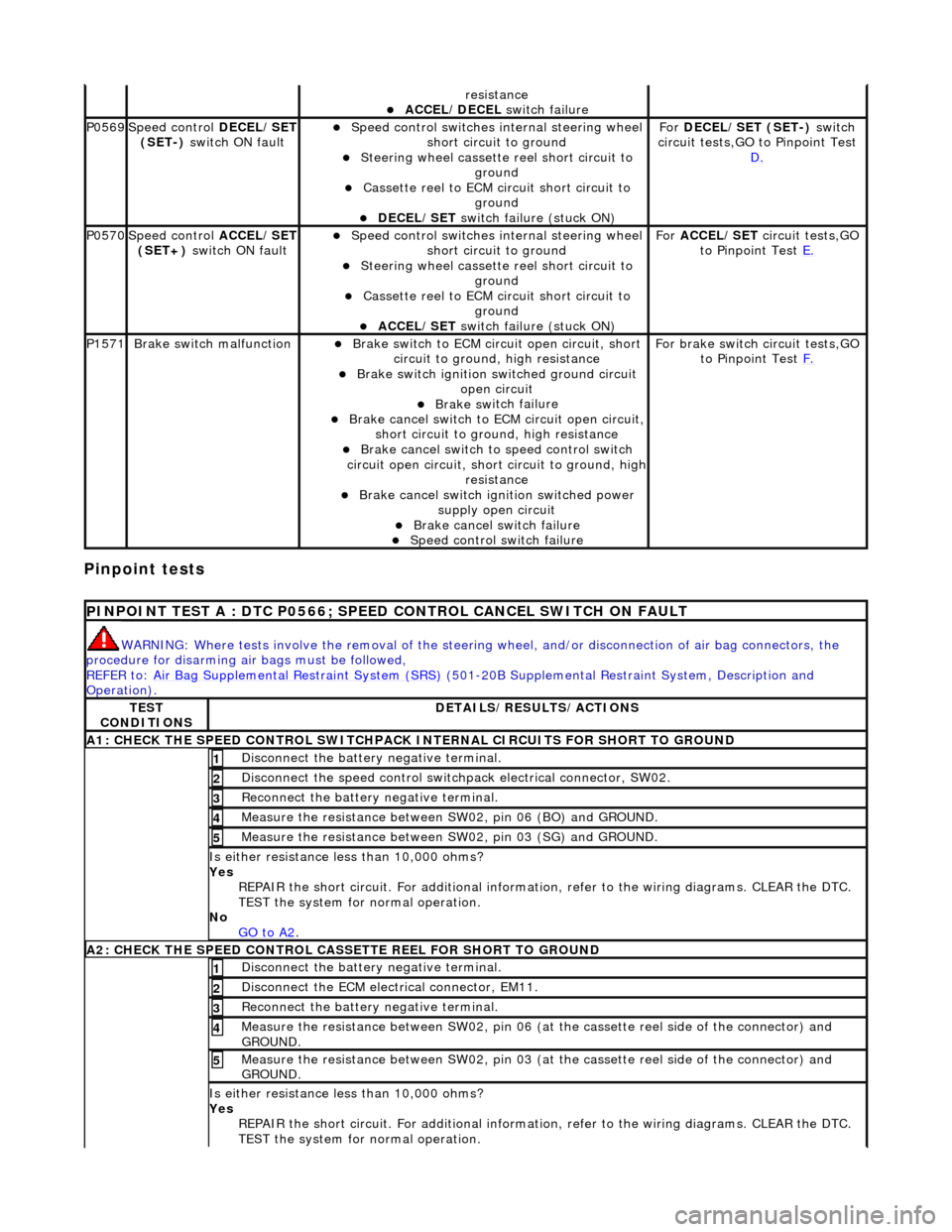

P0566Speed

c

ontrol

CANCEL

switch ON fault

пЃ¬Speed

control switches internal steering wheel

short circuit to ground

пЃ¬St

eering wheel cassette reel short circuit to

ground

пЃ¬Cassette reel to ECM circ

uit short circuit to

ground

пЃ¬CANCEL

switch failure (stuck ON)

Fo

r

CANCEL switch circuit

tests,GO to Pinpoint Test A.

P0567Speed c

ontrol

RESUME

switch ON fault

пЃ¬Speed

control switches internal steering wheel

short circuit to ground

пЃ¬St

eering wheel cassette reel short circuit to

ground

пЃ¬Cassette reel to ECM circ

uit short circuit to

ground

пЃ¬RESUME swit

ch failure (stuck ON)

For

RESUME switch circuit

tests,GO to Pinpoint Test B.

P0568Spee

d control switch

ground malfunction

пЃ¬Speed

control switches internal steering wheel

open circuit

пЃ¬St

eering wheel cassette reel open circuit or

high resistance

пЃ¬Cassette reel to ECM ci

rcuit open circuit or high

For

ACCEL/DECEL switch circuit

tests,GO to Pinpoint Test C.

Page 1745 of 2490

Pinpoint test

s

re

sistance

пЃ¬ACCEL/DECEL

swi

tch failure

P0569Speed

control

DECEL/SET

(SET-) switch ON fault

пЃ¬Speed

control switches internal steering wheel

short circuit to ground

пЃ¬S

teering wheel cassette

reel short circuit to

ground

пЃ¬Cassette reel

to ECM ci

rcuit short circuit to

ground

пЃ¬DEC

EL/SET

switch failure (stuck ON)

Fo

r

DECEL/SET (SET-) switch

circuit tests,GO to Pinpoint Test D.

P0570Speed

control

ACCEL/SET

(SET+) switch ON fault

пЃ¬Speed

control switches internal steering wheel

short circuit to ground

пЃ¬S

teering wheel cassette

reel short circuit to

ground

пЃ¬Cassette reel

to ECM ci

rcuit short circuit to

ground

пЃ¬ACC

EL/SET

switch failure (stuck ON)

Fo

r

ACCEL/SET circuit tests,GO

to Pinpoint Test E.

P1571Brake sw

itch malfunction

пЃ¬Brake sw

itch to ECM circuit open circuit, short

circuit to ground, high resistance

пЃ¬Brake sw

itch ignition switched ground circuit

open circuit

пЃ¬Brake sw

itch failure

пЃ¬Brake ca

ncel switch to

ECM circuit open circuit,

short circuit to ground, high resistance

пЃ¬Brake ca

ncel switch to speed control switch

circuit open circuit, shor t circuit to ground, high

resistance

пЃ¬Brake ca

ncel switch ignition switched power

supply open circuit

пЃ¬Brake ca

ncel switch failure

пЃ¬Spe

ed control switch failure

For brake swi

tch circuit tests,GO

to Pinpoint Test F.

P

INPOINT TEST A : DTC P0566; SPEED

CONTROL CANCEL SWITCH ON FAULT

WAR

NING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(501-20B Supplemental Restra

int System, Description and

Operation).

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE SPEED CONTROL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Di

sconnect the battery negative terminal.

1

Di

sconnect the speed control switch

pack electrical connector, SW02.

2

R

econnect the battery negative terminal.

3

Meas

ure the resistance between SW

02, pin 06 (BO) and GROUND.

4

Meas

ure the resistance between SW

02, pin 03 (SG) and GROUND.

5

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

R

econnect the battery negative terminal.

3

M

easure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

4

M

easure the resistance between SW02, pin 03 (at the cassette reel side of the connector) and

GROUND.

5

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

Page 1746 of 2490

No

GO to A3.

A3: CHECK THE SPEED CONTRO L CANCEL SWITCH

ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

CANCEL switch.

2

Do

es the resistance

vary by 680 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TEST B : DTC

P0567; SPEED

CONTROL RESUME SWITCH ON FAULT

WARN

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE SPEED CONTR

OL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Measure t

he resistance between SW

02, pin 06 (BO) and GROUND.

2

Measure t

he resistance between SW

02, pin 03 (SG) and GROUND.

3

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B2

.

B2: CHECK THE SPEED CONTR

OL CASSETTE REEL FOR SHORT TO GROUND

M

e

asure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

Me

asure the resistance between SW02, pin 03 (at the cassette reel side of the connector) and

GROUND.

2

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B3

.

B3: CHECK THE SPEED CONTR

OL RESUME SWITCH ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

RESUME switch.

2

Do

es the resistance

vary by 430 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TES

T C : DTC P0568; SPEED CONTROL SWITCH GROUND MALFUNCTION

WAR

N

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1: CHECK FOR CONTINUITY T

H

ROUGH STEERING WHEEL

CANCEL AND RESUME SWITCHES (SWITCHES OPEN)

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Check for c

ontinuity between SW02

, pins 06 (BO) and 03 (SG) wi th the steering wheel switches

inactive.

2

Page 1747 of 2490

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C2

.

C2

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL CANCEL SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C3

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C3

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL RESUME SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel RESUME

switch operated.

1

Is th

e circuit continuous?

Yes GO to C4

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C4

: CHECK FOR CONTINUITY THROUGH STEERING

WHEEL + AND - SWITCHES (SWITCHES OPEN)

Chec

k for continuity between SW02

, pins 06 (BO) and 04 (SR) with the steering wheel switches

inactive.

1

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C5

.

C5

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL + SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C6

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C6

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL - SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C7

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C7: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT #1)

Di

sconnect the steering wheel cassette electrical connector, SW01.

1

Meas

ure the resistance between SW01, pin 06

and SW02, pin 06 through the cassette reel.

2

Is th

e cassette reel continuous?

Yes GO to C8

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C8: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT 2)

Meas

ure the resistance between SW01, pin 03

and SW02, pin 03 through the cassette reel.

1

Is th

e cassette reel continuous?

Yes GO to C9

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C9: CHECK THE ECM

TO CASSETTE REEL

CIRCUIT FOR CONTINUITY (CIRCUIT 1)

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

Meas

ure the resistance between EM11, pin 01 (SR) and SW01, pin 04 (SR).

3