Seat JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 228 of 2490

In

stallation

35

. Clean hu

b and hub carrier.

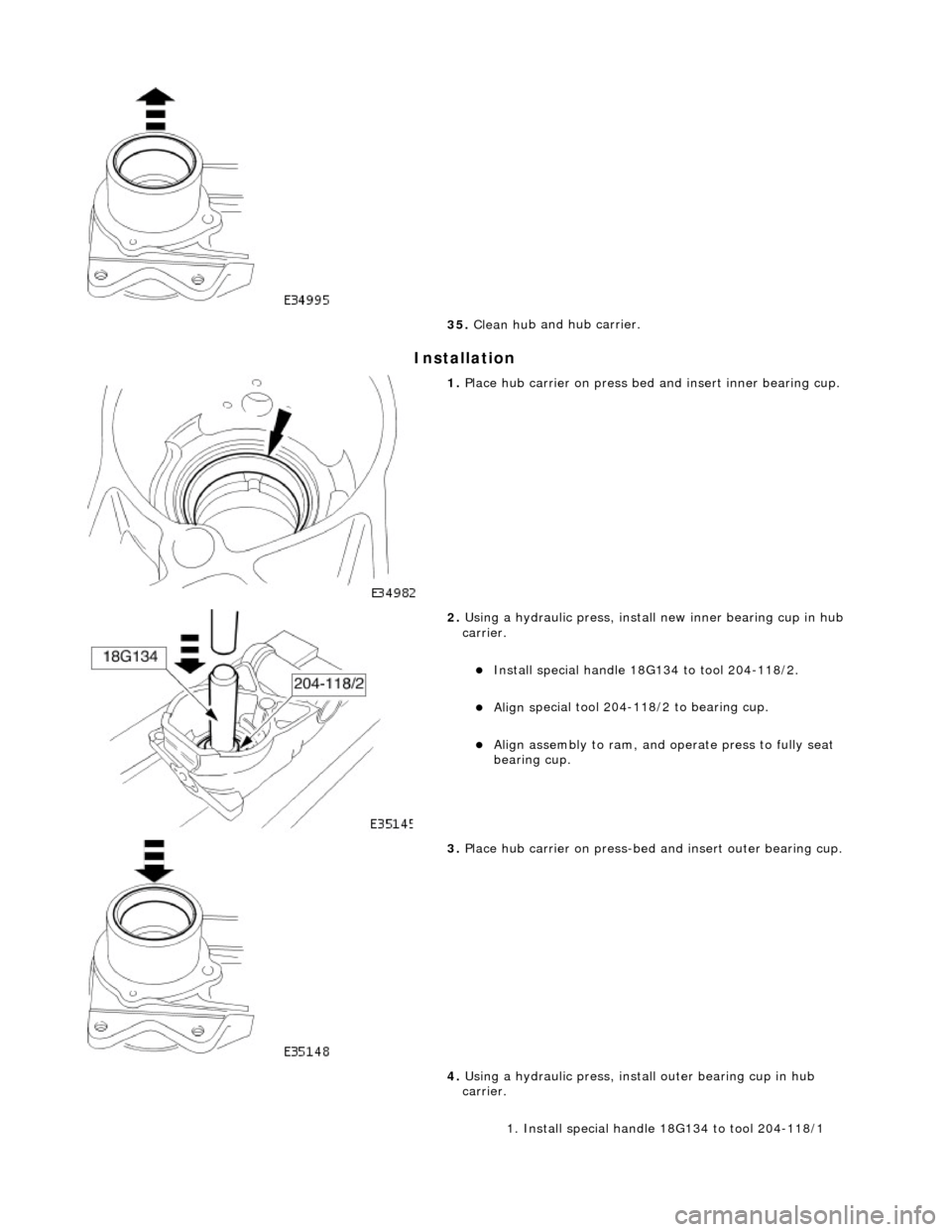

1. Pla c

e hub carrier on press bed

and insert inner bearing cup.

2. Using a h y

draulic press, instal

l new inner bearing cup in hub

carrier.

Ins t

all special handle 18G134 to tool 204-118/2.

Al

ign s

pecial tool 204-118/2 to bearing cup.

Al

ign assembly

to ram, and

operate press to fully seat

bearing cup.

3. Pla c

e hub carrier on press-bed

and insert outer bearing cup.

4. Using a hydraulic press, inst all outer bearing cup in hub

carrier.

1. Install special handle 18G134 to tool 204-118/1

Page 229 of 2490

2

. Align special tool 204-118/1 to bearing cup.

Al

ign assembly to ram, and

operate press to fully seat

bearing cup.

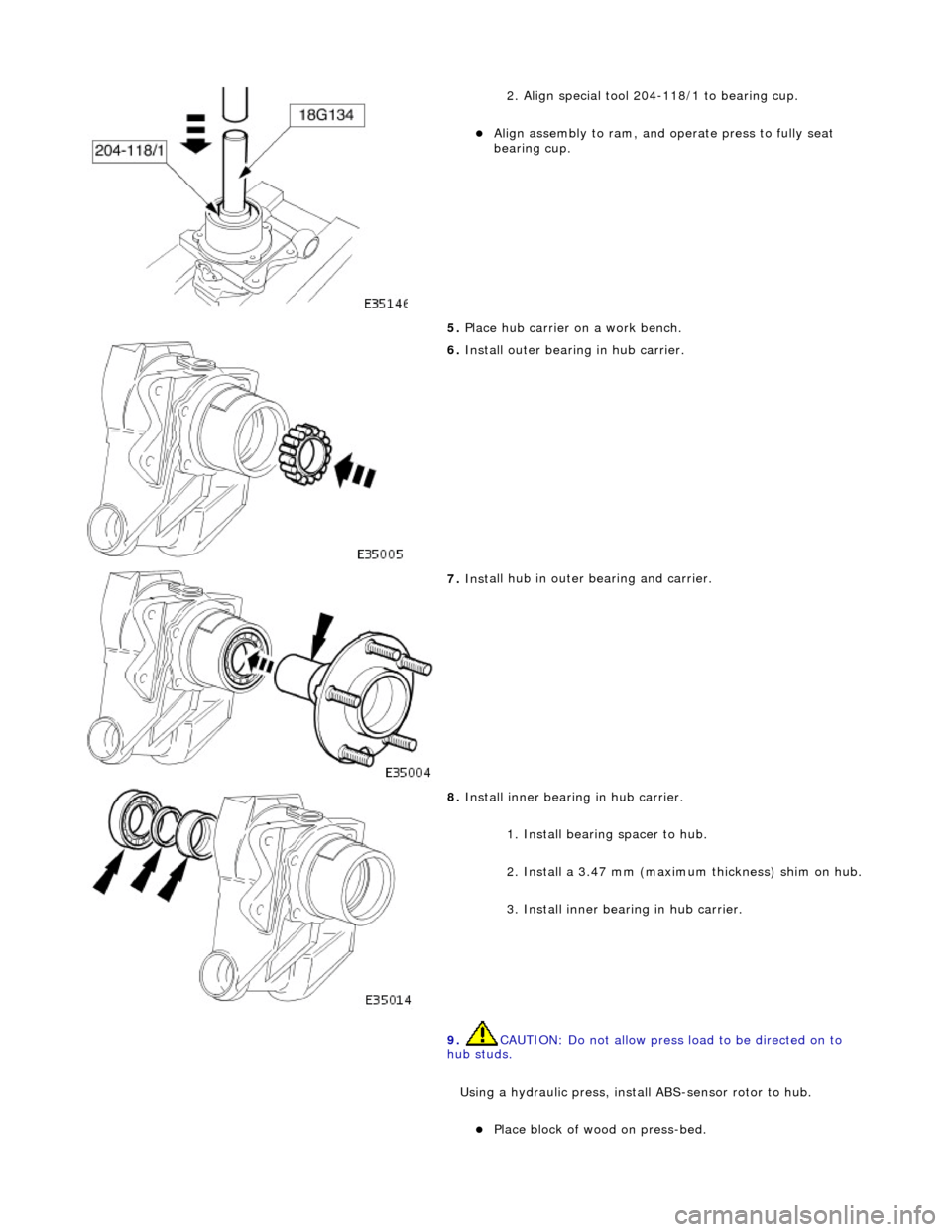

5. Place hub carrier on a work bench.

6. Install outer bearing in hu

b carrier.

7. Inst

all hub in outer

bearing and carrier.

8. Inst

all inner bearing in hub carrier.

1. Install bearing spacer to hub.

2. Install a 3.47 mm (maximum thickness) shim on hub.

3. Install inner bearing in hub carrier.

9. CAUTION: Do not allow press load to be directed on to

hub studs.

Using a hydraulic press, install ABS-sensor rotor to hub.

Pl

ace block of wood on press-bed.

Page 231 of 2490

Re

move bearin

g spacer.

Remove ou

ter bearing.

14. Pack new inner and outer bear ings with Shell Retinax 'A'

grease.

15

.

Install outer bearing and usin g special tool 205-234, fully

seat seal in hub carrier.

16

.

Using a press, install hub in carrier/bearing assembly.

17

.

Install inner bearing assembly.

1. Install bearing spacer.

2. Install bearing shim.

3. Install inner bearing.

18. Determine hub end float.

Measure an

d record end-float as a datum.

Calculating from datum, select

a sh

im that will achieve a

0.076 mm end-float.

19. Install new bearing shim.

Page 232 of 2490

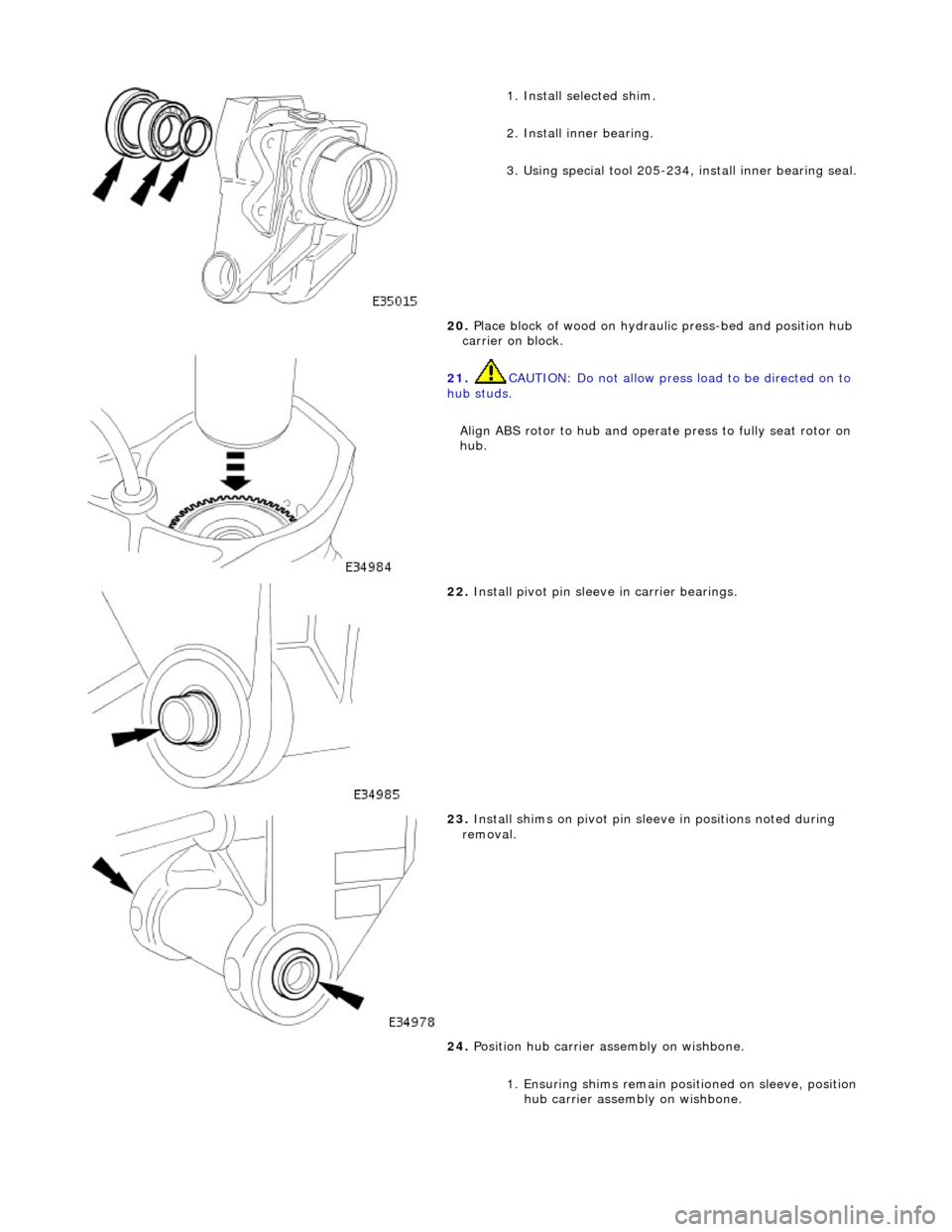

1. Ins

tall selected shim.

2. Install inner bearing.

3. Using special tool 205-234, install inner bearing seal.

20. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

21 . CAUTI

ON: Do not allow press load to be directed on to

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

22 . Install piv

ot pin sleeve in carrier bearings.

23 . Inst

all shims on pivot pin slee

ve in positions noted during

removal.

24. Position hub carrier as sembly on wishbone.

1. Ensuring shims remain posi tioned on sleeve, position

hub carrier assembly on wishbone.

Page 233 of 2490

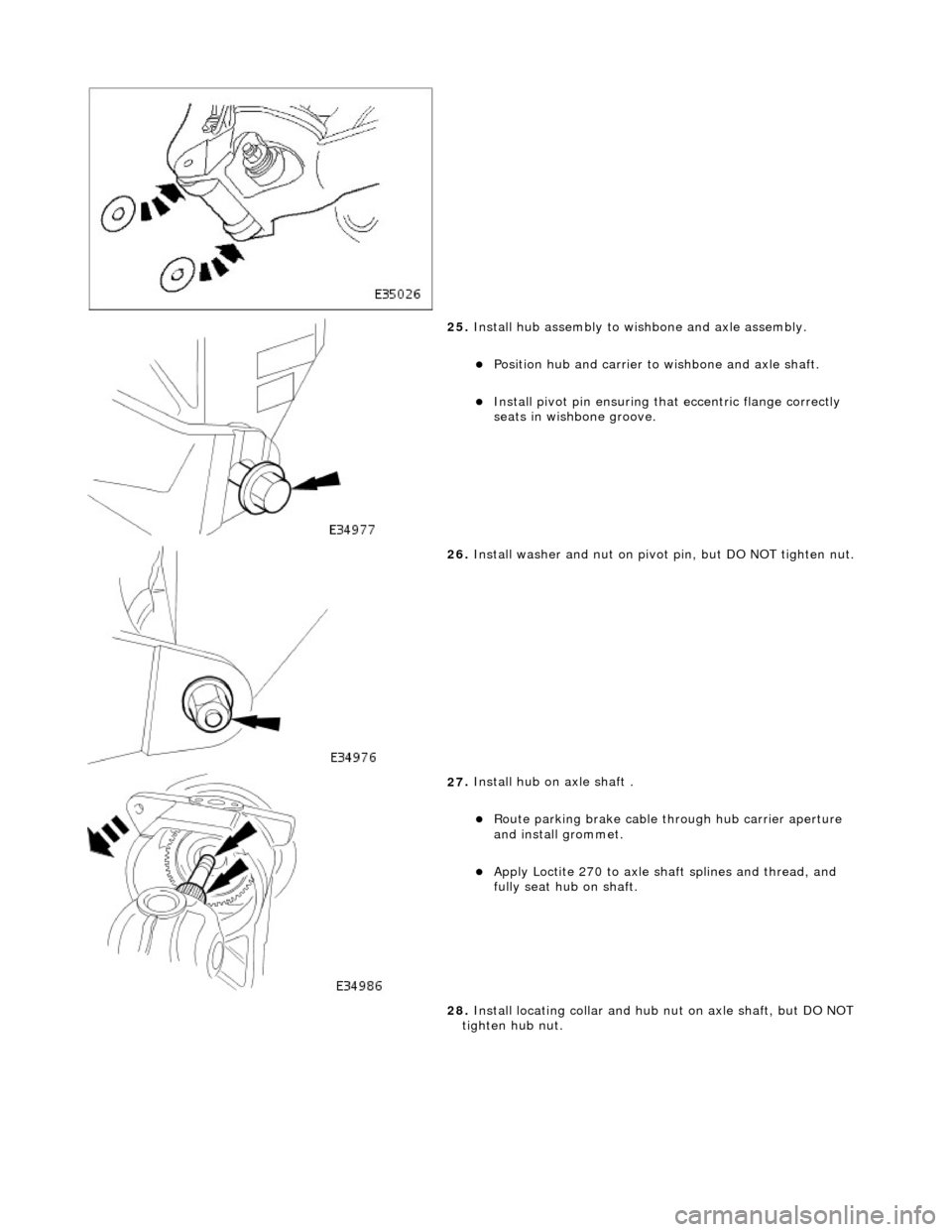

25

.

Install hub assembly to wi shbone and axle assembly.

Position hu

b and carrier to wishbone and axle shaft.

Install piv

ot pin ensuring that

eccentric flange correctly

seats in wishbone groove.

26

.

Install washer and nut on pivot pin, but DO NOT tighten nut.

27

.

Install hub on axle shaft .

Route parking brake cable throu

gh hub carrier aperture

and install grommet.

Appl

y Loctite 270 to axle shaft splines and thread, and

fully seat hub on shaft.

28. Install locating collar and hub nut on axle shaft, but DO NOT

tighten hub nut.

Page 243 of 2490

I

nstallation

33

.

Using approved cleaning agents:

Wash an

d thoroughly dry inner and outer bearings.

Thorough

ly clean hub carrier payi

ng particular attention to

bearing cups.

Thoroughl

y clean hub.

1. Grease bearings.

Pack inner and outer bea

ring races with Shell Retinax 'A'

grease:

Appl

y a film of shell Retinax

'A' grease to bearing cups

2. Install outer bearing in hu

b carrier and fully seat new seal

using special tool 205-234.

3. Apply a th

in film of Shell Retinax 'A' grease to hub shaft and

install hub in carrier /bearing assembly.

4. Install inner bearing assembly and seal.

1. Install bearing spacer.

Page 244 of 2490

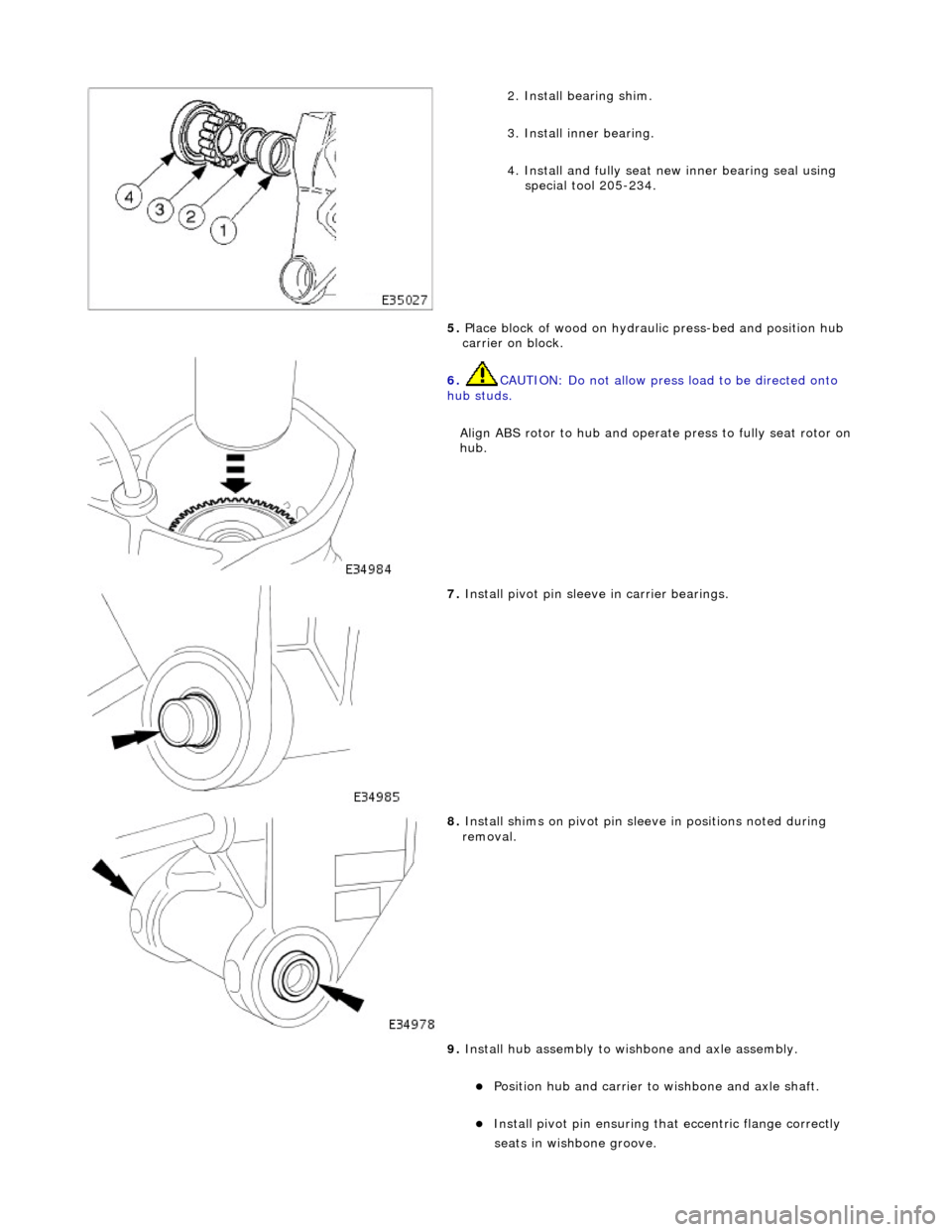

2.

Install bearing shim.

3. Install inner bearing.

4. Install and fully seat new inner bearing seal using special tool 205-234.

5. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

6. CAUTIO

N: Do not allow press

load to be directed onto

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

7. Install piv o

t pin sleeve in carrier bearings.

8. Inst al

l shims on pivot pin slee

ve in positions noted during

removal.

9. Install hub assembly to wi shbone and axle assembly.

Position hub and carr

ier to wishbone and axle shaft.

Install pivo

t pin ensuring that

eccentric flange correctly

seats i

n wishbone groove.

Page 245 of 2490

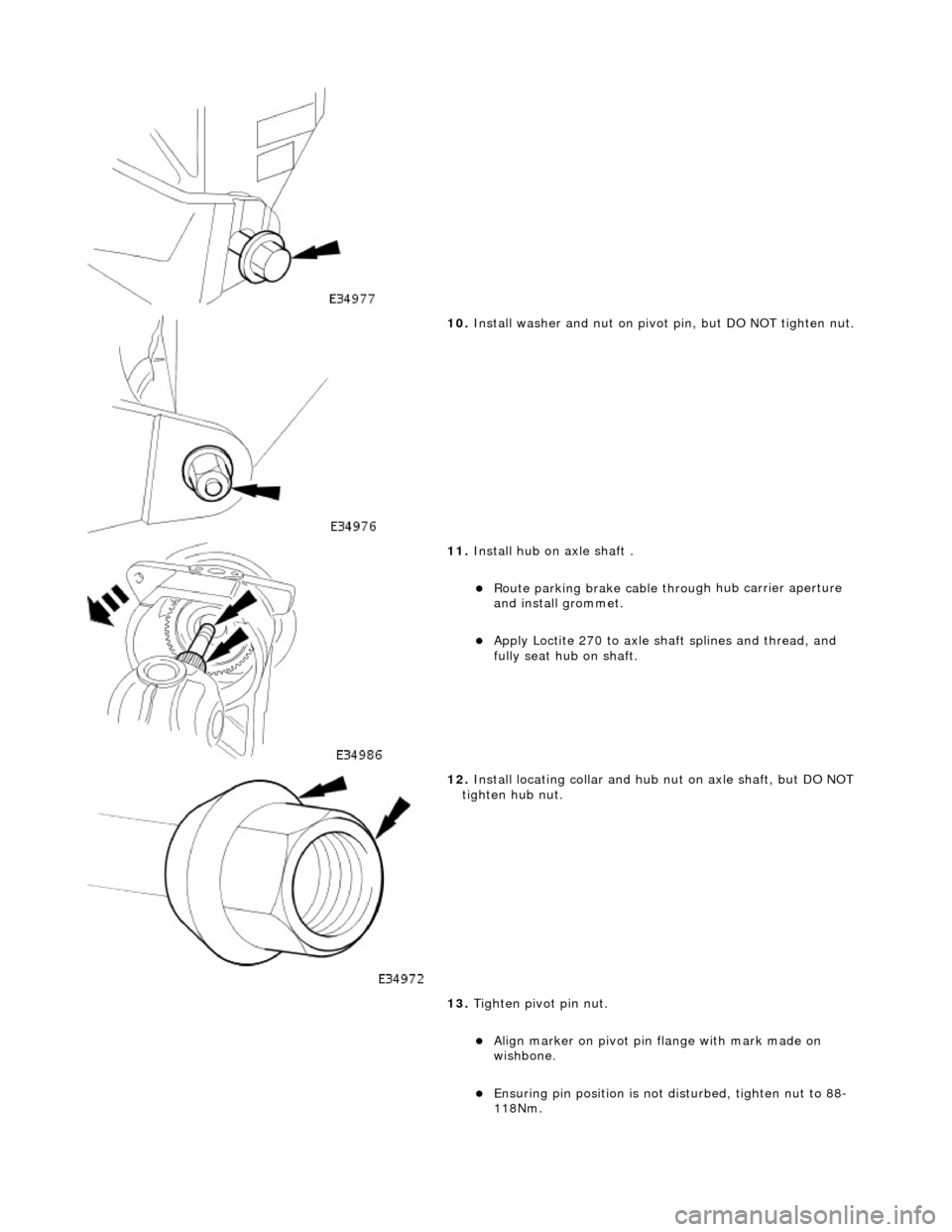

10

.

Install washer and nut on pivot pin, but DO NOT tighten nut.

11

.

Install hub on axle shaft .

Route parking brake cable throu

gh hub carrier aperture

and install grommet.

Appl

y Loctite 270 to axle shaft splines and thread, and

fully seat hub on shaft.

12

.

Install locating collar and hub nut on axle shaft, but DO NOT

tighten hub nut.

13. Tighten pivot pin nut.

Al

ign marker on pivot pin flange with mark made on

wishbone.

Ensuri

ng pin position is not

disturbed, tighten nut to 88-

118Nm.

Page 253 of 2490

I

nstallation

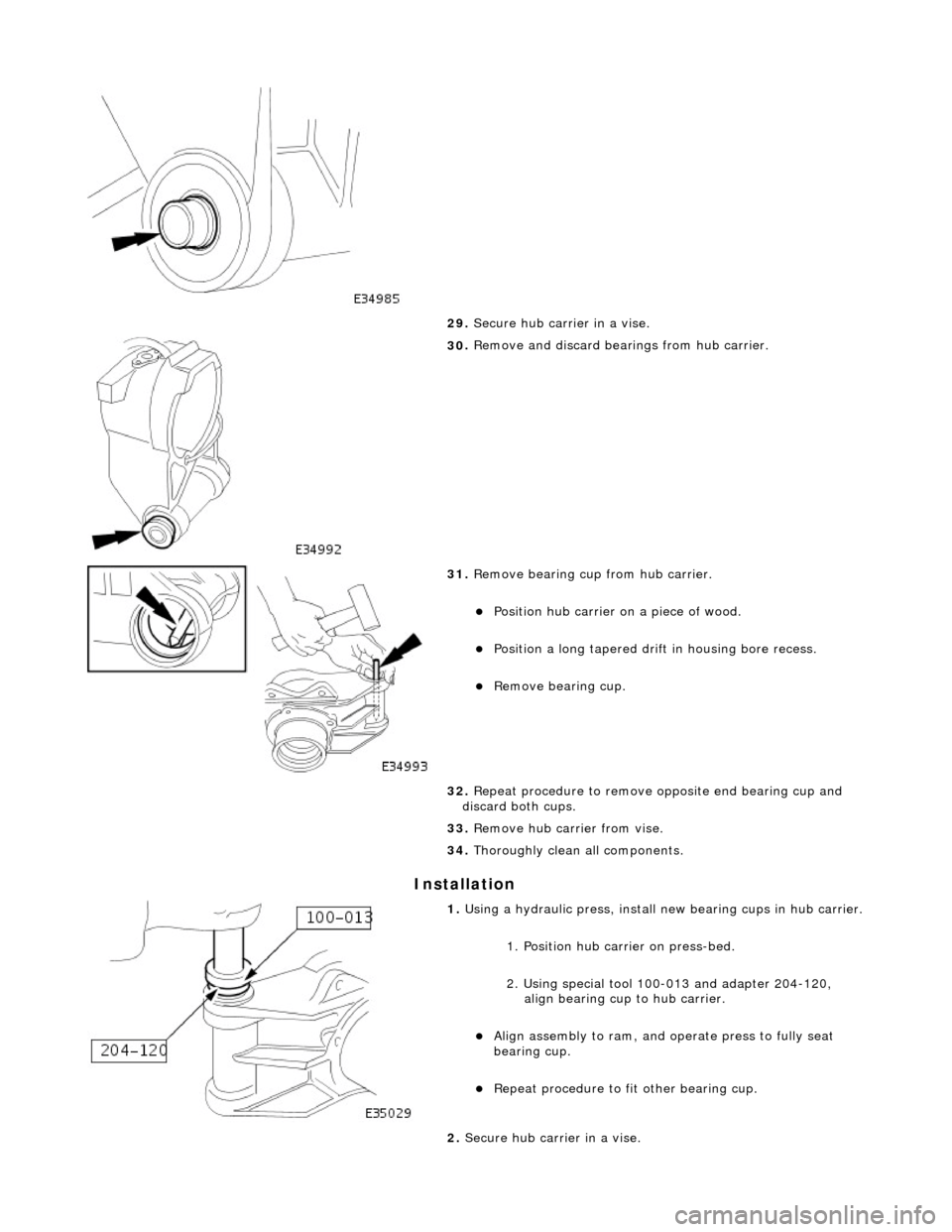

29

.

Secure hub carrier in a vise.

30

.

Remove and discard bear ings from hub carrier.

31

.

Remove bearing cup from hub carrier.

Posit

ion hub carrier on a piece of wood.

Position a lo

ng tapered drif

t in housing bore recess.

Remove bearin

g cup.

32. Repeat procedure to remove opposite end bearing cup and

discard both cups.

33. Remove hub carrier from vise.

34. Thoroughly clean all components.

1. Using a h

ydraulic press, install

new bearing cups in hub carrier.

1

. Position hub carri

er on press-bed.

2. Using special tool 100-013 and adapter 204-120, align bearing cup to hub carrier.

Al

ign assembly to ram, and

operate press to fully seat

bearing cup.

Repeat

procedure to fi

t other bearing cup.

2. Secure hub carri er in a vise.

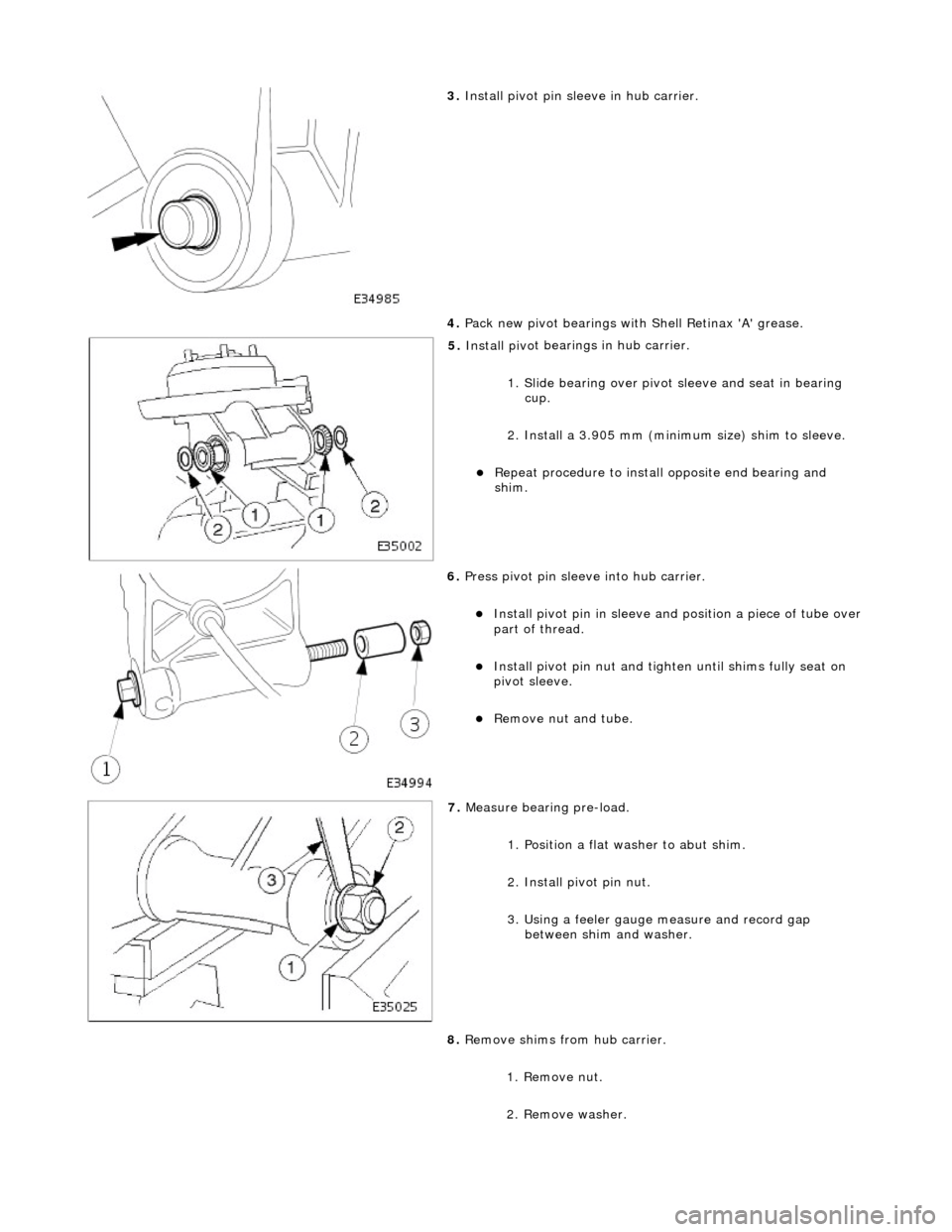

Page 254 of 2490

3. Install pivo

t pin sleeve in hub carrier.

4. Pack new pivot bearings with Shell Retinax 'A' grease.

5. Install piv o

t bearings in hub carrier.

1. Slide bearing over pivot sleeve and seat in bearing

cup.

2. Install a 3.905 mm (minimum size) shim to sleeve.

Repeat procedu

re to instal

l opposite end bearing and

shim.

6. Press piv o

t pin sleeve into hub carrier.

Install piv

o

t pin in sleeve and

position a piece of tube over

part of thread.

Install piv o

t pin nut and tighte

n until shims fully seat on

pivot sleeve.

Remove n u

t and tube.

7. Measure bearin g pre-load.

1. Position a flat washer to abut shim.

2. Install pivot pin nut.

3. Using a feeler gauge measure and record gap between shim and washer.

8. Remove shims from hub carrier.

1. Remove nut.

2. Remove washer.