JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1591 of 3039

1 Magnetic foil 2 Spacer 3 Ceramic surface 4 Magnet 5 Resistance film The film resistors are arranged in a linear arc with resistance ranging from 51.2 to 992.11 Ohms. The electrical output signal is

proportional to the amount of fuel in the tank and the position of the float arm. The measured resistance is processed by the

instrument cluster to implement an anti-slosh function. This monitors the signal and updates the fuel gauge pointer position

at regular intervals, preventing constant pointer movement caused by fuel movement in the tank due to cornering or braking.

A warning lamp is incorporated in the instrument cluster and illuminates when the fuel level is low.

The fuel level sender signal is converted into a CAN message by the instrument cluster as a direct interpretation of the fuel tank contents in liters. The ECM uses the CAN message to store additional OBD (on-board diagnostic) 'P' Codes for misfire detection when the fuel level is below a predetermined capacity.

JET PUMP

The fuel system incorporates two jet pumps. One jet pump is integrated into the fuel pump and draws fuel from the RH side of the fuel tank. The other jet pump is located on the fuel delivery module on the RH side of the tank. There is a pipe that is located in the LH side of the tank that allows fuel to be drawn over from the LH side of the tank, delivering fuel into the swirl pot. The jet pumps operate on a venturi effect created by the fuel at pump output pressure passing through the jet pump. This

draws additional fuel from the LH side of the tank through ports in the jet pump body, delivering additional fuel to the swirl pot.

FUEL VENT VALVE

The fuel level vent valve is located in the upper half of the tank and is connected into a separator which is connected to the

Roll Over Valve (ROV) tank breather. The main purpose of the fuel level vent valve is to control the fill volume of the tank.

During filling, air trapped inside the tank and a small amount of vapor is passed via the fuel level vent valve to the tank

breather. The air and vapor mix then vents to atmosphere through the breather. During filling, when the tank reaches its full

level, the fuel level vent valve closes and prevents air/vapor passing through to the tank breather. The resulting back pressure

causes refueling to stop automatically.

The fuel level vent valve is always open when the fuel tank is below full, providing an unrestricted air/vapor outlet to the tank

breather.

www.JagDocs.com

Page 1592 of 3039

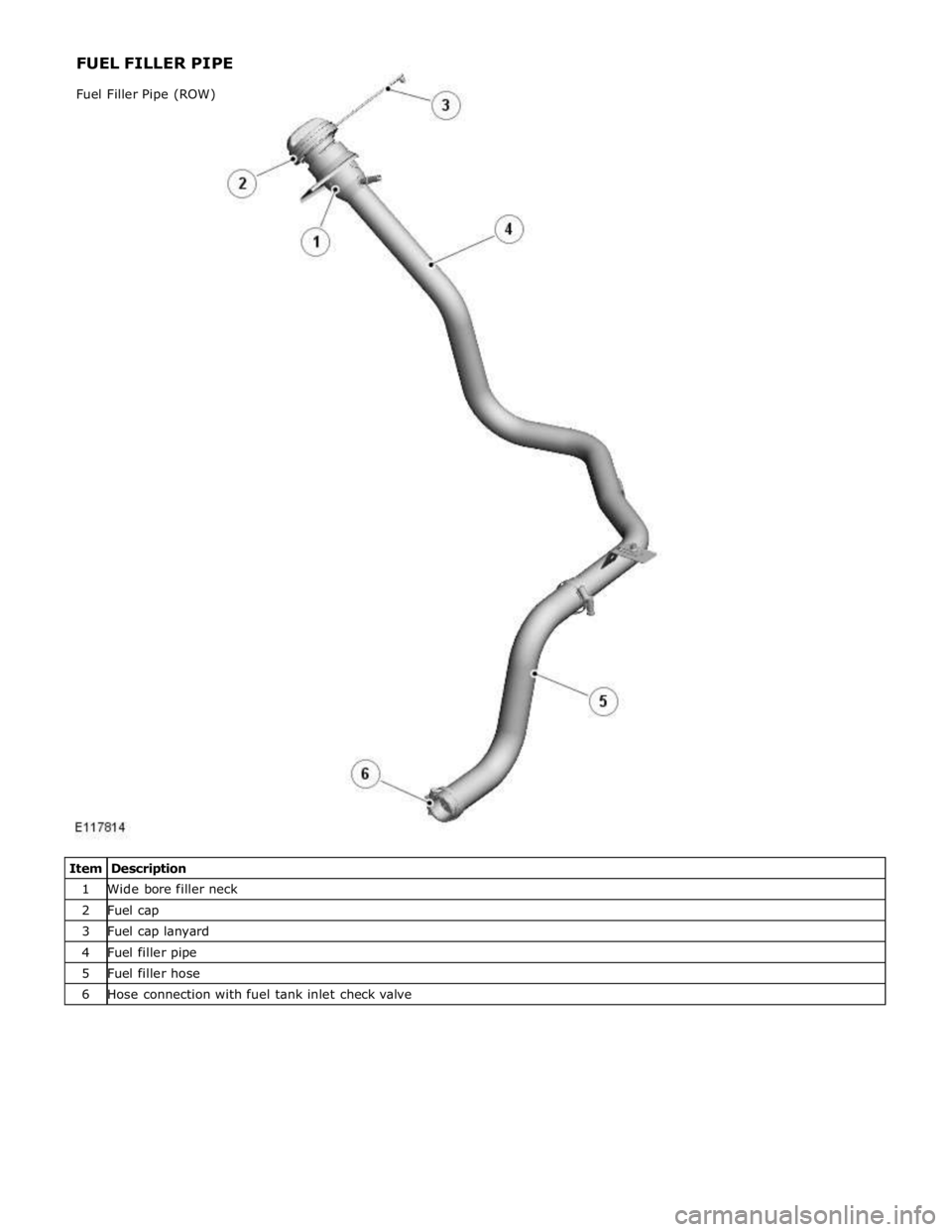

1 Wide bore filler neck 2 Fuel cap 3 Fuel cap lanyard 4 Fuel filler pipe 5 Fuel filler hose 6 Hose connection with fuel tank inlet check valve FUEL FILLER PIPE

Fuel Filler Pipe (ROW)

Page 1593 of 3039

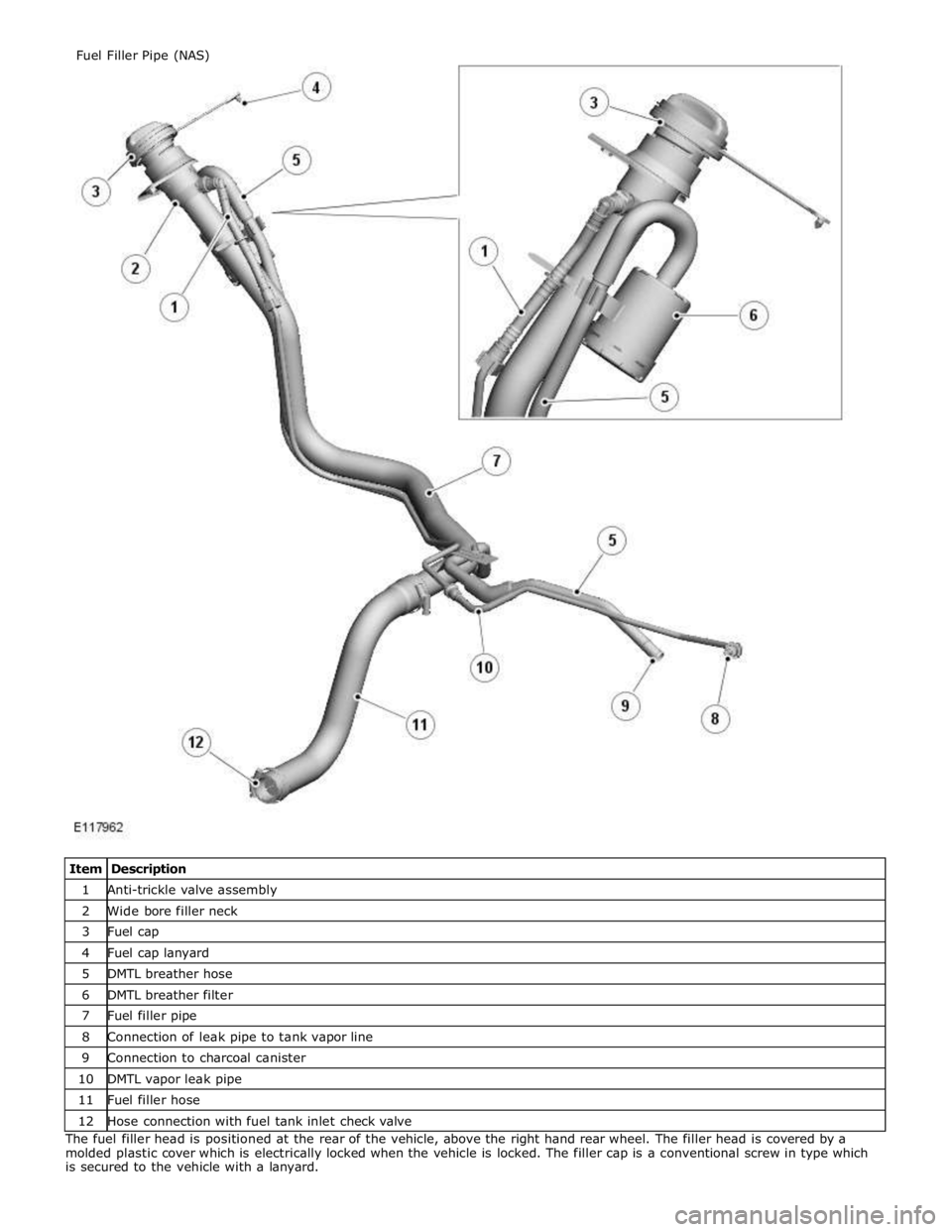

1 Anti-trickle valve assembly 2 Wide bore filler neck 3 Fuel cap 4 Fuel cap lanyard 5 DMTL breather hose 6 DMTL breather filter 7 Fuel filler pipe 8 Connection of leak pipe to tank vapor line 9 Connection to charcoal canister 10 DMTL vapor leak pipe 11 Fuel filler hose 12 Hose connection with fuel tank inlet check valve The fuel filler head is positioned at the rear of the vehicle, above the right hand rear wheel. The filler head is covered by a

molded plastic cover which is electrically locked when the vehicle is locked. The filler cap is a conventional screw in type which

is secured to the vehicle with a lanyard. Fuel Filler Pipe (NAS)

Page 1594 of 3039

installed in a manifold in the fuel delivery line. The manifold is located in the rear of the front LH wheelarch, behind the splash shield.

Page 1595 of 3039

Published: 28-Jul-2014

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Tank and

Lines

Diagnosis and Testing

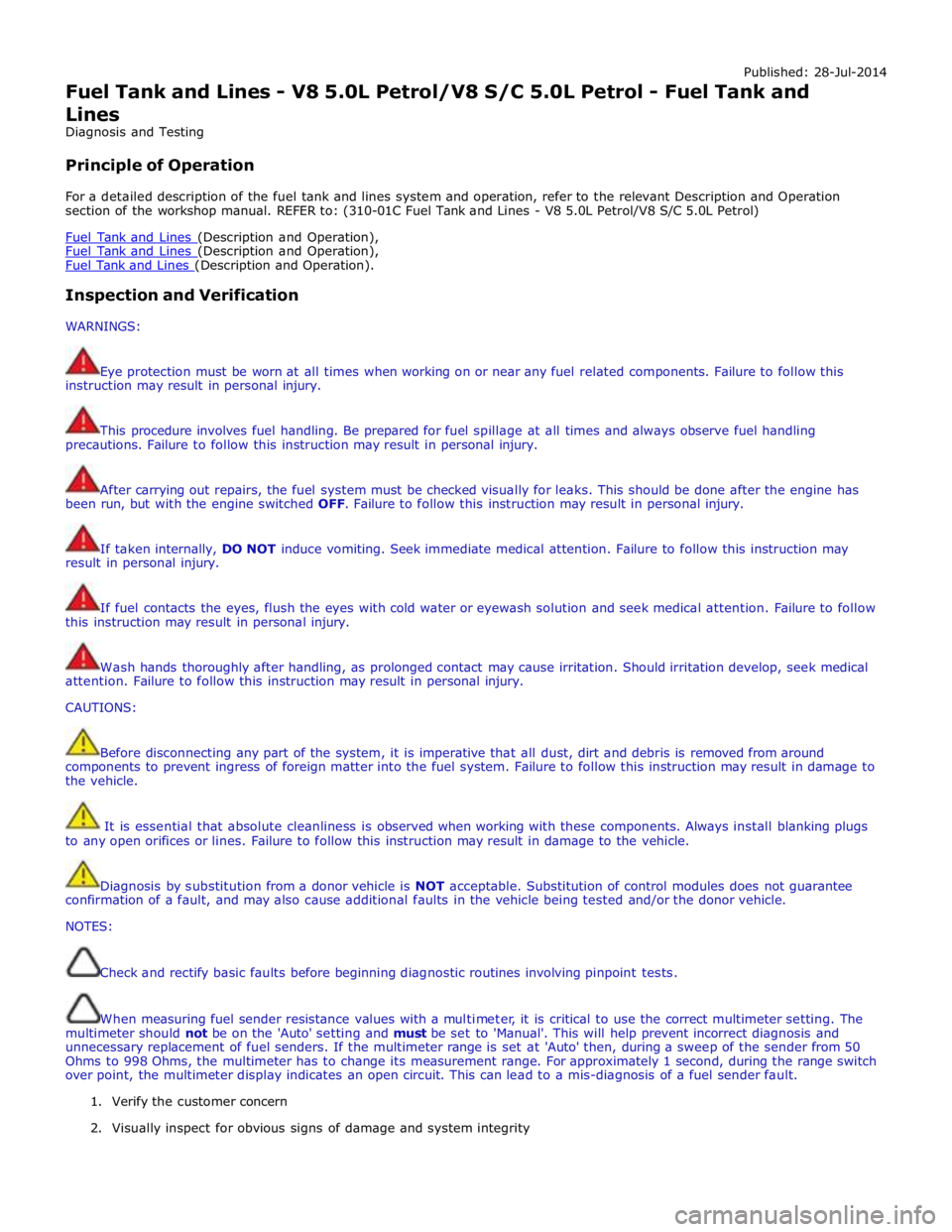

Principle of Operation

For a detailed description of the fuel tank and lines system and operation, refer to the relevant Description and Operation

section of the workshop manual. REFER to: (310-01C Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol)

Fuel Tank and Lines (Description and Operation), Fuel Tank and Lines (Description and Operation), Fuel Tank and Lines (Description and Operation).

Inspection and Verification

WARNINGS:

Eye protection must be worn at all times when working on or near any fuel related components. Failure to follow this

instruction may result in personal injury.

This procedure involves fuel handling. Be prepared for fuel spillage at all times and always observe fuel handling

precautions. Failure to follow this instruction may result in personal injury.

After carrying out repairs, the fuel system must be checked visually for leaks. This should be done after the engine has

been run, but with the engine switched OFF. Failure to follow this instruction may result in personal injury.

If taken internally, DO NOT induce vomiting. Seek immediate medical attention. Failure to follow this instruction may

result in personal injury.

If fuel contacts the eyes, flush the eyes with cold water or eyewash solution and seek medical attention. Failure to follow

this instruction may result in personal injury.

Wash hands thoroughly after handling, as prolonged contact may cause irritation. Should irritation develop, seek medical

attention. Failure to follow this instruction may result in personal injury.

CAUTIONS:

Before disconnecting any part of the system, it is imperative that all dust, dirt and debris is removed from around

components to prevent ingress of foreign matter into the fuel system. Failure to follow this instruction may result in damage to

the vehicle.

It is essential that absolute cleanliness is observed when working with these components. Always install blanking plugs

to any open orifices or lines. Failure to follow this instruction may result in damage to the vehicle.

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

When measuring fuel sender resistance values with a multimeter, it is critical to use the correct multimeter setting. The

multimeter should not be on the 'Auto' setting and must be set to 'Manual'. This will help prevent incorrect diagnosis and

unnecessary replacement of fuel senders. If the multimeter range is set at 'Auto' then, during a sweep of the sender from 50

Ohms to 998 Ohms, the multimeter has to change its measurement range. For approximately 1 second, during the range switch

over point, the multimeter display indicates an open circuit. This can lead to a mis-diagnosis of a fuel sender fault.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Page 1596 of 3039

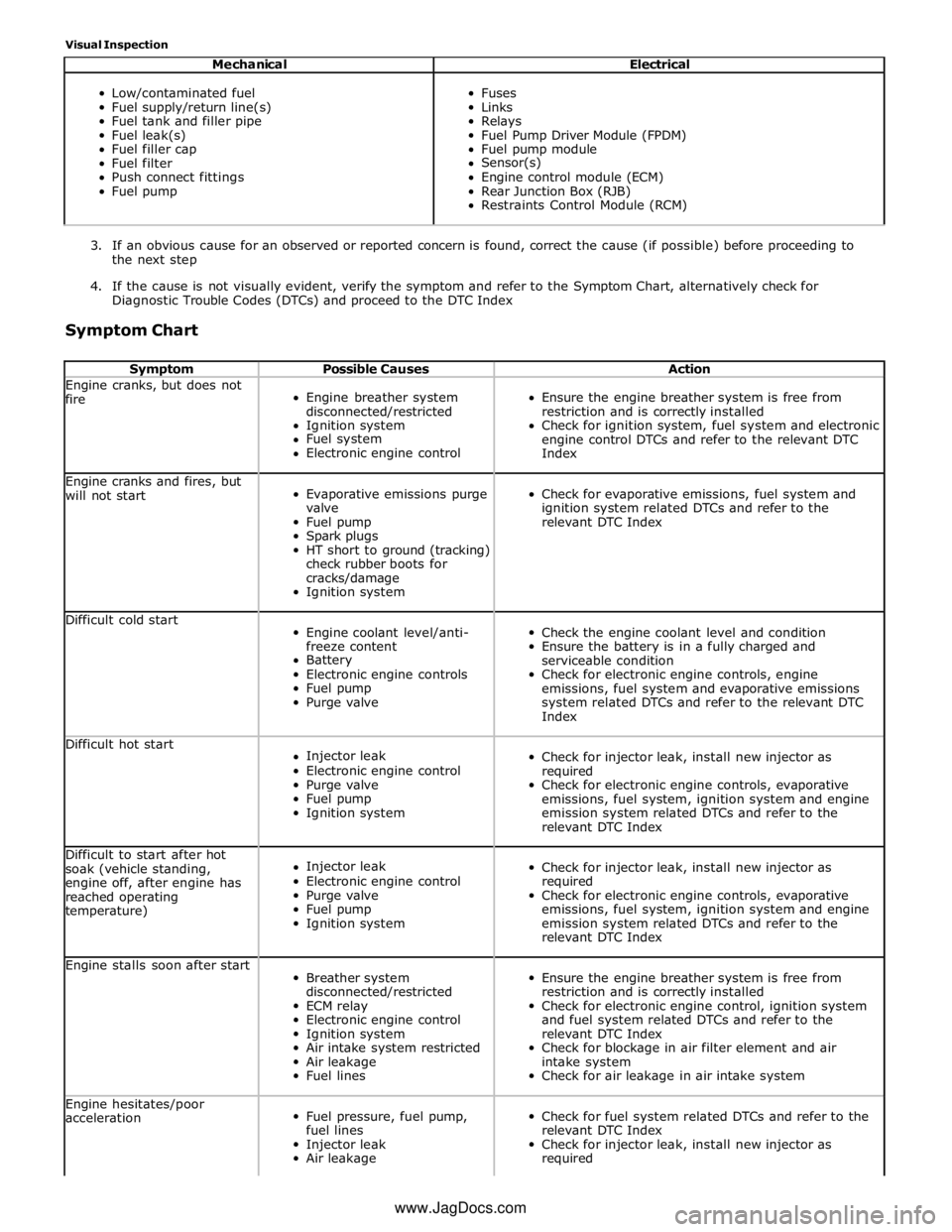

Visual Inspection

Mechanical Electrical

Low/contaminated fuel

Fuel supply/return line(s)

Fuel tank and filler pipe

Fuel leak(s)

Fuel filler cap

Fuel filter

Push connect fittings

Fuel pump

Fuses

Links

Relays

Fuel Pump Driver Module (FPDM)

Fuel pump module

Sensor(s)

Engine control module (ECM)

Rear Junction Box (RJB)

Restraints Control Module (RCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and proceed to the DTC Index

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control

Ensure the engine breather system is free from

restriction and is correctly installed

Check for ignition system, fuel system and electronic

engine control DTCs and refer to the relevant DTC

Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system

Check for evaporative emissions, fuel system and

ignition system related DTCs and refer to the

relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Fuel pump

Purge valve

Check the engine coolant level and condition

Ensure the battery is in a fully charged and

serviceable condition

Check for electronic engine controls, engine

emissions, fuel system and evaporative emissions

system related DTCs and refer to the relevant DTC

Index Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

Check for injector leak, install new injector as

required

Check for electronic engine controls, evaporative

emissions, fuel system, ignition system and engine

emission system related DTCs and refer to the

relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine control, ignition system

and fuel system related DTCs and refer to the

relevant DTC Index

Check for blockage in air filter element and air

intake system

Check for air leakage in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Check for fuel system related DTCs and refer to the

relevant DTC Index

Check for injector leak, install new injector as

required www.JagDocs.com

Page 1597 of 3039

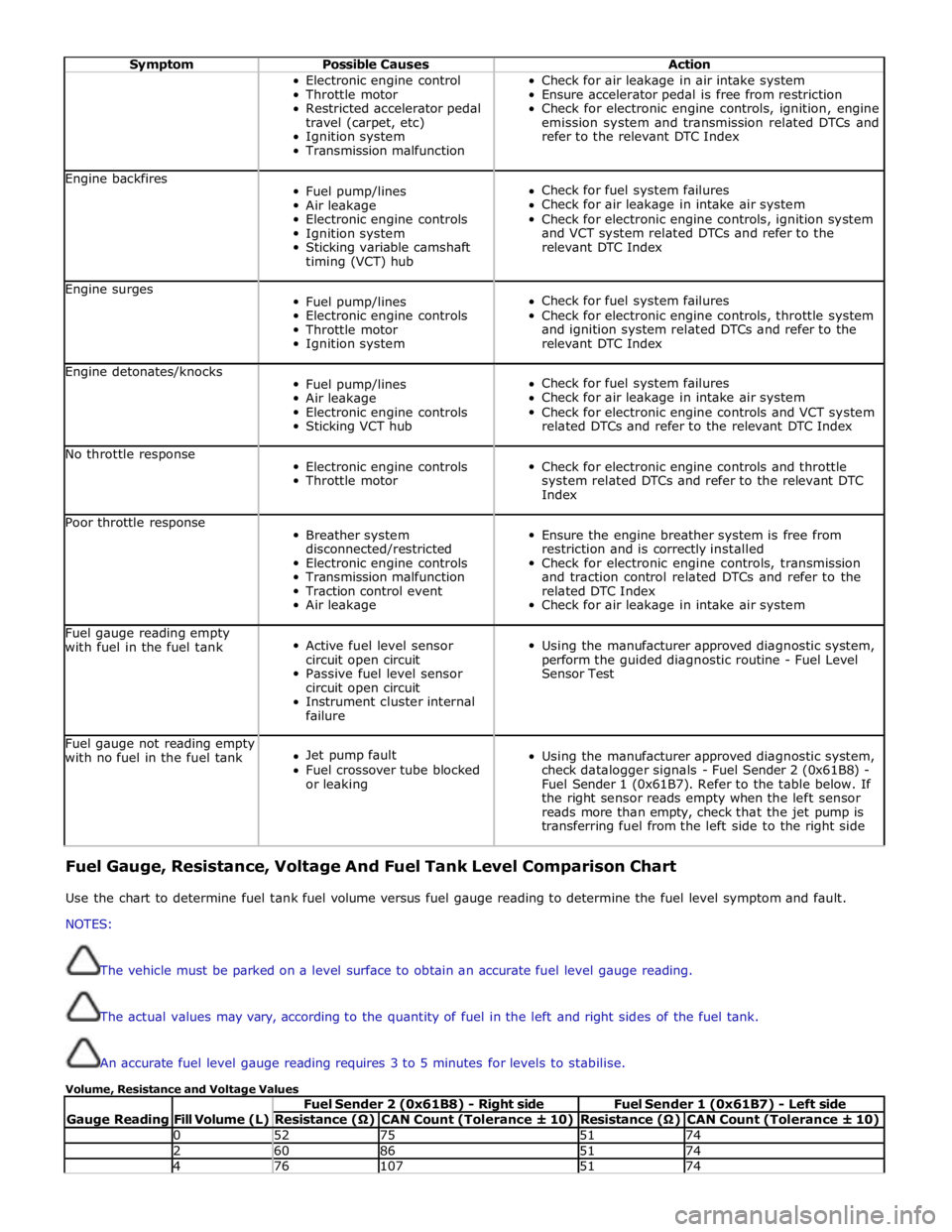

Symptom Possible Causes Action Electronic engine control

Throttle motor

Restricted accelerator pedal

travel (carpet, etc)

Ignition system

Transmission malfunction Check for air leakage in air intake system

Ensure accelerator pedal is free from restriction

Check for electronic engine controls, ignition, engine

emission system and transmission related DTCs and

refer to the relevant DTC Index Engine backfires

Fuel pump/lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls, ignition system

and VCT system related DTCs and refer to the

relevant DTC Index Engine surges

Fuel pump/lines

Electronic engine controls

Throttle motor

Ignition system

Check for fuel system failures

Check for electronic engine controls, throttle system

and ignition system related DTCs and refer to the

relevant DTC Index Engine detonates/knocks

Fuel pump/lines

Air leakage

Electronic engine controls

Sticking VCT hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls and VCT system

related DTCs and refer to the relevant DTC Index No throttle response

Electronic engine controls

Throttle motor

Check for electronic engine controls and throttle

system related DTCs and refer to the relevant DTC

Index Poor throttle response

Breather system

disconnected/restricted

Electronic engine controls

Transmission malfunction

Traction control event

Air leakage

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine controls, transmission

and traction control related DTCs and refer to the

related DTC Index

Check for air leakage in intake air system Fuel gauge reading empty

with fuel in the fuel tank

Active fuel level sensor

circuit open circuit

Passive fuel level sensor

circuit open circuit

Instrument cluster internal

failure

Using the manufacturer approved diagnostic system,

perform the guided diagnostic routine - Fuel Level

Sensor Test Fuel gauge not reading empty

with no fuel in the fuel tank

Jet pump fault

Fuel crossover tube blocked

or leaking

Using the manufacturer approved diagnostic system,

check datalogger signals - Fuel Sender 2 (0x61B8) -

Fuel Sender 1 (0x61B7). Refer to the table below. If

the right sensor reads empty when the left sensor

reads more than empty, check that the jet pump is

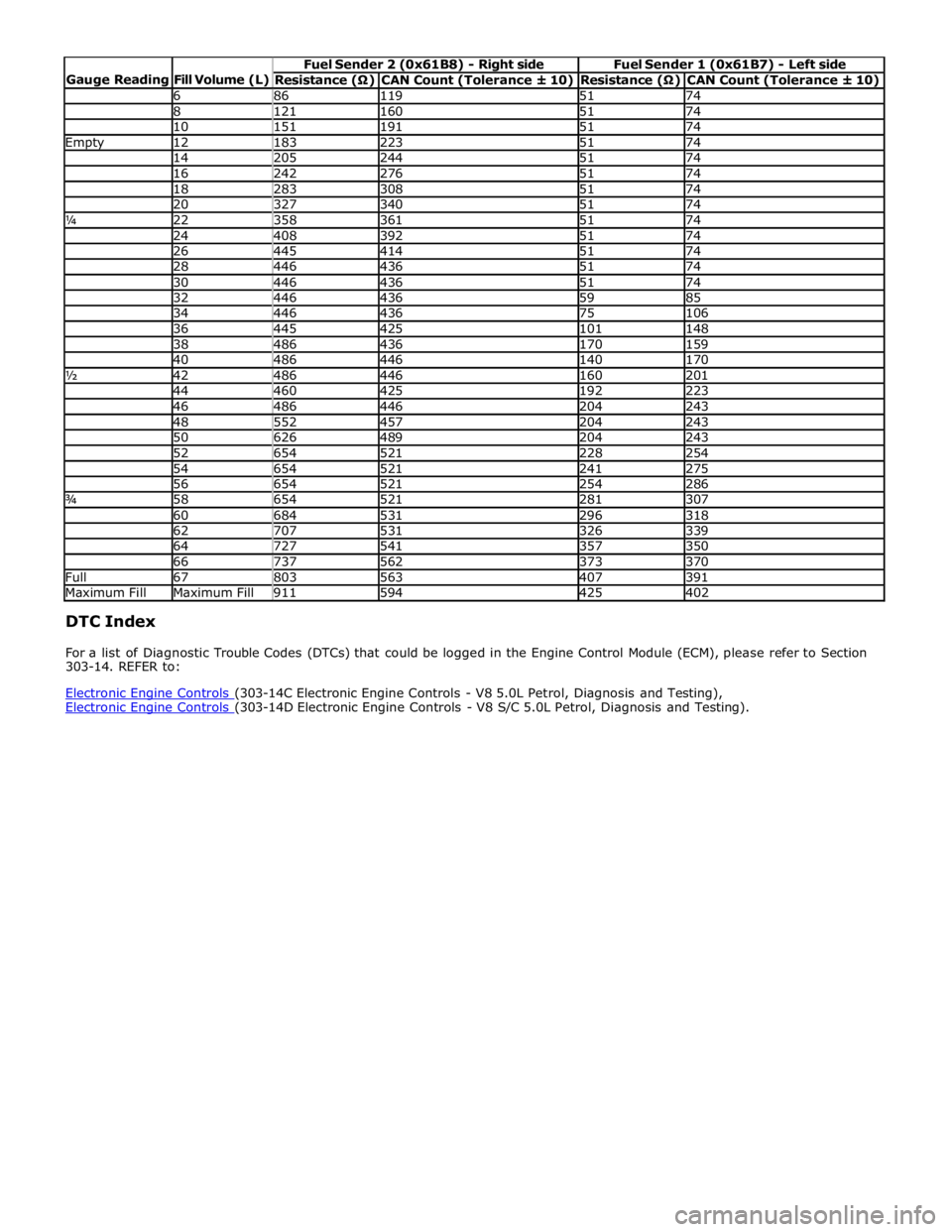

transferring fuel from the left side to the right side Fuel Gauge, Resistance, Voltage And Fuel Tank Level Comparison Chart

Use the chart to determine fuel tank fuel volume versus fuel gauge reading to determine the fuel level symptom and fault.

NOTES:

The vehicle must be parked on a level surface to obtain an accurate fuel level gauge reading.

The actual values may vary, according to the quantity of fuel in the left and right sides of the fuel tank.

An accurate fuel level gauge reading requires 3 to 5 minutes for levels to stabilise.

Volume, Resistance and Voltage Values

Gauge Reading

Fill Volume (L) Fuel Sender 2 (0x61B8) - Right side Fuel Sender 1 (0x61B7) - Left side Resistance (Ω) CAN Count (Tolerance ± 10) Resistance (Ω) CAN Count (Tolerance ± 10) 0 52 75 51 74 2 60 86 51 74 4 76 107 51 74

Page 1598 of 3039

Resistance (Ω) CAN Count (Tolerance ± 10) Resistance (Ω) CAN Count (Tolerance ± 10) 6 86 119 51 74 8 121 160 51 74 10 151 191 51 74 Empty 12 183 223 51 74 14 205 244 51 74 16 242 276 51 74 18 283 308 51 74 20 327 340 51 74 ¼ 22 358 361 51 74 24 408 392 51 74 26 445 414 51 74 28 446 436 51 74 30 446 436 51 74 32 446 436 59 85 34 446 436 75 106 36 445 425 101 148 38 486 436 170 159 40 486 446 140 170 ½ 42 486 446 160 201 44 460 425 192 223 46 486 446 204 243 48 552 457 204 243 50 626 489 204 243 52 654 521 228 254 54 654 521 241 275 56 654 521 254 286 ¾ 58 654 521 281 307 60 684 531 296 318 62 707 531 326 339 64 727 541 357 350 66 737 562 373 370 Full 67 803 563 407 391 Maximum Fill Maximum Fill 911 594 425 402 DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged in the Engine Control Module (ECM), please refer to Section

303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 1599 of 3039

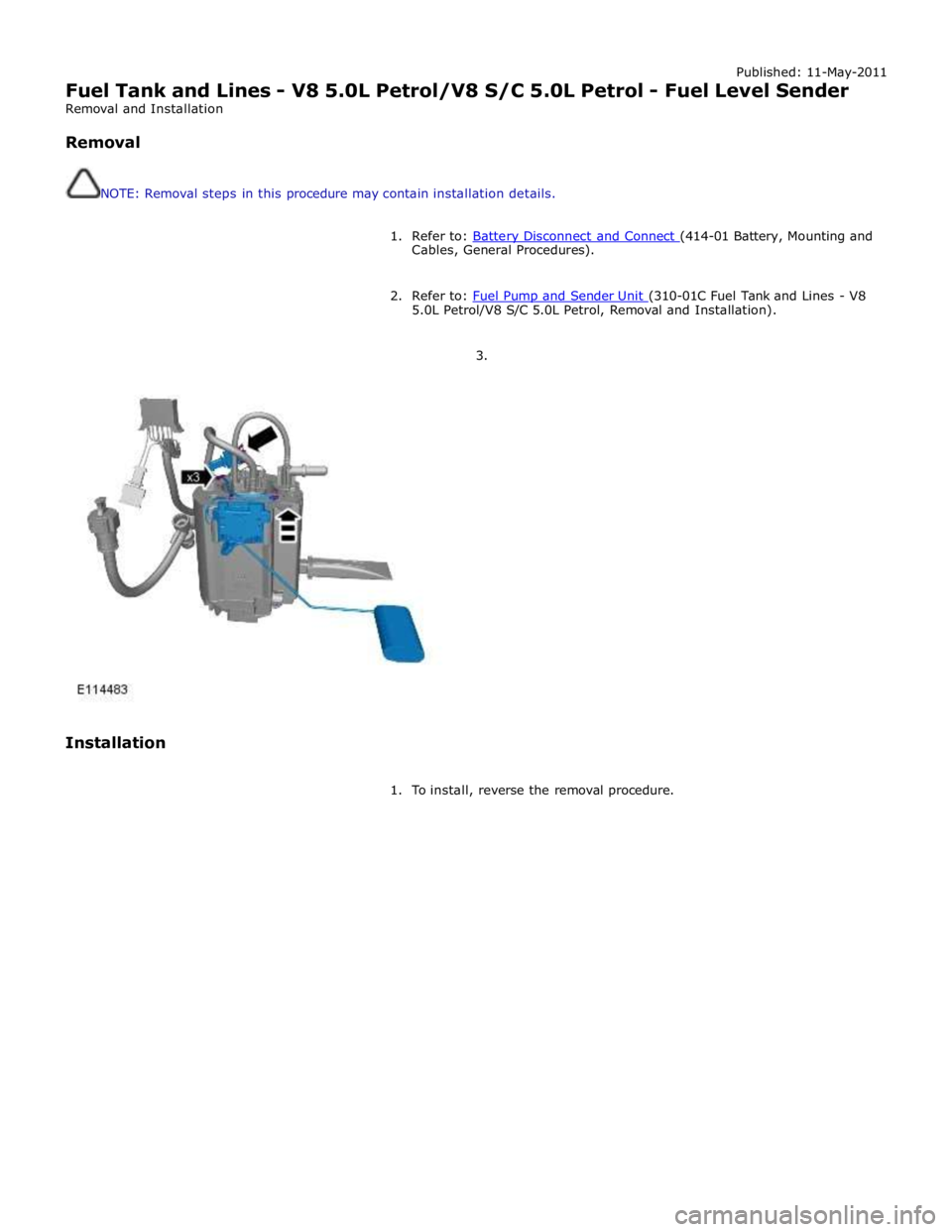

Published: 11-May-2011

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Level Sender

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Fuel Pump and Sender Unit (310-01C Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

3.

Installation

1. To install, reverse the removal procedure.

Page 1600 of 3039

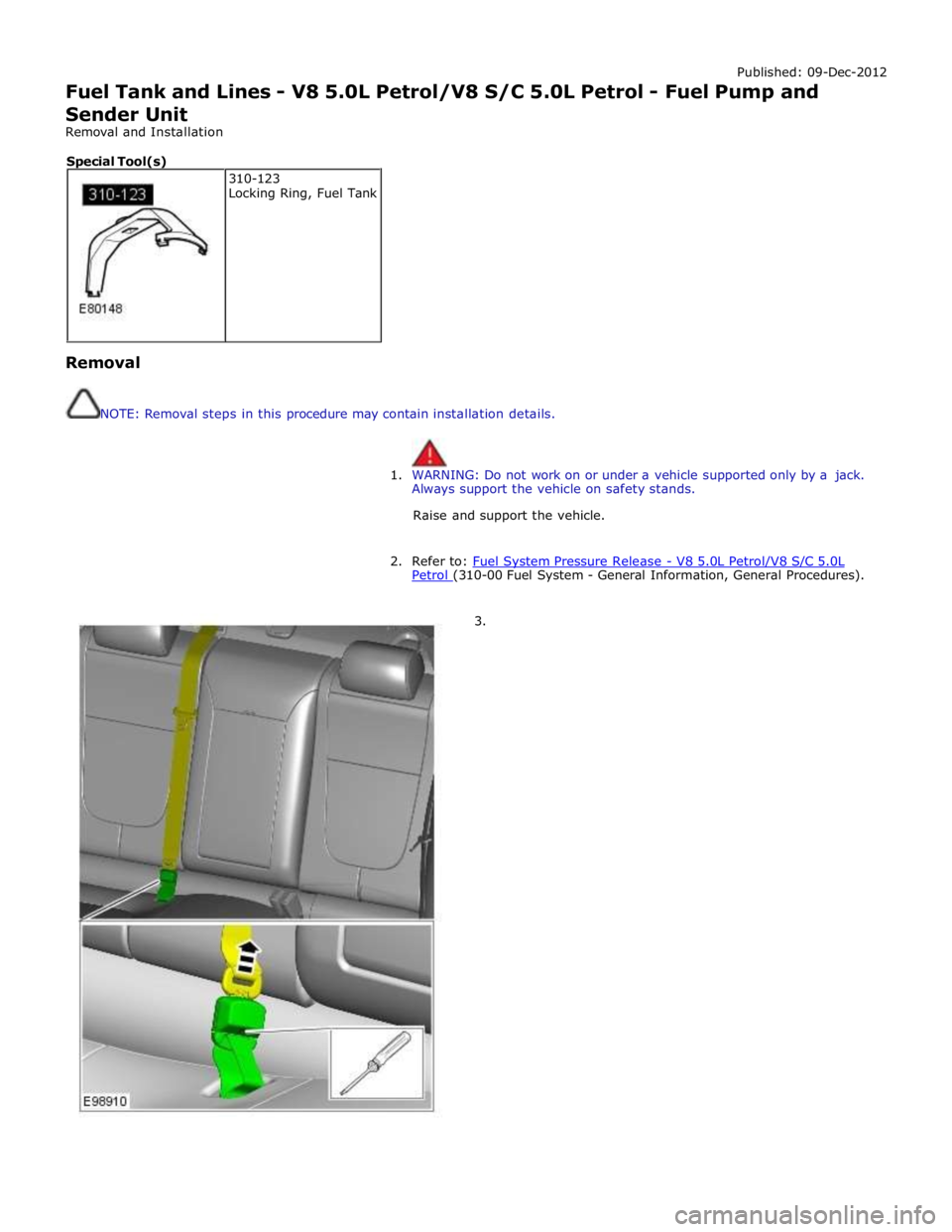

Published: 09-Dec-2012

Fuel Tank and Lines - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Fuel Pump and

Sender Unit

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

3. 310-123

Locking Ring, Fuel Tank Special Tool(s)