JAGUAR XFR 2010 1.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2981 of 3039

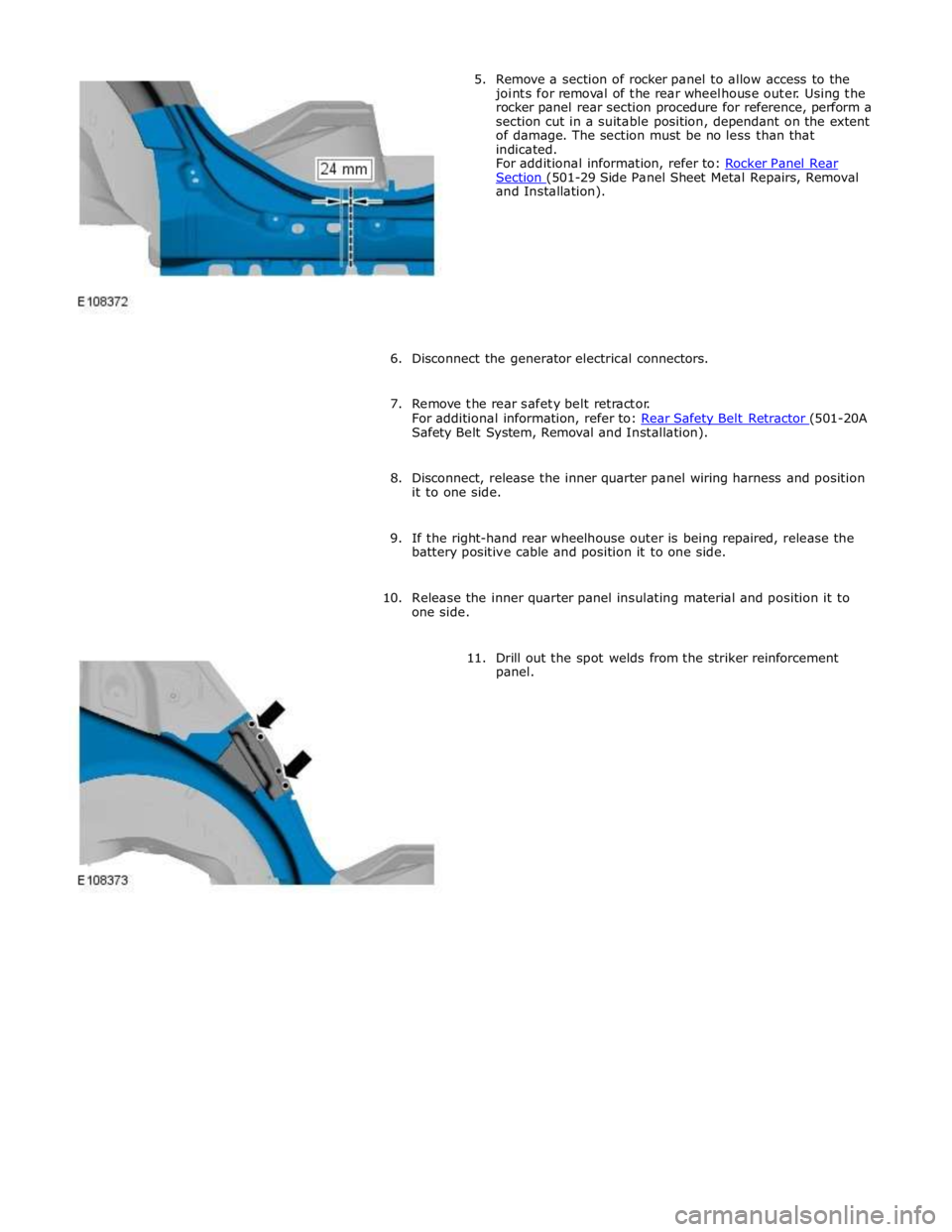

Section (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

6. Disconnect the generator electrical connectors.

7. Remove the rear safety belt retractor.

For additional information, refer to: Rear Safety Belt Retractor (501-20A Safety Belt System, Removal and Installation).

8. Disconnect, release the inner quarter panel wiring harness and position

it to one side.

9. If the right-hand rear wheelhouse outer is being repaired, release the

battery positive cable and position it to one side.

10. Release the inner quarter panel insulating material and position it to

one side.

11. Drill out the spot welds from the striker reinforcement

panel.

Page 2982 of 3039

12.

13.

14.

15. NOTE: A new striker reinforcement panel is supplied

on the quarter panel service panel.

Separate the joints, the adhesive and the NVH (noise,

vibration and harshness) component and remove the striker

reinforcement panel.

NOTE: Care should be taken when separating and

removing the ECM (engine control module) mounting

bracket if it is to be reused.

If the right-hand rear wheelhouse outer is to be repaired,

drill out the spot welds as indicated and remove the ECM

mounting bracket. Retain for reuse on installation.

NOTE: It is necessary to section the quarter panel

inner reinforcement at the point indicated, to make sure the

integrity of the safety belt anchorage point. The right-hand

panel is illustrated, the left-hand is similar.

Cut the quarter panel inner reinforcement, horizontally,

approximately 90mm from the centre of the safety belt bolt

anchorage point as indicated.

NOTE: The right-hand panel is illustrated, the

left-hand is similar although there are additional spot welds

to drill out.

Drill out the spot welds from the quarter panel inner

reinforcement section at the points indicated.

Page 2983 of 3039

16. NOTE: Retain the quarter panel inner reinforcement section as part

of this will be used as a template and to form a backing plate.

Separate the joints and remove the quarter panel inner reinforcement

section.

17.

18.

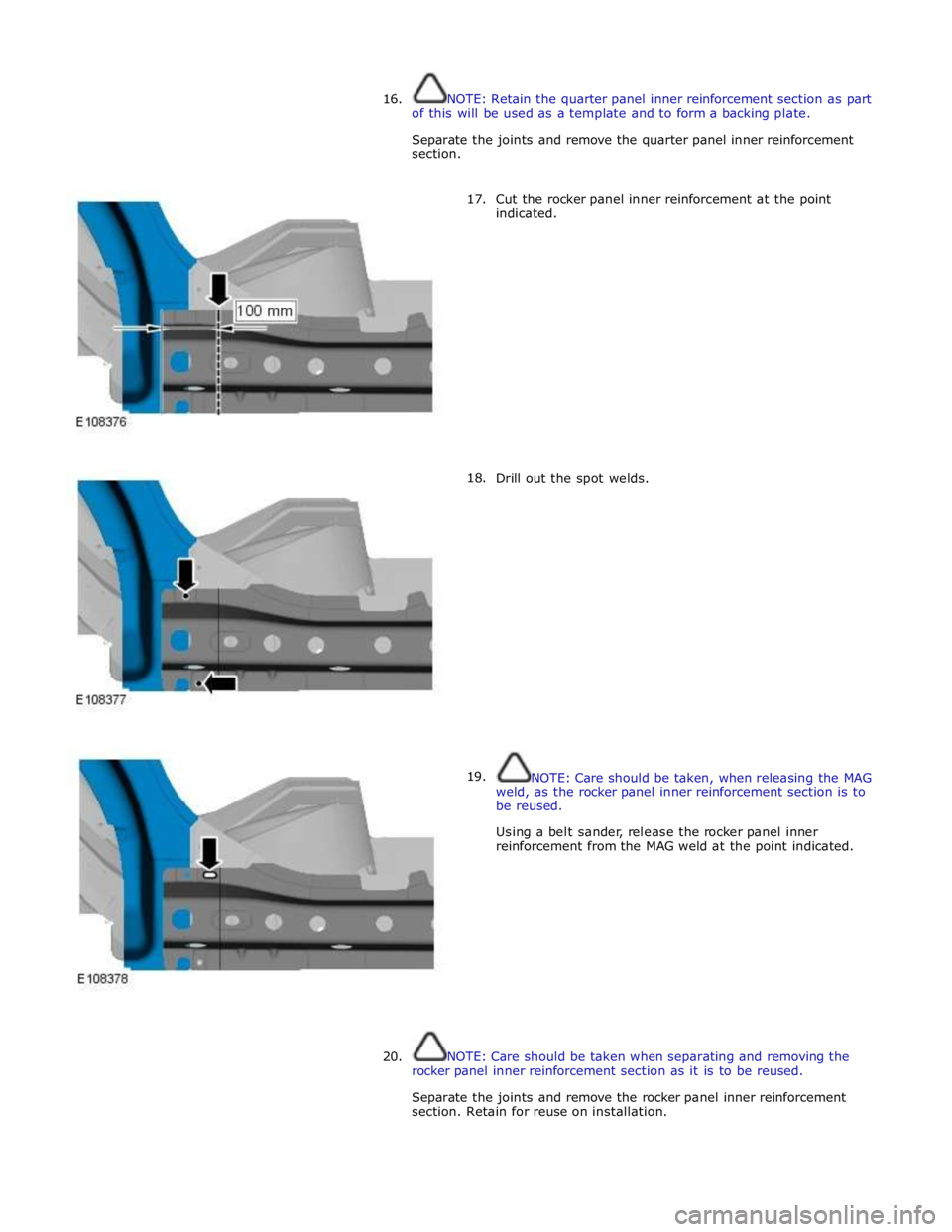

19. Cut the rocker panel inner reinforcement at the point

indicated.

Drill out the spot welds.

NOTE: Care should be taken, when releasing the MAG

weld, as the rocker panel inner reinforcement section is to

be reused.

Using a belt sander, release the rocker panel inner

reinforcement from the MAG weld at the point indicated.

20. NOTE: Care should be taken when separating and removing the

rocker panel inner reinforcement section as it is to be reused.

Separate the joints and remove the rocker panel inner reinforcement

section. Retain for reuse on installation.

Page 2984 of 3039

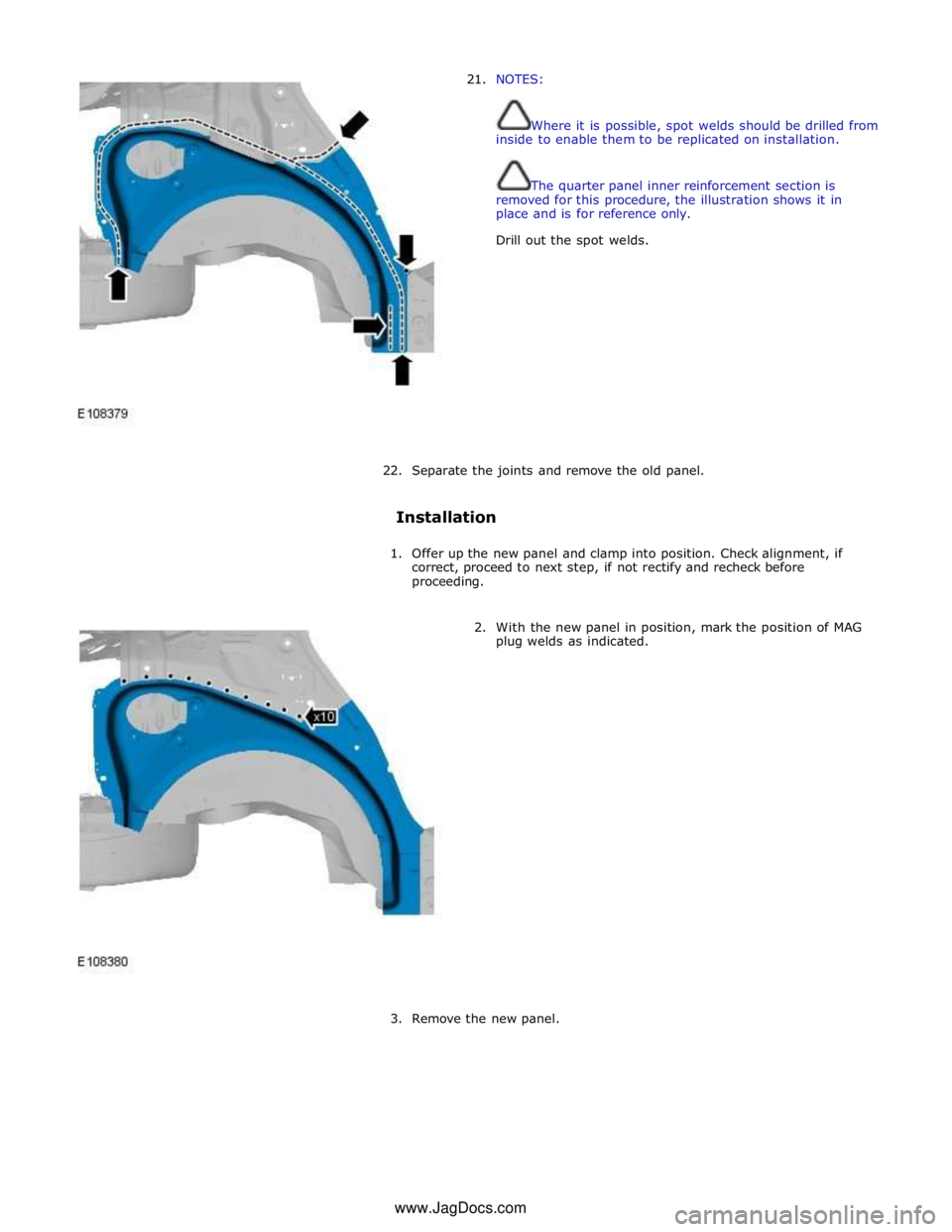

21. NOTES:

Where it is possible, spot welds should be drilled from

inside to enable them to be replicated on installation.

The quarter panel inner reinforcement section is

removed for this procedure, the illustration shows it in

place and is for reference only.

Drill out the spot welds.

22. Separate the joints and remove the old panel.

Installation

1. Offer up the new panel and clamp into position. Check alignment, if

correct, proceed to next step, if not rectify and recheck before

proceeding.

2. With the new panel in position, mark the position of MAG

plug welds as indicated.

3. Remove the new panel. www.JagDocs.com

Page 2985 of 3039

4. Drill holes ready for MAG plug welding, including those

previously marked.

5. Prepare the old and new panel joint surfaces.

6. NOTE: Spot welds must be installed 5mm away from the

originals and in the same quantities, whenever this is

possible. Where this is not possible, spot welds should be

installed adjacent to the original.

Spot weld.

Page 2986 of 3039

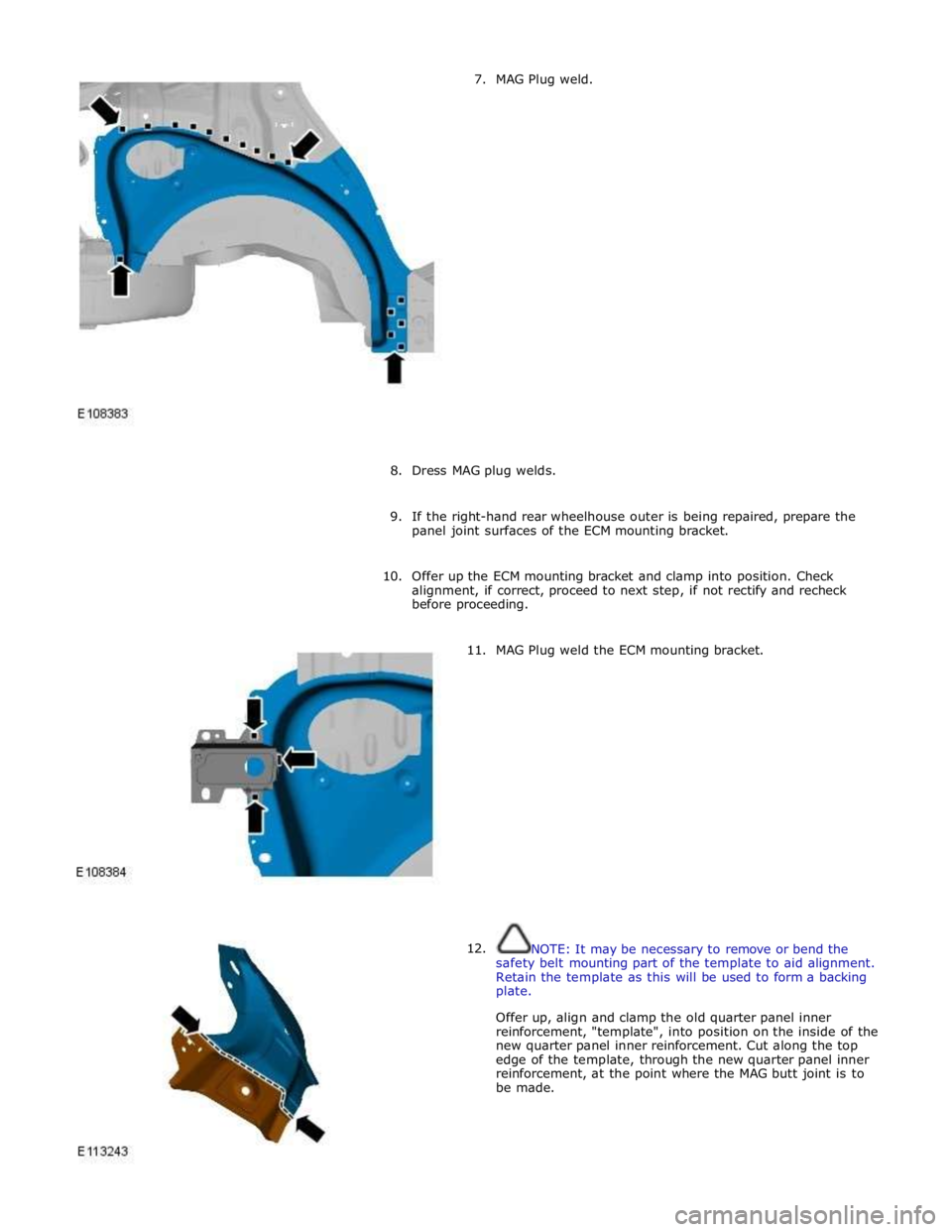

7. MAG Plug weld.

8. Dress MAG plug welds.

9. If the right-hand rear wheelhouse outer is being repaired, prepare the

panel joint surfaces of the ECM mounting bracket.

10. Offer up the ECM mounting bracket and clamp into position. Check

alignment, if correct, proceed to next step, if not rectify and recheck

before proceeding.

11.

12. MAG Plug weld the ECM mounting bracket.

NOTE: It may be necessary to remove or bend the

safety belt mounting part of the template to aid alignment.

Retain the template as this will be used to form a backing

plate.

Offer up, align and clamp the old quarter panel inner

reinforcement, "template", into position on the inside of the

new quarter panel inner reinforcement. Cut along the top

edge of the template, through the new quarter panel inner

reinforcement, at the point where the MAG butt joint is to

be made.

Page 2987 of 3039

13. Remove the template from the new quarter panel inner reinforcement.

14.

15. Cut and form a backing strip, a minimum of 40mm in width,

from the template as indicated.

NOTE: The backing strip should be positioned centrally

so that it will fit equally between the original and the new

quarter panel inner reinforcement sections, where the MAG

butt weld is to be performed.

Offer up the backing strip to the original quarter panel inner

reinforcement and clamp into position. Check alignment, if

correct, proceed to next step, if not rectify and recheck

before proceeding.

16. Remove the backing strip.

17. Drill holes in the original quarter panel inner reinforcement

ready for MAG plug welding as indicated.

18. Prepare the panel joint surfaces of the new and the original quarter

panel inner reinforcement and the backing strip.

19. Offer up the backing strip, align and clamp into position.

Page 2988 of 3039

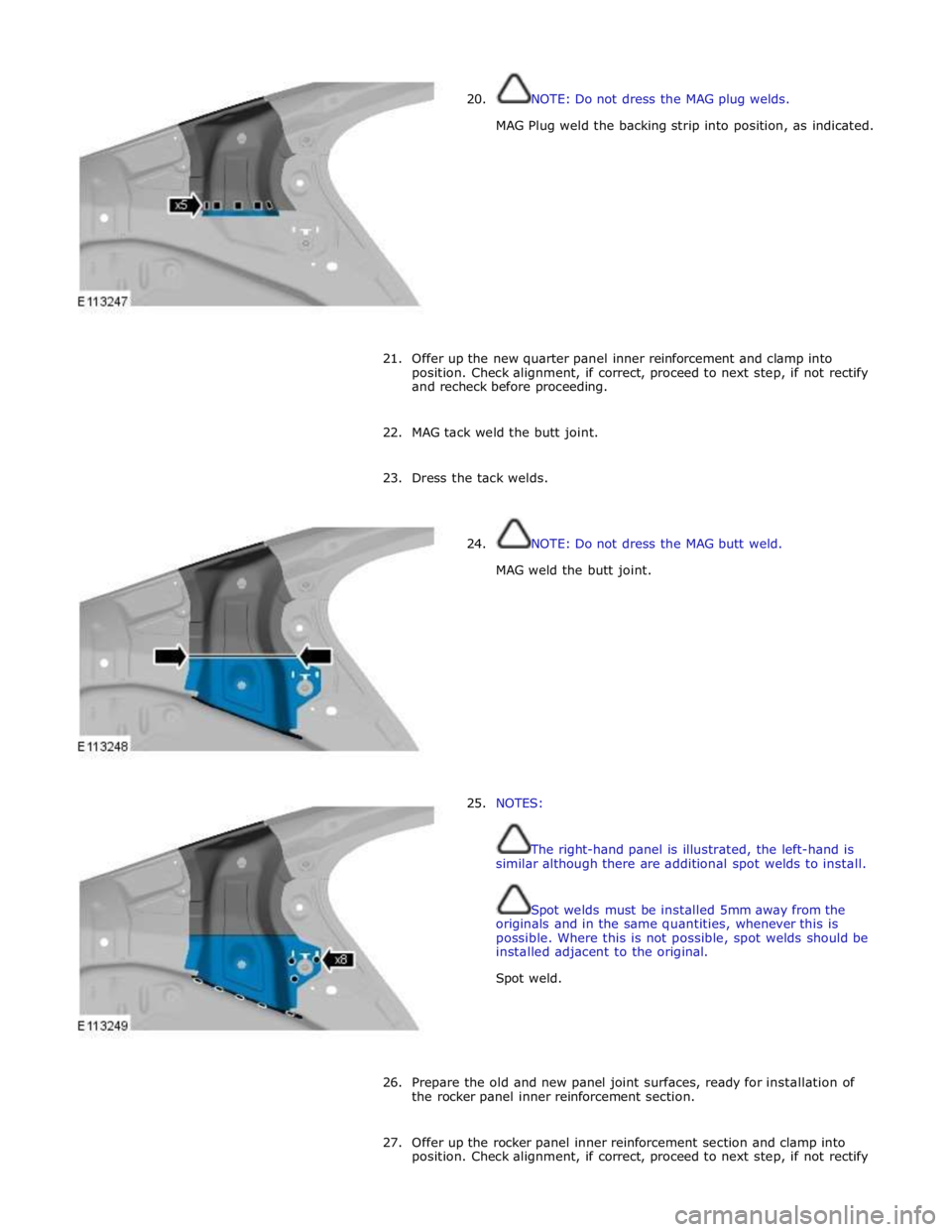

20. NOTE: Do not dress the MAG plug welds.

MAG Plug weld the backing strip into position, as indicated.

21. Offer up the new quarter panel inner reinforcement and clamp into

position. Check alignment, if correct, proceed to next step, if not rectify

and recheck before proceeding.

22. MAG tack weld the butt joint.

23. Dress the tack welds.

24.

25. NOTE: Do not dress the MAG butt weld.

MAG weld the butt joint.

NOTES:

The right-hand panel is illustrated, the left-hand is

similar although there are additional spot welds to install.

Spot welds must be installed 5mm away from the

originals and in the same quantities, whenever this is

possible. Where this is not possible, spot welds should be

installed adjacent to the original.

Spot weld.

26. Prepare the old and new panel joint surfaces, ready for installation of

the rocker panel inner reinforcement section.

27. Offer up the rocker panel inner reinforcement section and clamp into

position. Check alignment, if correct, proceed to next step, if not rectify

Page 2989 of 3039

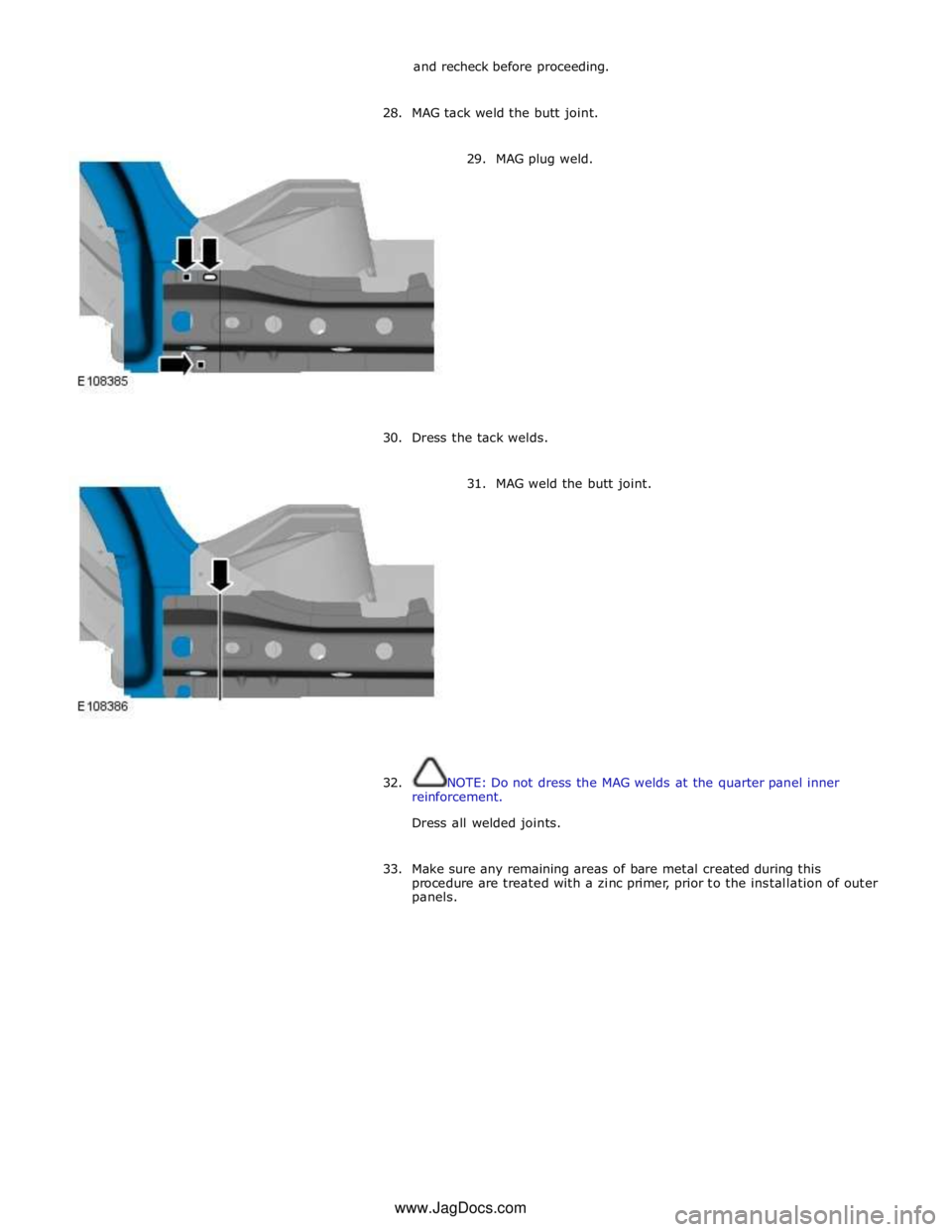

and recheck before proceeding.

28. MAG tack weld the butt joint.

29. MAG plug weld.

30.

Dress the tack welds.

31. MAG weld the butt joint.

32.

NOTE: Do not dress the MAG welds at the quarter panel inner

reinforcement.

Dress all welded joints.

33. Make sure any remaining areas of bare metal created during this

procedure are treated with a zinc primer, prior to the installation of outer

panels. www.JagDocs.com

Page 2990 of 3039

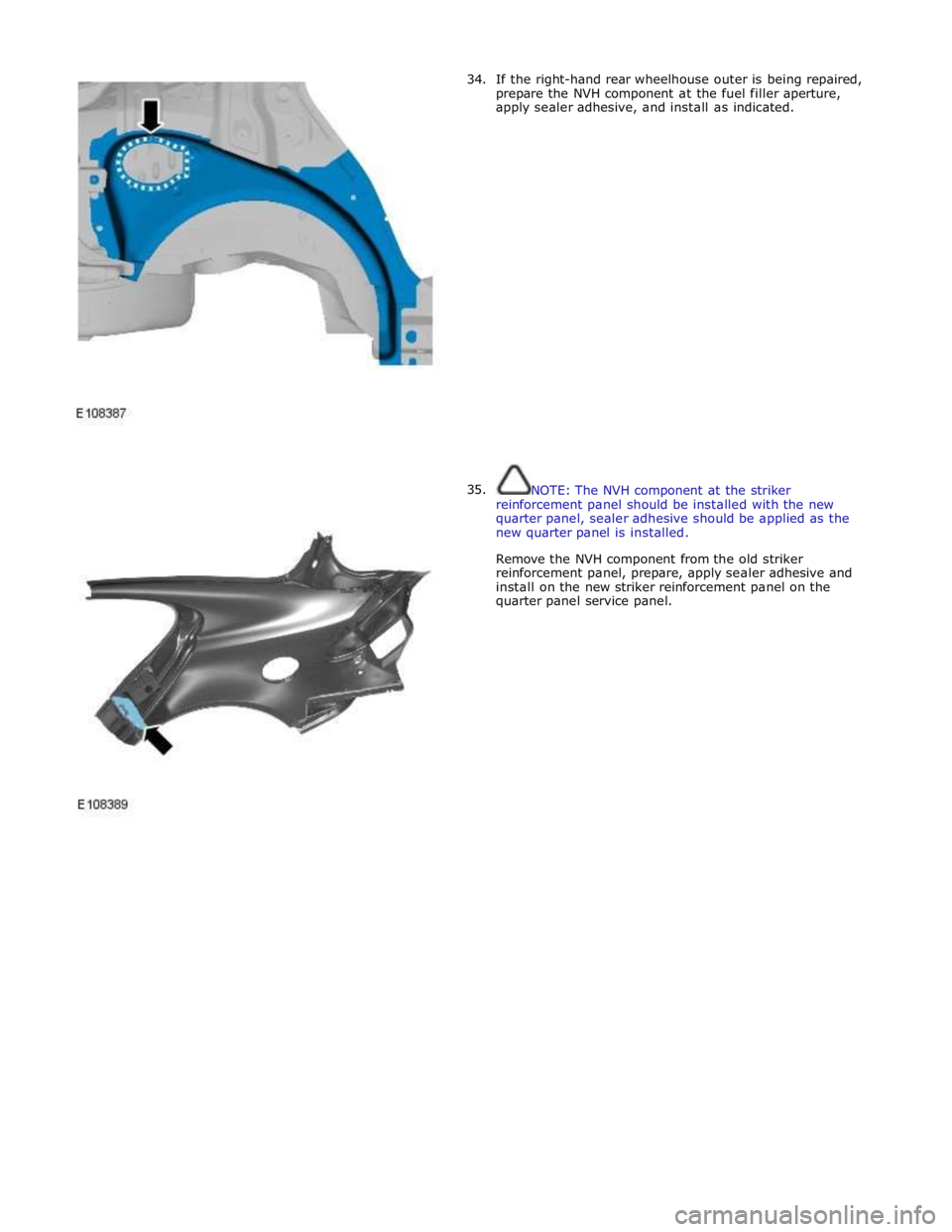

34.

35. If the right-hand rear wheelhouse outer is being repaired,

prepare the NVH component at the fuel filler aperture,

apply sealer adhesive, and install as indicated.

NOTE: The NVH component at the striker

reinforcement panel should be installed with the new

quarter panel, sealer adhesive should be applied as the

new quarter panel is installed.

Remove the NVH component from the old striker

reinforcement panel, prepare, apply sealer adhesive and

install on the new striker reinforcement panel on the

quarter panel service panel.