JAGUAR XFR 2010 1.G Workshop Manual

XFR 2010 1.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7642/w960_7642-0.png

JAGUAR XFR 2010 1.G Workshop Manual

Trending: pinpoint, water pump, fuse diagram, coolant expansion tank, transmission oil, Control module, height adjustment

Page 2991 of 3039

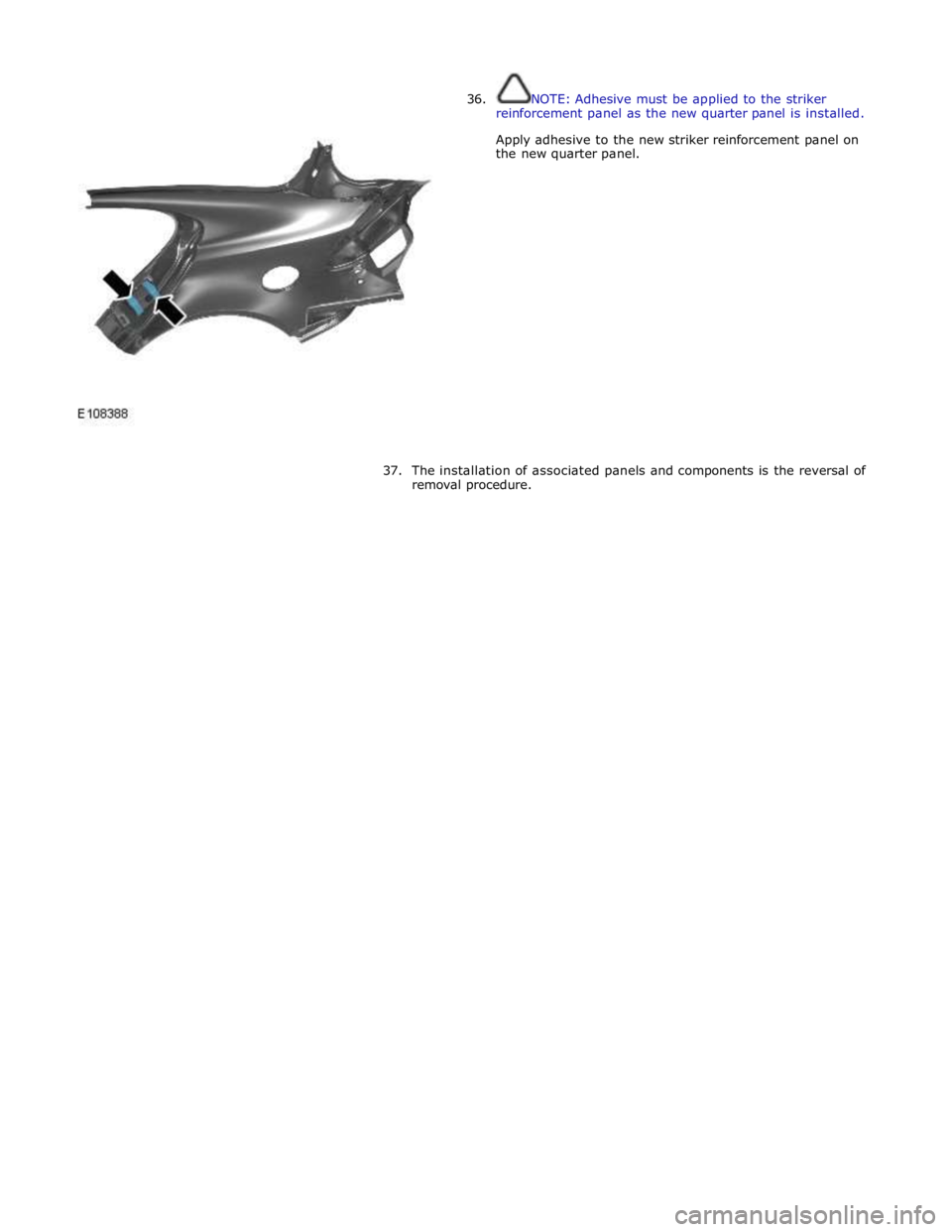

36. NOTE: Adhesive must be applied to the striker

reinforcement panel as the new quarter panel is installed.

Apply adhesive to the new striker reinforcement panel on

the new quarter panel.

37.

The installation of associated panels and components is the reversal of

removal procedure.

Page 2992 of 3039

Rear End Sheet Metal Repairs - Spare Wheel Well

Removal and Installation

Removal Published: 11-May-2011

1. NOTE: The spare wheel well is manufactured from mild steel.

The spare wheel well is serviced as a separate weld-on panel, it is not

serviced with the towing eye bracket, the spare wheel retaining bracket,

or its weld studs.

2. The spare wheel well is replaced in conjunction with:

Rear bumper cover

Rear bumper Back

panel

Towing eye bracket

Rear subframe and rear suspension, as an assembly

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the back panel.

For additional information, refer to: Back Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Page 2993 of 3039

5. Disconnect the generator electrical connectors.

6. Disconnect the battery positive cable and position it to one side.

7. Remove the rear subframe and rear suspension, as an assembly.

For additional information, refer to: Rear Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and

Installation).

8. Remove the fuel tank filler pipe.

For additional information, refer to: Fuel Tank Filler Pipe (310-01B,

Removal and Installation).

9. Release the left-hand and right-hand luggage floor wiring harnesses and

position them to one side.

10. Make sure that the rear seats are covered to prevent any damage during

this repair procedure.

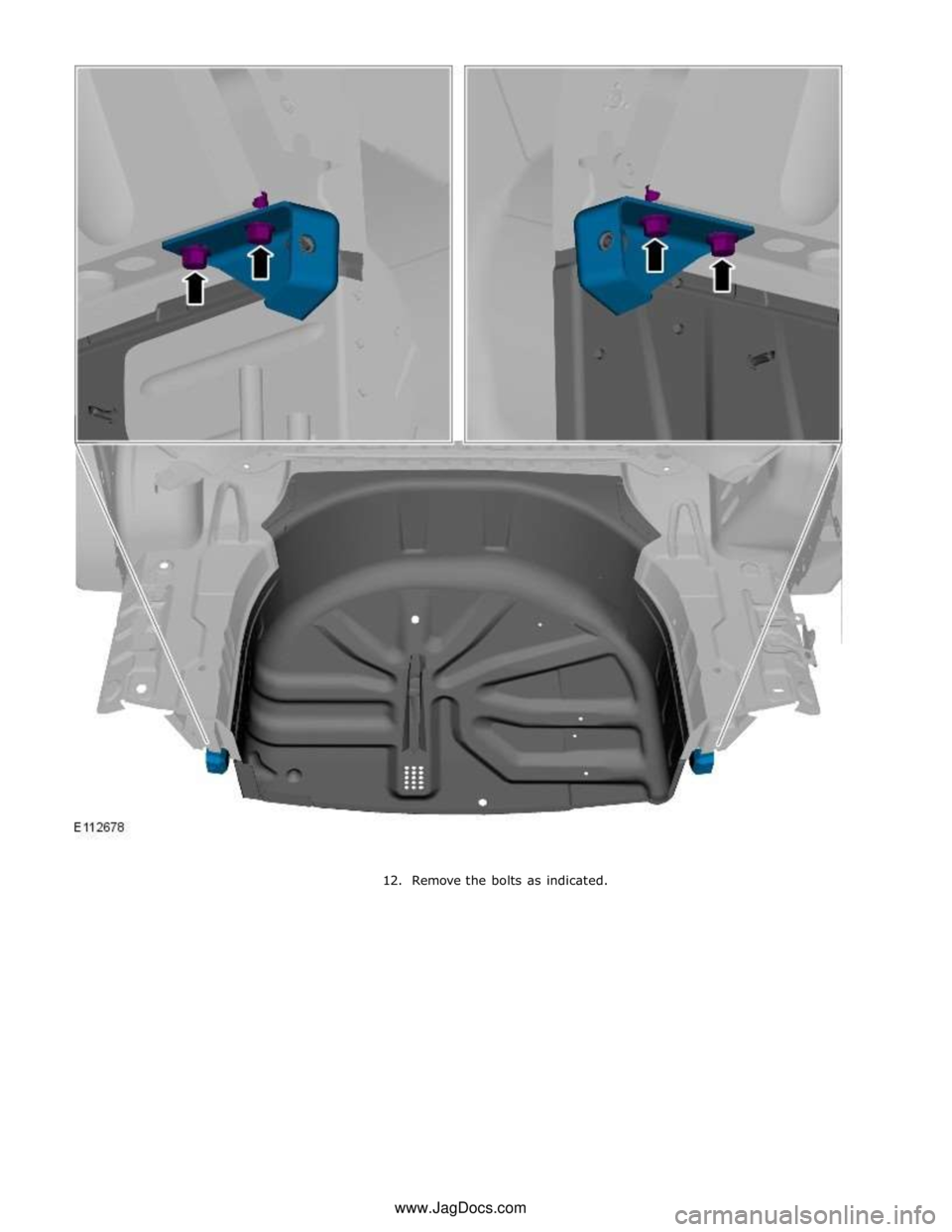

11. NOTE: If undamaged, the left-hand and right-hand rear bumper

retaining brackets should be reinstalled.

Remove the left-hand and right-hand rear bumper retaining brackets.

Page 2994 of 3039

Page 2995 of 3039

13. NOTE: Remove the sealer to expose the spot welds.

Drill out the spot welds.

Page 2996 of 3039

14. NOTE: Retain the old panel for reference to the weld stud location

points.

Separate the joints and remove the old panel.

15. NOTE: Drill out from inside the spare wheel well to allow spot

welds to be used in installation. If undamaged, retain the towing eye

bracket for re-use on installation.

Drill out the spot welds and remove the towing eye bracket from the old

panel.

Page 2997 of 3039

16. NOTE: Drill out from underneath to allow spot welds to be used in

installation. If undamaged, retain the spare wheel retaining bracket for

re-use on installation.

Drill out the spot welds and remove the spare wheel retaing bracket

from the old panel.

Page 2998 of 3039

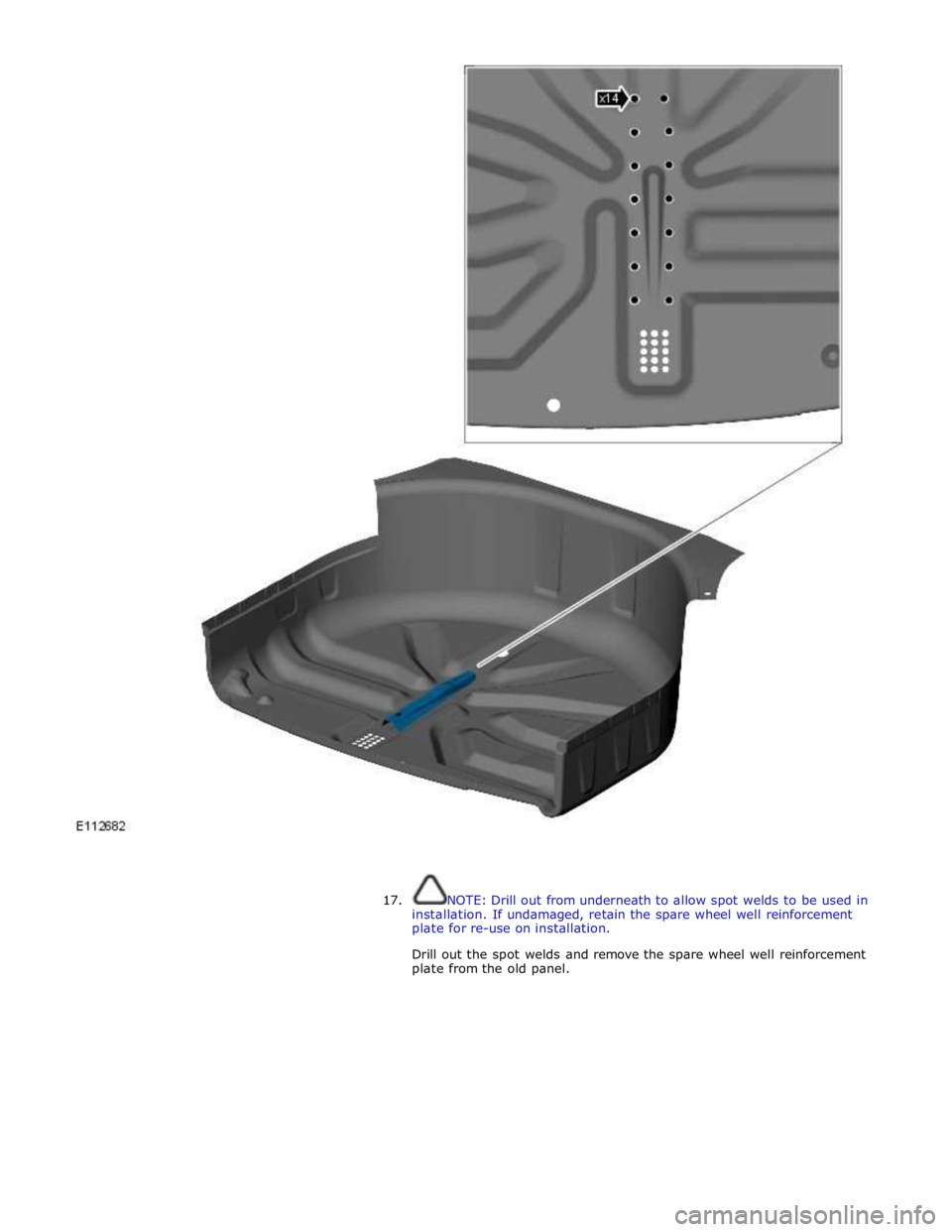

17. NOTE: Drill out from underneath to allow spot welds to be used in

installation. If undamaged, retain the spare wheel well reinforcement

plate for re-use on installation.

Drill out the spot welds and remove the spare wheel well reinforcement

plate from the old panel.

Page 2999 of 3039

Page 3000 of 3039

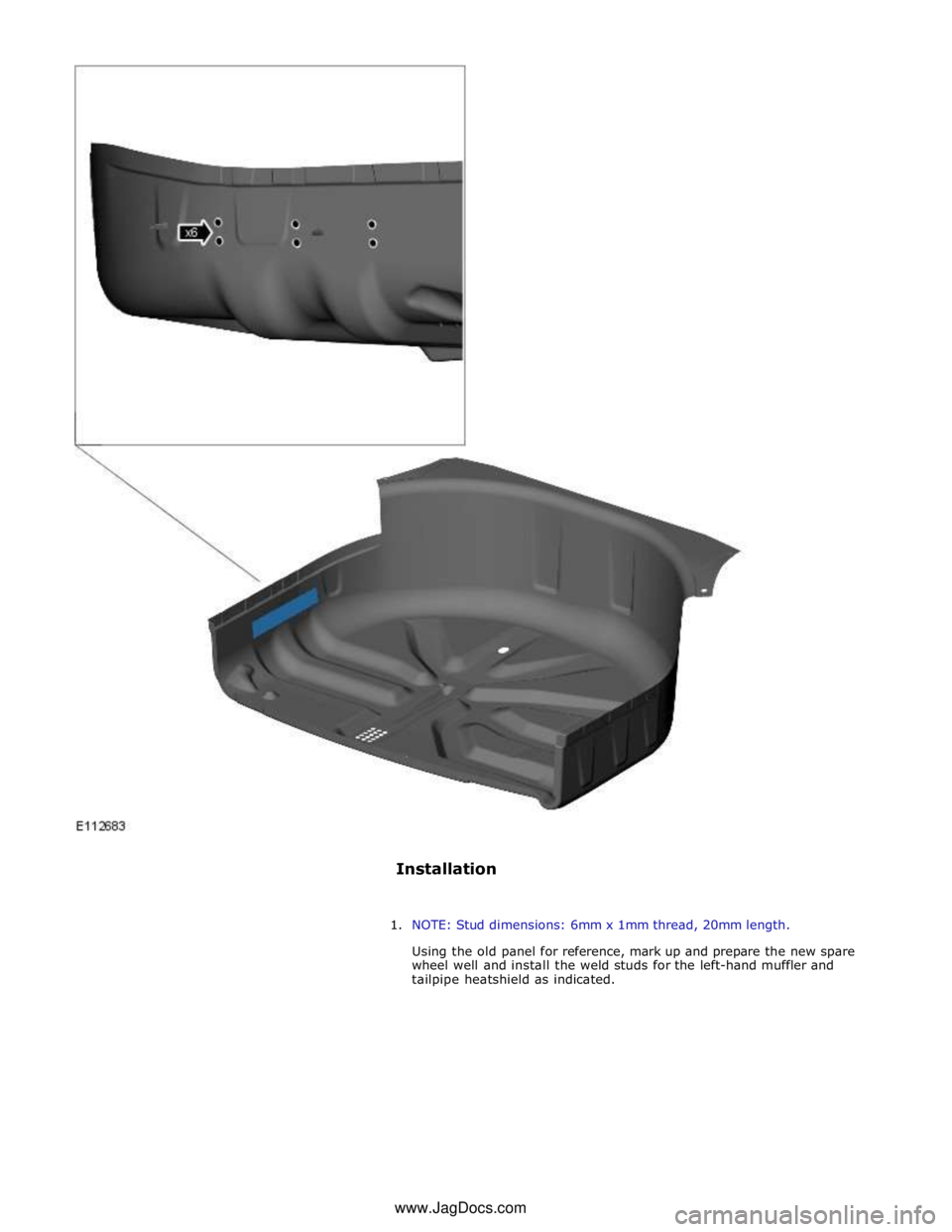

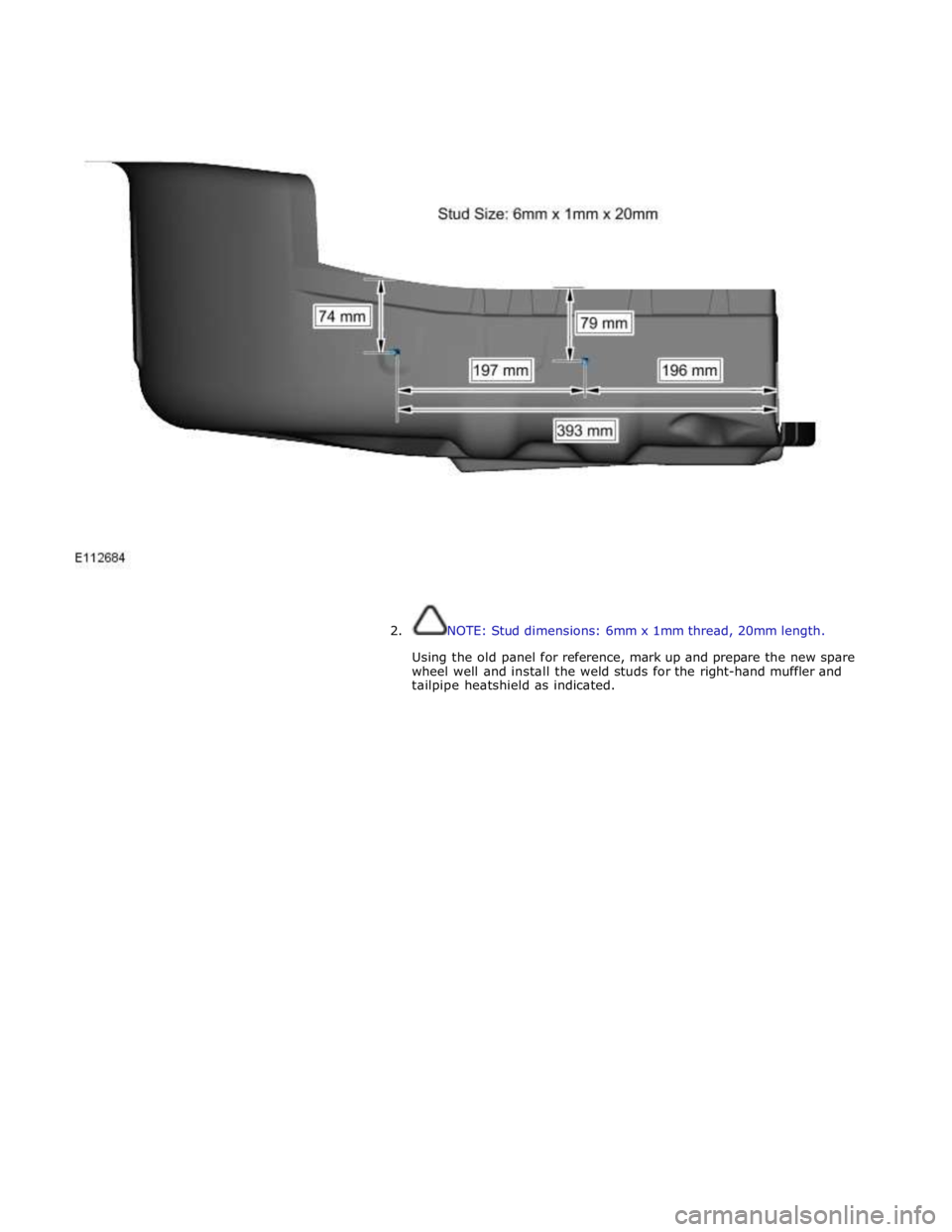

2. NOTE: Stud dimensions: 6mm x 1mm thread, 20mm length.

Using the old panel for reference, mark up and prepare the new spare

wheel well and install the weld studs for the right-hand muffler and

tailpipe heatshield as indicated.

Trending: b115913, wheel, U0404-68, wiring, remote control, B1B33-87, low oil pressure