JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1791 of 2198

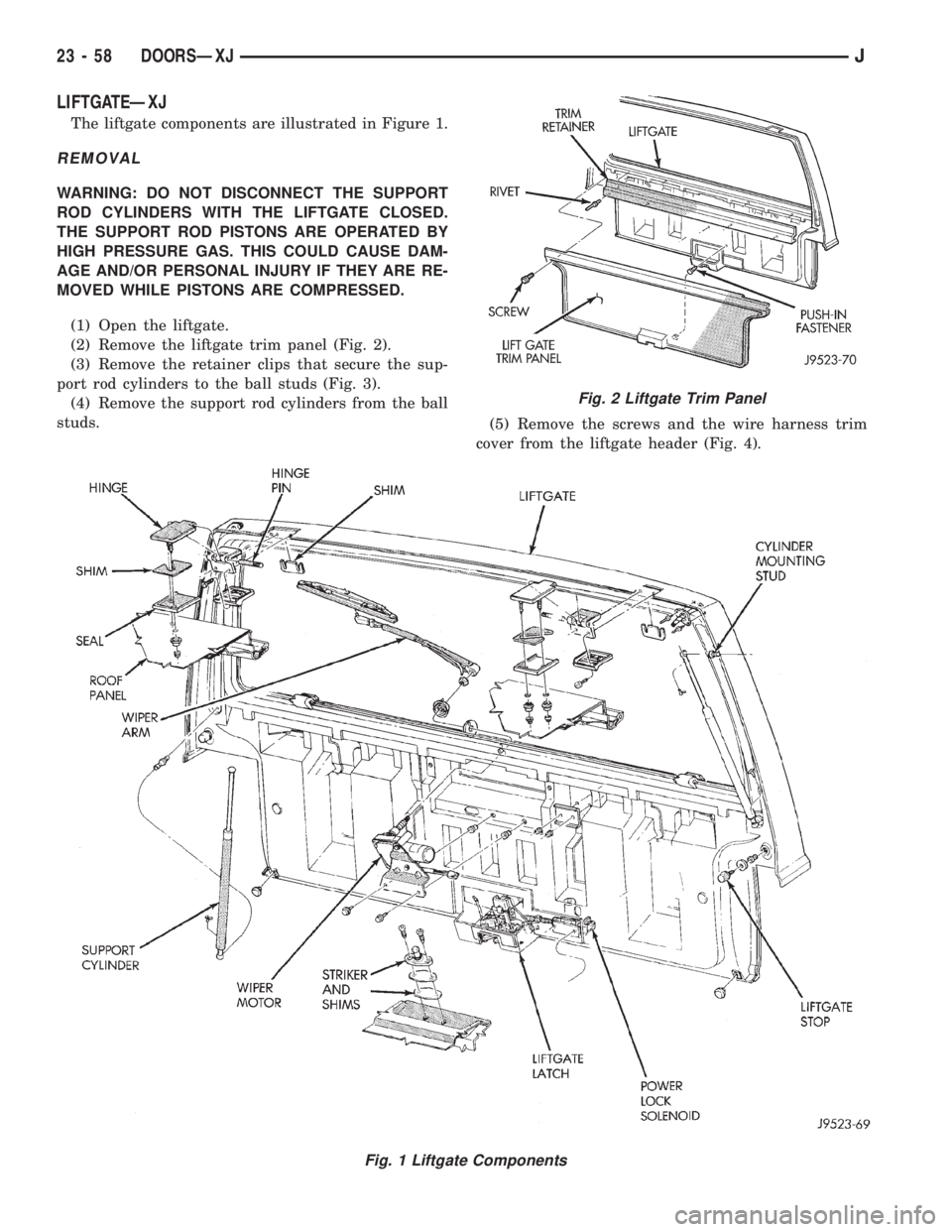

LIFTGATEÐXJ

The liftgate components are illustrated in Figure 1.

REMOVAL

WARNING: DO NOT DISCONNECT THE SUPPORT

ROD CYLINDERS WITH THE LIFTGATE CLOSED.

THE SUPPORT ROD PISTONS ARE OPERATED BY

HIGH PRESSURE GAS. THIS COULD CAUSE DAM-

AGE AND/OR PERSONAL INJURY IF THEY ARE RE-

MOVED WHILE PISTONS ARE COMPRESSED.

(1) Open the liftgate.

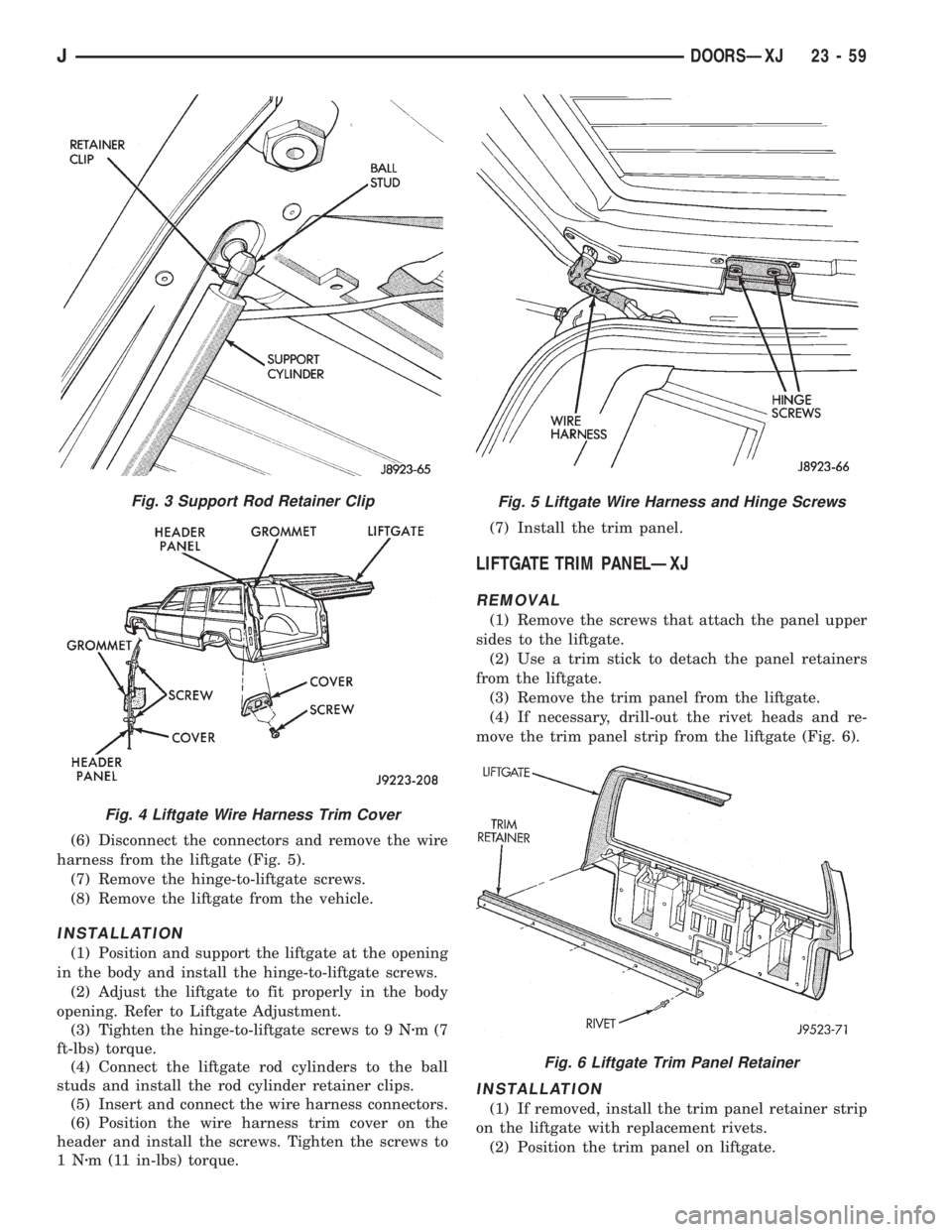

(2) Remove the liftgate trim panel (Fig. 2).

(3) Remove the retainer clips that secure the sup-

port rod cylinders to the ball studs (Fig. 3).

(4) Remove the support rod cylinders from the ball

studs.

(5) Remove the screws and the wire harness trim

cover from the liftgate header (Fig. 4).

Fig. 1 Liftgate Components

Fig. 2 Liftgate Trim Panel

23 - 58 DOORSÐXJJ

Page 1792 of 2198

(6) Disconnect the connectors and remove the wire

harness from the liftgate (Fig. 5).

(7) Remove the hinge-to-liftgate screws.

(8) Remove the liftgate from the vehicle.

INSTALLATION

(1) Position and support the liftgate at the opening

in the body and install the hinge-to-liftgate screws.

(2) Adjust the liftgate to fit properly in the body

opening. Refer to Liftgate Adjustment.

(3) Tighten the hinge-to-liftgate screws to 9 Nzm(7

ft-lbs) torque.

(4) Connect the liftgate rod cylinders to the ball

studs and install the rod cylinder retainer clips.

(5) Insert and connect the wire harness connectors.

(6) Position the wire harness trim cover on the

header and install the screws. Tighten the screws to

1Nzm (11 in-lbs) torque.(7) Install the trim panel.

LIFTGATE TRIM PANELÐXJ

REMOVAL

(1) Remove the screws that attach the panel upper

sides to the liftgate.

(2) Use a trim stick to detach the panel retainers

from the liftgate.

(3) Remove the trim panel from the liftgate.

(4) If necessary, drill-out the rivet heads and re-

move the trim panel strip from the liftgate (Fig. 6).

INSTALLATION

(1) If removed, install the trim panel retainer strip

on the liftgate with replacement rivets.

(2) Position the trim panel on liftgate.

Fig. 3 Support Rod Retainer Clip

Fig. 4 Liftgate Wire Harness Trim Cover

Fig. 5 Liftgate Wire Harness and Hinge Screws

Fig. 6 Liftgate Trim Panel Retainer

JDOORSÐXJ 23 - 59

Page 1793 of 2198

(3) Align the trim panel retainers with the holes in

the liftgate inner panel and force the trim panel in-

ward.

(4) Install the screws to attach the panel upper

sides to the liftgate.

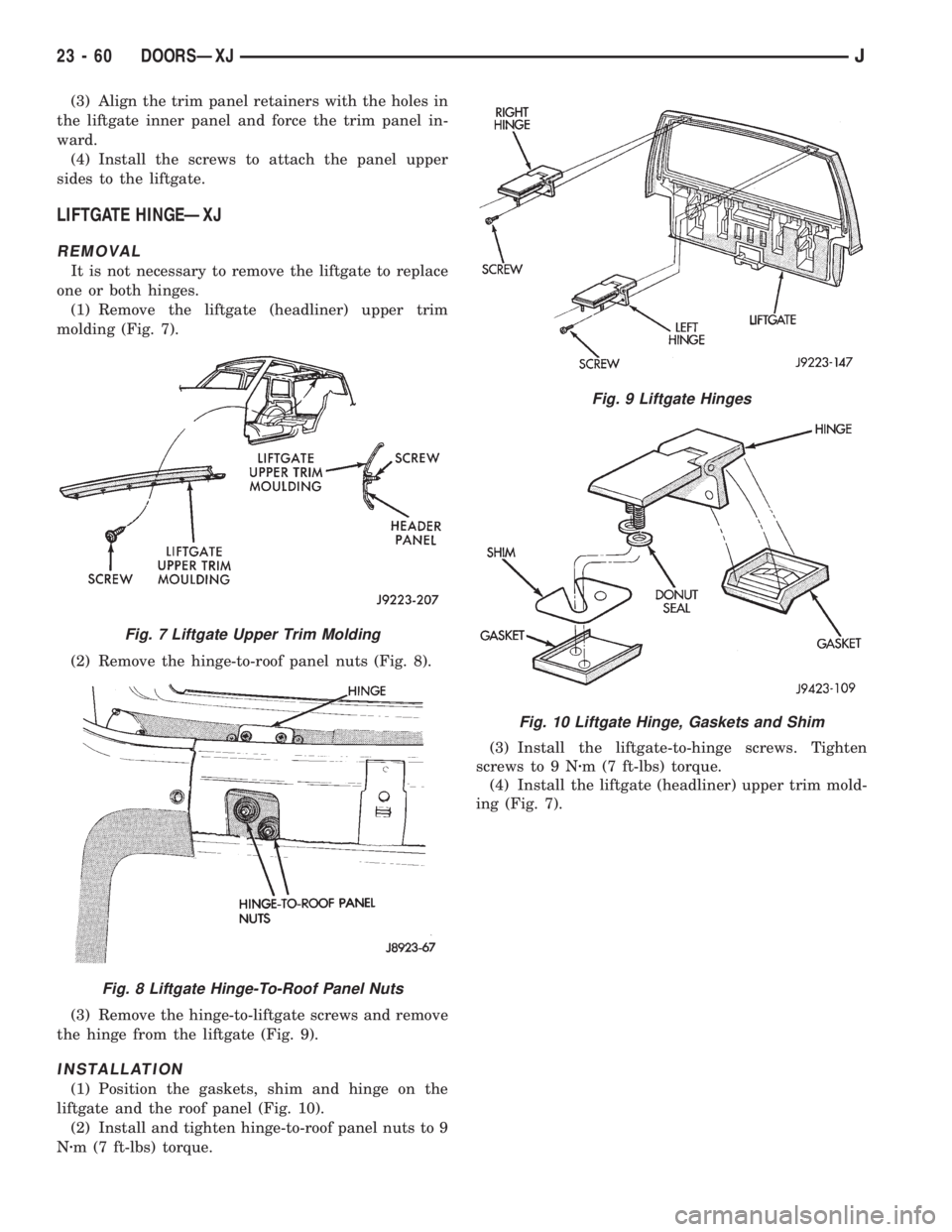

LIFTGATE HINGEÐXJ

REMOVAL

It is not necessary to remove the liftgate to replace

one or both hinges.

(1) Remove the liftgate (headliner) upper trim

molding (Fig. 7).

(2) Remove the hinge-to-roof panel nuts (Fig. 8).

(3) Remove the hinge-to-liftgate screws and remove

the hinge from the liftgate (Fig. 9).

INSTALLATION

(1) Position the gaskets, shim and hinge on the

liftgate and the roof panel (Fig. 10).

(2) Install and tighten hinge-to-roof panel nuts to 9

Nzm (7 ft-lbs) torque.(3) Install the liftgate-to-hinge screws. Tighten

screws to 9 Nzm (7 ft-lbs) torque.

(4) Install the liftgate (headliner) upper trim mold-

ing (Fig. 7).

Fig. 7 Liftgate Upper Trim Molding

Fig. 8 Liftgate Hinge-To-Roof Panel Nuts

Fig. 9 Liftgate Hinges

Fig. 10 Liftgate Hinge, Gaskets and Shim

23 - 60 DOORSÐXJJ

Page 1794 of 2198

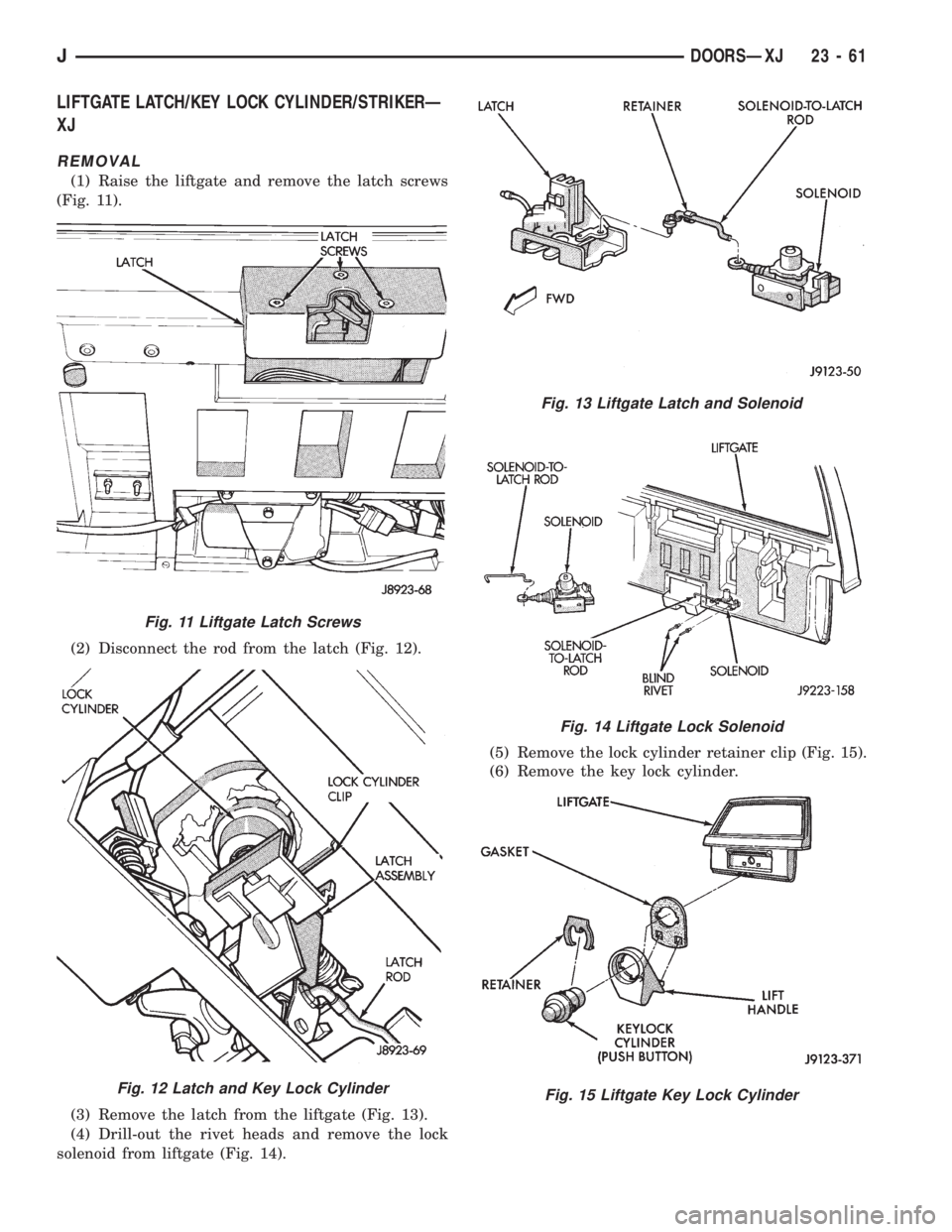

LIFTGATE LATCH/KEY LOCK CYLINDER/STRIKERÐ

XJ

REMOVAL

(1) Raise the liftgate and remove the latch screws

(Fig. 11).

(2) Disconnect the rod from the latch (Fig. 12).

(3) Remove the latch from the liftgate (Fig. 13).

(4) Drill-out the rivet heads and remove the lock

solenoid from liftgate (Fig. 14).(5) Remove the lock cylinder retainer clip (Fig. 15).

(6) Remove the key lock cylinder.

Fig. 11 Liftgate Latch Screws

Fig. 12 Latch and Key Lock Cylinder

Fig. 13 Liftgate Latch and Solenoid

Fig. 14 Liftgate Lock Solenoid

Fig. 15 Liftgate Key Lock Cylinder

JDOORSÐXJ 23 - 61

Page 1795 of 2198

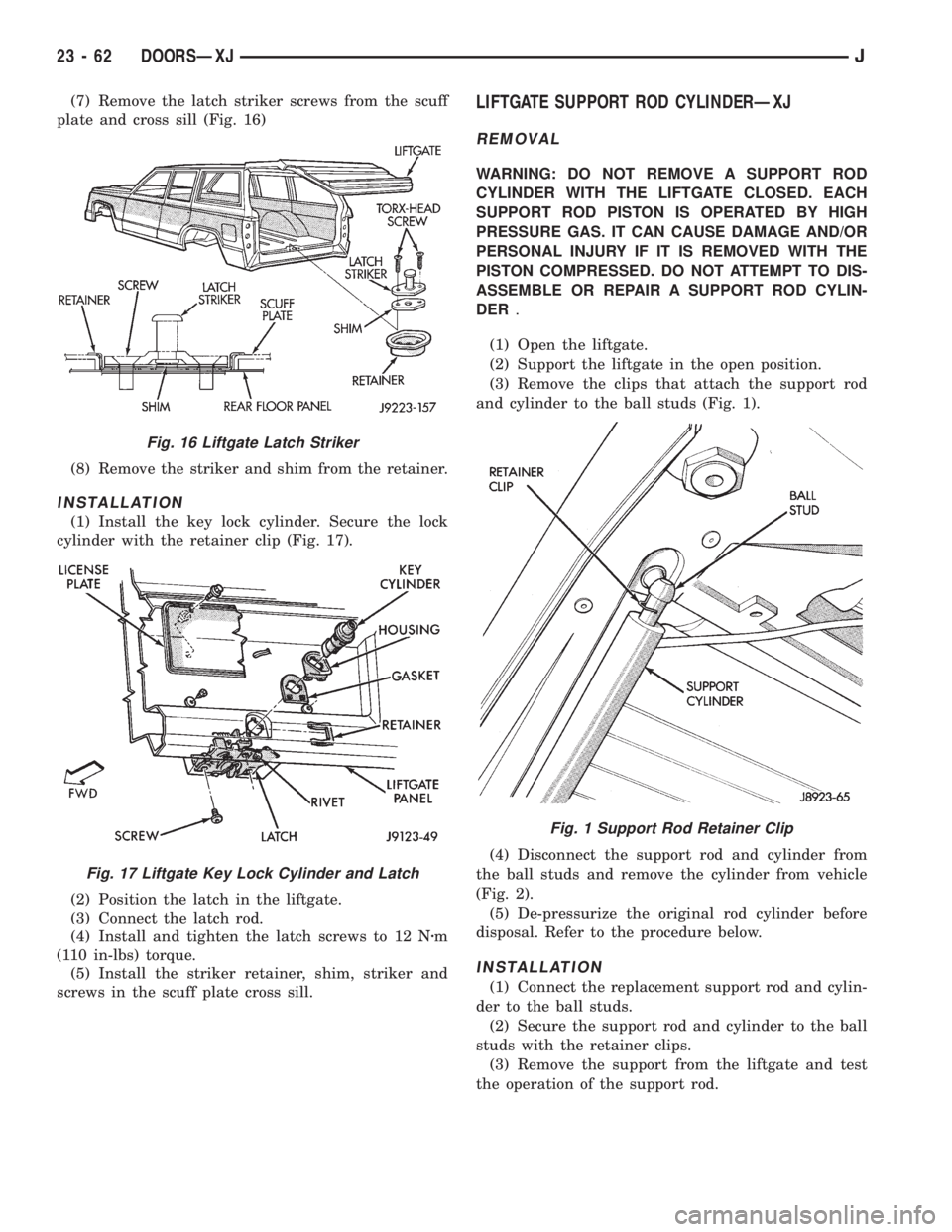

(7) Remove the latch striker screws from the scuff

plate and cross sill (Fig. 16)

(8) Remove the striker and shim from the retainer.

INSTALLATION

(1) Install the key lock cylinder. Secure the lock

cylinder with the retainer clip (Fig. 17).

(2) Position the latch in the liftgate.

(3) Connect the latch rod.

(4) Install and tighten the latch screws to 12 Nzm

(110 in-lbs) torque.

(5) Install the striker retainer, shim, striker and

screws in the scuff plate cross sill.

LIFTGATE SUPPORT ROD CYLINDERÐXJ

REMOVAL

WARNING: DO NOT REMOVE A SUPPORT ROD

CYLINDER WITH THE LIFTGATE CLOSED. EACH

SUPPORT ROD PISTON IS OPERATED BY HIGH

PRESSURE GAS. IT CAN CAUSE DAMAGE AND/OR

PERSONAL INJURY IF IT IS REMOVED WITH THE

PISTON COMPRESSED. DO NOT ATTEMPT TO DIS-

ASSEMBLE OR REPAIR A SUPPORT ROD CYLIN-

DER.

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the clips that attach the support rod

and cylinder to the ball studs (Fig. 1).

(4) Disconnect the support rod and cylinder from

the ball studs and remove the cylinder from vehicle

(Fig. 2).

(5) De-pressurize the original rod cylinder before

disposal. Refer to the procedure below.

INSTALLATION

(1) Connect the replacement support rod and cylin-

der to the ball studs.

(2) Secure the support rod and cylinder to the ball

studs with the retainer clips.

(3) Remove the support from the liftgate and test

the operation of the support rod.

Fig. 16 Liftgate Latch Striker

Fig. 17 Liftgate Key Lock Cylinder and Latch

Fig. 1 Support Rod Retainer Clip

23 - 62 DOORSÐXJJ

Page 1796 of 2198

LIFTGATE SUPPORT ROD CYLINDER DISPOSALÐ

XJ

WARNING: SAFETY GOGGLES MUST BE WORN

DURING THE DISPOSAL PROCEDURE. THE HIGH

PRESSURE GAS CHARGE IN THE SUPPORT ROD

CYLINDERS WILL BE RELEASED DURING THE

PROCEDURE.

(1) Remove the support rod cylinder(s) from the

liftgate.

(2) Position the support rod cylinder horizontally

in a vise and clamp the cylinder securely.

(3) Wrap the cylinder with 4-5 layers of shop tow-

els.

(4) Measure 1 and 1/2 inches inward from the end

of the cylinder. Mark this location on the towels with

chalk. The cylinder will be punctured at this location

to release the gas charge.

(5) Use a punch and hammer to puncture cylinder.

Force the punch through towels and into the cylinder

with a hammer. Continue striking the punch until

the gas begins to escapebut do not remove the

punch.

(6) Hold the towels and punch in position until all

the gas has escaped. Complete de-pressurization will

require about 4 to 10 seconds. After all the gas has

escaped, slowly remove the punch.

(7) Hold a towel over the hole in cylinder and press

the support rod piston all the way into the cylinder

to purge remaining oil.

(8) Remove the support rod cylinder from the vise

and discard it.

(9) If both support rod cylinders are being re-

placed, repeat this procedure for the remaining cylin-

der.

LIFTGATE SUPPORT ROD BALL STUD

REPLACEMENTÐXJ

REMOVAL

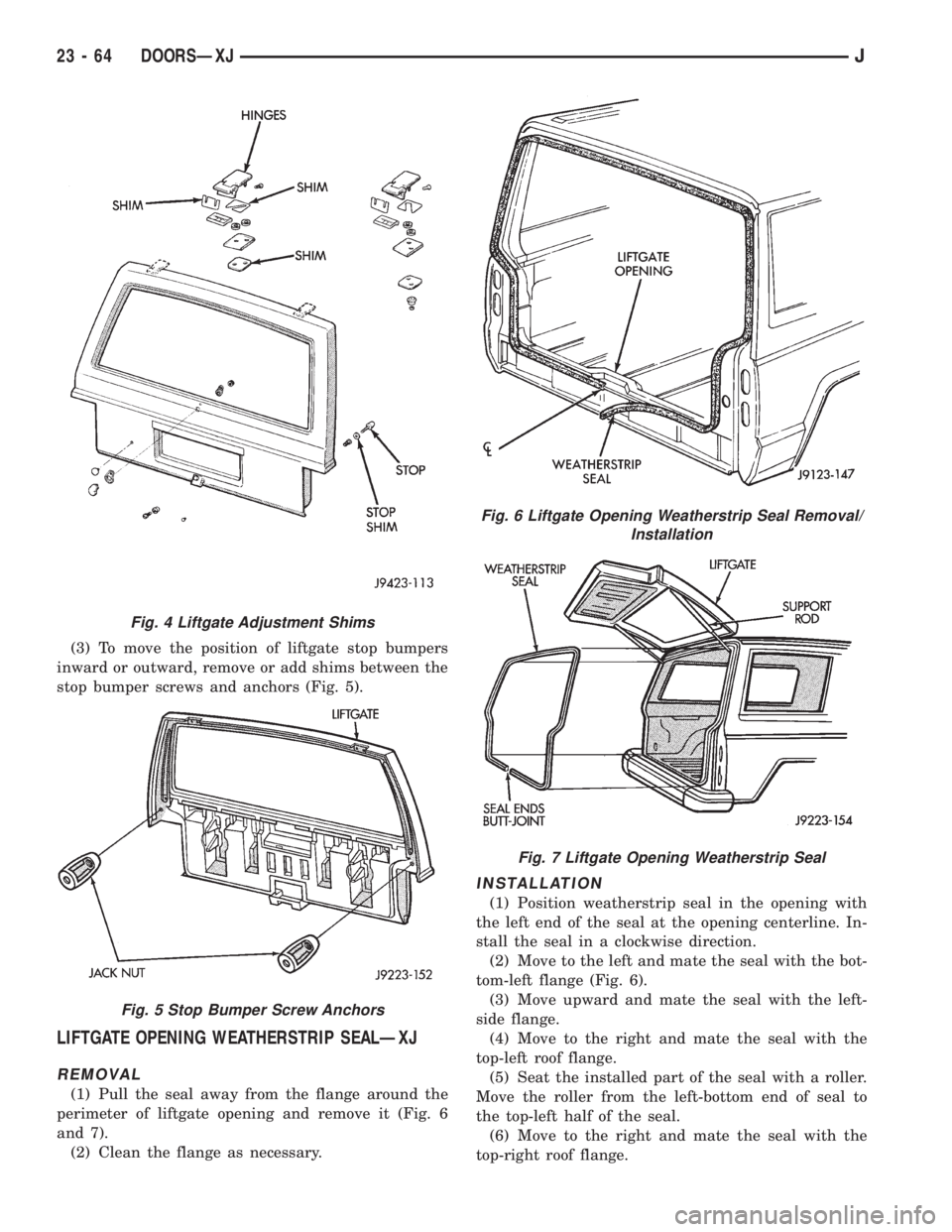

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the retainer clip that attaches the sup-

port rod and cylinder to the ball stud.

(4) Disconnect the support rod from the ball stud.

(5) Remove the ball stud from the liftgate with a

T-30 Torx-head socket wrench (Fig. 3).

INSTALLATION

(1) Install the replacement ball stud in the liftgate

with a T-30 Torx-head socket wrench. Tighten the

ball stud to 7 Nzm (62 in-lbs) torque.

(2) Connect the support rod to the ball stud.

(3) Secure the support rod to the ball stud with the

clip.

(4) Remove the support from the liftgate and test

the operation of support rod.

LIFTGATE ADJUSTMENTÐXJ

SERVICE INFORMATION

The position of the liftgate can be adjusted upward

or downward, and inward or outward by the use of

hinge shims. The liftgate stop bumpers must also be

adjusted if liftgate hinges are adjusted. The inward/

outward position of each stop bumper is adjusted by

the use of shims (Fig. 4).

ADJUSTMENT PROCEDURE

(1) To move the position of the liftgate inward or

outward, remove or add shims between the hinge-

halves and liftgate.

(2) To move the position of the liftgate upward or

downward, remove or add shims between the hinge-

halves and roof panel.

Fig. 2 Support Rod, Retainer Clips and Ball Studs

Fig. 3 Support Rod Ball Studs

JDOORSÐXJ 23 - 63

Page 1797 of 2198

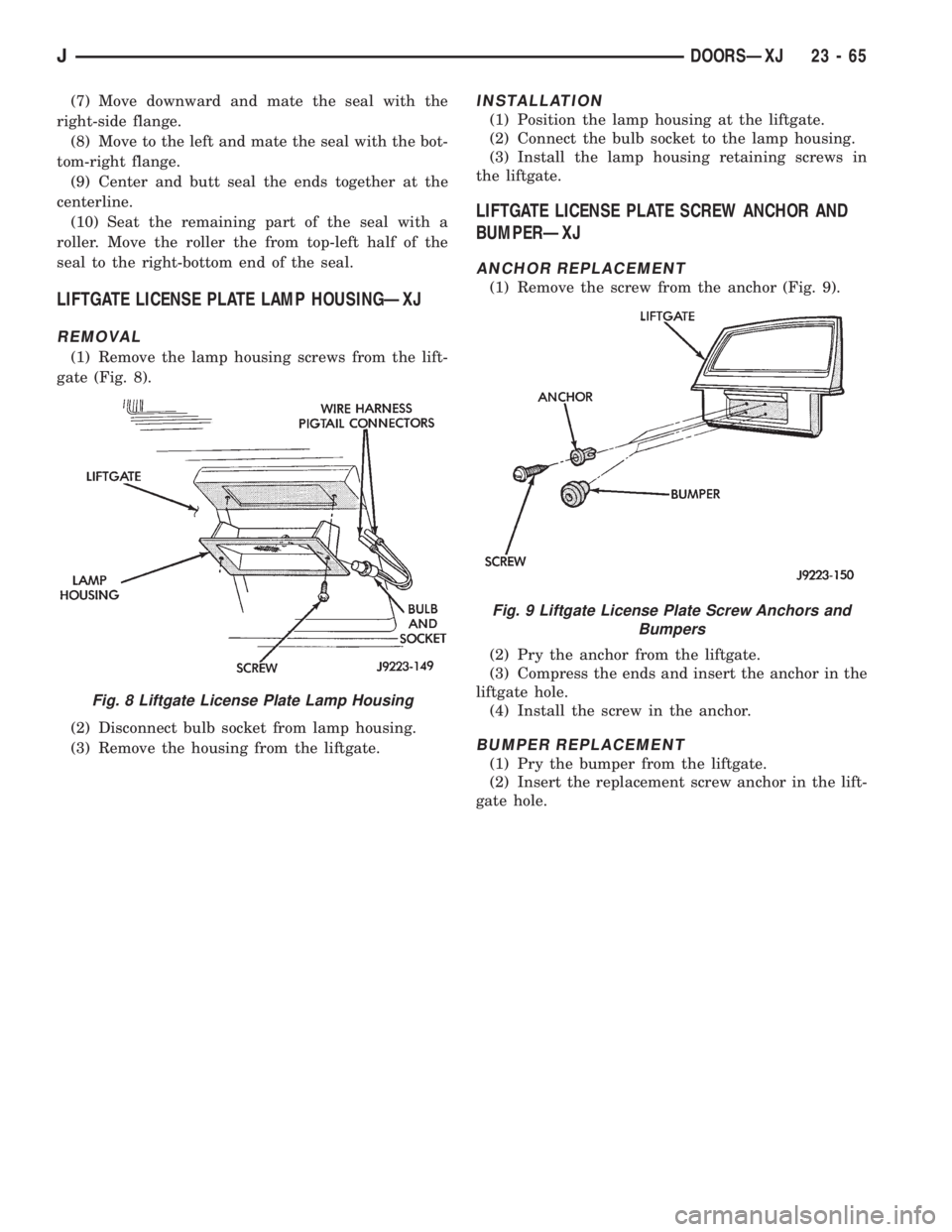

(3) To move the position of liftgate stop bumpers

inward or outward, remove or add shims between the

stop bumper screws and anchors (Fig. 5).

LIFTGATE OPENING WEATHERSTRIP SEALÐXJ

REMOVAL

(1) Pull the seal away from the flange around the

perimeter of liftgate opening and remove it (Fig. 6

and 7).

(2) Clean the flange as necessary.

INSTALLATION

(1) Position weatherstrip seal in the opening with

the left end of the seal at the opening centerline. In-

stall the seal in a clockwise direction.

(2) Move to the left and mate the seal with the bot-

tom-left flange (Fig. 6).

(3) Move upward and mate the seal with the left-

side flange.

(4) Move to the right and mate the seal with the

top-left roof flange.

(5) Seat the installed part of the seal with a roller.

Move the roller from the left-bottom end of seal to

the top-left half of the seal.

(6) Move to the right and mate the seal with the

top-right roof flange.

Fig. 4 Liftgate Adjustment Shims

Fig. 5 Stop Bumper Screw Anchors

Fig. 6 Liftgate Opening Weatherstrip Seal Removal/

Installation

Fig. 7 Liftgate Opening Weatherstrip Seal

23 - 64 DOORSÐXJJ

Page 1798 of 2198

(7) Move downward and mate the seal with the

right-side flange.

(8) Move to the left and mate the seal with the bot-

tom-right flange.

(9) Center and butt seal the ends together at the

centerline.

(10) Seat the remaining part of the seal with a

roller. Move the roller the from top-left half of the

seal to the right-bottom end of the seal.

LIFTGATE LICENSE PLATE LAMP HOUSINGÐXJ

REMOVAL

(1) Remove the lamp housing screws from the lift-

gate (Fig. 8).

(2) Disconnect bulb socket from lamp housing.

(3) Remove the housing from the liftgate.

INSTALLATION

(1) Position the lamp housing at the liftgate.

(2) Connect the bulb socket to the lamp housing.

(3) Install the lamp housing retaining screws in

the liftgate.

LIFTGATE LICENSE PLATE SCREW ANCHOR AND

BUMPERÐXJ

ANCHOR REPLACEMENT

(1) Remove the screw from the anchor (Fig. 9).

(2) Pry the anchor from the liftgate.

(3) Compress the ends and insert the anchor in the

liftgate hole.

(4) Install the screw in the anchor.

BUMPER REPLACEMENT

(1) Pry the bumper from the liftgate.

(2) Insert the replacement screw anchor in the lift-

gate hole.

Fig. 8 Liftgate License Plate Lamp Housing

Fig. 9 Liftgate License Plate Screw Anchors and

Bumpers

JDOORSÐXJ 23 - 65

Page 1799 of 2198

STATIONARY WINDOW GLASS

INDEX

page page

Interior Rearview MirrorÐXJ Removal and

Installation............................. 66

Interior Rearview Mirror Support Bracket

ReplacementÐXJ Preparation and Installation . . . 66

Description and Operation.......... ..........67

InstallationÐShort Method.......... ..........69

InstallationÐExtended Method........ ........71Rear Door Stationary Window Glass...... ......72

Rear Quarter Vent Window GlassÐXJ Removal

and Installation............. .............73

Rear Quarter Window Glass/Rear Quarter Plastic

InsertÐXJ Removal and Installation..... .....73

INTERIOR REARVIEW MIRRORÐXJ

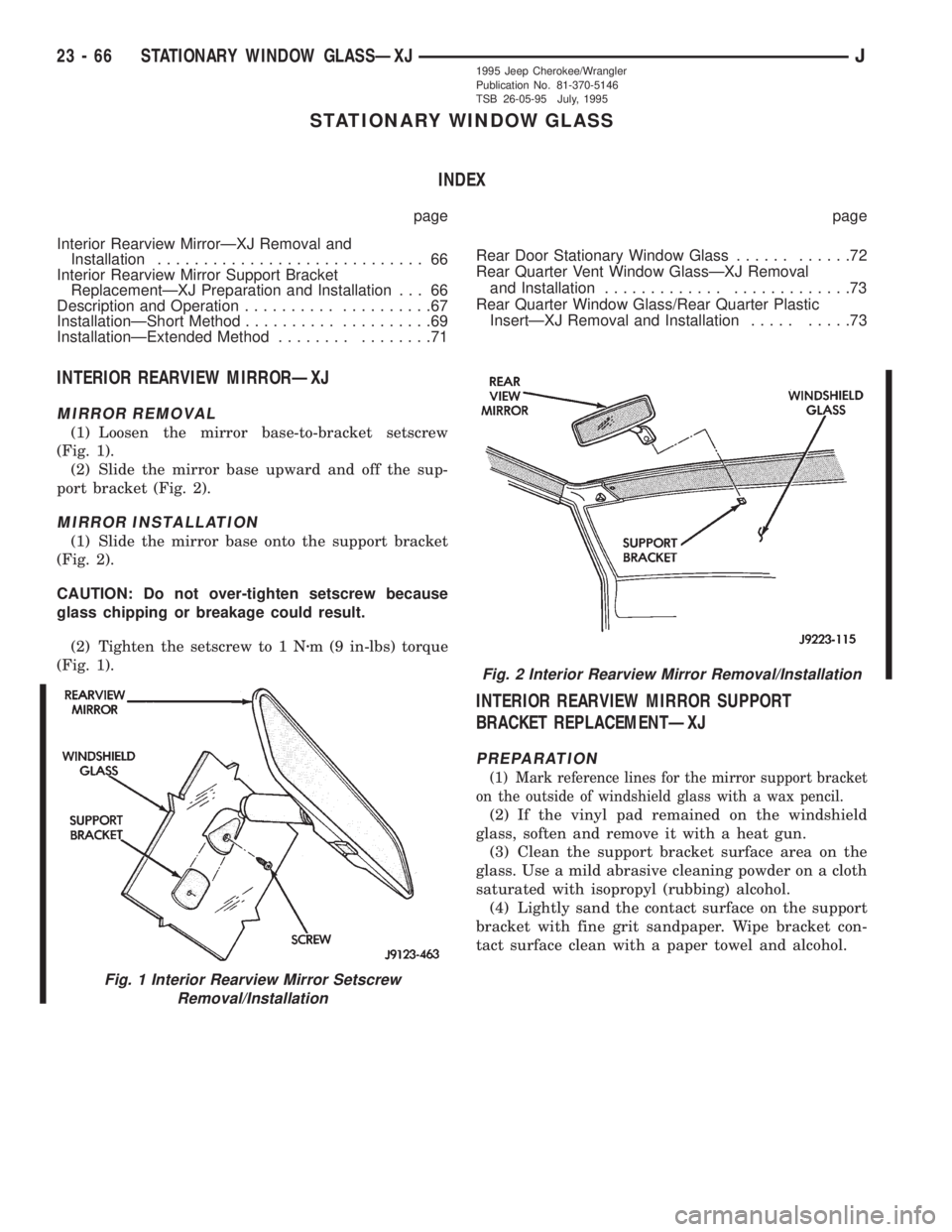

MIRROR REMOVAL

(1) Loosen the mirror base-to-bracket setscrew

(Fig. 1).

(2) Slide the mirror base upward and off the sup-

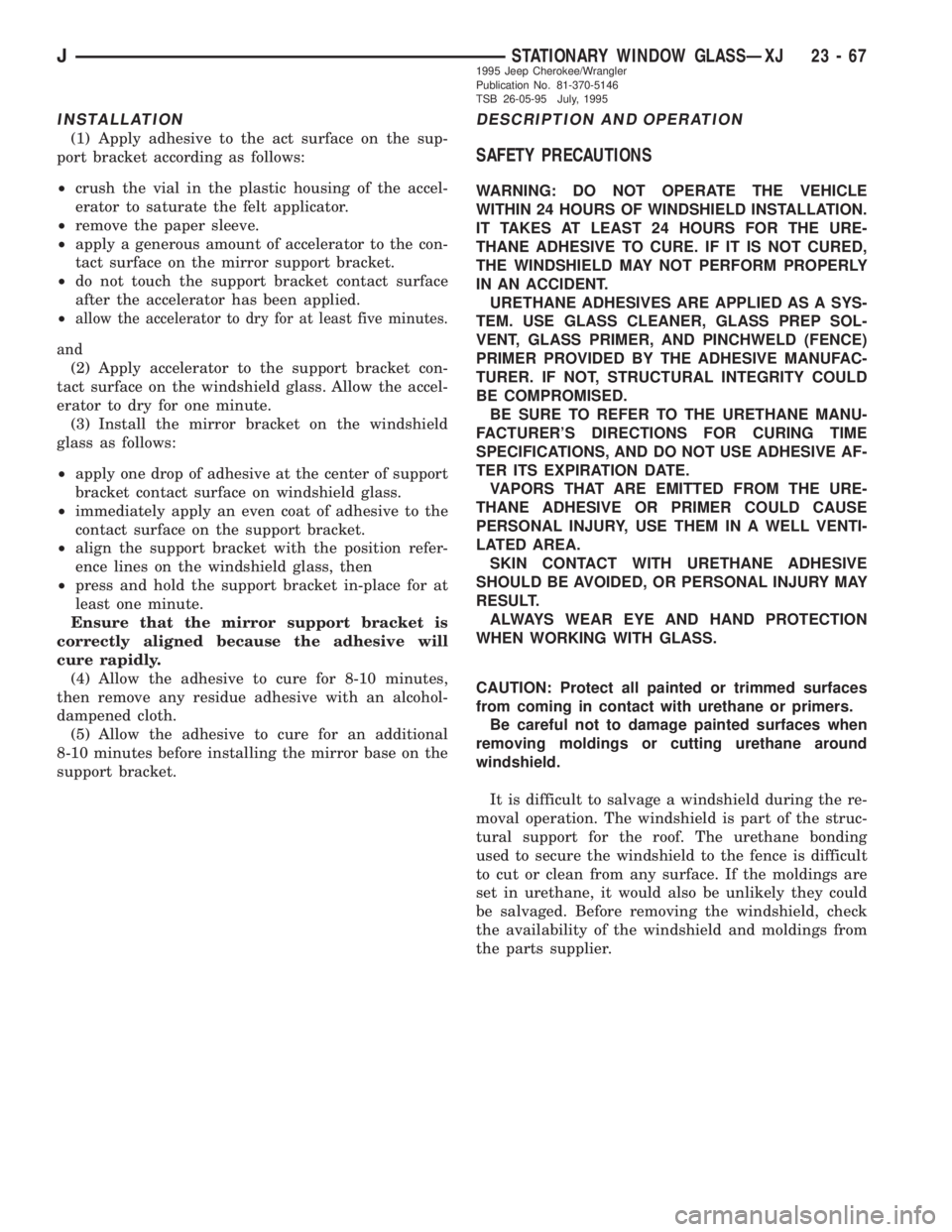

port bracket (Fig. 2).

MIRROR INSTALLATION

(1) Slide the mirror base onto the support bracket

(Fig. 2).

CAUTION: Do not over-tighten setscrew because

glass chipping or breakage could result.

(2) Tighten the setscrew to 1 Nzm (9 in-lbs) torque

(Fig. 1).

INTERIOR REARVIEW MIRROR SUPPORT

BRACKET REPLACEMENTÐXJ

PREPARATION

(1) Mark reference lines for the mirror support bracket

on the outside of windshield glass with a wax pencil.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun.

(3) Clean the support bracket surface area on the

glass. Use a mild abrasive cleaning powder on a cloth

saturated with isopropyl (rubbing) alcohol.

(4) Lightly sand the contact surface on the support

bracket with fine grit sandpaper. Wipe bracket con-

tact surface clean with a paper towel and alcohol.

Fig. 1 Interior Rearview Mirror Setscrew

Removal/Installation

Fig. 2 Interior Rearview Mirror Removal/Installation

23 - 66 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1800 of 2198

INSTALLATION

(1) Apply adhesive to the act surface on the sup-

port bracket according as follows:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator.

²remove the paper sleeve.

²apply a generous amount of accelerator to the con-

tact surface on the mirror support bracket.

²do not touch the support bracket contact surface

after the accelerator has been applied.

²

allow the accelerator to dry for at least five minutes.

and

(2) Apply accelerator to the support bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute.

(3) Install the mirror bracket on the windshield

glass as follows:

²apply one drop of adhesive at the center of support

bracket contact surface on windshield glass.

²immediately apply an even coat of adhesive to the

contact surface on the support bracket.

²align the support bracket with the position refer-

ence lines on the windshield glass, then

²press and hold the support bracket in-place for at

least one minute.

Ensure that the mirror support bracket is

correctly aligned because the adhesive will

cure rapidly.

(4) Allow the adhesive to cure for 8-10 minutes,

then remove any residue adhesive with an alcohol-

dampened cloth.

(5) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror base on the

support bracket.

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR THE URE-

THANE ADHESIVE TO CURE. IF IT IS NOT CURED,

THE WINDSHIELD MAY NOT PERFORM PROPERLY

IN AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, AND PINCHWELD (FENCE)

PRIMER PROVIDED BY THE ADHESIVE MANUFAC-

TURER. IF NOT, STRUCTURAL INTEGRITY COULD

BE COMPROMISED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE AF-

TER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY, USE THEM IN A WELL VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED, OR PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted or trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the re-

moval operation. The windshield is part of the struc-

tural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

JSTATIONARY WINDOW GLASSÐXJ 23 - 671995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995