Lancia Delta 2010 Owner handbook (in English)

Manufacturer: LANCIA, Model Year: 2010, Model line: Delta, Model: Lancia Delta 2010Pages: 276, PDF Size: 5.31 MB

Page 181 of 276

180IN AN EMERGENCY

INFLATION PROCEDURE

Put on the protective gloves provided togeth-

er with quick tyre repair kit.

❍Engage the handbrake. Unscrew the tyre valve cap,

take out the flexible filling pipe A-fig. 4 and screw

down the ring nut B on the tyre valve;

❍make sure that switch D-fig. 5 on the compressor is

in position 0 (off), start the engine, insert pin E-fig. 6

into the current socket and switch on the compressor

by placing switch D-fig. 5 in position 1 (on).

fig. 4L0E0077m

The cylinder contains ethylene glycol. Con-

tains latex: may cause an allergic reaction.

Harmful if swallowed. Irritates the eyes. May

cause sensitization by inhalation or contact. Avoid

contact with your eyes, skin and clothes. In the event

of contact, wash immediately with plenty of water.

Do not induce vomiting if swallowed. Rinse your

mouth and drink plenty of water. Call a doctor im-

mediately. Keep away from children. The product

must not be used by asthmatics. Do not breath in

the vapours during insertion and suction. Call a

doctor immediately if allergic reactions are noted.

Store the cylinder in the specific compartment, away

from sources of heat. The sealing fluid will expire.

Replace the cylinder containing expired seal-

ing liquid. Dispose of the cylinder and the

sealant liquid properly. Dispose according to

the national and local laws in force.

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 180

Page 182 of 276

IN AN EMERGENCY181

4

Inflate the tyre to the pressure specified in the “Infla-

tion pressure” paragraph, in chapter “6”. For a more

accurate reading, check pressure gauge F-fig. 5 with

the compressor off;

❍if a pressure value of a least 1.5 bars is not reached

within 5 minutes, disconnect the compressor from the

valve and current socket, move the vehicle forwards

by about 10 metres to distribute the sealant fluid in

the tyre and repeat the inflation procedure;❍if event then a pressure value of a least 1.8 bars, is

not reached within 5 minutes of switching on the com-

pressor, do not continue driving because the tyre is too

damaged to be repaired by the kit and the seal can-

not be guaranteed, contact a Lancia Dealership;

❍the tyre reaches the pressure specified in paragraph

“Inflation pressure” in chapter “6”, start driving im-

mediately;

fig. 5L0E0078m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 181

Page 183 of 276

182IN AN EMERGENCY

❍after driving for about 10 minutes, stop and check the

tyre pressure again; remember to engage the hand-

brake;❍if, on the other hand, a pressure of at least 1.8 bar pres-

sure is read, restore the correct pressure (with engine

running and handbrake on) and continue driving;

❍drive with the utmost care to the nearest Lancia Deal-

ership.

Apply the adhesive label in a position clear-

ly visible by the driver as a reminder that the

tyre has been treated with the quick repair

kit. Drive carefully, particularly on bends. Do not

exceed 80 km/h. Do not accelerate and brake sud-

denly.

Stop if the pressure has dropped to less than

1.8 bars: The automatic Fix & Go fast repair

kit cannot work properly because the tyre is

excessively damaged. Contact a Lancia Dealership.

Remember to inform the workshop that the

tyre has been treated with a quick repair kit.

Give the instruction booklet to the tyre repair

workshop personnel.

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 182

Page 184 of 276

IN AN EMERGENCY183

4

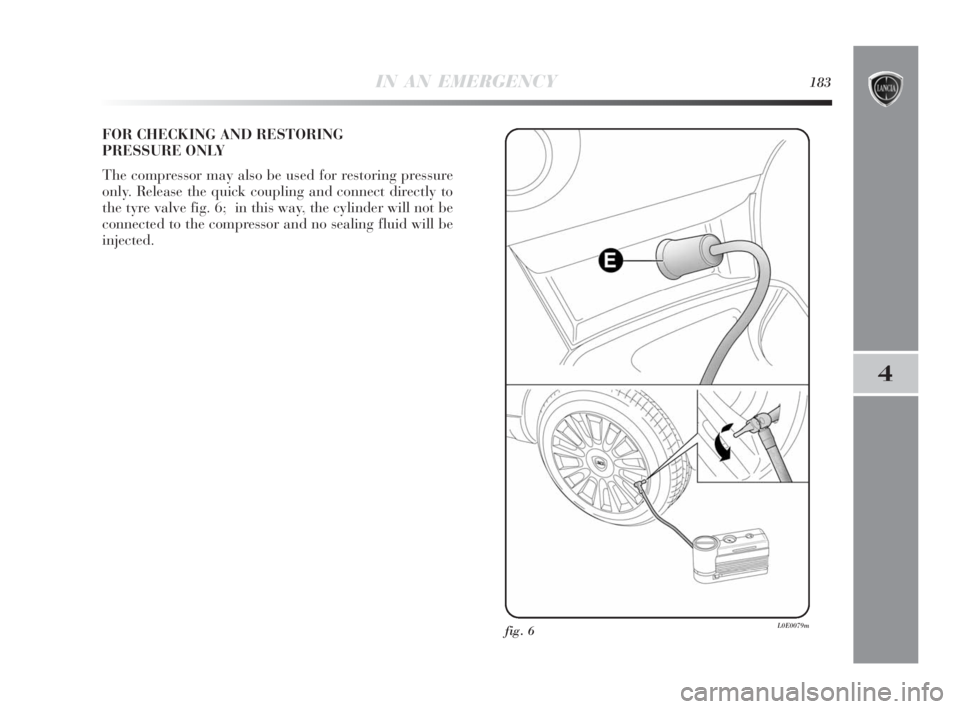

FOR CHECKING AND RESTORING

PRESSURE ONLY

The compressor may also be used for restoring pressure

only. Release the quick coupling and connect directly to

the tyre valve fig. 6; in this way, the cylinder will not be

connected to the compressor and no sealing fluid will be

injected.

fig. 6L0E0079m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 183

Page 185 of 276

184IN AN EMERGENCY

CYLINDER REPLACEMENT PROCEDURE

To replace the cylinder proceed as follows:

❍disconnect connection A-fig. 7;

❍turn the cylinder to be replaced anticlockwise and

raise it;

❍fit the new cylinder and turn it clockwise;

❍connect connection A to the cylinder and fit the trans-

parent tube B into the proper space.

fig. 7L0E0080m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 184

Page 186 of 276

IN AN EMERGENCY185

4

REPLACING A WHEEL

GENERAL INSTRUCTIONS

The vehicle can be provided with (if requested, for ver-

sions/markets, where provided) a small spare wheel.

Wheel changing and correct use of the jack and of the

small spare wheel call for some precautions as listed

below.

The small spare wheel (for versions/markets,

where provided) is specific for your car. Do

not use it on different models of car. Do not

use spare wheels from different models on your car.

The small spare wheel must only be used in an

emergency. Never use it for more than strictly nec-

essary and never exceed 80 km/h. On the small

spare wheel there is an orange label, summarizing

the main warnings regarding small spare wheel us-

age restrictions.

Never remove or cover the label. Never apply

any hub cap on the small spare wheel. The

label contains the following indications in

four languages: Warning! For temporary use only!

80 km/h max! Replace as soon as possible with a

standard service wheel. Never cover this indication.

If you choose to install wheels of a different type

(with alloy rims instead of steel ones) you must al-

so change all the wheel retaining bolts with others

of a suitable size.

Indicate that the car is stationary according

to the laws in force: hazard warning lights,

refracting warning triangle, etc. Passengers

should leave the car, particularly if it is very loaded

and wait for the wheel to be changed away from on-

coming traffic. In the event of a wheel change on a

slope or on unsurfaced roads, chock the wheels.

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 185

Page 187 of 276

186IN AN EMERGENCY

Vehicle handling is modified with the small

spare wheel fitted. Avoid violent acceleration

and braking, sharp steering and fast bend-

ing. The overall duration of the small spare wheel

is of about 3000 km, after which the relevant tyre

must be replaced with another one of the same type.

Never install a traditional tyre on a rim designed to

be used as a small spare wheel. Repair and refit the

standard wheel as soon as possible. Using two or

more small spare wheels at the same time is for-

bidden. Do not apply grease to the bolt threads be-

fore assembly: they might come unscrewed.The jack may only be used to replace wheels

on the car which it equips or other cars of the

same model. Never use the jack for other pur-

poses, such as lifting other car models. Never use

the jack to carry out repairs under the car. Incor-

rect positioning of the jack may cause the car to fall.

Do not use the jack for loads higher than those

shown on the label. Never install snow chains on the

small spare wheel; if a front tyre (driving wheel)

is punctured and you need to use snow chains, use

a standard wheel from the rear axle and install the

small spare wheel on the rear axle. This way, with

two normal front driving wheels, you can install the

snow chains on them, thus resolving the emergency.

If the hub cap is not installed properly, it can

detach itself when the vehicle is running. Nev-

er tamper with the inflation valve. Never in-

troduce tools of any kind between rim and tyre.

Check tyre and small spare wheel pressure regu-

larly referring to the values shown in chapter “6”.

Tool box (versions with Bose Hi-Fi)

There is a tool box located in the luggage compartment

for versions with Bose Hi-Fi.

This box contains:

❍screwdriver;

❍tow hook;

❍wheel bolt spanner;

❍wheel bolt access spanner;

❍alloy wheel centering;

❍jack.

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 186

Page 188 of 276

IN AN EMERGENCY187

4

REMOVING THE SUBWOOFER

(versions with Bose HI-FI system)

(for versions/markets, where provided)

IMPORTANT The following procedure only applies to ve-

hicles equipped with Bose Hi-Fi systems with Subwoofer

(for versions/markets, where provided).

SUBWOOFER AND SMALL SPARE WHEEL

Proceed as follows to remove the Subwoofer:

❍open the luggage compartment, pull tab A-fig. 10 and

lift up the mat;

❍undo locking device A-fig. 8 and lift up the Subwoofer.

Then remove connection cable B from Velcro attach-

ment C;❍rest the Subwoofer to one side in the luggage com-

partment, remove the container and take out the small

spare wheel;

❍replace the wheel as described in this chapter.

After tyre replacement:

❍reposition the container and place the Subwoofer on

top of it, taking care to position it according to the in-

structions on the container (fig. 9) so that the arrow

on the spacer is pointing in the direction of travel;

❍rest cable B-fig. 8 into Velcro Attachment C to avoid

pinching it. Then tighten locking device A-fig. 8. Re-

place the luggage compartment mat.

fig. 8L0E0176mfig. 9L0E0177m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 187

Page 189 of 276

188IN AN EMERGENCY

Taking out the small spare wheel

Important notes:

❍the jack weight is 1.76 kg;

❍the jack requires no adjustment;

❍the jack cannot be repaired; If it breaks it must be re-

placed with a new jack;

❍no tool other than the cranking device may be fitted

on the jack.

To replace a tyre proceed as follows:

❍stop the car in a position where it does not present a

danger for on-coming traffic and where you can re-

place the wheel safely. The ground must be flat and

compact;

❍turn the engine off and engage the handbrake;

❍engage first gear or reverse;

❍lift up the luggage compartment mat using handle A-

fig. 10 (in the presence of a double load platform, first

lift the upper cover and then the luggage compartment

mat);

❍loosen the fastener B-fig. 10;

❍take out the tool box C and place it next to the wheel

to be changed;

❍remove the small spare wheel D-fig. 10;

❍use the provided screwdriver to remove the hub cap,

levering the dedicated opening on the outer edge;

fig. 10L0E0081m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 188

Page 190 of 276

IN AN EMERGENCY189

4

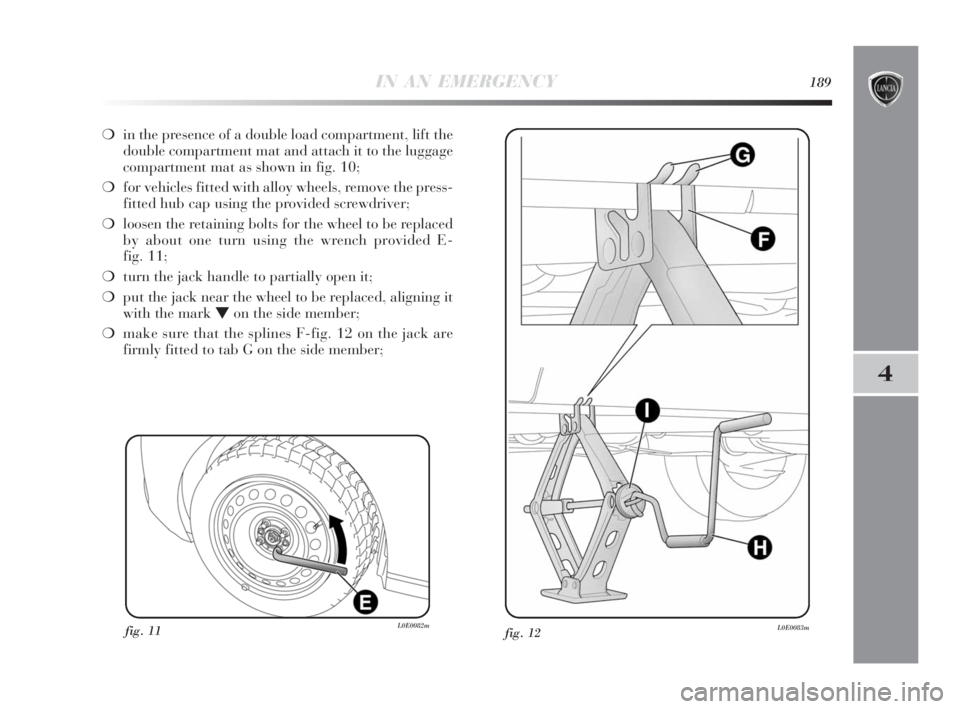

❍in the presence of a double load compartment, lift the

double compartment mat and attach it to the luggage

compartment mat as shown in fig. 10;

❍for vehicles fitted with alloy wheels, remove the press-

fitted hub cap using the provided screwdriver;

❍loosen the retaining bolts for the wheel to be replaced

by about one turn using the wrench provided E-

fig. 11;

❍turn the jack handle to partially open it;

❍put the jack near the wheel to be replaced, aligning it

with the mark

Oon the side member;

❍make sure that the splines F-fig. 12 on the jack are

firmly fitted to tab G on the side member;

fig. 11L0E0082mfig. 12L0E0083m

175-214 Delta 4ed gb 24-02-2010 14:36 Pagina 189