LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 731 of 1007

HOOD

76-7-6 REPAIRS

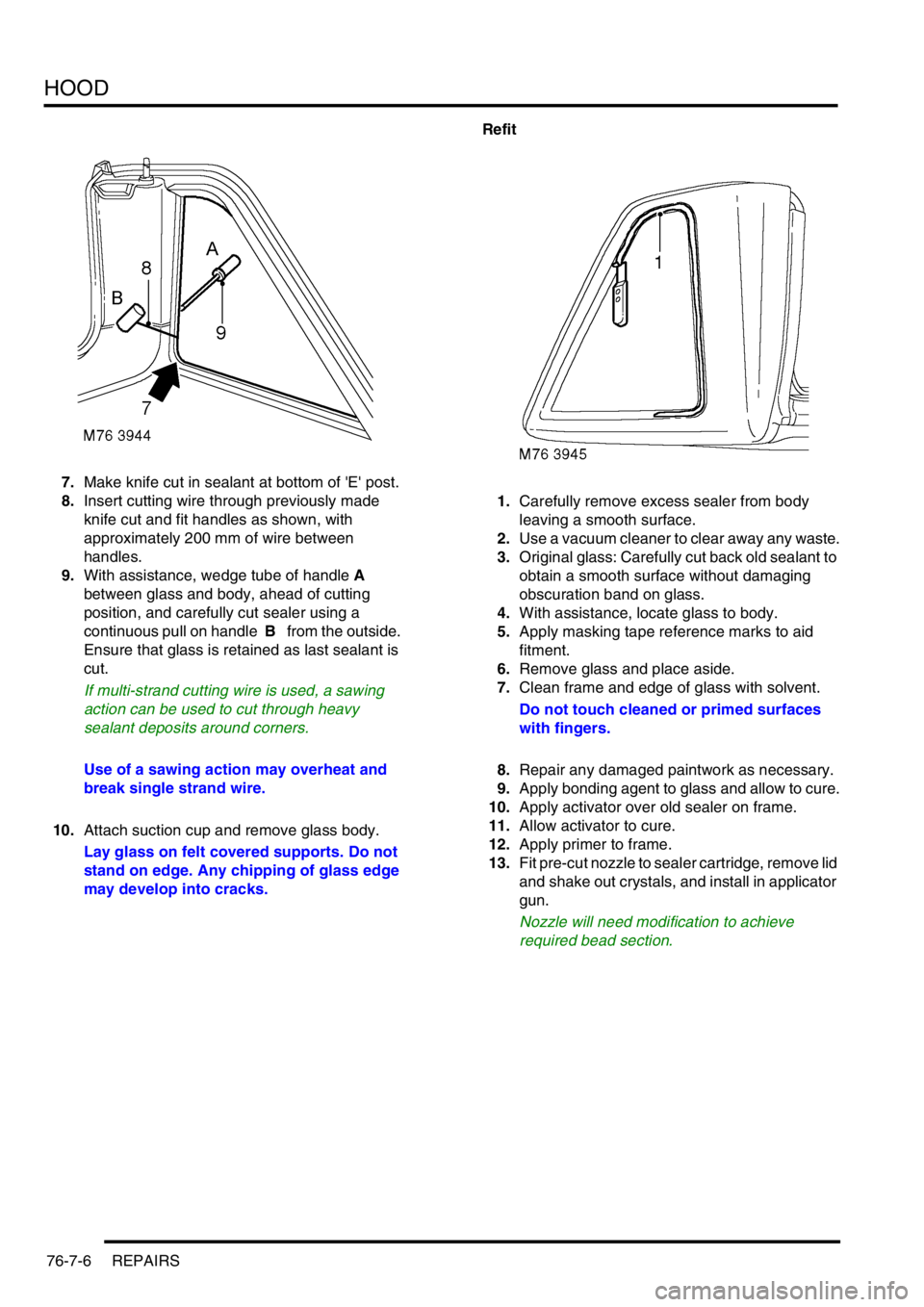

7.Make knife cut in sealant at bottom of 'E' post.

8.Insert cutting wire through previously made

knife cut and fit handles as shown, with

approximately 200 mm of wire between

handles.

9.With assistance, wedge tube of handle A

between glass and body, ahead of cutting

position, and carefully cut sealer using a

continuous pull on handle B from the outside.

Ensure that glass is retained as last sealant is

cut.

If multi-strand cutting wire is used, a sawing

action can be used to cut through heavy

sealant deposits around corners.

Use of a sawing action may overheat and

break single strand wire.

10.Attach suction cup and remove glass body.

Lay glass on felt covered supports. Do not

stand on edge. Any chipping of glass edge

may develop into cracks. Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealant to

obtain a smooth surface without damaging

obscuration band on glass.

4.With assistance, locate glass to body.

5.Apply masking tape reference marks to aid

fitment.

6.Remove glass and place aside.

7.Clean frame and edge of glass with solvent.

Do not touch cleaned or primed surfaces

with fingers.

8.Repair any damaged paintwork as necessary.

9.Apply bonding agent to glass and allow to cure.

10.Apply activator over old sealer on frame.

11.Allow activator to cure.

12.Apply primer to frame.

13.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

required bead section.

Page 732 of 1007

HOOD

REPAIRS 76-7-7

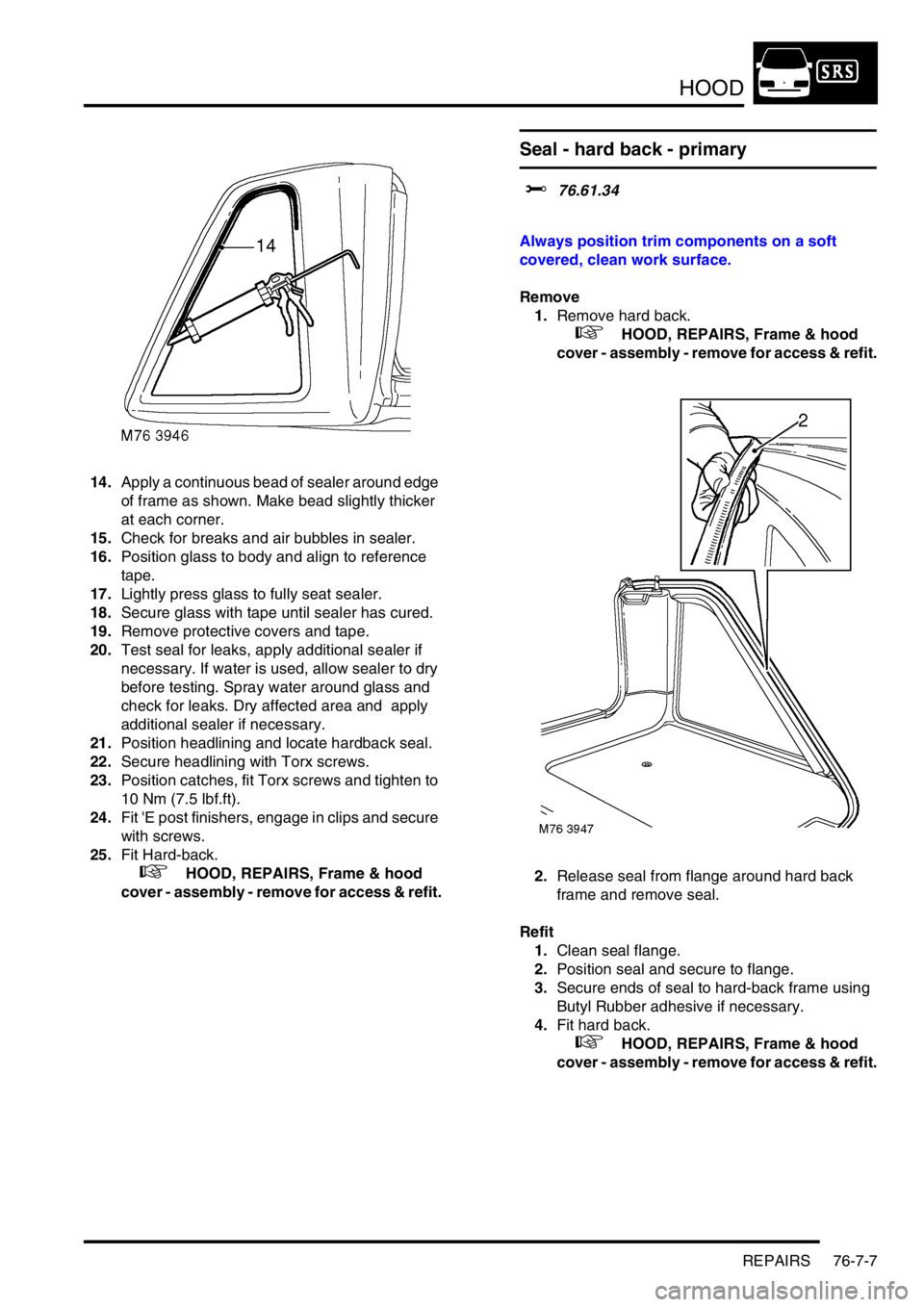

14.Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

15.Check for breaks and air bubbles in sealer.

16.Position glass to body and align to reference

tape.

17.Lightly press glass to fully seat sealer.

18.Secure glass with tape until sealer has cured.

19.Remove protective covers and tape.

20.Test seal for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Dry affected area and apply

additional sealer if necessary.

21.Position headlining and locate hardback seal.

22.Secure headlining with Torx screws.

23.Position catches, fit Torx screws and tighten to

10 Nm (7.5 lbf.ft).

24.Fit 'E post finishers, engage in clips and secure

with screws.

25.Fit Hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Seal - hard back - primary

$% 76.61.34

Always position trim components on a soft

covered, clean work surface.

Remove

1.Remove hard back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Release seal from flange around hard back

frame and remove seal.

Refit

1.Clean seal flange.

2.Position seal and secure to flange.

3.Secure ends of seal to hard-back frame using

Butyl Rubber adhesive if necessary.

4.Fit hard back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 733 of 1007

HOOD

76-7-8 REPAIRS

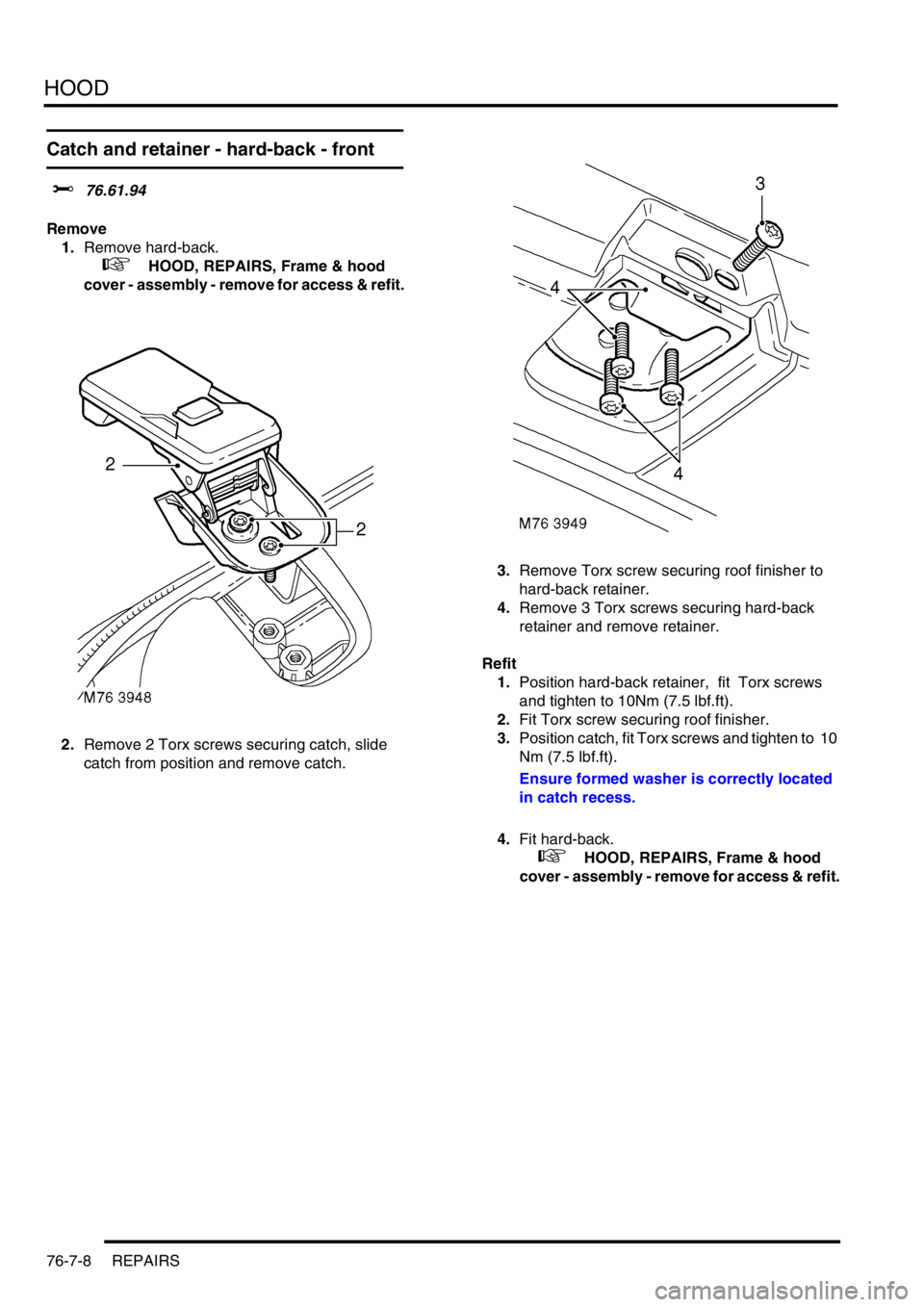

Catch and retainer - hard-back - front

$% 76.61.94

Remove

1.Remove hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

2.Remove 2 Torx screws securing catch, slide

catch from position and remove catch. 3.Remove Torx screw securing roof finisher to

hard-back retainer.

4.Remove 3 Torx screws securing hard-back

retainer and remove retainer.

Refit

1.Position hard-back retainer, fit Torx screws

and tighten to 10Nm (7.5 lbf.ft).

2.Fit Torx screw securing roof finisher.

3.Position catch, fit Torx screws and tighten to 10

Nm (7.5 lbf.ft).

Ensure formed washer is correctly located

in catch recess.

4.Fit hard-back.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 734 of 1007

HOOD

REPAIRS 76-7-9

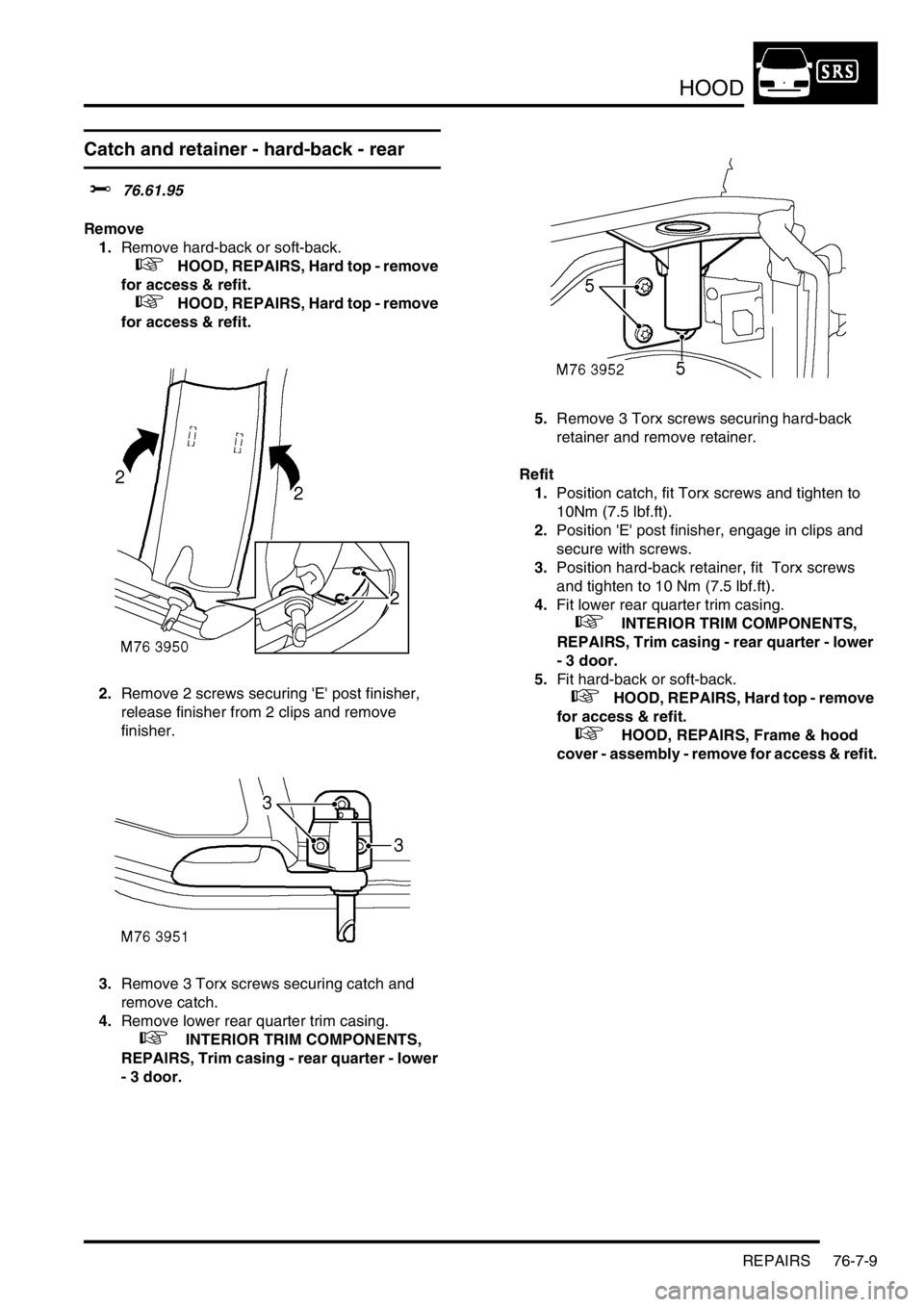

Catch and retainer - hard-back - rear

$% 76.61.95

Remove

1.Remove hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

2.Remove 2 screws securing 'E' post finisher,

release finisher from 2 clips and remove

finisher.

3.Remove 3 Torx screws securing catch and

remove catch.

4.Remove lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.5.Remove 3 Torx screws securing hard-back

retainer and remove retainer.

Refit

1.Position catch, fit Torx screws and tighten to

10Nm (7.5 lbf.ft).

2.Position 'E' post finisher, engage in clips and

secure with screws.

3.Position hard-back retainer, fit Torx screws

and tighten to 10 Nm (7.5 lbf.ft).

4.Fit lower rear quarter trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - lower

- 3 door.

5.Fit hard-back or soft-back.

+ HOOD, REPAIRS, Hard top - remove

for access & refit.

+ HOOD, REPAIRS, Frame & hood

cover - assembly - remove for access & refit.

Page 735 of 1007

Page 736 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-1

BODY DIMENSIONS BODY DIMENSIONS

Dimensional Information

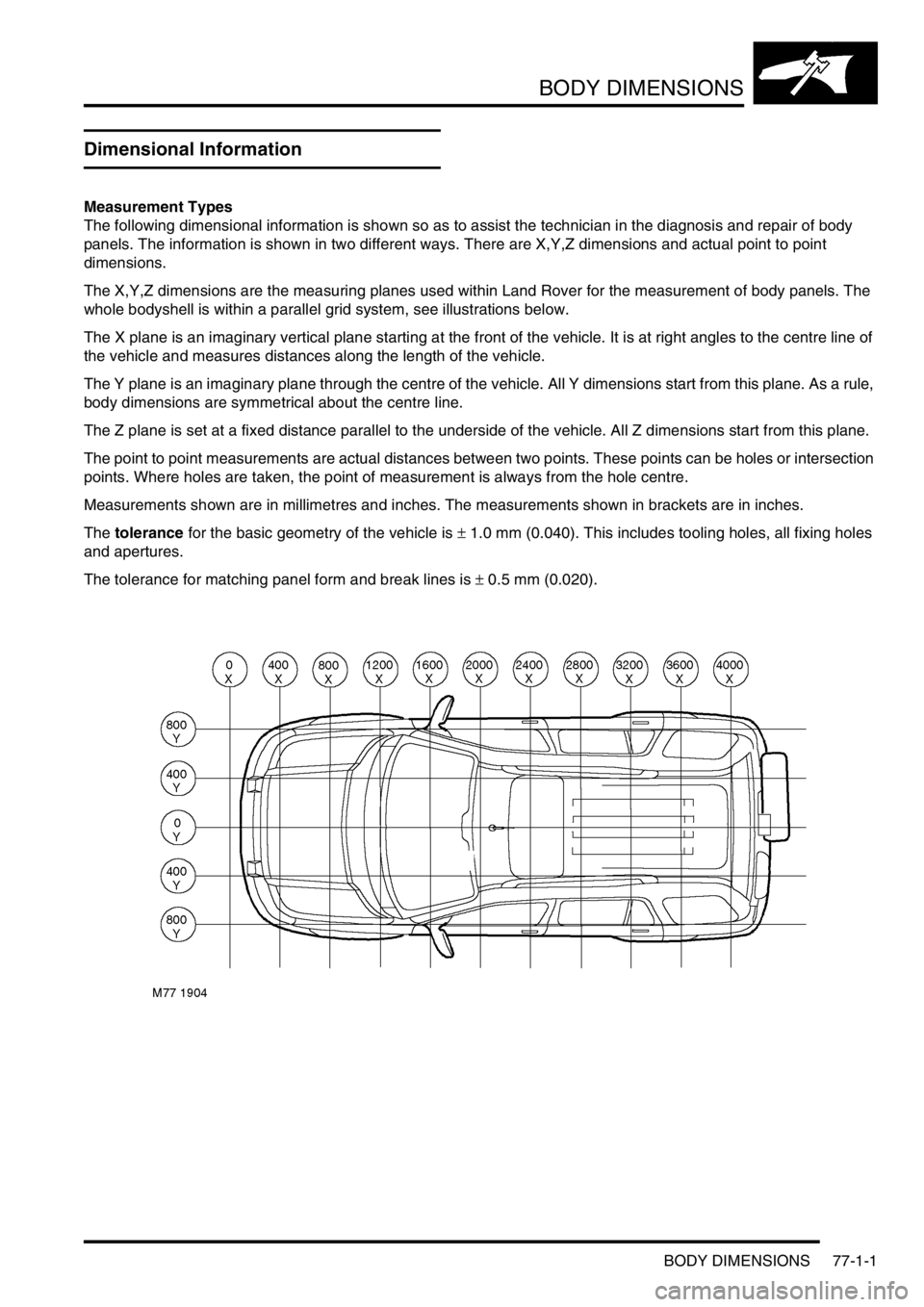

Measurement Types

The following dimensional information is shown so as to assist the technician in the diagnosis and repair of body

panels. The information is shown in two different ways. There are X,Y,Z dimensions and actual point to point

dimensions.

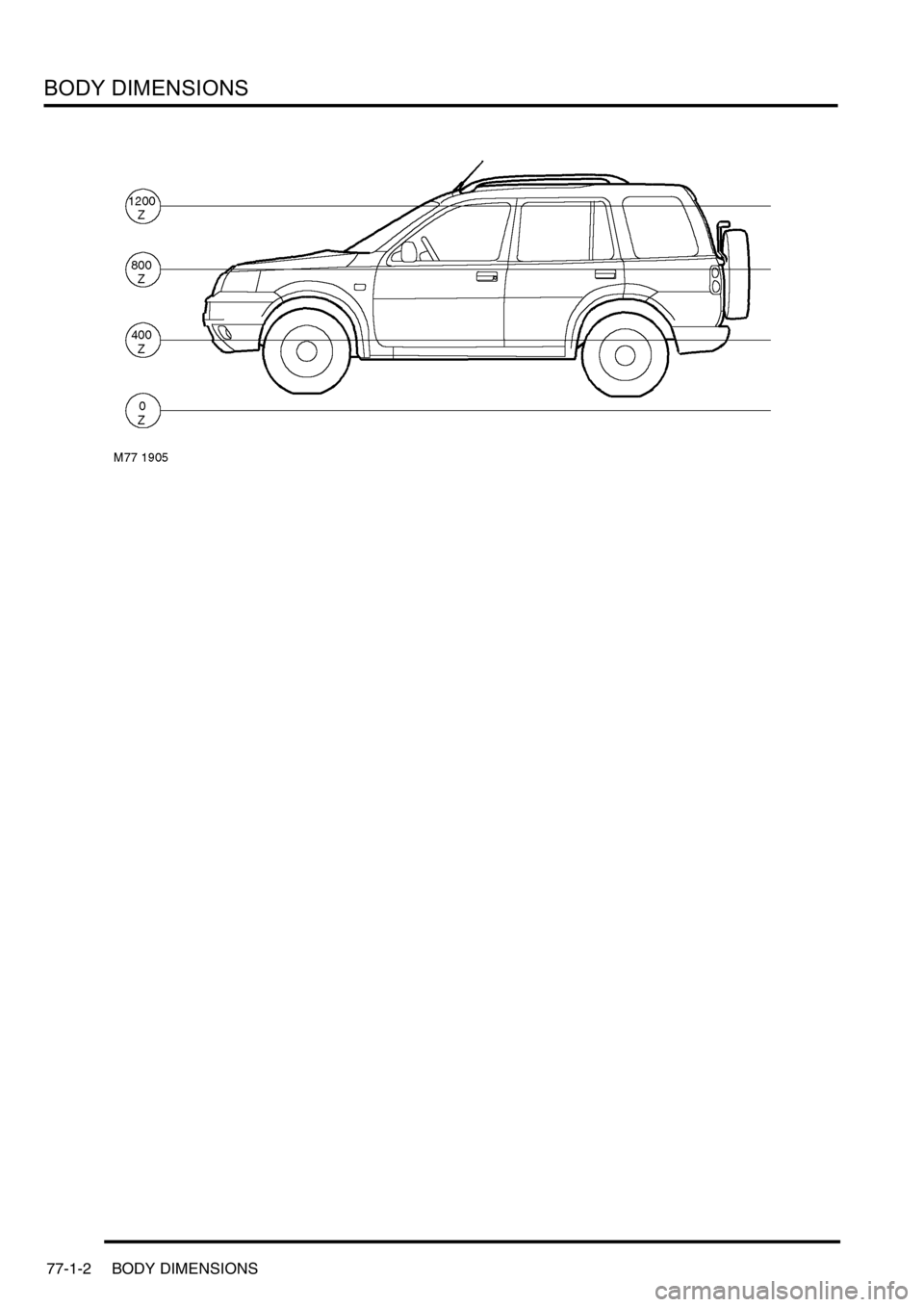

The X,Y,Z dimensions are the measuring planes used within Land Rover for the measurement of body panels. The

whole bodyshell is within a parallel grid system, see illustrations below.

The X plane is an imaginary vertical plane starting at the front of the vehicle. It is at right angles to the centre line of

the vehicle and measures distances along the length of the vehicle.

The Y plane is an imaginary plane through the centre of the vehicle. All Y dimensions start from this plane. As a rule,

body dimensions are symmetrical about the centre line.

The Z plane is set at a fixed distance parallel to the underside of the vehicle. All Z dimensions start from this plane.

The point to point measurements are actual distances between two points. These points can be holes or intersection

points. Where holes are taken, the point of measurement is always from the hole centre.

Measurements shown are in millimetres and inches. The measurements shown in brackets are in inches.

The tolerance for the basic geometry of the vehicle is ± 1.0 mm (0.040). This includes tooling holes, all fixing holes

and apertures.

The tolerance for matching panel form and break lines is ± 0.5 mm (0.020).

Page 737 of 1007

BODY DIMENSIONS

77-1-2 BODY DIMENSIONS

Page 738 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-3

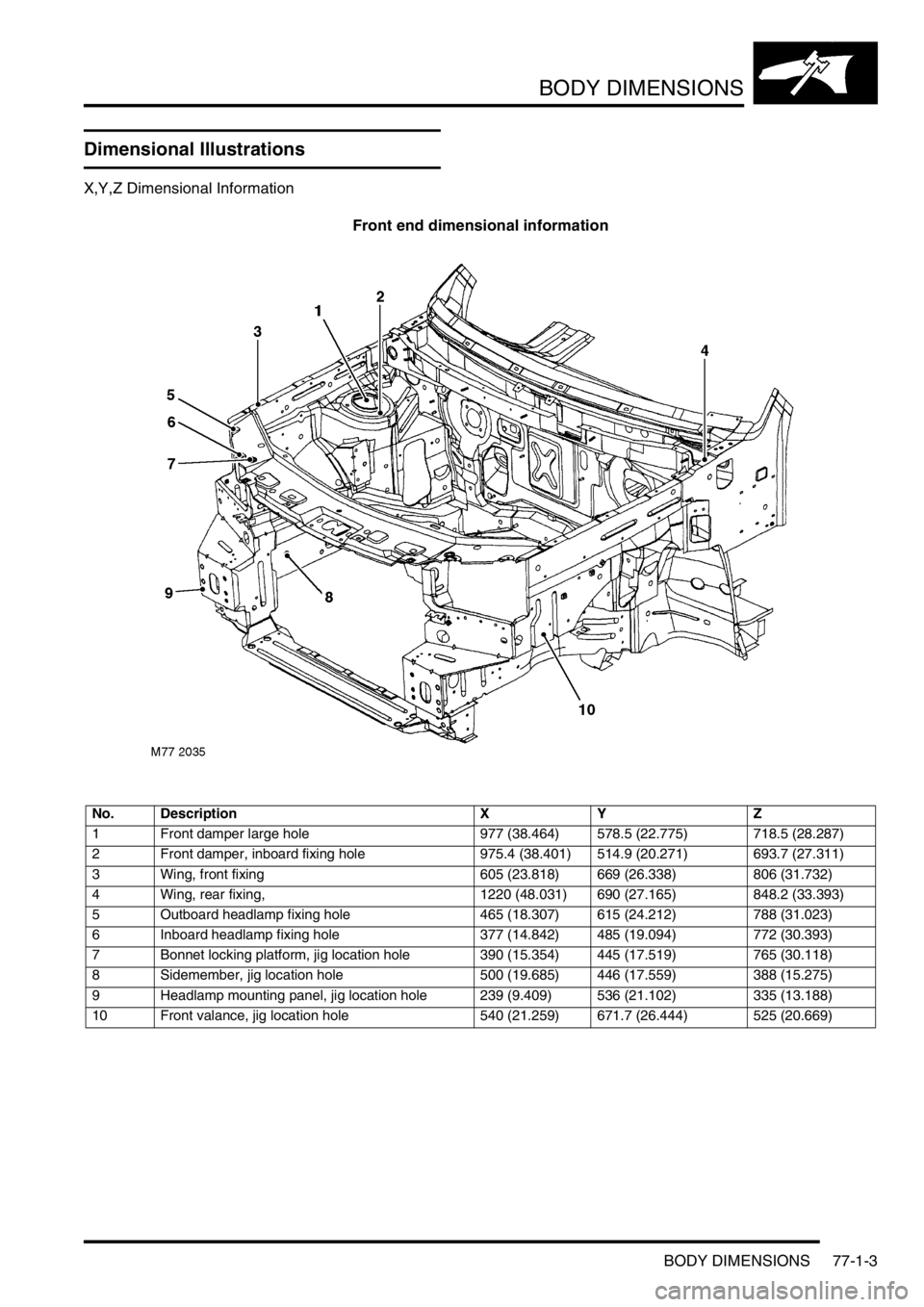

Dimensional Illustrations

X,Y,Z Dimensional Information

Front end dimensional information

No. Description X Y Z

1 Front damper large hole 977 (38.464) 578.5 (22.775) 718.5 (28.287)

2 Front damper, inboard fixing hole 975.4 (38.401) 514.9 (20.271) 693.7 (27.311)

3 Wing, front fixing 605 (23.818) 669 (26.338) 806 (31.732)

4 Wing, rear fixing, 1220 (48.031) 690 (27.165) 848.2 (33.393)

5 Outboard headlamp fixing hole 465 (18.307) 615 (24.212) 788 (31.023)

6 Inboard headlamp fixing hole 377 (14.842) 485 (19.094) 772 (30.393)

7 Bonnet locking platform, jig location hole 390 (15.354) 445 (17.519) 765 (30.118)

8 Sidemember, jig location hole 500 (19.685) 446 (17.559) 388 (15.275)

9 Headlamp mounting panel, jig location hole 239 (9.409) 536 (21.102) 335 (13.188)

10 Front valance, jig location hole 540 (21.259) 671.7 (26.444) 525 (20.669)

Page 739 of 1007

BODY DIMENSIONS

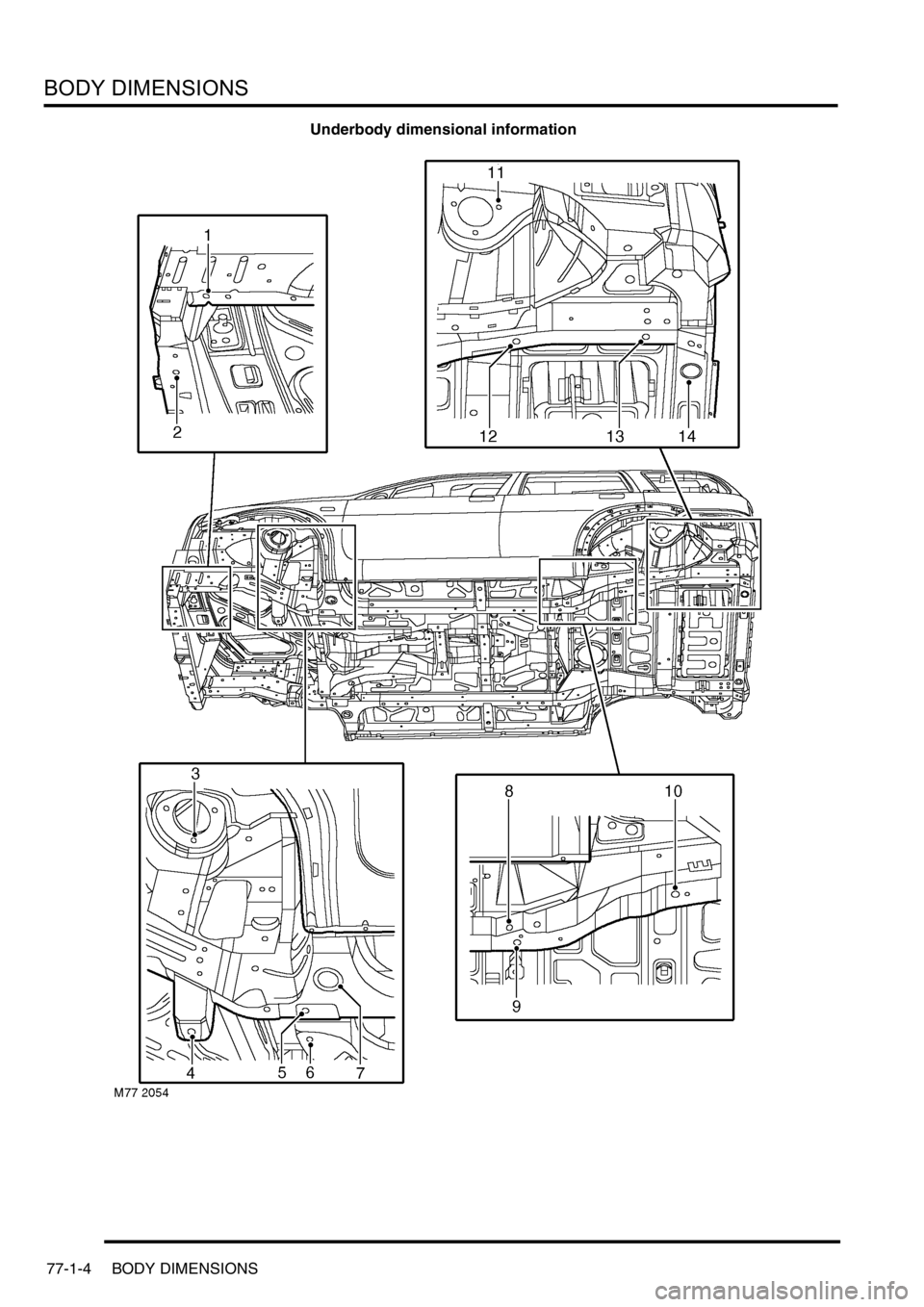

77-1-4 BODY DIMENSIONS

Underbody dimensional information

Page 740 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-5

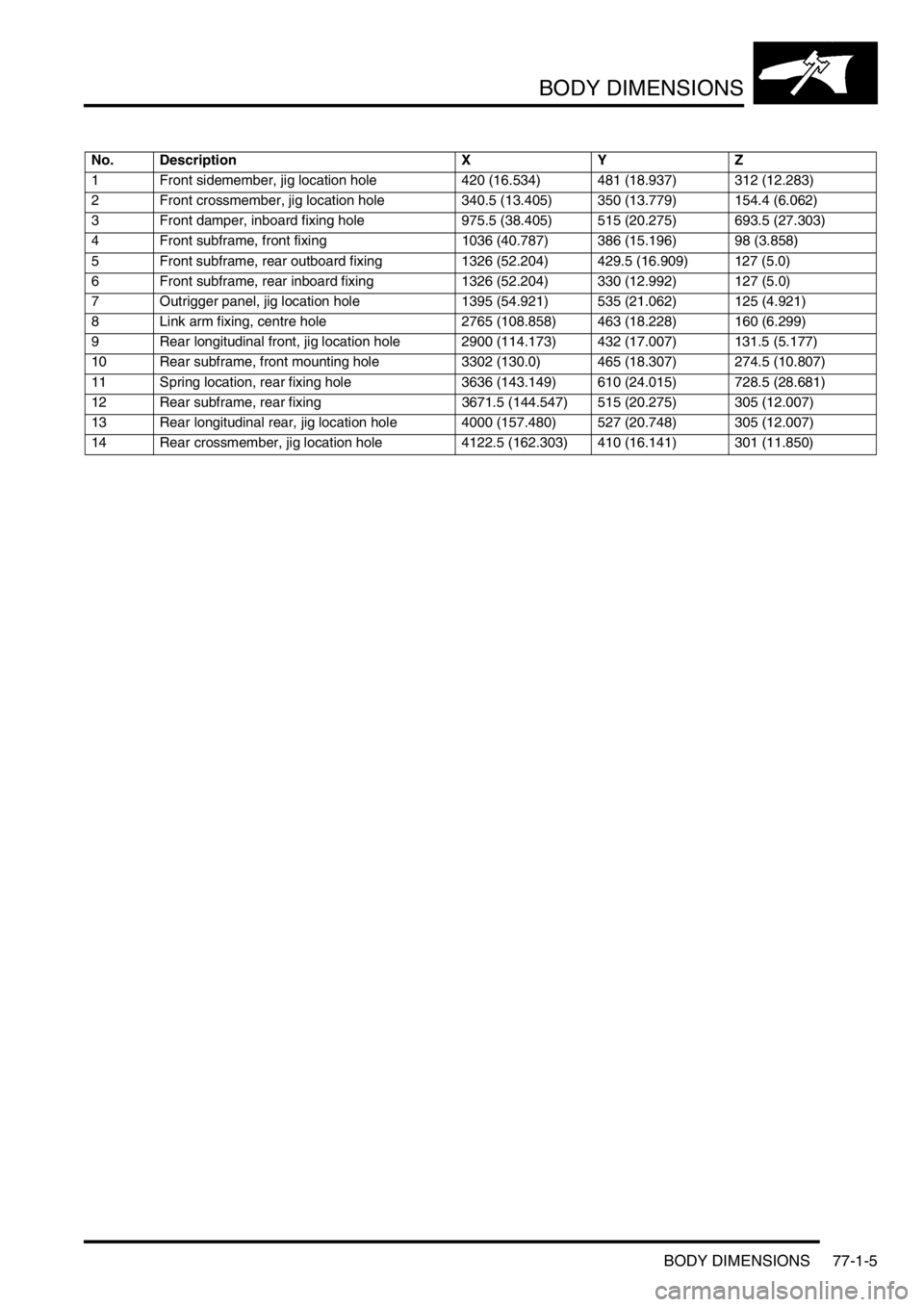

No. Description X Y Z

1 Front sidemember, jig location hole 420 (16.534) 481 (18.937) 312 (12.283)

2 Front crossmember, jig location hole 340.5 (13.405) 350 (13.779) 154.4 (6.062)

3 Front damper, inboard fixing hole 975.5 (38.405) 515 (20.275) 693.5 (27.303)

4 Front subframe, front fixing 1036 (40.787) 386 (15.196) 98 (3.858)

5 Front subframe, rear outboard fixing 1326 (52.204) 429.5 (16.909) 127 (5.0)

6 Front subframe, rear inboard fixing 1326 (52.204) 330 (12.992) 127 (5.0)

7 Outrigger panel, jig location hole 1395 (54.921) 535 (21.062) 125 (4.921)

8 Link arm fixing, centre hole 2765 (108.858) 463 (18.228) 160 (6.299)

9 Rear longitudinal front, jig location hole 2900 (114.173) 432 (17.007) 131.5 (5.177)

10 Rear subframe, front mounting hole 3302 (130.0) 465 (18.307) 274.5 (10.807)

11 Spring location, rear fixing hole 3636 (143.149) 610 (24.015) 728.5 (28.681)

12 Rear subframe, rear fixing 3671.5 (144.547) 515 (20.275) 305 (12.007)

13 Rear longitudinal rear, jig location hole 4000 (157.480) 527 (20.748) 305 (12.007)

14 Rear crossmember, jig location hole 4122.5 (162.303) 410 (16.141) 301 (11.850)