LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1581 of 3229

5-Exhaus t heat s hi eld

6-Fuel line underfloor prot ect ion t ray

7-Fuel ret urn l ine8-Fuel fi lt er as s embly

9-Fuel temperat ure sens or

10-Fuel supply line11-Fuel del ivery modul e

12-Hos e - fuel t ank breather

OVERVIEW

The TD4 dies el fuel s ys t em i ncorporat es a l ow and hi gh-pres sure (HP) ci rcuit t o provide the engine wit h s uffi cient fuel forall operat ing condi ti ons . The l ow-pres s ure (LP) sys tem compri ses :

Molded pl as t ic s addle-t ype fuel t ankFuel deli very module (wi th integral i n-t ank pump)Fuel l evel s ens orsFuel s upply and return li nesFuel fil ter as sembl y.

• NOTE: Fuel i s drawn from t he fuel t ank by the engine mount ed li ft pump. The i n-t ank pump does not deli ver fuel t o t heengi ne, and onl y delivers fuel through the 2 jet pumps t o maint ain fuel in t he fuel deli very pot.

The HP s ys tem features a Bos ch Generati on 3 common rail inject ion s ys tem.For addit ional informat ion, refer t o: Fuel Chargi ng and Cont rol s (303-04B Fuel Charging and Cont rols - TD4 2.2L Di esel ,Des cript ion and Operat ion).

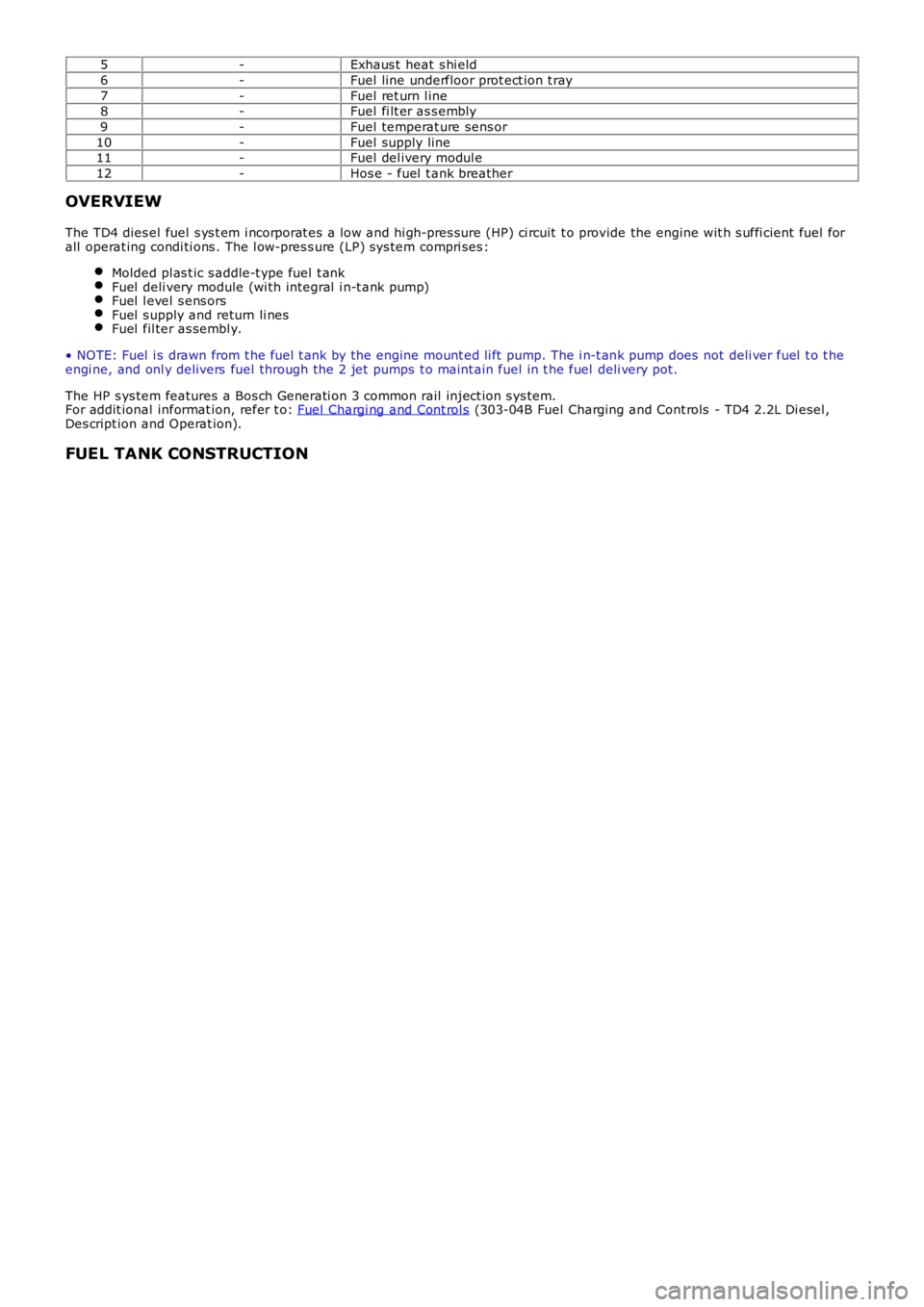

FUEL TANK CONSTRUCTION

Page 1582 of 3229

The fuel t ank has a useable capaci ty of 68.0 li ters (18.0 US gal lons) and i s des igned wit h a run dry s trat egy t o prevent ai rentering t he HP fuel s ys tem. The t ank is formed from a 6-layer lami nat ed blow-molded pl as t ic t o provi de high mechani cals trengt h and complet e emis s ions i ntegri ty. The t ank is a sealed uni t wit h i nt ernal acces s being via the fuel del iverymodule apert ure locat ed on t he Right -Hand (RH) s ide of t he tank.

The fuel t ank is l ocat ed cent rall y below the rear s eat posi ti on and is formed to s traddl e the drives haft and exhaus ts ys t em.

A mount ing cradl e and 6 bolt s s ecure t he fuel tank t o t he vehi cle. W hen t he cradle is at tached to the chass i s, t he t ank isposi ti vel y s ecured via foam pads t hat bear agai nst t he underfl oor. The cradle is manufact ured from st eel and incorporateslarge diamet er s t eel t ubing t o prot ect t he fuel t ank leading edge from underbody damage. The cradle al so provides thelocati on for t he parking brake cable bracket s .

A s addle s haped heat s hiel d is at t ached t o t he cradle t o prot ect the fuel t ank from exhaust s ys tem temperature.

Page 1583 of 3229

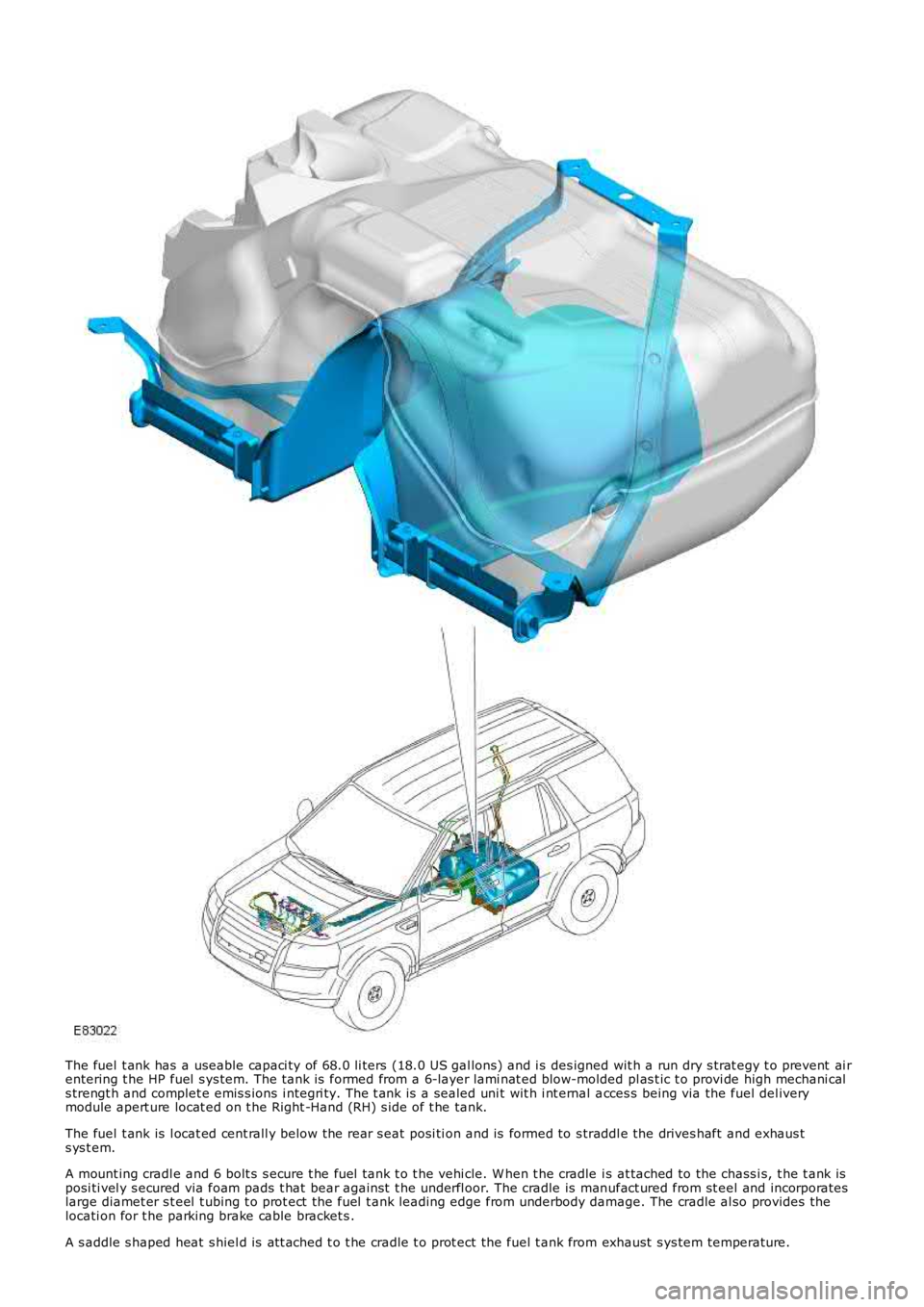

FUEL TANK INTERNAL COMPONENTS

ItemPart NumberDescription1-Fuel tank breat her valve

2-Cross over t ube

3-Coars e fil ter4-Fuel sender uni t fl oat (2 off)

5-MAgneti c Pass i ve Pos it ion Sens or (MAPPS) fuel s ender unit (2 off)

6-Fuel tank breat her hos e7-Fuel del ivery modul e

The fuel t ank compris es the foll owing i nternal component s:

Page 1584 of 3229

Int ernal mounti ng bracketFuel deli very module and cross over tube2 MAPPS t ype fuel s ender unit sBreat her valve.

Internal Mounting Bracket

The int ernal mount ing bracket i s molded i nto t he t ank cas ing and provi des the locat ion for the breather val ve, andcros sover tube as s embly.

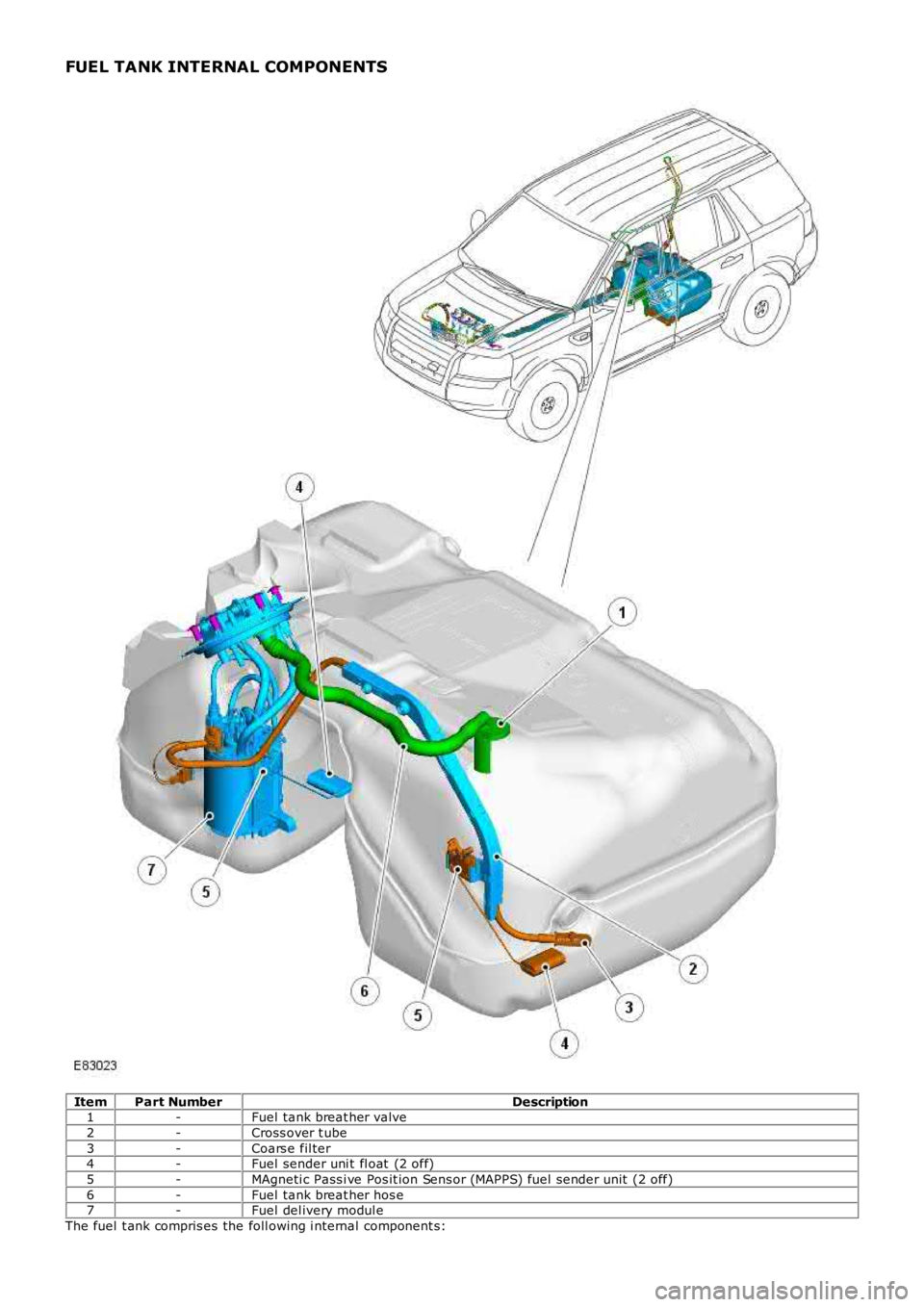

Fuel Delivery Module

ItemPart NumberDescription

1-In-t ank pump supply to jet pump

2-Fuel s upply t o engine fuel fil ter3-In-t ank pump

4-In-t ank pump supply to jet pump

5-Jet pump (us able s ide of t ank)6-Inl et from us able s ide of t ank

7-Return fuel from engi ne fuel fi lt er

8-Cros s over t ube (from unus able si de of tank)9-Jet pump (unus abl e s ide of t ank)

The fuel deli very module i s located in t he RH s i de of the t ank, and i s s ecured to the bot tom of the t ank wit h a weldedbayonet-t ype lock ri ng. The t op flange of the fuel del ivery module ass embly provides t he int ernal and ext ernal interface fort he tank elect rical and fuel connecti ons . The flange is formed wit h a 6-pin ext ernal el ect ri cal connector t hat is connect ed tot he 2 MAPPS fuel l evel s ens ors , and t he in-tank pump.

Page 1585 of 3229

The fuel deli very module flange i s s eal ed to the t ank wit h an O-ring and s ecured wi th a locki ng ring.

The lower part of t he fuel deli very module forms the fuel del ivery pot , and provides the locat ion for the in-t ank pump andt he 2 jet pumps . The delivery pot provi des a cons t ant res ervoir of fuel for t he engine drawn fuel supply. The engine fuels uppl y and ret urn l ines are immers ed in the del ivery pot .

The delivery pot is mai ntained full by t he 2 jet pumps . The i n-t ank pump draws fuel from wit hin the fuel deli very pot andforces the fuel t hrough t he 2 jet pumps . The flow of fuel t hrough each jet pump creat es a venturi effect t hat draws fuelfrom bot h s ides of t he fuel tank i nto the fuel deli very pot. Surpl us fuel entering the fuel deli very pot overflows into theus abl e s ide of t he fuel t ank.

A valve i s l ocated in t he l ower (usabl e tank s i de) jet pump s uppl y ori fi ce. The valve i s open when the i n-t ank pump isenergized and t he lower jet pump is s upplying fuel i nto the fuel del ivery pot . The val ve wil l cl os e when the i n-t ank pump isde-energized t o prevent fuel drai ni ng from the fuel del ivery pot .

The in-tank pump is energized by t he fuel pump relay l ocat ed in the Cent ral Juncti on Box (CJB). The Engine Cont rol Module(ECM) energi zes the fuel pump relay at al l ti mes when t he ignit ion i s in power modes 4 (Acces s ory) t o 9 (Engi ne crank).For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

A modi fi ed fuel delivery modul e i s ins tal led for col d climat e market vehicl es that feat ure a fuel fi red boos ter heater andauxi li ary fuel pump. The modified fuel del ivery modul e incorporat es a s eparate fuel supply line that connects t o anauxi li ary fuel pump, mounted on the ext erior RH si de of the tank. An addi ti onal fuel l ine connects the auxil iary fuel pumpt o the fuel fi red boos ter heat er.For addit ional informat ion, refer t o: Fuel Fired Boost er Heat er (412-02B Auxi liary Cli mate Cont rol , Des cri pti on andOperat ion).

Fuel Sender Units

The 2 MAPPS fuel s ender uni ts are located on eit her s ide of t he s addl e s haped tank, and connect t o t he int ernal elect ricalconnecti ons on the fuel del ivery modul e fl ange. Each s ens or provides an elect rical signal t o t he CJB t hat i s proport ionatet o the fuel level i n each s ide of t he tank.

The act ual fuel level i n t he t ank i s calculated by the CJB and t rans mit t ed via t he medium s peed Cont roll er Area Net work(CAN) bus t o t he ins t rument clus ter.

A warning l amp is incorporat ed in t he i ns t rument clus ter and wi ll il lumi nat e when t he fuel l evel is at, or below apredetermined l evel . On vehi cles wi th a high-l ine i nst rument clus ter, a mes s age is di spl ayed and a chi me i s s ounded t oinform the driver to refuel .

For addit ional informat ion, refer t o:

Ins trument Clus ter (413-01 Ins t rument Clus t er, Descripti on and Operat ion),Informat ion and Mes s age Cent er (413-08 Informati on and Mes sage Cent er, Descripti on and Operat ion).

Fuel Tank Breather Valve

The breat her valve i s located i n t he fuel t ank and is connected to the fuel deli very module fl ange vi a an i nt ernal breatherhose. The breat her valve al lows ai r to es cape and ent er the fuel tank t o compens at e for t he changing vol ume wit hin thet ank.

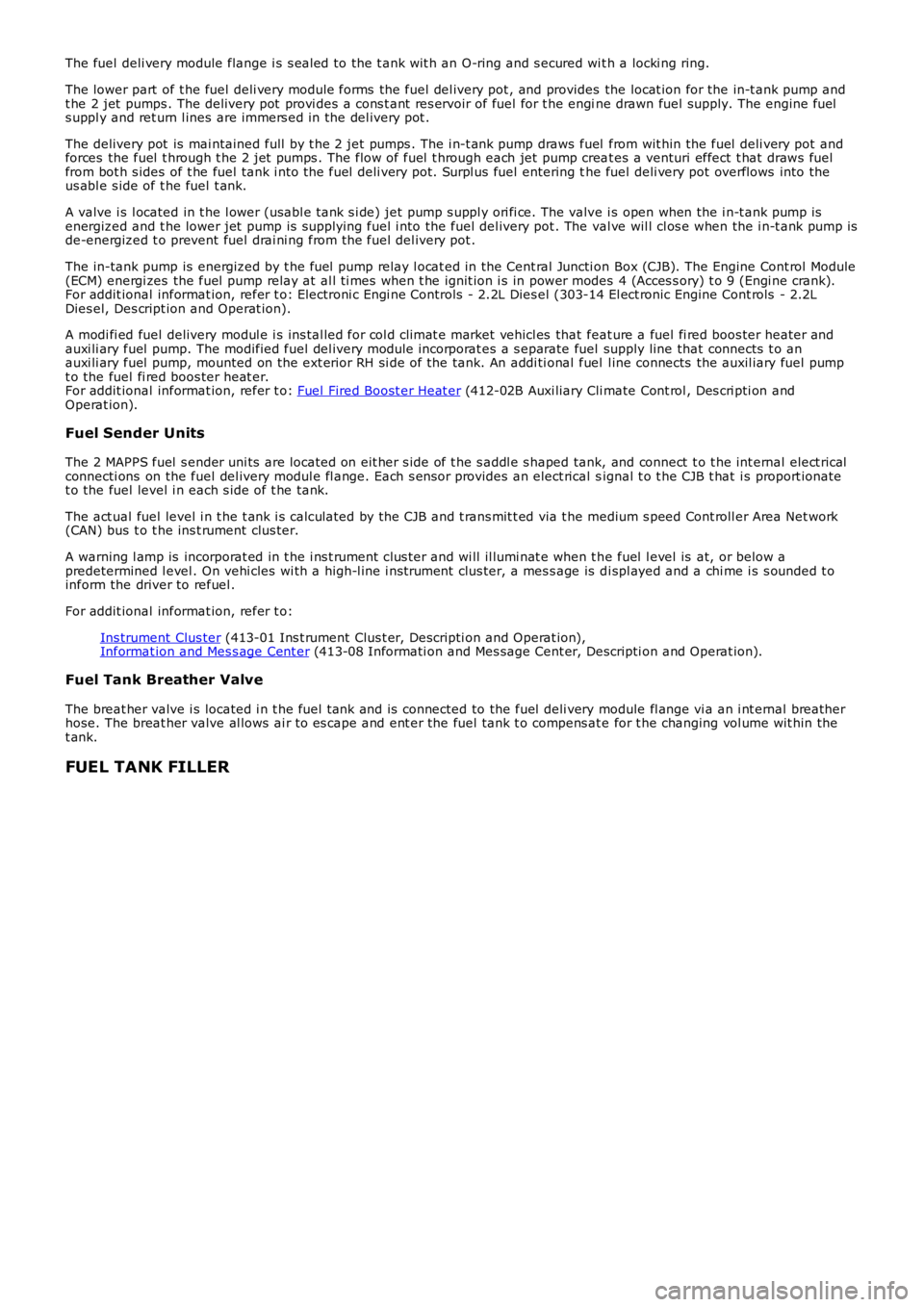

FUEL TANK FILLER

Page 1586 of 3229

ItemPart NumberDescription

1-Fi ll er cap and l anyard2-Tank ext ernal breather hos e

3-Fi ll er pi pe s tub hos e

4-Fi ll er pi peThe fuel t ank is fil led t hrough an alumi num fil ler pipe t hat is connected vi a a molded rubber s tub hos e t o t he rear RH s ideof the tank. A s crew cap i s ins tal led t o s eal t he fil ler pipe opening.

An i nl ine check val ve is mount ed ins ide the fil ler pipe s t ub hos e at t he t ank, and is ret ained in the cl os ed pos it ion by as pring. The check valve i s only opened when t he vehi cl e is refuel ed. The check val ve mini mizes fuel s pil lage in the eventt hat t he fill er pi pe is damaged during an accident .

A breat her hos e i s rout ed from the fuel fil ler pipe t o t he fuel deli very module flange. The breather hose connect s t o t he

Page 1587 of 3229

breat her pipe on the fuel del ivery modul e fl ange.

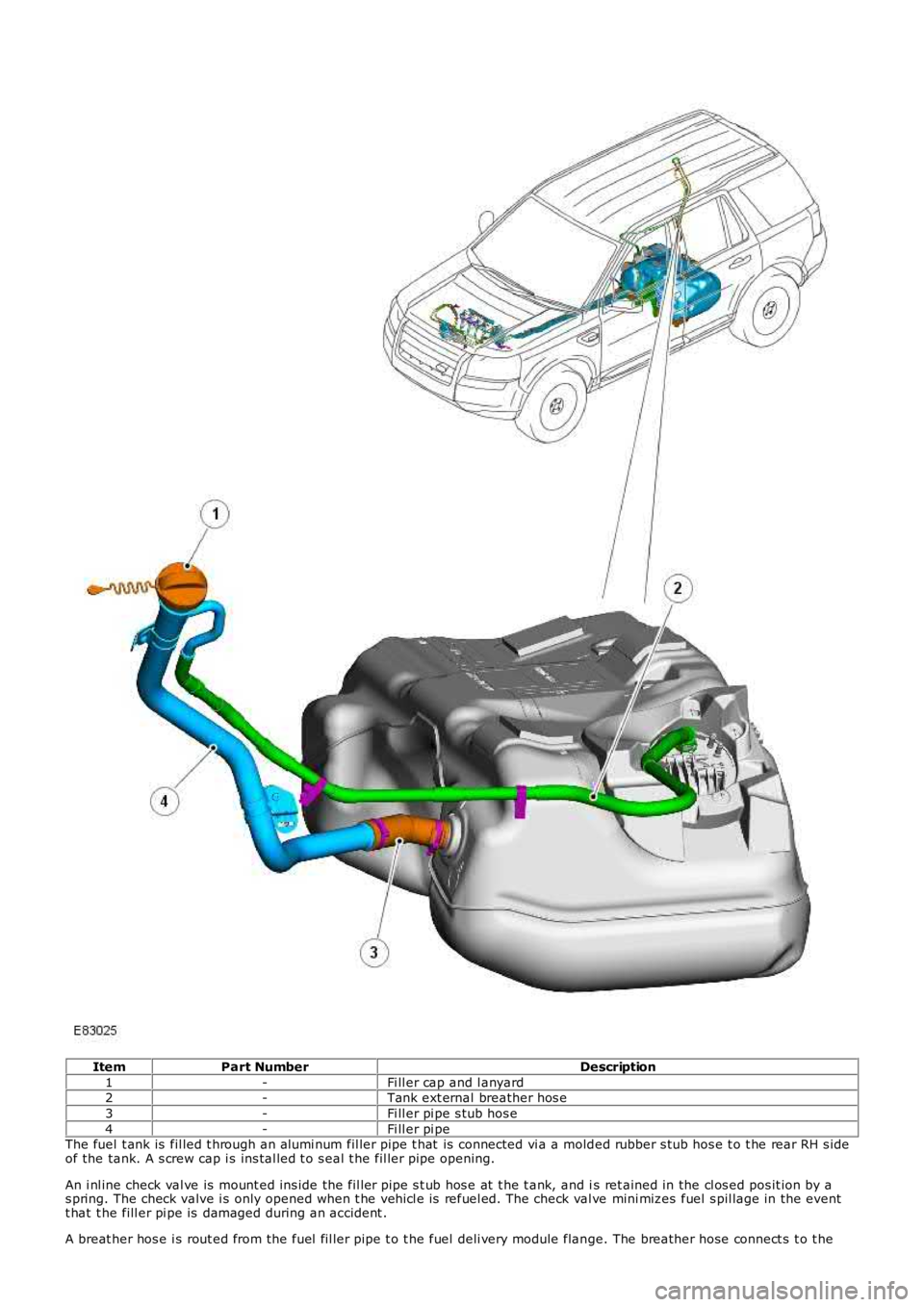

FUEL LINES

ItemPart NumberDescription1-Rear acces s cover

2-Quick-fit t ype connect or (4 off)

3-Fuel ret urn line4-Front access cover

5-Fuel s uppl y li ne

6-Underfl oor prot ecti on trayThe fuel s uppl y and ret urn lines are rout ed along t he vehi cl e underfl oor, and housed wit hi n a pl ast ic protecti on tray. The

Page 1588 of 3229

prot ect ion t ray is s ecured wit h i ntegral cli ps on the ins ide of t he tray t o s tuds along t he underfl oor.

CAUTION: The fuel l ine quick-fit t ype connect or is a new des ign connector i ns t alled to the TD4 vehicle. Duringmaint enance procedures t he quick-fi t t ype connect or must be releas ed and connected correct ly to prevent fuel l eakage.Us e t he correct met hod det ailed in t he rel evant s ect ion of t he Servi ce Repair Manual (SRP) t o rel eas e and connect t heconnector. Incorrect operati on of the qui ck-fi t type connector wi ll res ult in damage t o t he connector and caus e fuelleakage.

The quick-fit t ype fuel connect or is not a s elf s eali ng connector, and will not prevent fuel fl ow when dis connected.

The fuel s uppl y and ret urn lines are connected at each end wit h a qui ck-fi t type connect or. The connector is nots elf-s eal ing and will not prevent fuel fl ow when t he fuel li ne is separat ed.

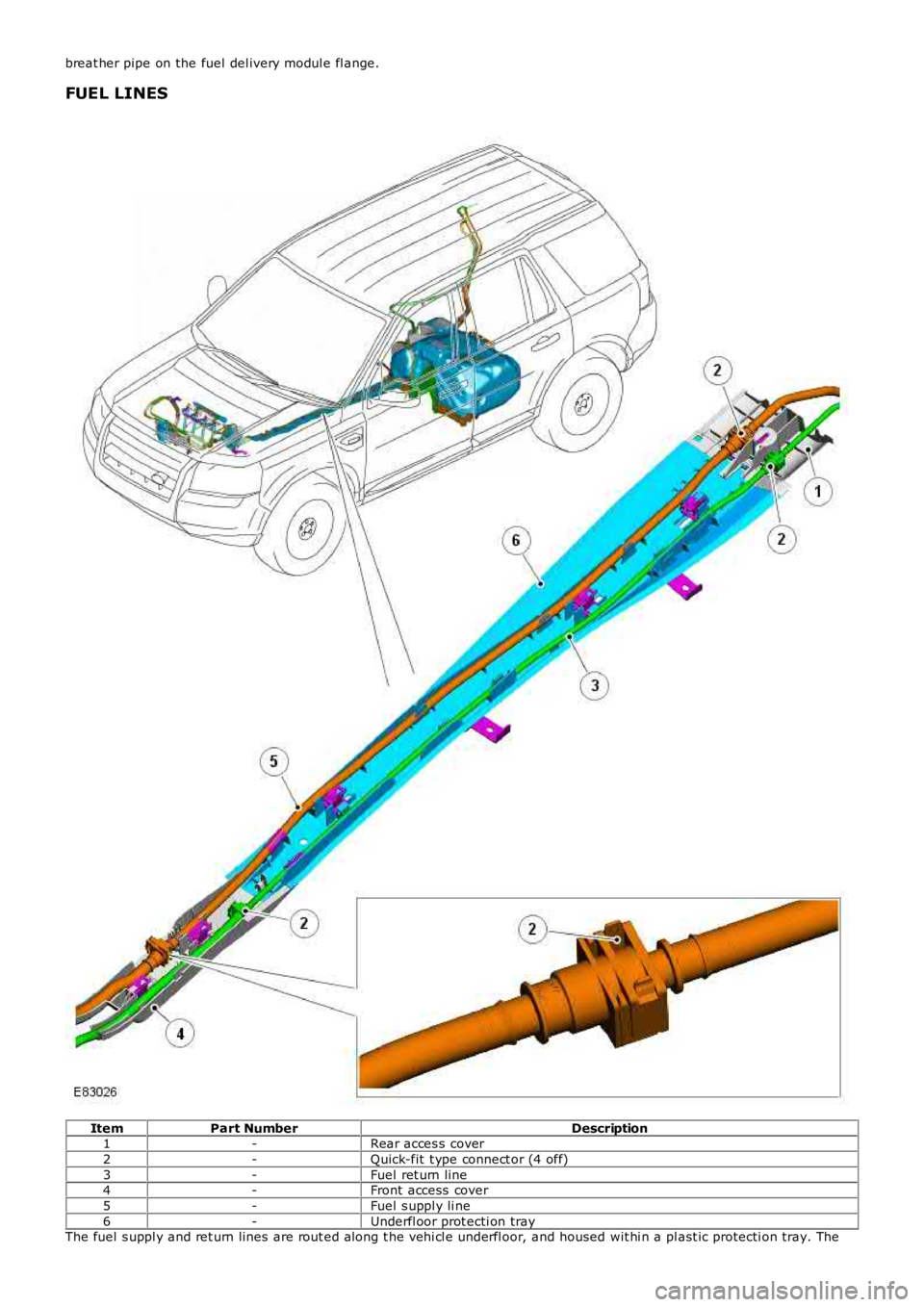

FUEL FILTER ASSEMBLY

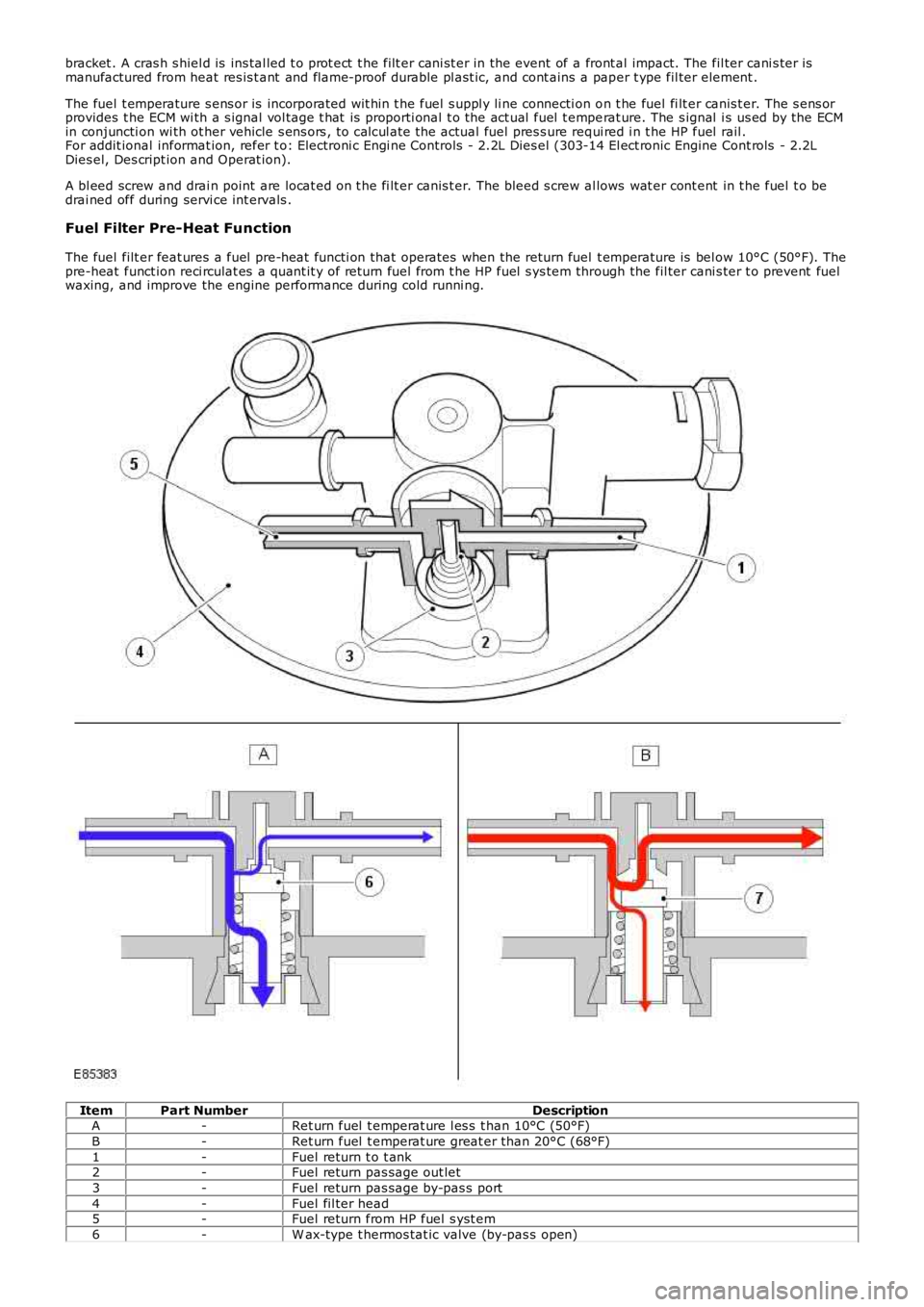

ItemPart NumberDescription

1-Fuel t emperat ure s ensor

2-Fuel s upply t o HP pump3-W at er drain screw

4-Fuel fil ter cani s ter

5-Fuel canis ter cras h s hiel d6-W at er drain poi nt

7-Fuel s upply from tank

8-Fuel return to tank9-Fuel return from HP fuel s ys t em

The fuel filt er cani st er is l ocat ed at the front RH si de of the engi ne compartment , and mount ed wi thi n an engine s upport

Page 1589 of 3229

bracket . A cras h s hiel d is ins tal led t o prot ect t he filt er cani st er in the event of a front al impact. The fil ter cani s ter ismanufactured from heat res is t ant and flame-proof durable pl ast ic, and cont ains a paper t ype fil ter element .

The fuel t emperature s ens or is incorporated wit hin t he fuel s uppl y li ne connecti on on t he fuel fi lt er canis t er. The s ens orprovides t he ECM wi th a s ignal vol tage t hat is proporti onal t o the act ual fuel t emperat ure. The s ignal i s us ed by the ECMin conjuncti on wi th ot her vehicle s ens ors , t o cal cul ate the actual fuel pres s ure requi red i n t he HP fuel rail .For addit ional informat ion, refer t o: Electroni c Engi ne Controls - 2.2L Dies el (303-14 El ect ronic Engine Cont rols - 2.2LDies el, Des cript ion and Operat ion).

A bl eed screw and drai n point are locat ed on t he fi lt er canis t er. The bleed s crew allows wat er cont ent in t he fuel t o bedrai ned off during servi ce int ervals .

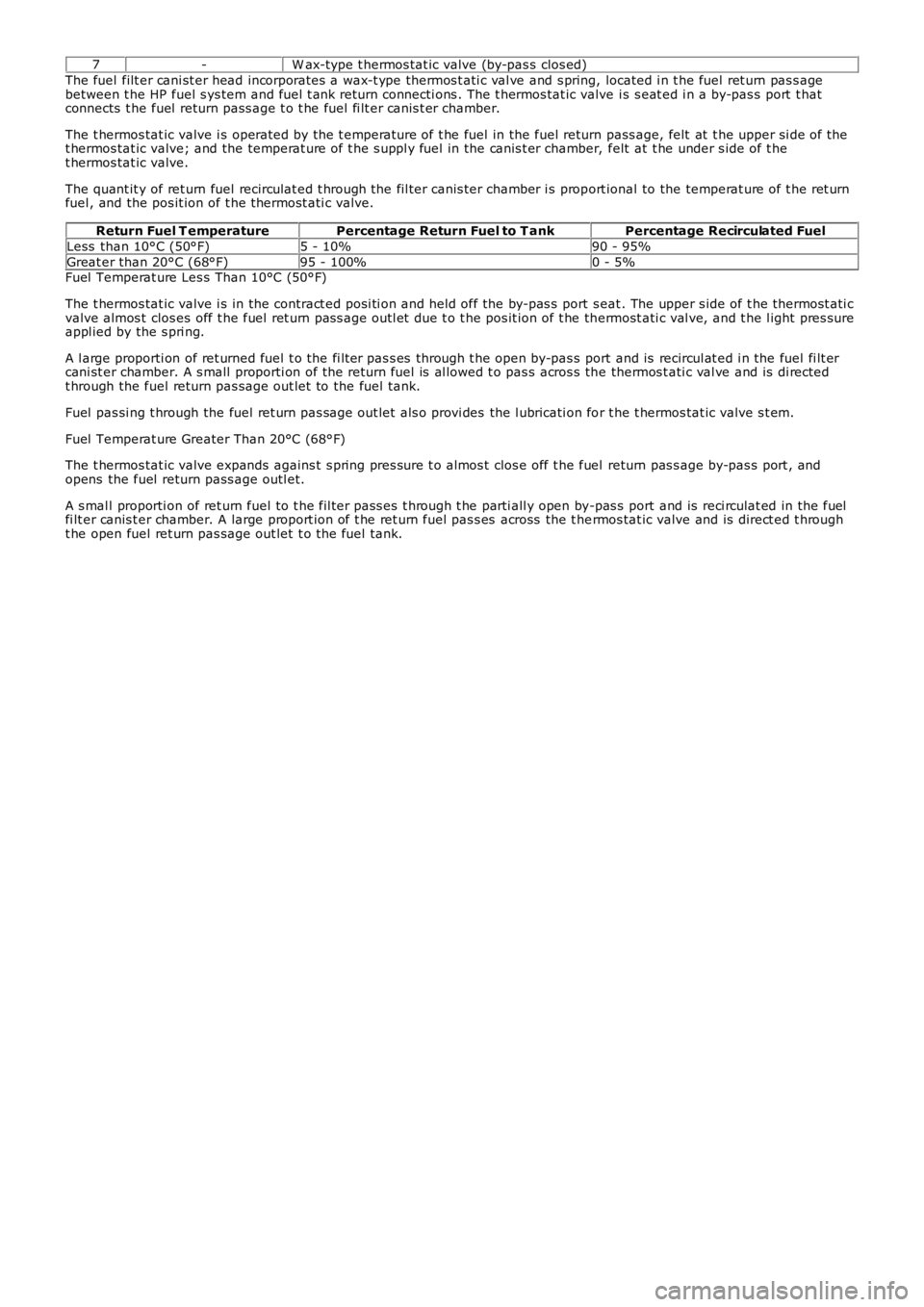

Fuel Filter Pre-Heat Function

The fuel filt er feat ures a fuel pre-heat functi on that operates when the return fuel t emperature is bel ow 10°C (50°F). Thepre-heat funct ion reci rculat es a quant it y of ret urn fuel from t he HP fuel s ys tem through the fil ter cani s ter t o prevent fuelwaxing, and improve the engine performance during cold runni ng.

ItemPart NumberDescriptionA-Ret urn fuel t emperat ure l es s t han 10°C (50°F)

B-Ret urn fuel t emperat ure great er than 20°C (68°F)

1-Fuel return t o t ank2-Fuel return pas sage out let

3-Fuel return pas sage by-pas s port

4-Fuel fil ter head5-Fuel return from HP fuel s yst em

6-W ax-type t hermos tat ic valve (by-pas s open)

Page 1590 of 3229

7-W ax-type t hermos tat ic valve (by-pas s clos ed)

The fuel filt er cani st er head incorporates a wax-t ype thermos t ati c val ve and s pring, located i n t he fuel ret urn pas s agebetween t he HP fuel s ys tem and fuel t ank return connecti ons . The t hermos tat ic valve i s s eat ed i n a by-pas s port t hatconnects t he fuel return pass age t o t he fuel fi lt er canis t er chamber.

The t hermos tat ic valve i s operated by the t emperat ure of t he fuel in the fuel return pass age, felt at t he upper si de of thet hermos tat ic valve; and the temperat ure of t he s uppl y fuel in the canis t er chamber, felt at t he under s ide of t het hermos tat ic valve.

The quant it y of ret urn fuel recirculat ed t hrough the fil ter canis ter chamber i s proport ional to the temperat ure of t he ret urnfuel , and the pos it ion of t he thermost ati c valve.

Return Fuel T emperaturePercentage Return Fuel to T ankPercentage Recirculated Fuel

Less than 10°C (50°F)5 - 10%90 - 95%

Great er than 20°C (68°F)95 - 100%0 - 5%Fuel Temperat ure Les s Than 10°C (50°F)

The t hermos tat ic valve i s in the contract ed posi ti on and held off the by-pas s port seat . The upper s ide of t he thermost ati cvalve almos t clos es off t he fuel ret urn pas s age outl et due t o t he pos it ion of t he thermost ati c val ve, and t he l ight pres sureappl ied by the s pri ng.

A l arge proporti on of ret urned fuel t o the fi lt er pas s es through t he open by-pas s port and is recircul at ed i n the fuel fi lt ercani st er chamber. A s mall proporti on of the return fuel is al lowed t o pas s acros s the thermos t ati c val ve and is di rectedt hrough the fuel return pas sage out let to the fuel tank.

Fuel pas si ng t hrough the fuel ret urn pas sage out let als o provi des the l ubricati on for t he t hermos tat ic valve s t em.

Fuel Temperat ure Greater Than 20°C (68°F)

The t hermos tat ic valve expands agains t s pring pres sure t o almos t clos e off t he fuel return pas s age by-pas s port , andopens the fuel return pass age outl et.

A s mal l proporti on of ret urn fuel to t he fil ter pass es t hrough t he parti all y open by-pas s port and is reci rculat ed in the fuelfi lt er canis t er chamber. A large proport ion of t he ret urn fuel pas s es across the t hermos tat ic valve and is direct ed t hrought he open fuel ret urn pas sage out let t o the fuel tank.