LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2901 of 3229

181

Wheels and tyres

R

Checking the tyre pressures

1. Tyre information label position on a

left-hand drive vehicle.

2. Tyre information label position on a

right-hand drive vehicle.

The following procedure should be used to

check and adjust the tyres pressures.

1. Remove the valve cap.

2. Firmly attach a tyre pressure gauge/inflator

to the valve.

3. Read the tyre pressure from the gauge,

and add air if required.

4. If air is added to the tyre, remove the gauge

and re-attach it be fore reading the

pressure. Failure to do so may result in an

inaccurate reading. 5.

If the tyre pressure is too high, remove the

gauge and allow air out of the tyre by

pressing the centre of the valve. Refit the

gauge to the valve and check the pressure.

6. Repeat the process a dding or removing air

as required until the co rrect tyre pressure

is reached.

7. Refit the valve cap.

Note: It is an offence in certain countries to

drive a vehicle with incorrect tyre pressures.

Note: It is the driver's responsibility to ensure

that the tyre pressures are correct.

Tyre valves

Keep the valve caps screwed down firmly to

prevent water or dirt entering the valve. Check

the valves for leaks when checking the tyre

pressures.

WARNING

Tyre pressures should be checked

regularly using an accurate pressure

gauge, when the tyres are cold. Failure to

properly maintain your tyre pressures could

increase the risk of tyre failure resulting in loss

of vehicle control and personal injury.

E83967

Page 2902 of 3229

Wheels and tyres

182

L

Pressure compensation for ambient

temperature changes

If the ambient temperature drops, the tyre

pressures will decrease, which may cause

under inflation. This should be borne in mind

when travelling to, or through, areas of lower

temperature.

Under inflation causes th e tyre side wall height

to reduce, which in turn results in uneven tyre

wear, and a risk of tyre failure.

Tyre pressures may be adjusted before setting

off on a journey to, or through, areas of low

temperature. Alternatively, the tyre pressures

can be adjusted when low temperature areas

are reached.

Note: If the tyre pressures are to be adjusted in

the lower temperature area, the vehicle should

be left standing for at least one hour prior to

adjustment.

Tyre pressures should be increased by 0.14

bar/14 kPa (2 lbf/in²) for each 10 °C (20 °F)

temperature decrease.

Flat spots

If the vehicle is stationary for a long period

when the ambient temperature is high, the

tyres may form flat spots. When the vehicle is

driven these flat spots will cause a vibration

which will steadily disappear as the tyres warm

up and regain their original shape.

In order to minimise fl at spotting, the tyre

pressures can be increased.

Tyre pressures should be increased by 0.14

bar/14 kPa (2 lbf/in²) for each 10 °C (20 °F)

temperature increase above 20 °C (68 °F).

Long term storage

Flat spotting can be minimised during long

term storage by increasing the tyre pressures

to the maximum indicated on the tyre sidewall.

Note: The tyre pressures s hould be reduced to

the correct pressure before the vehicle is

driven.

E80321

E80322

Page 2903 of 3229

183

Wheels and tyres

R

USING WINTER TYRES

If winter tyres are fitted to the vehicle, the tyre

manufacturers instructions should be

followed. Pay particular attention to

instructions regarding the maximum speed

that the vehicle can be driven, and the correct

pressures for the tyres.

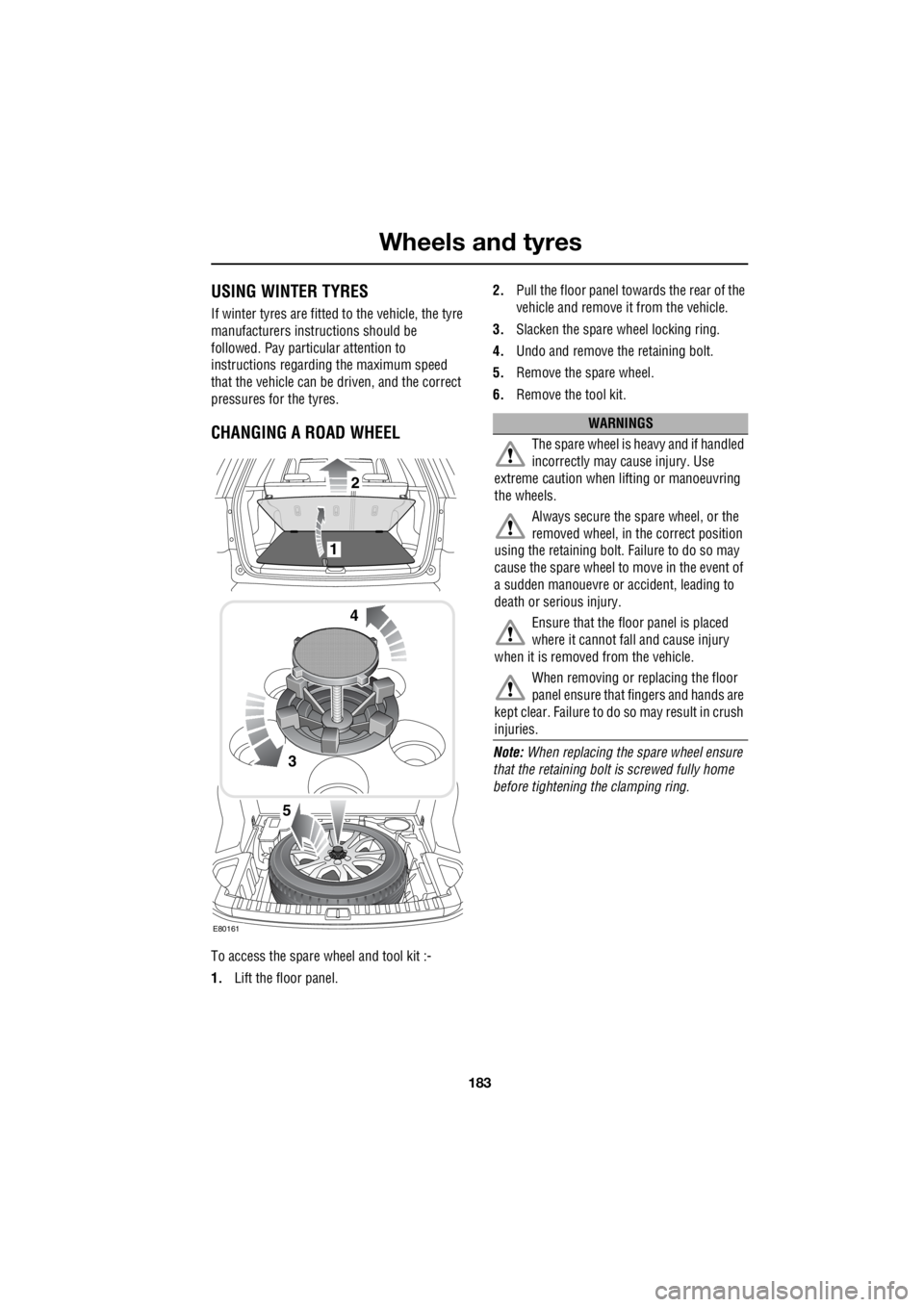

CHANGING A ROAD WHEEL

To access the spare wheel and tool kit :-

1. Lift the floor panel. 2.

Pull the floor panel towards the rear of the

vehicle and remove it from the vehicle.

3. Slacken the spare wheel locking ring.

4. Undo and remove the retaining bolt.

5. Remove the spare wheel.

6. Remove the tool kit.

Note: When replacing the spare wheel ensure

that the retaining bolt is screwed fully home

before tightening the clamping ring.

3

4

1

2

5

E80161

WARNINGS

The spare wheel is heavy and if handled

incorrectly may cause injury. Use

extreme caution when lifting or manoeuvring

the wheels.

Always secure the spare wheel, or the

removed wheel, in the correct position

using the retaining bolt. Failure to do so may

cause the spare wheel to move in the event of

a sudden manouevre or accident, leading to

death or serious injury.

Ensure that the floo r panel is placed

where it cannot fall and cause injury

when it is removed from the vehicle.

When removing or replacing the floor

panel ensure that fingers and hands are

kept clear. Failure to do so may result in crush

injuries.

Page 2904 of 3229

Wheels and tyres

184

L

Wheel changing safety

Before raising the vehicl e, or changing a wheel

ensure that you read, and comply with the

following warnings.

WARNINGS

Always find a safe pl ace to stop, off of

the highway and away from traffic.

Ensure that the vehicle is on firm level

ground.

Disconnect traile r/caravan from

vehicle.

Switch on the hazard warning lamps.

Ensure that all passengers, and

animals, are out of the vehicle, and in a

safe place away from the highway.

Place a warning triangle at a suitable

distance behind th e vehicle, facing

towards oncoming traffic.

Ensure that the front wheels are in the

straight ahead positi on, and engage the

steering lock.

Apply the parking br ake, and engage

Park in vehicles fitted with an automatic

transmission.

Apply the parking br ake, and engage

1st or reverse gear in vehicles fitted

with a manual transmission.

Ensure that the jack is on firm level

ground.

Never place anything between the jack

and the ground, or the jack and the

vehicle.

Always chock the whee ls using suitable

wheel chocks. Place the chocks on both

sides of the wheel diagonally opposite the

wheel to be changed.

If jacking the vehicle on a slight slope is

unavoidable, place the chocks on the

downhill side of the two opposite wheels.

Take care when lifting the spare wheel,

and removing the punctured wheel. The

wheels are heavy, and ca n cause injuries if not

handled correctly.

Remove the spare wheel prior to

jacking the vehicle. To avoid

destabilising the vehicle when raised.

Take care when loosening the wheel

nuts. The wheel brace may slip off if not

properly attached, and the wheel nuts may

give way suddenly. Either unexpected

movement may cause an injury.

WARNINGS

Page 2905 of 3229

185

Wheels and tyres

R

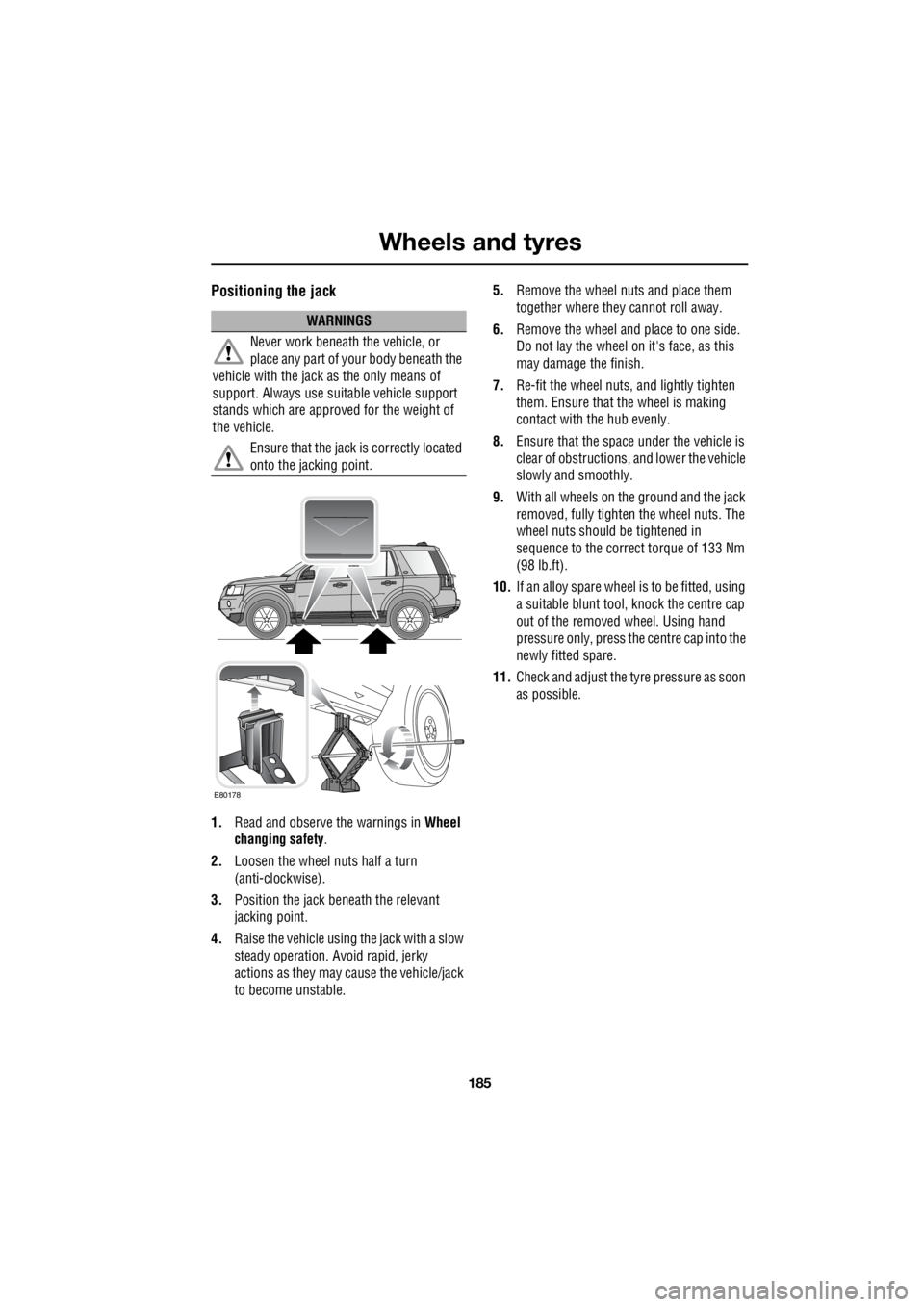

Positioning the jack

1. Read and observe the warnings in Wheel

changing safety .

2. Loosen the wheel nuts half a turn

(anti-clockwise).

3. Position the jack be neath the relevant

jacking point.

4. Raise the vehicle using the jack with a slow

steady operation. Avoid rapid, jerky

actions as they may cause the vehicle/jack

to become unstable. 5.

Remove the wheel nuts and place them

together where they cannot roll away.

6. Remove the wheel and place to one side.

Do not lay the wheel on it's face, as this

may damage the finish.

7. Re-fit the wheel nuts, and lightly tighten

them. Ensure that the wheel is making

contact with the hub evenly.

8. Ensure that the space under the vehicle is

clear of obstructions, and lower the vehicle

slowly and smoothly.

9. With all wheels on the ground and the jack

removed, fully tighte n the wheel nuts. The

wheel nuts should be tightened in

sequence to the correct torque of 133 Nm

(98 lb.ft).

10. If an alloy spare wheel is to be fitted, using

a suitable blunt tool, knock the centre cap

out of the removed wheel. Using hand

pressure only, press the centre cap into the

newly fitted spare.

11. Check and adjust the tyre pressure as soon

as possible.

WARNINGS

Never work beneath the vehicle, or

place any part of yo ur body beneath the

vehicle with the jack as the only means of

support. Always use su itable vehicle support

stands which are approved for the weight of

the vehicle.

Ensure that the jack is correctly located

onto the jacking point.

E80178

Page 2906 of 3229

Wheels and tyres

186

L

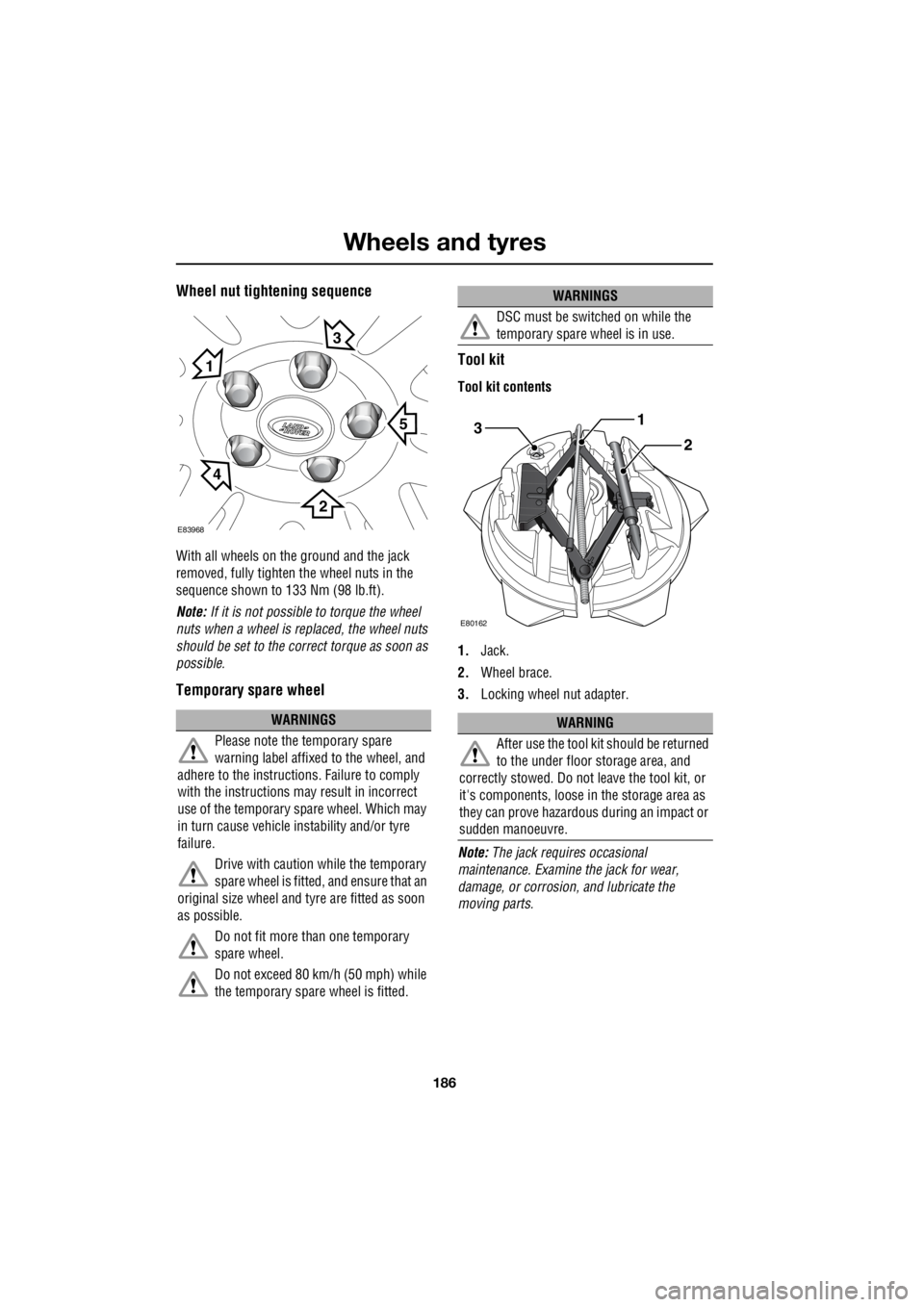

Wheel nut tightening sequence

With all wheels on the ground and the jack

removed, fully tighten the wheel nuts in the

sequence shown to 133 Nm (98 lb.ft).

Note: If it is not possible to torque the wheel

nuts when a wheel is replaced, the wheel nuts

should be set to the correct torque as soon as

possible.

Temporary spare wheel Tool kit

Tool kit contents

1.

Jack.

2. Wheel brace.

3. Locking wheel nut adapter.

Note: The jack requi res occasional

maintenance. Examine the jack for wear,

damage, or corrosion, and lubricate the

moving parts.

WARNINGS

Please note the temporary spare

warning label affixed to the wheel, and

adhere to the instructions. Failure to comply

with the instructions may result in incorrect

use of the temporary spare wheel. Which may

in turn cause vehicle instability and/or tyre

failure.

Drive with caution while the temporary

spare wheel is fitted, and ensure that an

original size wheel and tyre are fitted as soon

as possible.

Do not fit more than one temporary

spare wheel.

Do not exceed 80 km/h (50 mph) while

the temporary spare wheel is fitted.

E83968

5

1

3

2

4

DSC must be switched on while the

temporary spare wheel is in use.

WARNING

After use the tool kit should be returned

to the under floor storage area, and

correctly stowed. Do not leave the tool kit, or

it's components, loose in the storage area as

they can prove hazardous during an impact or

sudden manoeuvre.

WARNINGS

3

E80162

1

2

Page 2907 of 3229

187

Wheels and tyres

R

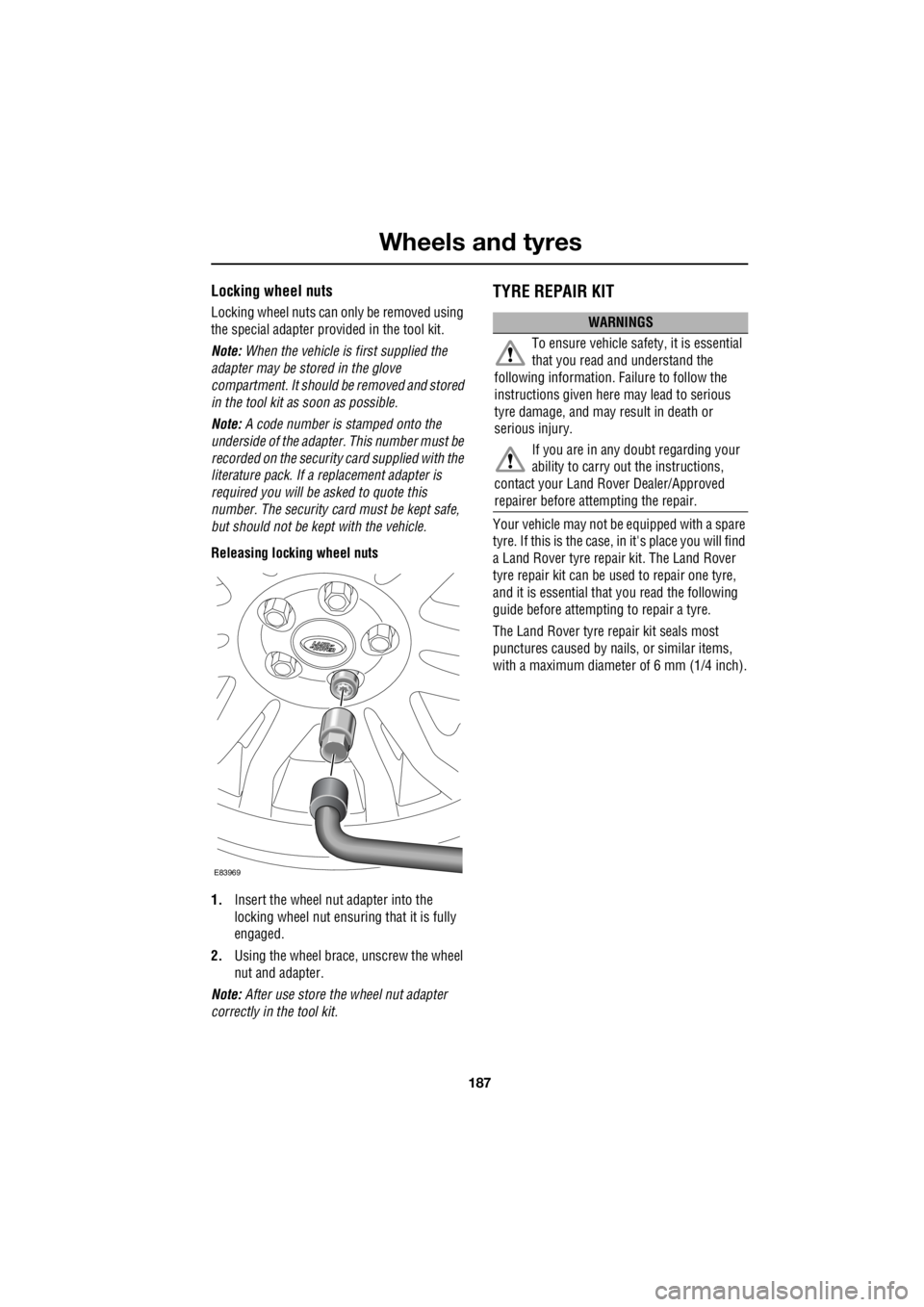

Locking wheel nuts

Locking wheel nuts can only be removed using

the special adapter provided in the tool kit.

Note: When the vehicle is first supplied the

adapter may be stored in the glove

compartment. It should be removed and stored

in the tool kit as soon as possible.

Note: A code number is stamped onto the

underside of the adapter. This number must be

recorded on the security card supplied with the

literature pack. If a replacement adapter is

required you will be asked to quote this

number. The security card must be kept safe,

but should not be kept with the vehicle.

Releasing locking wheel nuts

1. Insert the wheel nut adapter into the

locking wheel nut ensuri ng that it is fully

engaged.

2. Using the wheel brace, unscrew the wheel

nut and adapter.

Note: After use store the wheel nut adapter

correctly in the tool kit.

TYRE REPAIR KIT

Your vehicle may not be equipped with a spare

tyre. If this is the case, in it's place you will find

a Land Rover tyre repair kit. The Land Rover

tyre repair kit can be us ed to repair one tyre,

and it is essential that you read the following

guide before attempting to repair a tyre.

The Land Rover tyre repair kit seals most

punctures caused by nails , or similar items,

with a maximum diameter of 6 mm (1/4 inch).

E83969

WARNINGS

To ensure vehicle safety, it is essential

that you read and understand the

following information. Failure to follow the

instructions given here may lead to serious

tyre damage, and may result in death or

serious injury.

If you are in any doubt regarding your

ability to carry out the instructions,

contact your Land Ro ver Dealer/Approved

repairer before attempting the repair.

Page 2908 of 3229

Wheels and tyres

188

L

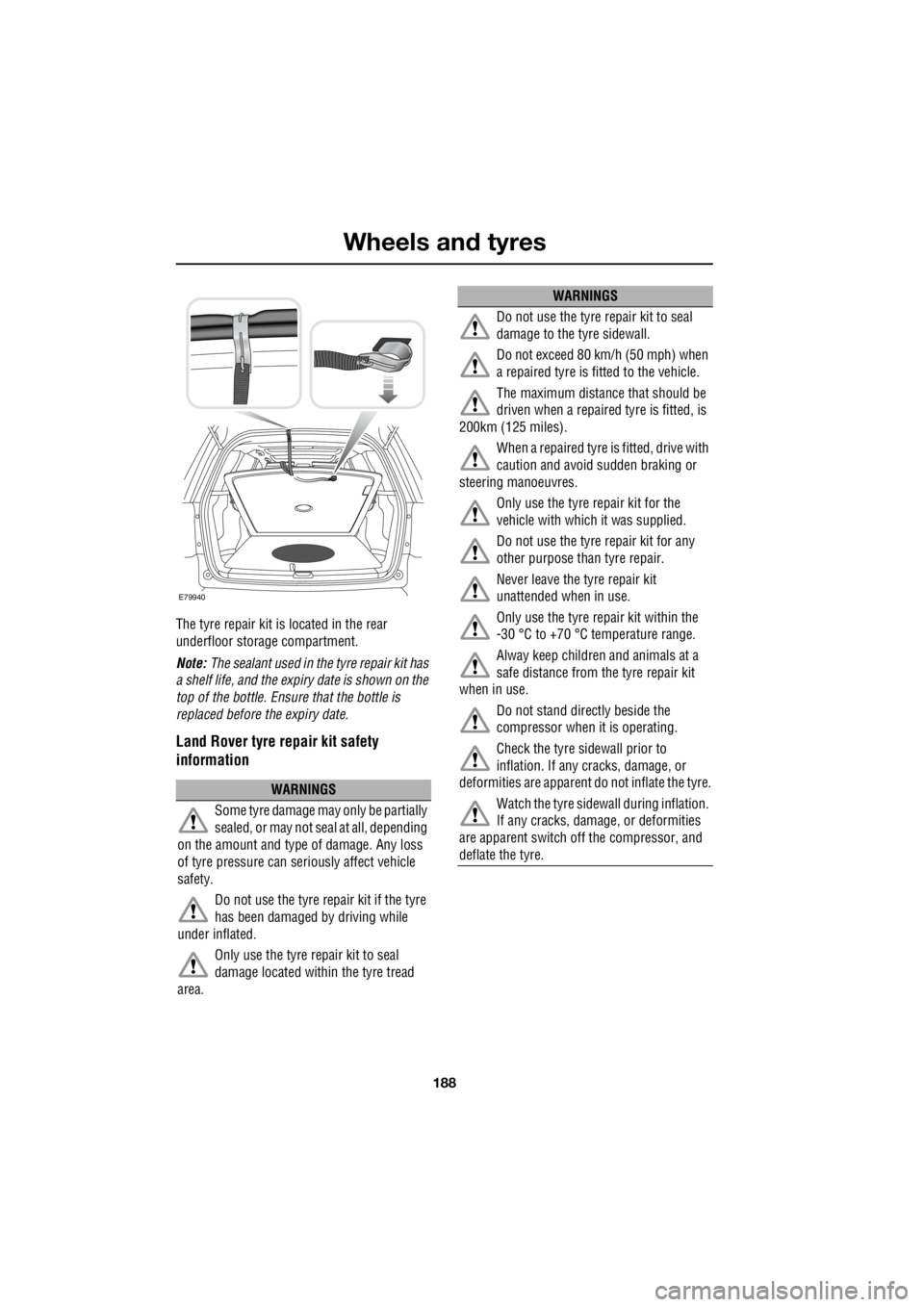

The tyre repair kit is located in the rear

underfloor storage compartment.

Note: The sealant used in the tyre repair kit has

a shelf life, and the expiry date is shown on the

top of the bottle. Ensur e that the bottle is

replaced before the expiry date.

Land Rover tyre repair kit safety

information

WARNINGS

Some tyre damage ma y only be partially

sealed, or may not seal at all, depending

on the amount and type of damage. Any loss

of tyre pressure can seriously affect vehicle

safety.

Do not use the tyre repair kit if the tyre

has been damaged by driving while

under inflated.

Only use the tyre repair kit to seal

damage located within the tyre tread

area.

E79940

Do not use the tyre repair kit to seal

damage to the tyre sidewall.

Do not exceed 80 km/h (50 mph) when

a repaired tyre is fitted to the vehicle.

The maximum distance that should be

driven when a repaired tyre is fitted, is

200km (125 miles).

When a repaired tyre is fitted, drive with

caution and avoid sudden braking or

steering manoeuvres.

Only use the tyre repair kit for the

vehicle with which it was supplied.

Do not use the tyre repair kit for any

other purpose than tyre repair.

Never leave the tyre repair kit

unattended when in use.

Only use the tyre repair kit within the

-30 °C to +70 °C temperature range.

Alway keep children and animals at a

safe distance from the tyre repair kit

when in use.

Do not stand dire ctly beside the

compressor when it is operating.

Check the tyre sidewall prior to

inflation. If any cracks, damage, or

deformities are a pparent do not inflate the tyre.

Watch the tyre sidewa ll during inflation.

If any cracks, damage, or deformities

are apparent switch off the compressor, and

deflate the tyre.

WARNINGS

Page 2909 of 3229

189

Wheels and tyres

R

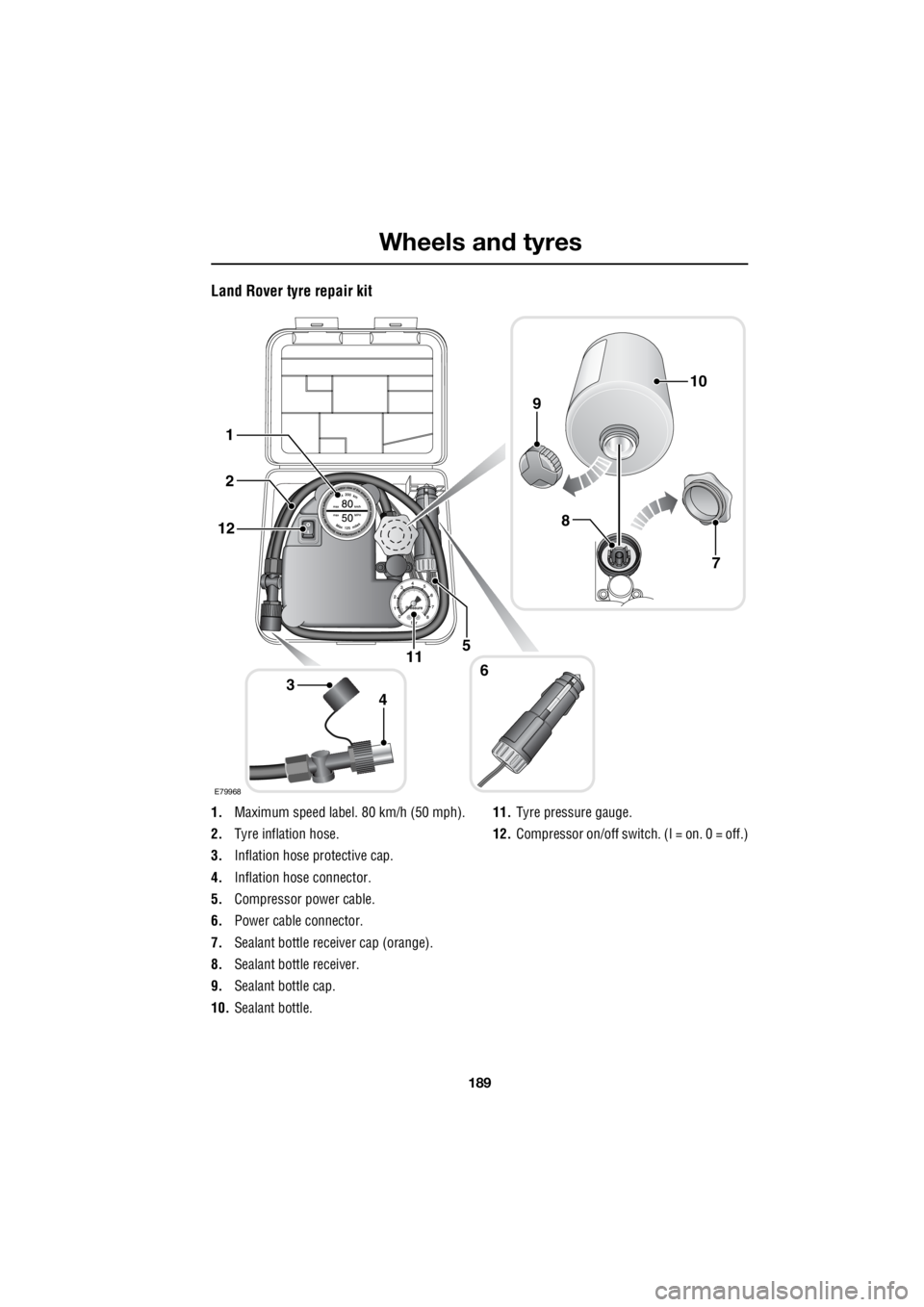

Land Rover tyre repair kit

1. Maximum speed label. 80 km/h (50 mph).

2. Tyre inflation hose.

3. Inflation hose protective cap.

4. Inflation hose connector.

5. Compressor power cable.

6. Power cable connector.

7. Sealant bottle receiver cap (orange).

8. Sealant bottle receiver.

9. Sealant bottle cap.

10. Sealant bottle. 11.

Tyre pressure gauge.

12. Compressor on/off switch. (I = on. 0 = off.)

E79968

34

2

6

5

1

12

11

8

9

10

7

Page 2910 of 3229

Wheels and tyres

190

L

Using the Land Rover tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre. Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the facia in the driver's field of view. Take

care not to obstruct any of the instruments

or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver, and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

• Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in the

sealant leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose, and c onnect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off ( O) position.

8. Insert the power cable connector into an

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 110).

9. Unless the vehicle is in an enclosed or

poorly ventilated area , start the engine.

10. Set the compressor switch to the on ( l)

position.

11. Inflate the tyre to a minimum of 1.8 bar (26

lb/in²) and a maximum of 3.5 bar (51

lb/in²).

†

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

Do not unscrew the sealant bottle from the

receiver until it is empty, as sealant will leak

out.

If the tyre inflation pressure does not

reach 1.8 bar (26 lb/in²) within seven

minutes, the tyre may have suffered excessive

damage. A temporary repair will not be

possible, and the vehicle should not be driven

until the tyre has been replaced.

CAUTIONS

Before attempting a tyre repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied,

and P is selected if an automatic

transmission is fitted.

Do not attempt to remove foreign objects

such as nails, screws, etc from the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed, or poorly ventilated space.

To prevent overheating do not operate

the compressor continuously for longer

than ten minutes.