LAND ROVER FRELANDER 2 2006 Repair Manual

FRELANDER 2 2006

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57251/w960_57251-0.png

LAND ROVER FRELANDER 2 2006 Repair Manual

Trending: brake, brake fluid, cabin filter, audio, rear entertainment, deactivate airbag, water pump

Page 591 of 3229

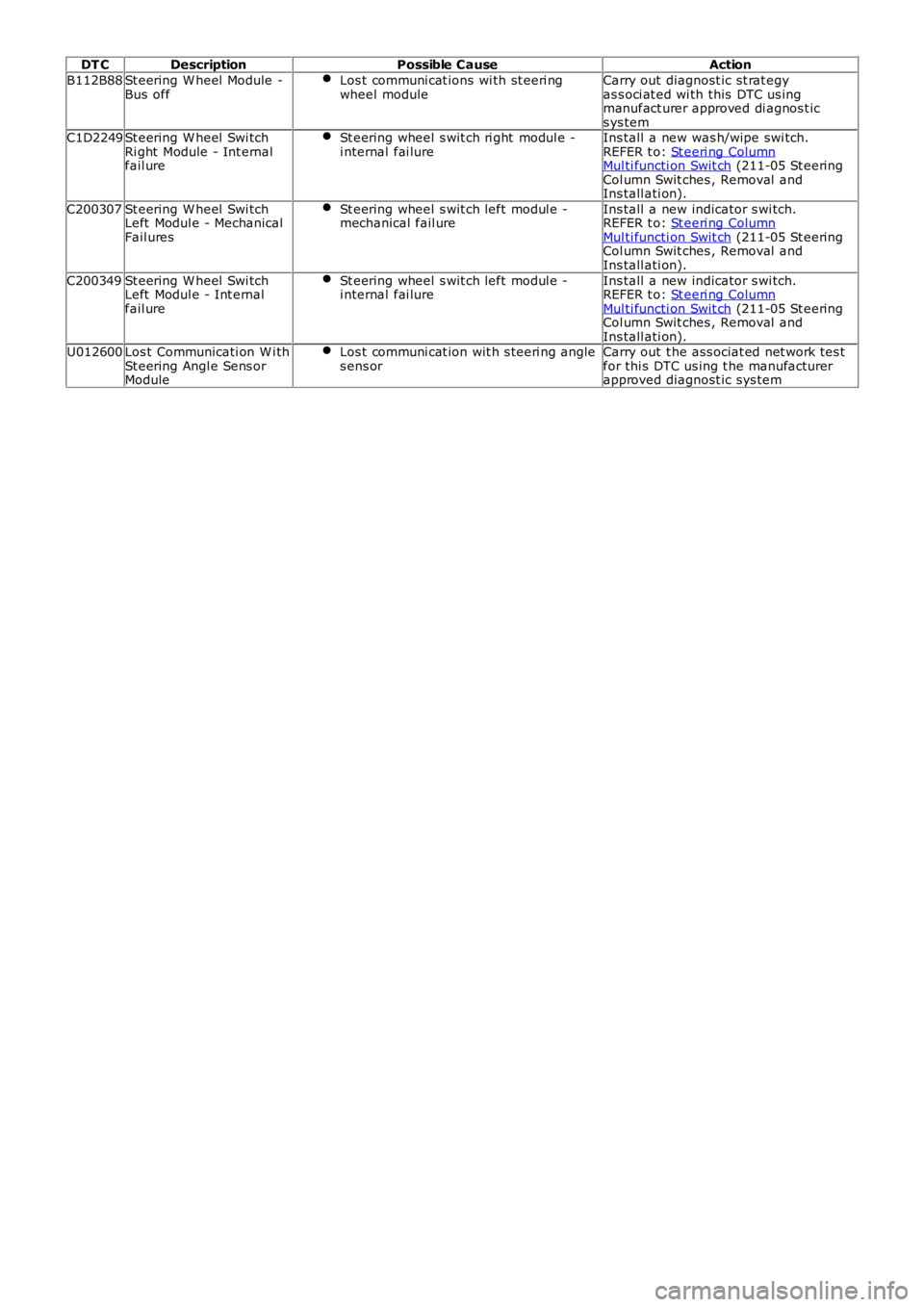

DT CDescriptionPossible CauseAction

B112B88St eering W heel Module -Bus offLos t communi cat ions wi th st eeri ngwheel moduleCarry out diagnost ic st rat egyas s oci at ed wi th this DTC us ingmanufact urer approved di agnos t ics ys temC1D2249St eering W heel Swi tchRi ght Module - Int ernalfail ure

St eering wheel s wit ch ri ght modul e -i nternal fai lureIns tall a new was h/wipe swi tch.REFER t o: St eeri ng ColumnMul ti functi on Swit ch (211-05 St eeringCol umn Swit ches , Removal andIns tall ati on).

C200307St eering W heel Swi tchLeft Modul e - MechanicalFail ures

St eering wheel s wit ch left modul e -mechanical fail ureIns tall a new indicator s wi tch.REFER t o: St eeri ng ColumnMul ti functi on Swit ch (211-05 St eeringCol umn Swit ches , Removal andIns tall ati on).

C200349St eering W heel Swi tchLeft Modul e - Int ernalfail ure

St eering wheel s wit ch left modul e -i nternal fai lureIns tall a new indicator s wi tch.REFER t o: St eeri ng ColumnMul ti functi on Swit ch (211-05 St eeringCol umn Swit ches , Removal andIns tall ati on).U012600Los t Communicati on W i thSt eering Angl e Sens orModule

Los t communi cat ion wit h s teeri ng angles ens orCarry out t he ass ociat ed net work tes tfor thi s DTC us ing t he manufacturerapproved diagnost ic sys tem

Page 592 of 3229

Publi s hed: 11-May-2011

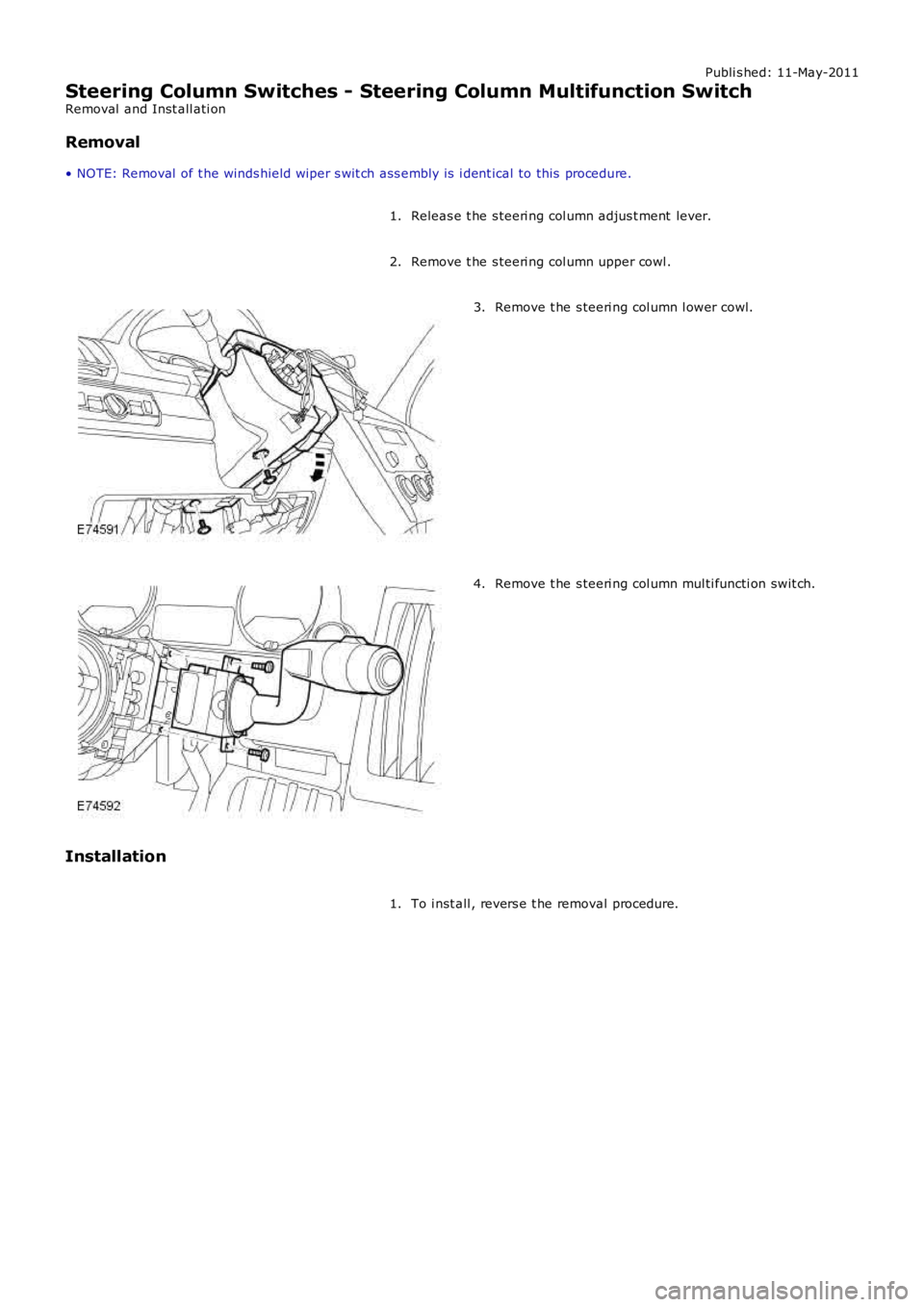

Steering Column Switches - Steering Column Multifunction Switch

Removal and Inst all ati on

Removal

• NOTE: Removal of t he winds hield wiper s wit ch ass embly is i dent ical to this procedure.

Releas e t he s teeri ng col umn adjus t ment lever.1.

Remove t he s teeri ng col umn upper cowl .2.

Remove t he s teeri ng col umn l ower cowl.3.

Remove t he s teeri ng col umn mul ti functi on swit ch.4.

Installation

To i nst all , revers e t he removal procedure.1.

Page 593 of 3229

Publi s hed: 11-May-2011

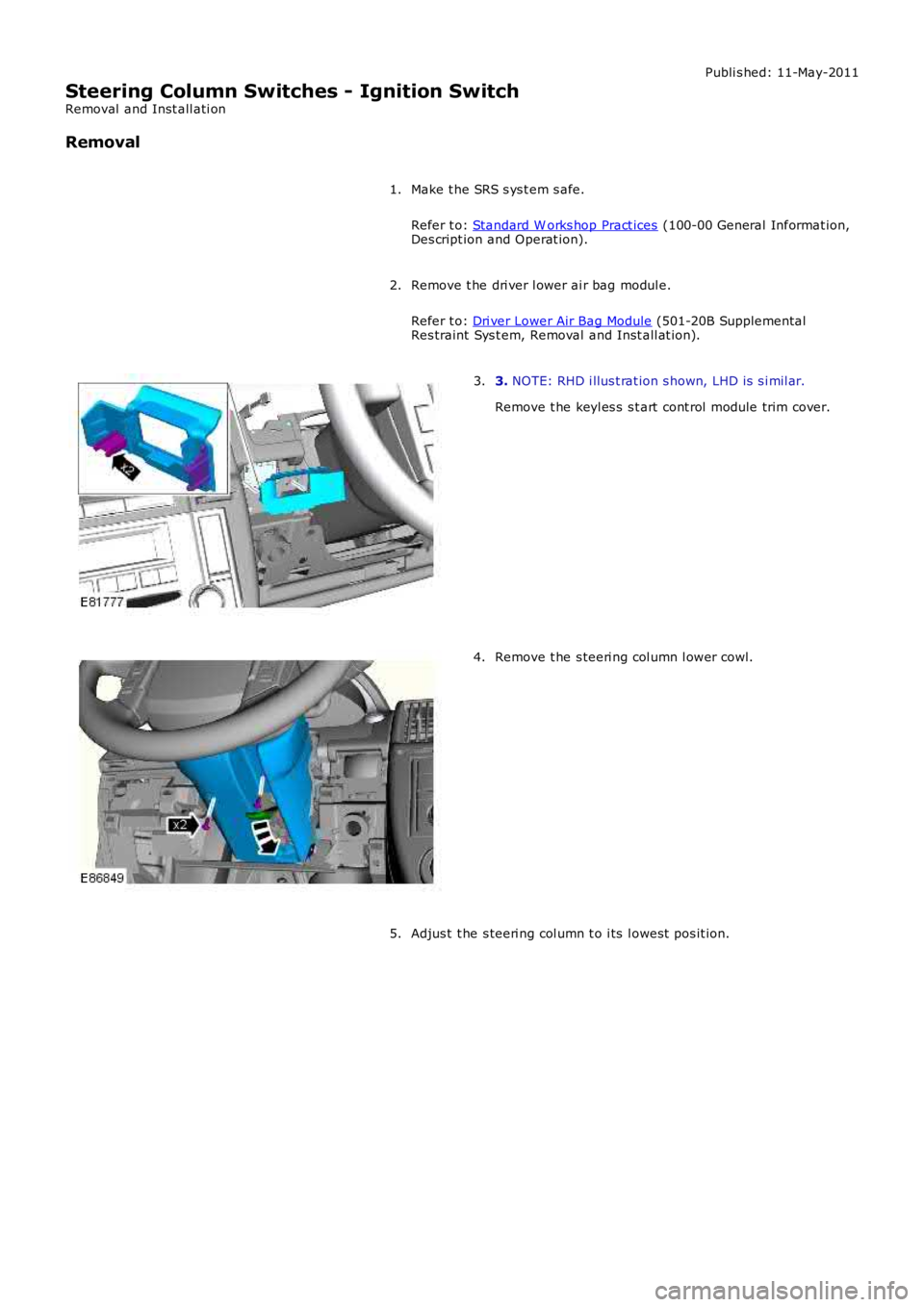

Steering Column Switches - Ignition Switch

Removal and Inst all ati on

Removal

Make t he SRS s ys t em s afe.

Refer t o: Standard W orks hop Pract ices (100-00 General Informat ion,Des cript ion and Operat ion).

1.

Remove t he dri ver l ower ai r bag modul e.

Refer t o: Dri ver Lower Air Bag Module (501-20B SupplementalRes traint Sys t em, Removal and Inst all at ion).

2.

3. NOTE: RHD i llus t rat ion s hown, LHD is s i mil ar.

Remove t he keyl es s s t art cont rol module trim cover.

3.

Remove t he s teeri ng col umn l ower cowl.4.

Adjus t t he s teeri ng col umn t o i ts l owest pos it ion.5.

Page 594 of 3229

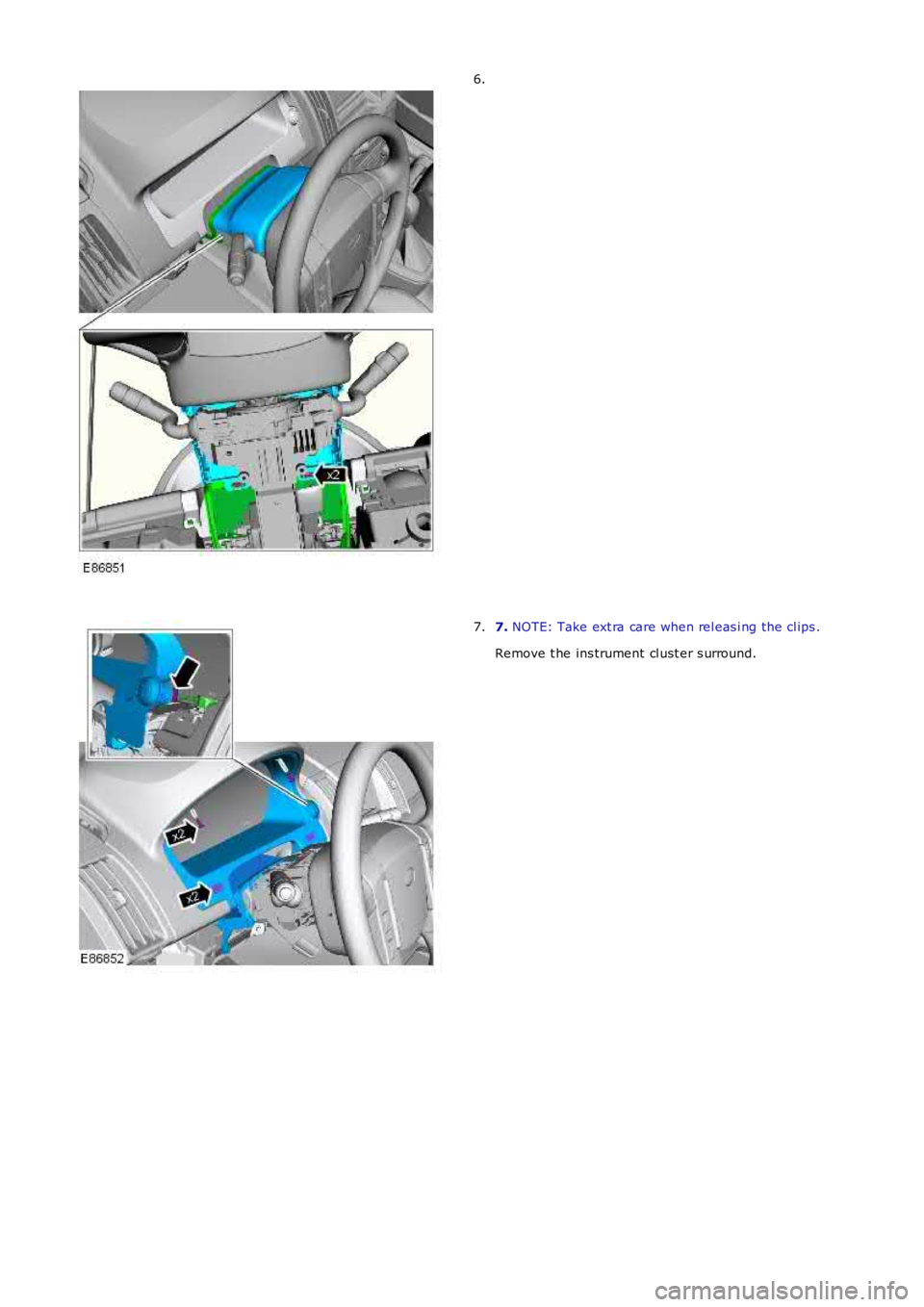

6.

7. NOTE: Take ext ra care when rel eas i ng the cl ips .

Remove t he ins trument cl ust er s urround.

7.

Page 595 of 3229

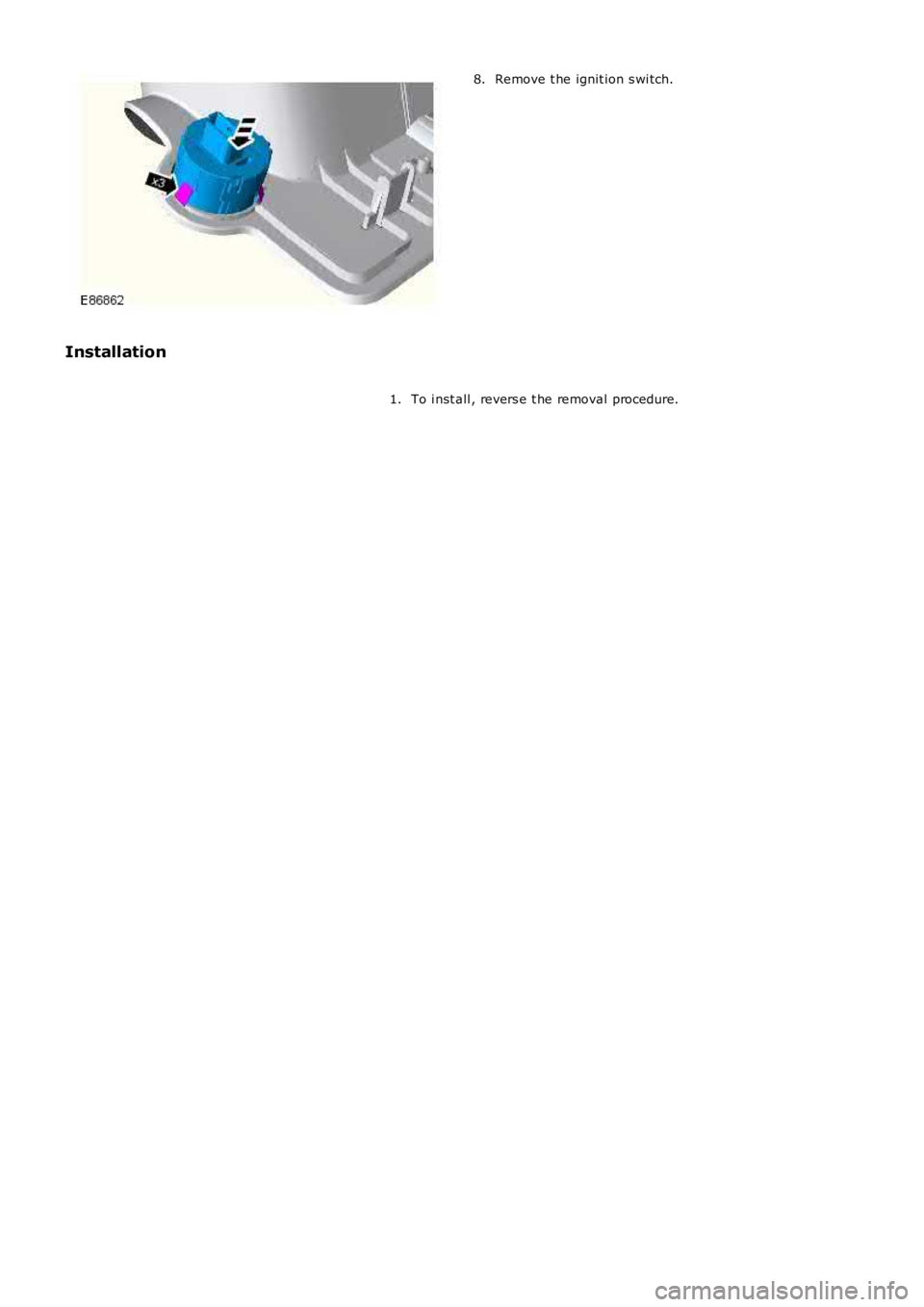

Remove t he ignit ion s wi tch.8.

Installation

To i nst all , revers e t he removal procedure.1.

Page 596 of 3229

Publi s hed: 11-May-2011

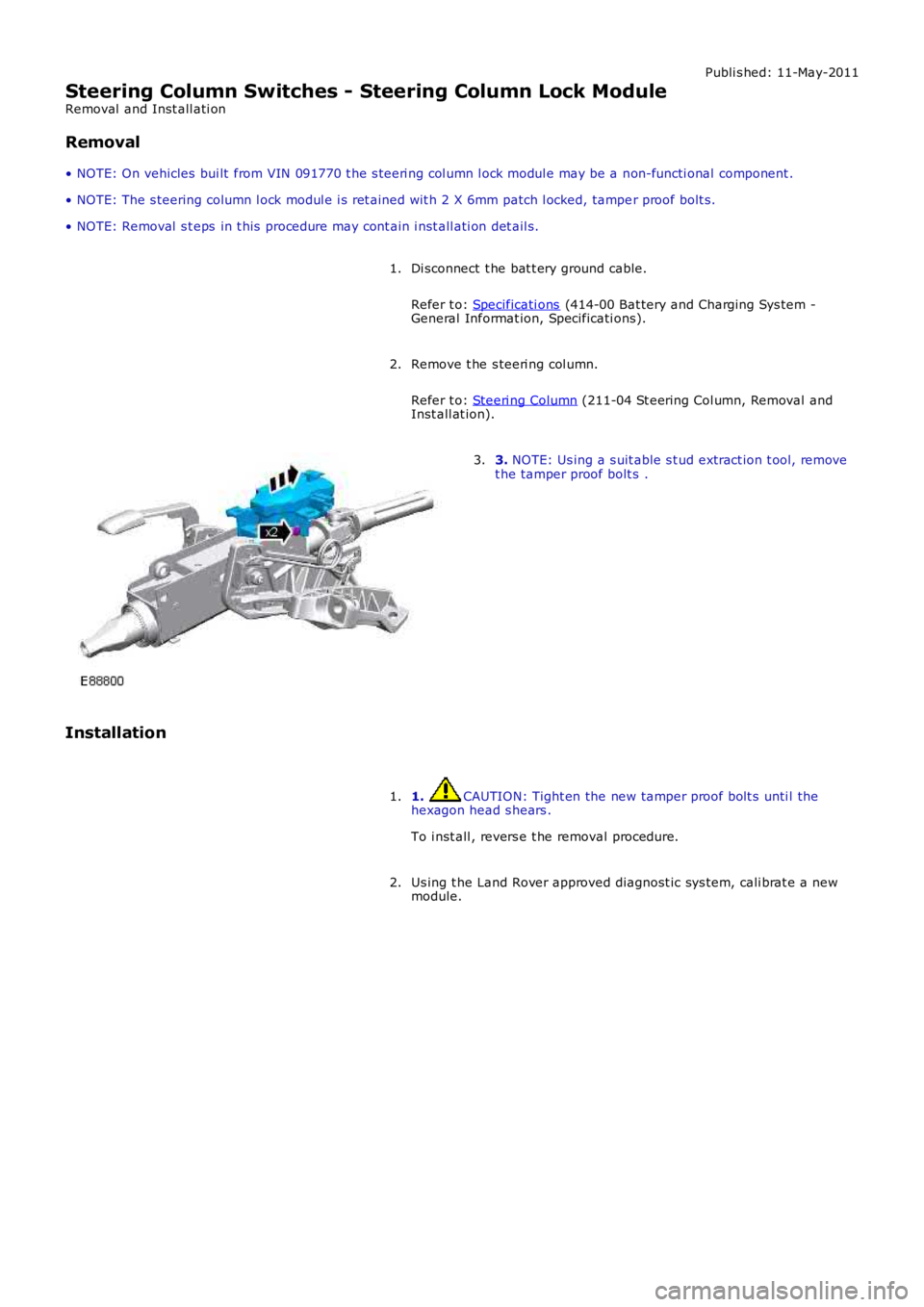

Steering Column Switches - Steering Column Lock Module

Removal and Inst all ati on

Removal

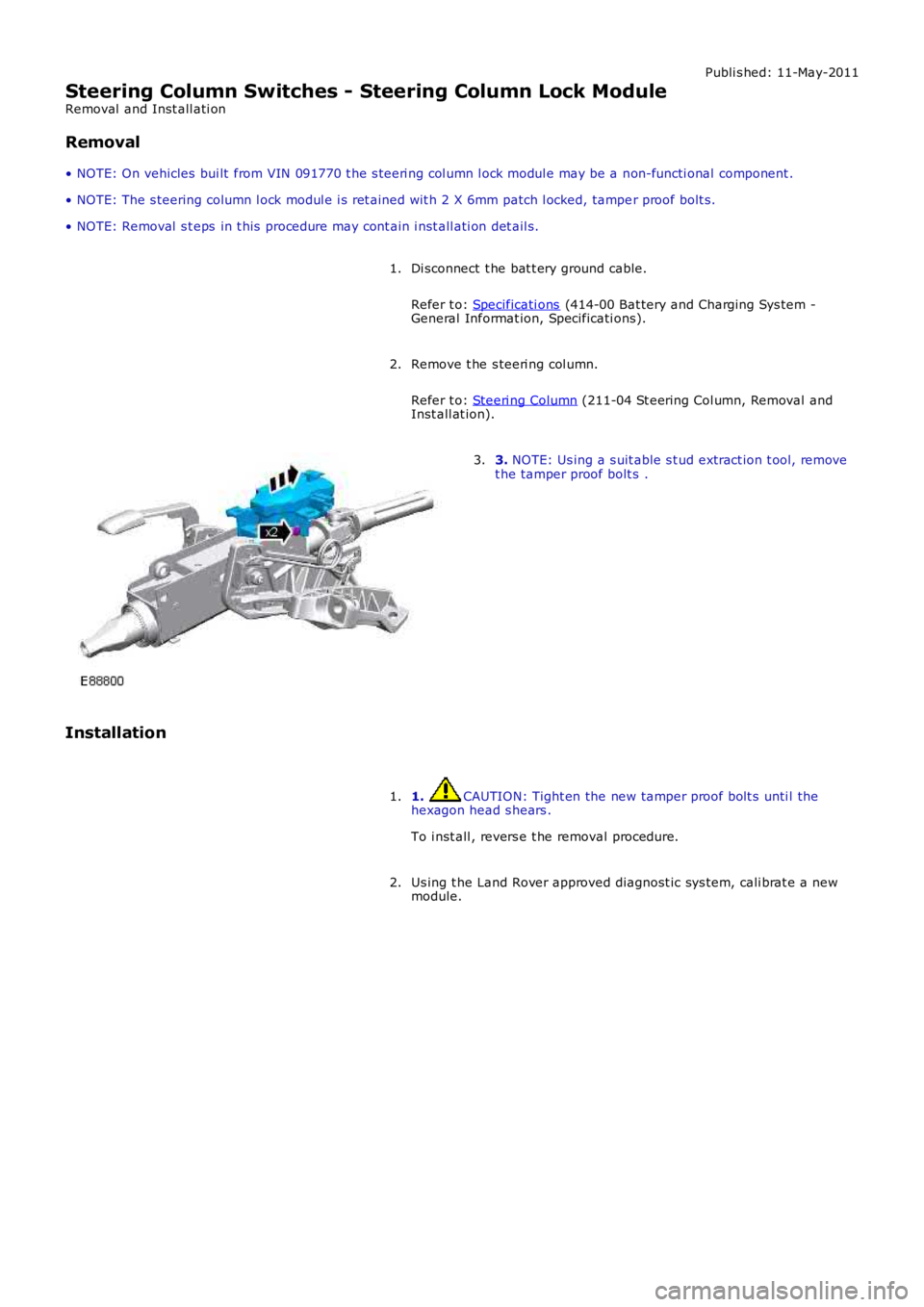

• NOTE: On vehicles bui lt from VIN 091770 t he s teeri ng col umn l ock modul e may be a non-functi onal component .

• NOTE: The s teering column l ock modul e i s ret ained wit h 2 X 6mm patch l ocked, tamper proof bolt s.

• NOTE: Removal s t eps in t his procedure may cont ain i nst all ati on det ail s.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he s teeri ng col umn.

Refer t o: Steeri ng Column (211-04 St eering Col umn, Removal andInst all at ion).

2.

3. NOTE: Us ing a s uit able s t ud extract ion t ool, removet he tamper proof bolt s .3.

Installation

1. CAUTION: Tight en the new tamper proof bolt s unti l thehexagon head s hears .

To i nst all , revers e t he removal procedure.

1.

Us ing t he Land Rover approved diagnost ic sys tem, cali brat e a newmodule.2.

Page 597 of 3229

Publi s hed: 11-May-2011

Engine System - General Information - Engine

Diagnosi s and Tes ti ng

For addit ional informat ion. REFER t o:

Engi ne (303-01A Engine - I6 3.2L Petrol, Diagnos is and Tes ti ng),Engi ne (303-01B Engine - TD4 2.2L Di esel , Diagnos is and Tes t ing).

Page 598 of 3229

Publi s hed: 11-May-2011

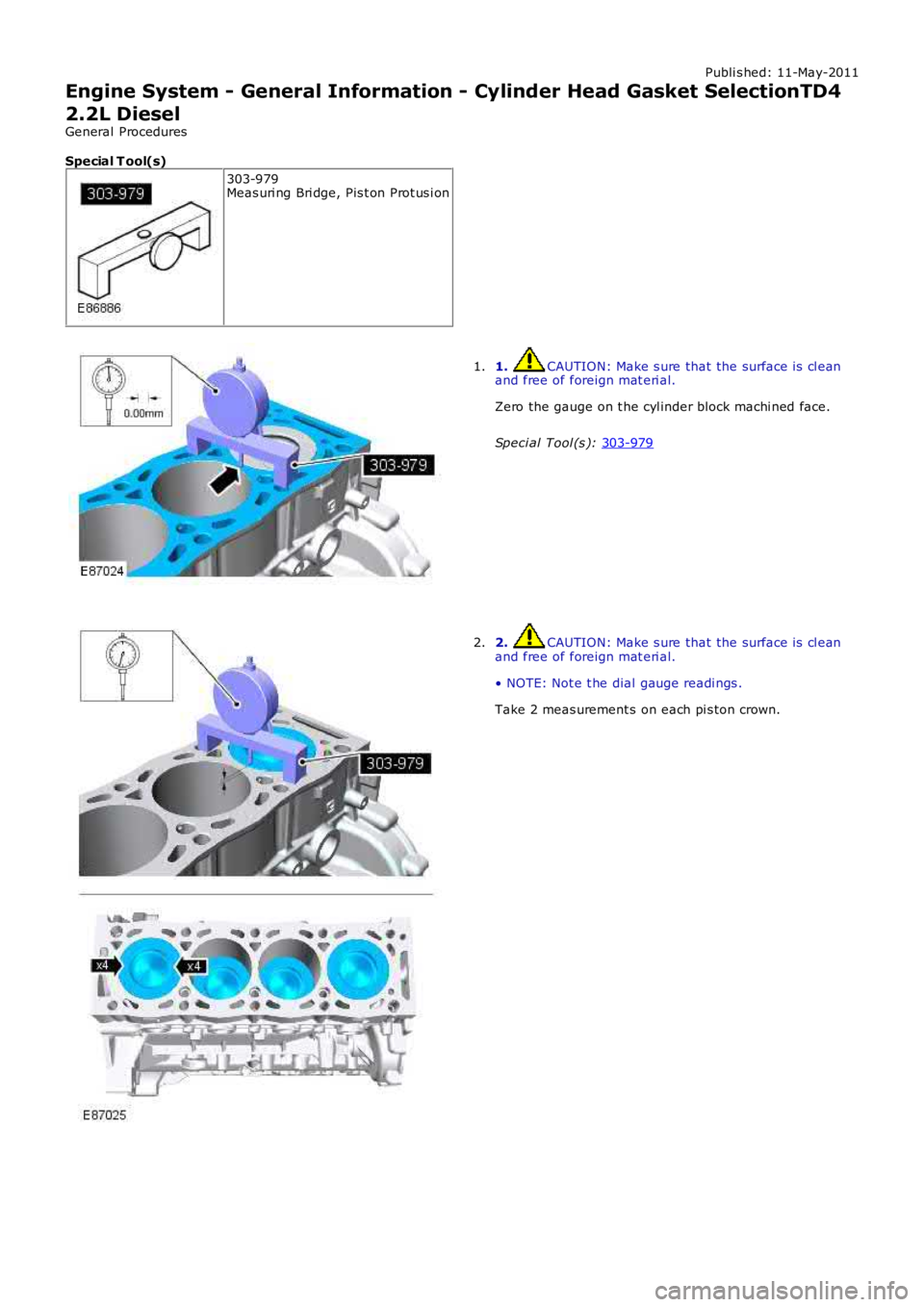

Engine System - General Information - Cylinder Head Gasket SelectionTD4

2.2L Diesel

General Procedures

Special T ool(s) 303-979

Meas uri ng Bri dge, Pis t on Prot us i on 1. CAUTION: Make s ure that the surface is cl ean

and free of foreign mat eri al.

Zero the gauge on t he cyl inder block machi ned face.

Speci al Tool (s ): 303-979 1.

2. CAUTION: Make s ure that the surface is cl ean

and free of foreign mat eri al.

• NOTE: Not e t he dial gauge readi ngs .

Take 2 meas urement s on each pi s ton crown.

2.

Page 599 of 3229

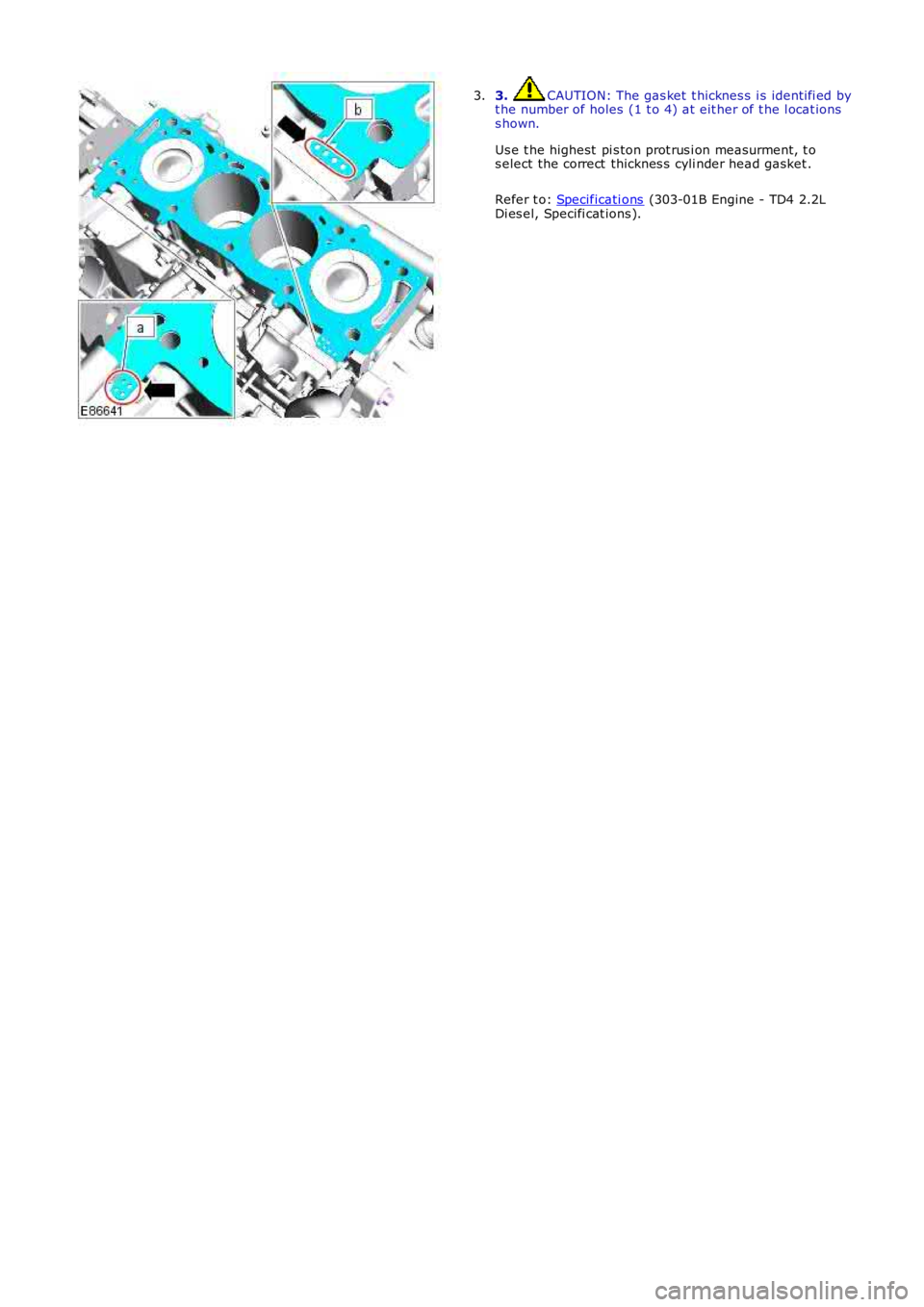

3. CAUTION: The gas ket t hicknes s i s identi fi ed byt he number of holes (1 t o 4) at eit her of t he l ocat ionss hown.

Us e t he highest pi s ton prot rus i on measurment, t os elect the correct thicknes s cyli nder head gasket .

Refer t o: Specificati ons (303-01B Engine - TD4 2.2LDi es el, Specifi cat ions ).

3.

Page 600 of 3229

Publ is hed: 02-Jun-2011

Engine System - General Information - Leakage Test Using Smoke Test

Equipment

General Procedures

CAUTION: The compres s ed air li ne s uppl y pres s ure mus t be bet ween 3.5 and 12 bar (50 and 175 psi ) for t he s moket es t equipment t o functi on correctl y. Do not exceed t hi s pres s ure. Fai lure t o fol low t his ins truct ion may res ult in damage tot he smoke tes t equi pment.

• NOTE: The vehi cle bat tery mus t be in good condit ion and ful ly charged before carryi ng out thi s procedure.

• NOTE: On vehicles wit h 3.0L TDV6, it wi ll be necess ary to ins ert s moke at bot h ai r cl eaner outl et pi pes independentl y ift he ri ght hand t urbocharger and as s oci at ed hos es are t o be t es ted.

• NOTE: In s ome cases i t may be necess ary to remove undert rays, t ri m or engine covers t o obt ai n acces s t o all potent ialleak l ocat ions.

• NOTE: Some vari ati on in the i ll us t rat ions may occur, but the es s ent ial informat ion i s always correct .

• NOTE: For furt her informati on regardi ng operati on of the tes t equi pment refer t o the manufacturers operat ors manuals uppl ied wi th the ki t.

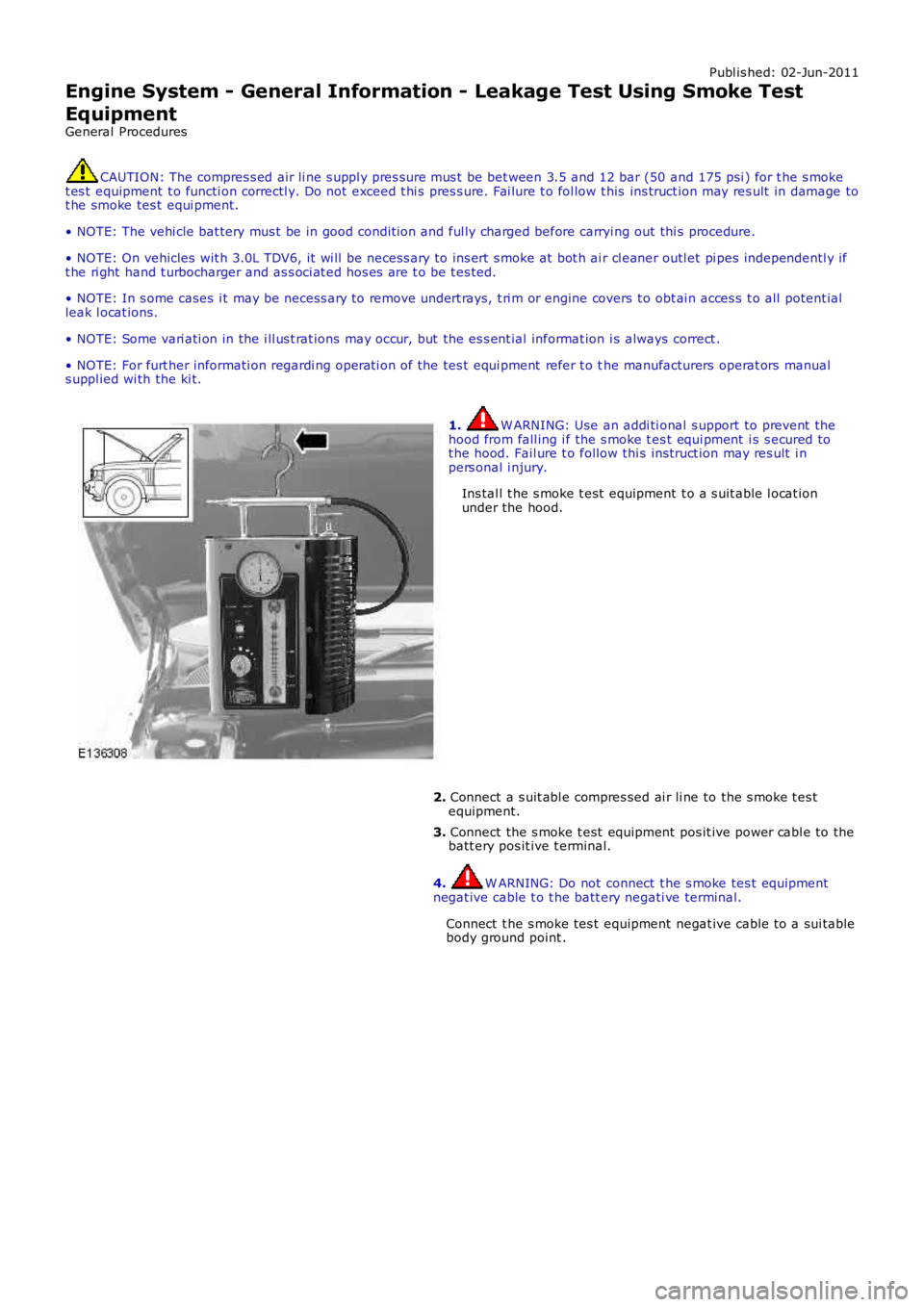

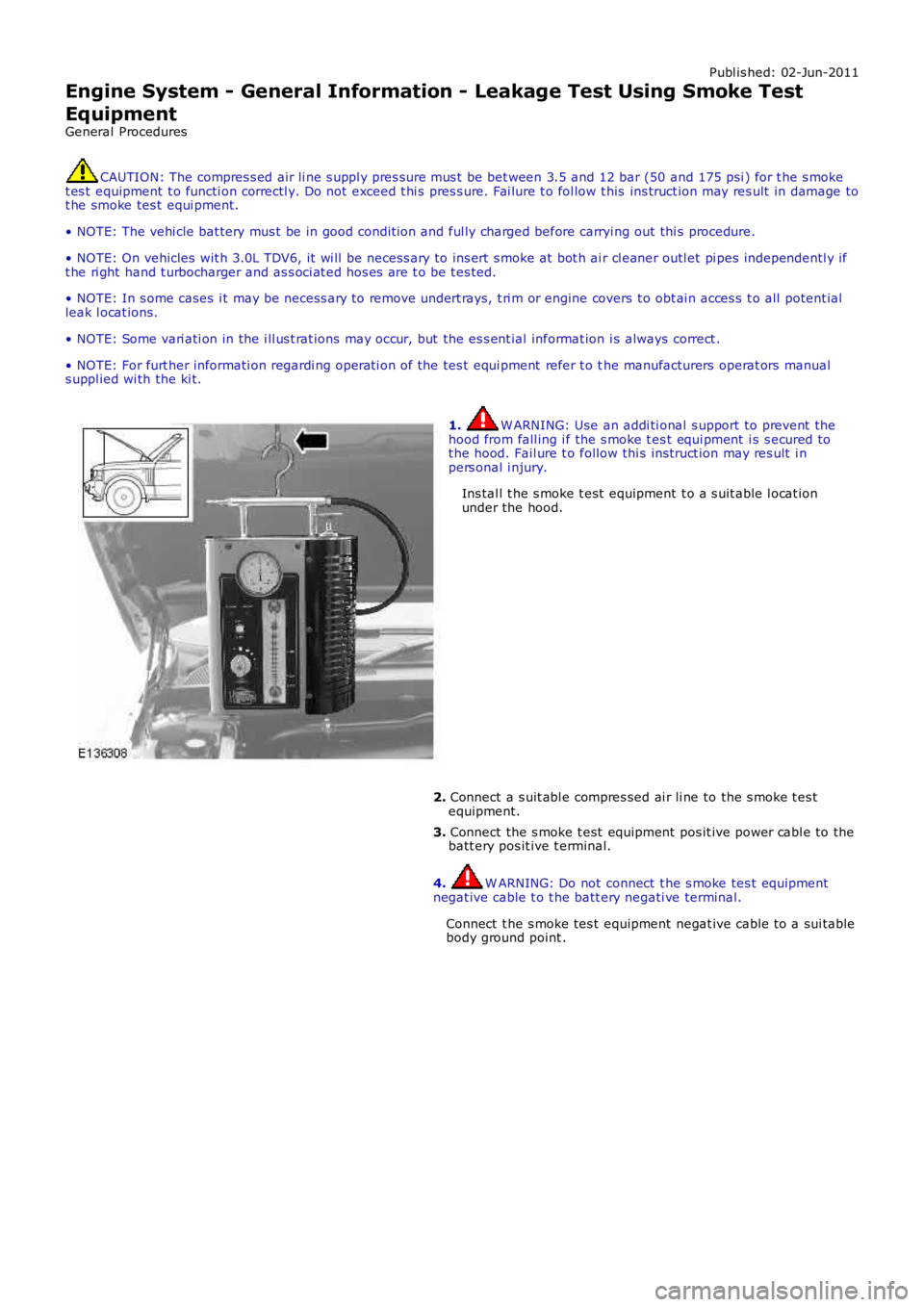

1. W ARNING: Use an addi ti onal s upport to prevent t hehood from fall ing i f the s moke t es t equi pment i s s ecured tot he hood. Fail ure t o follow thi s ins truct ion may res ult i npers onal i njury.

Ins tal l t he s moke t est equipment t o a s uit able l ocat ionunder the hood.

2. Connect a s uit abl e compres sed ai r li ne to the s moke t es tequipment.

3. Connect the s moke t est equipment pos it ive power cabl e to thebatt ery pos it ive t erminal.

4. W ARNING: Do not connect t he s moke tes t equipmentnegat ive cable t o t he batt ery negati ve terminal.

Connect t he s moke tes t equipment negat ive cable t o a sui tablebody ground point .

Trending: change wheel, brake sensor, light, climate settings, bulb, emergency key access, phone