LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 611 of 3229

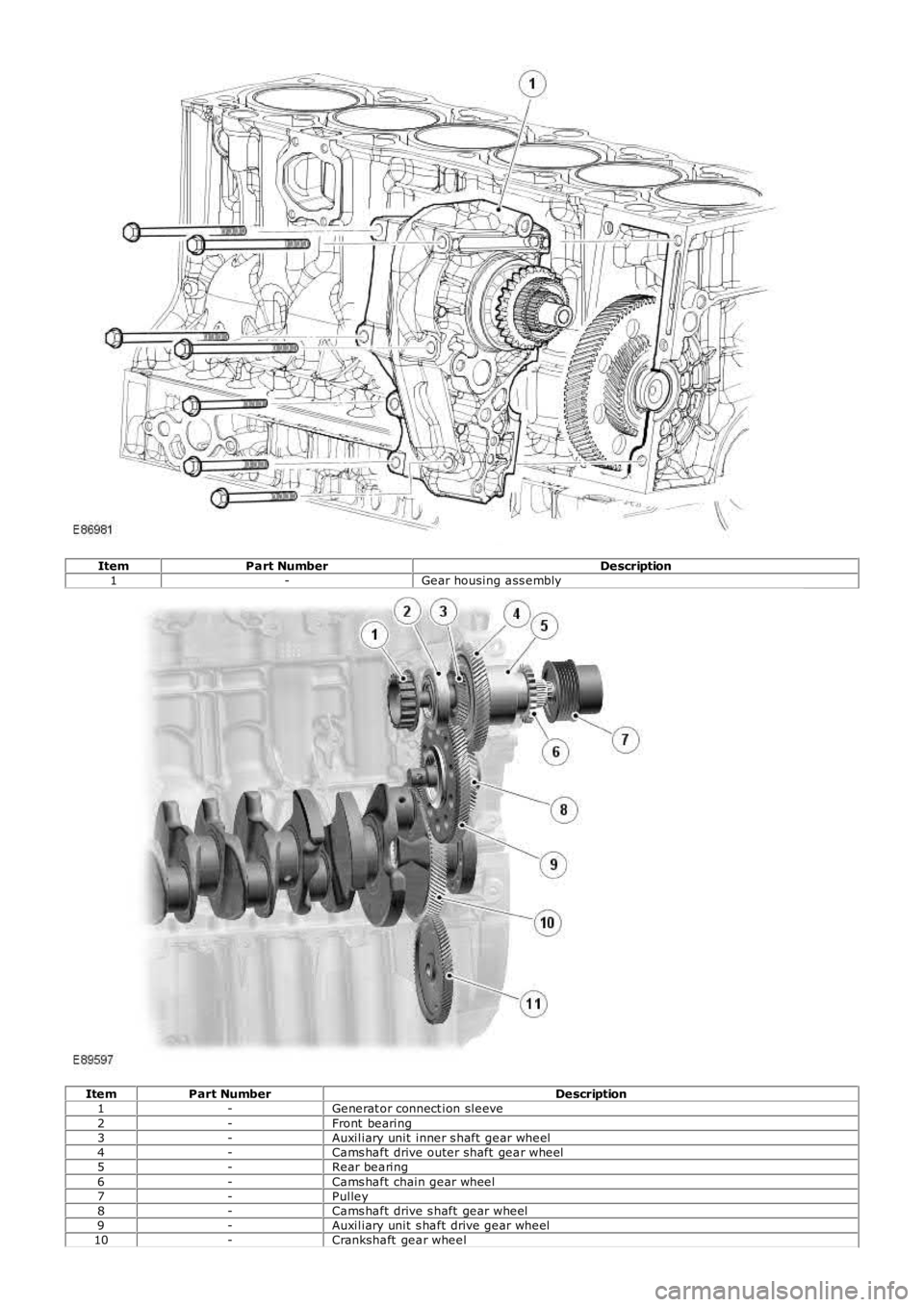

ItemPart NumberDescription1-Gear housing ass embly

ItemPart NumberDescription1-Generat or connect ion sleeve2-Front bearing3-Auxiliary unit inner s haft gear wheel4-Cams haft drive outer shaft gear wheel5-Rear bearing6-Cams haft chain gear wheel7-Pulley8-Cams haft drive s haft gear wheel9-Auxiliary unit s haft drive gear wheel10-Crankshaft gear wheel

Page 612 of 3229

11-O il pump gear wheel12-Int ermediat e s haft

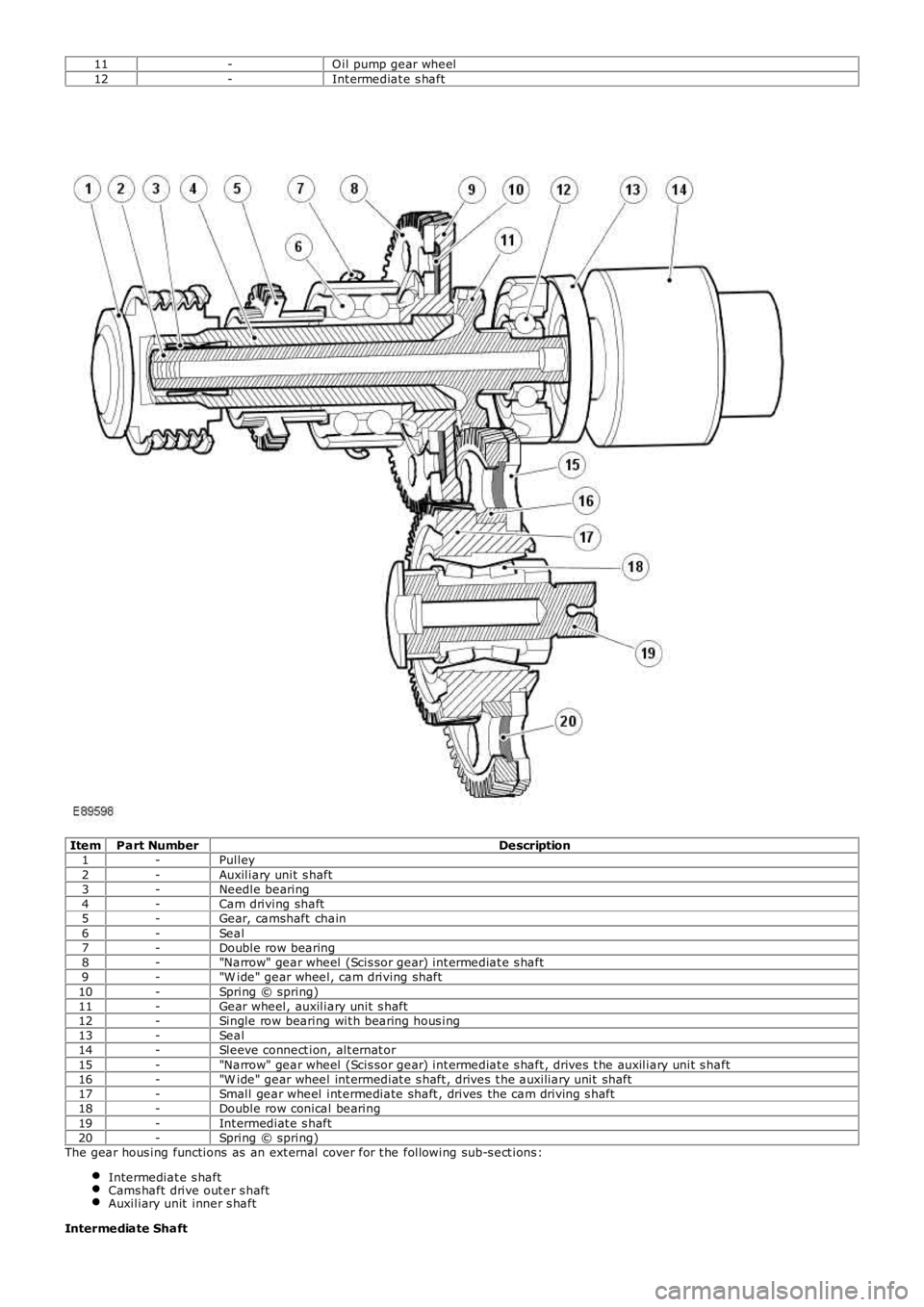

ItemPart NumberDescription1-Pulley2-Auxiliary unit s haft3-Needle bearing4-Cam driving shaft5-Gear, camshaft chain6-Seal7-Double row bearing8-"Narrow" gear wheel (Scis sor gear) int ermediat e s haft9-"W ide" gear wheel, cam driving shaft10-Spring © spring)11-Gear wheel, auxiliary unit s haft12-Single row bearing wit h bearing hous ing13-Seal14-Sleeve connect ion, alt ernat or15-"Narrow" gear wheel (Scis sor gear) int ermediat e s haft , drives t he auxiliary unit s haft16-"W ide" gear wheel int ermediat e s haft , drives t he auxiliary unit shaft17-Small gear wheel int ermediate shaft , drives the cam driving s haft18-Double row conical bearing19-Int ermediat e s haft20-Spring © spring)The gear hous ing functions as an ext ernal cover for t he following sub-s ect ions :

Intermediat e s haftCams haft drive out er s haftAuxiliary unit inner s haft

Intermediate Shaft

Page 613 of 3229

The intermediat e s haft is us ed to locat e the cams haft drive s haft gear wheel in t he cylinder block. The shaft is journaled wit h adouble conical roller bearing. The auxiliary unit s haft drive gear wheel is in 2 pieces , wit h t he narrow half being s pring tensioned inthe opposit e direct ion t o t he wide half. This feat ure reduces nois e becaus e gear play is eliminat ed. Only t he wide half drives theauxiliary unit's gear wheel. The cams haft chain gear wheel is of t he conventional design.

The s haft is sealed against the exhaust side (i.e. the rear s ide of t he cylinder block) by a s ealing was her. To remove or inst all t hewasher, t he flywheel/flexplate must be removed.

Camshaft Drive O uter Shaft

The cams haft drive outer s haft is journaled at the front end of t he s haft with a double row bearing in t he gear hous ing. Needlebearings are us ed at t he rear end (pulley s ide) against t he auxiliary unit s haft . The camshaft drive out er s haft gear wheel is in 2pieces , a wide and a narrow half t o reduce nois e. The cams haft chain gear wheel is als o locat ed on the s haft and is us ed to drivethe cams hafts chain.

Auxiliary Unit Inner Shaft

The auxiliary unit inner s haft is journaled at t he front end of t he shaft (generator s ide) in t he gear housing with a s ingle rowbearing. Needle bearings are used at the rear end (pulley s ide) against the cams haft drive shaft . There is a pulley at t he rear endof the s haft that drives t he Air Condit ioning (AC) compress or and the power s t eering pump, via a polyvee belt . The shaft als odrives t he generat or at t he front end, via a sleeve connect or.

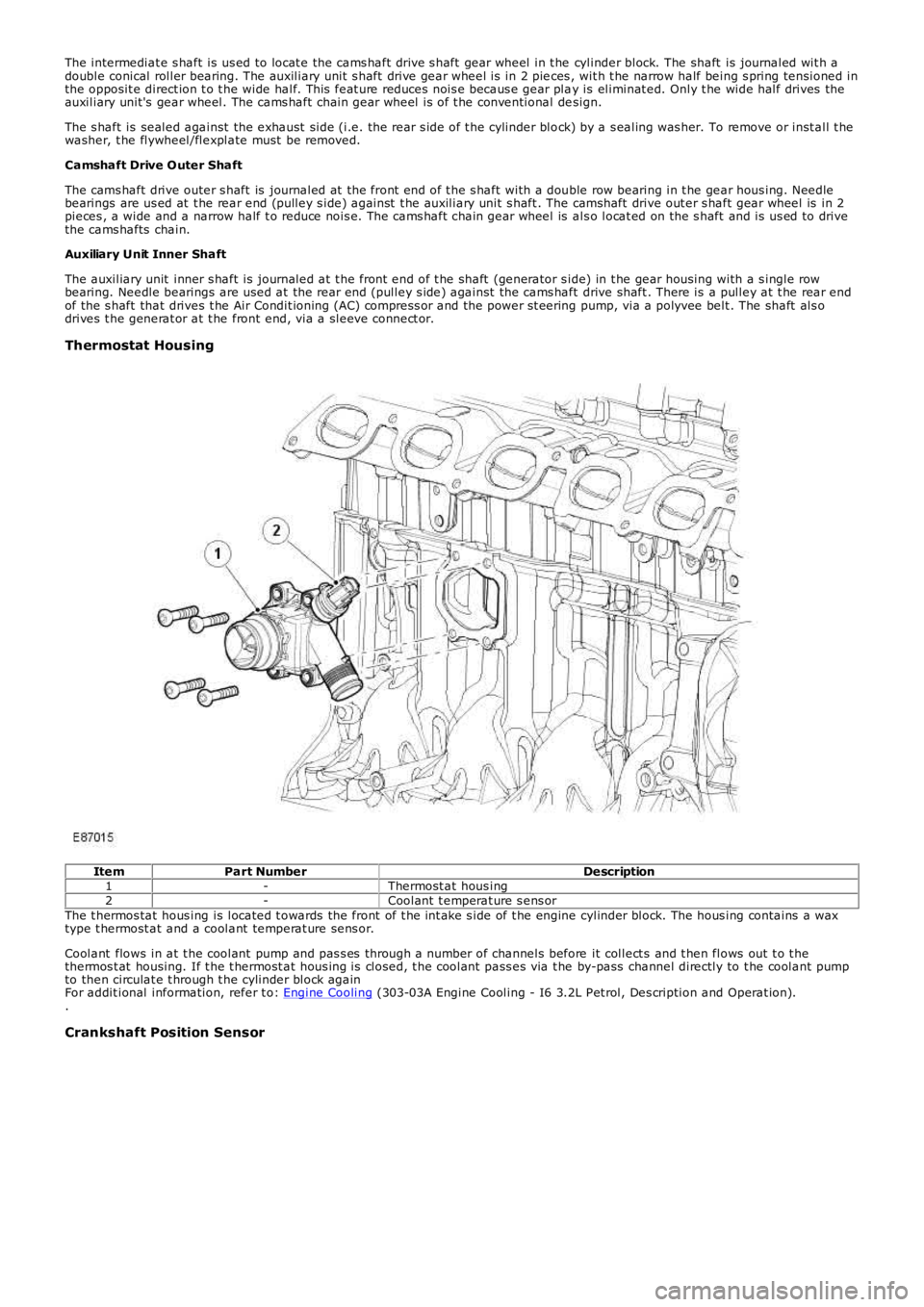

Thermostat Housing

ItemPart NumberDescription1-Thermost at hous ing2-Coolant t emperat ure s ens orThe t hermos tat hous ing is located t owards the front of t he int ake s ide of t he engine cylinder block. The hous ing contains a waxtype t hermost at and a coolant temperat ure sens or.

Coolant flows in at t he coolant pump and pas s es through a number of channels before it collect s and t hen flows out t o t hethermos t at housing. If t he t hermost at hous ing is closed, t he coolant pass es via t he by-pass channel directly to t he coolant pumpto then circulat e t hrough t he cylinder block againFor addit ional information, refer t o: Engine Cooling (303-03A Engine Cooling - I6 3.2L Pet rol, Des cription and Operat ion)..

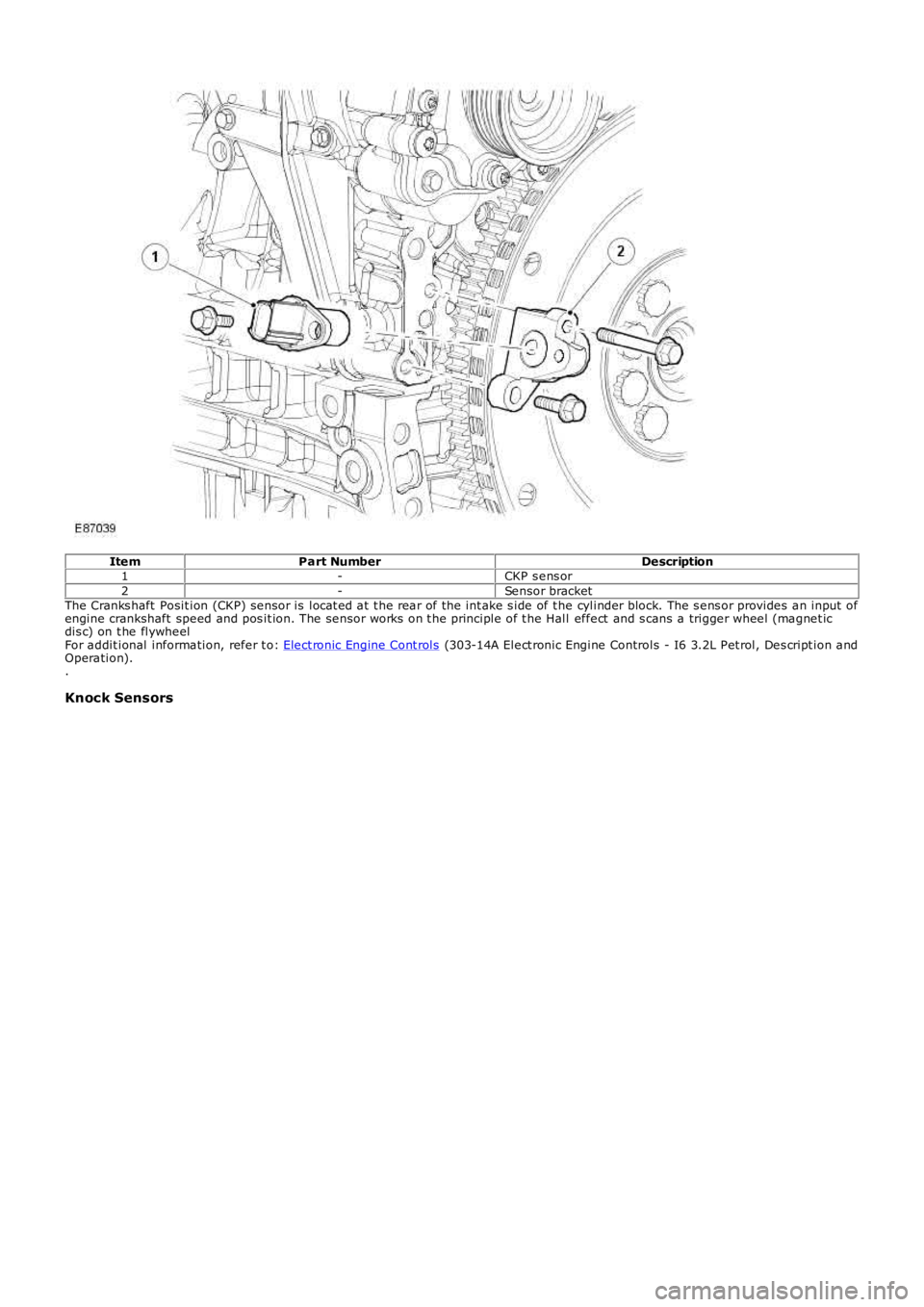

Crankshaft Position Sensor

Page 614 of 3229

ItemPart NumberDescription1-CKP s ens or2-Sensor bracketThe Cranks haft Posit ion (CKP) sensor is locat ed at t he rear of the int ake s ide of t he cylinder block. The s ens or provides an input ofengine crankshaft speed and pos it ion. The sensor works on t he principle of t he Hall effect and s cans a trigger wheel (magnet icdis c) on t he flywheelFor addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation)..

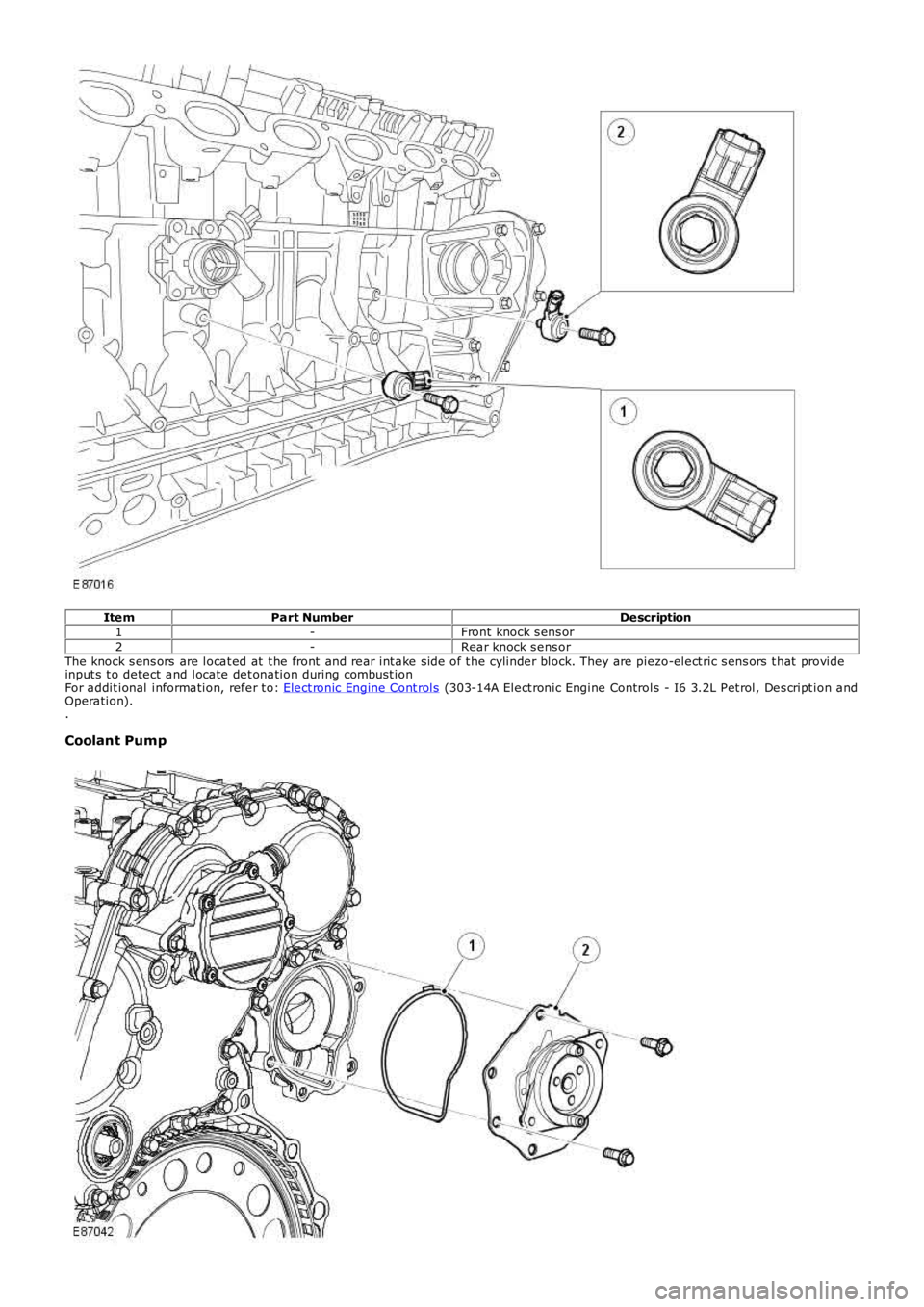

Knock Sensors

Page 615 of 3229

ItemPart NumberDescription1-Front knock s ens or2-Rear knock s ens orThe knock s ens ors are locat ed at t he front and rear int ake side of t he cylinder block. They are piezo-elect ric s ens ors t hat provideinput s t o detect and locate det onation during combust ionFor addit ional information, refer t o: Elect ronic Engine Cont rols (303-14A Elect ronic Engine Controls - I6 3.2L Pet rol, Des cript ion andOperation)..

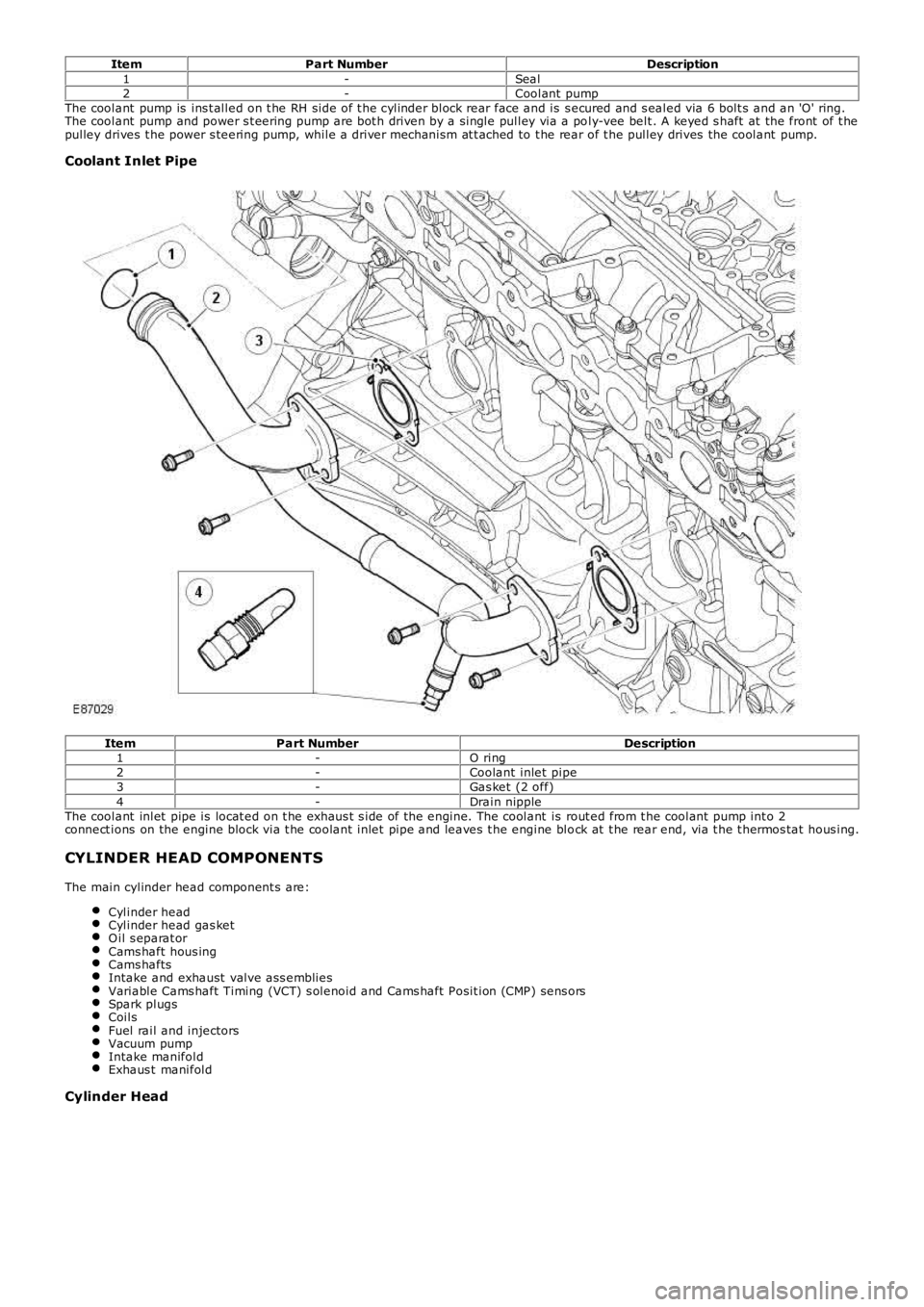

Coolant Pump

Page 616 of 3229

ItemPart NumberDescription1-Seal2-Coolant pumpThe coolant pump is ins t alled on t he RH side of t he cylinder block rear face and is s ecured and s ealed via 6 bolt s and an 'O' ring.The coolant pump and power s t eering pump are bot h driven by a single pulley via a poly-vee belt . A keyed s haft at the front of t hepulley drives t he power s teering pump, while a driver mechanism at t ached to t he rear of t he pulley drives the coolant pump.

Coolant Inlet Pipe

ItemPart NumberDescription1-O ring2-Coolant inlet pipe3-Gas ket (2 off)4-Drain nippleThe coolant inlet pipe is locat ed on t he exhaus t s ide of the engine. The coolant is rout ed from t he coolant pump int o 2connect ions on the engine block via t he coolant inlet pipe and leaves t he engine block at t he rear end, via t he t hermos tat hous ing.

CYLINDER HEAD COMPONENTS

The main cylinder head component s are:

Cylinder headCylinder head gas ketO il s eparat orCams haft hous ingCams haftsIntake and exhaust valve ass embliesVariable Cams haft Timing (VCT) s olenoid and Cams haft Posit ion (CMP) sens orsSpark plugsCoilsFuel rail and injectorsVacuum pumpIntake manifoldExhaus t manifold

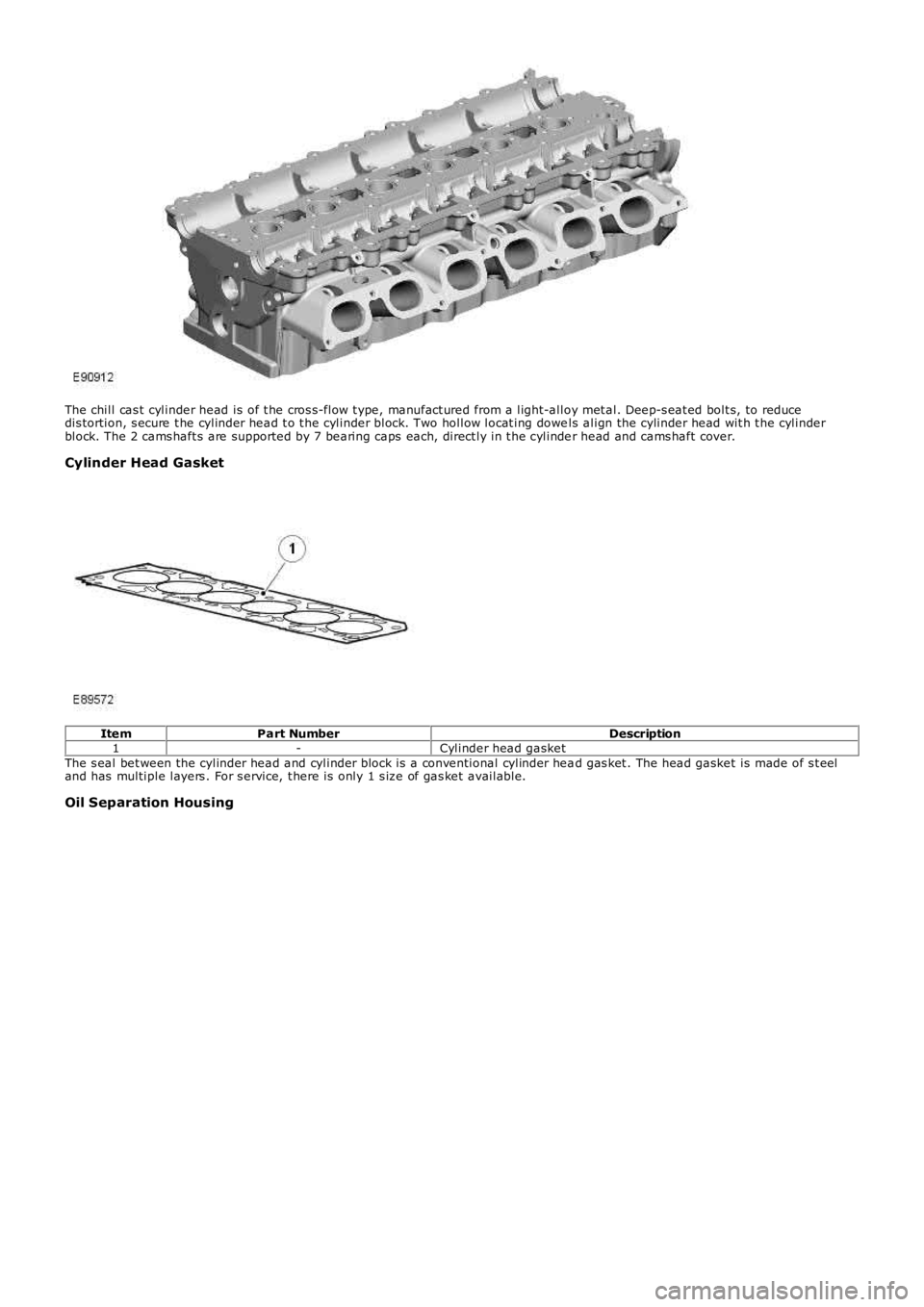

Cylinder Head

Page 617 of 3229

The chill cas t cylinder head is of t he cros s-flow t ype, manufact ured from a light-alloy met al. Deep-s eat ed bolt s, to reducedis tortion, s ecure t he cylinder head t o t he cylinder block. Two hollow locat ing dowels align the cylinder head wit h t he cylinderblock. The 2 cams haft s are supported by 7 bearing caps each, direct ly in t he cylinder head and cams haft cover.

Cylinder Head Gasket

ItemPart NumberDescription1-Cylinder head gasketThe s eal bet ween the cylinder head and cylinder block is a conventional cylinder head gas ket . The head gasket is made of s t eeland has multiple layers . For s ervice, t here is only 1 s iz e of gas ket available.

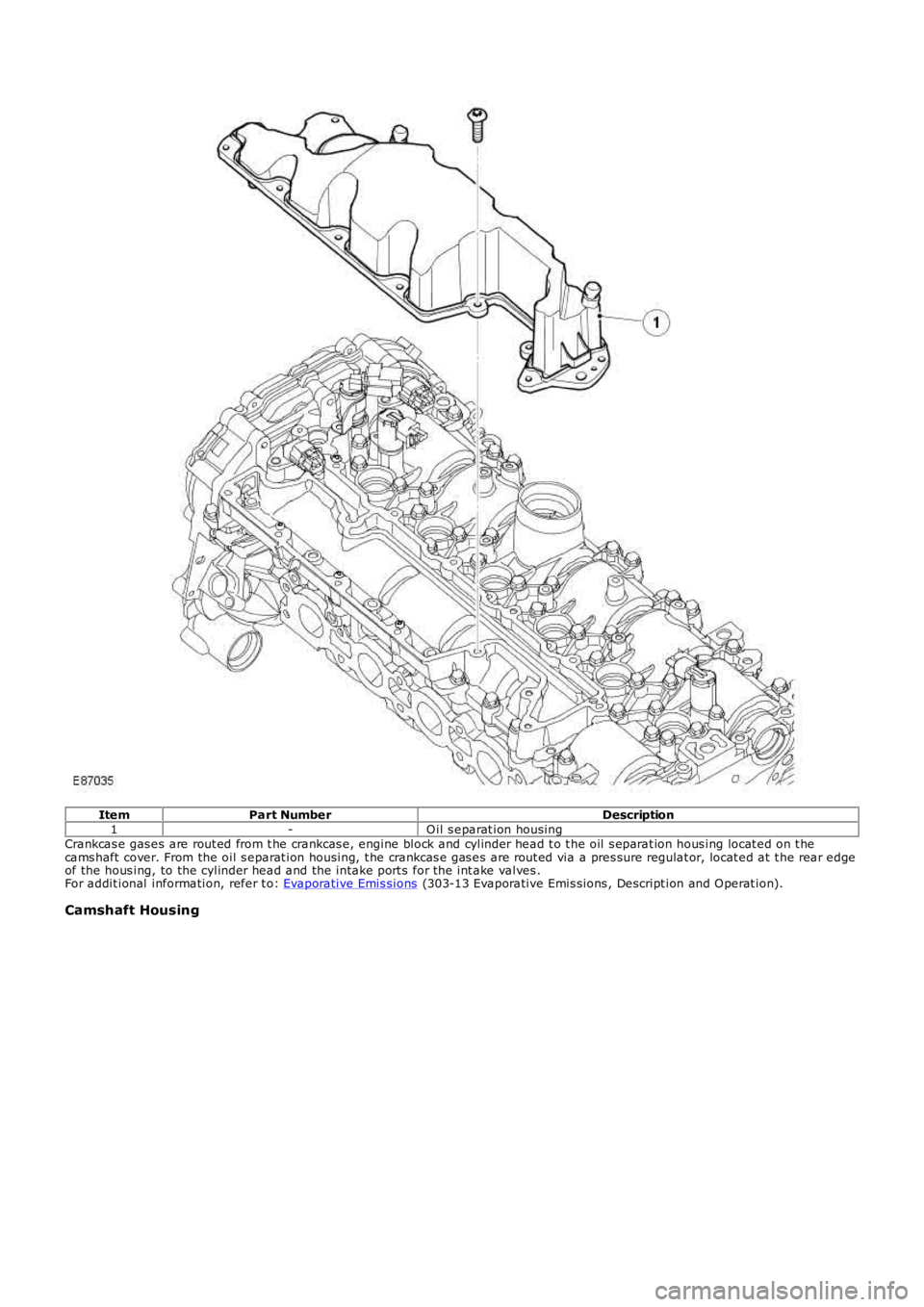

Oil Separation Housing

Page 618 of 3229

ItemPart NumberDescription1-O il s eparat ion housingCrankcas e gas es are rout ed from t he crankcas e, engine block and cylinder head t o t he oil s eparat ion hous ing locat ed on t hecams haft cover. From the oil s eparat ion housing, t he crankcas e gas es are rout ed via a pres sure regulat or, locat ed at t he rear edgeof the hous ing, to the cylinder head and the intake port s for t he int ake valves .For addit ional information, refer t o: Evaporative Emis sions (303-13 Evaporative Emis sions , Descript ion and O perat ion).

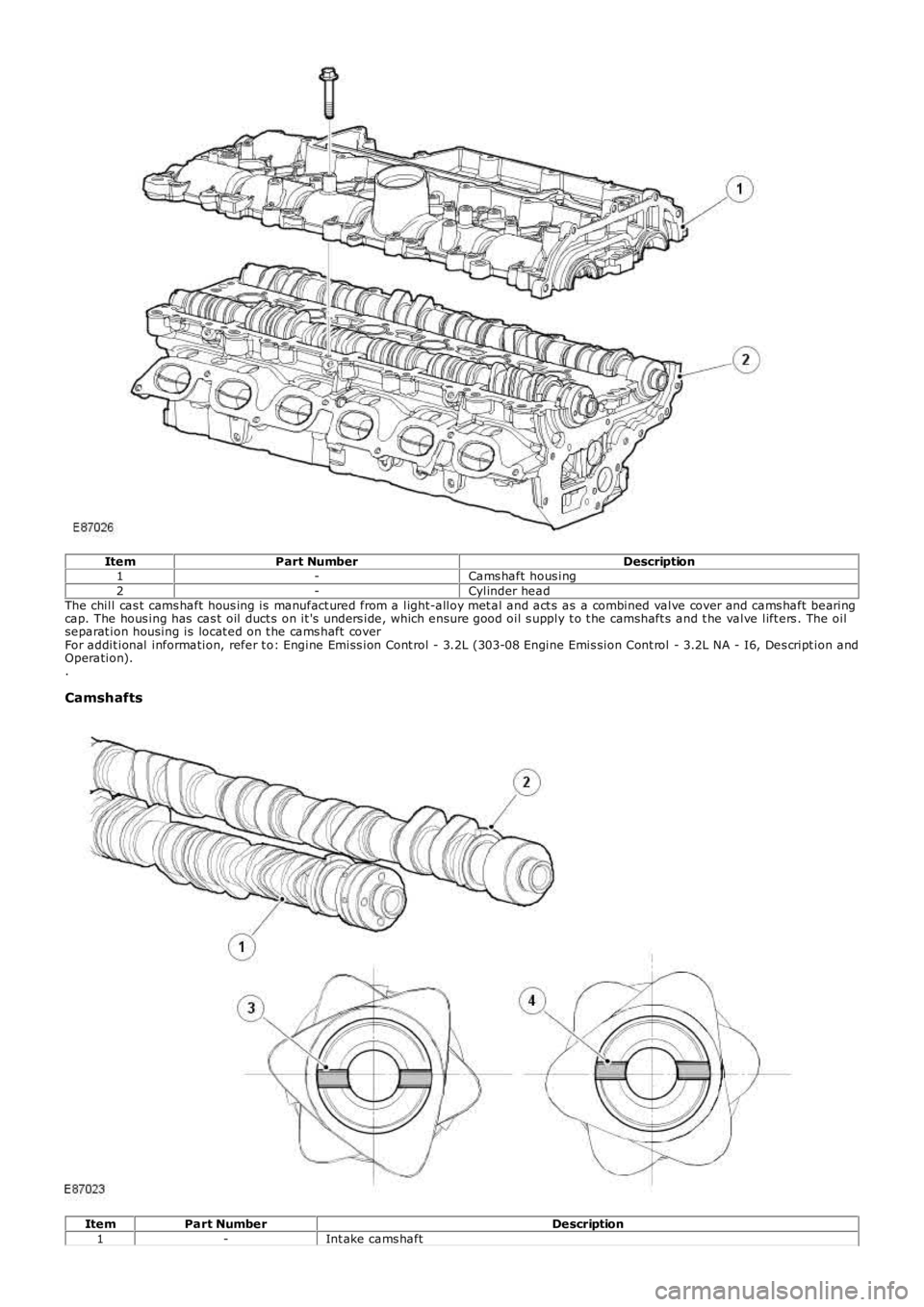

Camshaft Housing

Page 619 of 3229

ItemPart NumberDescription1-Cams haft hous ing2-Cylinder headThe chill cas t cams haft hous ing is manufact ured from a light-alloy met al and act s as a combined valve cover and cams haft bearingcap. The hous ing has cas t oil duct s on it 's unders ide, which ensure good oil s upply t o t he camshaft s and t he valve lift ers . The oilseparat ion housing is locat ed on t he cams haft coverFor addit ional information, refer t o: Engine Emiss ion Cont rol - 3.2L (303-08 Engine Emis sion Cont rol - 3.2L NA - I6, Des cript ion andOperation)..

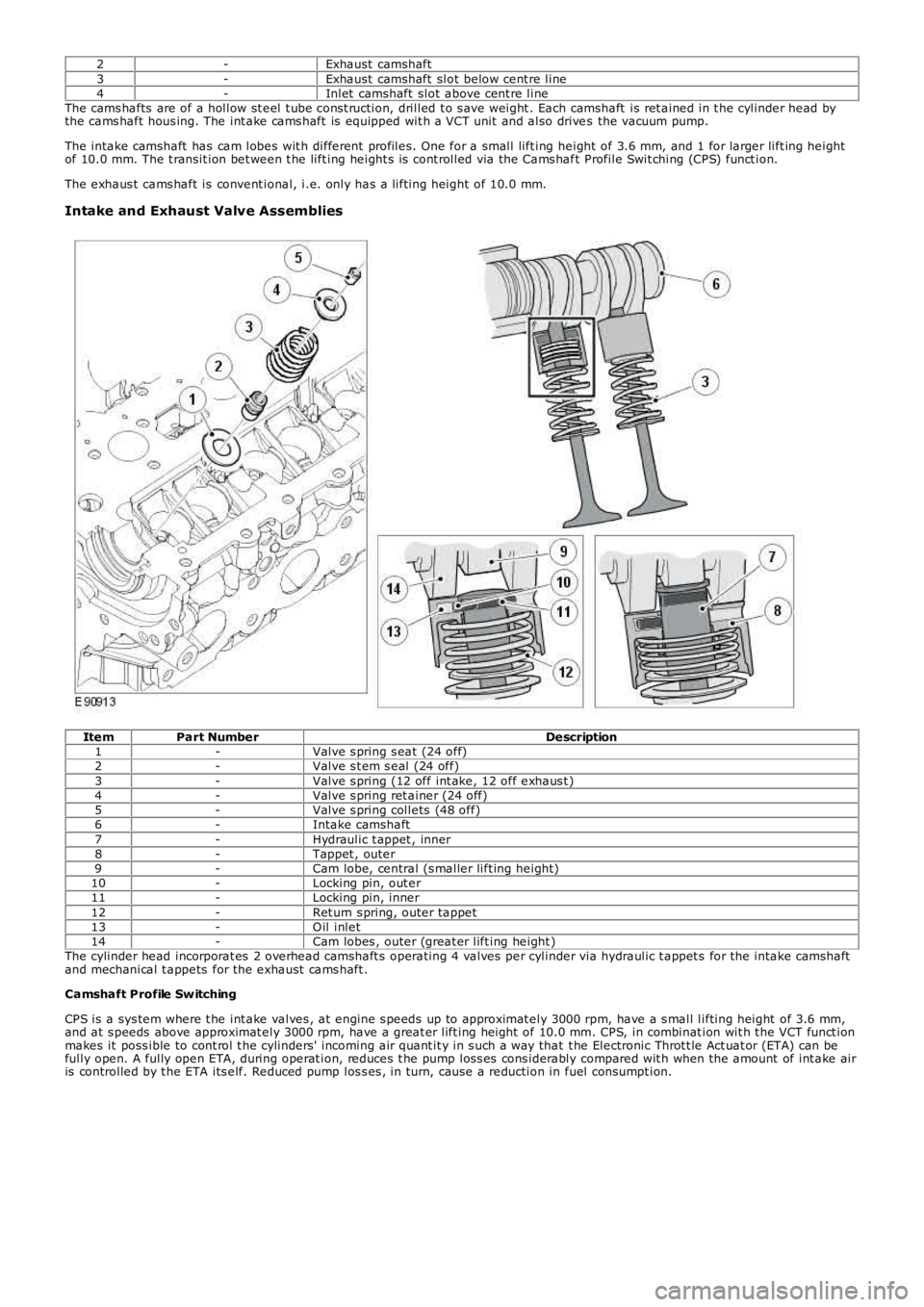

Camshafts

ItemPart NumberDescription1-Int ake cams haft

Page 620 of 3229

2-Exhaust camshaft3-Exhaust camshaft slot below cent re line4-Inlet camshaft slot above cent re lineThe cams hafts are of a hollow st eel t ube cons t ruction, drilled t o s ave weight . Each camshaft is ret ained in t he cylinder head bythe cams haft hous ing. The int ake cams haft is equipped wit h a VCT unit and also drives the vacuum pump.

The intake camshaft has cam lobes wit h different profiles. One for a small lift ing height of 3.6 mm, and 1 for larger lift ing heightof 10.0 mm. The t ransit ion bet ween t he lift ing height s is cont rolled via the Cams haft Profile Swit ching (CPS) funct ion.

The exhaus t cams haft is convent ional, i.e. only has a lifting height of 10.0 mm.

Intake and Exhaust Valve Assemblies

ItemPart NumberDescription1-Valve s pring s eat (24 off)2-Valve s t em s eal (24 off)3-Valve s pring (12 off int ake, 12 off exhaus t )4-Valve s pring ret ainer (24 off)5-Valve s pring collets (48 off)6-Intake camshaft7-Hydraulic t appet , inner8-Tappet , outer9-Cam lobe, central (s maller lift ing height)10-Locking pin, out er11-Locking pin, inner12-Ret urn s pring, outer tappet13-O il inlet14-Cam lobes , outer (great er lift ing height )The cylinder head incorporat es 2 overhead camshaft s operating 4 valves per cylinder via hydraulic t appet s for the intake camshaftand mechanical t appets for the exhaust cams haft .

Camshaft Profile Sw itching

CPS is a sys tem where t he int ake valves , at engine s peeds up to approximat ely 3000 rpm, have a s mall lifting height of 3.6 mm,and at s peeds above approximat ely 3000 rpm, have a great er lift ing height of 10.0 mm. CPS, in combinat ion wit h t he VCT funct ionmakes it poss ible to cont rol t he cylinders' incoming air quant it y in s uch a way that t he Electronic Throt t le Act uat or (ETA) can befully open. A fully open ETA, during operat ion, reduces t he pump los s es cons iderably compared wit h when the amount of int ake airis controlled by t he ETA its elf. Reduced pump los s es , in turn, cause a reduction in fuel consumpt ion.