LAND ROVER FRELANDER 2 2006 Repair Manual

FRELANDER 2 2006

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57251/w960_57251-0.png

LAND ROVER FRELANDER 2 2006 Repair Manual

Trending: start stop button, fuse box, ground clearance, light, child restraint, weight, power steering fluid

Page 571 of 3229

Publi s hed: 11-May-2011

Steering Column - Steering Column

Des cript ion and Operat ion

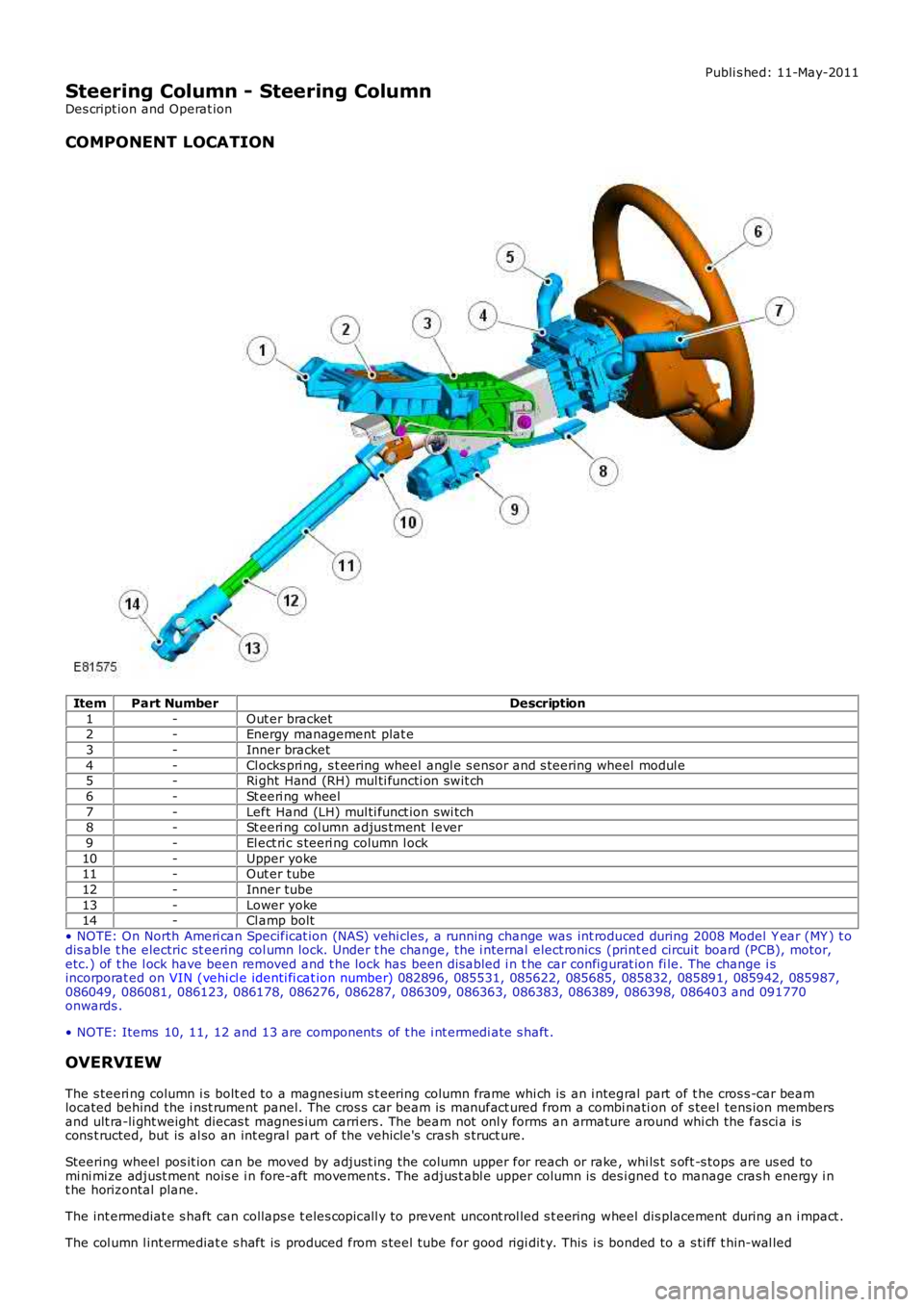

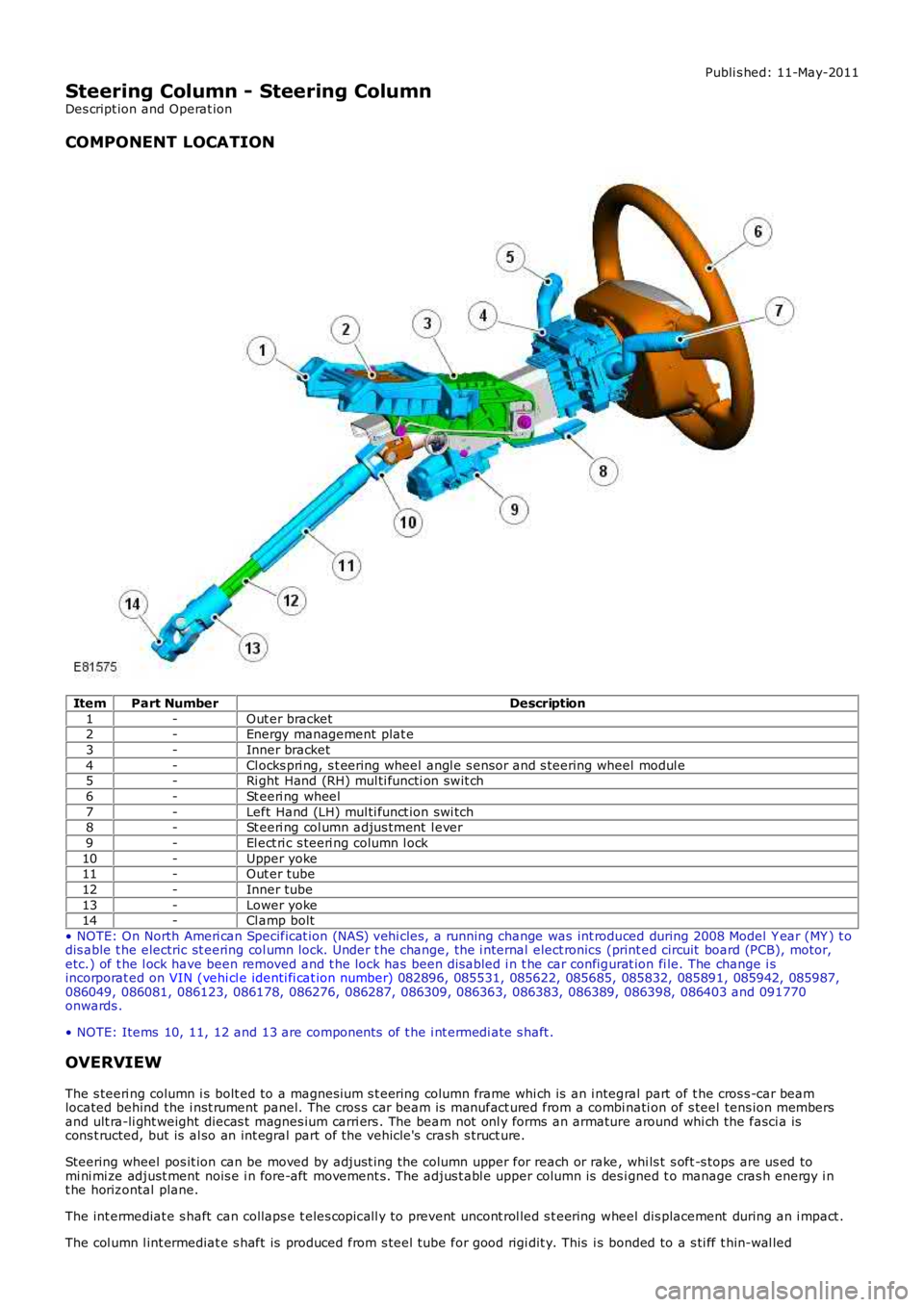

COMPONENT LOCATION

ItemPart NumberDescription

1-Out er bracket2-Energy management plat e

3-Inner bracket

4-Cl ocks pri ng, s t eering wheel angl e s ensor and s teering wheel modul e5-Ri ght Hand (RH) mul ti functi on swit ch

6-St eeri ng wheel

7-Left Hand (LH) mul ti funct ion swi tch8-St eeri ng col umn adjus tment l ever

9-El ect ri c s teeri ng column l ock

10-Upper yoke11-Out er tube

12-Inner tube

13-Lower yoke14-Cl amp bolt

• NOTE: On North Ameri can Specificat ion (NAS) vehi cles , a running change was int roduced during 2008 Model Y ear (MY ) t odis able t he electric st eering col umn lock. Under t he change, the i nternal elect ronics (print ed circuit board (PCB), motor,etc.) of t he l ock have been removed and t he lock has been dis abled i n t he car configurat ion fi le. The change i sincorporat ed on VIN (vehi cl e identi fi cat ion number) 082896, 085531, 085622, 085685, 085832, 085891, 085942, 085987,086049, 086081, 086123, 086178, 086276, 086287, 086309, 086363, 086383, 086389, 086398, 086403 and 091770onwards .

• NOTE: Items 10, 11, 12 and 13 are components of t he i nt ermedi ate s haft .

OVERVIEW

The s teeri ng column i s bolt ed to a magnesi um s t eering column frame whi ch is an i ntegral part of t he cros s -car beamlocated behind the i nst rument panel. The cros s car beam is manufact ured from a combinati on of s teel tens ion membersand ult ra-li ght weight diecas t magnes ium carri ers . The beam not onl y forms an armature around whi ch the fasci a iscons t ructed, but is al so an int egral part of the vehicle's crash s truct ure.

Steering wheel pos it ion can be moved by adjust ing the column upper for reach or rake, whi ls t s oft -s tops are us ed tomi ni mi ze adjust ment nois e i n fore-aft movement s. The adjus t abl e upper column is des igned t o manage cras h energy i nt he horizontal plane.

The int ermediat e s haft can collaps e t eles copicall y to prevent uncont rol led s t eering wheel dis placement during an i mpact .

The col umn l int ermediat e s haft is produced from s teel tube for good rigi dit y. This is bonded to a s ti ff t hin-wal led

Page 572 of 3229

elas tomer t o i sol at e road nois e.

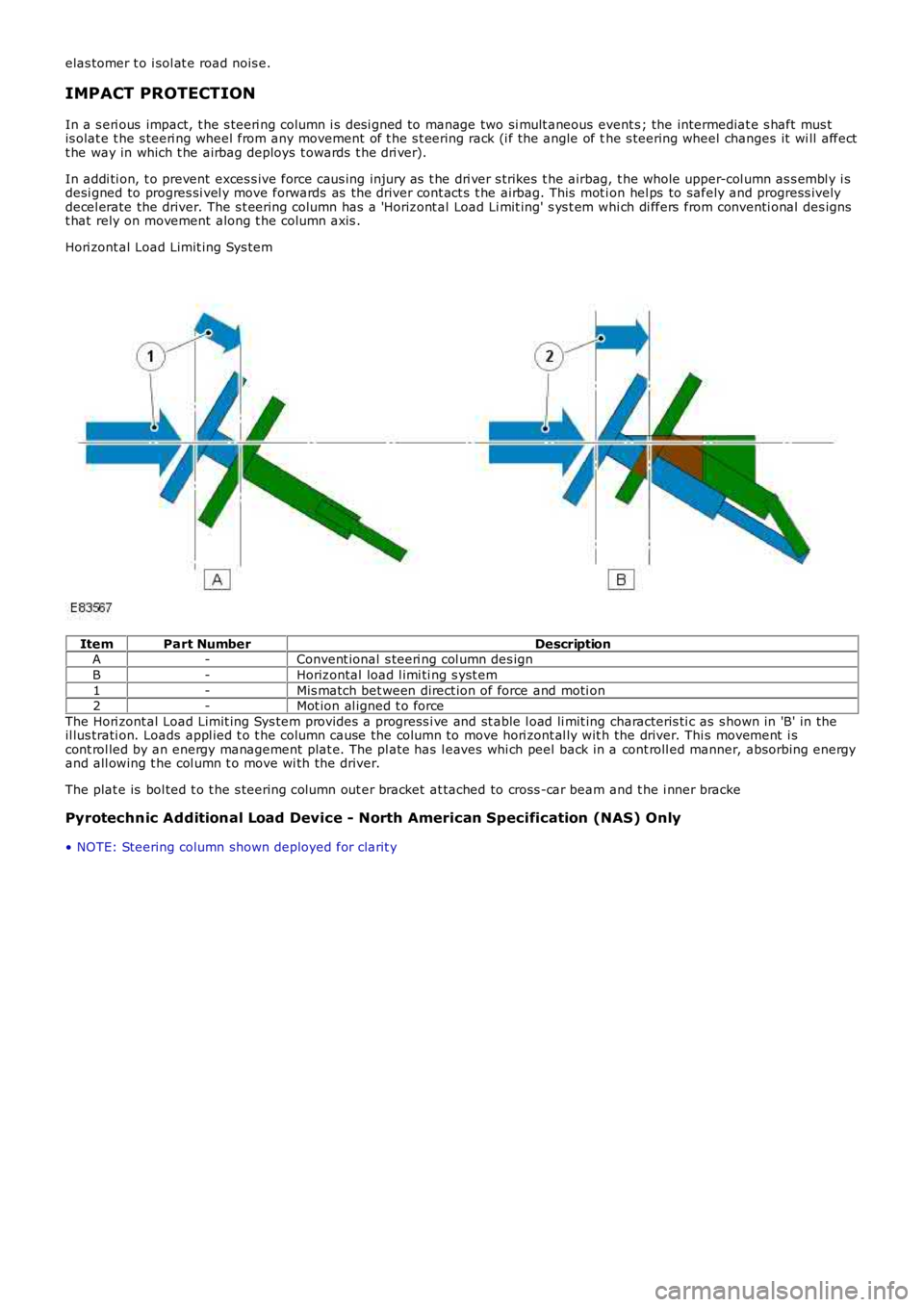

IMPACT PROTECTION

In a s eri ous impact, t he s teeri ng column i s desi gned to manage two si mult aneous event s ; the intermediat e s haft mus tis olat e t he s teeri ng wheel from any movement of t he s t eering rack (i f the angle of the s teering wheel changes it wi ll affectt he way in which t he airbag deploys t owards t he dri ver).

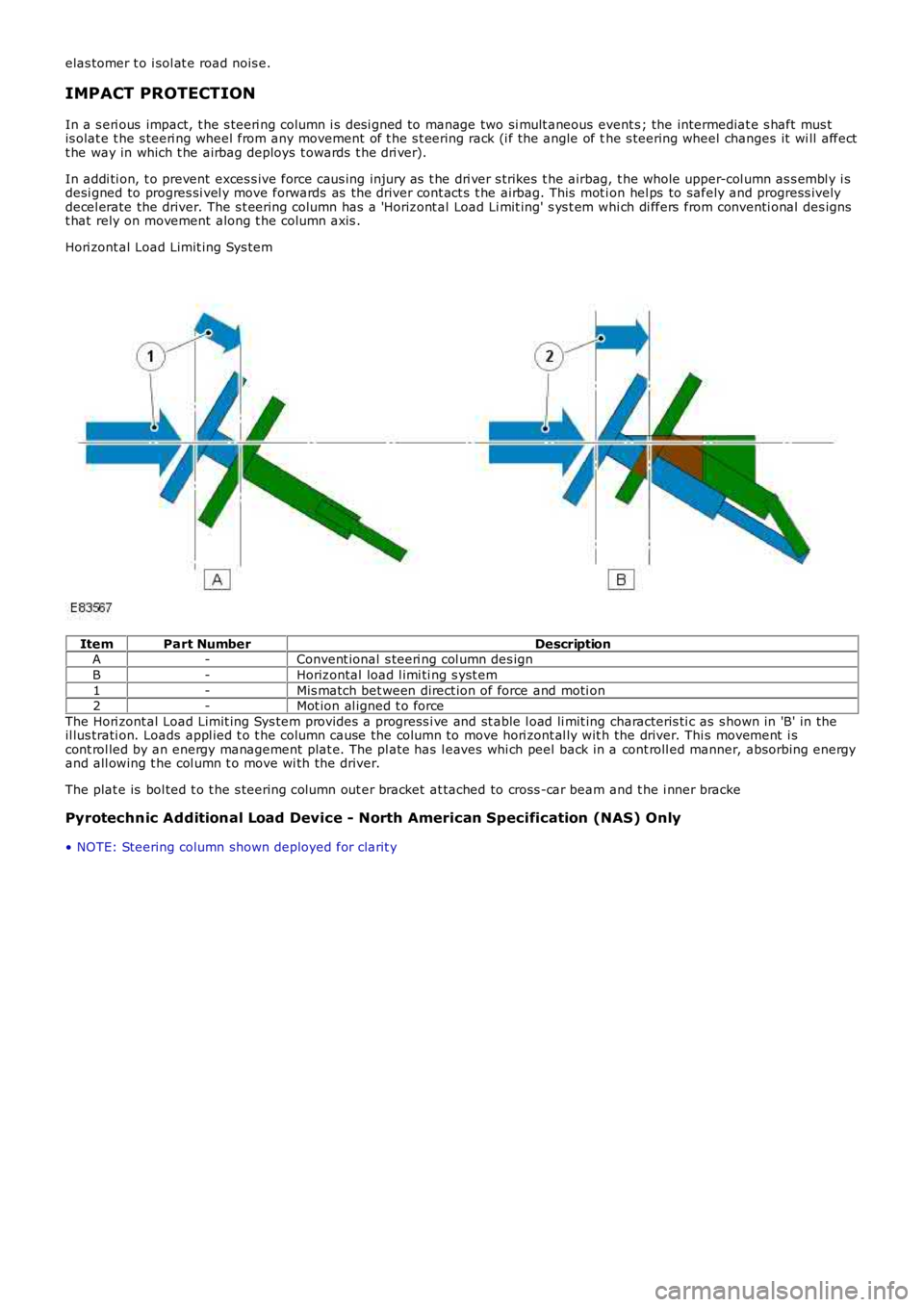

In addi ti on, t o prevent exces s ive force caus ing injury as t he dri ver s trikes t he airbag, t he whole upper-col umn as s embl y i sdesi gned to progres si vel y move forwards as the driver cont act s t he airbag. This mot ion hel ps to safely and progress ivelydecel erate the driver. The s t eering column has a 'Horizont al Load Li mit ing' s ys t em whi ch di ffers from conventi onal des ignst hat rely on movement along t he column axis .

Hori zont al Load Limit ing Sys tem

ItemPart NumberDescriptionA-Convent ional s teeri ng col umn des ign

B-Horizontal load l imi ti ng s yst em

1-Mis match bet ween direct ion of force and moti on2-Mot ion al igned t o force

The Hori zont al Load Limit ing Sys tem provides a progress i ve and st able l oad li mit ing characteris ti c as s hown in 'B' in theil lus trati on. Loads appl ied t o t he column cause the column to move hori zont al ly wit h the driver. Thi s movement i scont rol led by an energy management plat e. The pl ate has l eaves whi ch peel back in a cont roll ed manner, absorbing energyand all owing t he col umn t o move wi th the driver.

The plat e is bol ted t o t he s teering column out er bracket at tached to cross -car beam and t he i nner bracke

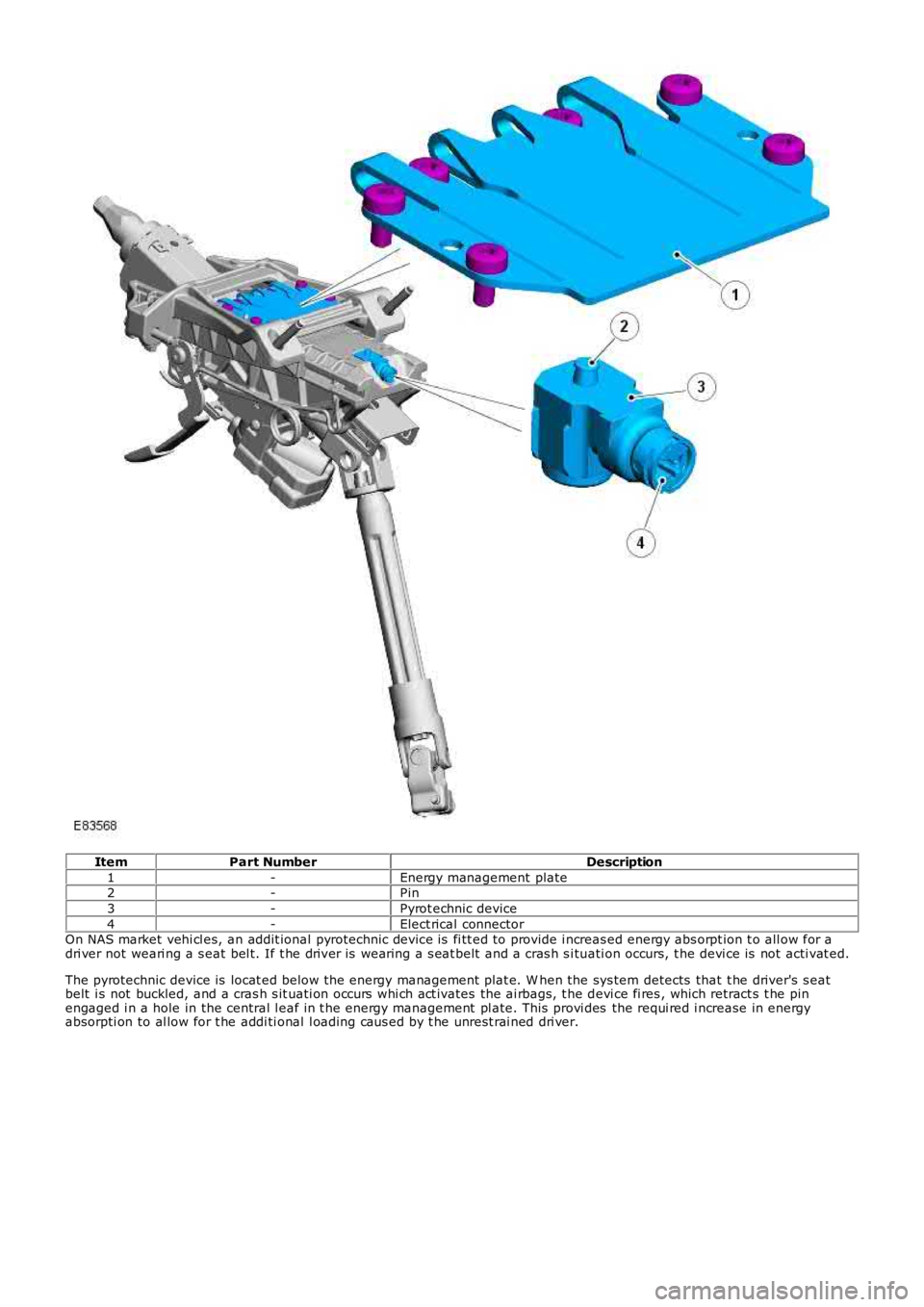

Pyrotechnic Additional Load Device - North American Specification (NAS) Only

• NOTE: Steering column shown deployed for clarit y

Page 573 of 3229

ItemPart NumberDescription

1-Energy management plate2-Pin

3-Pyrot echnic device

4-Elect rical connectorOn NAS market vehi cl es, an addit ional pyrotechnic device is fi tt ed to provide i ncreas ed energy abs orpt ion t o all ow for adri ver not weari ng a s eat bel t. If t he driver is wearing a s eat belt and a cras h s i tuati on occurs, t he devi ce is not acti vat ed.

The pyrotechnic device is locat ed below the energy management plat e. W hen the sys tem detects that t he driver's s eatbelt i s not buckled, and a cras h s it uati on occurs whi ch act ivates the ai rbags, t he devi ce fi res , which retract s t he pinengaged i n a hole in the central l eaf in t he energy management pl ate. This provi des the requi red i ncrease in energyabsorpti on to al low for t he addi ti onal l oading caus ed by t he unrest rai ned dri ver.

Page 574 of 3229

Publi s hed: 11-May-2011

Steering Column - Steering Column

Diagnosi s and Tes ti ng

For addit ional informat ion.

REFER to: St eering Sys tem (211-00 Steeri ng Sys t em - General Informati on, Di agnos is and Tes ti ng).

Page 575 of 3229

Publi s hed: 11-May-2011

Steering Column - Steering Wheel

Removal and Inst all ati on

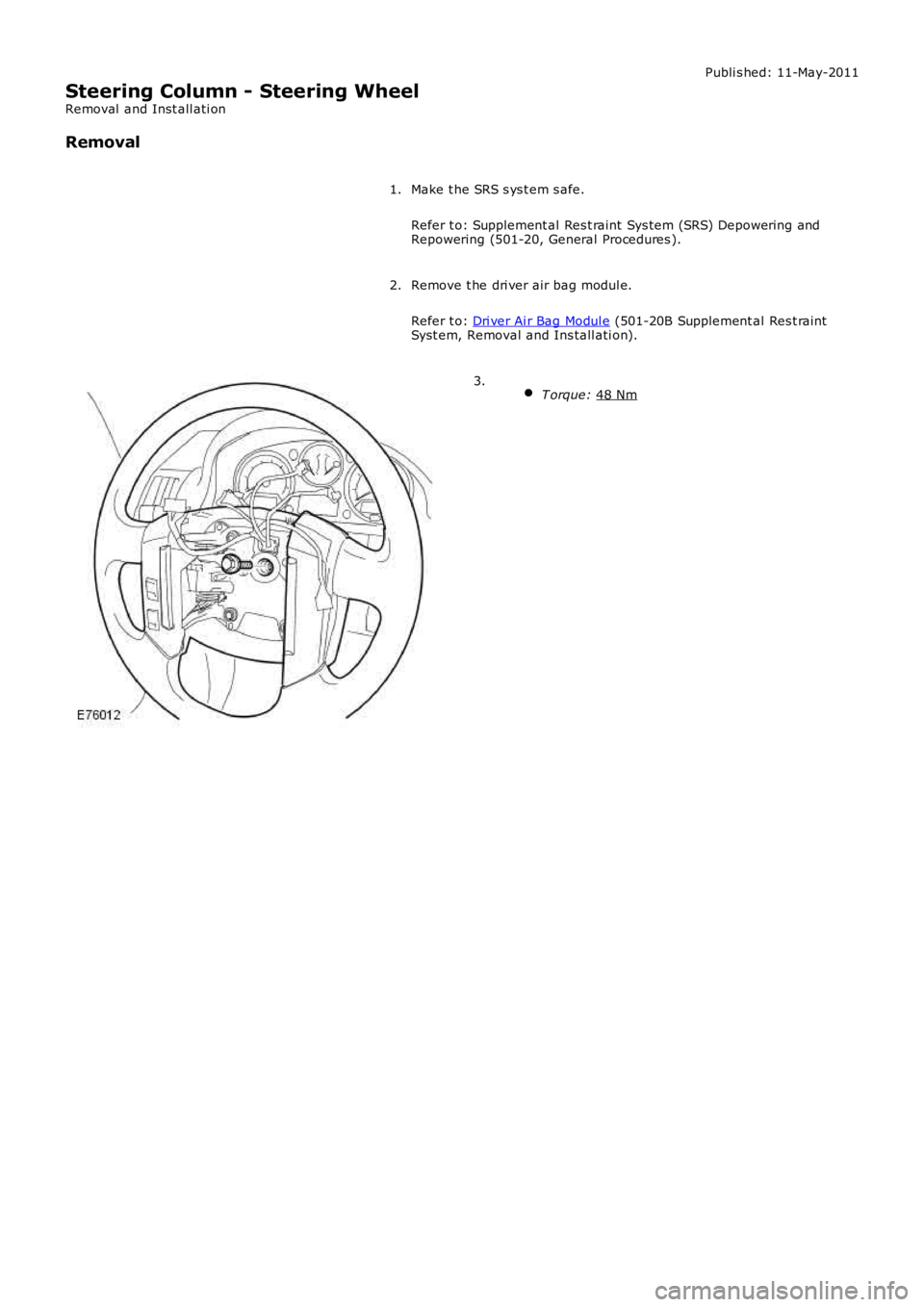

Removal

Make t he SRS s ys t em s afe.

Refer t o: Supplement al Res t raint Sys tem (SRS) Depowering and

Repowering (501-20, General Procedures ).

1.

Remove t he dri ver air bag modul e.

Refer t o: Dri ver Ai r Bag Modul e (501-20B Supplement al Res t raint

Syst em, Removal and Ins tall ati on).

2.

T orque: 48 Nm 3.

Page 576 of 3229

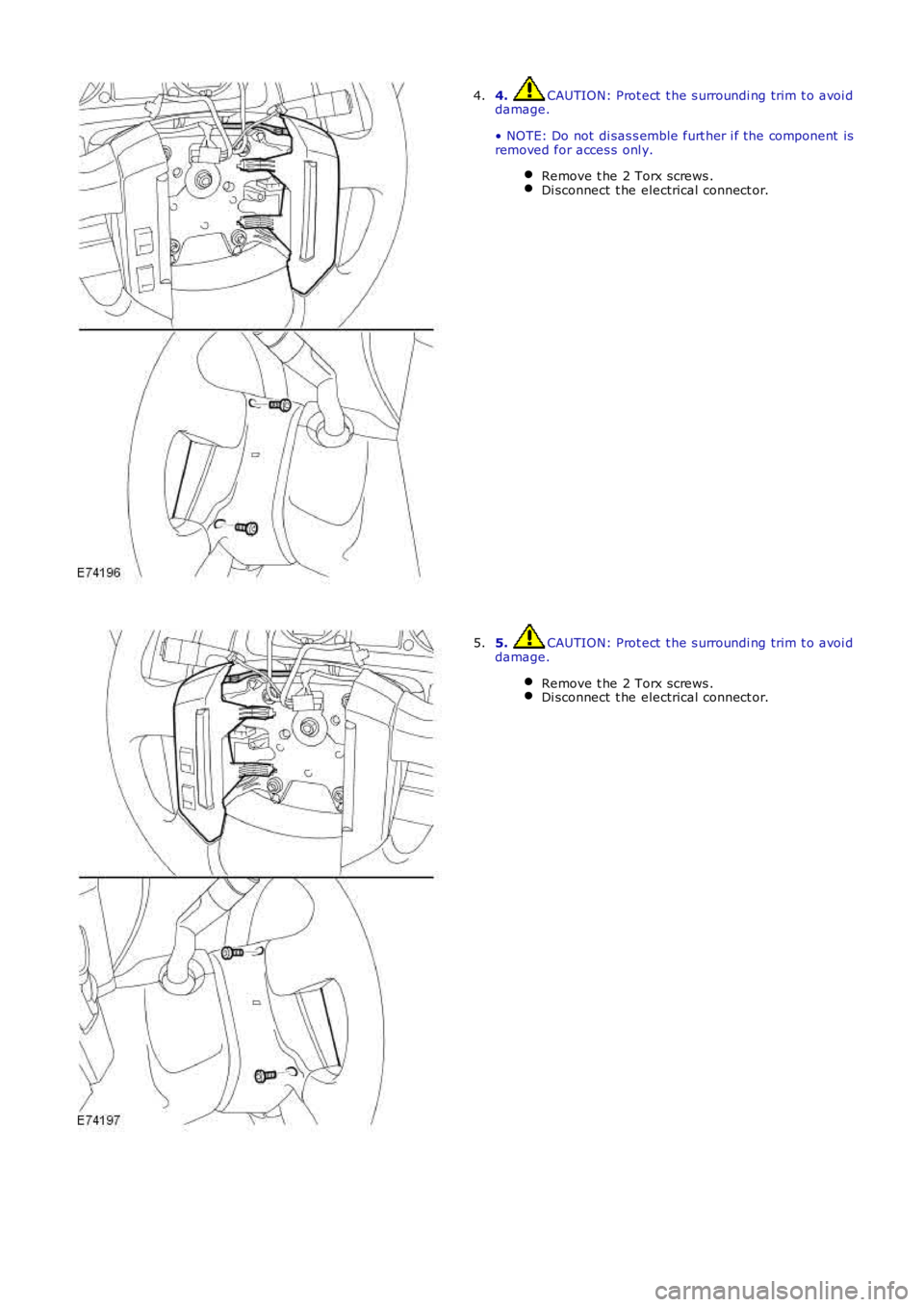

4. CAUTION: Prot ect t he s urroundi ng trim t o avoi ddamage.

• NOTE: Do not di sas s emble furt her i f the component isremoved for acces s onl y.

Remove t he 2 Torx screws .Di sconnect t he electrical connect or.

4.

5. CAUTION: Prot ect t he s urroundi ng trim t o avoi ddamage.

Remove t he 2 Torx screws .Di sconnect t he electrical connect or.

5.

Page 577 of 3229

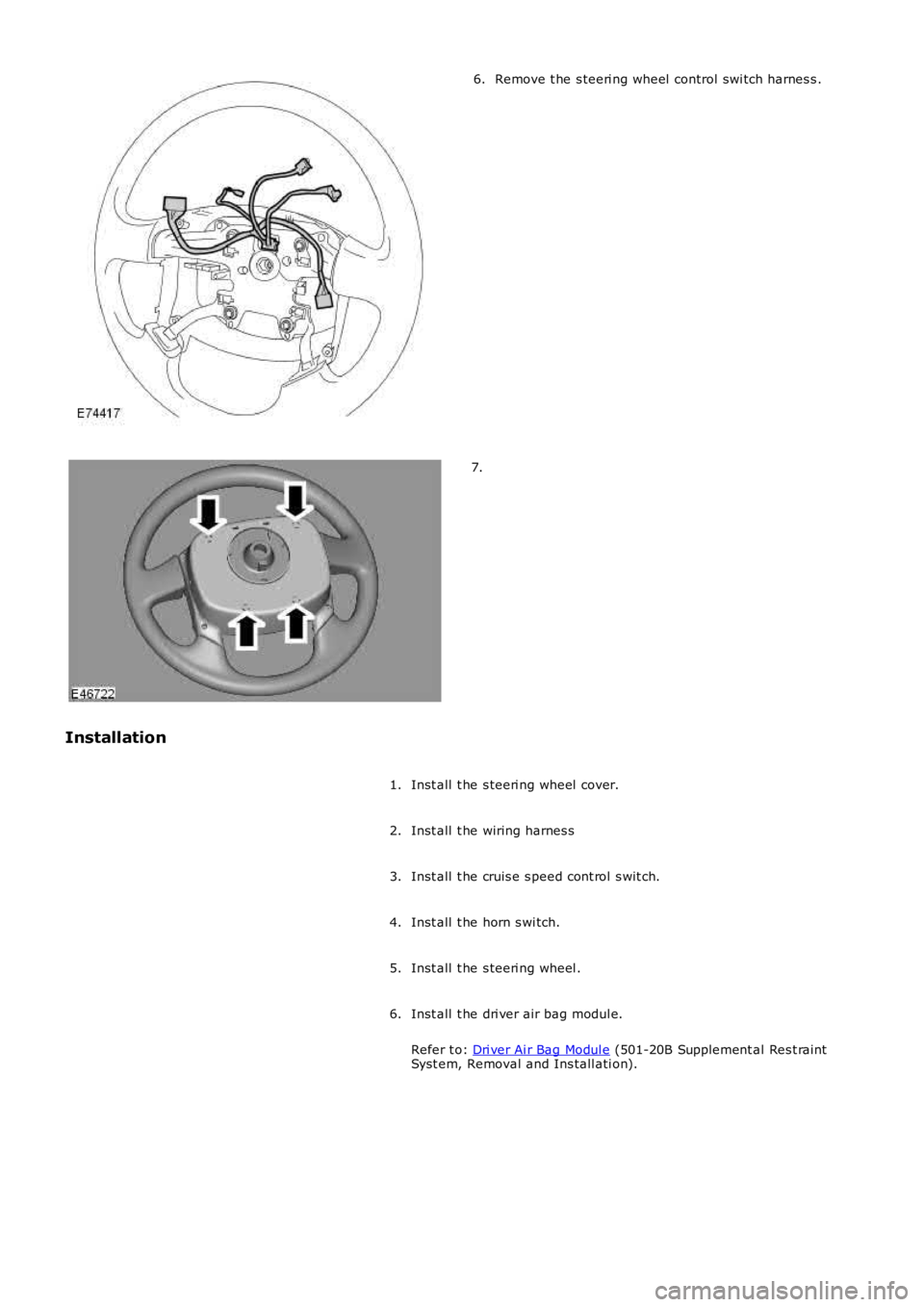

Remove t he s teeri ng wheel control swi tch harnes s .6.

7.

Installation

Inst all t he s teeri ng wheel cover.1.

Inst all t he wiring harnes s2.

Inst all t he cruis e s peed cont rol s wit ch.3.

Inst all t he horn s wi tch.4.

Inst all t he s teeri ng wheel .5.

Inst all t he dri ver air bag modul e.

Refer t o: Dri ver Ai r Bag Modul e (501-20B Supplement al Res t raintSyst em, Removal and Ins tall ati on).

6.

Page 578 of 3229

Publi s hed: 11-May-2011

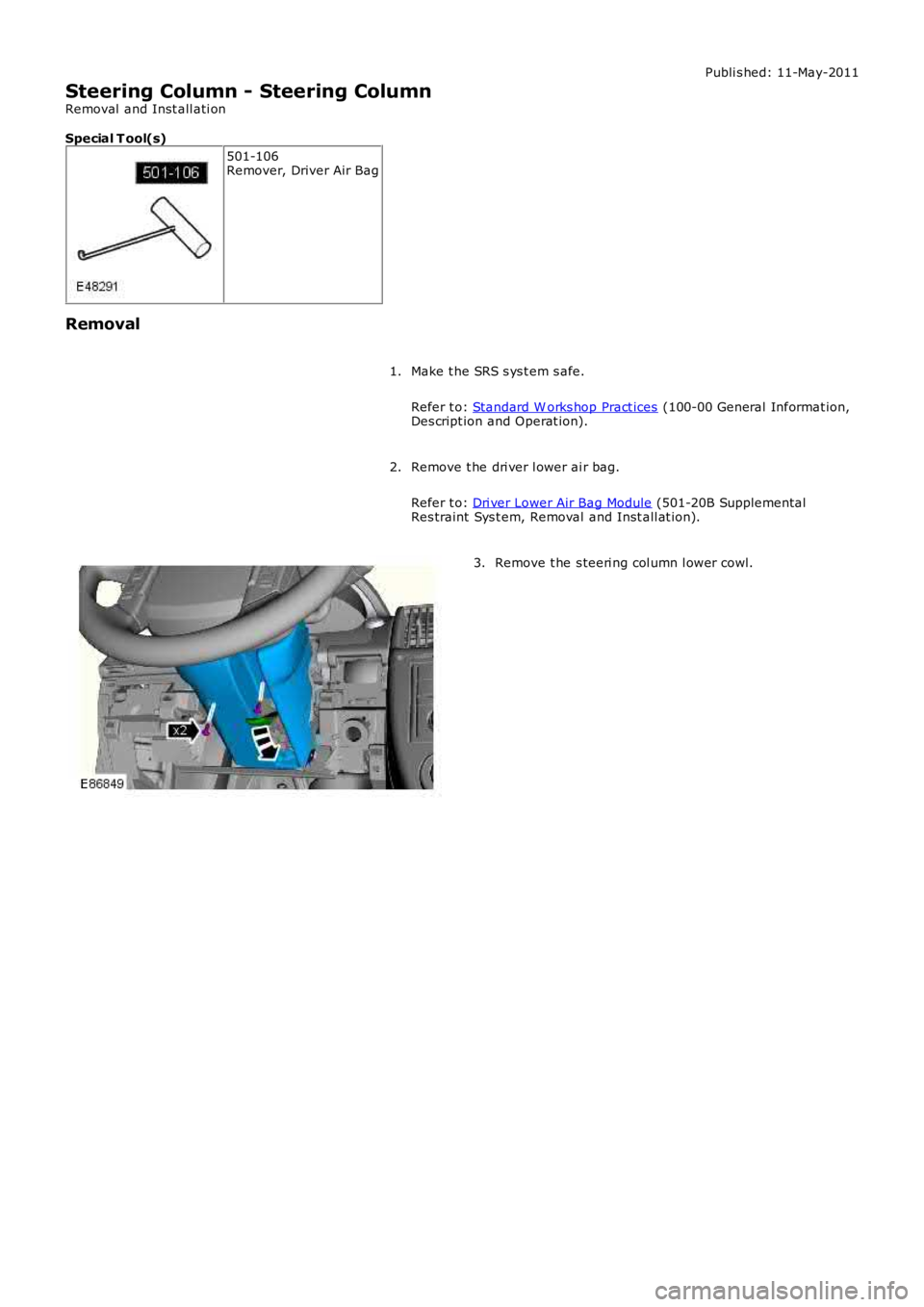

Steering Column - Steering Column

Removal and Inst all ati on

Special T ool(s)

501-106Remover, Driver Air Bag

Removal

Make t he SRS s ys t em s afe.

Refer t o: Standard W orks hop Pract ices (100-00 General Informat ion,Des cript ion and Operat ion).

1.

Remove t he dri ver l ower ai r bag.

Refer t o: Dri ver Lower Air Bag Module (501-20B SupplementalRes traint Sys t em, Removal and Inst all at ion).

2.

Remove t he s teeri ng col umn l ower cowl.3.

Page 579 of 3229

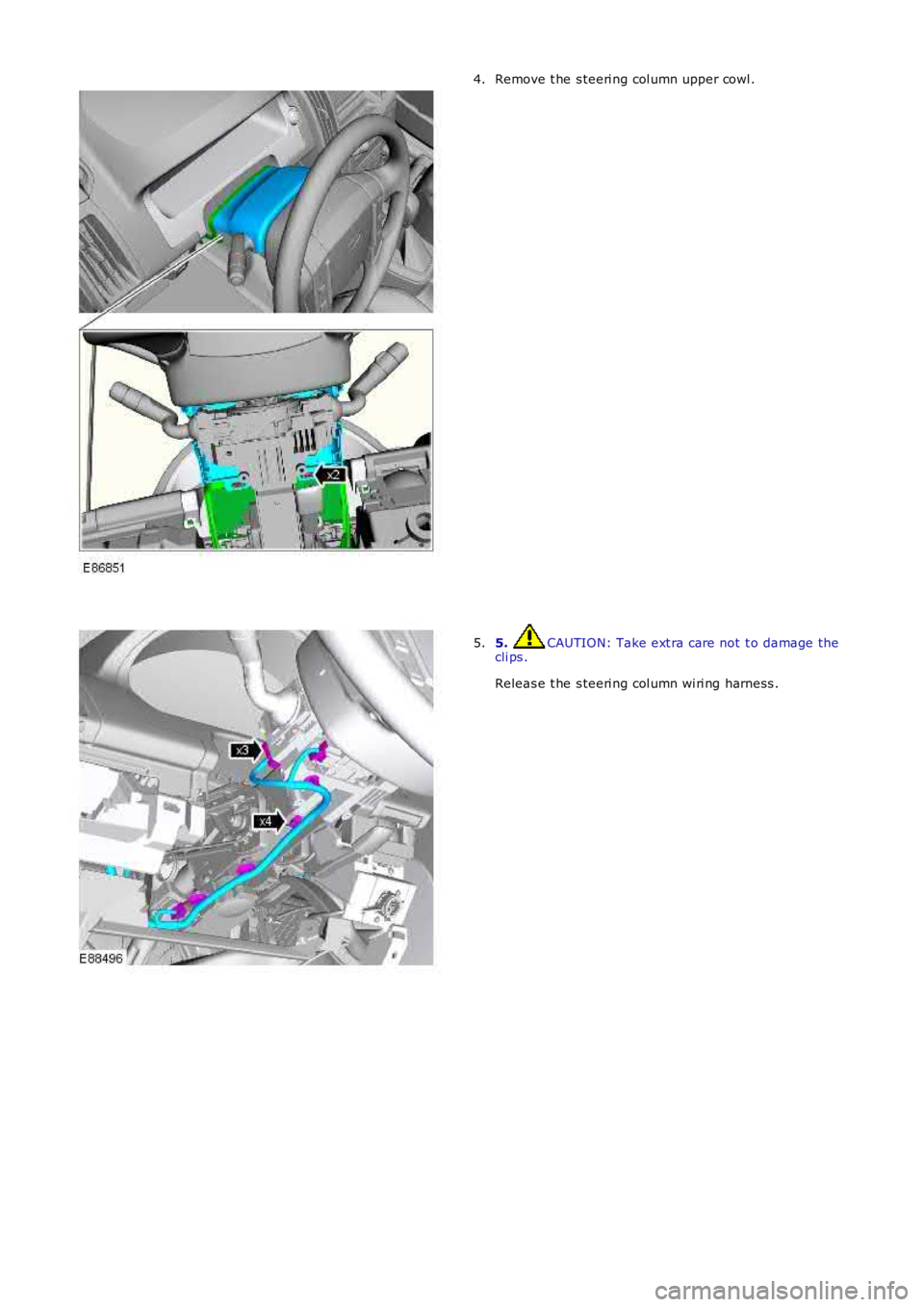

Remove t he s teeri ng col umn upper cowl .4.

5. CAUTION: Take ext ra care not t o damage thecli ps .

Releas e t he s teeri ng col umn wi ri ng harness .

5.

Page 580 of 3229

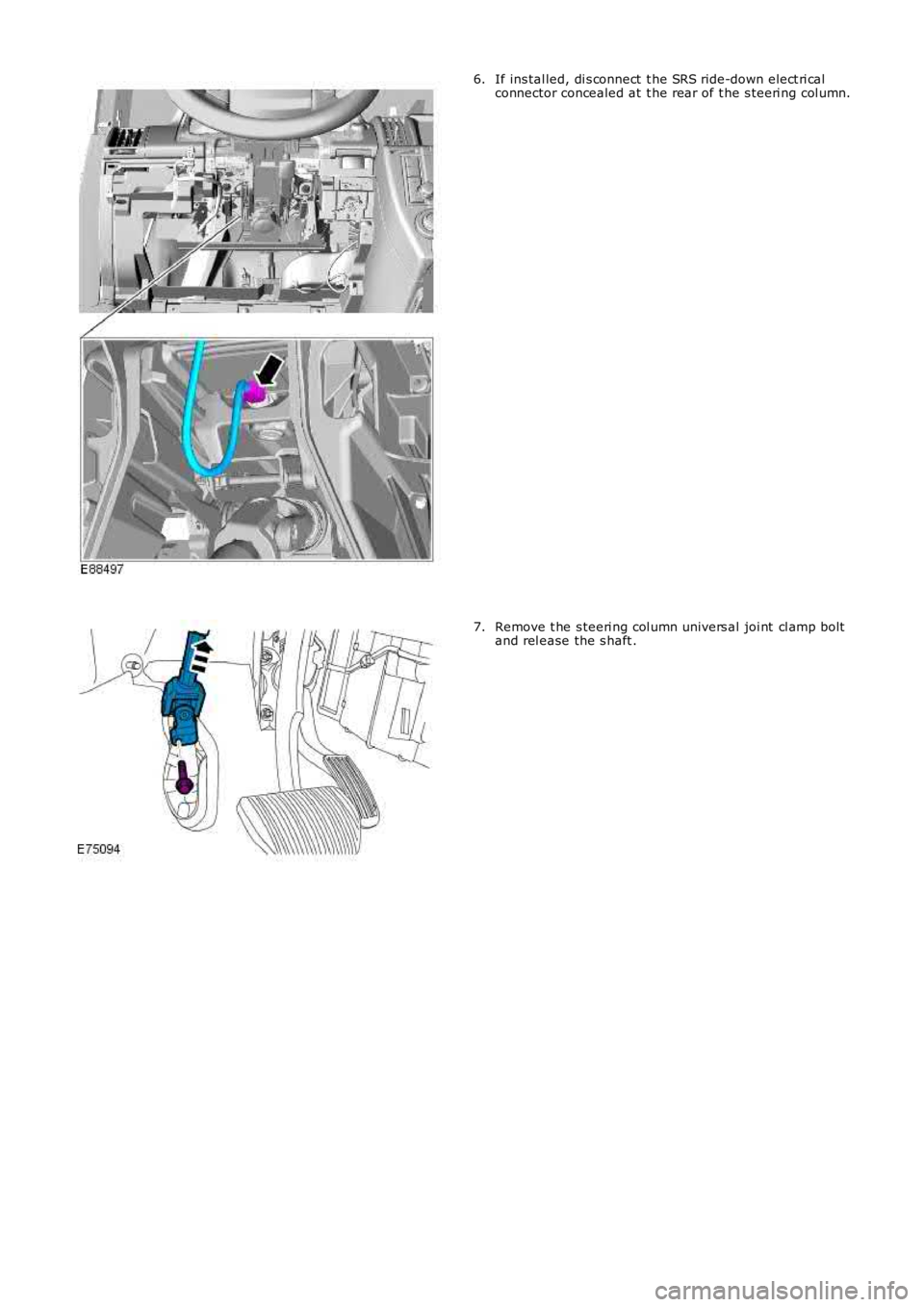

If ins tal led, di s connect t he SRS ride-down el ect ri calconnector concealed at t he rear of t he s teeri ng col umn.6.

Remove t he s teeri ng col umn univers al joi nt cl amp boltand rel ease the s haft .7.

Trending: brake, seats, refrigerant type, fuel cap release, tire size, spark plugs, cabin filter