LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: STARTER, sensor, child lock, wipers, length, head, camshaft service

Page 1041 of 4500

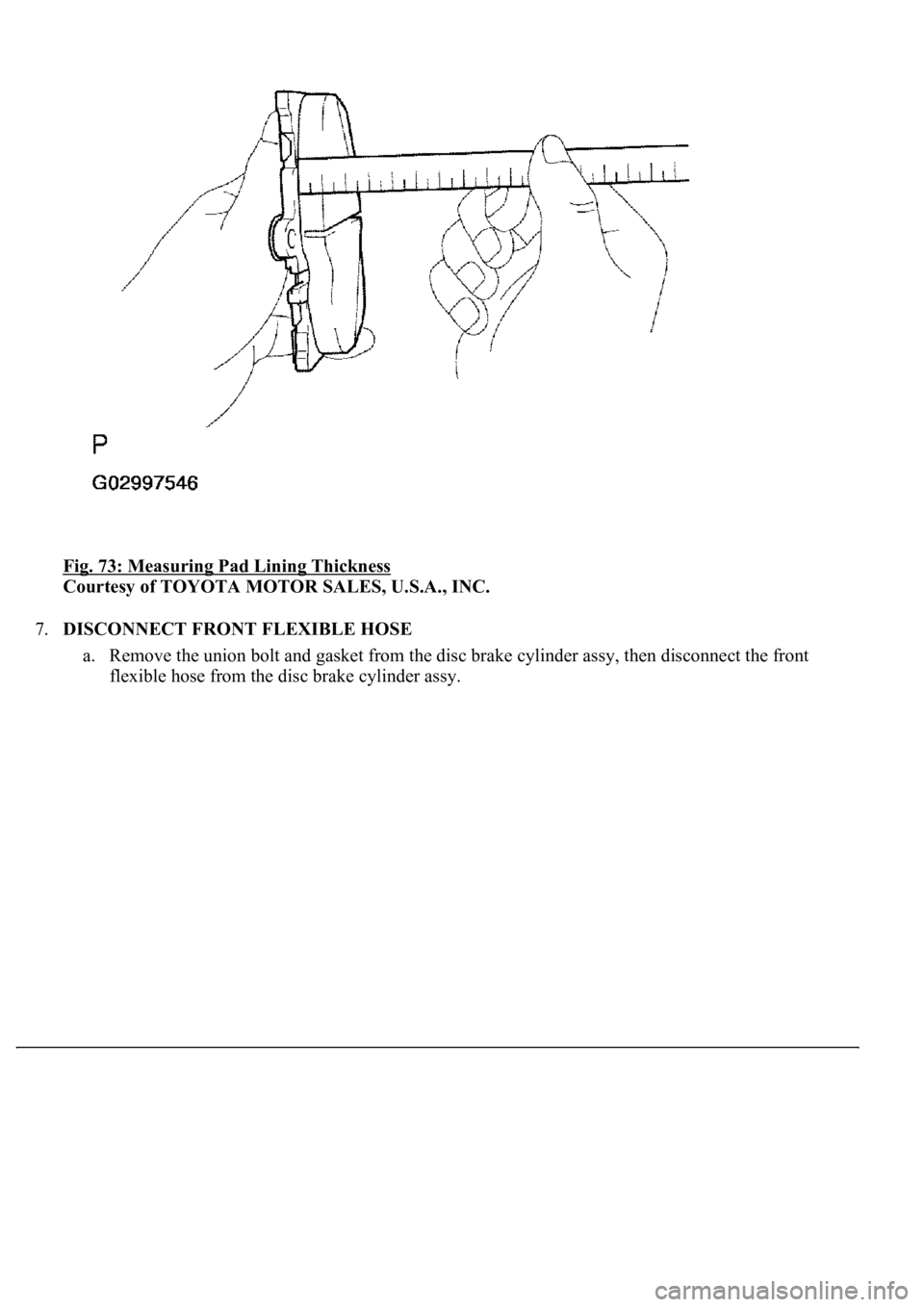

Fig. 73: Measuring Pad Lining Thickness

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

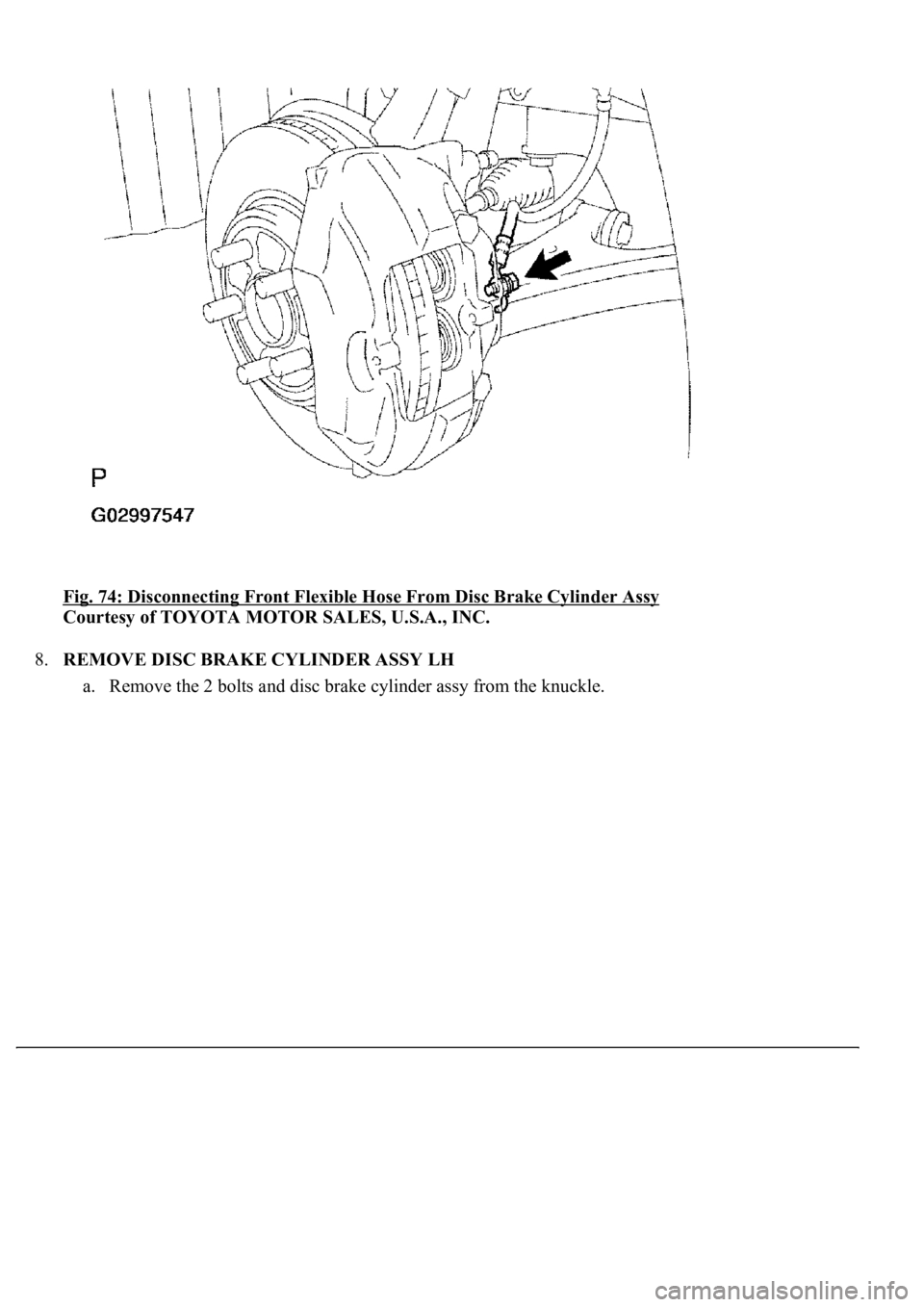

7.DISCONNECT FRONT FLEXIBLE HOSE

a. Remove the union bolt and gasket from the disc brake cylinder assy, then disconnect the front

flexible hose from the disc brake c

ylinder assy.

Page 1042 of 4500

Fig. 74: Disconnecting Front Flexible Hose From Disc Brake Cylinder Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

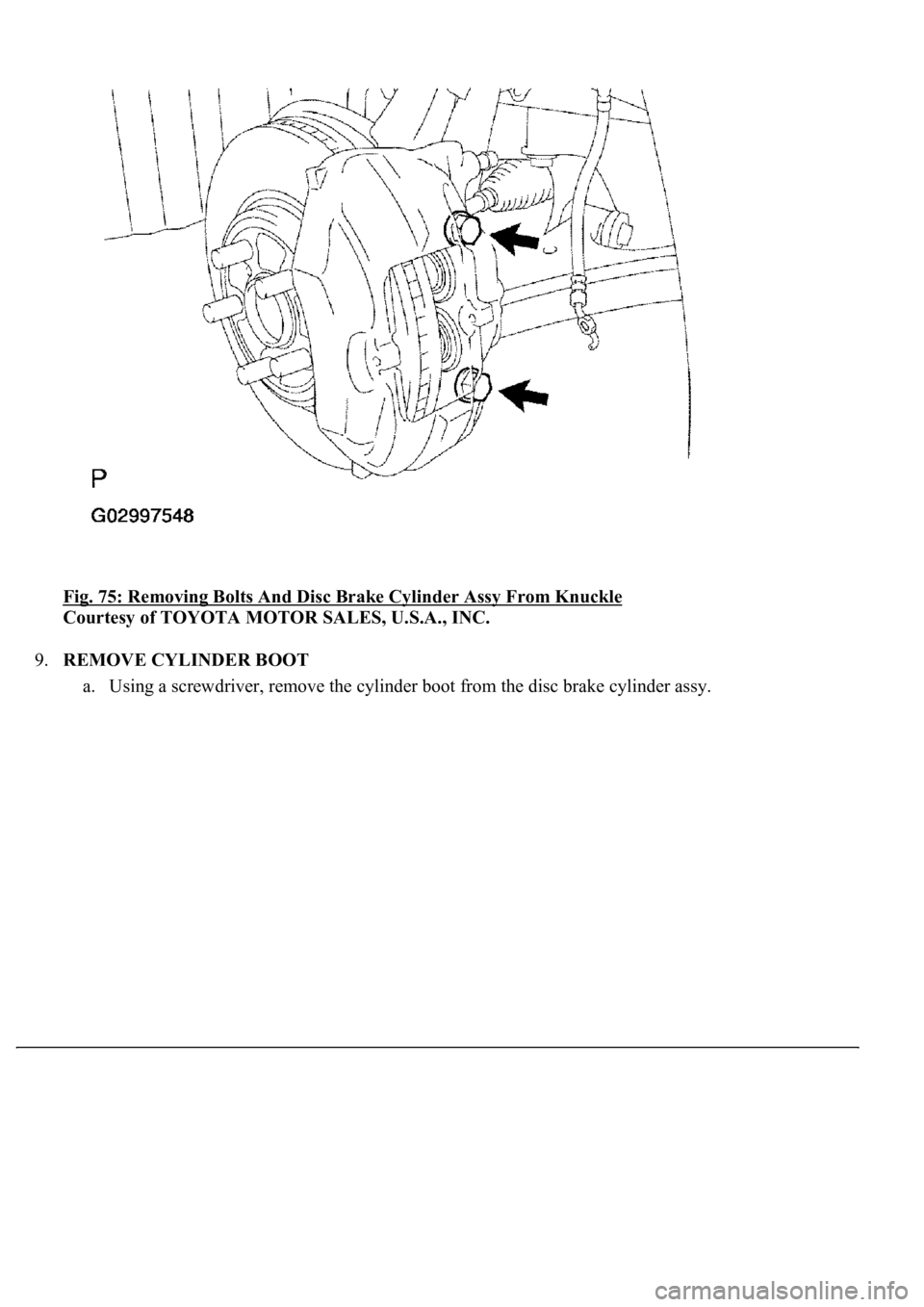

8.REMOVE DISC BRAKE CYLINDER ASSY LH

a. Remove the 2 bolts and disc brake c

ylinder assy from the knuckle.

Page 1043 of 4500

Fig. 75: Removing Bolts And Disc Brake Cylinder Assy From Knuckle

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

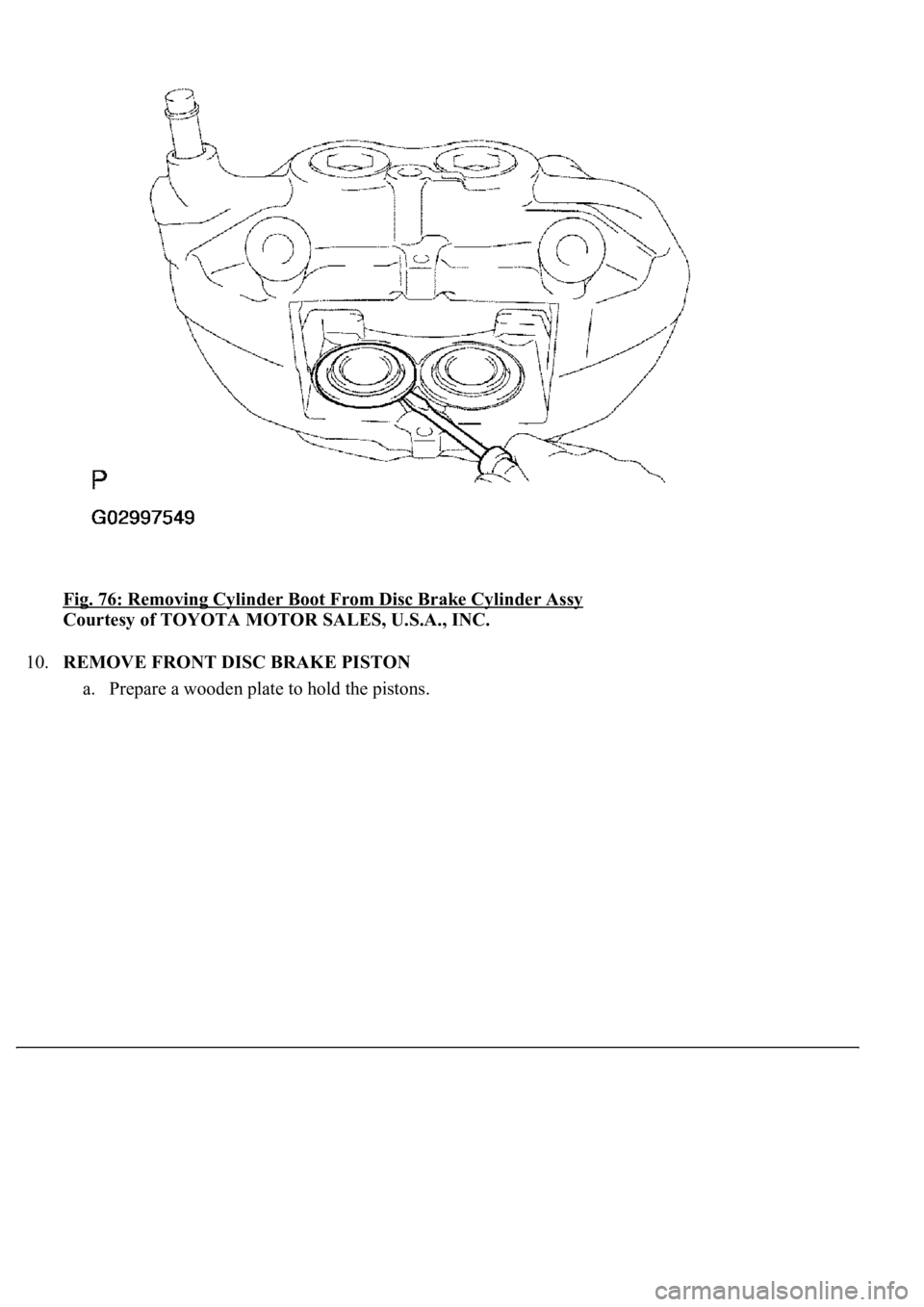

9.REMOVE CYLINDER BOOT

a. Using a screwdriver, remove the cylinder boot from the disc brake cylinder assy.

Page 1044 of 4500

Fig. 76: Removing Cylinder Boot From Disc Brake Cylinder Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10.REMOVE FRONT DISC BRAKE PISTON

a. Prepare a wooden plate to hold the pistons.

Page 1045 of 4500

Fig. 77: Preparing Wooden Plate To Hold Pistons

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Place the plate between the pistons and insert a pad into one side.

c. Use compressed air to remove the pistons alternately from the disc brake cylinder assy.

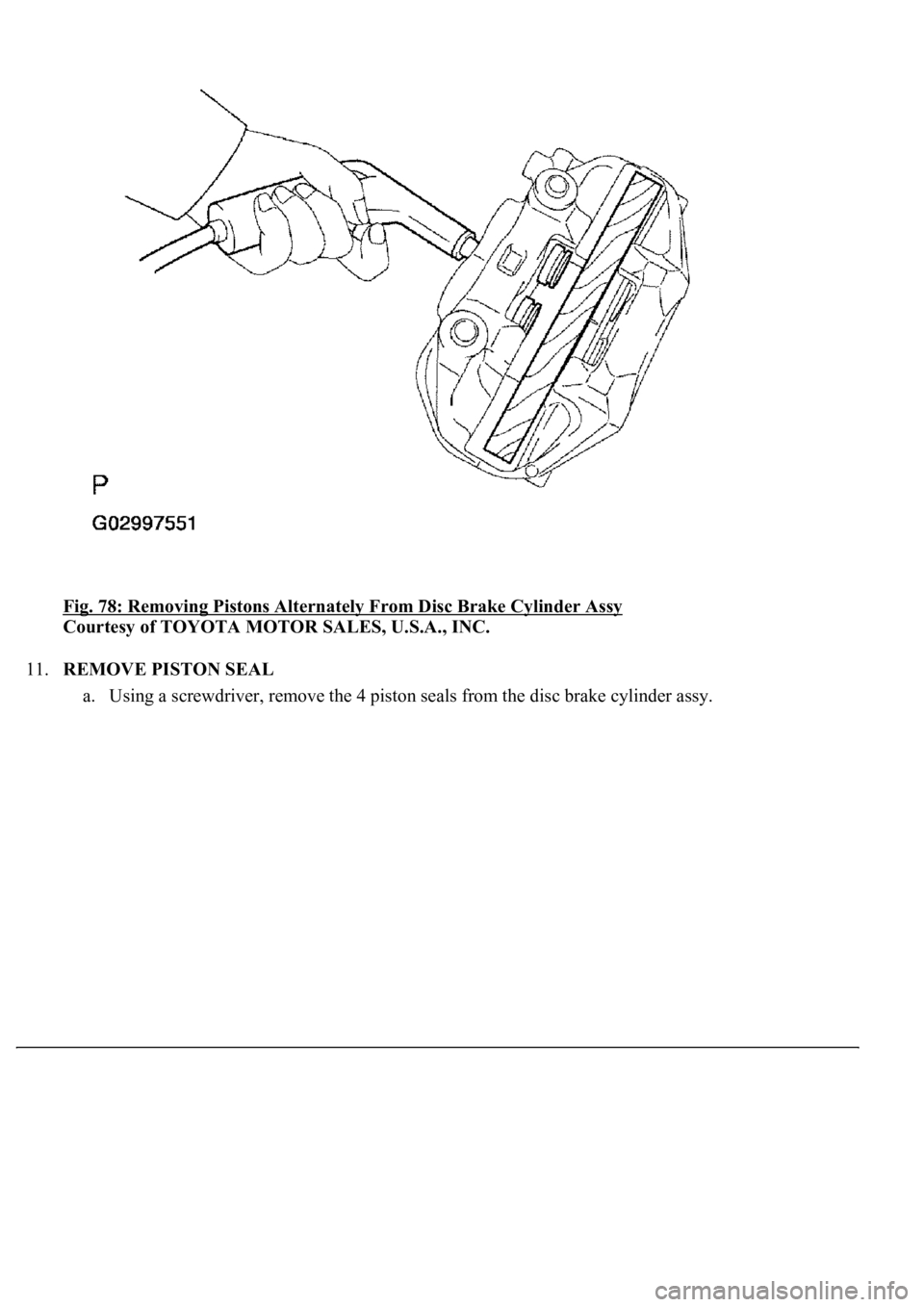

Page 1046 of 4500

Fig. 78: Removing Pistons Alternately From Disc Brake Cylinder Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

11.REMOVE PISTON SEAL

a. Usin

g a screwdriver, remove the 4 piston seals from the disc brake cylinder assy.

Page 1047 of 4500

Fig. 79: Removing Piston Seals From Disc Brake Cylinder Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

12.REMOVE FRONT DISC BRAKE BLEEDER PLUG

a. Remove the front disc brake bleeder plug from the disc brake cylinder assy.

13.INSPECT DISC THICKNESS

a. Using a micrometer, measure the disc thickness.

Standard thickness: 30.0 mm (1.181 in.)

Minimum thickness: 28.0 mm (1.102 in.)

If the disc thickness is less than the minimum, replace the disc.

Page 1048 of 4500

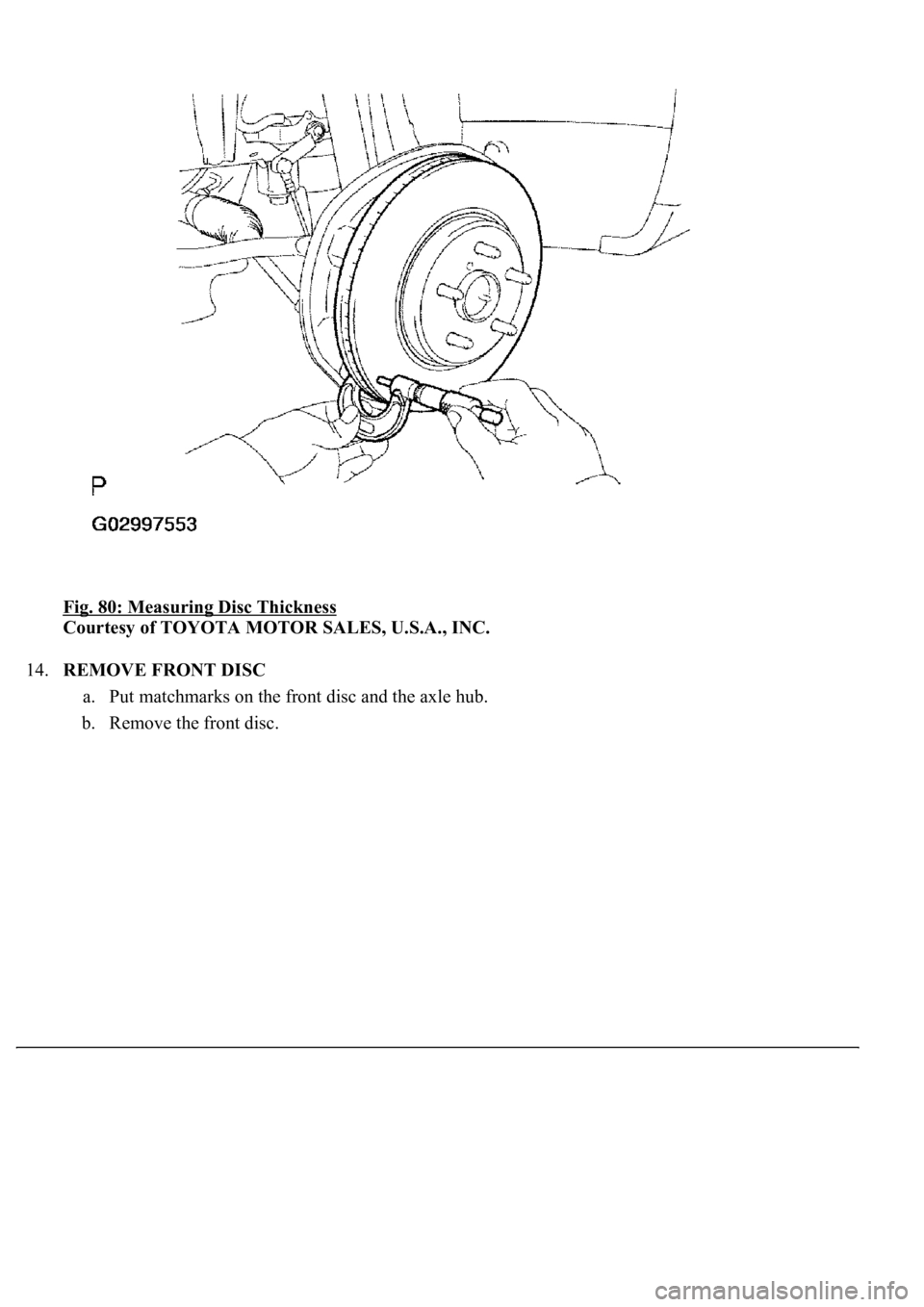

Fig. 80: Measuring Disc Thickness

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

14.REMOVE FRONT DISC

a. Put matchmarks on the front disc and the axle hub.

b. Remove the front disc.

Page 1049 of 4500

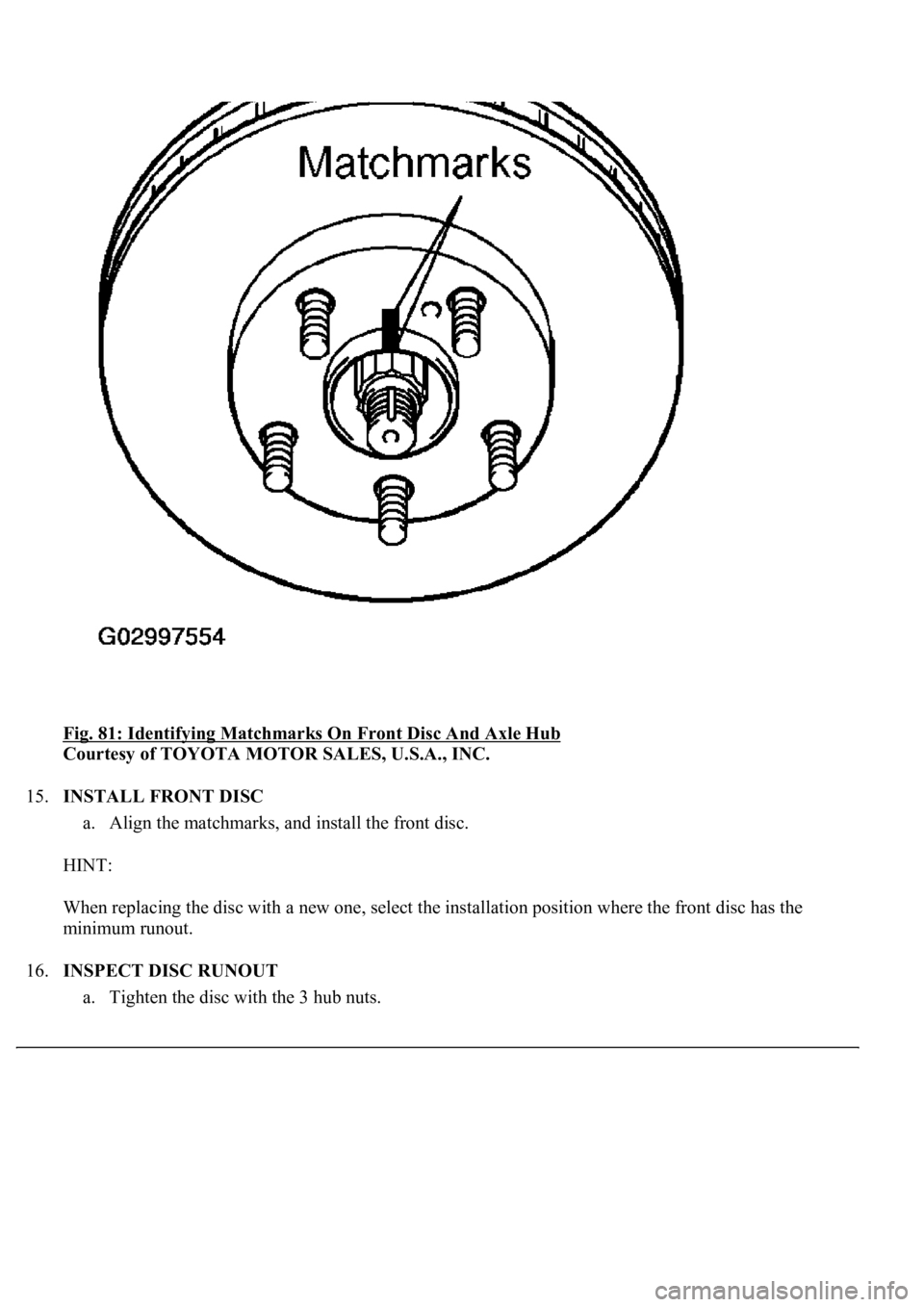

Fig. 81: Identifying Matchmarks On Front Disc And Axle Hub

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

15.INSTALL FRONT DISC

a. Align the matchmarks, and install the front disc.

HINT:

When replacing the disc with a new one, select the installation position where the front disc has the

minimum runout.

16.INSPECT DISC RUNOUT

a. Ti

ghten the disc with the 3 hub nuts.

Page 1050 of 4500

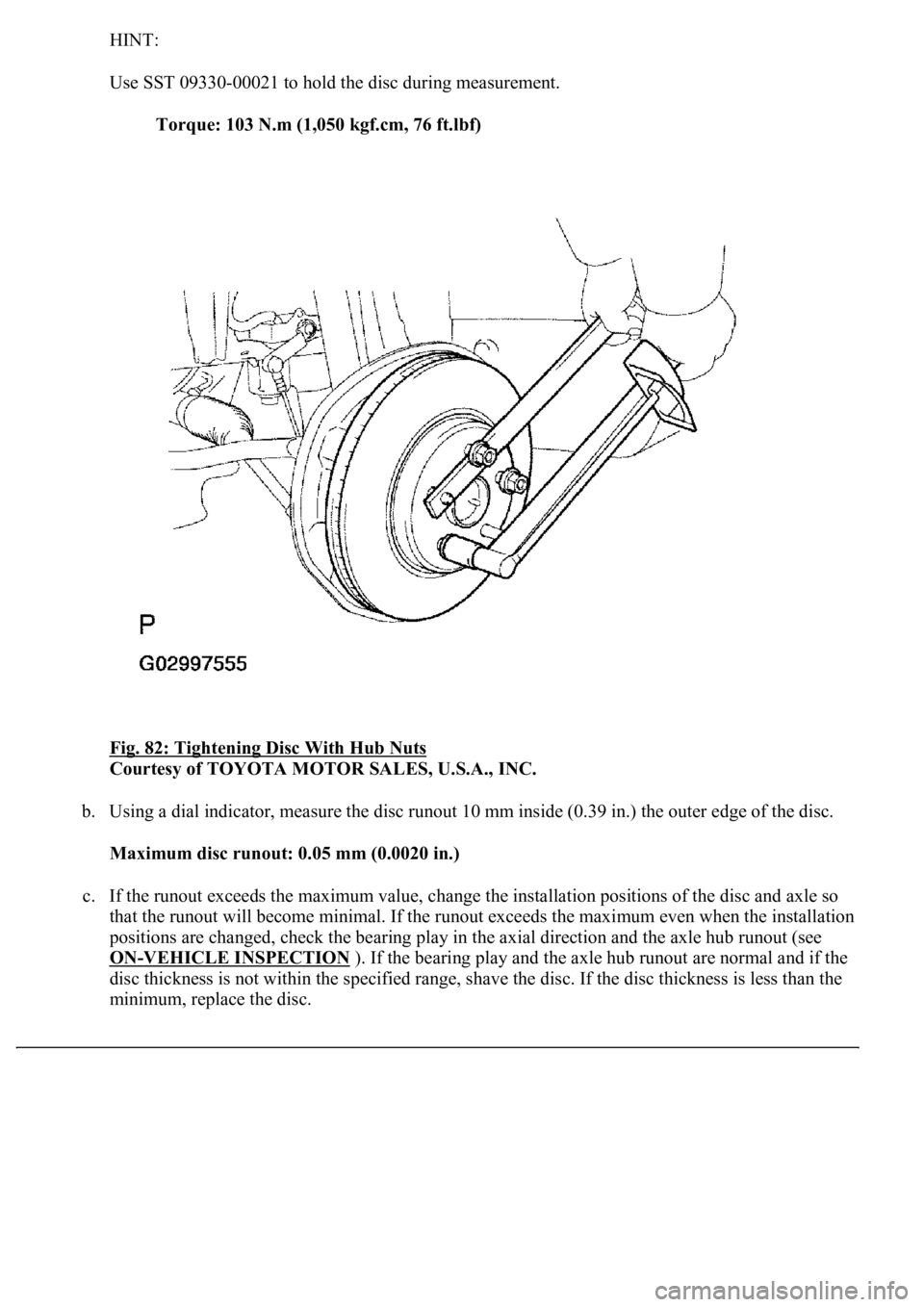

HINT:

Use SST 09330-00021 to hold the disc during measurement.

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

Fig. 82: Tightening Disc With Hub Nuts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Using a dial indicator, measure the disc runout 10 mm inside (0.39 in.) the outer edge of the disc.

Maximum disc runout: 0.05 mm (0.0020 in.)

c. If the runout exceeds the maximum value, change the installation positions of the disc and axle so

that the runout will become minimal. If the runout exceeds the maximum even when the installation

positions are changed, check the bearing play in the axial direction and the axle hub runout (see

ON

-VEHICLE INSPECTION ). If the bearing play and the axle hub runout are normal and if the

disc thickness is not within the specified range, shave the disc. If the disc thickness is less than the

minimum, replace the disc.

Trending: hood release, B2419 bean, USB, remove seats, oil temperature, Rear suspension, cooling