LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: Air Conditioning Compressor, alternator, key battery, Soft hard, lights, CD changer, CD player

Page 2921 of 4500

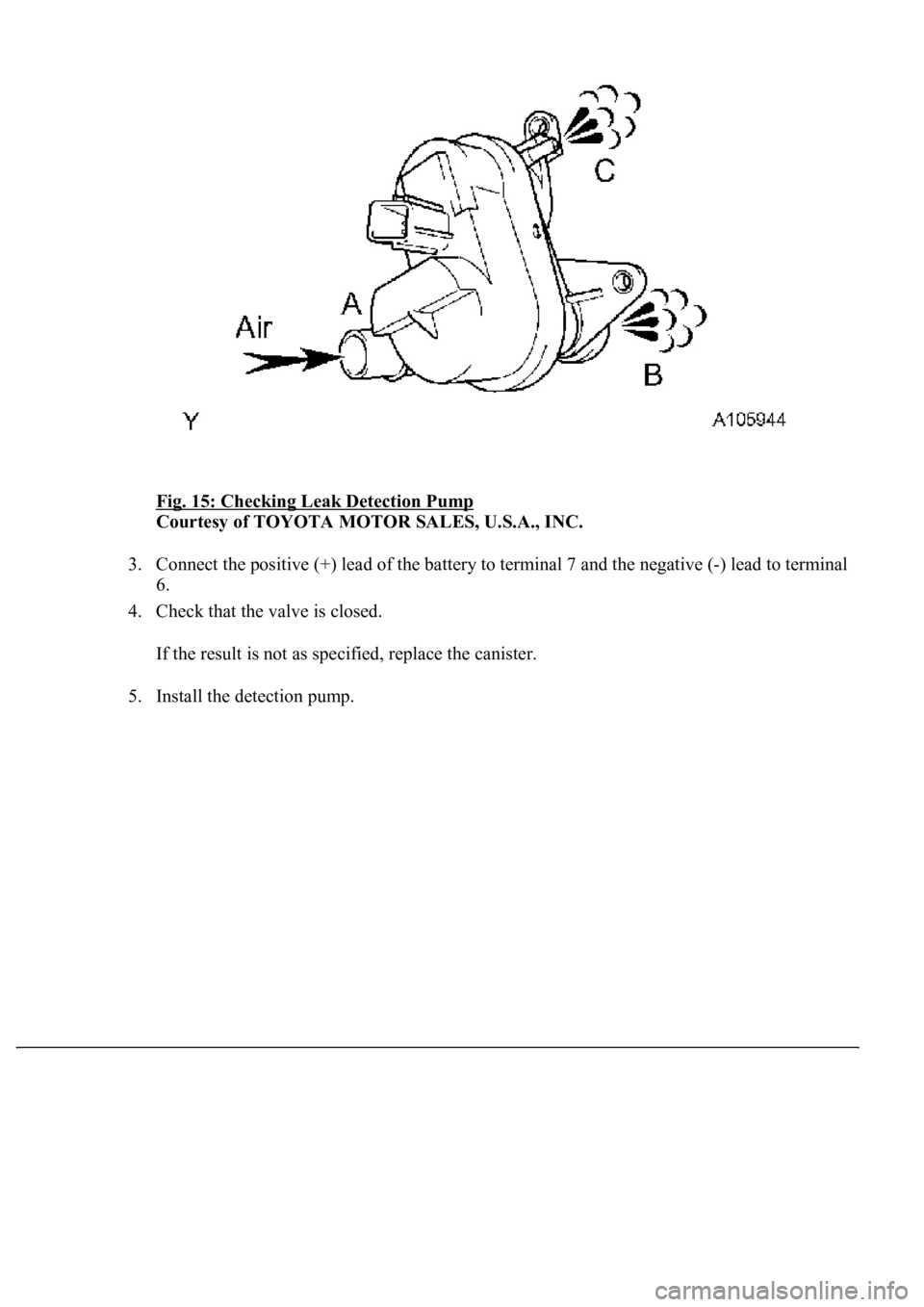

Fig. 15: Checking Leak Detection Pump

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Connect the positive (+) lead of the battery to terminal 7 and the negative (-) lead to terminal

6.

4. Check that the valve is closed.

If the result is not as specified, replace the canister.

5. Install the detection pump.

Page 2922 of 4500

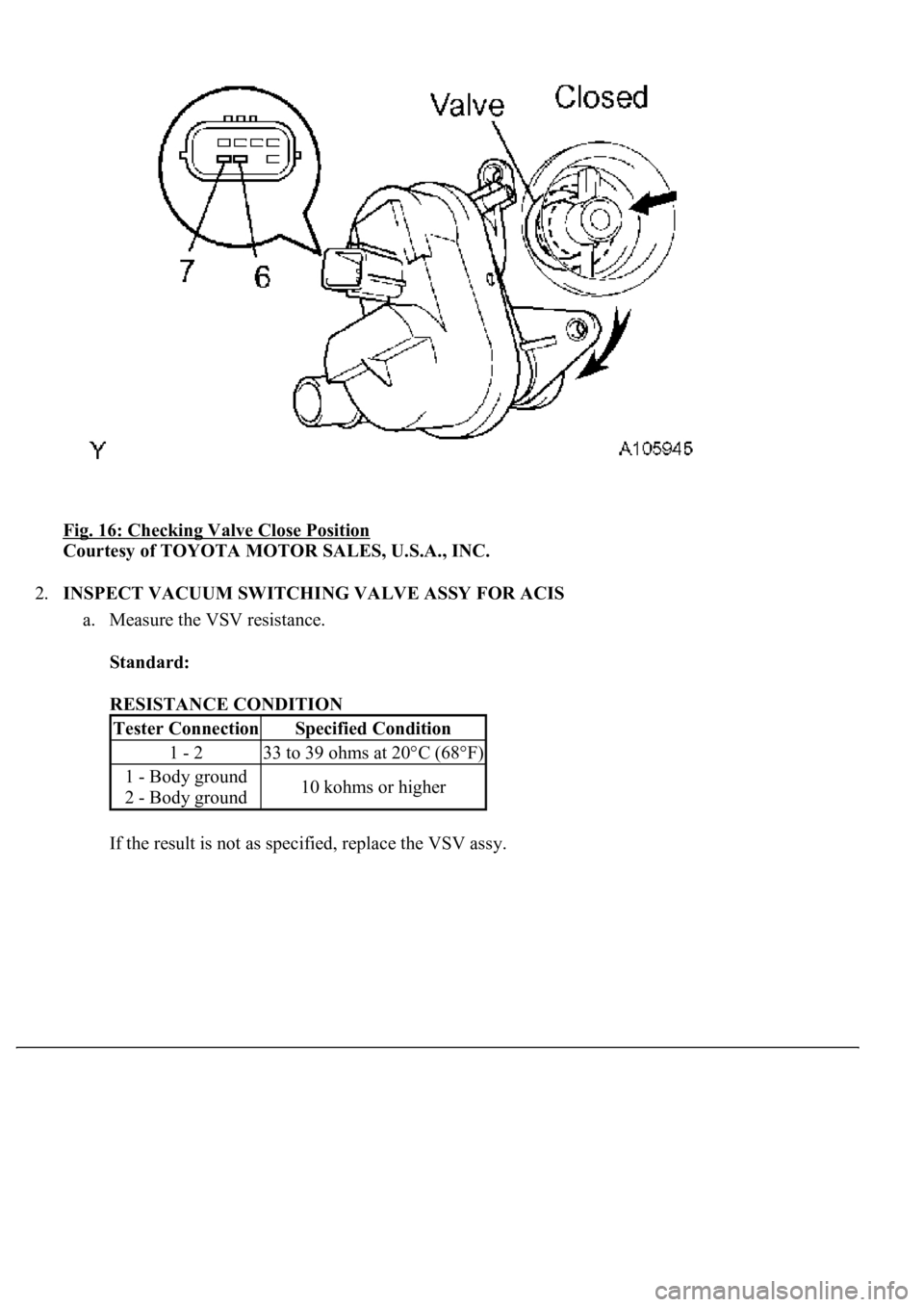

Fig. 16: Checking Valve Close Position

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.INSPECT VACUUM SWITCHING VALVE ASSY FOR ACIS

a. Measure the VSV resistance.

Standard:

RESISTANCE CONDITION

If the result is not as specified, replace the VSV ass

y.

Tester ConnectionSpecified Condition

1 - 233 to 39 ohms at 20°C (68°F)

1 - Body ground

2 - Body ground10 kohms or higher

Page 2923 of 4500

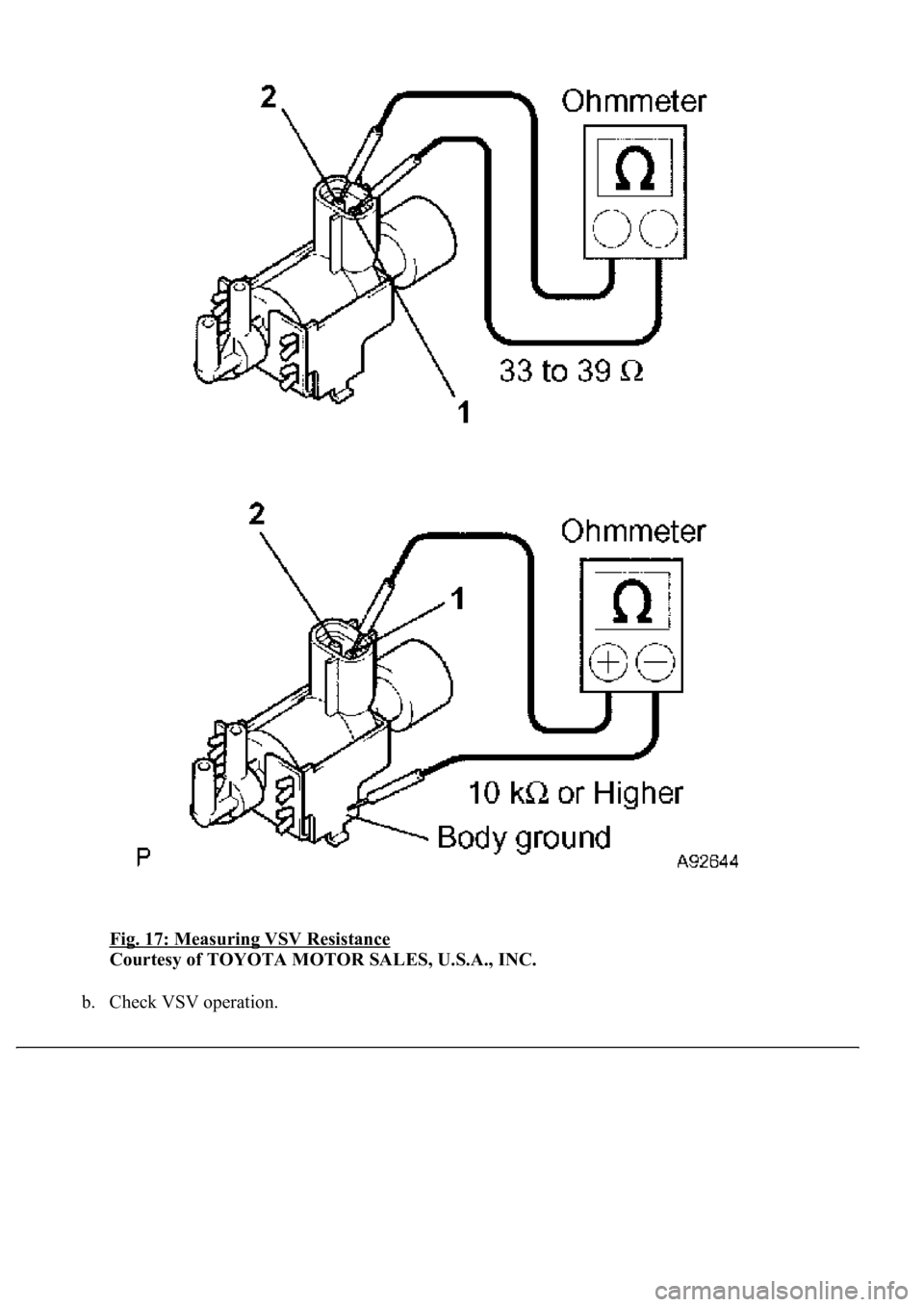

Fig. 17: Measuring VSV Resistance

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Check VSV operation.

Page 2924 of 4500

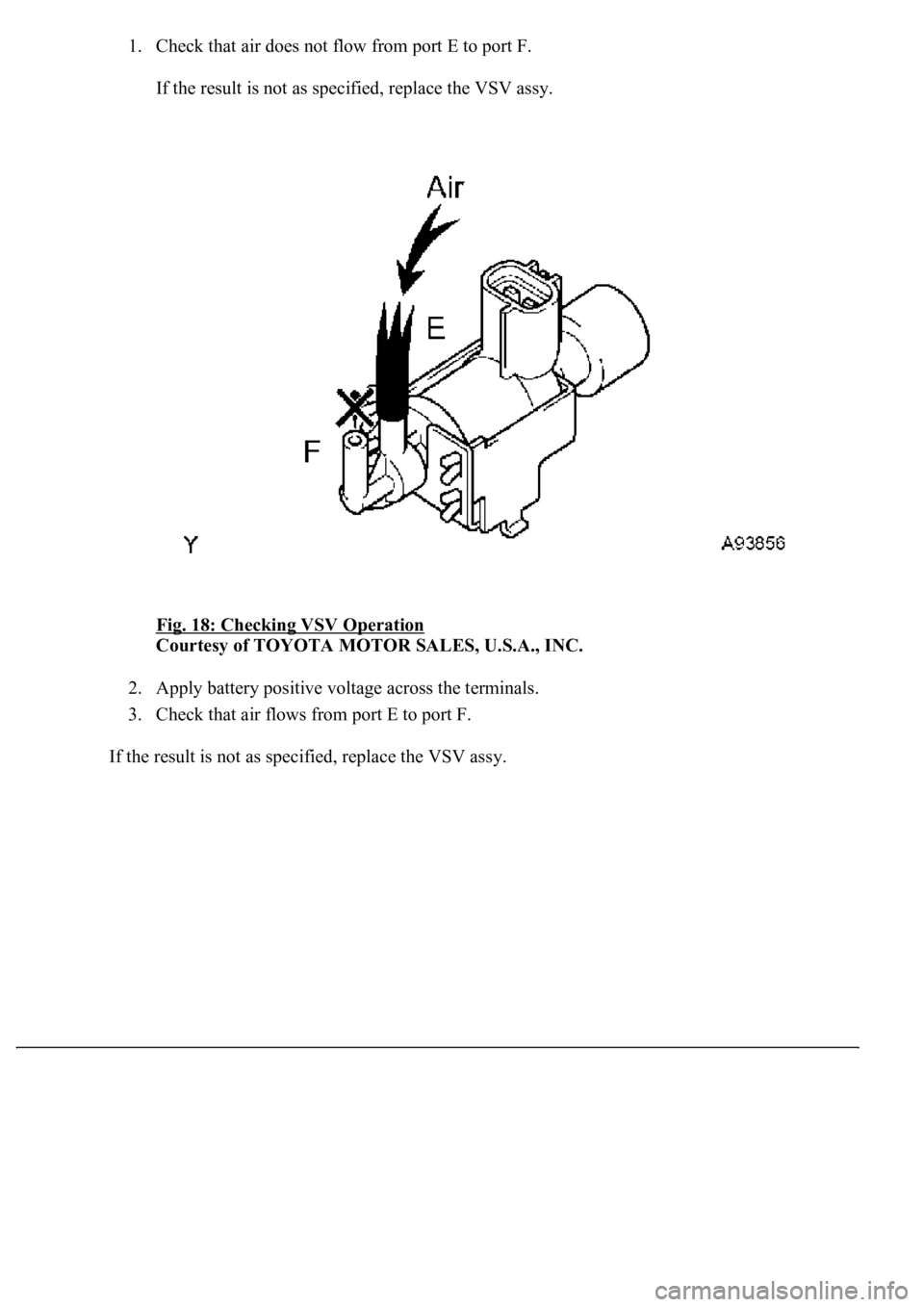

1. Check that air does not flow from port E to port F.

If the result is not as specified, replace the VSV assy.

Fig. 18: Checking VSV Operation

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

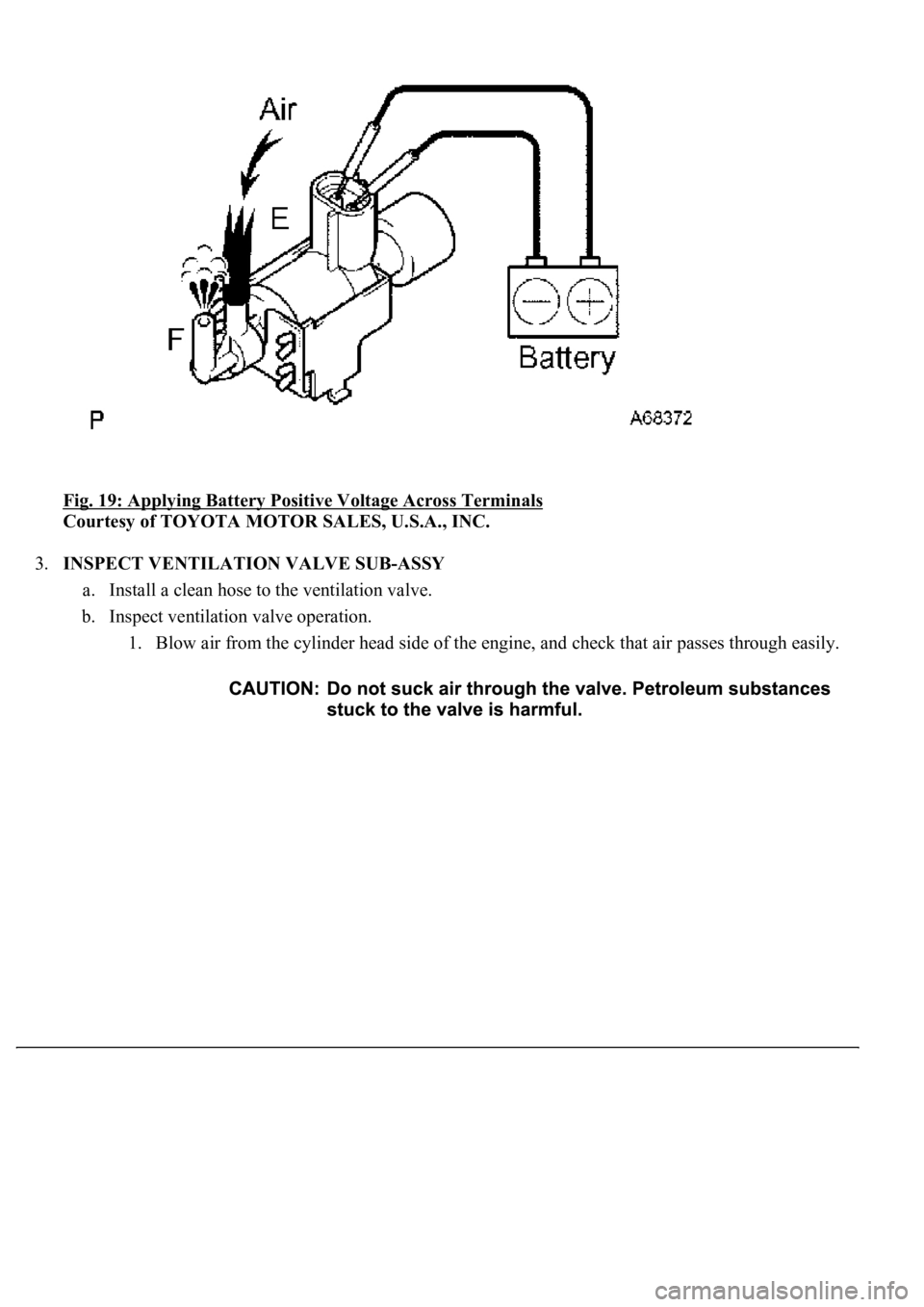

2. Apply battery positive voltage across the terminals.

3. Check that air flows from port E to port F.

If the result is not as specified, replace the VSV ass

y.

Page 2925 of 4500

Fig. 19: Applying Battery Positive Voltage Across Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

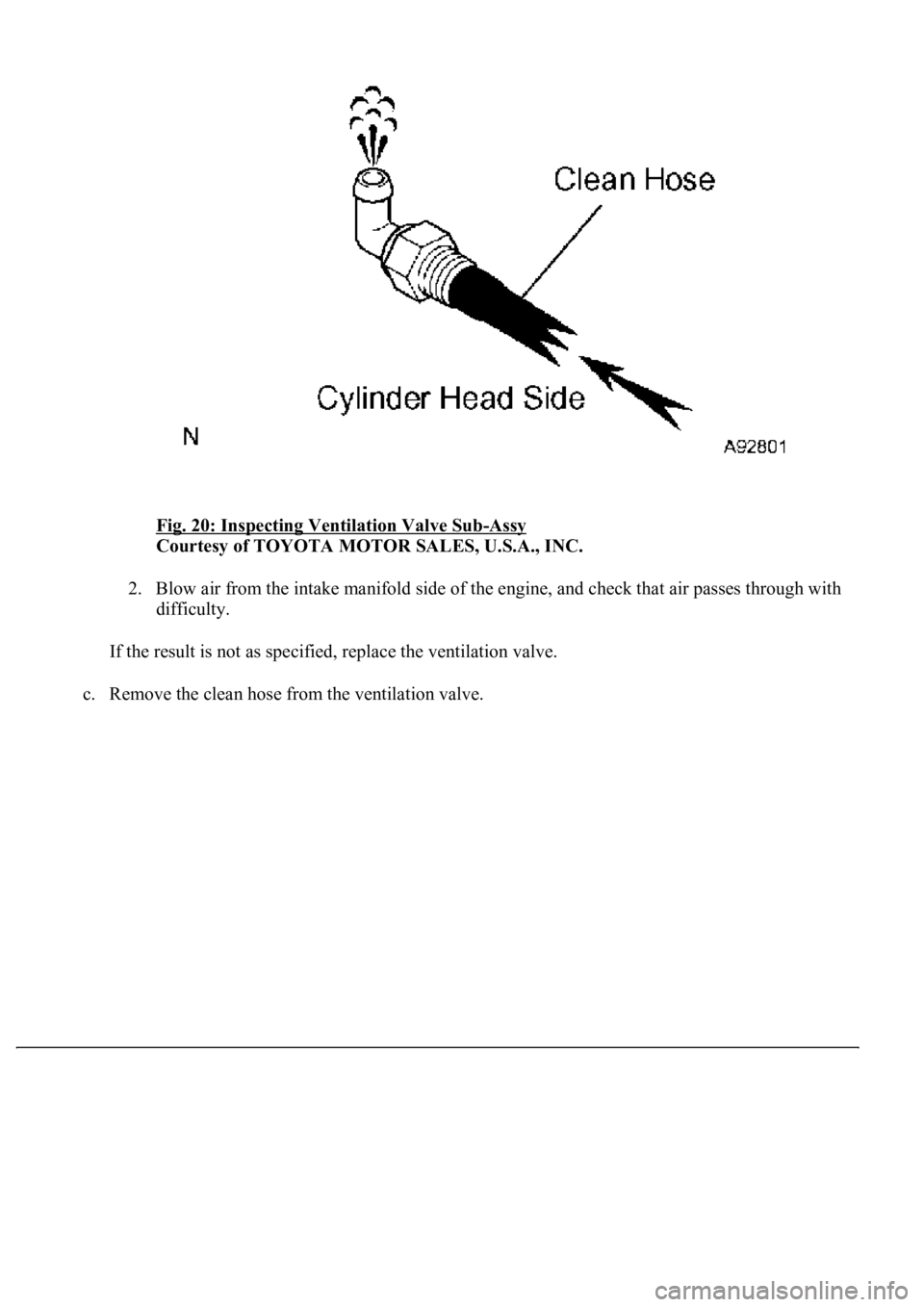

3.INSPECT VENTILATION VALVE SUB-ASSY

a. Install a clean hose to the ventilation valve.

b. Inspect ventilation valve operation.

1. Blow air from the cylinder head side of the engine, and check that air passes through easily.

Page 2926 of 4500

Fig. 20: Inspecting Ventilation Valve Sub-Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. Blow air from the intake manifold side of the engine, and check that air passes through with

difficulty.

If the result is not as specified, replace the ventilation valve.

c. Remove the clean hose from the ventilation valve.

Page 2927 of 4500

Fig. 21: Blowing Air From Intake Manifold Side Of Engine

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

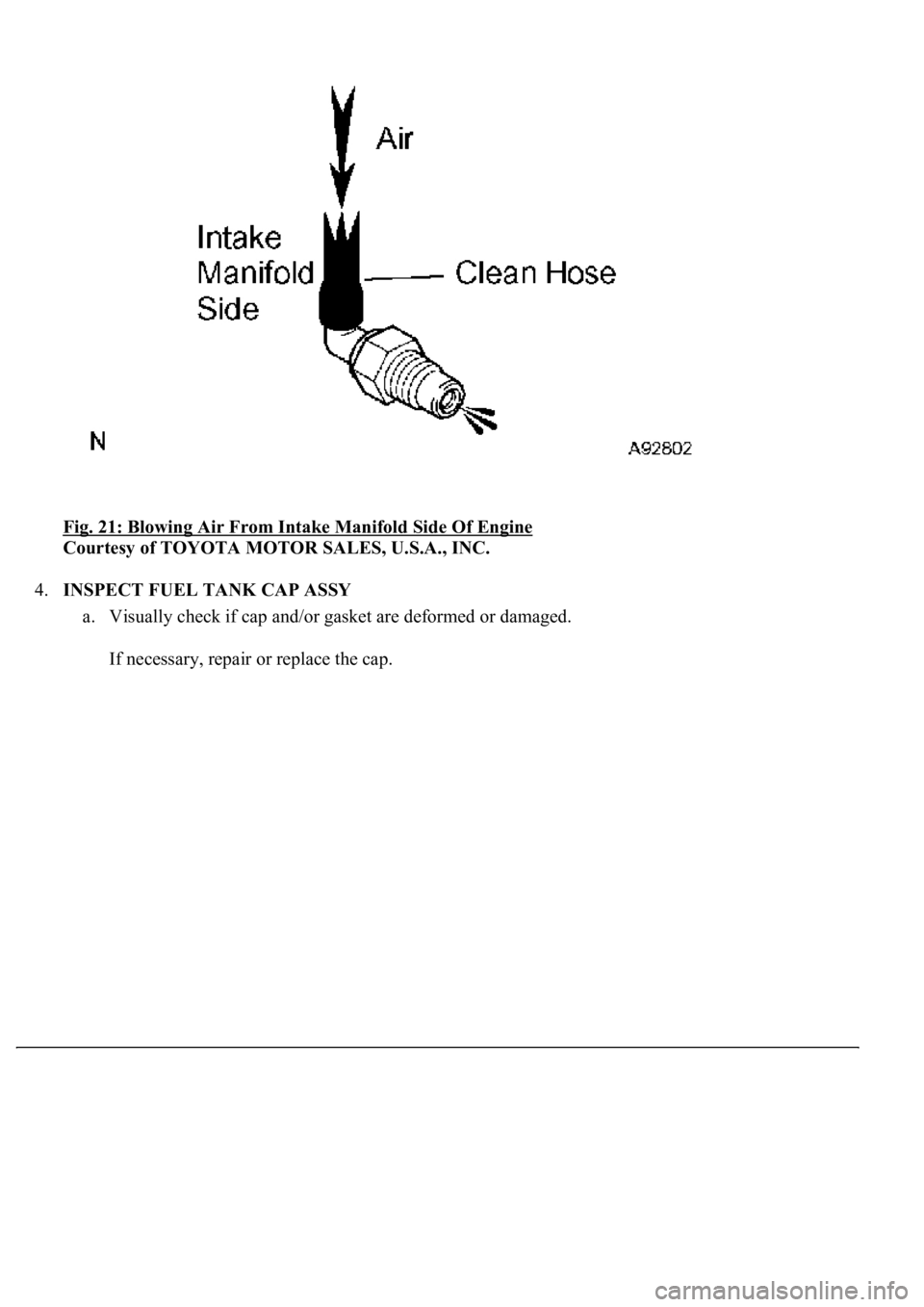

4.INSPECT FUEL TANK CAP ASSY

a. Visually check if cap and/or gasket are deformed or damaged.

If necessar

y, repair or replace the cap.

Page 2928 of 4500

Fig. 22: Inspecting Fuel Tank Cap Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

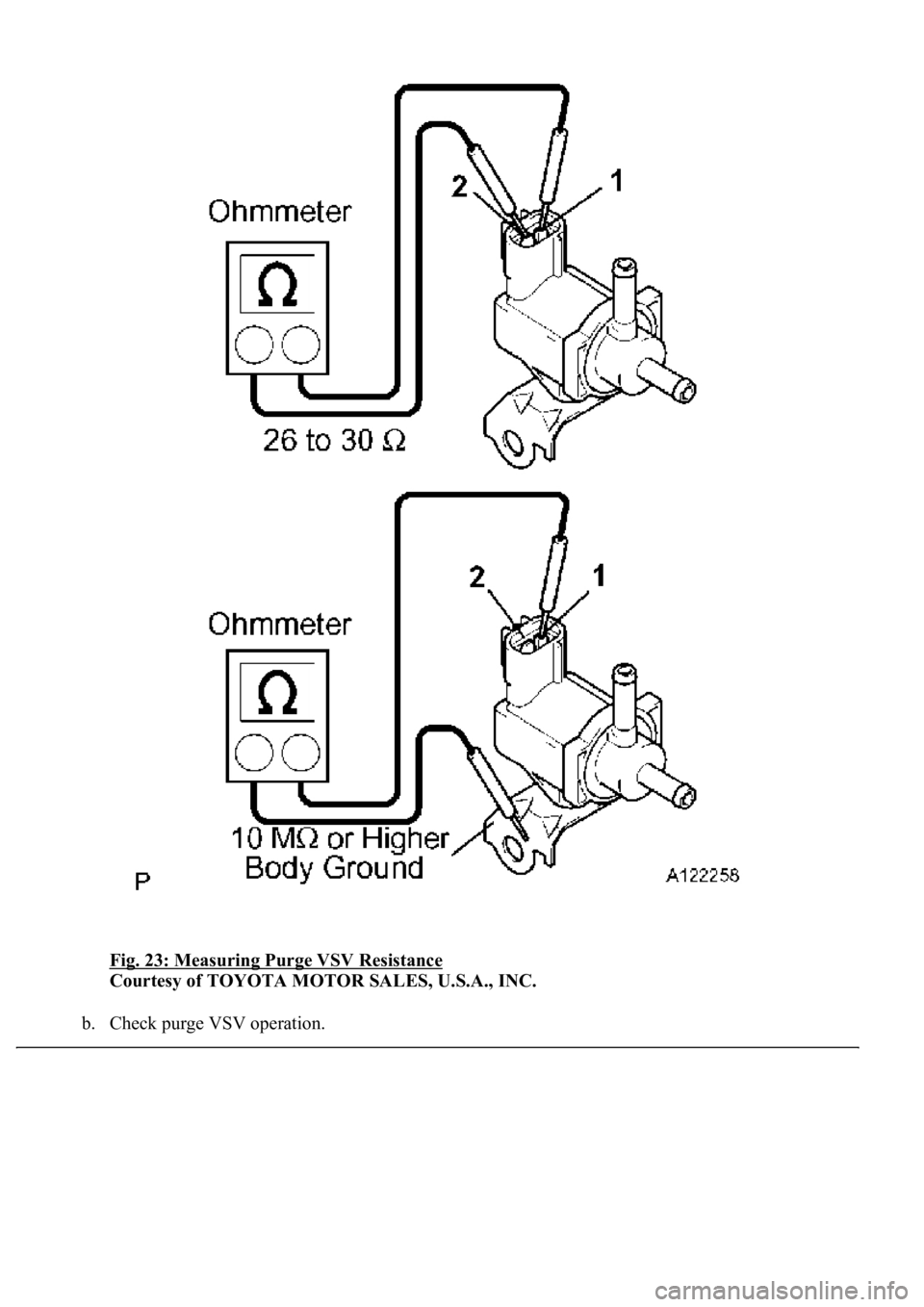

5.INSPECT PURGE VSV

a. Measure the purge VSV resistance.

Standard:

RESISTANCE CONDITION

If the result is not as specified, replace the pur

ge VSV.

Tester ConnectionSpecified Condition

1 - 226 to 30 ohms at 20°C (68°F)

1 - Body ground

2 - Body ground10 Mohms or higher

Page 2929 of 4500

Fig. 23: Measuring Purge VSV Resistance

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Check purge VSV operation.

Page 2930 of 4500

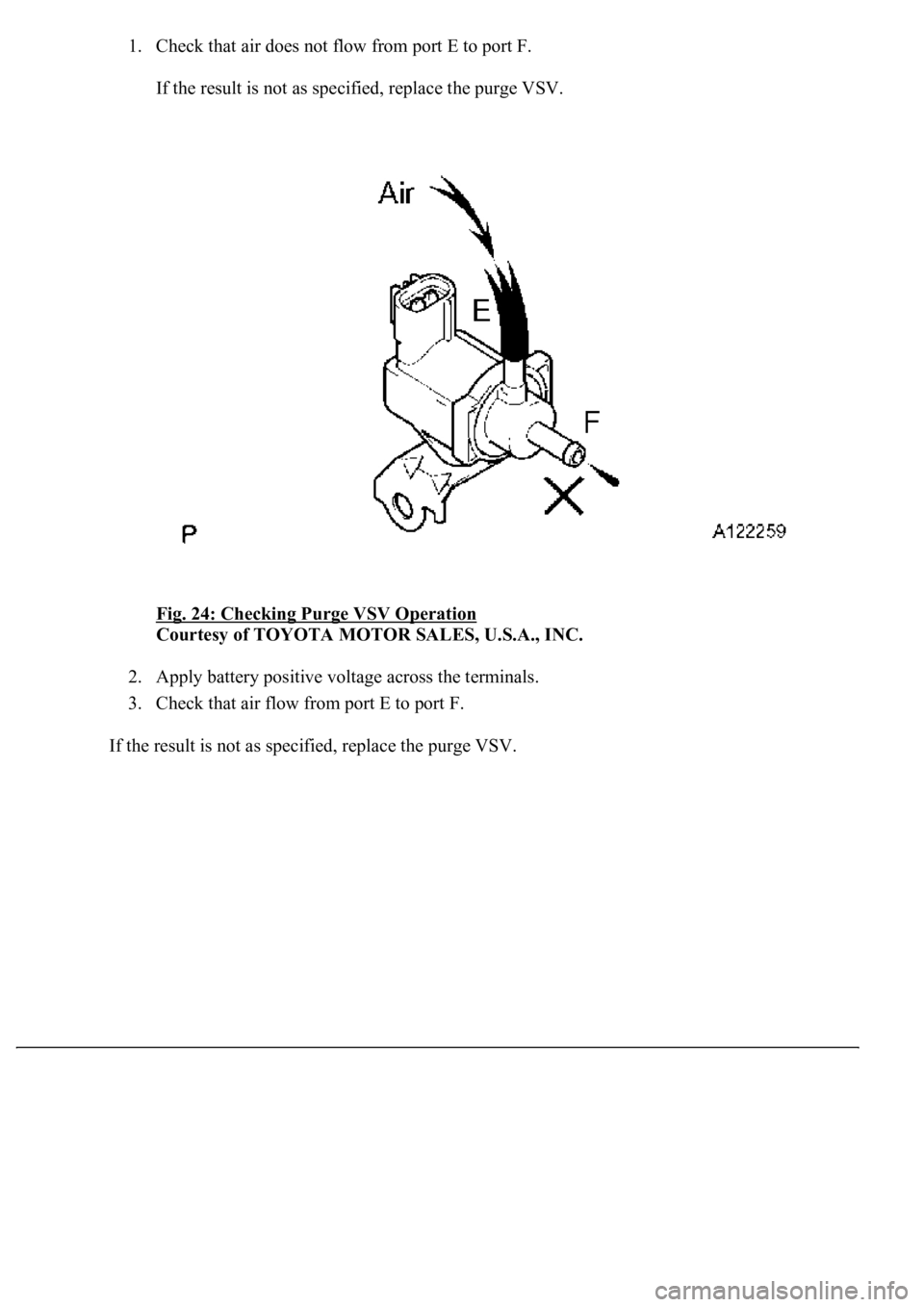

1. Check that air does not flow from port E to port F.

If the result is not as specified, replace the purge VSV.

Fig. 24: Checking Purge VSV Operation

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. Apply battery positive voltage across the terminals.

3. Check that air flow from port E to port F.

If the result is not as specified, replace the pur

ge VSV.

Trending: diagnostic menu, audio, coolant level, c1725, evaporator, radiator cap, wheel bolt torque