LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: AC Compressor control valve, vacuum switching valve, oil change, garage door opener, water pump, Max cool damper sensor, C1752

Page 3771 of 4500

Fig. 482: Installing Piston And Connecting Rod

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

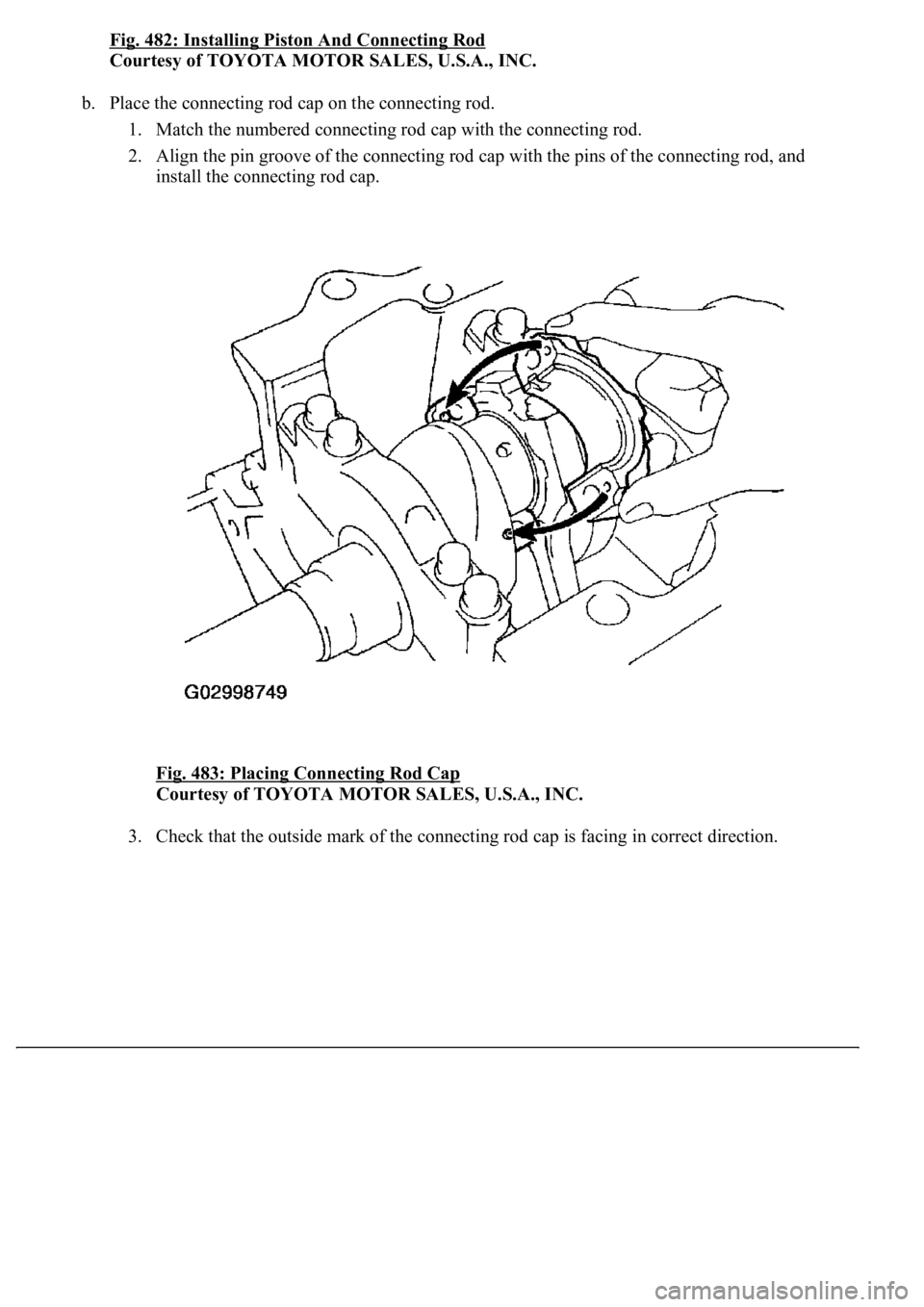

b. Place the connecting rod cap on the connecting rod.

1. Match the numbered connecting rod cap with the connecting rod.

2. Align the pin groove of the connecting rod cap with the pins of the connecting rod, and

install the connecting rod cap.

Fig. 483: Placing Connecting Rod Cap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Check that the outside mark of the connectin

g rod cap is facing in correct direction.

Page 3772 of 4500

Page 3773 of 4500

Fig. 484: Identifying Outside Mark Of Connecting Rod Cap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

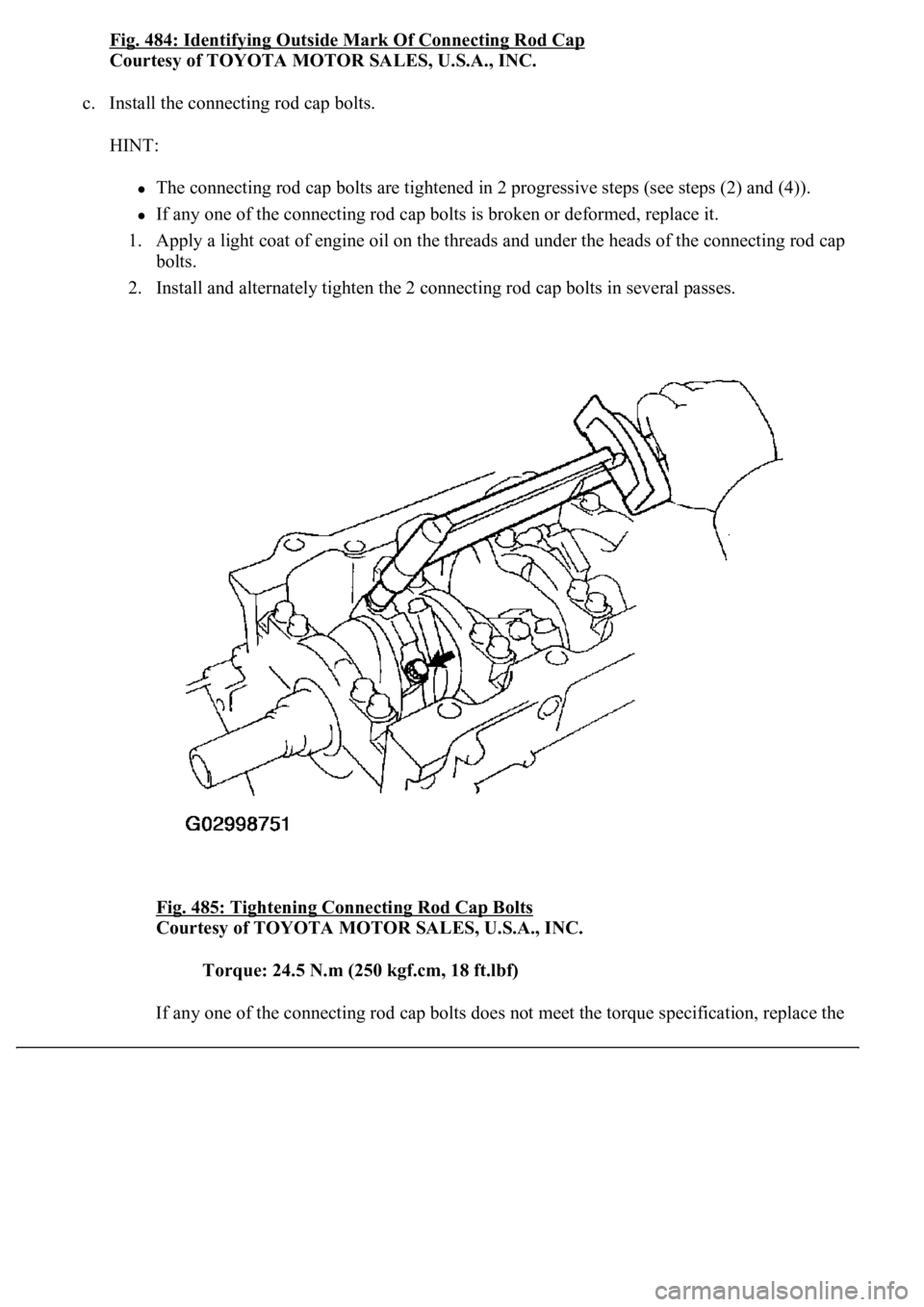

c. Install the connecting rod cap bolts.

HINT:

The connecting rod cap bolts are tightened in 2 progressive steps (see steps (2) and (4)).

If any one of the connecting rod cap bolts is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the heads of the connecting rod cap

bolts.

2. Install and alternately tighten the 2 connecting rod cap bolts in several passes.

Fig. 485: Tightening Connecting Rod Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Torque: 24.5 N.m (250 kgf.cm, 18 ft.lbf)

If an

y one of the connecting rod cap bolts does not meet the torque specification, replace the

Page 3774 of 4500

connecting rod cap bolts.

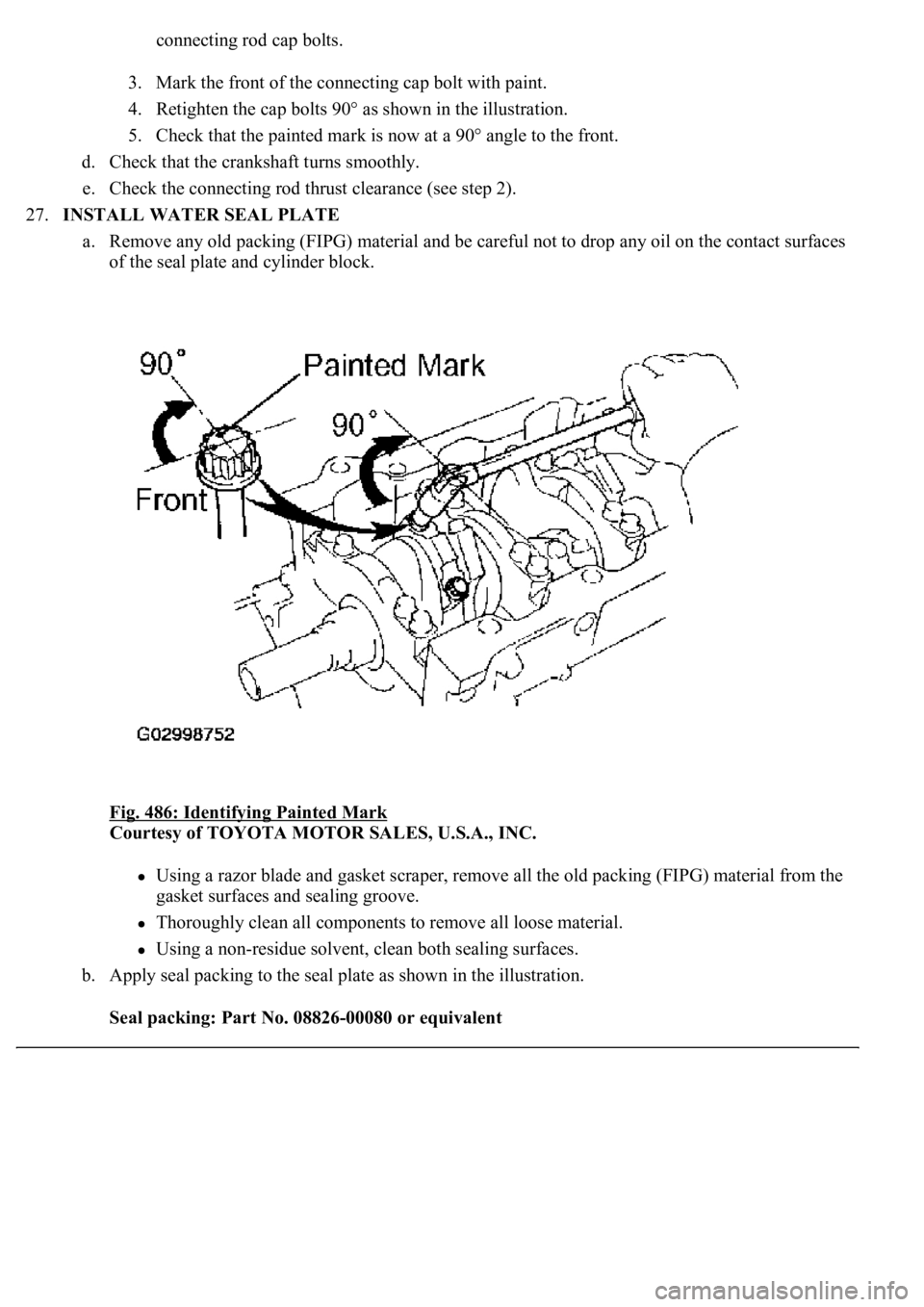

3. Mark the front of the connecting cap bolt with paint.

4. Retighten the cap bolts 90° as shown in the illustration.

5. Check that the painted mark is now at a 90° angle to the front.

d. Check that the crankshaft turns smoothly.

e. Check the connecting rod thrust clearance (see step 2).

27.INSTALL WATER SEAL PLATE

a. Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces

of the seal plate and cylinder block.

Fig. 486: Identifying Painted Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the

gasket surfaces and sealing groove.

Thoroughly clean all components to remove all loose material.

Using a non-residue solvent, clean both sealing surfaces.

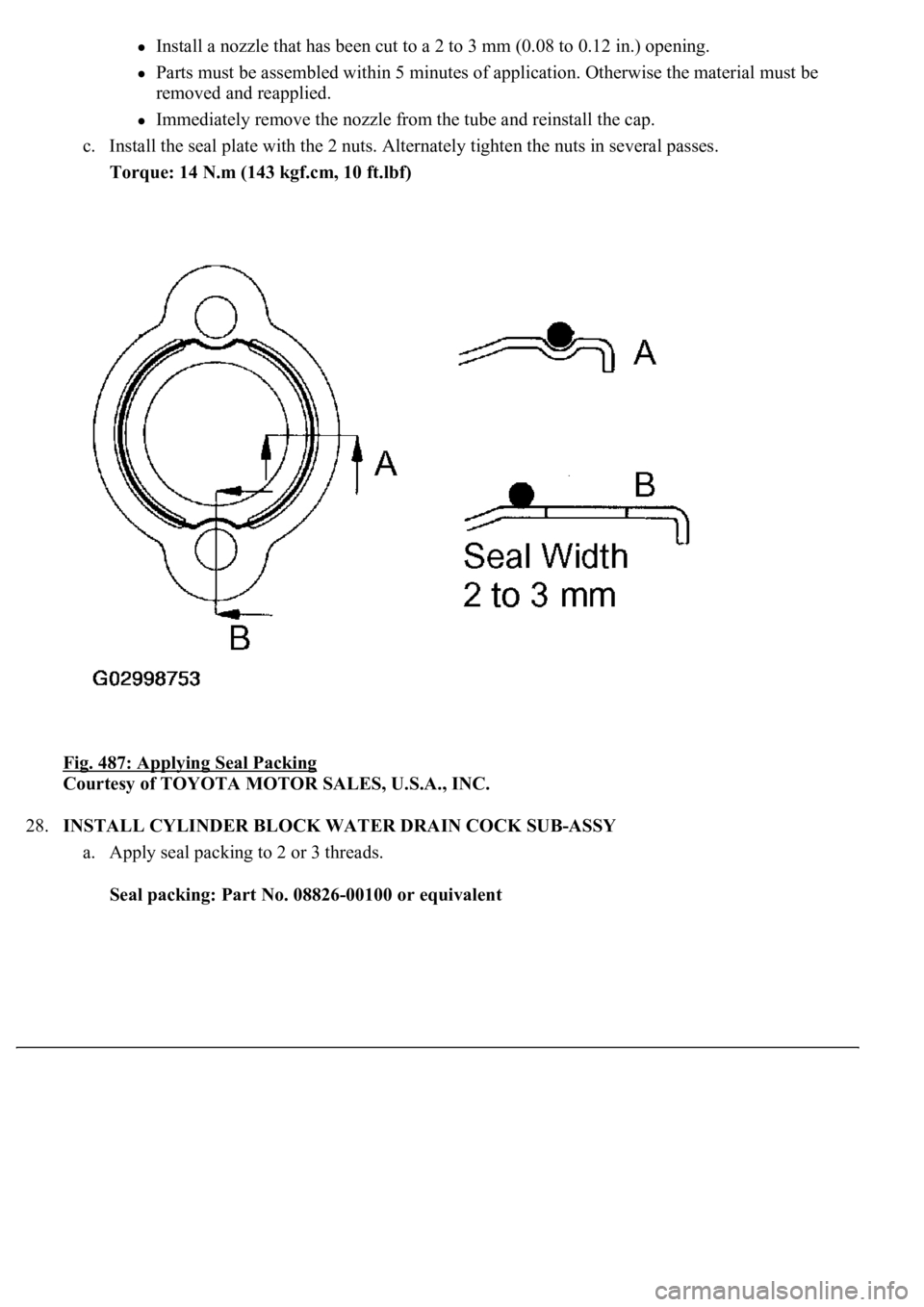

b. Apply seal packing to the seal plate as shown in the illustration.

Seal packing: Part No. 08826-00080 or equivalent

Page 3775 of 4500

<002c0051005600570044004f004f00030044000300510052005d005d004f004800030057004b004400570003004b00440056000300450048004800510003004600580057000300570052000300440003001500030057005200030016000300500050000300

0b001300110013001b00030057005200030013001100140015[ in.) opening.

Parts must be assembled within 5 minutes of application. Otherwise the material must be

removed and reapplied.

Immediately remove the nozzle from the tube and reinstall the cap.

c. Install the seal plate with the 2 nuts. Alternately tighten the nuts in several passes.

Torque: 14 N.m (143 kgf.cm, 10 ft.lbf)

Fig. 487: Applying Seal Packing

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

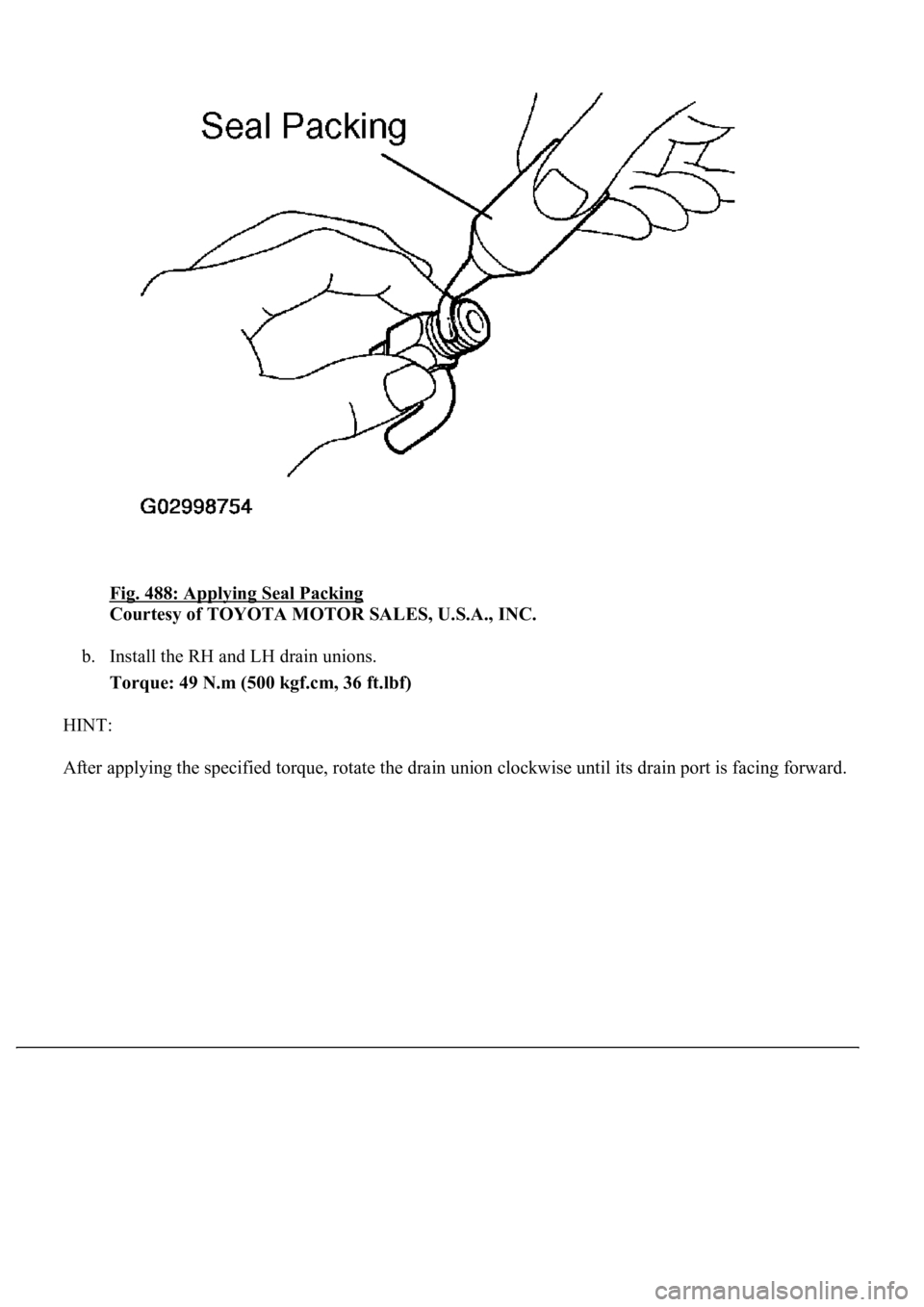

28.INSTALL CYLINDER BLOCK WATER DRAIN COCK SUB-ASSY

a. Apply seal packing to 2 or 3 threads.

Seal packing: Part No. 08826-00100 or equivalent

Page 3776 of 4500

Fig. 488: Applying Seal Packing

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Install the RH and LH drain unions.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

HINT:

After appl

ying the specified torque, rotate the drain union clockwise until its drain port is facing forward.

Page 3777 of 4500

Fig. 489: Installing RH And LH Drain Unions

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3778 of 4500

Fig. 1: Exploded View Of Exhaust Pipe Assy Components And Replacements (USA And Canada)

Page 3779 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Fig. 2: Exploded View Of Exhaust Pipe Assy Components And Replacements (Korea)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3780 of 4500

1.REMOVE FRONT FLOOR BRACE CENTER

a. Remove the 4 bolts and floor brace.

2.Bank 1, 2 sensor 2:

REMOVE HEATED OXYGEN SENSOR

a. Remove the 2 sensors.

3.REMOVE EXHAUST PIPE ASSY FRONT

a. Loosen the clamp.

b. Remove the 4 bolts, 4 nuts, pipe and 2 gaskets.

4.REMOVE EXHAUST PIPE ASSY CENTER

a. Loosen the 2 clamps.

b. Remove the pipe.

5.REMOVE EXHAUST PIPE ASSY TAIL (LH)

a. Remove the pipe from the 3 rings.

6.REMOVE EXHAUST PIPE ASSY TAIL (RH)

a. Remove the pipe from the 3 rings.

7.INSTALL EXHAUST PIPE ASSY FRONT

a. Install the 2 new gaskets to the pipe.

b. Install the pipe to the TWC with the 4 bolts and 4 nuts.

Torque: 44 N.m (450 kgf.cm, 32 ft.lbf)

8.Bank 1, 2 sensor 2:

INSTALL HEATED OXYGEN SENSOR

a. Install the 2 sensors.

Torque: 44 N.m (450 kgf.cm, 32 ft.lbf)

HINT:

Before installing the sensor, twist the sensor wire counterclockwise 3 and 1/2 turns.

After installing the sensor, check that the sensor wire is not twisted. If it is twisted, remove the

sensor and reinstall it.

9.INSTALL EXHAUST PIPE ASSY CENTER

a. Install the pipe.

b. Tighten the clamp.

Standard dimension (A): 13 to 15 mm (0.51 to 0.59 in.)

Trending: oil type, AC Compressor control valve, odometer, Diagram AC, brake pads, snow chains, airbag off