LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: steering wheel adjustment, navigation system, cylinder head, spark plugs, cruise control, intake manifold inlet, turn signal

Page 3761 of 4500

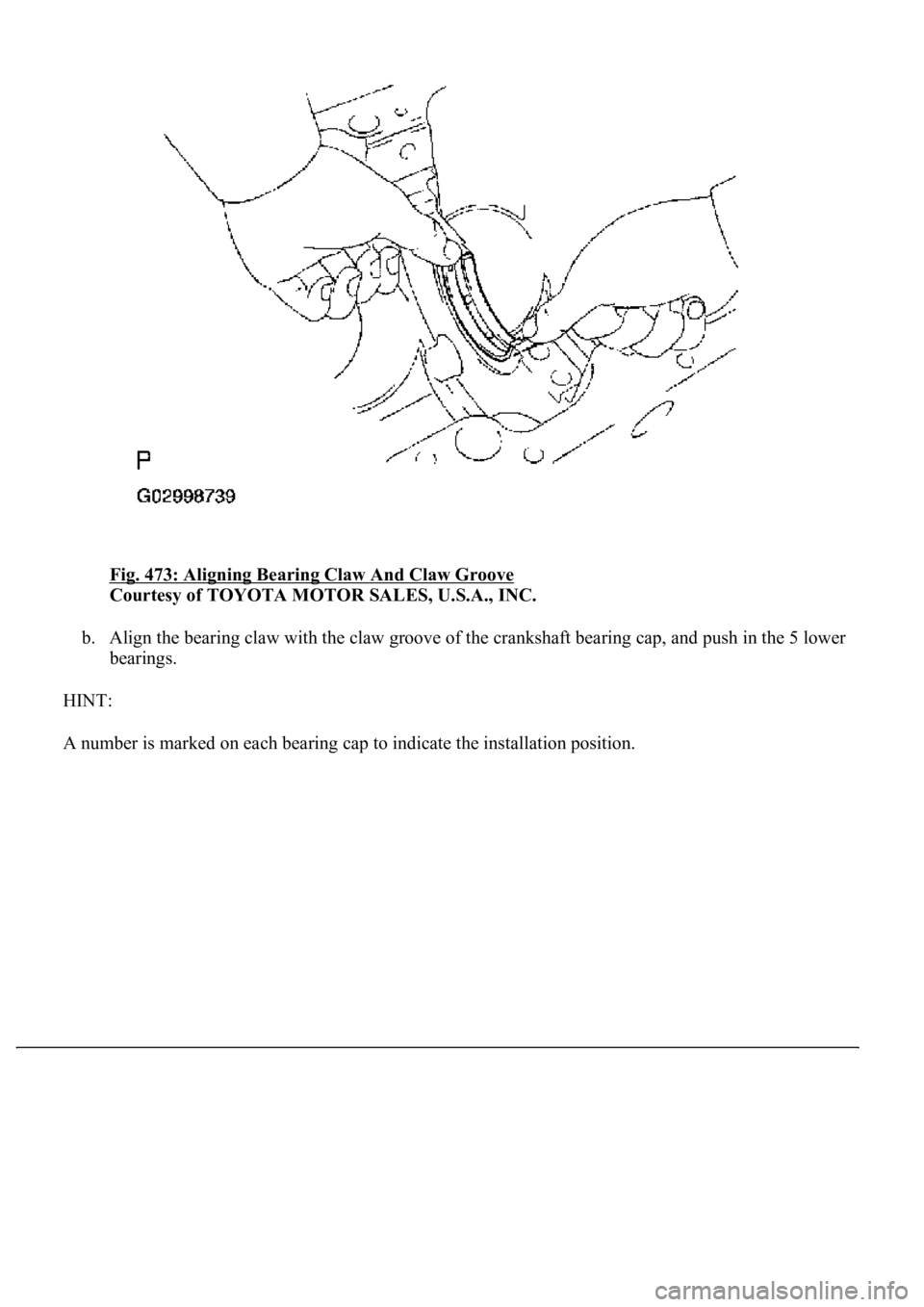

Fig. 473: Aligning Bearing Claw And Claw Groove

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Align the bearing claw with the claw groove of the crankshaft bearing cap, and push in the 5 lower

bearings.

HINT:

A number is marked on each bearin

g cap to indicate the installation position.

Page 3762 of 4500

Fig. 474: Identifying Bearing Cap Installation Position

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

24.INSTALL CRANKSHAFT THRUST WASHER SET

a. Install the 2 thrust washers under the No. 3 journal position of the cylinder block with the oil

grooves facing outward.

Page 3763 of 4500

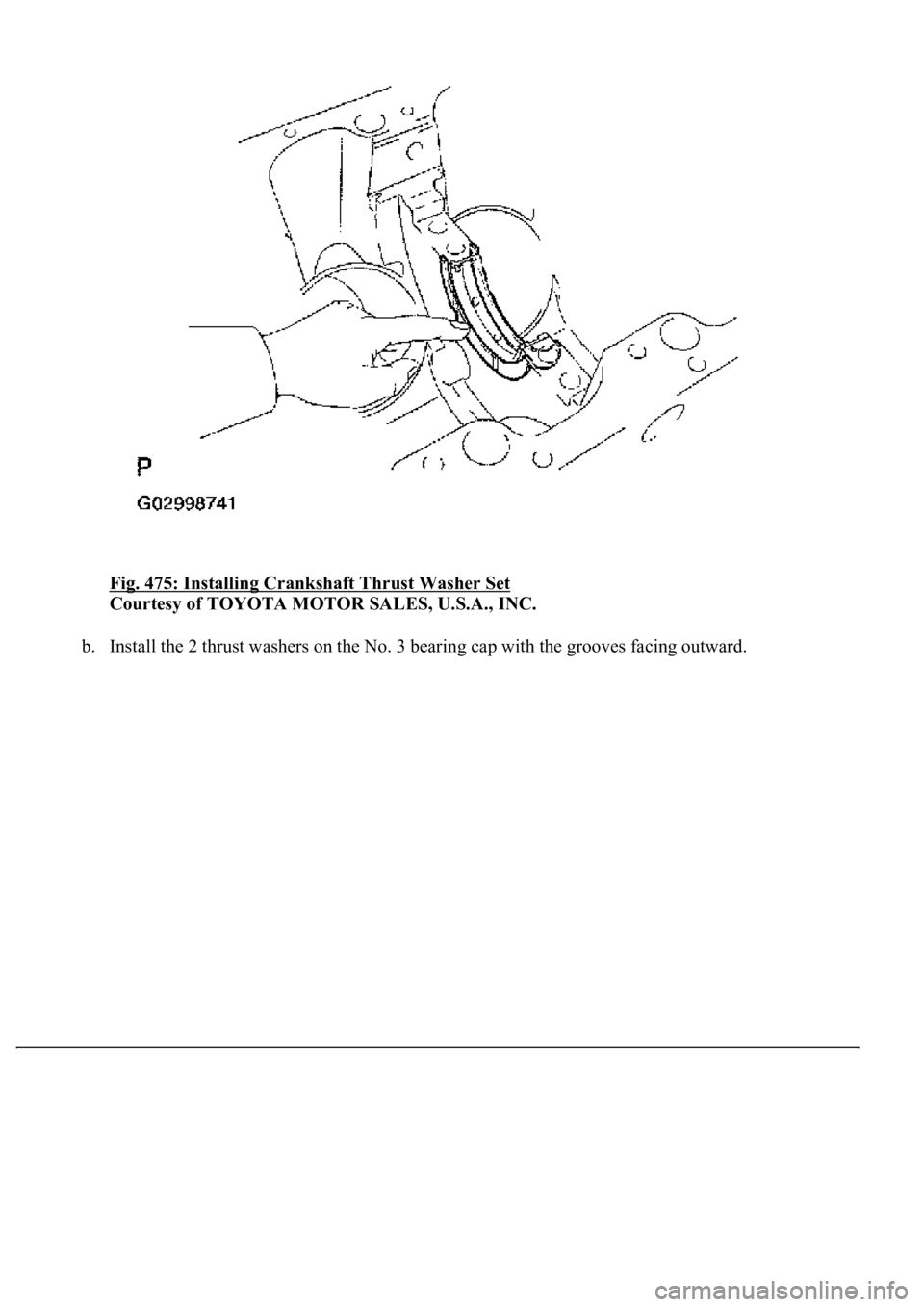

Fig. 475: Installing Crankshaft Thrust Washer Set

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Install the 2 thrust washers on the No. 3 bearing cap with the grooves facing outward.

Page 3764 of 4500

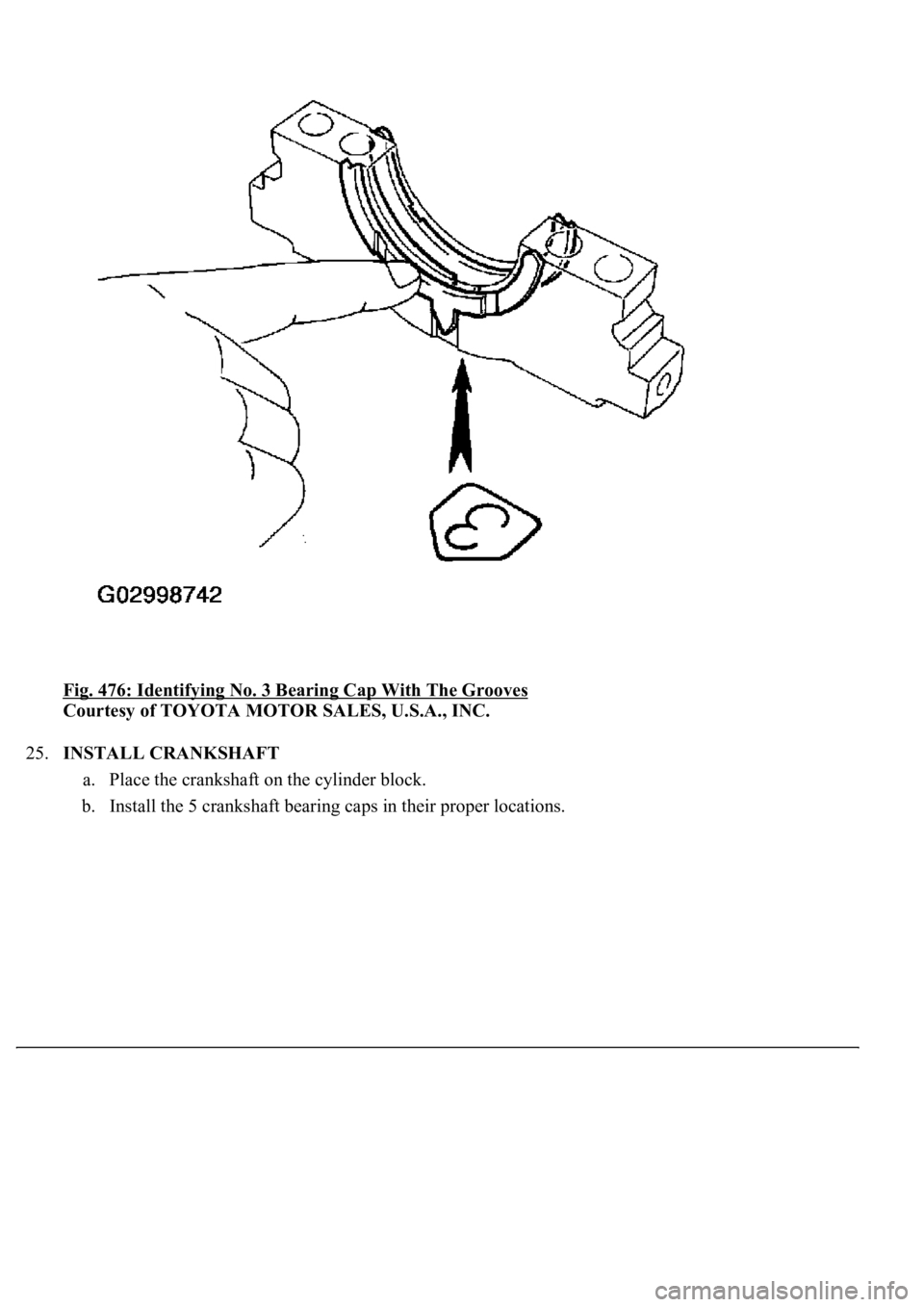

Fig. 476: Identifying No. 3 Bearing Cap With The Grooves

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

25.INSTALL CRANKSHAFT

a. Place the crankshaft on the cylinder block.

b. Install the 5 crankshaft bearing caps in their proper locations.

Page 3765 of 4500

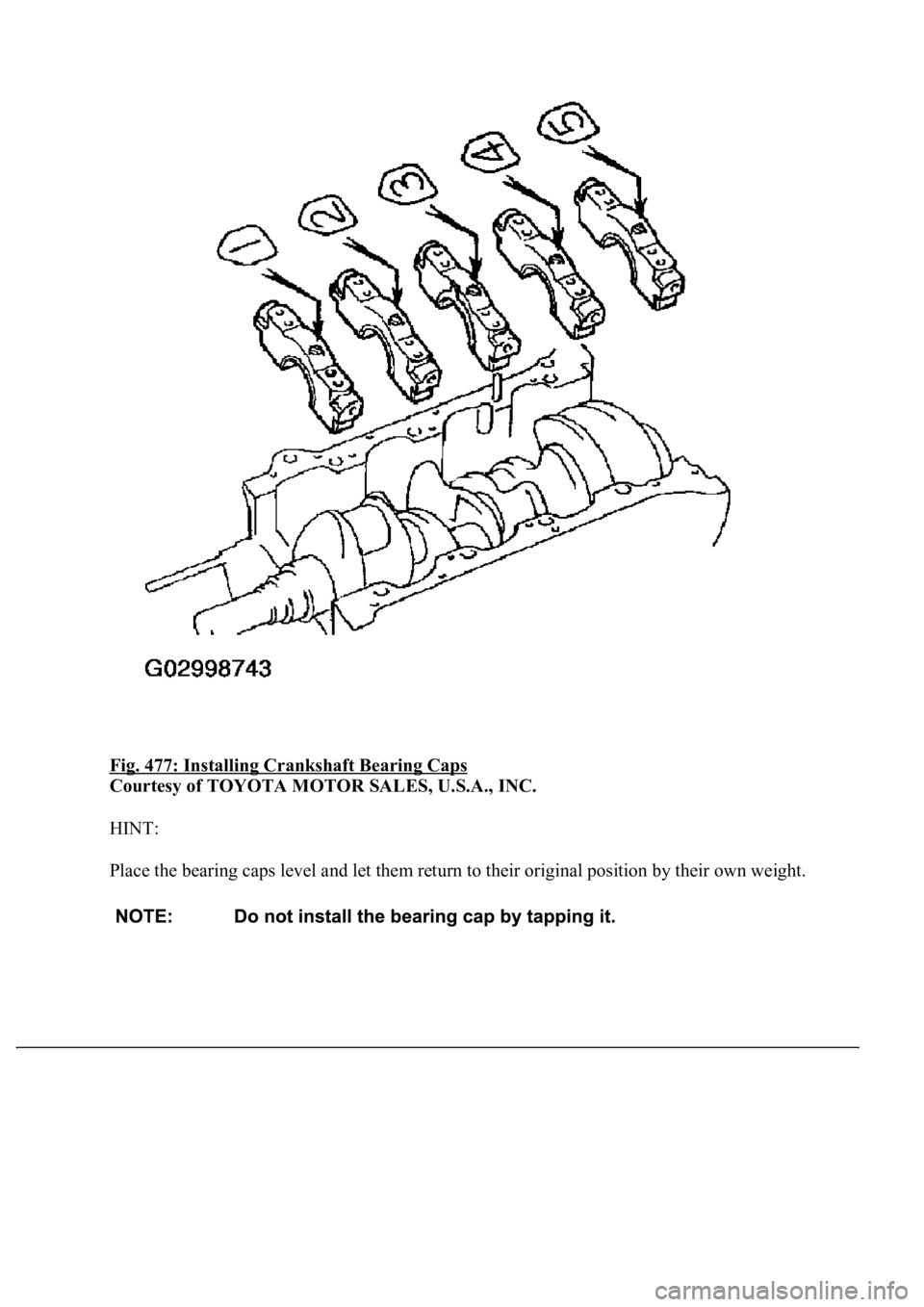

Fig. 477: Installing Crankshaft Bearing Caps

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Place the bearing caps level and let them return to their original position by their own weight.

Page 3766 of 4500

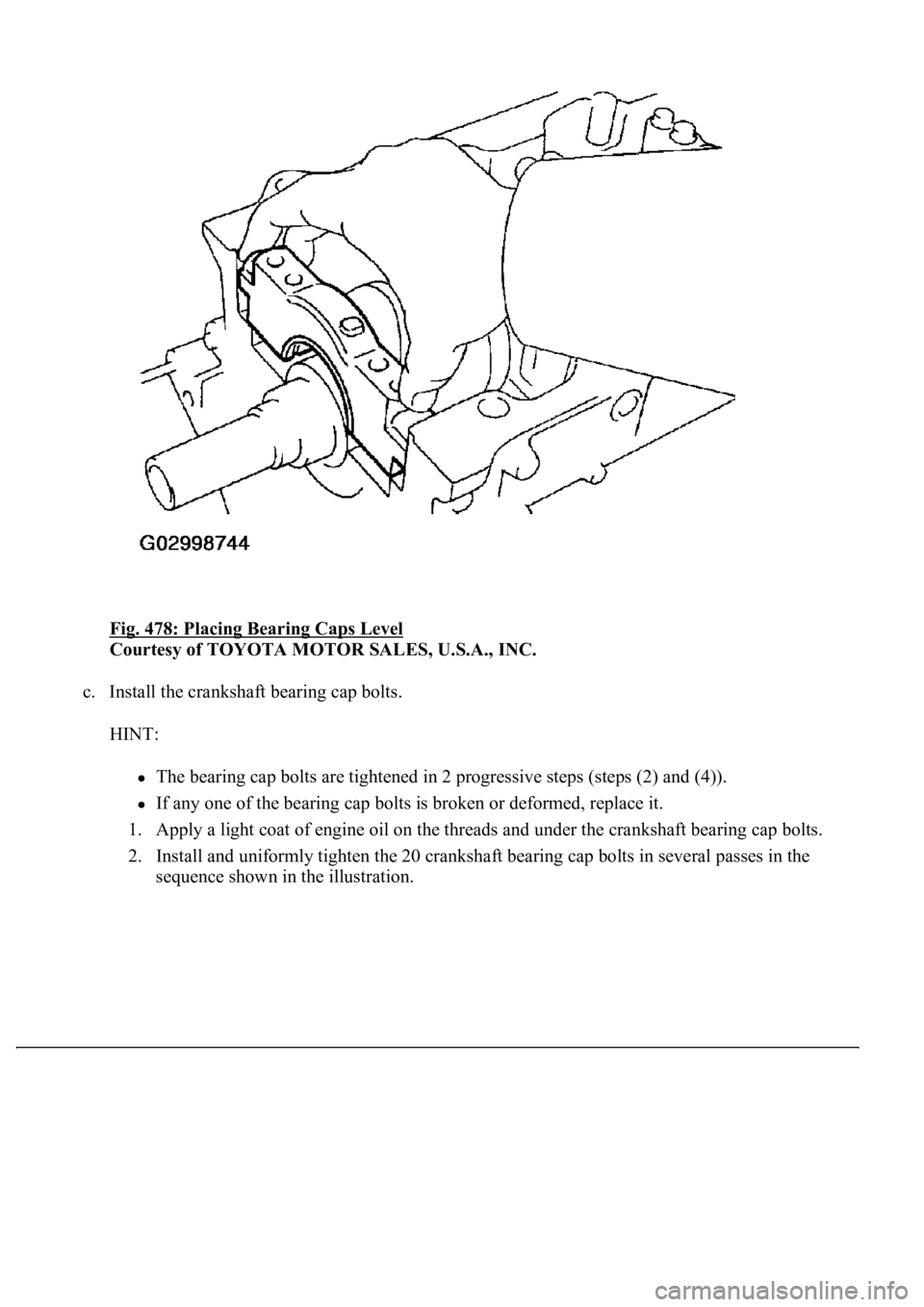

Fig. 478: Placing Bearing Caps Level

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Install the crankshaft bearing cap bolts.

HINT:

The bearing cap bolts are tightened in 2 progressive steps (steps (2) and (4)).

If any one of the bearing cap bolts is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the crankshaft bearing cap bolts.

2. Install and uniformly tighten the 20 crankshaft bearing cap bolts in several passes in the

sequence shown in the illustration.

Page 3767 of 4500

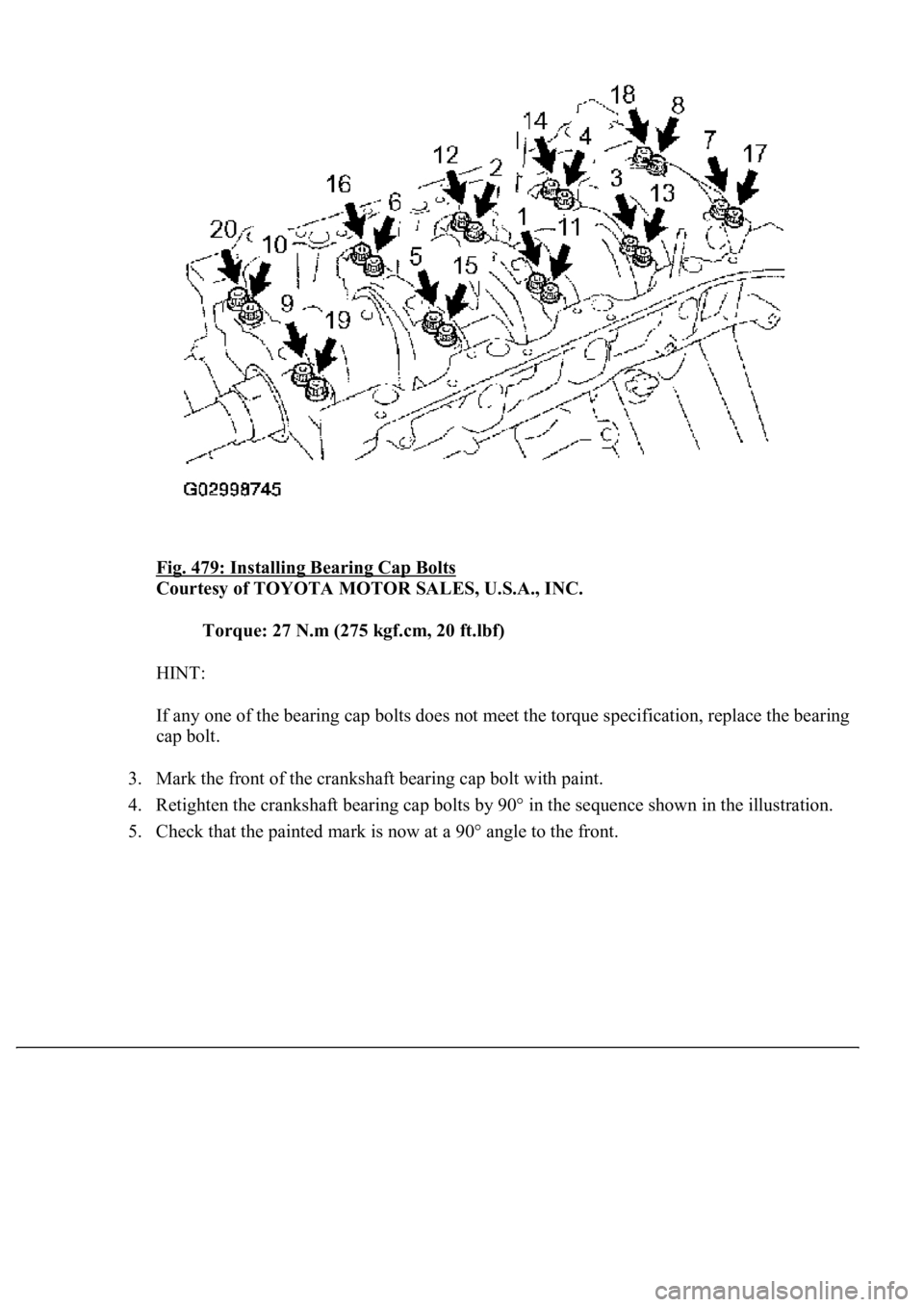

Fig. 479: Installing Bearing Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Torque: 27 N.m (275 kgf.cm, 20 ft.lbf)

HINT:

If any one of the bearing cap bolts does not meet the torque specification, replace the bearing

cap bolt.

3. Mark the front of the crankshaft bearing cap bolt with paint.

4. Retighten the crankshaft bearing cap bolts by 90° in the sequence shown in the illustration.

5. Check that the painted mark is now at a 90° an

gle to the front.

Page 3768 of 4500

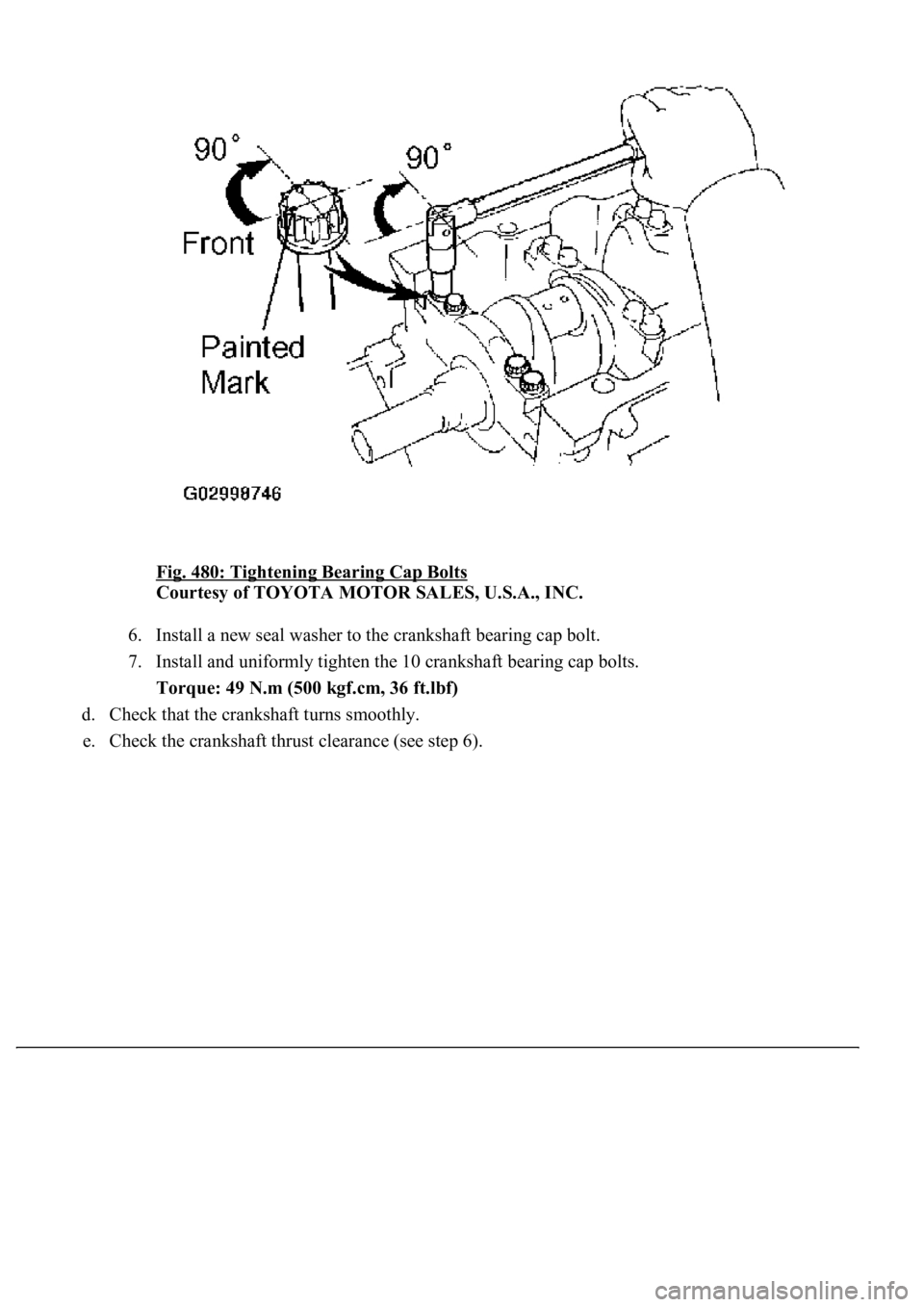

Fig. 480: Tightening Bearing Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6. Install a new seal washer to the crankshaft bearing cap bolt.

7. Install and uniformly tighten the 10 crankshaft bearing cap bolts.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

d. Check that the crankshaft turns smoothly.

e. Check the crankshaft thrust clearance (see step 6).

Page 3769 of 4500

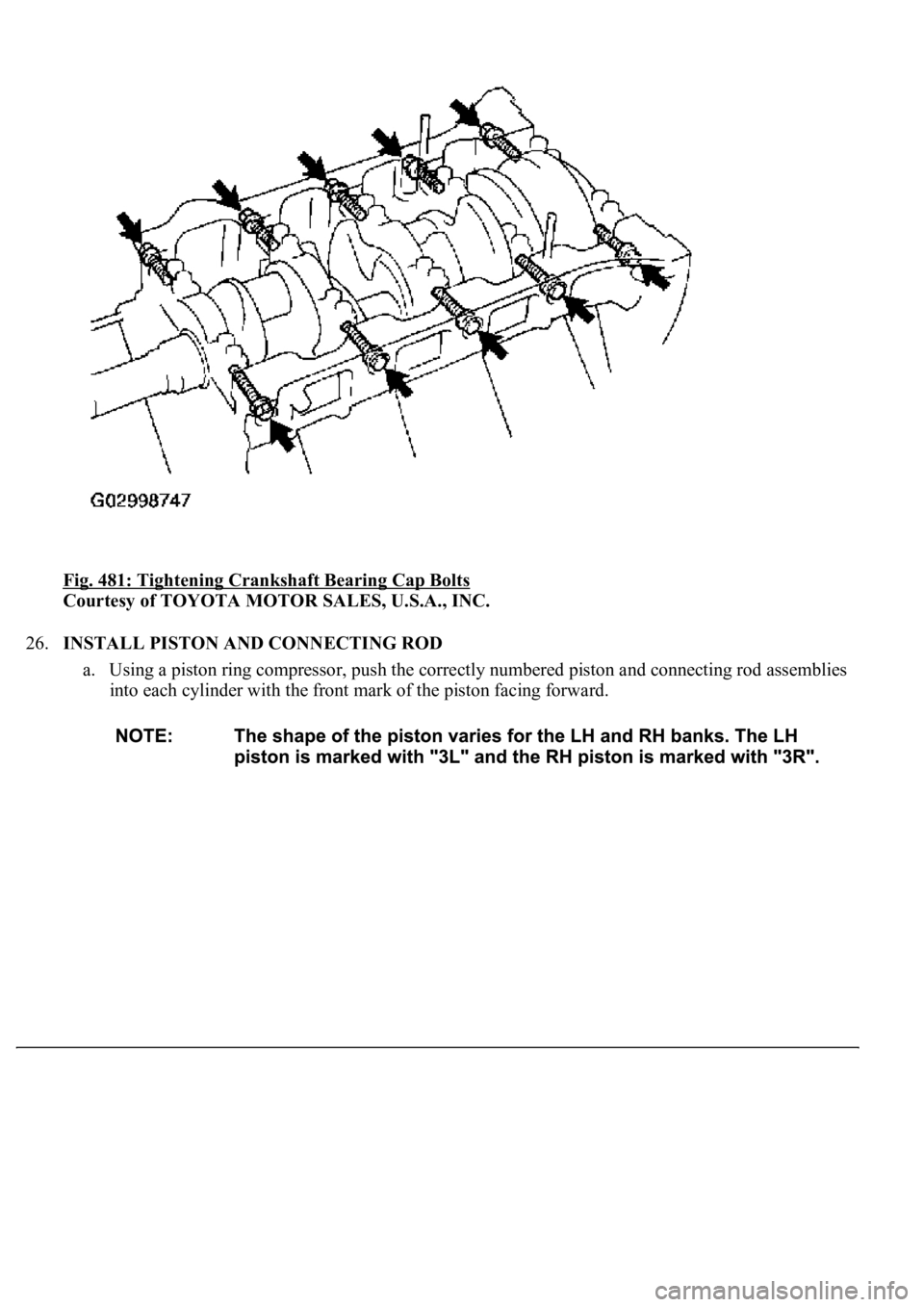

Fig. 481: Tightening Crankshaft Bearing Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

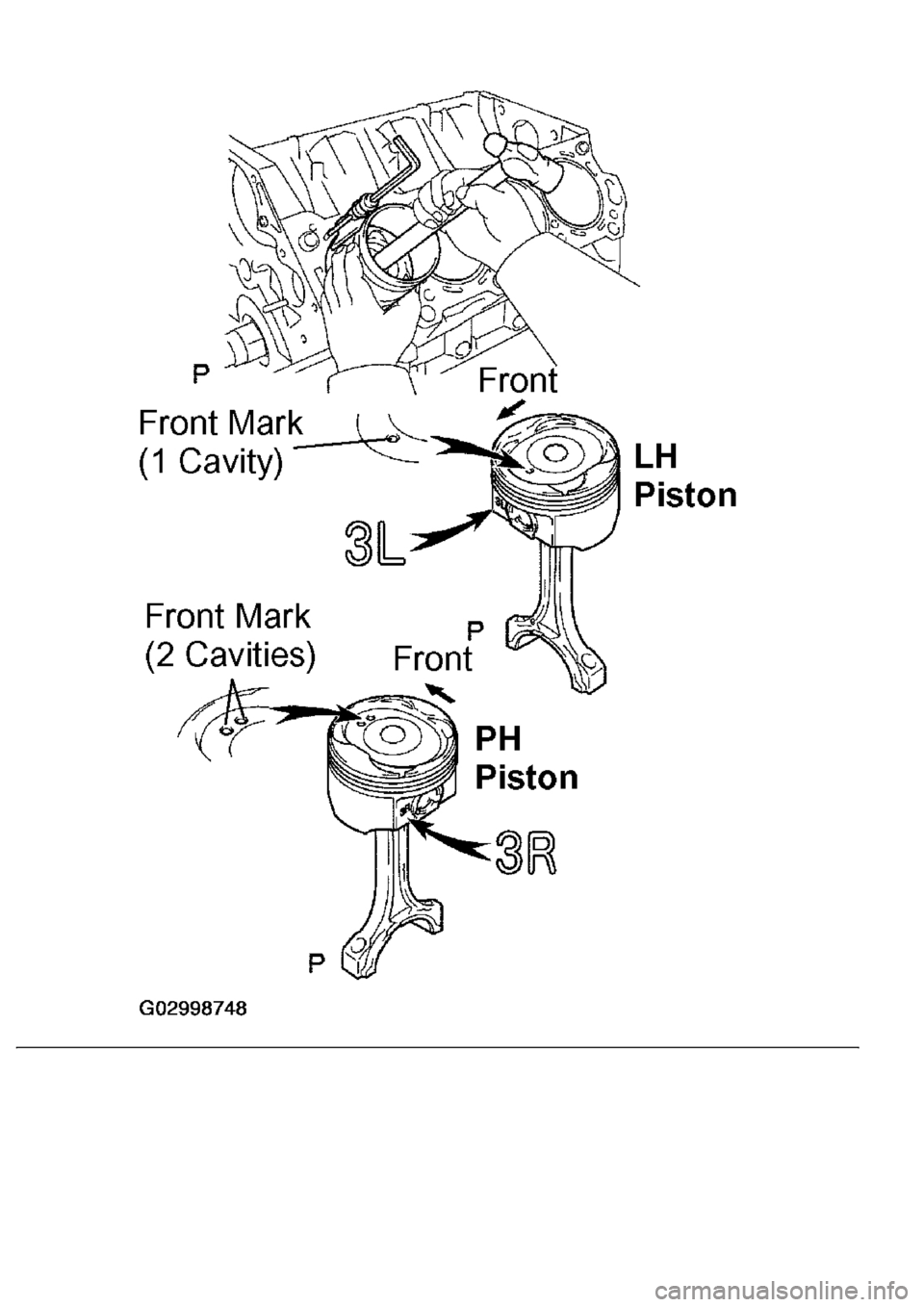

26.INSTALL PISTON AND CONNECTING ROD

a. Using a piston ring compressor, push the correctly numbered piston and connecting rod assemblies

into each cylinder with the front mark of the piston facing forward.

Page 3770 of 4500

Trending: Sp2, Spark plug firing order, Lock actuator, suspension, engine, C1752, Door lock