LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: roof rack, brake pads, heater, center console, light, torque, rear seat back

Page 3751 of 4500

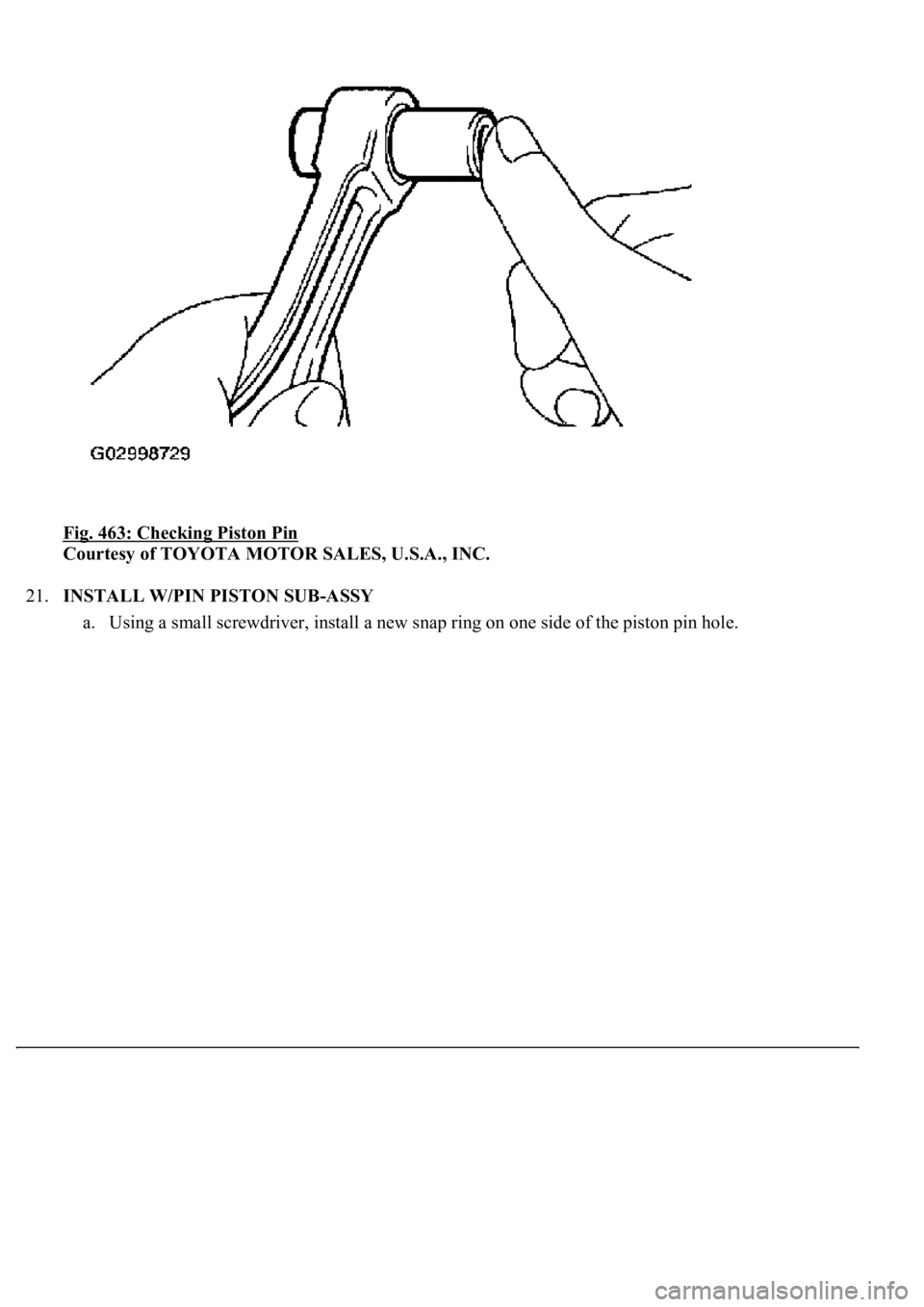

Fig. 463: Checking Piston Pin

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

21.INSTALL W/PIN PISTON SUB-ASSY

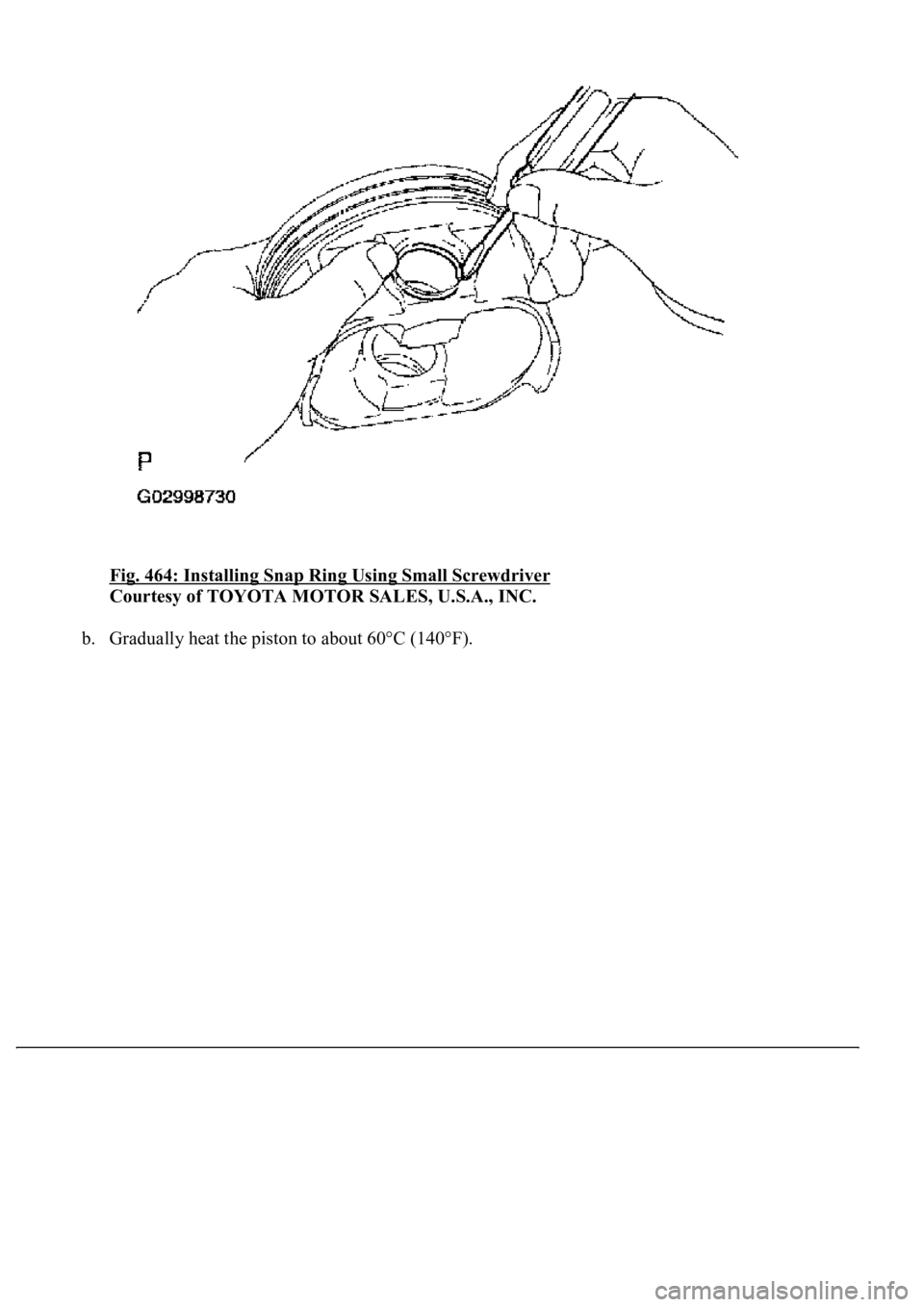

a. Using a small screwdriver, install a new snap ring on one side of the piston pin hole.

Page 3752 of 4500

Fig. 464: Installing Snap Ring Using Small Screwdriver

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b.Gradually heat the piston to about 60°C (140°F).

Page 3753 of 4500

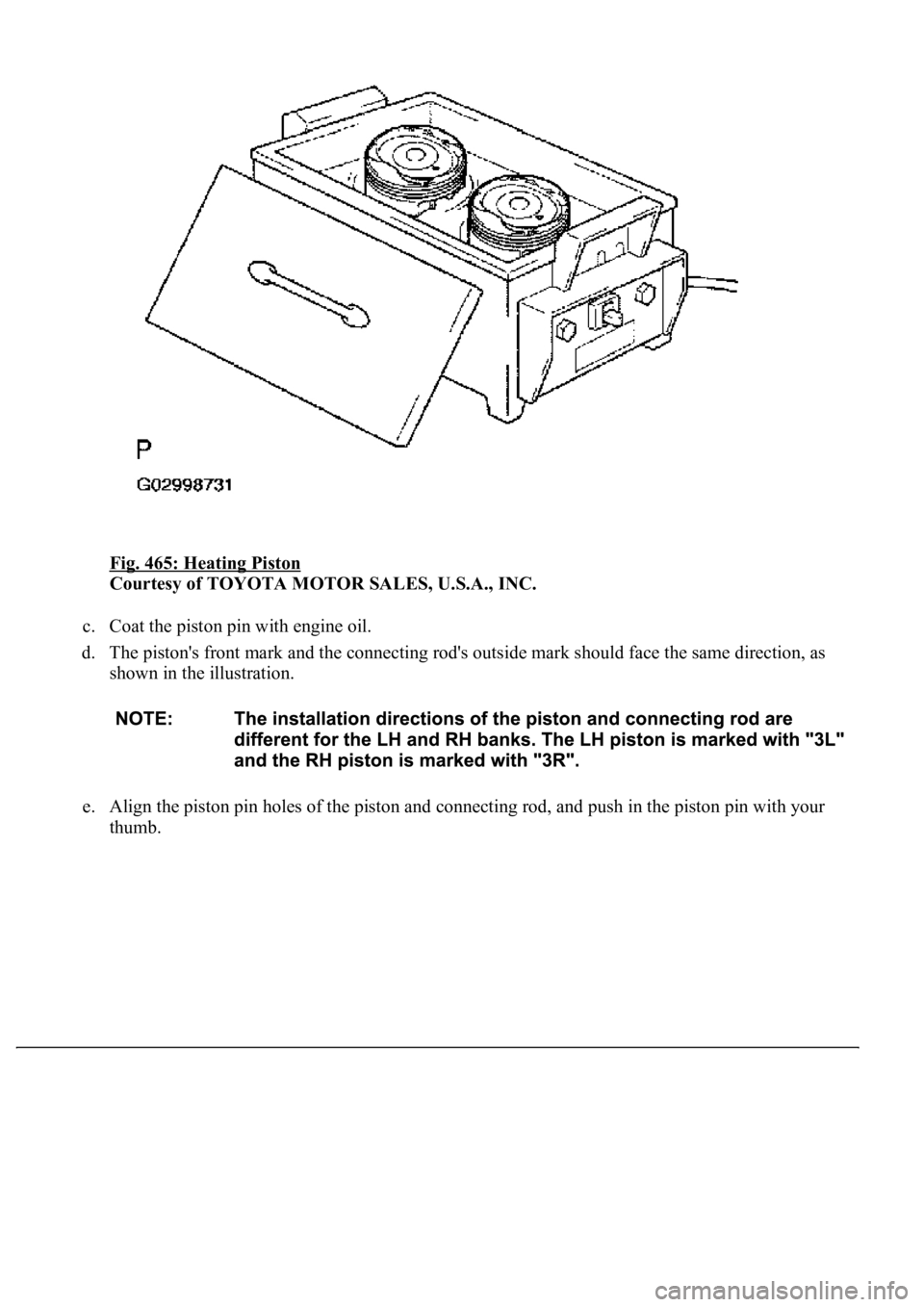

Fig. 465: Heating Piston

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Coat the piston pin with engine oil.

d. The piston's front mark and the connecting rod's outside mark should face the same direction, as

shown in the illustration.

e. Align the piston pin holes of the piston and connecting rod, and push in the piston pin with your

thumb.

Page 3754 of 4500

Page 3755 of 4500

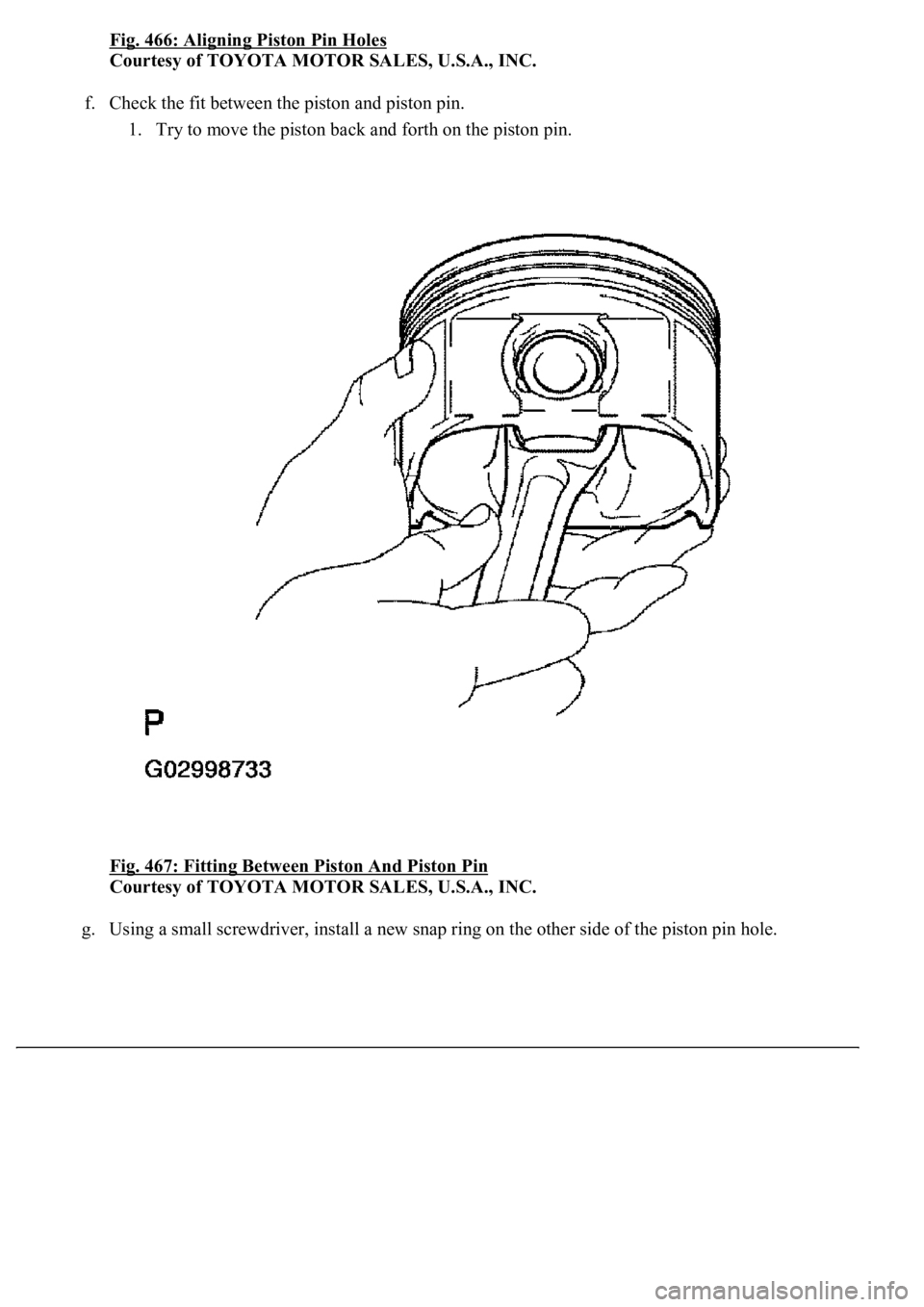

Fig. 466: Aligning Piston Pin Holes

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

f. Check the fit between the piston and piston pin.

1. Try to move the piston back and forth on the piston pin.

Fig. 467: Fitting Between Piston And Piston Pin

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

g.Using a small screwdriver, install a new snap ring on the other side of the piston pin hole.

Page 3756 of 4500

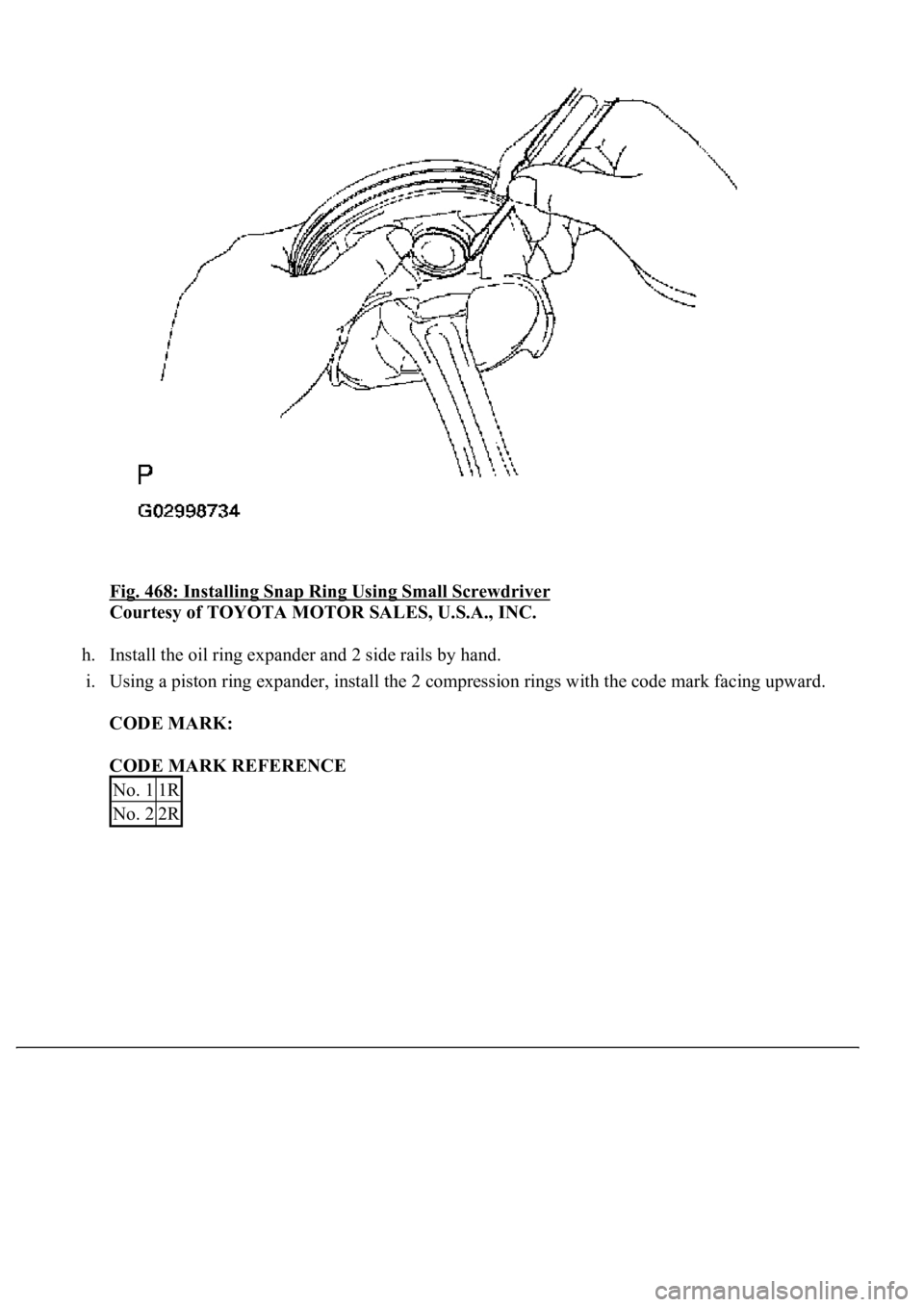

Fig. 468: Installing Snap Ring Using Small Screwdriver

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

h. Install the oil ring expander and 2 side rails by hand.

i. Using a piston ring expander, install the 2 compression rings with the code mark facing upward.

CODE MARK:

CODE MARK REFERENCE

No. 11R

No. 22R

Page 3757 of 4500

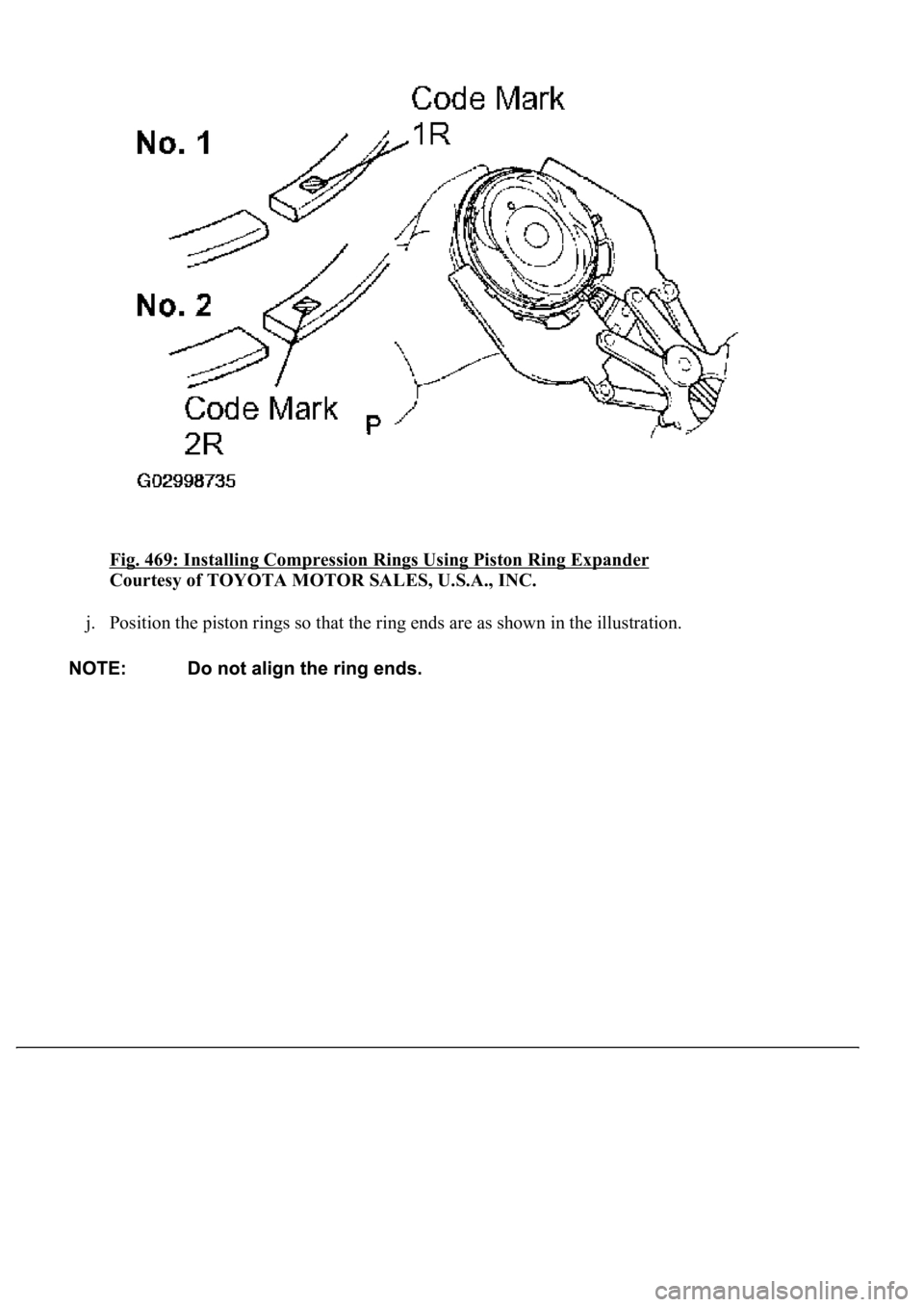

Fig. 469: Installing Compression Rings Using Piston Ring Expander

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

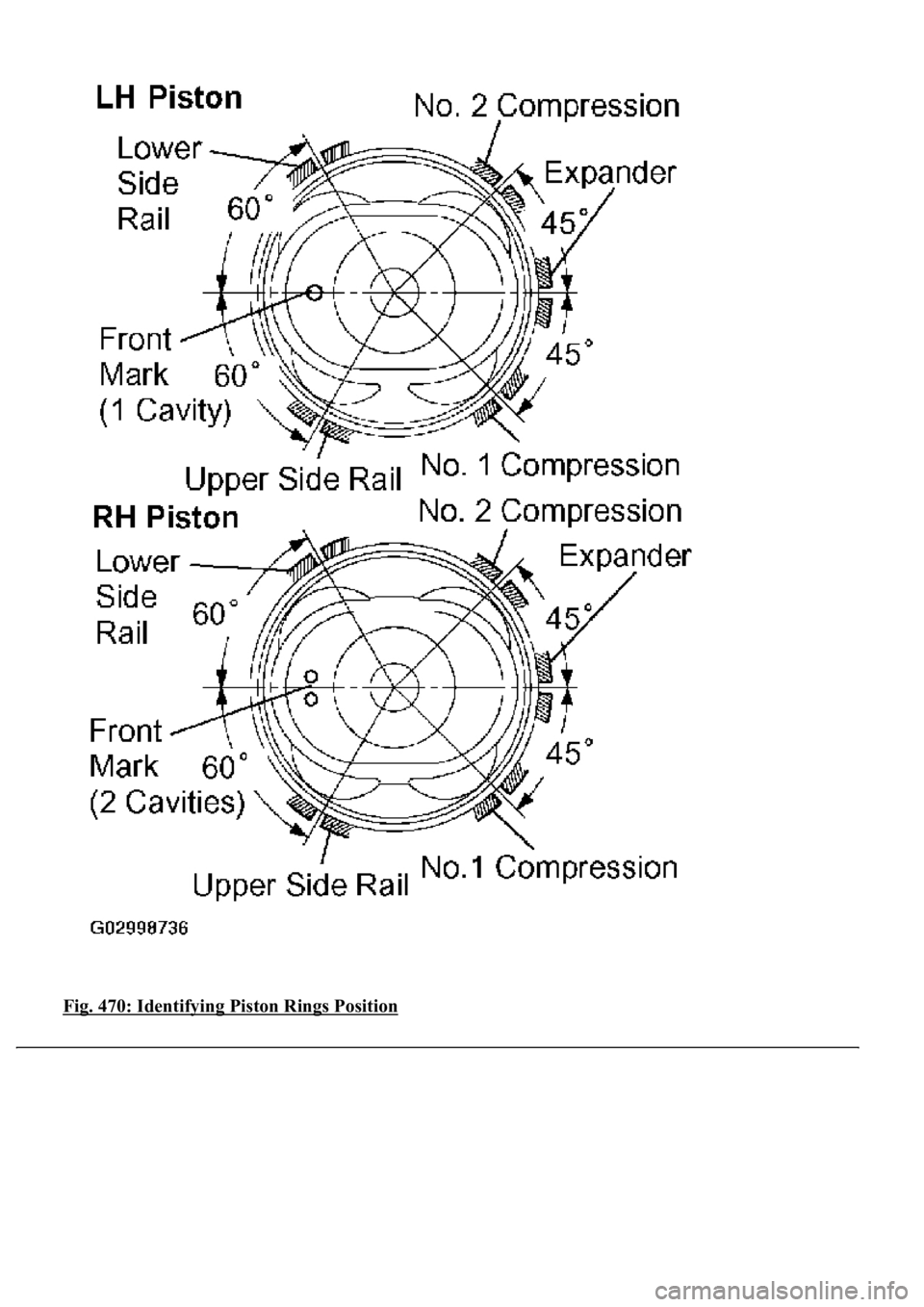

j. Position the piston rings so that the ring ends are as shown in the illustration.

Page 3758 of 4500

Fig. 470: Identifying Piston Rings Position

Page 3759 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

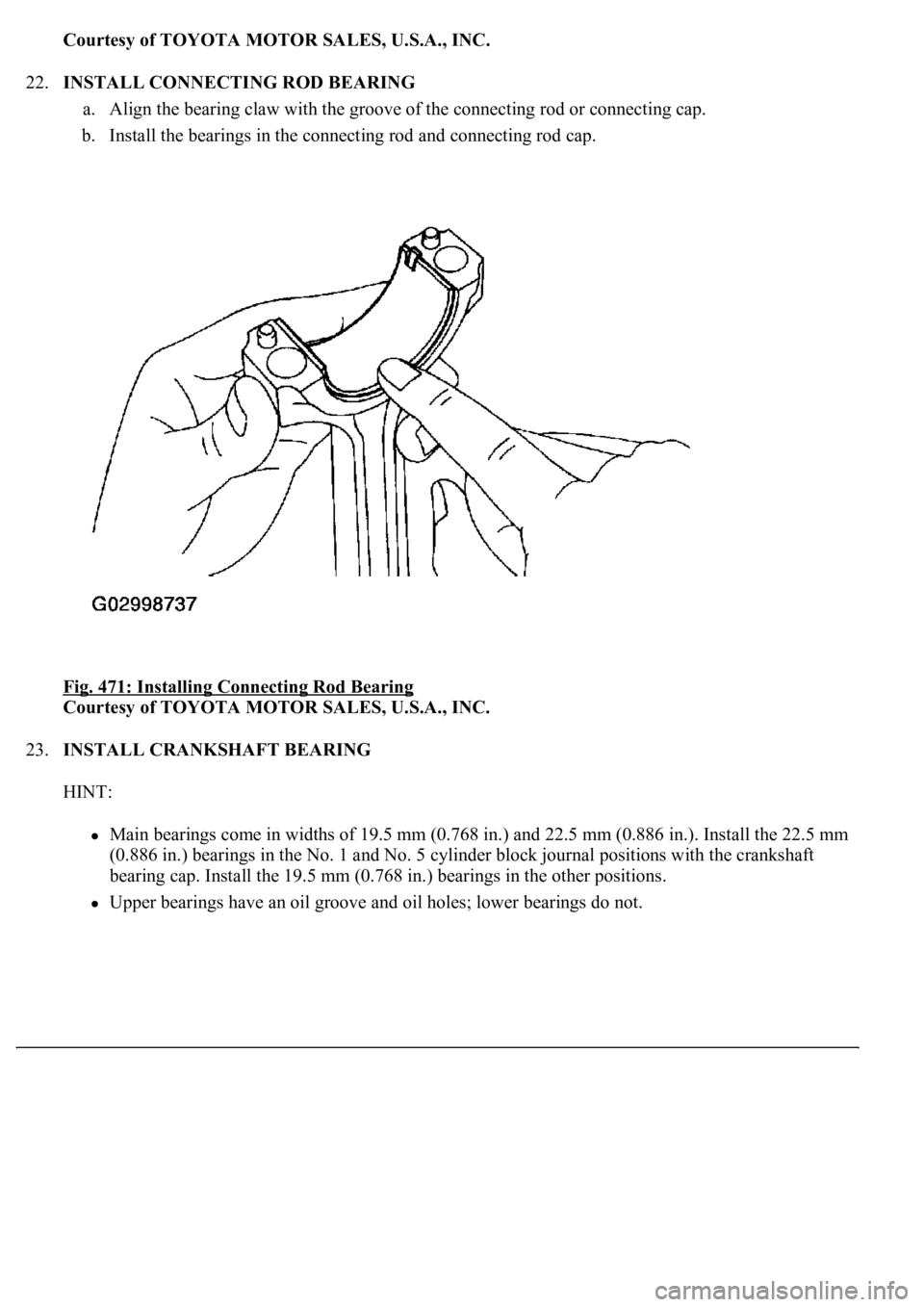

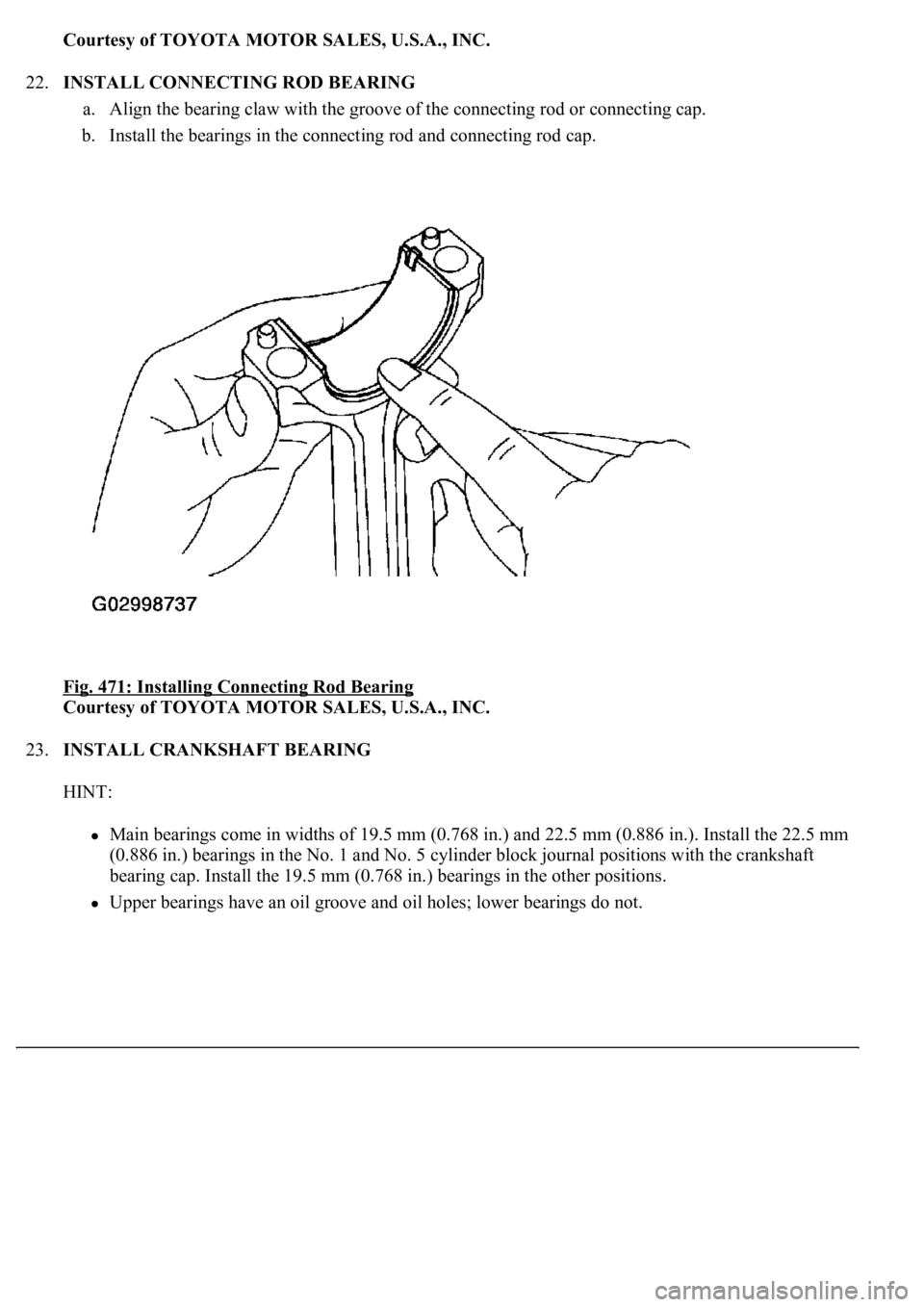

22.INSTALL CONNECTING ROD BEARING

a. Align the bearing claw with the groove of the connecting rod or connecting cap.

b. Install the bearings in the connecting rod and connecting rod cap.

Fig. 471: Installing Connecting Rod Bearing

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

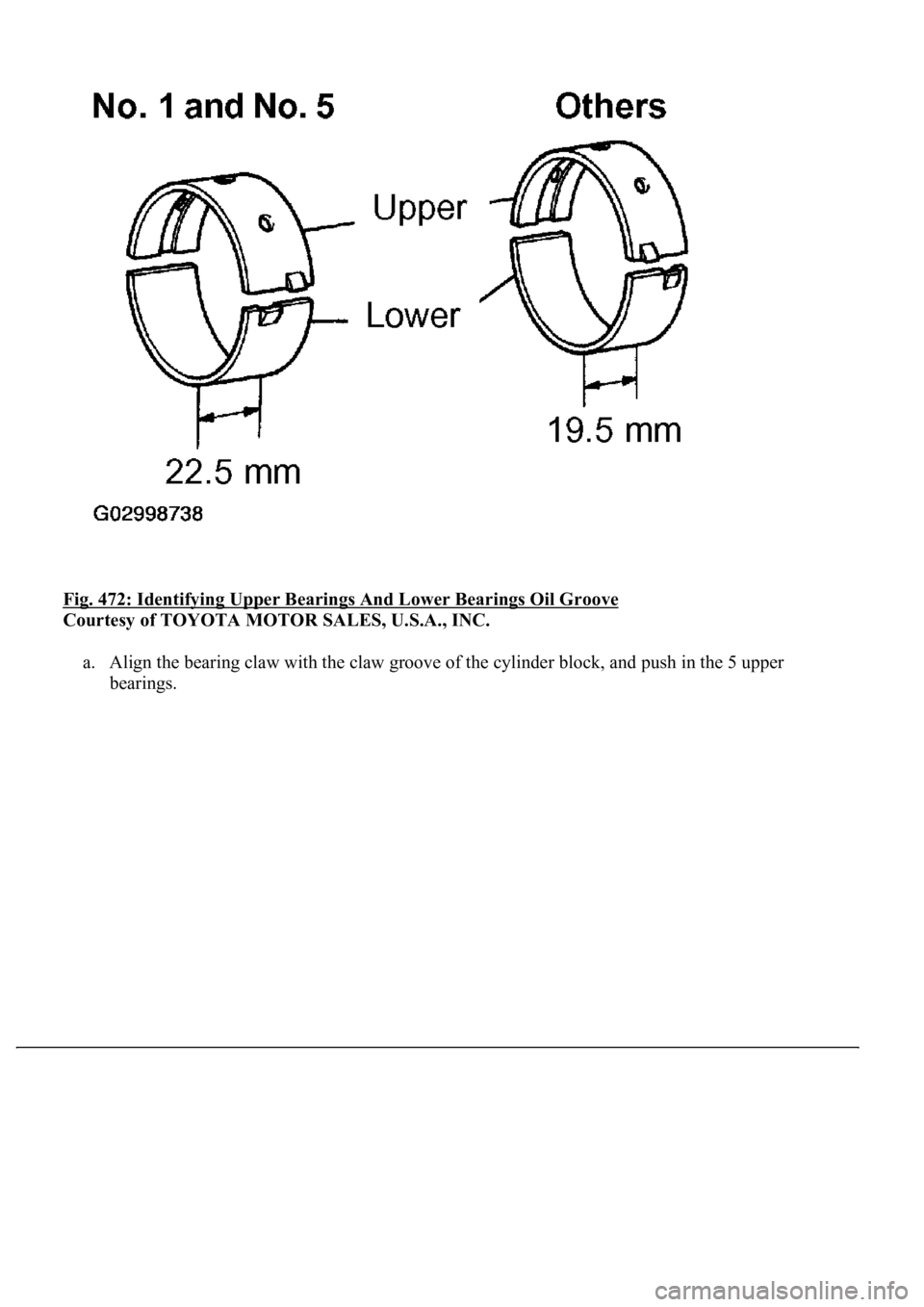

23.INSTALL CRANKSHAFT BEARING

HINT:

<00300044004c005100030045004800440055004c0051004a0056000300460052005000480003004c00510003005a004c00470057004b005600030052004900030014001c001100180003005000500003000b00130011001a0019001b0003004c0051001100

0c000300440051004700030015001500110018000300500050[ (0.886 in.). Install the 22.5 mm

(0.886 in.) bearings in the No. 1 and No. 5 cylinder block journal positions with the crankshaft

<0045004800440055004c0051004a000300460044005300110003002c0051005600570044004f004f00030057004b004800030014001c001100180003005000500003000b00130011001a0019001b0003004c00510011000c00030045004800440055004c00

51004a00560003004c005100030057004b0048000300520057[her positions.

Upper bearings have an oil groove and oil holes; lower bearings do not.

Page 3760 of 4500

Fig. 472: Identifying Upper Bearings And Lower Bearings Oil Groove

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Align the bearing claw with the claw groove of the cylinder block, and push in the 5 upper

bearings.

Trending: ABS, oil temperature, roof rack, shock absorber, airbag, ESP, fuel pressure