MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 111 of 909

FUEL SYSTEM

F1–23

F1

FUEL TANK REMOVAL/INSTALLATIONA6E391242110201

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

1. Level the vehicle.

2. Complete the “BEFORE REPAIR PROCEDURE”.

3. Disconnect the negative battery cable.

4. Remove the fuel pump unit. (See F1–26 FUEL PUMP UNIT REMOVAL/INSTALLATION.)

5. Remove the fuel gauge sender sub-unit. (See T–27 Fuel Gauge Sender Sub-Unit.)

6. Siphon the fuel from the service hole.

7. Remove the presilencer. (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the TWC. (See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

9. Remove the propeller shaft. (See L–5 PROPELLER SHAFT REMOVAL/INSTALLATION.)

FUEL SYSTEM

Page 112 of 909

F1–24

FUEL SYSTEM

10. Remove in the order indicated in the table.

11. Install in the reverse order of removal.

12. Complete the “AFTER REPAIR PROCEDURE”.

.

44—60

{4.5—6.1, 33—44}

7

5

4

3

2

1

6

A

N·m {kgf·m, ft·lbf} 44—60

{4.5—6.1, 33—44}

44—60

{4.5—6.1, 33—44}8.9—12.7 N·m

{91—120 kgf·cm, 79—110 in·lbf}

8.9—12.7 N·m

{91—120 kgf·cm, 79—110 in·lbf}

A6E39122008

1 Joint hose

(See F1–25 Joint Hose Installation Note)

2 Breather hose

(See F1–25 Breather Hose Installation Note)

3 Evaporative hose

(See F1–25 Evaporative Hose Installation Note)4 Fuel tank

5 Fuel-filler pipe

6 C-ring

7 Filler cap

Page 113 of 909

FUEL SYSTEM

F1–25

F1

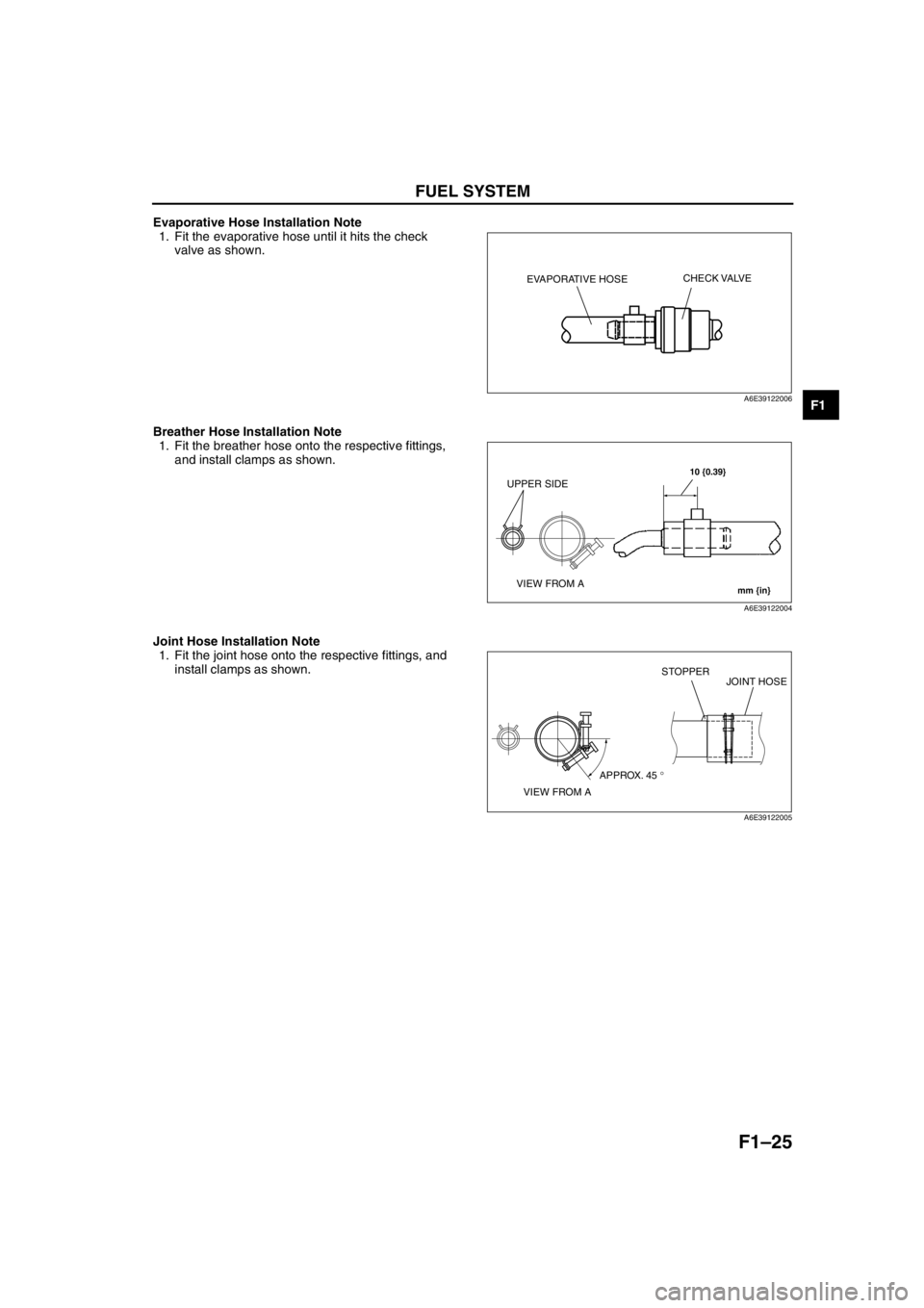

Evaporative Hose Installation Note

1. Fit the evaporative hose until it hits the check

valve as shown.

Breather Hose Installation Note

1. Fit the breather hose onto the respective fittings,

and install clamps as shown.

Joint Hose Installation Note

1. Fit the joint hose onto the respective fittings, and

install clamps as shown.

End Of Sie

EVAPORATIVE HOSECHECK VALVE

A6E39122006

10 {0.39}

mm {in}

UPPER SIDE

VIEW FROM A

A6E39122004

VIEW FROM AAPPROX. 45 °STOPPER

JOINT HOSE

A6E39122005

Page 114 of 909

F1–26

FUEL SYSTEM

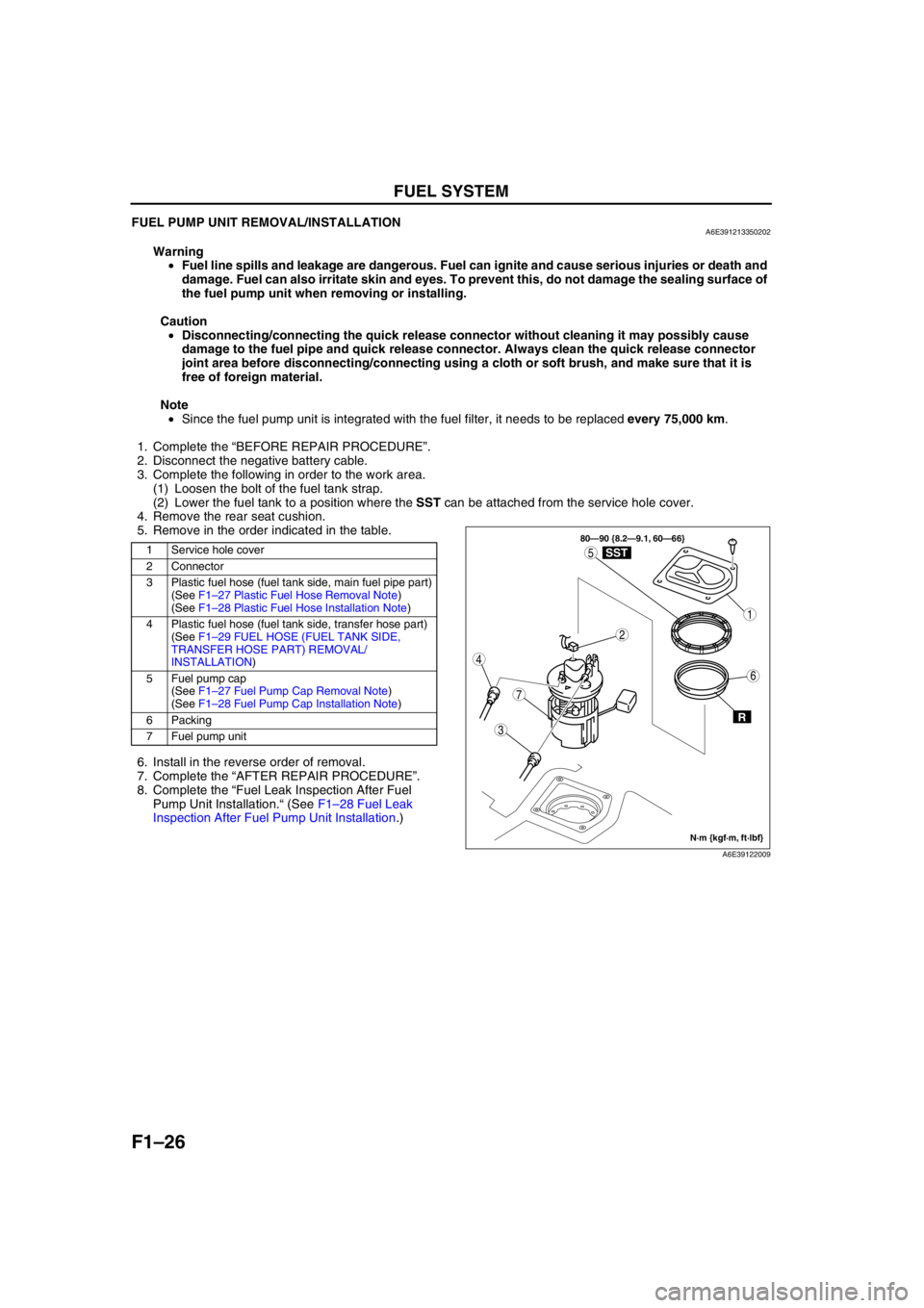

FUEL PUMP UNIT REMOVAL/INSTALLATIONA6E391213350202

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

•Since the fuel pump unit is integrated with the fuel filter, it needs to be replaced every 75,000 km.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel Leak Inspection After Fuel

Pump Unit Installation.“ (See F1–28 Fuel Leak

Inspection After Fuel Pump Unit Installation.)

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, main fuel pipe part)

(See F1–27 Plastic Fuel Hose Removal Note)

(See F1–28 Plastic Fuel Hose Installation Note)

4 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

5Fuel pump cap

(See F1–27 Fuel Pump Cap Removal Note)

(See F1–28 Fuel Pump Cap Installation Note)

6 Packing

7 Fuel pump unit

3

7

1

4

5

2

6

80—90 {8.2—9.1, 60—66}

R

SST

N·m {kgf·m, ft·lbf}

A6E39122009

Page 115 of 909

FUEL SYSTEM

F1–27

F1

Plastic Fuel Hose Removal Note

Caution

•The quick release connector may be damaged if the tab is bent excessively. Do not expand the tab

over the stopper.

1. Disconnect the quick release connector.

(1) Push the tab on the locking coupler 90

degrees until it stops.

(2) Pull the fuel hose straight back.

Note

•The stopper may be removed from the quick

connector. Take care not to lose it.

Reinstall it to the quick release connector

before reconnecting the fuel line.

•The locking coupler has two internal locking

tabs which retain the fuel pipe. Be sure that

the tab on the locking coupler is rotated until

it stops to release two internal locking tabs.

2. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Fuel Pump Cap Removal Note

1. Using the SST, remove the fuel pump cap.

FUEL PIPE

STOPPER TAB

A6E3912W001

LOCKING TAB

A6E3912W002

A6E39122015

49 T042 001A

A6E39122012

Page 116 of 909

F1–28

FUEL SYSTEM

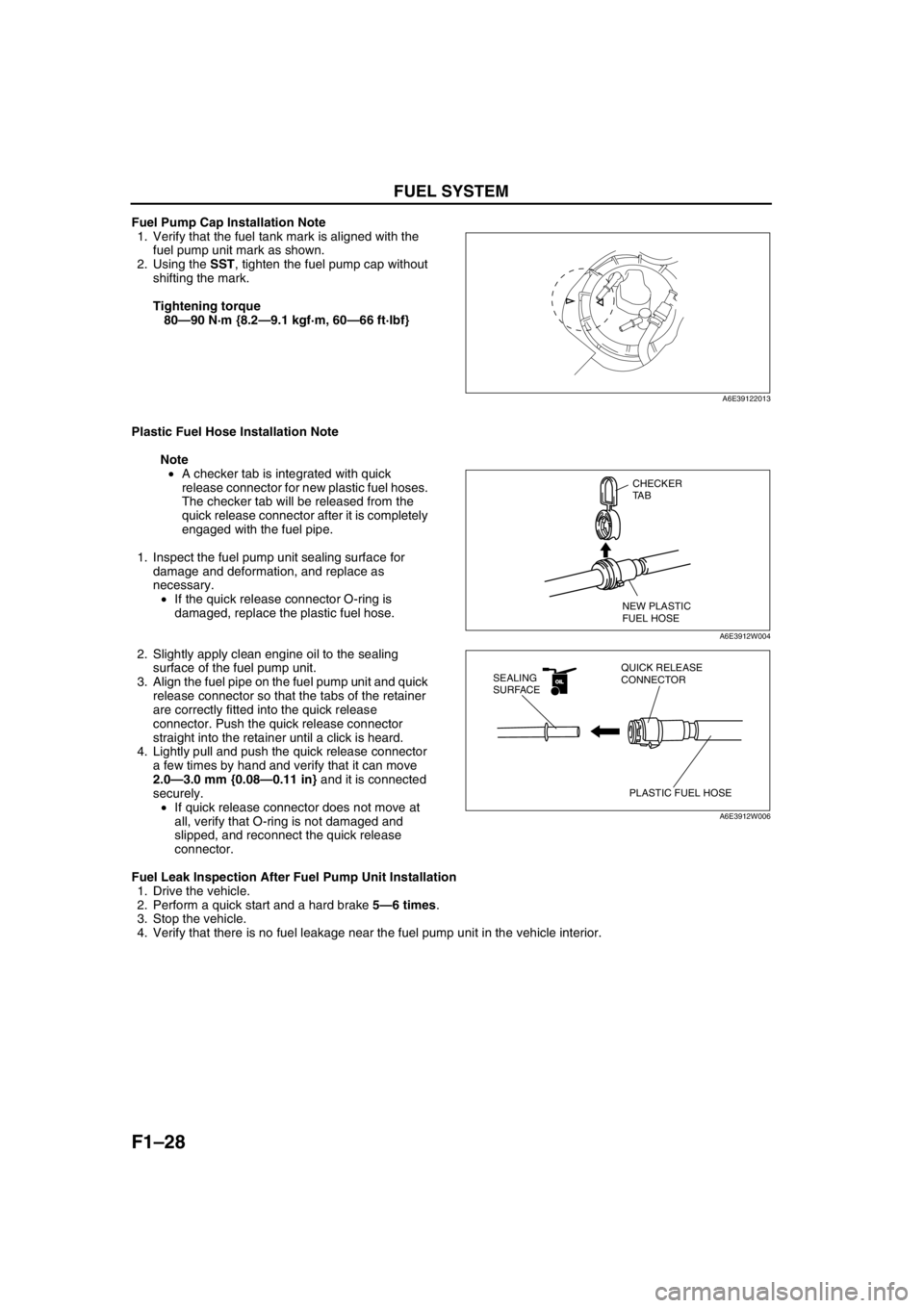

Fuel Pump Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump unit mark as shown.

2. Using the SST, tighten the fuel pump cap without

shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

2. Slightly apply clean engine oil to the sealing

surface of the fuel pump unit.

3. Align the fuel pipe on the fuel pump unit and quick

release connector so that the tabs of the retainer

are correctly fitted into the quick release

connector. Push the quick release connector

straight into the retainer until a click is heard.

4. Lightly pull and push the quick release connector

a few times by hand and verify that it can move

2.0—3.0 mm {0.08—0.11 in} and it is connected

securely.

•If quick release connector does not move at

all, verify that O-ring is not damaged and

slipped, and reconnect the quick release

connector.

Fuel Leak Inspection After Fuel Pump Unit Installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

A6E39122013

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

Page 117 of 909

FUEL SYSTEM

F1–29

F1

FUEL HOSE (FUEL TANK SIDE, TRANSFER HOSE PART) REMOVAL/INSTALLATIONA6E391242692202

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel pump unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

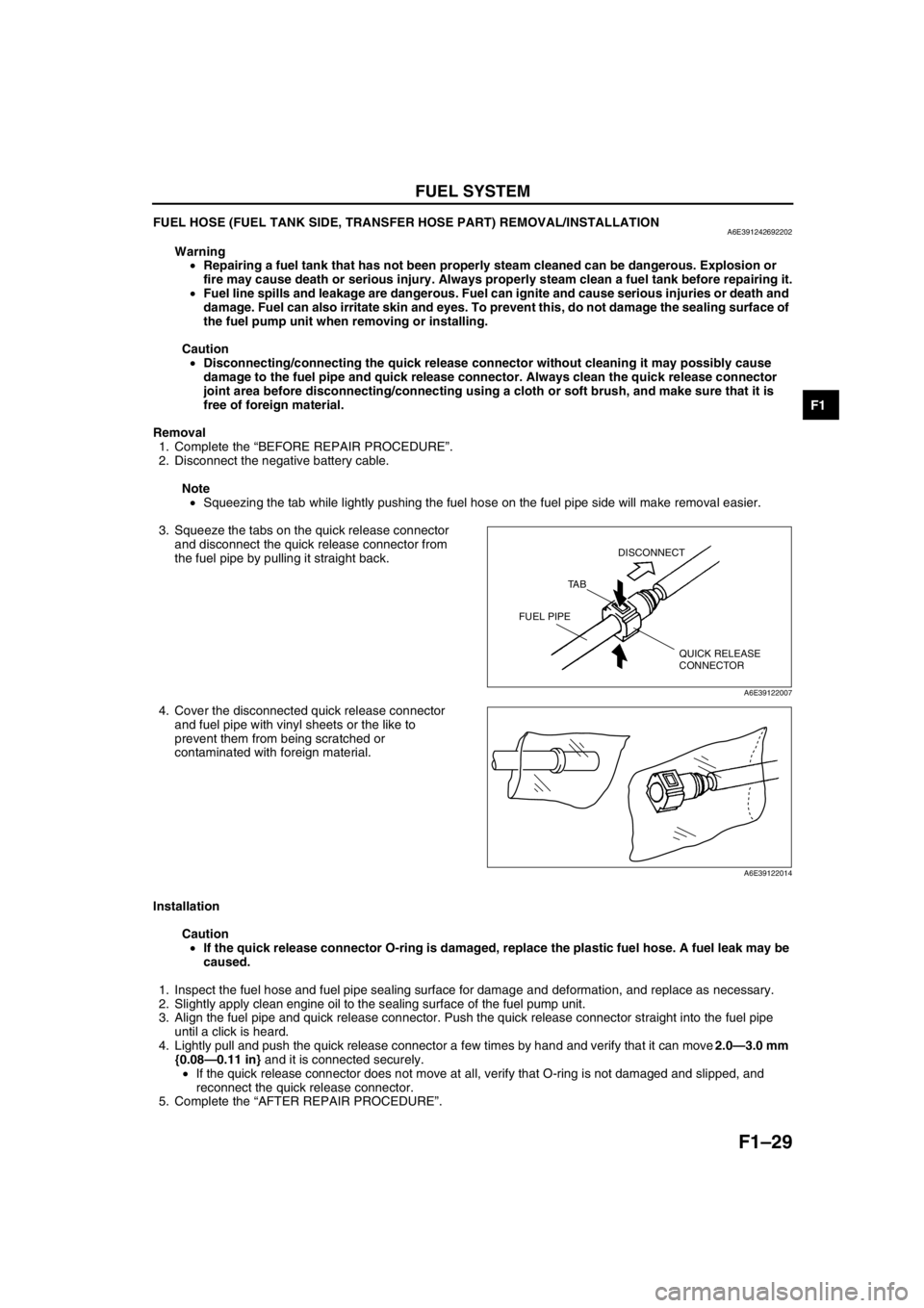

Removal

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

Note

•Squeezing the tab while lightly pushing the fuel hose on the fuel pipe side will make removal easier.

3. Squeeze the tabs on the quick release connector

and disconnect the quick release connector from

the fuel pipe by pulling it straight back.

4. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Installation

Caution

•If the quick release connector O-ring is damaged, replace the plastic fuel hose. A fuel leak may be

caused.

1. Inspect the fuel hose and fuel pipe sealing surface for damage and deformation, and replace as necessary.

2. Slightly apply clean engine oil to the sealing surface of the fuel pump unit.

3. Align the fuel pipe and quick release connector. Push the quick release connector straight into the fuel pipe

until a click is heard.

4. Lightly pull and push the quick release connector a few times by hand and verify that it can move 2.0—3.0 mm

{0.08—0.11 in} and it is connected securely.

•If the quick release connector does not move at all, verify that O-ring is not damaged and slipped, and

reconnect the quick release connector.

5. Complete the “AFTER REPAIR PROCEDURE”.

End Of Sie

QUICK RELEASE

CONNECTOR TA BDISCONNECT

FUEL PIPE

A6E39122007

A6E39122014

Page 118 of 909

F1–30

EXHAUST SYSTEM

EXHAUST SYSTEM REMOVAL/INSTALLATIONA6E391440000203

Warning

•When the engine and exhaust system are hot, they can badly burn. Turn off the engine and wait

until they are cool before removing the exhaust system.

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

.

EXHAUST SYSTEM

R

37.3—52.0

{3.9—5.3, 28—38} 40—55

{4.1—5.6, 30—40} 43—64

{4.4—6.5, 32—47}

2

1

R

R

R

7

4

36

5

8

RA

SST

29—49 {3.0—4.9, 22—36}SST

R

A

10

38—51 {3.9—5.2, 29—37}N·m {kgf·m, ft·lbf} 38—51 {3.9—5.2, 29—37} 38—51 {3.9—5.2, 29—37} 38—51 {3.9—5.2, 29—37} 7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf}

7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf} 7.8—10.8 N·m

{80—110 kgf·cm, 70—95 in·lbf} 29—49 {3.0—4.9, 22—36}

9

A6E39142004

Page 119 of 909

EXHAUST SYSTEM

F1–31

F1HO2S Removal Note

1. Using the SST, remove the HO2S.

Exhaust Manifold Insulator (Lower) Installation Note

1. Tighten the exhaust manifold insulator (lower)

installation bolts in the order shown.

2. Verify that there is 3.0—7.0 mm {0.12—0.27 in}

gap between the exhaust manifold and the

exhaust manifold insulator (lower).

1 Main silencer

2 Presilencer

3TWC

4 Exhaust manifold insulator (upper)

(See F1–32 Exhaust Manifold Insulator (Upper)

Installation Note)

5Bracket

(See F1–32 Bracket Installation Note)

6 Exhaust manifold

(See F1–32 Exhaust Manifold Installation Note)7 Exhaust manifold gasket

8 Exhaust manifold insulator (lower)

(See F1–31 Exhaust Manifold Insulator (Lower)

Installation Note)

9 HO2S (front)

(See F1–31 HO2S Removal Note)

10 HO2S (rear)

(See F1–31 HO2S Removal Note)

49 L018 001

A6J39142003

5

4

3

1

2

A6E39142005

3.0—7.0 {0.12—0.27}

EXHAUST MANIFOLD

EXHAUST MANIFOLD

INSULATOR (LOWER)

mm {in}

A6E39142002

Page 120 of 909

F1–32

EXHAUST SYSTEM

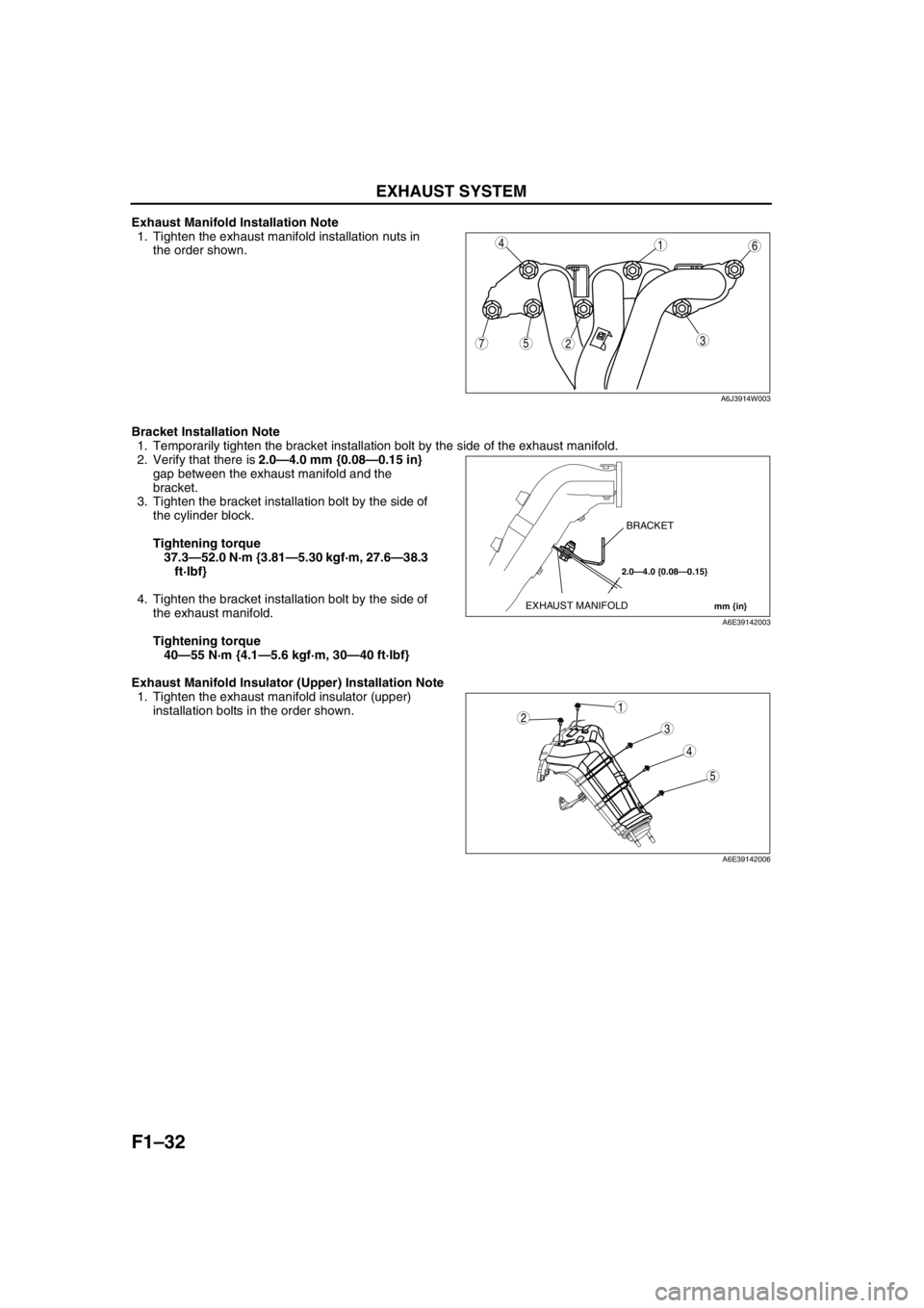

Exhaust Manifold Installation Note

1. Tighten the exhaust manifold installation nuts in

the order shown.

Bracket Installation Note

1. Temporarily tighten the bracket installation bolt by the side of the exhaust manifold.

2. Verify that there is 2.0—4.0 mm {0.08—0.15 in}

gap between the exhaust manifold and the

bracket.

3. Tighten the bracket installation bolt by the side of

the cylinder block.

Tightening torque

37.3—52.0 N·m {3.81—5.30 kgf·m, 27.6—38.3

ft·lbf}

4. Tighten the bracket installation bolt by the side of

the exhaust manifold.

Tightening torque

40—55 N·m {4.1—5.6 kgf·m, 30—40 ft·lbf}

Exhaust Manifold Insulator (Upper) Installation Note

1. Tighten the exhaust manifold insulator (upper)

installation bolts in the order shown.

End Of Sie

75

4

3

1

2

6

A6J3914W003

2.0—4.0 {0.08—0.15}

mm {in}EXHAUST MANIFOLDBRACKET

A6E39142003

5

4

3

12

A6E39142006