MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 381 of 909

TROUBLESHOOTING

F2–229

F2

ENGINE CONTROL SYSTEM OPERATION INSPECTIONA6E408018881230Intake Shutter Valve Operation Inspection

1. Start the engine and warm up completely.

2. Turn off the A/C switch.

3. Connect the WDS or equivalent to the DLC-2.

4. Monitor the following PIDs using the WDS or equivalent.

—If not as specified, inspect each sensor and related harness.

ECT PID

Above 60 °C {140 °F}

MAF PID

1.7—1.9 V

RPM PID

725—825 rpm

Note

•The position of the shutter valve, VSC shutter valve and EGR valve may not be as specified when idle

speed is maintained for several minutes. If this occurs, briefly increase engine speed to 1,500 rpm and

then re-check the position at idle speed.

5. Increase the engine speed and inspect that the intake shutter valve position changes as specified.

•If not as specified, inspect the following.

—Vacuum hose

—Intake shutter solenoid valve actuator

—Intake shutter solenoid valve and related harness.

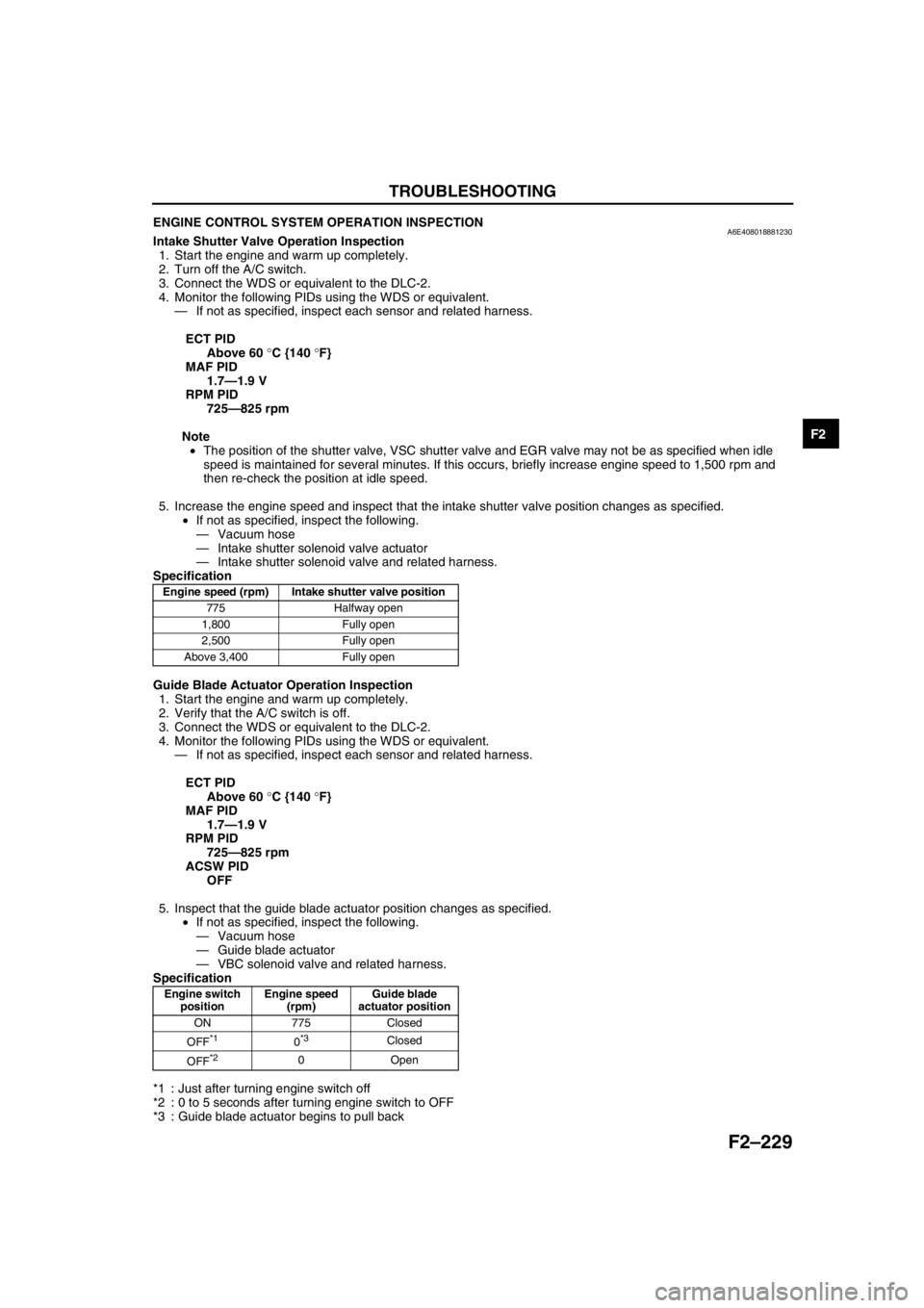

Specification

Guide Blade Actuator Operation Inspection

1. Start the engine and warm up completely.

2. Verify that the A/C switch is off.

3. Connect the WDS or equivalent to the DLC-2.

4. Monitor the following PIDs using the WDS or equivalent.

—If not as specified, inspect each sensor and related harness.

ECT PID

Above 60 °C {140 °F}

MAF PID

1.7—1.9 V

RPM PID

725—825 rpm

ACSW PID

OFF

5. Inspect that the guide blade actuator position changes as specified.

•If not as specified, inspect the following.

—Vacuum hose

—Guide blade actuator

—VBC solenoid valve and related harness.

Specification

*1 : Just after turning engine switch off

*2 : 0 to 5 seconds after turning engine switch to OFF

*3 : Guide blade actuator begins to pull back

Engine speed (rpm) Intake shutter valve position

775 Halfway open

1,800 Fully open

2,500 Fully open

Above 3,400 Fully open

Engine switch

positionEngine speed

(rpm)Guide blade

actuator position

ON 775 Closed

OFF

*10*3Closed

OFF

*20 Open

Page 382 of 909

F2–230

TROUBLESHOOTING

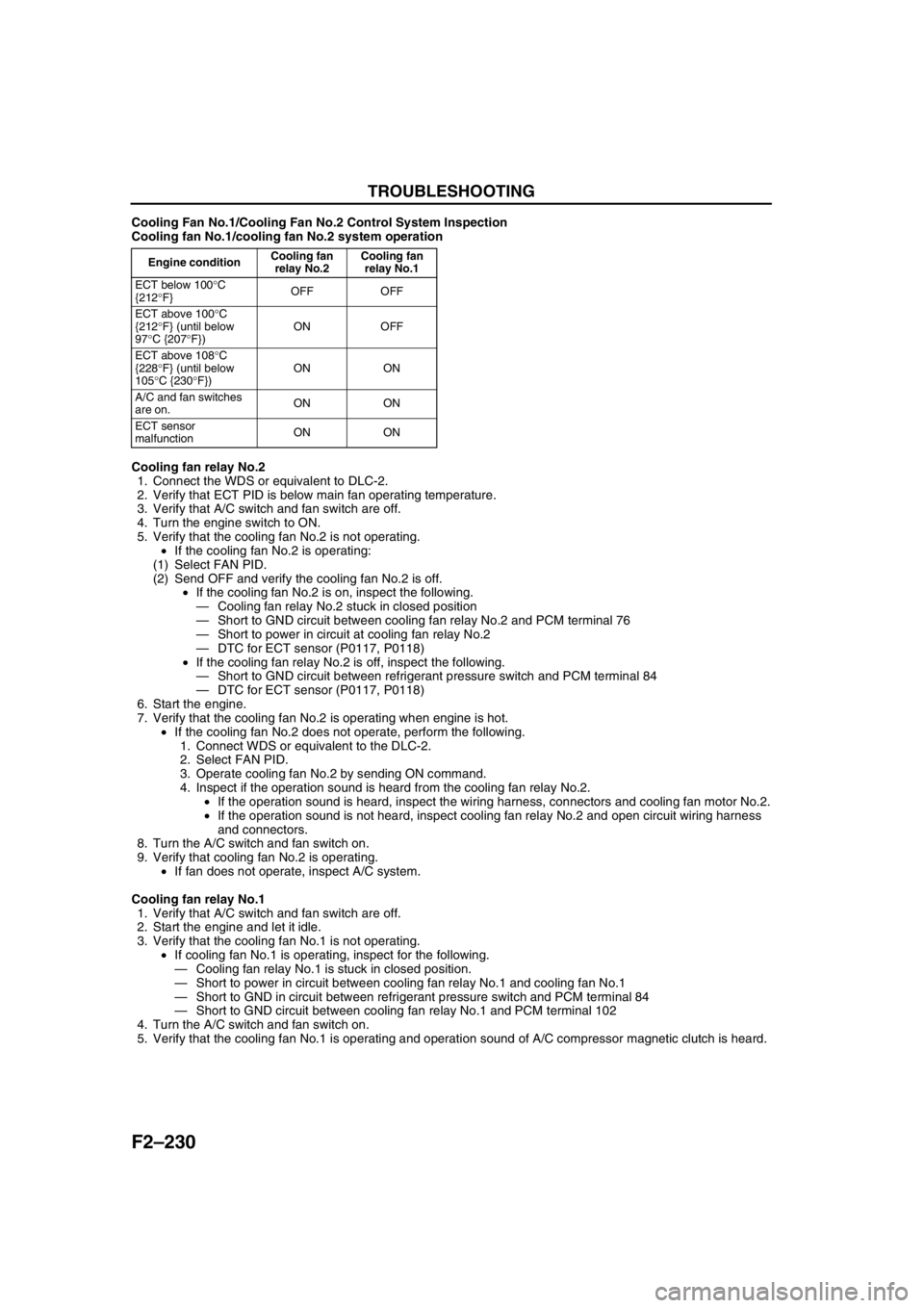

Cooling Fan No.1/Cooling Fan No.2 Control System Inspection

Cooling fan No.1/cooling fan No.2 system operation

Cooling fan relay No.2

1. Connect the WDS or equivalent to DLC-2.

2. Verify that ECT PID is below main fan operating temperature.

3. Verify that A/C switch and fan switch are off.

4. Turn the engine switch to ON.

5. Verify that the cooling fan No.2 is not operating.

•If the cooling fan No.2 is operating:

(1) Select FAN PID.

(2) Send OFF and verify the cooling fan No.2 is off.

•If the cooling fan No.2 is on, inspect the following.

—Cooling fan relay No.2 stuck in closed position

—Short to GND circuit between cooling fan relay No.2 and PCM terminal 76

—Short to power in circuit at cooling fan relay No.2

—DTC for ECT sensor (P0117, P0118)

•If the cooling fan relay No.2 is off, inspect the following.

—Short to GND circuit between refrigerant pressure switch and PCM terminal 84

—DTC for ECT sensor (P0117, P0118)

6. Start the engine.

7. Verify that the cooling fan No.2 is operating when engine is hot.

•If the cooling fan No.2 does not operate, perform the following.

1. Connect WDS or equivalent to the DLC-2.

2. Select FAN PID.

3. Operate cooling fan No.2 by sending ON command.

4. Inspect if the operation sound is heard from the cooling fan relay No.2.

•If the operation sound is heard, inspect the wiring harness, connectors and cooling fan motor No.2.

•If the operation sound is not heard, inspect cooling fan relay No.2 and open circuit wiring harness

and connectors.

8. Turn the A/C switch and fan switch on.

9. Verify that cooling fan No.2 is operating.

•If fan does not operate, inspect A/C system.

Cooling fan relay No.1

1. Verify that A/C switch and fan switch are off.

2. Start the engine and let it idle.

3. Verify that the cooling fan No.1 is not operating.

•If cooling fan No.1 is operating, inspect for the following.

—Cooling fan relay No.1 is stuck in closed position.

—Short to power in circuit between cooling fan relay No.1 and cooling fan No.1

—Short to GND in circuit between refrigerant pressure switch and PCM terminal 84

—Short to GND circuit between cooling fan relay No.1 and PCM terminal 102

4. Turn the A/C switch and fan switch on.

5. Verify that the cooling fan No.1 is operating and operation sound of A/C compressor magnetic clutch is heard.

Engine conditionCooling fan

relay No.2Cooling fan

relay No.1

ECT below 100°C

{212°F}OFF OFF

ECT above 100°C

{212°F} (until below

97°C {207°F})ON OFF

ECT above 108°C

{228°F} (until below

105°C {230°F})ON ON

A/C and fan switches

are on.ON ON

ECT sensor

malfunctionON ON

Page 383 of 909

TROUBLESHOOTING

F2–231

F2

6. Turn the A/C switch and fan switch off.

•If the cooling fan No.1 does not operate but operation sound of A/C compressor magnetic clutch is heard,

inspect for the following.

—Open circuit between ignition switch and cooling fan relay No.1

—Open circuit between battery and cooling fan relay No.1

—Open circuit between cooling fan relay No.1 and PCM terminal 102

—Open circuit between cooling fan relay No.1 and cooling fan motor No.1 or fan motor GND

—Cooling fan relay No.1 is stuck open.

—Cooling fan motor No.1

•If both additional fan and A/C compressor do not operate, inspect the following.

—A/C system

End Of Sie

Page 384 of 909

G–1

G

GENGINE ELECTRICAL SYSTEM

OUTLINE............................................................... G-2

OUTLINE OF CONSTRUCTION......................... G-2

SPECIFICATIONS .............................................. G-2

STRUCTURAl VIEW ........................................... G-3

OUTLINE............................................................... G-4

SUPPLEMENTAL SERVICE INFORMATION .... G-4

LOCATION INDEX .............................................. G-4

CHARGING SYSTEM............................................ G-5

BATTERY REMOVAL/INSTALLATION .............. G-5

BATTERY INSPECTION..................................... G-6

BATTERY RECHARGING .................................. G-6

GENERATOR REMOVAL/INSTALLATION ........ G-7

GENERATOR INSPECTION .............................. G-7

STARTING SYSTEM............................................. G-9

STARTER REMOVAL/INSTALLATION .............. G-9

STARTER INSPECTION .................................. G-11 FEATURES

SERVICE

Page 385 of 909

G–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E470202000201•The construction and operation of the engine electrical system for the new Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model is the same as the current Mazda 323 (BJ) RF engine model. (European specs.) (See

Mazda 323 Training Manual 3324-10-98E.)

•The construction and operation of the engine electrical system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) L8, LF, and L3 engine models. (See Mazda6 Training

Manual 3359-1*-02C, Mazda6 Workshop Manual 1730-1*-02C.)

End Of Sie

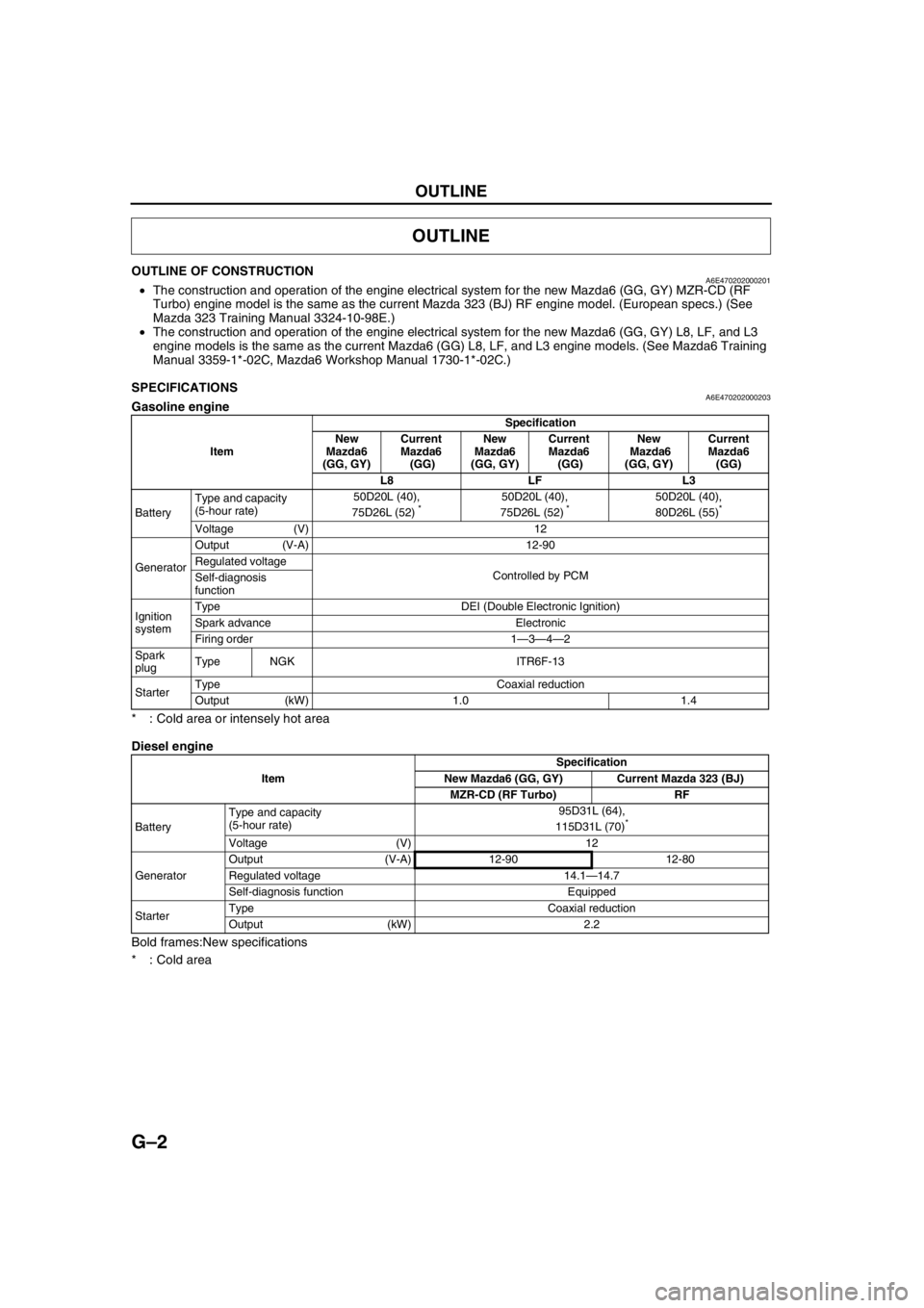

SPECIFICATIONSA6E470202000203Gasoline engine

* : Cold area or intensely hot area

Diesel engine

Bold frames:New specifications

* : Cold area

End Of Sie

OUTLINE

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3

BatteryType and capacity

(5-hour rate)50D20L (40),

75D26L (52)

*50D20L (40),

75D26L (52) *50D20L (40),

80D26L (55)*

Voltage (V) 12

GeneratorOutput (V-A) 12-90

Regulated voltage

Controlled by PCM

Self-diagnosis

function

Ignition

systemType DEI (Double Electronic Ignition)

Spark advance Electronic

Firing order 1—3—4—2

Spark

plugType NGK ITR6F-13

StarterType Coaxial reduction

Output (kW) 1.0 1.4

ItemSpecification

New Mazda6 (GG, GY) Current Mazda 323 (BJ)

MZR-CD (RF Turbo) RF

BatteryType and capacity

(5-hour rate)95D31L (64),

115D31L (70)

*

Voltage (V) 12

GeneratorOutput (V-A) 12-90 12-80

Regulated voltage 14.1—14.7

Self-diagnosis function Equipped

StarterType Coaxial reduction

Output (kW) 2.2

Page 386 of 909

OUTLINE

G–3

G

STRUCTURAL VIEWA6E470202000205MZR-CD (RF Turbo)

.

End Of Sie

3

1

2

A6E4702W100

1Battery

2 Generator 3Starter

Page 387 of 909

G–4

OUTLINE

SUPPLEMENTAL SERVICE INFORMATIONA6E470202000204•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Battery

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

•Recharging procedure has been added. (MZR-CD (RF Turbo) engine model)

Generator

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

Starter

•Removal/Installation procedure has been added.

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

End Of Sie

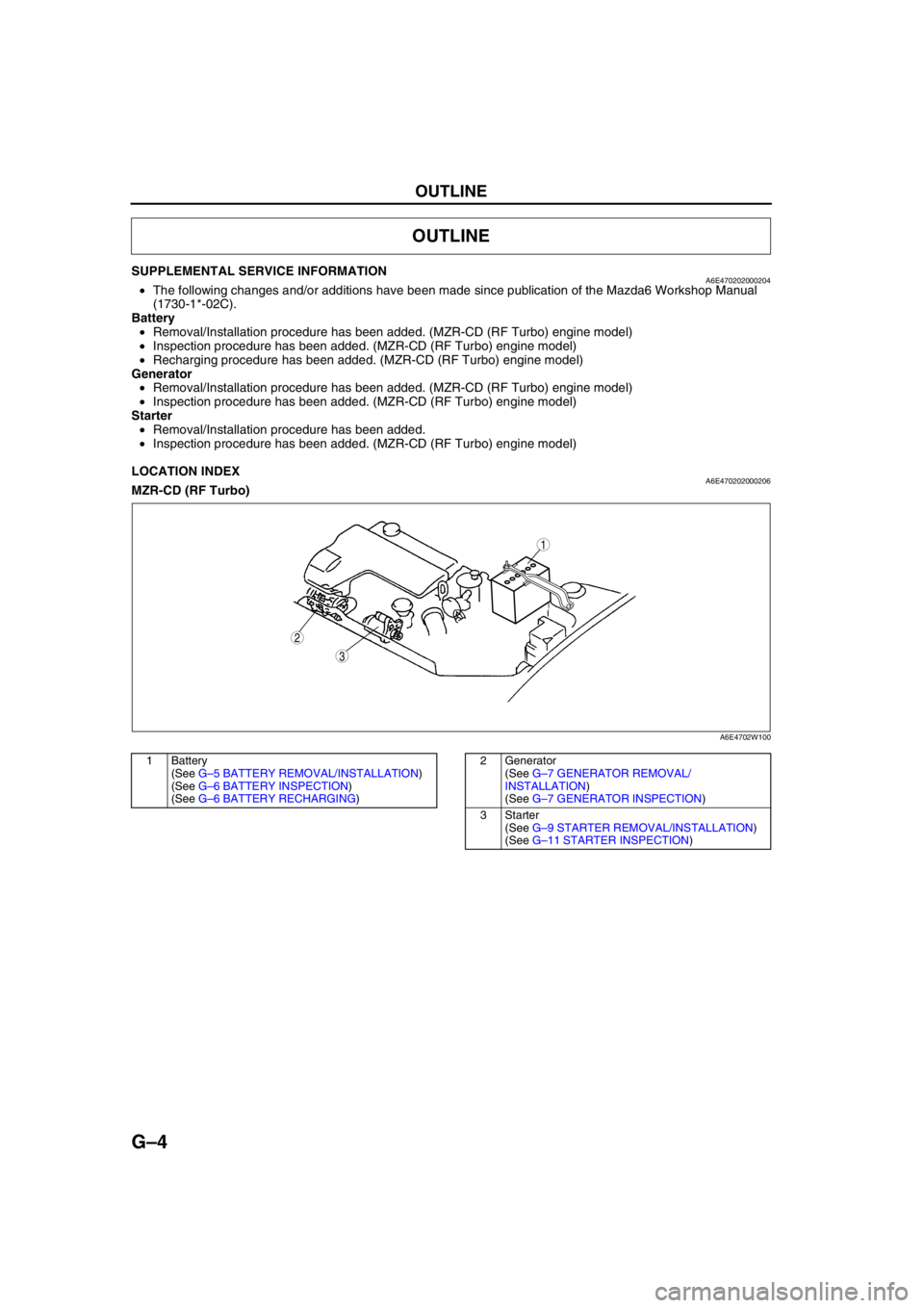

LOCATION INDEXA6E470202000206MZR-CD (RF Turbo)

.

End Of Sie

OUTLINE

3

1

2

A6E4702W100

1 Battery

(See G–5 BATTERY REMOVAL/INSTALLATION)

(See G–6 BATTERY INSPECTION)

(See G–6 BATTERY RECHARGING)2 Generator

(See G–7 GENERATOR REMOVAL/

INSTALLATION)

(See G–7 GENERATOR INSPECTION)

3Starter

(See G–9 STARTER REMOVAL/INSTALLATION)

(See G–11 STARTER INSPECTION)

Page 388 of 909

CHARGING SYSTEM

G–5

G

BATTERY REMOVAL/INSTALLATIONA6E471018520201MZR-CD (RF Turbo)

1. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

End Of Sie

CHARGING SYSTEM

4.0—6.8 N·m

{40.8—69.3 kgf·cm, 35.5—60.1 in·lbf}

7.9—11.7 N·m

{80.6—119.3 kgf·cm, 70.0—103.5 in·lbf}

5

4

3

1

2

A6E4710W103

1 Negative battery cable

2 Positive battery cable

3 Battery clamp4 Battery

5 Battery tray

Page 389 of 909

G–6

CHARGING SYSTEM

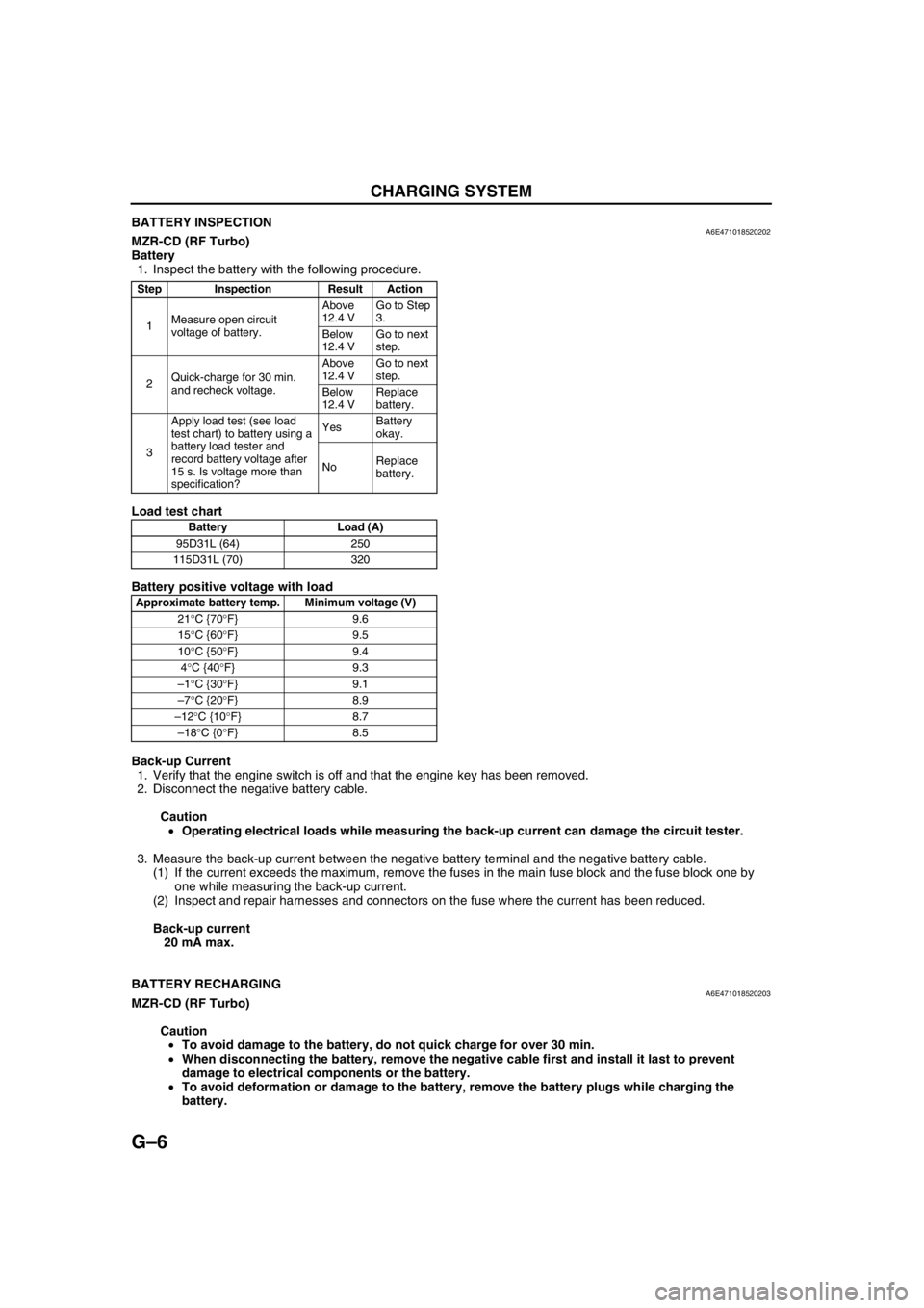

BATTERY INSPECTIONA6E471018520202MZR-CD (RF Turbo)

Battery

1. Inspect the battery with the following procedure.

Load test chart

Battery positive voltage with load

Back-up Current

1. Verify that the engine switch is off and that the engine key has been removed.

2. Disconnect the negative battery cable.

Caution

•Operating electrical loads while measuring the back-up current can damage the circuit tester.

3. Measure the back-up current between the negative battery terminal and the negative battery cable.

(1) If the current exceeds the maximum, remove the fuses in the main fuse block and the fuse block one by

one while measuring the back-up current.

(2) Inspect and repair harnesses and connectors on the fuse where the current has been reduced.

Back-up current

20 mA max.

End Of Sie

BATTERY RECHARGINGA6E471018520203MZR-CD (RF Turbo)

Caution

•To avoid damage to the battery, do not quick charge for over 30 min.

•When disconnecting the battery, remove the negative cable first and install it last to prevent

damage to electrical components or the battery.

•To avoid deformation or damage to the battery, remove the battery plugs while charging the

battery.

Step Inspection Result Action

1Measure open circuit

voltage of battery.Above

12.4 VGo to Step

3.

Below

12.4 VGo to next

step.

2Quick-charge for 30 min.

and recheck voltage.Above

12.4 VGo to next

step.

Below

12.4 VReplace

battery.

3Apply load test (see load

test chart) to battery using a

battery load tester and

record battery voltage after

15 s. Is voltage more than

specification?YesBattery

okay.

NoReplace

battery.

Battery Load (A)

95D31L (64) 250

115D31L (70) 320

Approximate battery temp. Minimum voltage (V)

21°C {70°F} 9.6

15°C {60°F} 9.5

10°C {50°F} 9.4

4°C {40°F} 9.3

–1°C {30°F} 9.1

–7°C {20°F} 8.9

–12°C {10°F} 8.7

–18°C {0°F} 8.5

Page 390 of 909

CHARGING SYSTEM

G–7

G

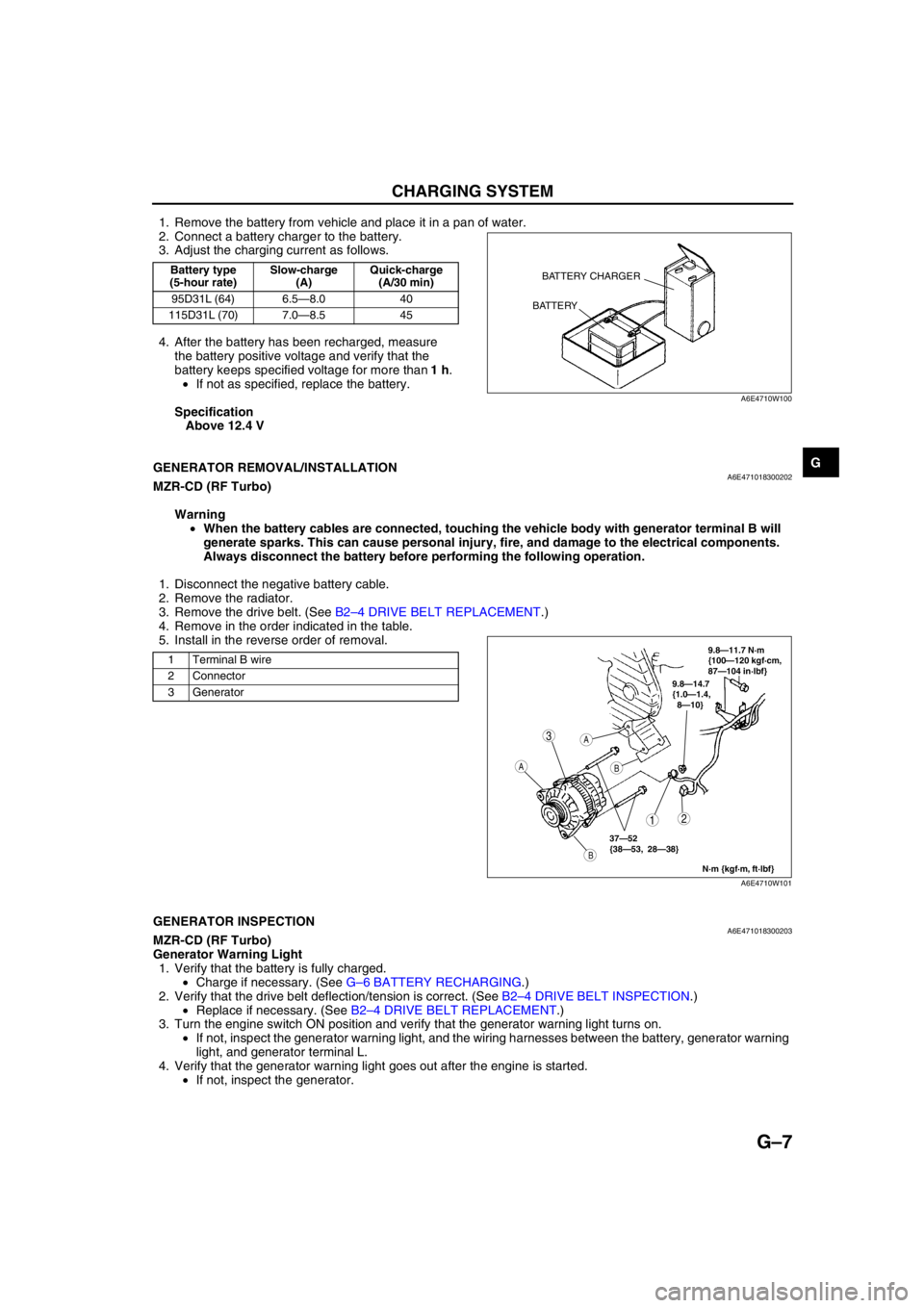

1. Remove the battery from vehicle and place it in a pan of water.

2. Connect a battery charger to the battery.

3. Adjust the charging current as follows.

4. After the battery has been recharged, measure

the battery positive voltage and verify that the

battery keeps specified voltage for more than 1 h.

•If not as specified, replace the battery.

Specification

Above 12.4 V

End Of Sie

GENERATOR REMOVAL/INSTALLATIONA6E471018300202MZR-CD (RF Turbo)

Warning

•When the battery cables are connected, touching the vehicle body with generator terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the radiator.

3. Remove the drive belt. (See B2–4 DRIVE BELT REPLACEMENT.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of SieGENERATOR INSPECTIONA6E471018300203MZR-CD (RF Turbo)

Generator Warning Light

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Verify that the drive belt deflection/tension is correct. (See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Turn the engine switch ON position and verify that the generator warning light turns on.

•If not, inspect the generator warning light, and the wiring harnesses between the battery, generator warning

light, and generator terminal L.

4. Verify that the generator warning light goes out after the engine is started.

•If not, inspect the generator.

Battery type

(5-hour rate)Slow-charge

(A)Quick-charge

(A/30 min)

95D31L (64) 6.5—8.0 40

115D31L (70) 7.0—8.5 45BATTERY CHARGER

BATTERY

A6E4710W100

1 Terminal B wire

2 Connector

3 Generator

3

12

A

B

A

B

9.8—14.7

{1.0—1.4,

8—10}

N·m {kgf·m, ft·lbf}

37—52

{38—53, 28—38}

9.8—11.7 N·m

{100—120 kgf·cm,

87—104 in·lbf}

A6E4710W101