MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 371 of 909

TROUBLESHOOTING

F2–219

F2

End Of Sie

14 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

15 Turn turbocharger compressor wheel by hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

16 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

17 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step.

18 Is any engine oil found inside turbocharger

compressor housing?Yes Wipe oil off of vehicle, then go to next step.

No Go to next step.

19 Is any exhaust gas leakage found around

location where turbocharger is attached to

exhaust manifold?Yes Remove turbocharger.

Inspect for cracks on center housing inlet surface.

If cracks are found, replace turbocharger.

No Go to next step.

20 Are any center housing and turbine housing

attaching bolts loose?Yes Retighten loose bolts.

If a bolt is found to be missing, attach appropriate new

bolts.

No Turbocharger is okay.

Install all parts removed in Step 13.

Go to next step.

21 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION)

22 Inspect fuel injector and fuel injector gasket.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Inspect for following:

•Metal flow

•Bent connecting rod

•Damaged valve seat

•Incorrect valve clearance

No Repair or replace as necessary.

23 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 372 of 909

F2–220

TROUBLESHOOTING

NO.22 VIBRATION CONCERNS (ENGINE)A6E408018881224

Diagnostic Procedure

22 VIBRATION CONCERNS (ENGINE)

DESCRIPTION•Vibration from under hood or driveline.

POSSIBLE

CAUSE•Loose attaching bolts or worn parts

•Cooling fan No.1 or cooling fan No.2 seat are improper

•Engine or transaxle mounts are improperly installed

•Components malfunction such as worn parts

•Erratic signal from CMP sensor

•ECT sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•MAF/IAT sensor or related circuit malfunction

•Idle switch or related circuit malfunction

•Incorrect adjustment of accelerator position sensor and/or idle switch

•Fuel injector malfunction

•Vacuum leakage

•Improper tension or damaged drive belts

•Improper balance of wheels or tires

•Driveline malfunction

•Suspension malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect following components for loose attaching

bolts or worn parts:

•Cooling fan No.1

•Cooling fan No.2

•Cooling fan No.1 and cooling fan No.2 seat

•Drive belt and pulley

•Engine mounts

•Exhaust system

Are all items okay?Yes Go to next step.

No Readjust or retighten engine mount installation

position.

Service as necessary for other parts.

2 Inspect vacuum leakage.

Are vacuum hoses okay?Yes Go to next step.

No Service as necessary.

Repeat Step 2.

Page 373 of 909

TROUBLESHOOTING

F2–221

F2

End Of Sie

3 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

4 Inspect adjustment of accelerator position

sensor and idle switch.

(See F2–72 ACCELERATOR POSITION

SENSOR INSPECTION)

(See F2–70 IDLE SWITCH INSPECTION)

Are accelerator position sensor and idle switch

adjusted correctly?Yes Go to next step.

No Adjust accelerator position sensor and idle switch

correctly.

(See F2–73 ACCELERATOR POSITION SENSOR

ADJUSTMENT)

(See F2–71 IDLE SWITCH ADJUSTMENT)

5 Inspect adjustment of neutral switch.

(See F2–69 NEUTRAL SWITCH INSPECTION)

Is neutral switch adjusted correctly?Yes Go to next step.

No Adjust neutral switch correctly.

6 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•RPM

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

7 Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Inspect following systems:

•Wheels

•Transaxle and mounts

•Driveline

•Suspension

Service as necessary.

No Repair or replace as necessary.

8 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 374 of 909

F2–222

TROUBLESHOOTING

NO.23 A/C DOES NOT WORK SUFFICIENTLYA6E408018881225

Diagnostic Procedure

End Of Sie

23 A/C DOES NOT WORK SUFFICIENTLY

DESCRIPTION•A/C compressor magnetic clutch does not engage when A/C switch is turned on.

POSSIBLE

CAUSE•Improper refrigerant charge amount

•Open A/C switch magnetic clutch

•Open circuit between A/C relay and A/C magnetic clutch

•Poor GND of A/C magnetic clutch

•Improper A/C magnetic clutch clearance

•Refrigerant pressure switch is stuck open

•A/C relay is stuck open

•Improper A/C cut-off control

•Open circuit between A/C switch and PCM through both refrigerant pressure switch and A/C amplifier

STEP INSPECTION RESULTS ACTION

1 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

YesNo DTC is displayed:

Go to appropriate DTC test.

2 Disconnect A/C compressor connector.

Start engine and turn A/C switch to ON.

Is there correct voltage at terminal of A/C

compressor magnetic clutch connector?

Specification

More than 10.5 VYes Inspect for GND condition of magnetic clutch on A/C

compressor.

If GND condition is okay, inspect magnetic clutch coil

for open circuit.

No Go to next step.

3 Disconnect refrigerant pressure switch

connector.

Connect jumper wire between terminals of

refrigerant pressure switch connector.

Turn engine switch to ON.

Turn A/C switch on and set blower fan at any

speed.

Measure PCM terminal 84 voltage.

Is voltage below 1.0 V?Yes Inspect refrigerant pressure switch operation.

If switch is okay, go to next step.

No Inspect for following:

•A/C switch is stuck open

•Open circuit between refrigerant pressure switch

and PCM terminal 84

•Open circuit of blower motor fan switch and

resistor (if blower motor does not operate)

•Evaporator temperature sensor and A/C amplifier

4 Inspect A/C cut-off operation.

Does A/C cut-off work properly?Yes Go to next step.

No Repair or replace malfunctioning part according to A/C

cut-off system inspection results.

5 Remove jumper wire from switch connector.

Reconnect connector to refrigerant pressure

switch.

Start engine and turn A/C switch on.

Does fan operate?Yes Inspect for stuck open A/C relay.

Replace if necessary.

No Inspect following and repair or replace as necessary:

•Refrigerant charging amount

•Seized A/C compressor

6 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 375 of 909

TROUBLESHOOTING

F2–223

F2

NO.24 A/C ALWAYS ON OR A/C COMPRESSOR RUNS CONTINUOUSLYA6E408018881226

Diagnostic Procedure

End Of Sie

24 A/C ALWAYS ON OR A/C COMPRESSOR RUNS CONTINUOUSLY

DESCRIPTION•A/C compressor magnetic clutch does not disengage.

POSSIBLE

CAUSE•A/C compressor magnetic clutch stuck engagement

•A/C relay is stuck closed

•Improper A/C compressor magnetic clutch clearance

•Short to GND circuit between A/C switch and PCM

•Short to GND circuit between A/C relay and PCM

•A/C relay to magnetic clutch circuit shorts to battery power

STEP INSPECTION RESULTS ACTION

1 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to appropriate DTC test.

2 Start engine and run it at idle.

Turn A/C switch on.

Remove A/C relay.

Does A/C magnetic clutch disengage?Yes Inspect for following:

•A/C relay is stuck closed

•Short to GND circuit between A/C relay and PCM

terminal 73

If both items are okay, go to next step.

No Inspect if circuit between A/C relay and magnetic

clutch shorts to battery power circuit.

If circuit is okay, inspect magnetic clutch stuck

engagement or clearance.

3 Start engine and turn A/C switch on.

Measure PCM terminal 84 voltage while

disconnecting refrigerant pressure switch

connector.

Note

•PCM terminal 84 voltage should read B+

when disconnecting connector. If PCM

terminal 84 voltage reading remains

below 1.0 V, short to GND circuit may be

present.

Is voltage B+?Yes Inspect for short to GND circuit between refrigerant

pressure switch and PCM terminal 84.

No Go to next step.

4 Reconnect refrigerant pressure switch

connector.Measure PCM terminal 84 voltage

while turning off A/C switch.

Note

•PCM terminal 84 voltage should read B+

when turning A/C switch off. If PCM

terminal 84 voltage reading remains

below 1.0 V, short to GND circuit maybe

present.

Does voltage remain B+?Yes Inspect for following:

•Short to GND circuit between A/C switch and A/C

amplifier.

•Short to GND circuit between A/C amplifier and

refrigerant pressure switch.

No Inspect for stuck closed A/C switch.

5 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 376 of 909

F2–224

TROUBLESHOOTING

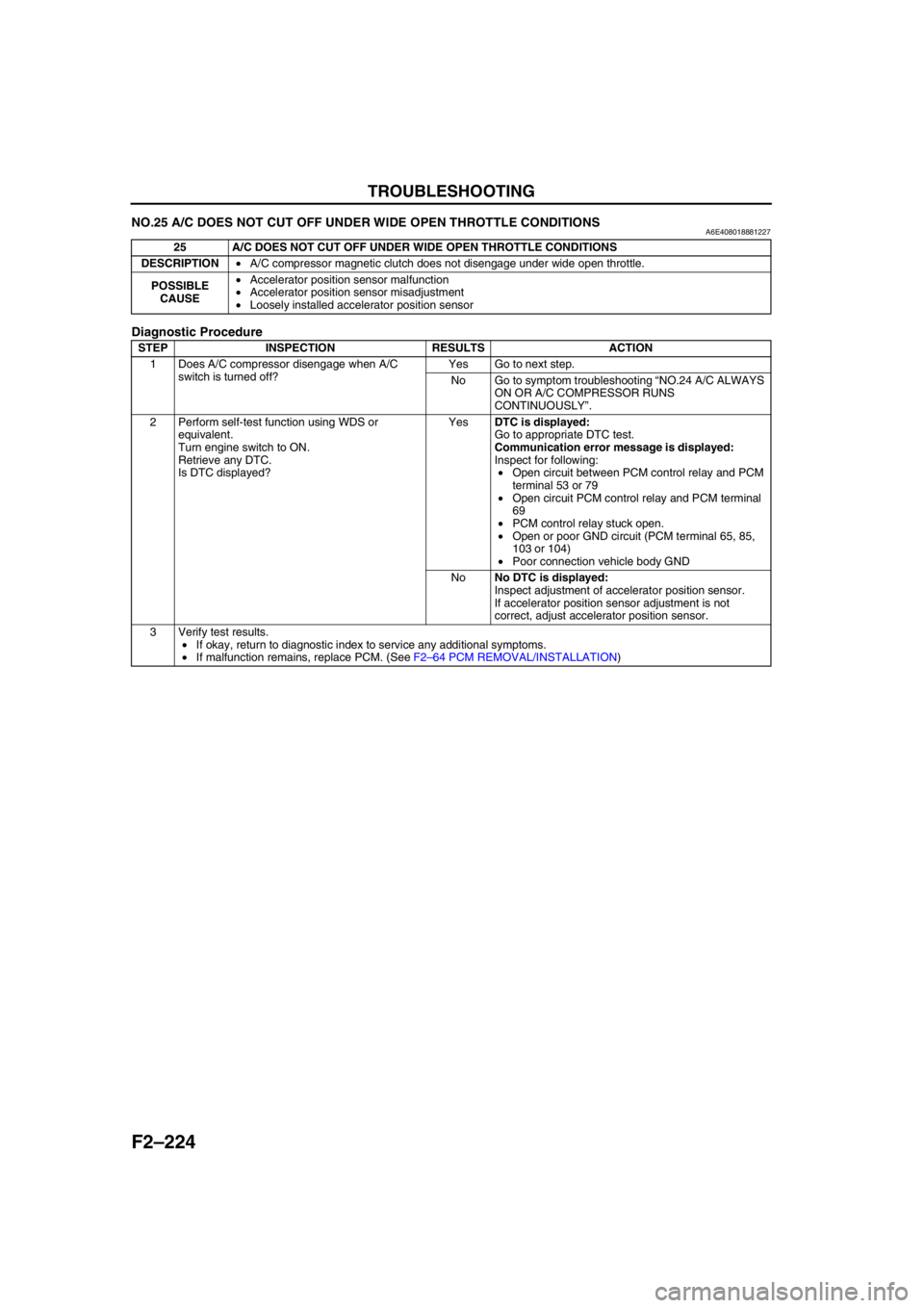

NO.25 A/C DOES NOT CUT OFF UNDER WIDE OPEN THROTTLE CONDITIONSA6E408018881227

Diagnostic Procedure

End Of Sie

25 A/C DOES NOT CUT OFF UNDER WIDE OPEN THROTTLE CONDITIONS

DESCRIPTION•A/C compressor magnetic clutch does not disengage under wide open throttle.

POSSIBLE

CAUSE•Accelerator position sensor malfunction

•Accelerator position sensor misadjustment

•Loosely installed accelerator position sensor

STEP INSPECTION RESULTS ACTION

1 Does A/C compressor disengage when A/C

switch is turned off?Yes Go to next step.

No Go to symptom troubleshooting “NO.24 A/C ALWAYS

ON OR A/C COMPRESSOR RUNS

CONTINUOUSLY”.

2 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open.

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Inspect adjustment of accelerator position sensor.

If accelerator position sensor adjustment is not

correct, adjust accelerator position sensor.

3 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

Page 377 of 909

TROUBLESHOOTING

F2–225

F2

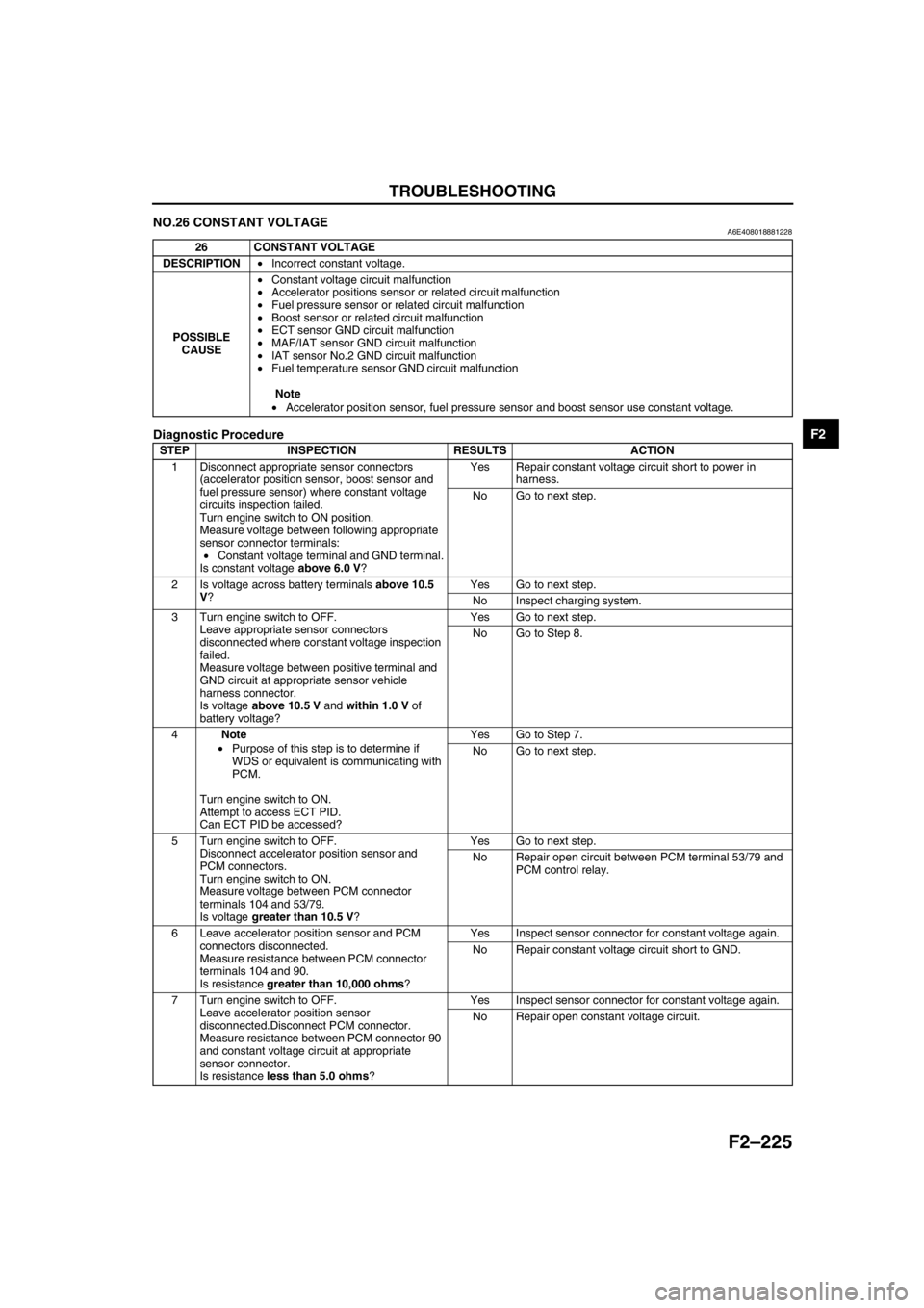

NO.26 CONSTANT VOLTAGEA6E408018881228

Diagnostic Procedure

26 CONSTANT VOLTAGE

DESCRIPTION•Incorrect constant voltage.

POSSIBLE

CAUSE•Constant voltage circuit malfunction

•Accelerator positions sensor or related circuit malfunction

•Fuel pressure sensor or related circuit malfunction

•Boost sensor or related circuit malfunction

•ECT sensor GND circuit malfunction

•MAF/IAT sensor GND circuit malfunction

•IAT sensor No.2 GND circuit malfunction

•Fuel temperature sensor GND circuit malfunction

Note

•Accelerator position sensor, fuel pressure sensor and boost sensor use constant voltage.

STEP INSPECTION RESULTS ACTION

1 Disconnect appropriate sensor connectors

(accelerator position sensor, boost sensor and

fuel pressure sensor) where constant voltage

circuits inspection failed.

Turn engine switch to ON position.

Measure voltage between following appropriate

sensor connector terminals:

•Constant voltage terminal and GND terminal.

Is constant voltage above 6.0 V?Yes Repair constant voltage circuit short to power in

harness.

No Go to next step.

2 Is voltage across battery terminals above 10.5

V?Yes Go to next step.

No Inspect charging system.

3 Turn engine switch to OFF.

Leave appropriate sensor connectors

disconnected where constant voltage inspection

failed.

Measure voltage between positive terminal and

GND circuit at appropriate sensor vehicle

harness connector.

Is voltage above 10.5 V and within 1.0 V of

battery voltage?Yes Go to next step.

No Go to Step 8.

4Note

•Purpose of this step is to determine if

WDS or equivalent is communicating with

PCM.

Turn engine switch to ON.

Attempt to access ECT PID.

Can ECT PID be accessed?Yes Go to Step 7.

No Go to next step.

5 Turn engine switch to OFF.

Disconnect accelerator position sensor and

PCM connectors.

Turn engine switch to ON.

Measure voltage between PCM connector

terminals 104 and 53/79.

Is voltage greater than 10.5 V?Yes Go to next step.

No Repair open circuit between PCM terminal 53/79 and

PCM control relay.

6 Leave accelerator position sensor and PCM

connectors disconnected.

Measure resistance between PCM connector

terminals 104 and 90.

Is resistance greater than 10,000 ohms?Yes Inspect sensor connector for constant voltage again.

No Repair constant voltage circuit short to GND.

7 Turn engine switch to OFF.

Leave accelerator position sensor

disconnected.Disconnect PCM connector.

Measure resistance between PCM connector 90

and constant voltage circuit at appropriate

sensor connector.

Is resistance less than 5.0 ohms?Yes Inspect sensor connector for constant voltage again.

No Repair open constant voltage circuit.

Page 378 of 909

F2–226

TROUBLESHOOTING

End Of Sie

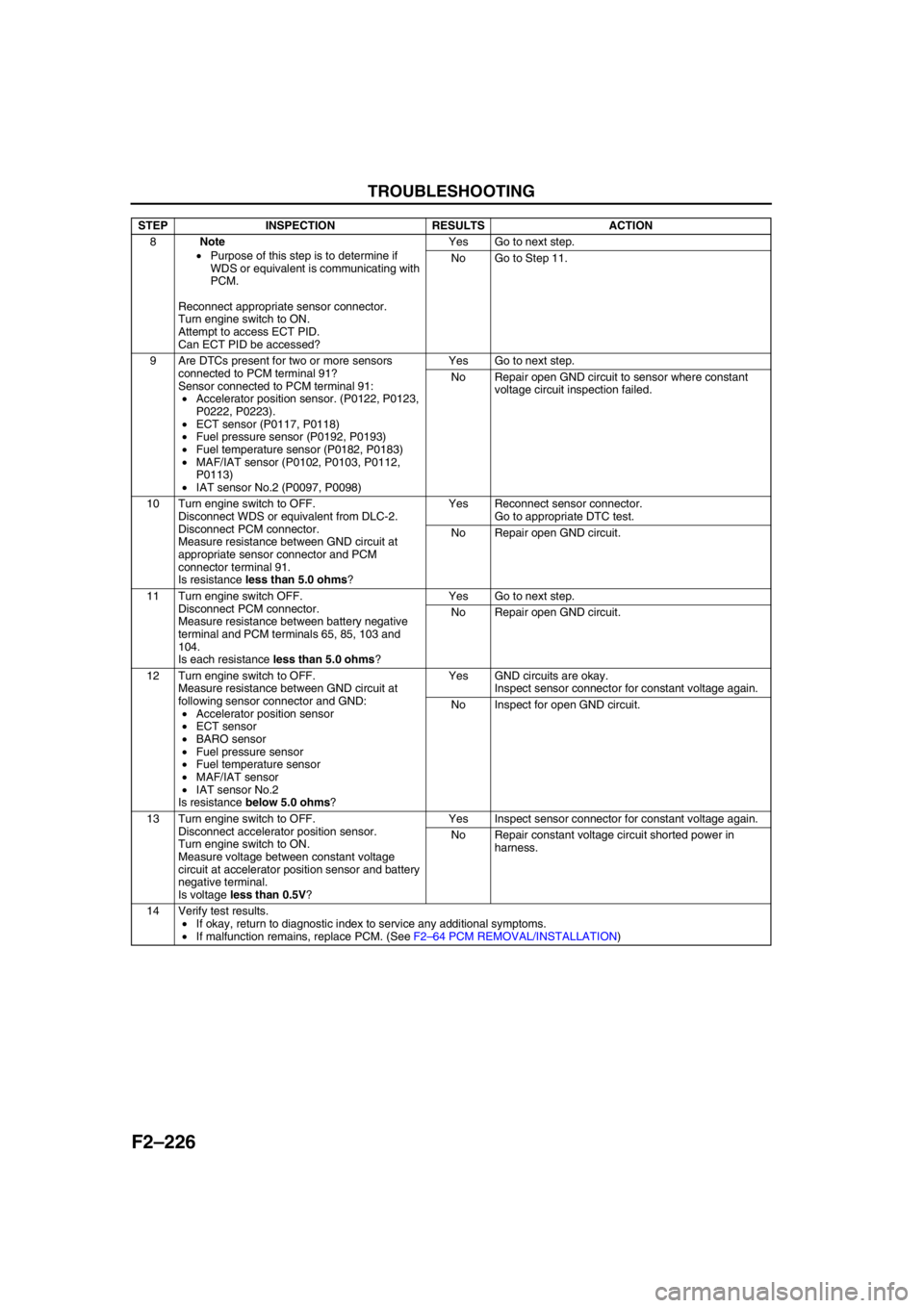

8Note

•Purpose of this step is to determine if

WDS or equivalent is communicating with

PCM.

Reconnect appropriate sensor connector.

Turn engine switch to ON.

Attempt to access ECT PID.

Can ECT PID be accessed?Yes Go to next step.

No Go to Step 11.

9 Are DTCs present for two or more sensors

connected to PCM terminal 91?

Sensor connected to PCM terminal 91:

•Accelerator position sensor. (P0122, P0123,

P0222, P0223).

•ECT sensor (P0117, P0118)

•Fuel pressure sensor (P0192, P0193)

•Fuel temperature sensor (P0182, P0183)

•MAF/IAT sensor (P0102, P0103, P0112,

P0113)

•IAT sensor No.2 (P0097, P0098)Yes Go to next step.

No Repair open GND circuit to sensor where constant

voltage circuit inspection failed.

10 Turn engine switch to OFF.

Disconnect WDS or equivalent from DLC-2.

Disconnect PCM connector.

Measure resistance between GND circuit at

appropriate sensor connector and PCM

connector terminal 91.

Is resistance less than 5.0 ohms?Yes Reconnect sensor connector.

Go to appropriate DTC test.

No Repair open GND circuit.

11 Turn engine switch OFF.

Disconnect PCM connector.

Measure resistance between battery negative

terminal and PCM terminals 65, 85, 103 and

104.

Is each resistance less than 5.0 ohms?Yes Go to next step.

No Repair open GND circuit.

12 Turn engine switch to OFF.

Measure resistance between GND circuit at

following sensor connector and GND:

•Accelerator position sensor

•ECT sensor

•BARO sensor

•Fuel pressure sensor

•Fuel temperature sensor

•MAF/IAT sensor

•IAT sensor No.2

Is resistance below 5.0 ohms?Yes GND circuits are okay.

Inspect sensor connector for constant voltage again.

No Inspect for open GND circuit.

13 Turn engine switch to OFF.

Disconnect accelerator position sensor.

Turn engine switch to ON.

Measure voltage between constant voltage

circuit at accelerator position sensor and battery

negative terminal.

Is voltage less than 0.5V?Yes Inspect sensor connector for constant voltage again.

No Repair constant voltage circuit shorted power in

harness.

14 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 379 of 909

TROUBLESHOOTING

F2–227

F2

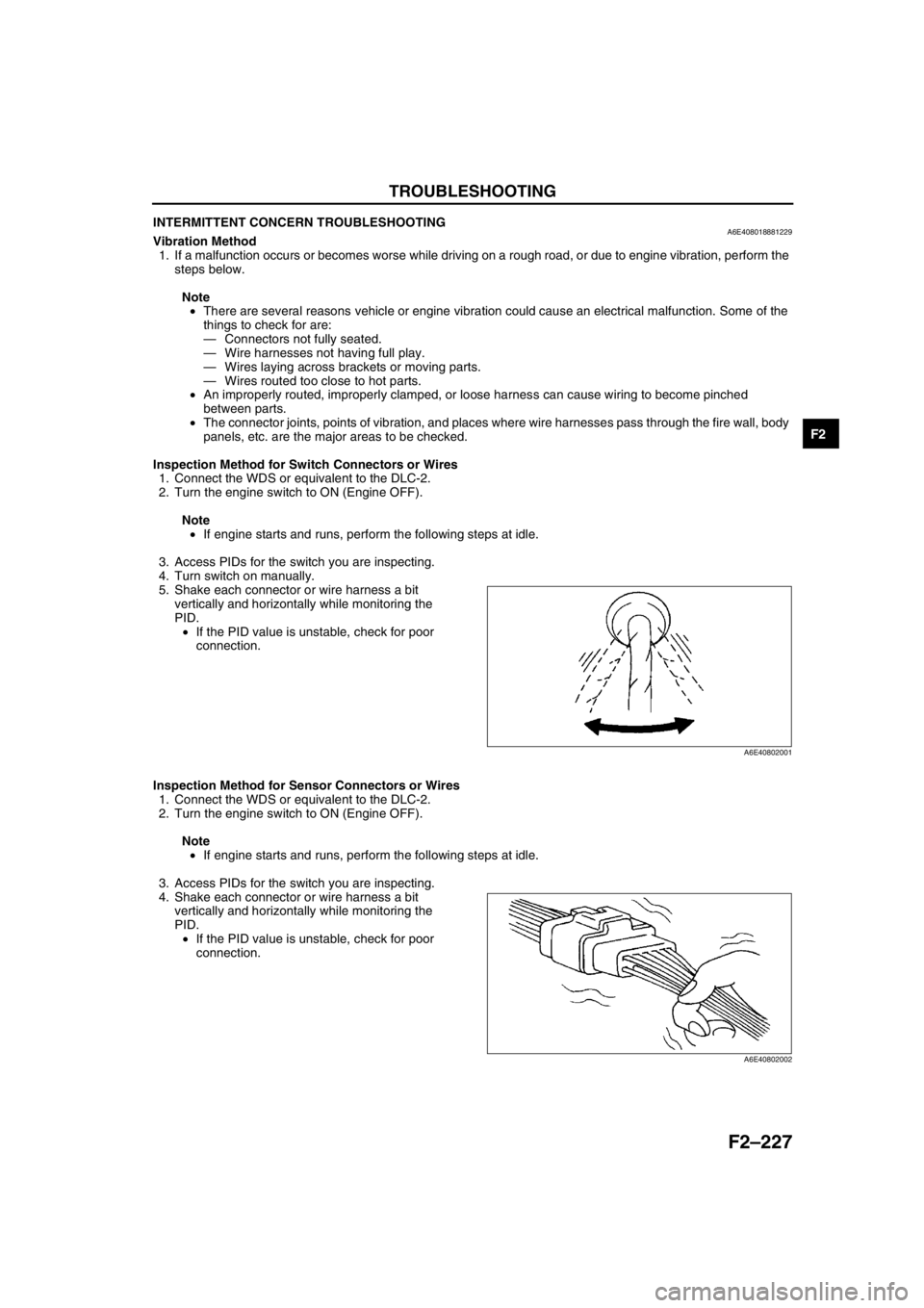

INTERMITTENT CONCERN TROUBLESHOOTINGA6E408018881229Vibration Method

1. If a malfunction occurs or becomes worse while driving on a rough road, or due to engine vibration, perform the

steps below.

Note

•There are several reasons vehicle or engine vibration could cause an electrical malfunction. Some of the

things to check for are:

—Connectors not fully seated.

—Wire harnesses not having full play.

—Wires laying across brackets or moving parts.

—Wires routed too close to hot parts.

•An improperly routed, improperly clamped, or loose harness can cause wiring to become pinched

between parts.

•The connector joints, points of vibration, and places where wire harnesses pass through the fire wall, body

panels, etc. are the major areas to be checked.

Inspection Method for Switch Connectors or Wires

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If engine starts and runs, perform the following steps at idle.

3. Access PIDs for the switch you are inspecting.

4. Turn switch on manually.

5. Shake each connector or wire harness a bit

vertically and horizontally while monitoring the

PID.

•If the PID value is unstable, check for poor

connection.

Inspection Method for Sensor Connectors or Wires

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If engine starts and runs, perform the following steps at idle.

3. Access PIDs for the switch you are inspecting.

4. Shake each connector or wire harness a bit

vertically and horizontally while monitoring the

PID.

•If the PID value is unstable, check for poor

connection.

A6E40802001

A6E40802002

Page 380 of 909

F2–228

TROUBLESHOOTING

Inspection Method for Sensors

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Access PIDs for the switch you are inspecting.

4. Vibrate the sensor slightly with your finger.

•If the PID value is unstable or malfunction occurs, check for poor connection and/or poorly mounted

sensor.

Inspection Method for Actuators or Relays

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Prepare the Output State Control for actuators or relays that you are inspecting.

4. Vibrate the actuator or relay with your finger for 3

seconds after Output State Control is activated.

•If a variable click sound is heard, check for

poor connection and/or poorly mounted

actuator or relay.

Note

•Vibrating relays too strongly may result in

open relays.

Water Sprinkling Method

Caution

•Indirectly change the temperature and humidity by spraying water onto the front of the radiator.

•If a vehicle is subject to water leakage, the leakage may damage the control module. When testing

a vehicle with a water leakage problem, special caution must be used.

If malfunction occurs only during high humidity or rainy/snowy weather, perform the following steps.

1. Connect the WDS or equivalent to the DLC-2 if you are inspecting sensors or switches.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Access PIDs for sensor or switch if you are inspecting sensors or switches.

4. If you are inspecting a switch, turn it on manually.

5. Spray water onto the vehicle or run it through a

car wash.

•If the PID value is unstable or malfunction

occurs, repair or replace part as necessary.

End Of Sie

A6E40802003

A6E40802004