MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 581 of 909

K2–166

ON-BOARD DIAGNOSTIC

DTC P0773A6E577018901225

DTC P0773 Neutral shift solenoid valve circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in neutral shift solenoid signal system (while TCM monitors solenoid output voltage, the

voltage that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL does not illuminate.

•PENDING CODE is not available.

•FREEZE FRAME DATA is not available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between neutral shift solenoid valve terminal A and TCM terminal 2D

•Short to ground between neutral shift solenoid valve terminal A and TCM terminal 2D

•Short to power between neutral shift solenoid vale terminal A and TCM terminal 2D

•Neutral shift solenoid valve malfunction

•Damaged connector between neutral shift solenoid valve and TCM

•TCM malfunction

CPU

2D

H

B

A TCM

AT X

TCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTORNEUTRAL SHIFT

SOLENOID VALVE

NEUTRAL SHIFT

SOLENOID VALVE

HARNESS SIDE CONNECTOR

Page 582 of 909

ON-BOARD DIAGNOSTIC

K2–167

K2

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) FOR POOR CONNECTION

•Turn ignition key to OFF.

•Disconnect terminal component No.1 (12-pin).

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair or replace terminals, then go to Step 12.

3INSPECT RESISTANCE

•Check resistance between terminal component

No.1 (12-pin) terminal H (transaxle case side)

and body ground.

•Is resistance within 14—18 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Go to Step 8.

No Go to next step.

4INSPECT COUPLER COMPONENT (10-PIN)

FOR POOR CONNECTION

•Disconnect coupler component (10-pin)

connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Is terminal okay?Yes Go to next step.

No Repair or replace terminal, then go to Step 12.

5INSPECT RESISTANCE

•Check resistance between coupler component

(10-pin) terminal B (part side) and body

ground.

•Is resistance within 14—18 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Repair or replace terminal component No.1 (12-pin), then

go to Step 12.

No Go to next step.

6INSPECT NEUTRAL SHIFT SOLENOID VALVE

CONNECTOR FOR POOR CONNECTION

•Disconnect neutral shift solenoid valve

connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Is terminal okay?Yes Go to next step.

No Repair or replace terminal, then go to Step 12.

7INSPECT RESISTANCE

•Check resistance between neutral shift

solenoid valve connector terminal A (part side)

and body ground.

•Is resistance within 14—18 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Repair or replace coupler component (10-pin), then go to

Step 12.

No Verify neutral shift solenoid valve installation.

•If neutral shift solenoid valve is installed correctly,

replace neutral shift solenoid valve, then go to Step 12

(See K2–90 SOLENOID VALVE REMOVAL/

INSTALLATION.)

8INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Disconnect TCM connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

9INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR OPEN CIRCUIT

•Check continuity between TCM terminal 2D

(harness-side) and terminal component No.1

(12-pin) terminal H (harness-side).

•Is there continuity between terminals?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

10INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR SHORT TO POWER

•Turn ignition key to ON (engine OFF).

•Check voltage at terminal component No.1 (12-

pin) terminal H (harness-side).

•Is voltage 0 V?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

Page 583 of 909

K2–168

ON-BOARD DIAGNOSTIC

End Of Sie

11INSPECT TCM CIRCUIT FOR SHORT TO

GROUND

•Turn ignition key to OFF.

•Check continuity between TCM terminal 2D

(harness-side) and body ground.

•Is there any continuity?Yes Repair or replace harness, then go to next step.

No Go to next step.

12VERIFY TROUBLESHOOTING OF DTC P0773

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 584 of 909

ON-BOARD DIAGNOSTIC

K2–169

K2

DTC P0778A6E577018901226

DTC P0778 2-4 brake solenoid valve circuit malfunction (open/short)

DETECTION

CONDITION•Open or short in 2-4 brake solenoid signal system (while TCM monitors solenoid output voltage, the

voltage that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL does not illuminates.

•PENDING CODE is not available.

•FREEZE FRAME DATA is not available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•Short to ground between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•Short to power between 2-4 brake solenoid valve terminal A and TCM terminal 2V

•2-4 brake solenoid valve malfunction

•Damaged connector between 2-4 brake solenoid valve and TCM

•TCM malfunction

CPU

CPU2V

A

D

A

A J 2PB TCM

AT X

TCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTOR2-4 BRAKE

SOLENOID VALVE

2-4 BRAKE

SOLENOID VALVE

HARNESS SIDE CONNECTOR

Page 585 of 909

K2–170

ON-BOARD DIAGNOSTIC

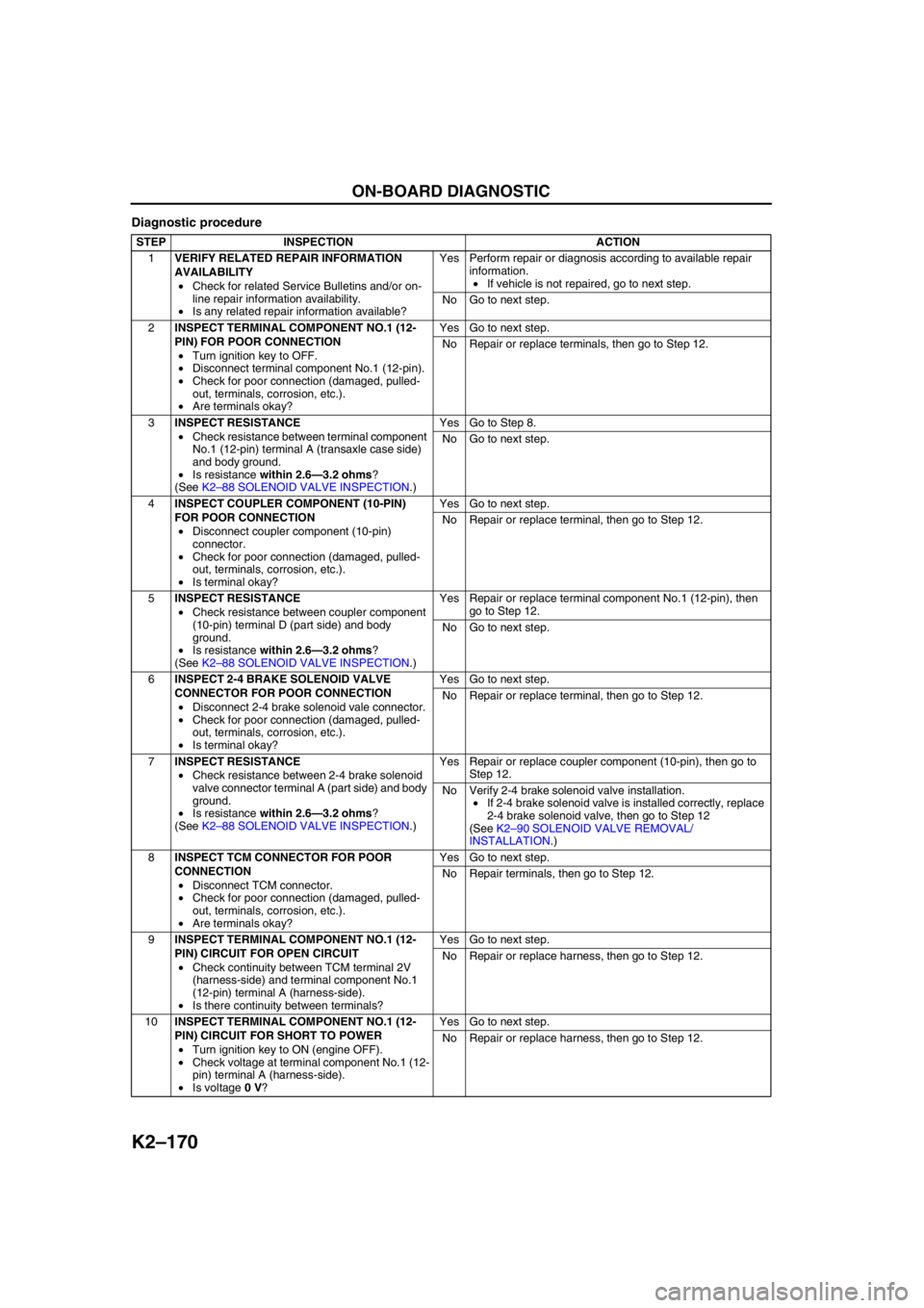

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

2INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) FOR POOR CONNECTION

•Turn ignition key to OFF.

•Disconnect terminal component No.1 (12-pin).

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair or replace terminals, then go to Step 12.

3INSPECT RESISTANCE

•Check resistance between terminal component

No.1 (12-pin) terminal A (transaxle case side)

and body ground.

•Is resistance within 2.6—3.2 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Go to Step 8.

No Go to next step.

4INSPECT COUPLER COMPONENT (10-PIN)

FOR POOR CONNECTION

•Disconnect coupler component (10-pin)

connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Is terminal okay?Yes Go to next step.

No Repair or replace terminal, then go to Step 12.

5INSPECT RESISTANCE

•Check resistance between coupler component

(10-pin) terminal D (part side) and body

ground.

•Is resistance within 2.6—3.2 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Repair or replace terminal component No.1 (12-pin), then

go to Step 12.

No Go to next step.

6INSPECT 2-4 BRAKE SOLENOID VALVE

CONNECTOR FOR POOR CONNECTION

•Disconnect 2-4 brake solenoid vale connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Is terminal okay?Yes Go to next step.

No Repair or replace terminal, then go to Step 12.

7INSPECT RESISTANCE

•Check resistance between 2-4 brake solenoid

valve connector terminal A (part side) and body

ground.

•Is resistance within 2.6—3.2 ohms?

(See K2–88 SOLENOID VALVE INSPECTION.)Yes Repair or replace coupler component (10-pin), then go to

Step 12.

No Verify 2-4 brake solenoid valve installation.

•If 2-4 brake solenoid valve is installed correctly, replace

2-4 brake solenoid valve, then go to Step 12

(See K2–90 SOLENOID VALVE REMOVAL/

INSTALLATION.)

8INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Disconnect TCM connector.

•Check for poor connection (damaged, pulled-

out, terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

9INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR OPEN CIRCUIT

•Check continuity between TCM terminal 2V

(harness-side) and terminal component No.1

(12-pin) terminal A (harness-side).

•Is there continuity between terminals?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

10INSPECT TERMINAL COMPONENT NO.1 (12-

PIN) CIRCUIT FOR SHORT TO POWER

•Turn ignition key to ON (engine OFF).

•Check voltage at terminal component No.1 (12-

pin) terminal A (harness-side).

•Is voltage 0 V?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

Page 586 of 909

ON-BOARD DIAGNOSTIC

K2–171

K2

End Of Sie

11INSPECT TCM CIRCUIT FOR SHORT TO

GROUND

•Turn ignition key to OFF.

•Check continuity between TCM terminal 2V

(harness-side) and body ground.

•Is there any continuity?Yes Repair or replace harness, then go to next step.

No Go to next step.

12VERIFY TROUBLESHOOTING OF DTC P0778

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle in D range and make sure that

gears shift smoothly from 1GR to 5GR.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 587 of 909

K2–172

ON-BOARD DIAGNOSTIC

DTC P0791A6E577018901227

DTC P0791 Intermediate sensor circuit malfunction (open/short)

DETECTION

CONDITION•Rotation speed of output gear (intermediate sensor) is low when vehicle speed and engine speed exceed

the preprogrammed value.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction condition.

•PENDING CODE is not available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Intermediate sensor malfunction.

•Short to ground between intermediate sensor terminal B and TCM terminal 1K

•Short to ground between intermediate sensor terminal A and TCM terminal 1X

•Open circuit between intermediate sensor terminal B and TCM terminal 1K

•Open circuit between intermediate sensor terminal A and TCM terminal 1X

•Damaged connectors between intermediate sensor and TCM.

•TCM malfunction.

D

B

AC

1K

1X CDTCM

AT X

TCM

HARNESS SIDE CONNECTOR

TERMINAL COMPONENT

NO.2(8-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(8-PIN)

PART SIDE CONNECTORINTERMEDIATE SENSOR

HARNESS SIDE CONNECTOR INTERMEDIATE

SENSOR

Page 588 of 909

ON-BOARD DIAGNOSTIC

K2–173

K2

Diagnostic procedure

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CONNECTOR FOR POOR CONNECTION

•Turn ignition key to OFF.

•Disconnect terminal component No.2 (8-pin)

connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair or replace terminals, then go to Step 12.

4INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between terminal

component No.2 (8-pin) (transaxle case side).

•Is resistance within 513—627 ohms between

terminal component No.2 (8-pin) terminal C

and D (transaxle case side)?Yes Go to next step.

No Go to Step 8

5INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Disconnect TCM connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

6INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CIRCUIT FOR OPEN

•Check terminal component No.2 (8-pin)

terminals (harness-side) and TCM terminals

(harness-side).

—C and 1K

—D and 1X

•Is there continuity?Yes Go to next step.

No Repair or replace harness, then go to Step 12.

7INSPECT TERMINAL COMPONENT NO.2 (8-

PIN) CIRCUIT FOR SHORT TO GROUND

•Check terminal component No.2 (8-pin)

terminal (harness-side) and body ground.

—C and body ground

—D and body ground

•Is there any continuity?Yes Repair or replace harness, then go to Step 12.

No Go to Step 12.

8INSPECT COUPLER COMPONENT (8-PIN)

CONNECTOR FOR POOR CONNECTION

•Disassemble the control valve body cover.

•Disconnect coupler component (8-pin)

connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

9INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between coupler

component (8-pin).

•Is resistance within 513—627 ohms between

coupler component (8-pin) terminal D and C

(part side)?Yes Repair or replace coupler component, then go to Step 12.

No Go to next step.

Page 589 of 909

K2–174

ON-BOARD DIAGNOSTIC

End Of Sie

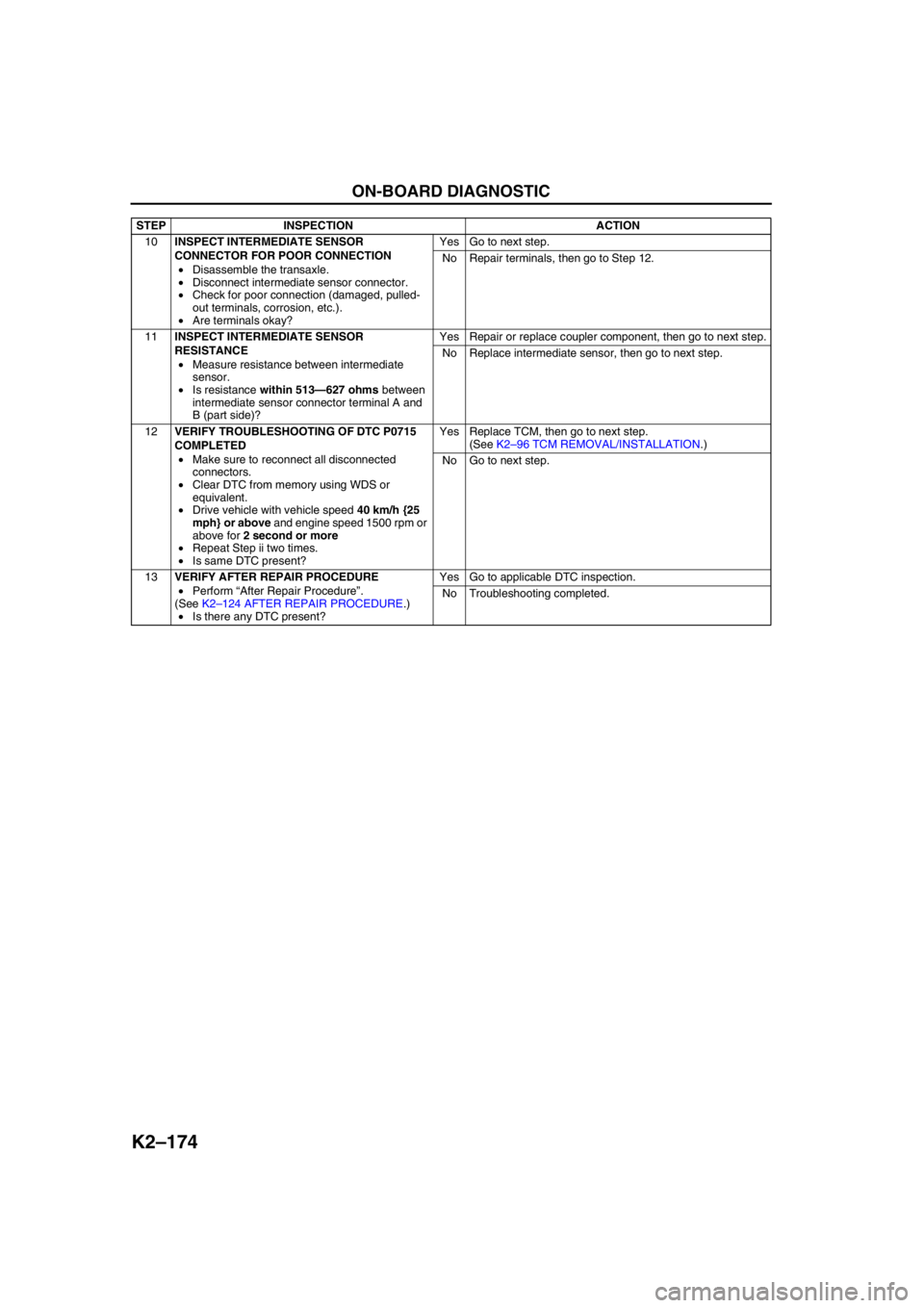

10INSPECT INTERMEDIATE SENSOR

CONNECTOR FOR POOR CONNECTION

•Disassemble the transaxle.

•Disconnect intermediate sensor connector.

•Check for poor connection (damaged, pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

11INSPECT INTERMEDIATE SENSOR

RESISTANCE

•Measure resistance between intermediate

sensor.

•Is resistance within 513—627 ohms between

intermediate sensor connector terminal A and

B (part side)?Yes Repair or replace coupler component, then go to next step.

No Replace intermediate sensor, then go to next step.

12VERIFY TROUBLESHOOTING OF DTC P0715

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above and engine speed 1500 rpm or

above for 2 second or more

•Repeat Step ii two times.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 590 of 909

ON-BOARD DIAGNOSTIC

K2–175

K2

DTC P0798A6E577018901228

DTC P0798 High clutch solenoid valve circuit malfunction (open/short)

DETECTION

CONDITION•Open or short is high clutch solenoid signal system (while TCM monitors solenoid output voltage, the

voltage that differs from the ON/OFF signal output by CPU in TCM is detected).

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL does not illuminate.

•PENDING CODE is not available.

•FREEZE FRAME DATA is not available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•Open circuit between high clutch solenoid valve terminal A and TCM terminal 2U

•Short to ground between high clutch solenoid valve terminal A and TCM terminal 2U

•Short to power between high clutch solenoid valve terminal A and TCM terminal 2U

•high clutch solenoid valve malfunction

•Damaged connector between high clutch solenoid valve and TCM

•TCM malfunction

C

F

A

A J 2PB 2U TCM

CPU

CPUAT X

TCM

HARNESS SIDE CONNECTOR

TERMINAL COMPONENT

NO.1(12-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT

(10-PIN)

PART SIDE CONNECTORHIGH CLUTCH

SOLENOID VALVE

HIGH CLUTCH SOLENOID VALVE

HARNESS SIDE CONNECTOR