MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: seat adjustment, oil type, oil temperature, gas type, fuel cap, open gas tank, AUX

Page 151 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation note

Cylinder head

1. Thoroughly remove all dirt and oil from the top of

the cylinder block with a rag.

2. Place a new cylinder head gasket in position.

86U01X-035

® © © (D ® 3. Set the cylinder head in place.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86

N

m (8.2—8.8 m-kg, 59—64 ft-lb)

86U01X-036

Cylinder head cover

1. Apply silicon sealant to the shaded area as shown

in the figure.

2. Install the cylinder head cover and gasket.

Tightening torque:

4—6 N-m (40—60 cm-kg, 35—52 in-lb)

76G01B-033

Timing belt

1. Align the mating marks of the camshaft pulleys with

the seal plate timing mark.

Note

For intake side camshaft pulley, align "I"

mark.

For exhaust side camshaft pulley, align "E"

mark.

2. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE.)

76G01B-034

1B—20

Page 152 of 1865

ON-VEHICLE MAINTENANCE (CYLINDER HEAD) 1 B

Distributor

1. Apply engine oil to the O-ring, and position it on

the distributor.

2. Apply engine oil to the blade.

3. Install the distributor.

4. Loosely tighten the distributor mounting bolt.

76G01A-035

Engine harness connector

Install the engine harness connectors.

1. IG coil

2. Heat gauge unit

3. Speed sensor

4. P/S switch

5. Engine ground

6. Water tempera-

ture sensor

7. Water thermo

switch

8. Crank angle

sensor

9. Oxygen sensor

10. Linear solenoid

11. Solenoid valve

(idle speed

control)

12. Throttle position

sensor

13. Injection harness

76G01B-035

Steps After Installation

1. Fill the radiator with the specified amount and type

of coolant.

2. Perform the necessary engine adjustments. (Re-

fer to TUNE-UP PROCEDURE.)

86U01X-041

1B-21

Page 153 of 1865

1B REMOVAL

REMOVAL

Warning: Release the fuel pressure. (Refer to Section 4C.)

1. Disconnect the negative battery cable.

2. Drain the engine oil and coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01B-036

1B—22

Page 154 of 1865

REMOVAL 1B

1. Battery and battery carrier

2. Air cleaner assembly

3. High-tension lead

4. Accelerator cable

5. Fuel hose

6. Radiator hose

7. Radiator harness

8. Radiator and electric fan

9. EGI harness

10. Engine harness

11. Brake vacuum hose

12. Canister hose (Unleaded

fuel)

13. Heater hose

14. Transaxle harness

15. Speedometer cable

16. Clutch release cylinder

17. Drive belt

18. A/C compressor and

bracket

19. P/S oil pump

20. Engine side cover

21. Front wheel

22. Tie-rod end

23. Stabilizer control rod

24. Lower arm bushing

25. Driveshaft

26. Change rod

27. Extension bar

28. Exhaust pipe

29. Engine mount

30. Engine and transaxle

31. Transaxle

76G01B-037

Removal Note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep sparks and open flame away from the

fuel area.

Plug the disconnected hoses to avoid fuel leakage.

76G01A-11£

P/S pump, A/C compressor

Remove the P/S pump and A/C compressor with the

hoses still connected to them, secure the pump and

compressor as shown in the figure.

67U01X-029

Driveshaft

Remove the driveshafts. (Refer to Section 9.) Slide

the SST into the transaxle.

86U01X-060

1B—23

Page 155 of 1865

1 B DISASSEMBLY (AUXILIARY PARTS)

DISASSEMBLY

1. Remove in the sequence shown in the figure referring to the disassembly note for specially marked

parts.

2. Code all identical parts (such as pistons, piston rings, connecting rods, and valve springs) so that

they can be reinstalled in the cylinder from which they were removed.

3. Clean the parts with steam, blow off any remaining water with compressed air.

Note

Care should be taken during the disassembly of any part or system to study its order of

assembly. Any deformation, wear, or damage should also be noted.

AUXILIARY PARTS

76G01A-119

1B—24

Page 156 of 1865

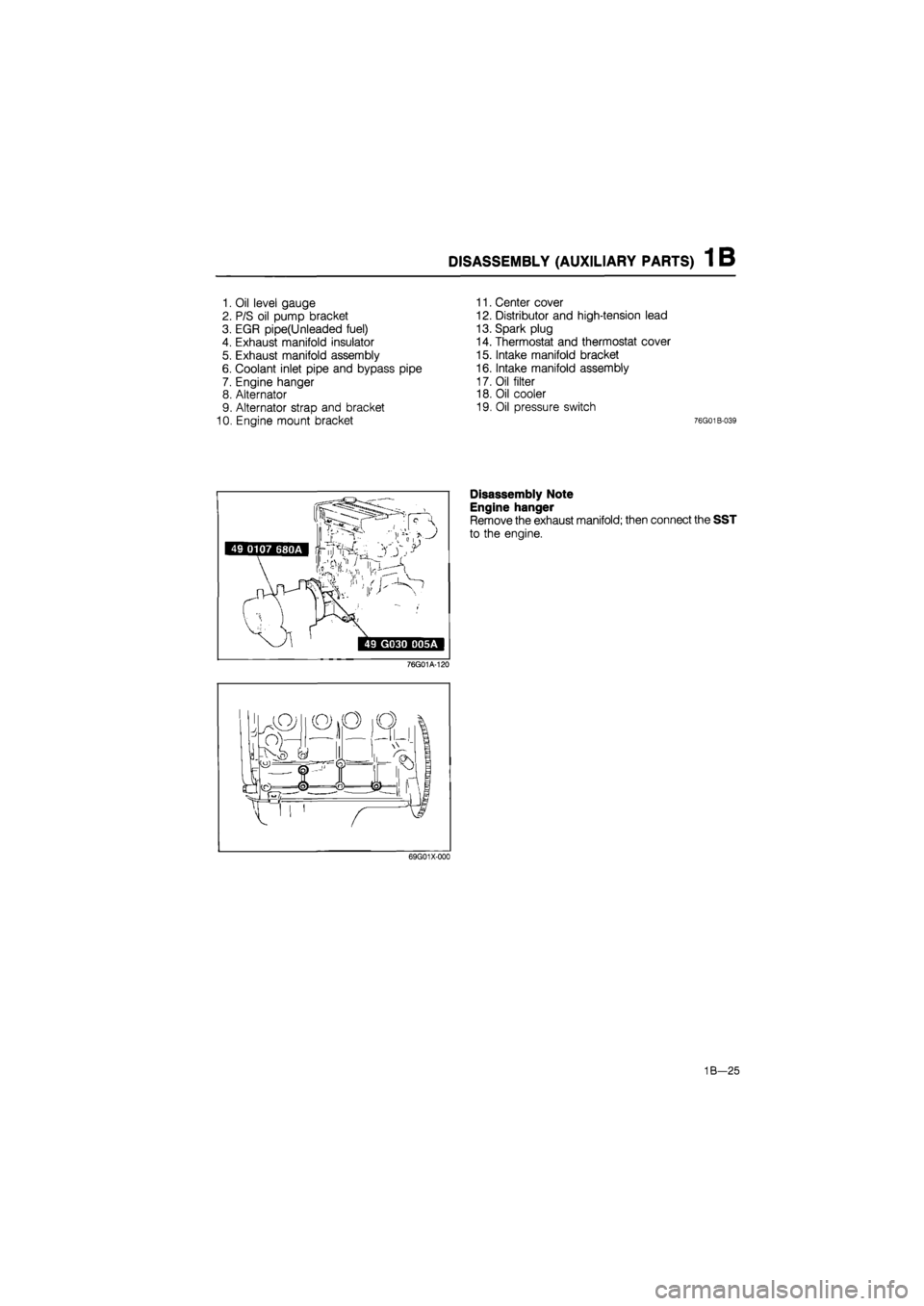

DISASSEMBLY (AUXILIARY PARTS) 1 B

1. Oil level gauge

2. P/S oil pump bracket

3. EGR pipe(Unleaded fuel)

4. Exhaust manifold insulator

5. Exhaust manifold assembly

6. Coolant inlet pipe and bypass pipe

7. Engine hanger

8. Alternator

9. Alternator strap and bracket

10. Engine mount bracket

11. Center cover

12. Distributor and high-tension lead

13. Spark plug

14. Thermostat and thermostat cover

15. Intake manifold bracket

16. Intake manifold assembly

17. Oil filter

18. Oil cooler

19. Oil pressure switch

76G01B-039

49 0107 680A Irf^Ys'^

,v,, I

' ir

>

49 G030 D05A

76G01A-120

Disassembly Note

Engine hanger

Remove the exhaust manifold; then connect the SST

to the engine.

69G01X-000

1B—25

Page 157 of 1865

1 B DISASSEMBLY (TIMING BELT)

TIMING BELT

69G01B-072

1. Crankshaft pulley 6. Timing belt idler pulley

2. Upper timing belt cover 7. Timing belt

3. Lower timing belt cover 8. Camshaft pulley

4. Baffle plate 9. Timing belt pulley

5. Timing belt tensioner and spring

1B—26

Page 158 of 1865

DISASSEMBLY (TIMING BELT) 1 B

Mark the

direction of

rotation

76G01A-121

76G01B-119

Disassembly Note

Crankshaft pulley

1. Set the SST against the flywheel.

2. Remove the crankshaft pulley.

Timing belt

1. Loosen the tensioner lock bolt, and remove the ten-

sioner spring.

2. Mark the timing belt rotation for proper reinstalla-

tion if it is reused.

3. Remove the timing belt.

Caution

Be careful not to allow oil or grease on the

belt.

Camshaft pulley

Remove the pulley lock bolt using a screw driver to

prevent the camshaft from turning.

76G01A-123

1B—27

Page 159 of 1865

1 B DISASSEMBLY (CYLINDER HEAD)

CYLINDER HEAD

1. Cylinder head cover

2. Seal plate

3. Camshaft cap

4. Camshaft

5. Hydraulic lash adjuster

6. Cylinder head bolt

7. Cylinder head

8. Cylinder head gasket

9. Valve keeper

10. Upper spring seat

11. Outer valve spring

12. Inner valve spring

13. Lower spring seat

14. Valve

15. Valve seal

76G01B-040

1B—28

Page 160 of 1865

DISASSEMBLY (CYLINDER HEAD) 1 B

76G01B-041

76G01B-042

Disassembly Note

Camshaft

Before removing the camshaft, clean the bearings

and journals, and measure the following points.

1. Camshaft end play. (Refer to page 1B—41.)

2. Camshaft journal oil clearance. (Refer to page

1B—40.)

Hydraulic lash adjuster (HLA)

Remove the HLA from the cylinder head.

Note

Mark each HLA so that they can be reinstalled

in the position from which they were removed.

Cylinder head bolt

Loosen the cylinder head bolts in two or three steps

in the order shown in the figure.

86U01X-068

Valve

Remove the valves from the cylinder head with the

SST.

86U01X-069

1B—29

Trending: fuse box diagram, alarm, stop start, wiring diagram, oil filter, warning, fuel tank removal