MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: dimensions, checking oil, oil capacity, jump cable, fuel pump, height adjustment, buttons

Page 191 of 1865

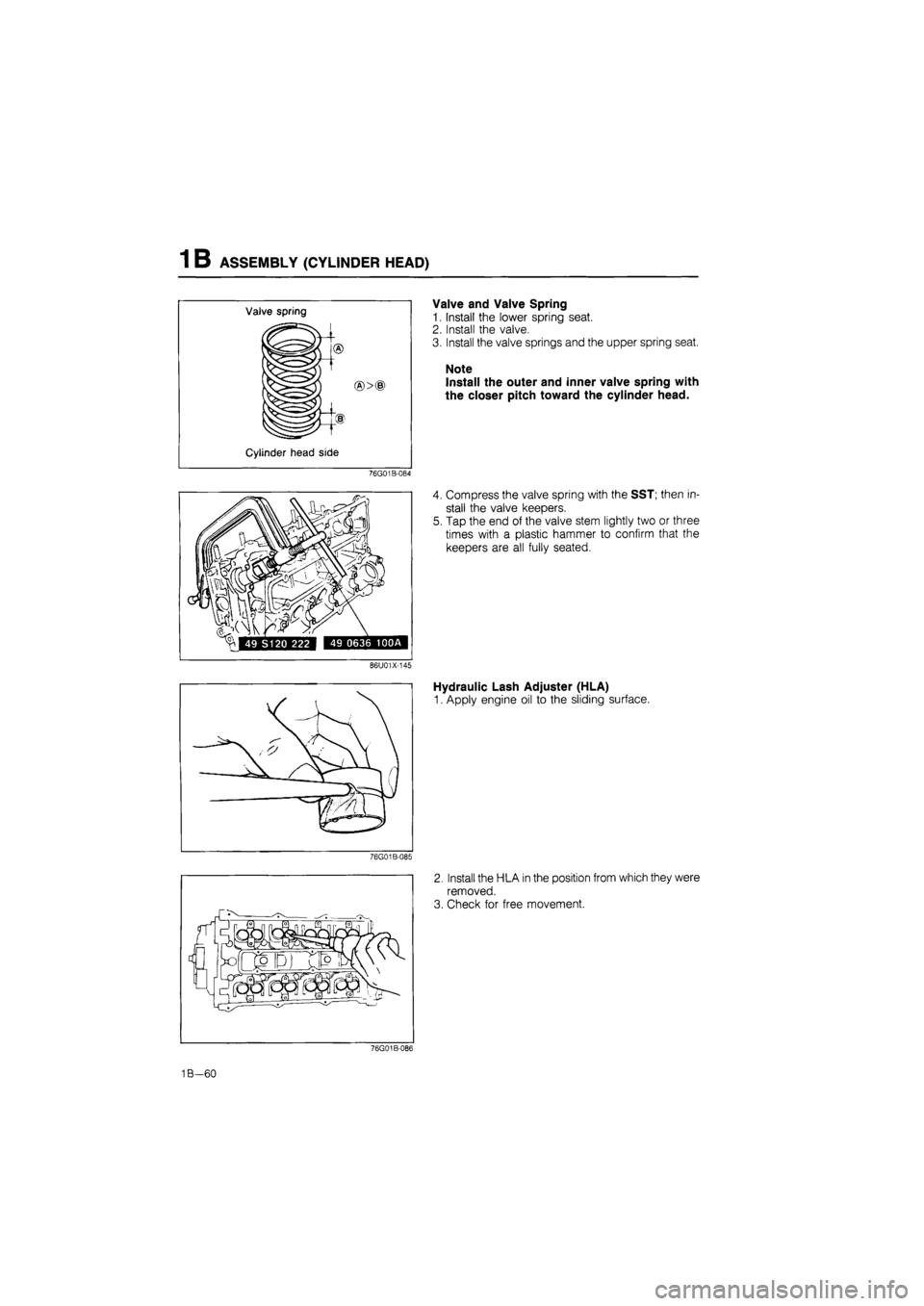

1 B ASSEMBLY (CYLINDER HEAD)

Valve spring

®>®

Cylinder head side

76G01B-084

86U01X-145

76G01B-085

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

3. Install the valve springs and the upper spring seat.

Note

Install the outer and inner valve spring with

the closer pitch toward the cylinder head.

4. Compress the valve spring with the SST; then in-

stall the valve keepers.

5. Tap the end of the valve stem lightly two or three

times with a plastic hammer to confirm that the

keepers are all fully seated.

Hydraulic Lash Adjuster (HLA)

1. Apply engine oil to the sliding surface.

2. Install the HLA in the position from which they were

removed.

3. Check for free movement.

76G01B-086

1B—60

Page 192 of 1865

ASSEMBLY (CYLINDER HEAD) 1 B

86U01X-146

© ® d> ®

® © ® © (D

86U01X-147

86U01X-148

Cylinder Head

1. Thoroughly remove all dirt, oil, or other material

from the top of the cylinder block.

2. Place the new cylinder head gasket in position.

3. Install the cylinder head.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80—86 Nm (8.2—8.8 m-kg, 59—64 ft-lb)

Camshaft

1. Apply a liberal amount of engine oil to the journals

and bearings.

2. Place the camshaft in position with the dowel pin

facing straight up.

Camshaft Oil Seal

1. Apply liberal amount of clean engine oil to the cam-

shaft oil seal and cylinder head.

2. Install the camshaft oil seal.

76G01B-087

1B-61

Page 193 of 1865

1 B ASSEMBLY (CYLINDER HEAD)

76G01B-088

Camshaft Cap

1. Apply liberal amount of clean engine oil to the cam

lobes and journals.

2. Apply silicon sealant to the front camshaft cap

surface.

3. Position the camshaft caps according to the cap

number and mark.

4. Install the camshaft caps. Tighten the bolts in two

or three steps in the order shown in the figure.

Tightening torque:

18—26 Nm (1.8—2.7 m-kg, 13—20 ft-lb)

Seal Plate

Install the seal plate.

Tightening torque:

8—12

N

m (80—120 cm-kg, 69—104 in-lb)

1B—62

Page 194 of 1865

ASSEMBLY (CYLINDER HEAD) 1 B

Cylinder Head Cover

1. Apply silicon sealant to the shaded area shown in

the figure.

2. Install the cylinder head cover.

Tightening torque:

4—6

N

m (40—60 cm-kg, 35—52 in-lb)

76G01B-092

1B—63

Page 195 of 1865

1 B ASSEMBLY (TIMING BELT)

TIMING BELT

Torque Specifications

47-65 N m (4.8—6,6 m-kg, 35—49

7—10 N-m (70—100 cm-kg, 61—87 in-ll'

12—17 Nm (1.25—1.75 m-kg, 109—152 in-lbj

167—167 N*m (16.0-17.0 m-kg, 116—123 tt-tti)

1B—64

69G01B-160

Page 196 of 1865

ASSEMBLY (TIMING BELT) 1 B

Camshaft Pulley

1. Install the camshaft pulley on the camshaft with the

dowel pin fit into the hole at the I mark (intake side)

and E mark (exhanst side).

76G01B-127

2. Tighten the camshaft pulley lock bolt.

Tightening torque:

47—65 Nm (4.8—6.6 m-kg, 35—48 ft-lb)

76G01A-141

3. Align the mating mark on the camshaft pulleys with

the alignment mark on the seal plate.

Note

For intake side camshaft pulley, align "I"

mark.

For exhanst side camshaft pulley, align "E"

mark.

76G01B-094

Timing Belt Pulley

1. Reverse the direction of the SST (ring gear brake).

2. Install the crankshaft key.

3. Install the timing belt pulley on the crankshaft.

Tightening torque: 157—167 N m

(16.0—17.0 m-kg, 116—123 ft-lb)

4. Release the ring gear brake.

5. Align the timing belt pulley and the pump body

alignment marks.

86U01X-160

1B—65

Page 197 of 1865

1 B ASSEMBLY (TIMING BELT)

69G01B-165

76G01B-095

79G01C-097

Timing Belt Idler Pulley

Install the timing belt idler pulley.

Tightening torque:

37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

Timing Belt Tensioner

1. Install the timing belt tensioner and tensioner

spring.

2. Tentatively secure the tensioner with the spring fully

extended.

Timing Belt

1. Install the timing belt so that there is no looseness

at the tension side, and at the two camshaft pulleys.

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

2. Loosen the tensioner lock bolt.

3. Turn the crankshaft twice in the direction of rotation.

4. Check that the mating marks are correctly aligned.

If not aligned, remove the timing belt and tension-

er, and repeat the above-mentioned procedure.

5. Turn the crankshaft to align the S mark of the right

side camshaft pulley with seal plate mating mark.

6. Tighten the timing belt tensioner lock bolt.

Tightening torque:

37—52

N

m (3.8—5.3 m-kg, 27—38 ft-lb)

76G01B-096

1B-66

Page 198 of 1865

ASSEMBLY (TIMING BELT) 1 B

76G01B-097

86U01X-163

7. Check the timing belt deflection. If the deflection

is not correct, loosen the tensioner lock bolt and

repeat steps 3—5 above. Replace the tensioner

spring if necessary.

Belt deflection:

7.5—8.5 mm (0.30—0.33 in)

/ 98 N (10 kg, 22 lb)

Baffle Plate

Position the baffle plate on the timing belt pulley.

Timing Belt Cover

Install the lower timing belt cover, upper timing belt

cover, and new gaskets.

Tightening torque:

7—10 Nm (70—100 cm-kg, 61—87 in-lb)

Crankshaft Pulley

Install the crankshaft pulley.

Tightening torque: 12—17 N-m

(1.25—1.75 m-kg, 109—152 in-lb)

69G01B-170

1B—67

Page 199 of 1865

DISASSEMBLY

(AUXILIARY PARTS) 1 B

AUXILIARY PARTS

Torque Specifications

37—63 N-m (3.8—6.4 m-kg, 27—46 ft-lb) 19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

85—117 N-m (8.7—11.9 m 63—86 ft-lb)

19—30 N-m (1.9—3.1 m-kg 14—22 ft-lb)

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

37—63 N-m (3.8—6.4 m-kg, 27—46 ft-lb)

34—49 N-m (3.5—5.0 m-kg, 25-36 ft-lb)

19—30 N-m (1.9—3.1 m-kg, 14-22 ft-lb)

37—52 N-m '(If (3.8—5.3 m-kg, | / 27—38 ft-lb)

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

34—44 N-m (3.5—4.5 m-kg, 25—33 ft-lb)

19—30 N-m (1.9—3.1 m-kg, 14—2 Z ft-lb)

86U01X-164

1B—68

Page 200 of 1865

ASSEMBLY (AUXILIARY PARTS) 1 B

Oil Pressure Switch

Install the oil pressure switch.

Tightening torque: 12—18 N-m

(1.2—1.8 m-kg, 104—156 in-lb)

76G01A-087

Oil Cooler

Install the oil cooler.

Tightening torque:

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

Oil Filter

1. Apply a small amount of engine oil to the rubber

seal of the new filter.

2. Install the oil filter and tighten it by hand until the

rubber seal contacts the base.

3. Then tighten the filter

1

and 1/6 turn with a wrench.

76G01B-099

Intake Manifold Assembly

1. Place the new gasket in position.

2. Install the intake manifold assembly.

3. Tighten the nuts in two or three steps.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

86U01X-167

Intake Manifold Bracket

Install the intake manifold bracket.

Tightening torque:

19—30 N-m (1.9—3.1 m-kg, 14—22 ft-lb)

86U01X-168

expert22 fl/ia http://rutracker.org

1B-69

Trending: fuse box diagram, flat tire, spark plugs, boot, oil type, buttons, mirror