MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 151 of 1164

ON-VEHICLE MAINTENANCE B2

- 05UOBX-04:

---_____~

OWOBX 04

----

05UOBX-03

4

2. Loosen the tensioner lock bolt.

Caution

l To prevent damage to the tensioner, secure it with

a rag.

3. Temporarily secure the tensioner with the spring fully ex-

tended.

Caution

Q Do not allow any oil or grease on the timing belt.

4. Remove the timing belt and secure it out of the way to pre-

vent damage during removal and installation of the cylin-

der head.

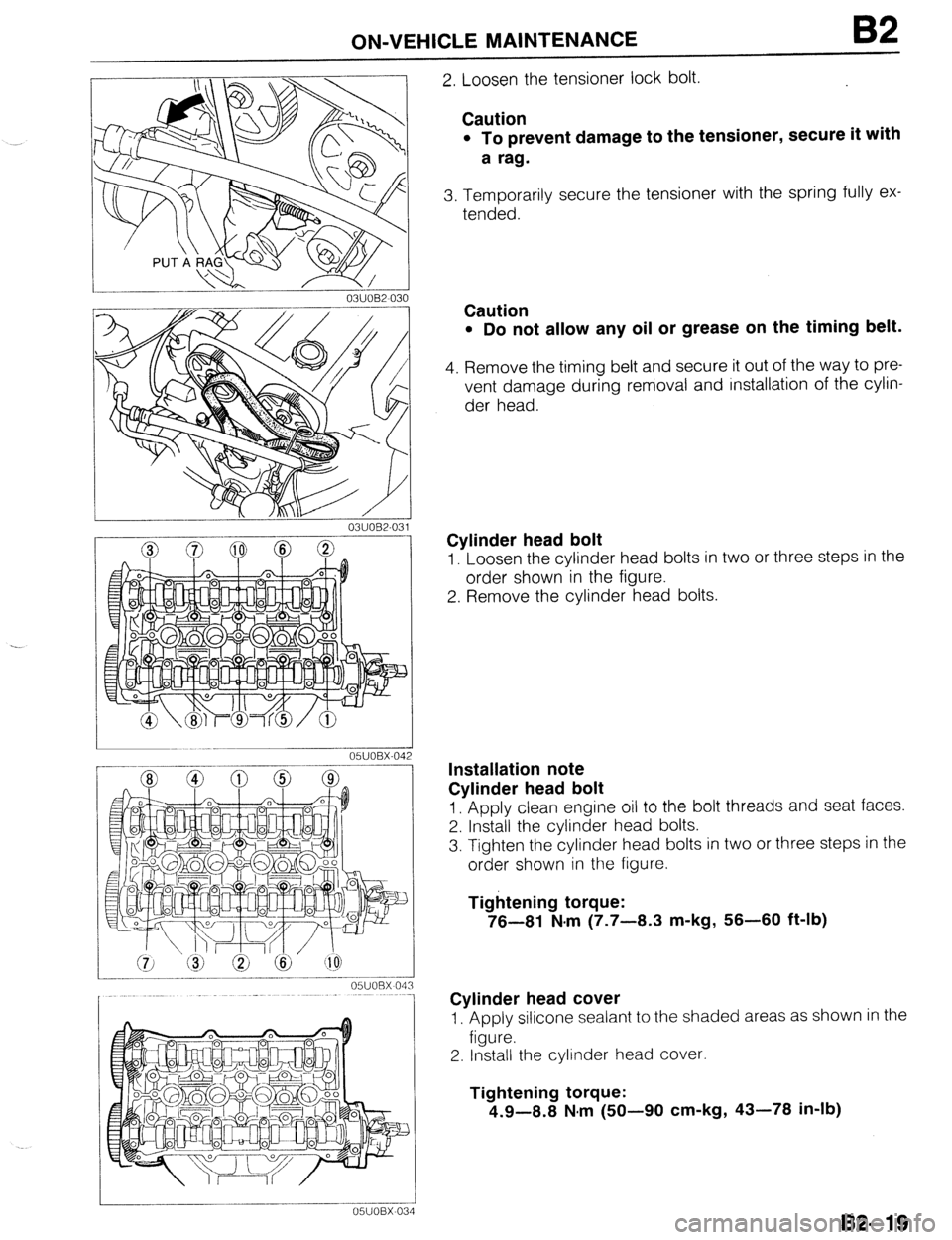

Cylinder head bolt

1. Loosen the cylinder head bolts in two or three steps in the

order shown in the figure.

2. Remove the cylinder head bolts.

Installation note

Cylinder head bolt

1. Apply clean engine oil to the bolt threads and seat faces.

2. Install the cylinder head bolts.

3. Tighten the cylinder head bolts in two or three steps in the

order shown in the figure.

Tightening torque:

76-81 N-m (7.7-8.3 m-kg, 56-60 ft-lb)

Cylinder head cover

1, Apply silicone sealant to the shaded areas as shown in the

figure.

2. Install the cylinder head cover.

Tightening torque:

4.9-8.8 N-m (50-90 cm-kg, 43-78 in-lb)

B2-19

Page 152 of 1164

B2 ON-VEHICLE MAINTENANCE

03UOB2-033

FOUR TEETH

13UOB2-015

05UOBX-032

B2-20

Timing belt

1. Check that the ignition timing mark (yellow) on the crank-

shaft pulley and the timing mark on the timing belt cover

are aligned.

2. Verify that the camshaft pulley marks are aligned with the

seal plate marks.

Caution

l For intake side, align the I mark.

l For exhaust side, align the E mark.

3. Install the timing belt so that there is no looseness at the

idler side or between the two camshaft pulleys.

Caution

l Do not turn the crankshaft counterclockwise.

4. Turn the crankshaft two turns clockwise, and align the tim-

ing belt pulley mark with the timing mark.

5. Verify that the camshaft pulley marks are aligned with the

seal plate marks.

If not aligned, remove the timing belt and repeat from ten-

sioner installation.

6. Turn the crankshaft 1 and 5/6 turns clockwise, and align

the fourth tooth from the

I mark with the seal plate mark.

7. Loosen the tensioner lock bolt to apply tension to the tim-

ing belt.

8. Tighten the tensioner lock bolt.

Tightening torque:

37-52 N#rn (3.8-5.3 m-kg, 27-38 ft-lb)

9. Turn the crankshaft 2 and l/6 turns clockwise and verify

that the timing marks are correctly aligned.

Page 153 of 1164

ON-VEHICLE MAINTENANCE

DEFLECTION CHECKING POINT

05UOBX-03 3 10. Measure the timing belt deflection by applying moderate

pressure (98 N, 10 kg, 22 lb) midway between the two cam-

shaft pulleys.

If the deflection is not correct, repeat from Step 7 above.

Deflection:

9.0-11.5mm (0.35-0.45 in) at 98 N (10 kg, 22 lb)

Harness

1. Connect the harness connectors. (Refer to page 82-l 8.)

Hose

1. Connect the hoses. (Refer to page 82-17.)

03UOB2-035

Accelerator cable

1. Install the accelerator cable.

2. Check the accelerator cable deflection.

If the deflection is not correct, adjust by turning nut A.

Deflection: l-3mm (0.04-0.12 In)

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to Section E.)

2. Connect the negative battery cable.

3. Start the engine and check as follows:

(1) Engine oil and engine coolant leakage.

(2) Ignition timing, idle speed. (Refer to page B2-8.)

(3) Operation of emission control system.

4. Recheck the engine coolant levels.

2311082-022

B2-21

Page 154 of 1164

B2 ON-VEHICLE MAINTENANCE

HLA

Removal / Installation

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure, referring to

Removal Note.

3. install in the reverse order of removal, referring to Installation Note --- ----- -__ __-- ,‘.

11.3-14.2 N.m

(1.15-1.45 m-\g, 100-126 in-lb)

49-61

(5.0~6.2,-36-45)

4.9-6.6 N.m

(50-90 cm-kg, 43-76 in-lb)

7.6All N-m

(80-110 cm-kg, 69-95 in-lb) 1 Q’-25

(1.9-2.6, 14-19)

N.m (m-kg, ft-lb)

0311082-03

1. High-tension lead

10. Cylinder head cover

2. Distributor

Installation Note..

....................

Installation Note.. ......................

page 62-25

11. Camshaft pulley

3. P/S and/or A/C drive belt

Removal note ..........................

Removal / Installation..

.............. page E32-

6

Installation Note .......................

4. Alternator drive belt

12. Seal plate

Removal / Installation

......... . ...... page B2- 6

13. Camshaft

5. Water pump pulley

Removal Note.. ........................

6. Timing belt cover, upper

Installation Note.. .....................

7. Timing belt cover, middle

14. HLA

8. Spark plug

Removal note ..........................

9. Timing belt

Installation

Note.. .....................

Removal Note.. .........................

page B2-18 Inspection

................................

Installation Note.. ......................

page B2-20

7

page 62-19

page 82-23

page 82-24

page B2-23

page 62-23

page B2-23

page B2-23 ‘--’

page 82-60

82-22

Page 155 of 1164

ON-VEHICLE MAINTENANCE 82

I 05UOBX-049

05UOBX-C

05UOBX-0

03UOB2-1

Removal note

Camshaft pulley

1, Hold the camshaft with a wrench at hexagonal portion.

2. Remove the camshaft pulley lock bolt.

3. Remove the camshaft pulley.

Camshaft

1. Loosen the camshaft cap bolts in two or three steps in the

order shown in the figure.

2. Remove the camshaft caps.

3. Remove the camshaft.

4. Remove the camshaft oil seal from the camshaft.

HLA

Caution

l Mark the HLA with a felt pen so that they can be rein-

stalled in the position from which they were

removed.

1. Remove the HLA from the cylinder head.

Installation note

HLA

1. Apply clean engine oil to the friction surfaces.

2. If the HLA are being reused, install them in the position from

which they were removed.

3. Verify that the HLA move smoothly in their bores.

Camshaft

Note

l The intake camshaft is grooved for the distributor

drive.

1. Apply clean engine oil to the camshaft journals and bearings.

2. Install the camshaft in position.

82-23

Page 156 of 1164

ON-VEHICLE MAINTENANCE

OWOBX-05.

OxJOBX-05,

ENOBX-056

--

Caution

l Do not allow any sealant on the camshaft journal

surfaces.

.-

3. Apply silicone sealant to the shaded areas shown in the

figure.

4. Install the camshaft caps according to the cap number and

arrow mark.

5. install the camshaft cap bolts and tighten them in two or

three steps in the order shown in the figure.

Tightening torque:

11.3-l 4.2 N-m (1 .15--l .45 m-kg, loo-126 in-lb)

6. Apply a small amount of clean engine oil to the lip of a new

camshaft oil seal.

7. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the camshaft cap.

8. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 46mm (1.69 in)

Camshaft pulley

1. Turn the camshafts until the camshaft dowel pins face

straight up.

2. Install the camshaft pulleys with the I mark (intake side) or

the E mark (exhaust side) straight up.

I II’- ,

J

05UOBX-057

B2-24

Page 157 of 1164

ON-VEHICLE MAINTENANCE B2

05UOBX-05

BLA-DE 0-dlNG

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 82-8.) 3. Install the camshaft pulley lock bolts.

4. Hold the camshaft with a wrench.

5. Tighten the camshaft pulley lock bolt.

Tightening torque:

49-61 N-m (5.0-6.2 m-kg, 36-45 ft-lb)

Distributor

1. Apply grease to a new O-ring and the blade.

2. Install the distributor and loosely tighten the installation bolt.

3. Connect the distributor connector.

0311082-039

B2-25

Page 158 of 1164

B2 ON-VEHICLE MAINTENANCE

FRONT OIL SEAL

Replacement

1. Disconnect the negative battery cable.

2. Raise the vehicle on a lift and remove the right front wheel.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal, referring to Installation Note.

I

@Em

157-167 (16-17, 116-123)

N.m (m-kg, ft-lb

1. Timing belt related parts.. ............ page B2-12

2. Pulley lock bolt

Removal Note ..................................... below

Installation Note.. page B2-27 ......................

3. Pulley boss

4. Timing belt

Removal Note.. ......................... page B2-13

Installation Note ........................ page B2-14 5. Timing belt pulley

Installation Note..

...................... page B2-27

6. Oil seal

Removal Note.. ......................... page B2-27

Installation Note.. ...................... page B2-27

Removal Note

Pulley lock bolt

1. Hold the pulley boss with the SST.

2. Loosen and remove the pulley lock bolt.

Page 159 of 1164

ON-VEHICLE MAINTENANCE

I 05UOBX-063

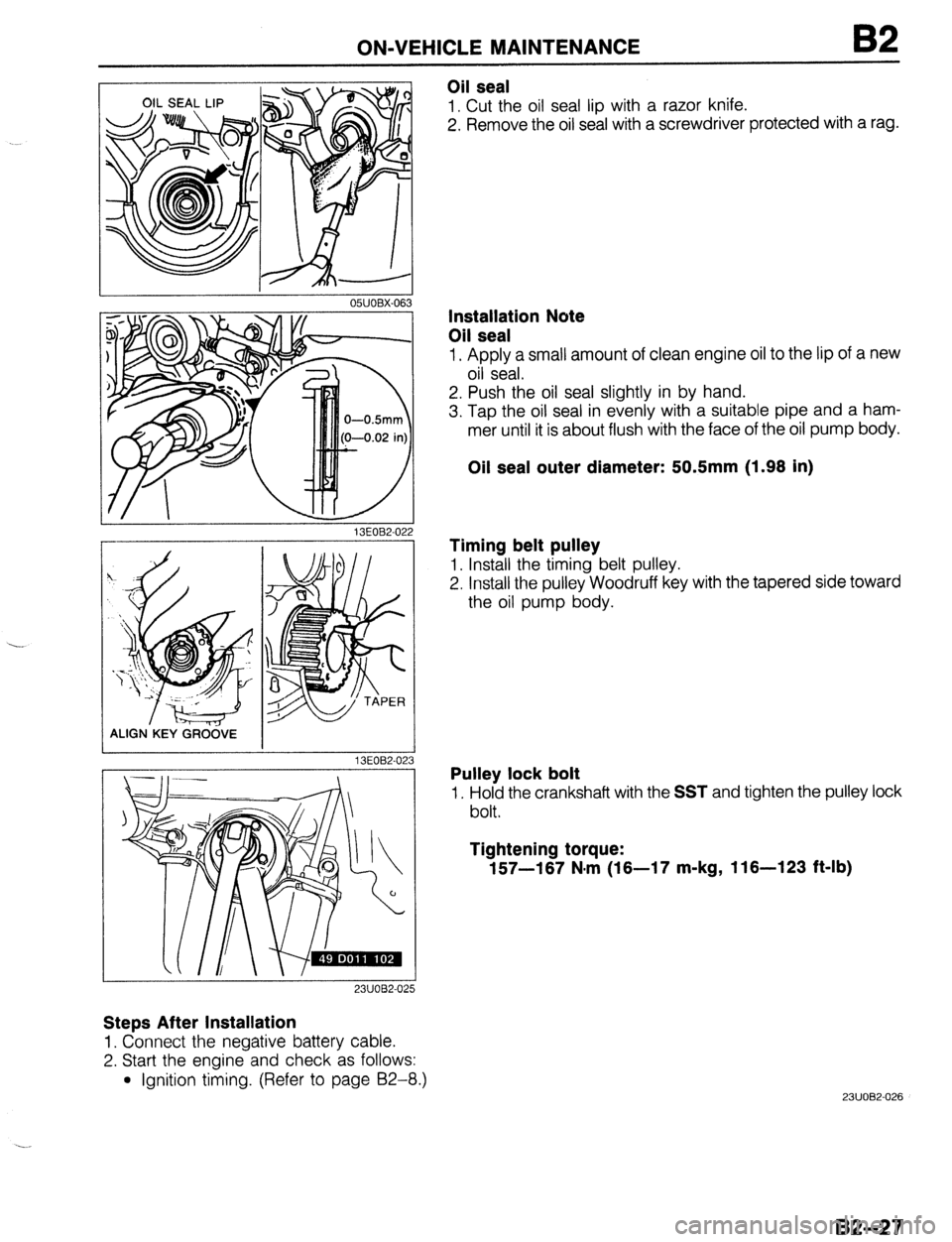

Oil seal

1. Cut the oil seal lip with a razor knife.

2. Remove the oil seal with a screwdriver protected with a rag.

13EOB2-02

ALIGN.KEY GRCi&E

13EOB2-02

23UOB2-025

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 92-8.)

3

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

3. Tap the oil seal in evenly with a suitable pipe and a ham-

mer until it is about flush with the face of the oil pump body.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley Woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-187 N.m (18-17 m-kg, 116-123 ft-lb)

23UOB2-026

82-27

Page 160 of 1164

B2 ON-VEHICLE MAINTENANCE

REAR OIL SEAL

Replacement

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure, referring to

Removal Note.

3. install in the reverse order of removal, referring to Installation Note.

t

I 1

ITX 16-26 (1.6-2.7, 13-20)

L

\TX

N.m (m-kg, ft-It 0

23UOBZ-027

1. Transaxle

MTX

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section J2

ATX

Service . . . , . . . . ,.......................... Section K

2. Clutch cover, clutch disc (MTX)

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section H

3. Flywheel (MTX)

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Installation Note .,.....,..,............. page 82-29 4. Drive plate (ATX)

Removal Note ..,........................ page B2-29

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 62-30

5. Oil seal

Removal Note .,......................... page 52-29

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-29

23UOB2-05

82-28

il

Removal note

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.