MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 181 of 1164

DISASSEMBLY

23UOW056

03UOB2-073

Disassembly Note

Timing belt pulley

1. Hold the flywheel or the drive plate with the SST or

equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt.

4. Remove the timing belt pulley.

5. Remove the pulley Woodruff key.

23UOB2-049

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.

Backing plate, drive plate, and adapter (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

Oil pan

1. Remove the oil pan mounting bolts.

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Remove the oil pan.

82-49

Page 182 of 1164

82 DISASSEMBLY

-. 05UOBX-10

-

REAR COVER

-.

05UOBX-10

Main bearing support plate (MBSP)

1, Remove the MBSP mounting bolts.

Caution

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool at the points shown

in the figure.

3. Remove the MBSP.

Front oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

Rear oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

92-50

Page 183 of 1164

B2

CYLINDER BLOCK (INTERNAL PARTS)

1. Disassemble in the order shown in the fioure, referring to Disassembly Note.

I. Connecting rod cap 7. Piston

Disassembly Note ,..,.,., ,.,..... ,, ,. page B2-52 Inspection ,.. . . ,.. . . . . . . . . . page 82-62

2. Connecting rod 8. Main bearing cap

Disassembly Note ..,.. . . . . . . ,. page B2-52 Disassembly Note .,,,..,..,...... ~.,. page 82-53

Inspection . . . . . . . . . . . . . . . . . . . . . . . page B2-63 9. Crankshaft

3. Connecting rod bearing Disassembly Note ,... . . . . . . page 92-53

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-64 Inspection ,......,,.,._.................... page B2-64

4. Piston ring 10. Main bearing

Disassembly Note .,...........,.,..,. page B2-52 Inspection ., ,... . . . page B2-64

Inspection ..~ ,., . . . . . . . . . page B2-62 Il. Thrust bearing

5. Piston pin clip 12. Oil jet

6. Piston pin Inspection ,..,..,., ,..,.., . . . . . . . . . . . . . . . . page B2-61

Disassembly Note ,.. . . . . . . page B2-52 13. Cylinder block

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 82-63 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-60

B2-51

Page 184 of 1164

82 DISASSEMBLY

03UOB2-071 6

- ____-______---..----. 05UOBX 113

------ -__ .---

7

Disassembly Note

Connecting rod cap

1. Before removing the connecting rod caps, measure the con-

necting rod side clearance. (Refer to page B2-71.) 1

Connecting rod

1. Before removing the connecting rods, measure the connect-

ing rod oil clearance. (Refer to page B2-71.)

2. Remove the Plastigage from the crankpin journals,

Caution

l Do not scratch the crankshaft journal or the cylin-

der wall.

-,

3. Use the handle of a hammer to remove the piston and con-

necting rod assembly through the top of the cylinder block.

Piston ring

Caution

l Do not apply excessive tension, which may cause

the rings to snap out.

1. Remove the piston rings with a piston ring expander (com-

mercially available).

Piston pin

1. Remove the piston pin with the SST.

Page 185 of 1164

DISASSEMBLY

03UOBZO7i

Main bearing cap

1. Before removing the main bearing caps, measure the crank-

shaft end play. (Refer to page 62-70.)

2. Loosen the main bearing cap bolts in two or three steps

in the order shown in the figure.

3. Remove the main bearing caps.

Crankshaft

1. Before removing the crankshaft, measure the main bear-

ing oil clearances. (Refer to page 82-69.)

03UOB2-079

B2-53

Page 186 of 1164

I32 INSPECTION / REPAIR

INSPECTION / REPAIR

PREPARATION

SST

49 6012 005 49 6012 005

Remover & Remover &

installer, valve installer, valve

guide guide

49 LO12 002

Body

(Part of

49 LO12 OAO)

49 LO12 004

Nut

(Part of

49 LO12 OAO) For

removal of

valve guide

For

installation of

valve guide

For

installation of

valve guide 49 LO12 OAO

Installer set,

valve seal &

valve guide

49 LO12 003

Installer

(Part of

49 LO12 OAO) For

installation of

valve guide

For

installation of

valve guide

05UOBX-1

1. Clean all parts, being sure to remove all gasket fragments, dirt, oil or grease, carbon, moisture residue,

and other foreign materials.

2. Inspection and repairs must be performed in the order specified. -.,

Caution

l Do not damage the joints or friction surfaces of aluminum alloy components (such as the cyl-

inder head or pistons).

0311082-162

03UOB2-70 OWOBX-119

CYLINDER HEAD

1, Inspect the cylinder head for damage, cracks, and leakage

of water and oil. Replace the cylinder head if necessary.

2. Measure the cylinder head distortion in the six directions

shown in the figure.

Distortion: O.lOmm (0.004 in) max.

Cautlon

l Before grinding the cylinder head, check the follow-

ing and repair or replace the cylinder head as

necessary.

Sinking of valve seats

Damage of manifold contact surface

Camshaft oil clearances and end play

3. If the cylinder head distortion exceeds specification, grind

the cylinder head surface.

If the cylinder head height is not within specification, replace

it. Height: 133.8-l 34.0mm (5.268-5.276

in)

Grinding: O.lOmm (0.004 in) max.

62-64

Page 187 of 1164

INSPECTION / REPAIR B2

0311082-007

I!!?

STEM TIP

23UOBZ03f

23UOW03i

IL VALVE STEM

OWOBX-125 CLEARANCE

4. Measure the manifold contact surface distortion in the four

directions shown in the figure.

Distortion: 0.15mm (0.006 In) max.

5. If distortion exceeds specification, grind the surface or re-

place the cylinder head.

VALVE MECHANISM

Valve and Valve Guide

1. inspect each valve for the following. Replace or resurface

the valve if necessary.

(1) Damaged or bent stem.

(2) Rough or damaged face.

(3) Damaged or unevenly worn stem tip.

2. Measure the valve head margin thickness of each valve.

Replace the valve if necessary.

Margin thickness

IN : 0.9mm (0.0354 in)

EX: l.Omm (0.0394 in)

3. Measure the length of each valve.

Length

Standard

IN : 101.34mm (3.9696 in)

EX: 101.44mm (3.9937 in)

Minimum

IN : 100.64mm (3.9701 in)

EX: 100.94mm (3.9740 in)

4. Measure the stem diameter of each valve at the points

shown.

Diameter

IN : 5.970-5965mm (0.2350-0.2356 in)

EX: 5.965-5960mm (0.2346-0.2354 in)

5. Measure the inner diameter of each valve guide at the points

shown.

Inner diameter

IN : 6.01-6.03mm (0.2366-0.2374 in)

EX: 6.01-6.03mm (0.2366-0.2374 in)

6. Calculate the valve stem to guide clearance.

Subtract the outer diameter of the valve stem from the in-

ner diameter of the corresponding valve guide.

Clearance

IN : 0.025-0.060mm (0.0010-0.0024 in)

EX: 0.030-0.065mm (0.0012-0.0026 in)

Maximum: 0.20mm (0.006 in)

7. If the clearance exceeds specification, replace the valve

and/or valve guide.

B2-55

Page 188 of 1164

82 INSPECTION / REPAIR

03UOB2-082

13UOB2-0.

1

9MUOB2-112

I

03UOB2-08:

8. Measure the height @of each valve guide. Replace the

valve guide if necessary.

Height: 18.3-l 8.9mm (0.720-0.744 in)

Replacement of valve guide

Note

l The valve guides are different between intake and

exhaust sides, use the correct valve guide.

Removal

1. Remove the valve guide from the side opposite the com-

bustion chamber with the

SST.

Installation

1. Assemble the SST so that depth L is as specified.

Depth L: 18.3-18.9mm (0.720-0.744 in)

2. lighten the locknut.

3. Tap the valve guide in from the side opposite the combus-

tion chamber until the

SST contacts the cylinder head.

4. Verify that the valve guide height is within specification.

5. If not within specification, repeat Steps 1-4.

82-56

Page 189 of 1164

INSPECTION / REPAIR 82

OWOBX-13

SEAT CONTACT WIDTH

I OWOBX-132

IN EX

700

Li!!b!J

700

45O 450

r

----

0311082 Oe

_---- _---

1

05UOBX-1:

Gi

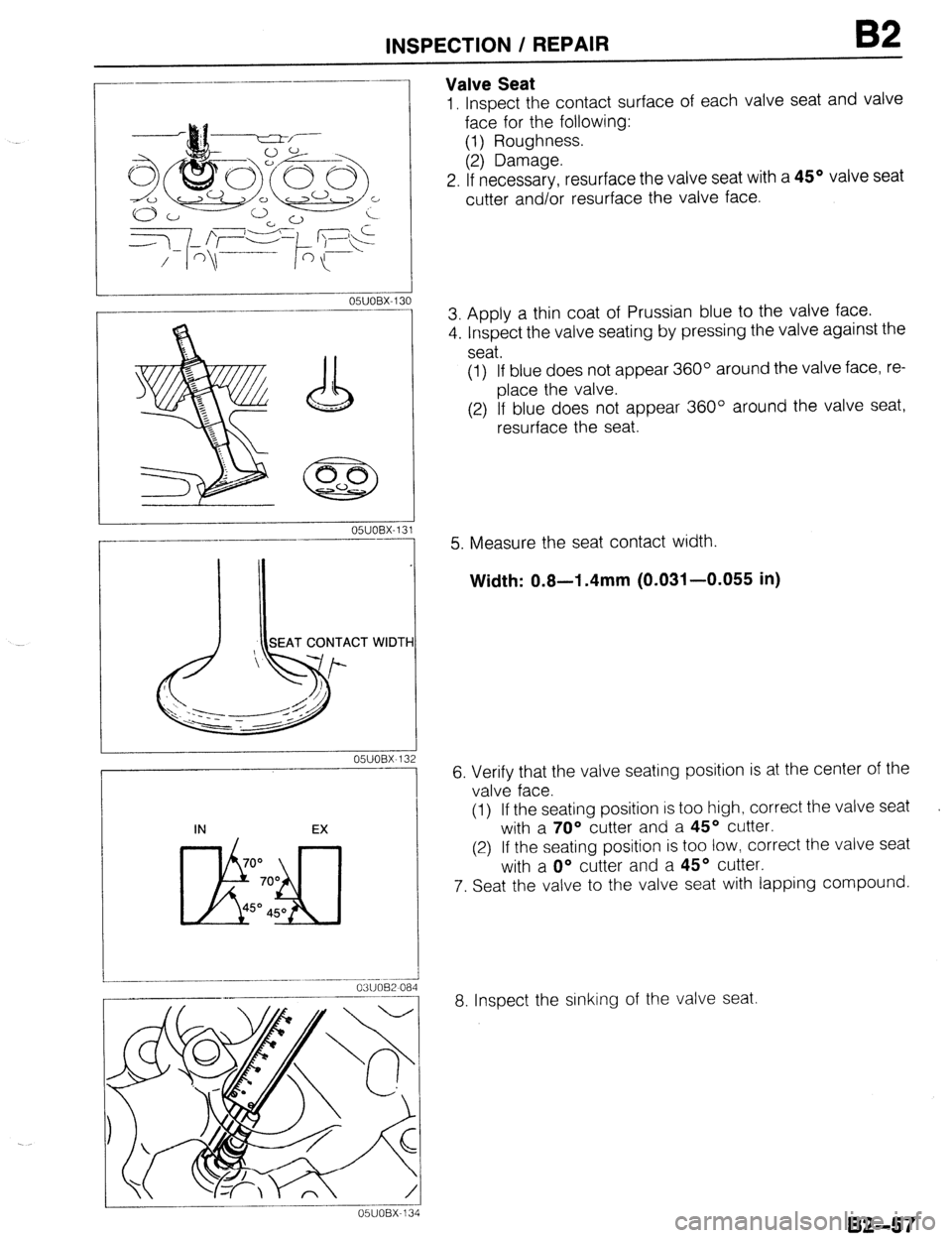

Valve Seat

1, Inspect the contact surface of each valve seat and valve

face for the following:

(1) Roughness.

(2) Damage.

2. If necessarv, resurface the valve seat with a 45’ valve seat

cutter and/br resurface the valve face.

3. Apply a thin coat of Prussian blue to the valve face.

4. Inspect the valve seating by pressing the valve against the

seat.

(1) If blue does not appear 360° around the valve face, re-

place the valve.

(2) If blue does not appear 360° around the valve seat,

resurface the seat.

5. Measure the seat contact width.

Width: 0.8-l .4mm (0.031-0.055 in)

6. Verify that the valve seating position is at the center of the

valve face.

(1) If the seating position is too high, correct the valve seat

with a 70° cutter and a 45O cutter.

(2) If the seating position is too low, correct the valve seat

with a O” cutter and a 45’ cutter.

7. Seat the valve to the valve seat with lapping compound.

8. Inspect the sinking of the valve seat.

B2-57

Page 190 of 1164

B2 INSPECTION / REPAIR

23UOB2-060

i$

03UOB2-08

ANGLE LIMIT

Ii

0311082.Ot

w v

05UOBX-138

03UOB2-OE

82-58

I8

9. Measure the protruding length (dimension L) of the valve

stem.

Dimension L: 45.0mm (1.7717 in)

(1) If L is 45.0-45.5mm (1.772-l .791 in), no correc-

tion needed.

(2) If L is 45.5-46.5mm (1.791-l .831 in), adjust with

washer on spring seat area of cylinder head.

(3) If L is 46.5mm (1.831 in) or more, replace cylinder

head.

Valve Spring

1. Inspect each valve spring for cracks or damage.

2. Measure the free length and out-of-square. Replace the

valve spring if necessary.

Free length

Standard: 46.26mm (1.821 in)

Minimum:

224-253 N (22.8-25.8 kg, 50-57 lb)/

395mm (1.555 in)

Out-of-square: 1.62mm (0.064 in) max.

CAMSHAFT

1. Set the front and rear journals on V-blocks.

2. Measure the camshaft runout. Replace the camshaft if

necessary.

Runout: 0.03mm (0.0012 in) max.

3. Inspect the camshaft for wear or damage. Replace the cam-

shaft if necessary.

4. Measure the cam lobe heights at the two points as shown.

Height

Standard

IN : 44.094mm (1.7360 in)

EX: 44.600mm (1.7560 in)

Minimum

IN : 43.894mm (1.7281 in)

EX: 44.400mm (1.7480 in)