MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 161 of 1164

ON-VEHICLE MAINTENANCE

Drive plate (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

2311082-052

I

Oil seal

1. Cut the oil seal lip with a razor knife.

2. Remove the oil seal with a screwdriver protected with a rag.

I I

I

05UOBX-063

Installation note

Oil seal

1, Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

OWOBX-069

APPLY SEALANT

03UOB2.04

Caution

l The oil seal must be tapped in untjl it is flush with

the edge of the rear cover.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 1OOmm (3.94 in)

Flywheel (MTX)

1. Remove the sealant from the flywheel bolt holes in the crank-

shaft and from the flywheel bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the flywheel onto the crankshaft.

3. Apply sealant to the flywheel bolts and install them.

4. Hold the flywheel with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown

in the figure.

Tightening torque:

1 96-103 N-m (9.6-10.5 m-kg, 71-76 ft-lb)

2311082-053

B2--29

Page 162 of 1164

B2 ON-VEHICLE MAINTENANCE

0311082-04

23UOB2-05 4

Drive plate (ATX)

1. Remove the sealant from the drive plate holes in the crank-

shaft and from the drive plate lock bolts.

Caution

..i

l if ail the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the adapter, drive plate, and backing plate onto the

crankshaft,

3. Apply sealant to the drive plate bolts and install them.

4. Hold the drive plate with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown

in the figure.

Tightening torque:

96-103 N-m (9.6-10.6 m-kg, 71-76 ft-lb)

Steps After installation

1. Connect the negative battery cable.

2. Start the engine and perform engine adjustments as necessary.

OWOBX-072

82-30

Page 163 of 1164

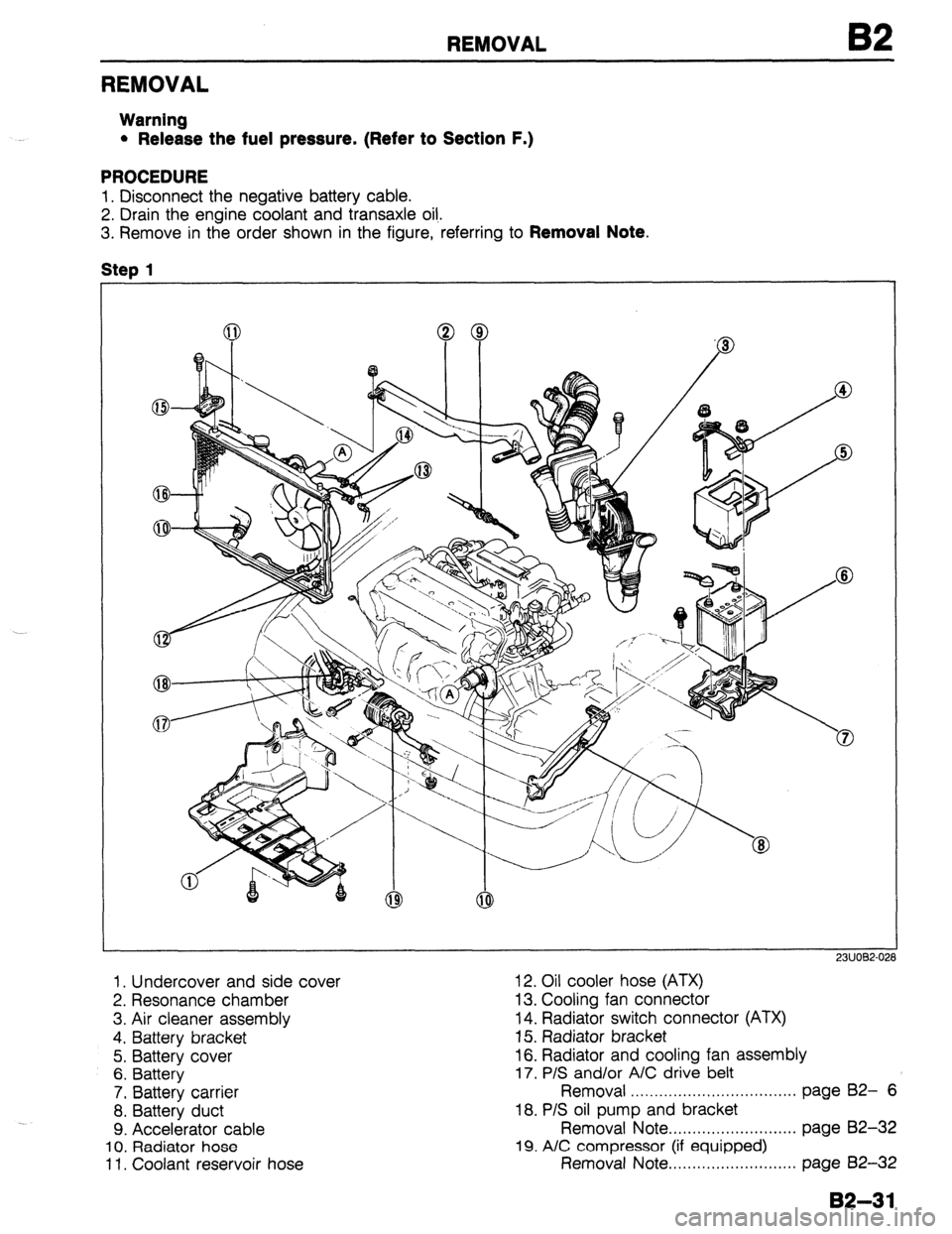

REMOVAL

REMOVAL

Warning

l Release the fuel pressure. (Refer to Section F.)

PROCEDURE

1. Disconnect the negative battery cable.

2. Drain the engine coolant and transaxle oil,.

3. Remove in the order shown in the figure, referring to

Removal Note.

Step

1

1. Undercover and side cover 12. Oil cooler hose (ATX)

2. Resonance chamber 13. Cooling fan connector

3. Air cleaner assembly 14. Radiator switch connector (ATX)

4. Battery bracket 15. Radiator bracket

5. Battery cover 16. Radiator and cooling fan assembly

6. Battery

17. P/S and/or A/C drive belt

7. Battery carrier Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2- 6

8. Battery duct 18. P/S oil pump and bracket

9. Accelerator cable Removal Note . . . . . . . . . . . . . . . . . . . . + . . . . . . page 82-32

10. Radiator hose 19. A/C compressor (if equipped)

11. Coolant reservoir hose Removal Note.. . . . . . . . . . . . . . . . . . . . . . . . . . page 82-32

B2-31

Page 164 of 1164

REMOVAL

0311082-046

Removal note

P/S oil pump and bracket

Caution

l Do not damage the hoses.

1. Remove the P/S oil pump and bracket with the hoses still

connected.

2. Position the pump away from the engine and affix it with wire.

A/C compressor (if equipped)

Caution

l Do not damage the hoses.

1. Remove the A/C compressor with the hoses still connected.

2. Position the compressor away from the engine and affix it

with wire.

Step 2

1. Disconnect the harness connectors shown in the figure.

OIL PRESSURE SWITCH ATX

THROTTLE INHIBITOR SWITCH

ALTERNATOR

I SENSOR 1

II

rl (MTX)

-03UOB2-05( .-,’

Page 165 of 1164

REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

J”“DC-” I I

1. Fuel hose

3. Brake vacuum hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

4. Vacuum hose (Purge control)

2. Heater hose

Removal Note . . . . . . . . . . . . . , . . . . . . . . . . . .

05UOBX-078

0311082-052

. . . . .

below 5. Vacuum hose (Cruise control)

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

82-33

Page 166 of 1164

82 REMOVAL

Won A

ATX

I e- ENGINE MOUNT MEMBER

COTTER PIN, REPLACE

1. Speedometer cable

2. Clutch release cylinder (MTX)

Removal Note . . . . .., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

3. Shift control rod (MTX)

4. Extension bar (MTX)

5. Shift control cable (ATX)

1311082.Ol!

82-34

3

6. Exhaust pipe

7, Stabilizer

8. Tie-rod end

Removal Note ..,......,................. page B2--35

9. Driveshaft

Removal Note. ,............,............ page 82-35

Removal note

Clutch release cylinder (MTX)

1, Remove the release cylinder pipe bracket from the transaxle.

Caution

l Do not damage the pipe or hose.

2. Position the release cylinder away from the transaxle for eas-

ier removal with the hose still connected. . __

Page 167 of 1164

REMOVAL B2

13UOB2-021

0311082-059

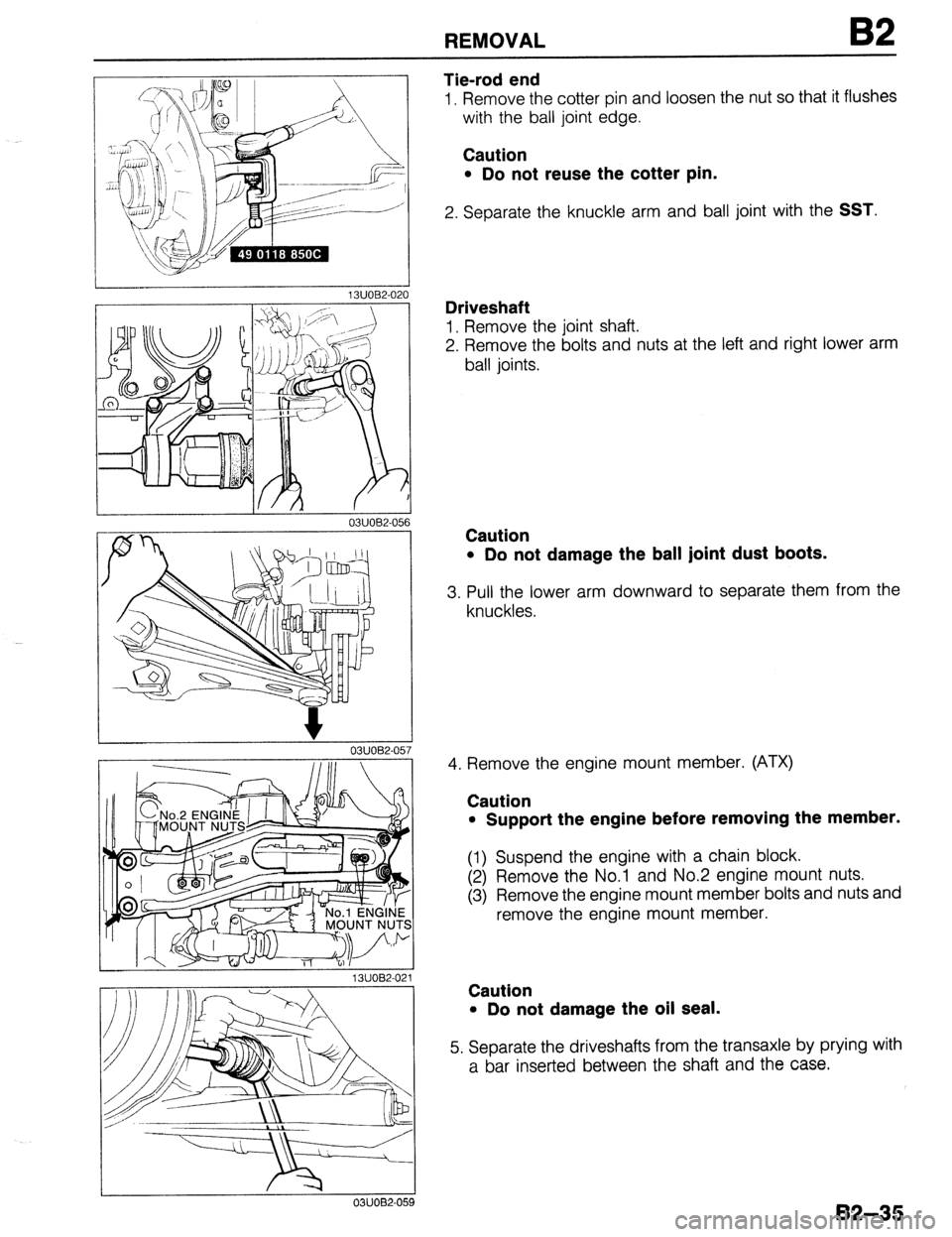

Tie-rod end

1. Remove the cotter pin and loosen the nut so that it flushes

with the ball joint edge.

Caution

l Do not reuse the cotter pin.

2. Separate the knuckle arm and ball joint with the SST.

Driveshaft

1. Remove the joint shaft.

2. Remove the bolts and nuts at the left and right lower arm

ball joints.

Caution

l Do not damage the ball joint dust boots.

3. Pull the lower arm downward to separate them from the

knuckles.

4. Remove the engine mount member. (ATX)

Caution

l Support the engine before removing the member.

(1) Suspend the engine with a chain block.

(2) Remove the No.1 and No.2 engine mount nuts.

(3) Remove the engine mount member bolts and nuts and

remove the engine mount member.

Caution

l Do not damage the oil seal.

5. Separate the driveshafts from the transaxle by prying with

a bar inserted between the shaft and the case.

B2-35

Page 168 of 1164

B2 REMOVAL

Step 5

., 13UOB2-02:

1. No.1 engine mount nuts (MTX)

5. No.4 engine mount rubber and bracket

2. No.2 engine mount nuts (MTX)

6. Engine support bracket (MTX)

3. Dynamic damper

7. Engine and transaxle assembly

4. No.3 engine mount rubber

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

Removal note

Engine and transaxle assembly

Caution

l Do not damage any components in the engine com-

partment.

1. Lift the engine and transaxle assembly out as a unit.

03UOB2.061

B2-36

Page 169 of 1164

REMOVAL

* 62

Step 6

1. intake manifold bracket

2. Starter

3. Throttle cable (ATX)

4. No.2 engine mount rubber and bracket

5. Torque converter nuts (ATX) 6. Transaxle mounting bolts

7. Manual transaxle

8. Automatic transaxle

9. Engine assembly

03UOB2.06

B2-37

Page 170 of 1164

82 ENGINE STAND MOUNTING

ENGINE STAND MOUNTING

PREPARATION

SST

49 0107 680A

Engine stand For

49 LO10 1AO For

disassembly and

f% disassembly and

assembly of Hanger set, assembly of

engine engine stand

f&b engine

t4b3

49 LO10 101 For

49 LO10 102 For

disassembly and disassembly and

Plate assembly of Arms assembly of

(Part of engine (Part of engine

49 LO10 1AO)

49 LO10 IAO)

49 LO10 103

Hooks

(Part of

49 LO10 1AO)

49 LO10 105

49 LO10 1AO)

62-38