MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 171 of 1164

ENGINE STAND MOUNTING B2

PROCEDURE

Step 1

1. Remove in the order shown in the figure.

r

GASKET, REPLACE

1. Exhaust manifold insulator

2. Exhaust manifold

3. Water bypass pipe

OSUOBX-084

4. A/C compressor bracket (if equipped)

5. Water inlet pipe

6. Exhaust pipe bracket

Step 2

Caution

l When installing the SST (engine hanger), use the

holes shown in the figure.

82-39

Page 172 of 1164

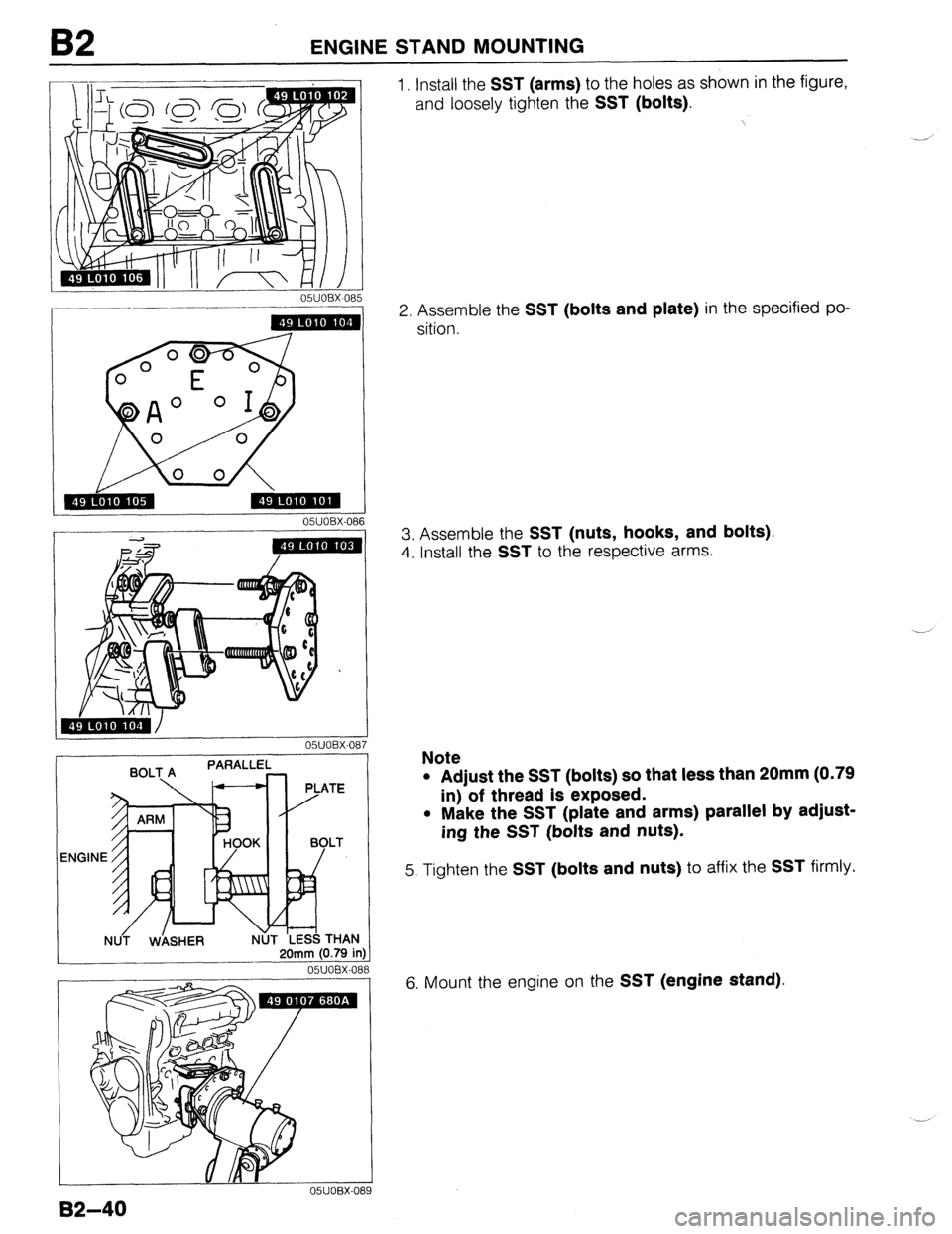

B2 ENGINE STAND MOUNTING

051JOBX-08

05UOBX.086

20mm (0.79 in 20mm (0.79 in

05UOEX-OE

05UOBX-01

1. Install the SST (arms) to the holes as shown in the figure,

and loosely tighten the

SST (bolts).

2. Assemble the SST (bolts and plate) in the specified po-

sition.

3. Assemble the

SST (nuts, hooks, and bolts).

4. Install the SST to the respective arms.

Note

l Adjust the SST (bolts) so that less than 20mm (0.79

in) of thread is exposed.

l Make the SST (plate and arms) parallel by adjust-

ing the SST (bolts and nuts).

5. Tighten the SST (bolts and nuts) to affix the SST firmly.

6. Mount the engine on the

SST (engine stand).

82-40

Page 173 of 1164

DISASSEMBLY B2

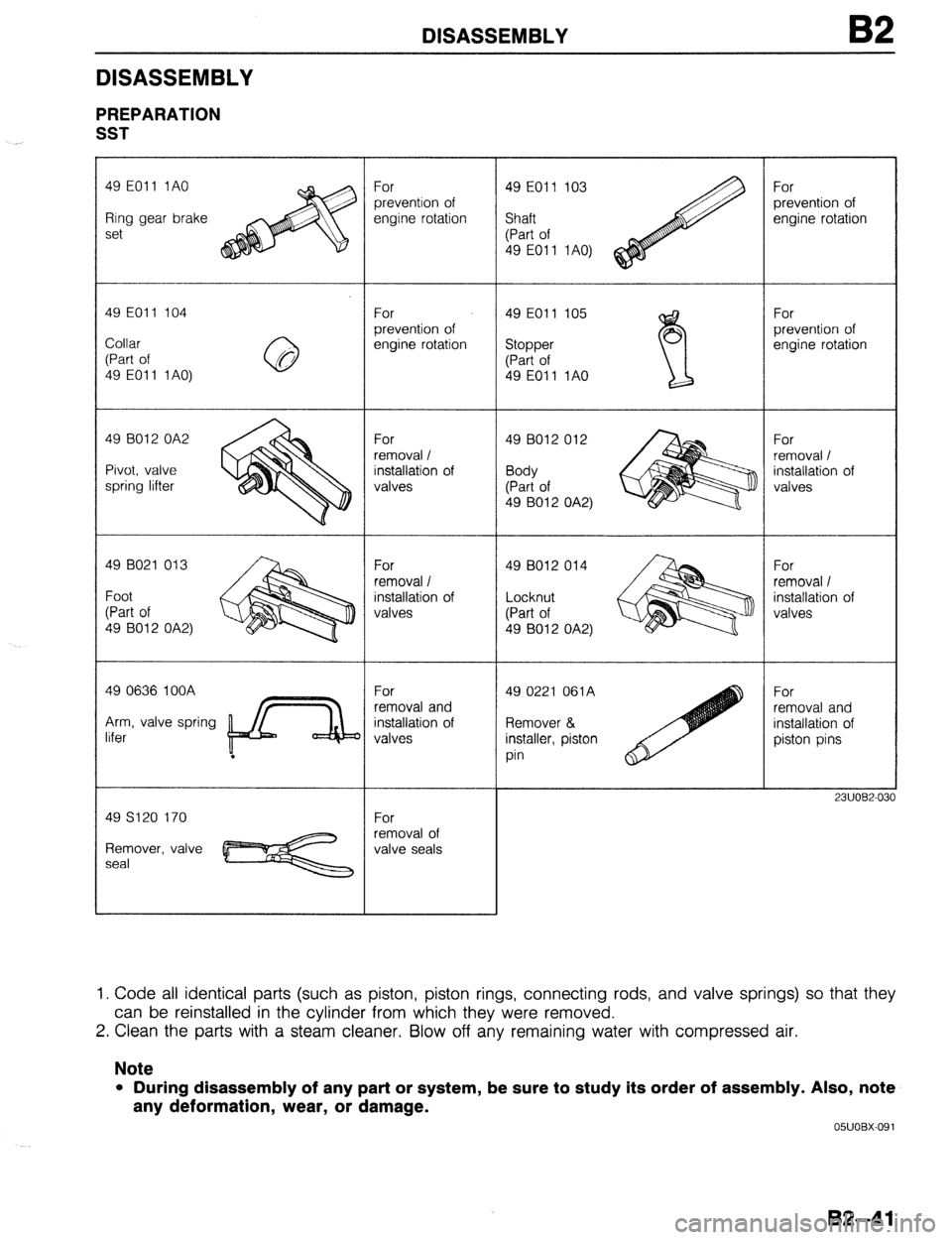

DISASSEMBLY

PREPARATION

SST

._

49 EOll 1AO

Ring gear brake

set

49 EOll 104

Collar

(Part of

49 EOI 1 1 AO)

49 8012 OA2

Pivot, valve

spring lifter

49 B021 013

Foot

(Part of

49 B012 OA2)

49 0636 IOOA

Arm, valve spring

lifer

.

Remover, valve

seal For

prevention of

engine rotation

For

prevention of

engine rotation

For

removal /

installation of

valves

For

removal /

installation of

valves

For

removal and

installation of

valves

For

removal of

valve seals 49 EOll 103

Shaft

(Part of

49 EOll 1AO)

49 EOll 105 49 EOll 105

Stopper Stopper 0

(Part of (Part of

49 E011 1AO 49 E011 1AO

w

49 B012 012

Body

(Part of

49 8012 OA2)

49 8012 014

Locknut

(Part of

49 8012 OA2)

49 0221 061A

Remover &

installer, piston

pin For

prevention of

engine rotation

For

prevention of

engine rotation

For

removal /

installation of

valves

For

removal /

installation of

valves

For

removal and

installation of

piston pins

2311082.03

1. Code all identical parts (such as piston, piston rings, connecting rods, and valve springs) so that they

can be reinstalled in the cylinder from which they were removed.

2. Clean the parts with a steam cleaner. Blow off any remaining water with compressed air.

Note

l During disassembly of any part or system, be sure to study its order of assembly. Also, note

any deformation, wear, or damage.

05UOBX-091

B2-41

Page 174 of 1164

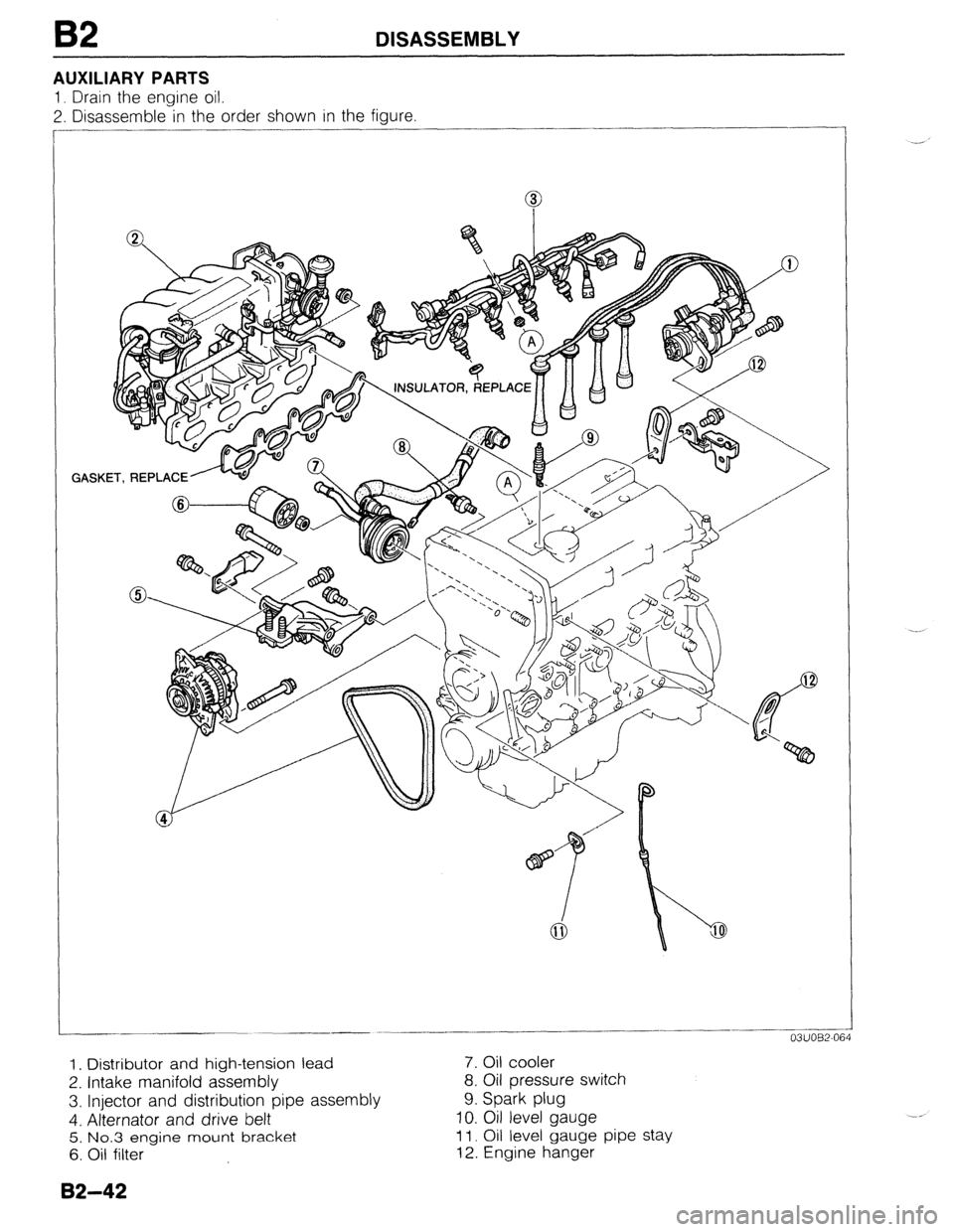

B2 DISASSEMBLY

AUXILIARY PARTS

1, Drain the engine oil.

2. Disassemble in the order shown in the figure

GASKET, REPLACE ..______-.

-___ -

03UOB2-064

1. Distributor and high-tension lead 7. Oil cooler

2. Intake manifold assembly 8. Oil pressure switch

3. Injector and distribution pipe assembly 9. Spark plug

4. Alternator and drive belt 10. Oil level gauge

5. No.3 engine mount bracket 11. Oil level gauge pipe stay

6. Oil filter 12. Engine hanger

82-42

Page 175 of 1164

DISASSEMBLY 82

TIMING BELT

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

23UOB2-0:

1. Water pump pulley

2. Crankshaft pulley

3. Timing belt cover, upper

4. Timing belt cover, middle

5. Timing belt cover, lower

6. Pulley lock bolt

7. Pulley boss

8. Timing belt

Disassembly Note . . . . . . . . . . . . . . . . . . . . page B2-44

9. Tensioner and tensioner spring

10. Idler

Disassembly Note . . . . . . . . . . . . . . . . . . . . page B2-44

B2-43

Page 176 of 1164

B2 DISASSEMBLY

23UOB2-055

13EOB2-030

Disassembly Note

Pulley lock bolt

1. Hold the flywheel (MTX) or drive plate (ATX) with the SST

or equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt.

Timing belt

1. Loosen the tensioner lock bolt and using a suitable bar, pry

the tensioner outward.

Caution

l Protect the tensioner with a rag before prying.

2. Tighten the lock bolt with the tensioner spring fully extended.

Note

l Mark the timing belt rotation for proper reinstal-

lation.

3. Remove the timing belt.

82-44

Page 177 of 1164

DISASSEMBLY B2

CYLINDER HEAD

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

OIL SEAL, REPLACE

GASKET, REPLACE

1. Cylinder head cover 11. Cylinder head

2. Camshaft pulley Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-54

Disassembly Note . . . .., ,.... . . . . . . . . . page 82-46 12. Cylinder head gasket

Inspection . . . . . . . . . . . . . . . .., . . . . . . . . . . . . . page 82-65 13. Valve keeper

3. Seal plate Disassembly Note . . . . . . . . . . . . . . . . . . . . page B2-46

4. Camshaft 14. Valve spring seat, upper

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 82-46 15. Valve spring

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-58 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 82-58

5. HLA 16. Valve spring seat, lower

Disassembly Note . . . . . . . . . . . . . . . . . . . . page B2-46 17. Valve

Inspection ,........,,..,.,....,..,,.,..,... page B2-60 Inspection ..,.............................. page 82-55

6. Thermostat cover 18. Valve seal

7. Thermostat Disassembly Note ..,................. page B2-47

8. Water thermoswitch Inspect for wear or damage

9. Heat gauge unit 19. Valve guide

IO. Cylinder head bolt Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-55

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 82-46 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-56

82-45

Page 178 of 1164

82 DISASSEMBLY

2311082-03

r HLA

r

05UOBX-04!

2311082-03

I

05UOBX-1C

82-46

Disassembly Note

Camshaft pulley

1, Hold the camshaft with a wrench at hexagonal portion.

2. Remove the camshaft pulley lock bolt.

3. Remove the camshaft pulley.

Camshaft

1. Loosen the camshaft cap bolts in two or three steps in the

order shown in the figure.

2. Remove the camshaft caps

3. Remove the camshaft.

4. Remove the camshaft oil seal from the camshaft.

Caution

l Mark the HLA with a felt pen so that they can be reln-

stalled in the position from which they were

removed.

1. Remove the HLA from the cylinder head.

Cylinder head bolts

1. Loosen the cylinder head bolts in two or three steps in the

order shown in the figure.

2. Remove the cylinder head bolts.

Valve keeper

1. Set the SST against the upper valve spring seat as shown

in the figure.

2. Remove the valve keepers.

Page 179 of 1164

DISASSEMBLY 82

Valve seal

1 I Remove the valve seal with the SST.

02-47

Page 180 of 1164

B2 DISASSEMBLY

CYLINDER BLOCK (EXTERNAL PARTS)

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

I

@ma @a% GASST, REPLACE

GASKET,

REPLACE

/

d I @REPLACE

23UOB2-0

1. Water pump

Service ..,....,..,......,.,.,,.....,,.,.......... Section E

2. Timing belt pulley and lock bolt

Disassembly Note . . . . . ..,.,........,. page 82-49

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 82-65

3. Clutch cover, clutch disc (MTX)

Service . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section H

4. Flywheel (MTX)

Disassembly Note ,.. . . . . . . . . . . . . . . . . . page 82-49

Inspect for wear or damage

5. Backing plate, drive plate, and adapter (ATX)

Disassembly Note . . . . ,., ,..... . . . . . . . page B2-49

6. End plate 7. Oil pan and gasket

Disassembly Note .,.................. page 82-49

Inspect for damage

8. Oil strainer

9. Main bearing support plate (MBSP)

Disassembly Note . . . ., . . . . . ..,.... . . . page B2-50

Inspect for damage

10. Oil pump

Service . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section D

11. Front oil seal

Disassembly Note .,.................. page 82-50

12. Rear cover

13. Rear oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . page B2-50

B2--48