MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 341 of 1164

![MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati](/img/28/57077/w960_57077-340.png)

TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operation, stop and go driving, extended winter

warm-up periods, etc., as opposed to “trip” mileage, an attempt should be made to determine these factors when con-

fronted with “poor mileage” conditions. However, since the operator is not always at fault, the following is offered.

@II Operator depressing accelerator more than usual due to

@ Air/Fuel mixture too rich

low engine power

l Poor ignition *High fuel line pressure

@ Alcohol blended fuel used

*Low intake air amount

l Electronic spark advance control system malfunction @ High vehicle load l Low tire pressure

*Clutch slipping/ATX slipping l Incorrect tire size l Exhaust component restricted l Brake dragging ;TEP

INSPECTION ACTION

1

Check factors other than engine Yes

Go to next step

l Low tire pressure = Section Q 9 Unrecommended tire srze v Section Q l Clutch slipping w Section H l Brake dragging No

0 Section P Repair

l Exhaust component restricted cz= page F-136

2

Check if air hoses are connected correctly - Yes

Go to next step CI page F-109

No

Repair 3

Check if “00” IS displayed on Self-Diagnosis

Yes

Checker with ignition switch ON Go to next step W page F-82 No

SYSTEM SELECT: 1 Service Code No. displayed Check for cause (Refer to specified

check sequence) w page F-63

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU CT= page F-149 e If not OK, check wiring between

ECU and Self-Diagnosis Checker 4

Check for correct intake manifold vacuum at idle

Yes Go to next step Vacuum: More than 450 mmHg (17.7 inHg) No

Check for air leakage at intake air sys-

tem components 5

Check if air cleaner element is clean Yes

Go to next step CT= page F-79

No

Replace air cleaner element

F-75

Page 342 of 1164

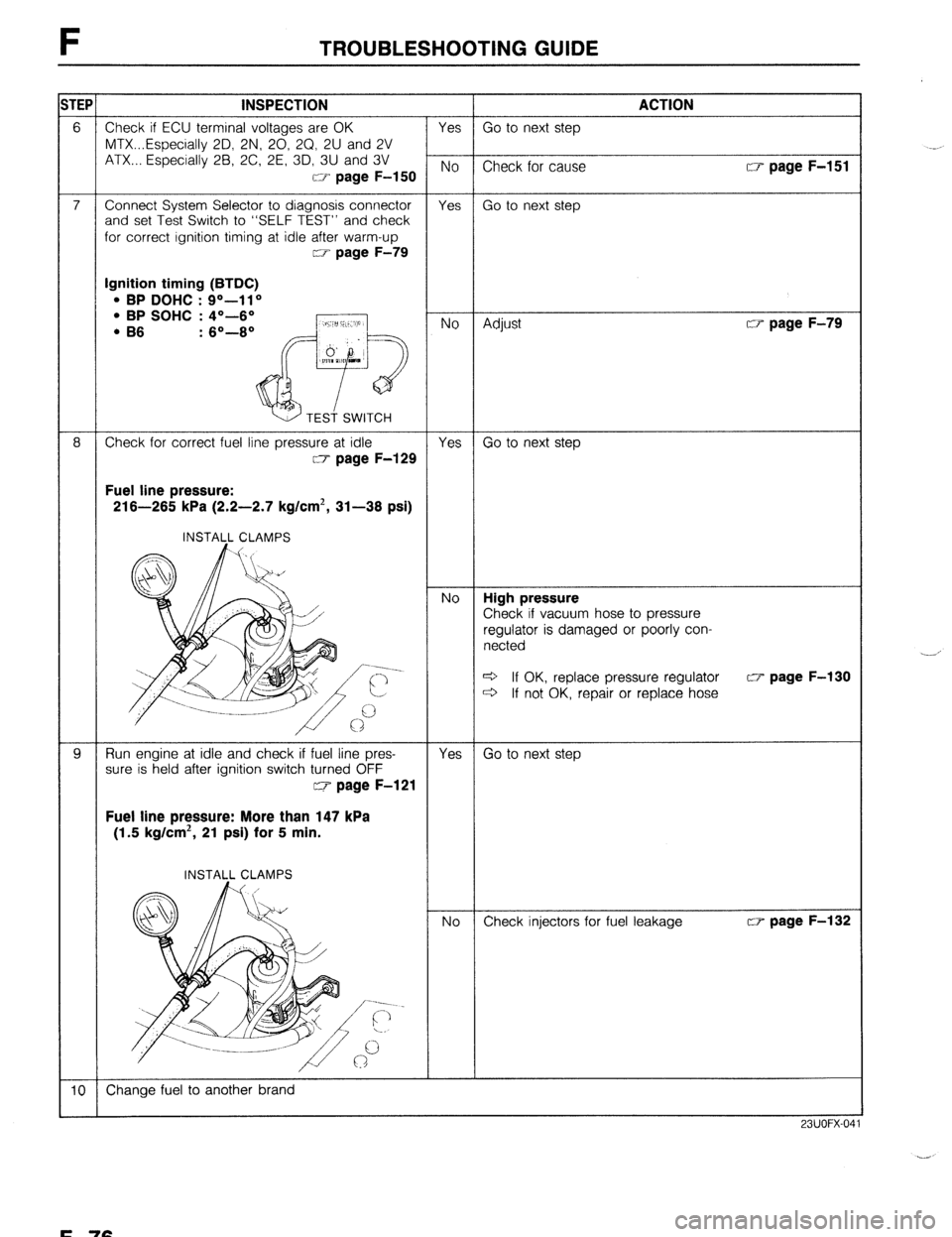

F TROUBLESHOOTING GUIDE

s

-

Ignition timing (BTDC) l BP DOHC : Q”-11 o l BP SOHC : 4O-6“

Fuel line pressure:

216-265 kPa (2.2-2.7 kg/cm*, 31-36 psi)

INSTALL CLAMPS

hose to pressure

ged or poorly con-

c3 If OK, replace pressure regulator w page F-130

c3 If not OK, repair or replace hose

Fuel line pressure: More than 147 kPa

(1.5 kg/cm*, 21 psi) for 5 min.

INSTALL CLAMPS

23UOFX-041

F-76

Page 343 of 1164

![MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l E MAZDA PROTEGE 1992 Workshop Manual TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l E](/img/28/57077/w960_57077-342.png)

TROUBLESHOOTING GUIDE

27 MIL ALWAYS ON

DESCRIP- *Self-Diagnosis Checker does not indicate Malfunction Code No. but MIL always ON

TION

[TROUBLESHOOTING HINTS]

*Short circuit in wiring harness

l ECU malfunction

iTEF 1

1

-

s

Disconnect (Y/B) wire from ECU and check if

MIL goes off

‘YIB

ATX YIB

INSPECTION ACTION

Yes Replace ECU CT page F-149

No Check for short circuit in wiring be-

tween instrument cluster and ECU

23UOFX-042

28

MIL NEVER ON

IESCRIP- *Self-Diagnosis Checker indicates Malfunction Code No. of input device but MIL never ON

RON *Other indicator and warning lamps OK

:TROUBLESHOOTING HINTS]

b Bulb burned

‘Open circuit in wiring harness

m ECU malfunction

TEP INSPECTION

ACTION

1 Ground (Y/B) wire at ECU with jumper wire and

Yes Check connection of ECU connector

check if MIL comes on

MTX e If OK, replace ECU w page F-149

I- i -!~ !r--~r’:~;-‘;- --~_:- ,

1 i r 1 1 1 ;-.:,~;~$~& {-;&# ,$&]j 4 If not OK, repair ECU connector

! No

Check if bulb is OK

ATX 13 If OK, repair (Y/B) wire between

ECU and instrument cluster

e If not OK, replace bulb CT page T-83

23UOFX-043

29 A/C DOES NOT WORK

DESCRIP- *Blower fan operates but magnet clutch does not operate

TION

[TROUBLESHOOTING HINTS]

*Open or short circuit in wiring harness

*A/C relay, A/C switch, or magnetic clutch malfunction

l ECU malfunction

TEP/ INSPECTION ACTION

1 1 Check ECU

terminal 10 (MTX) 10 (ATX) voltage 1

Yes Check ECU terminal 1 J (MTX) 1 L (ATX)

OK

CT= page F-152

MTX

T7J++!;i”-

L

ATX

No voltage OK

CT page F-152

1-3 If OK, check A/C system

c3- page U-30

~3 If not OK, replace ECU CT page F-149

Check for cause w page F-153

F-77

Page 344 of 1164

F ENGINE TUNE-UP

ENGINE TUNE-UP

PREPARATlON

SST

I

I I

49 BO19 9AO

System Selector For

inspection of igni-

tion timing and

idle speed

hA ‘I

03UOFX-04

03UOFX-04

03UOFX-04

NG POINT

03UOFX-04 03UOFX-045

BASIC INSPECTION

Engine Oil

1. Remove the engine oil level gauge and check the engine

oil level and oil condition.

2. Add or change the oil as necessary.

Coolant

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap before carefully

removing it.

1. Remove the coolant level gauge from the coolant reservoir.

2. Check that the coolant level is between the L and F marks

of the gauge.

3. Add coolant if necessary.

Battery

1. Check for corrosion on the terminals and for loose cable

connections. If necessary, clean the clamps and tighten

them firmly.

2. Check that the electrolyte level is between the UPPER LEV-

EL and LOWER LEVEL marks.

3. Add distilled water if necessary.

4. Check the specific gravity with a hydrometer.

Gravity: 1.27-l .29 (at 20% [68OF] )

Page 345 of 1164

ENGINE TUNE-UP F

03UOFX.051

03UOFX-051

- w4TEN I

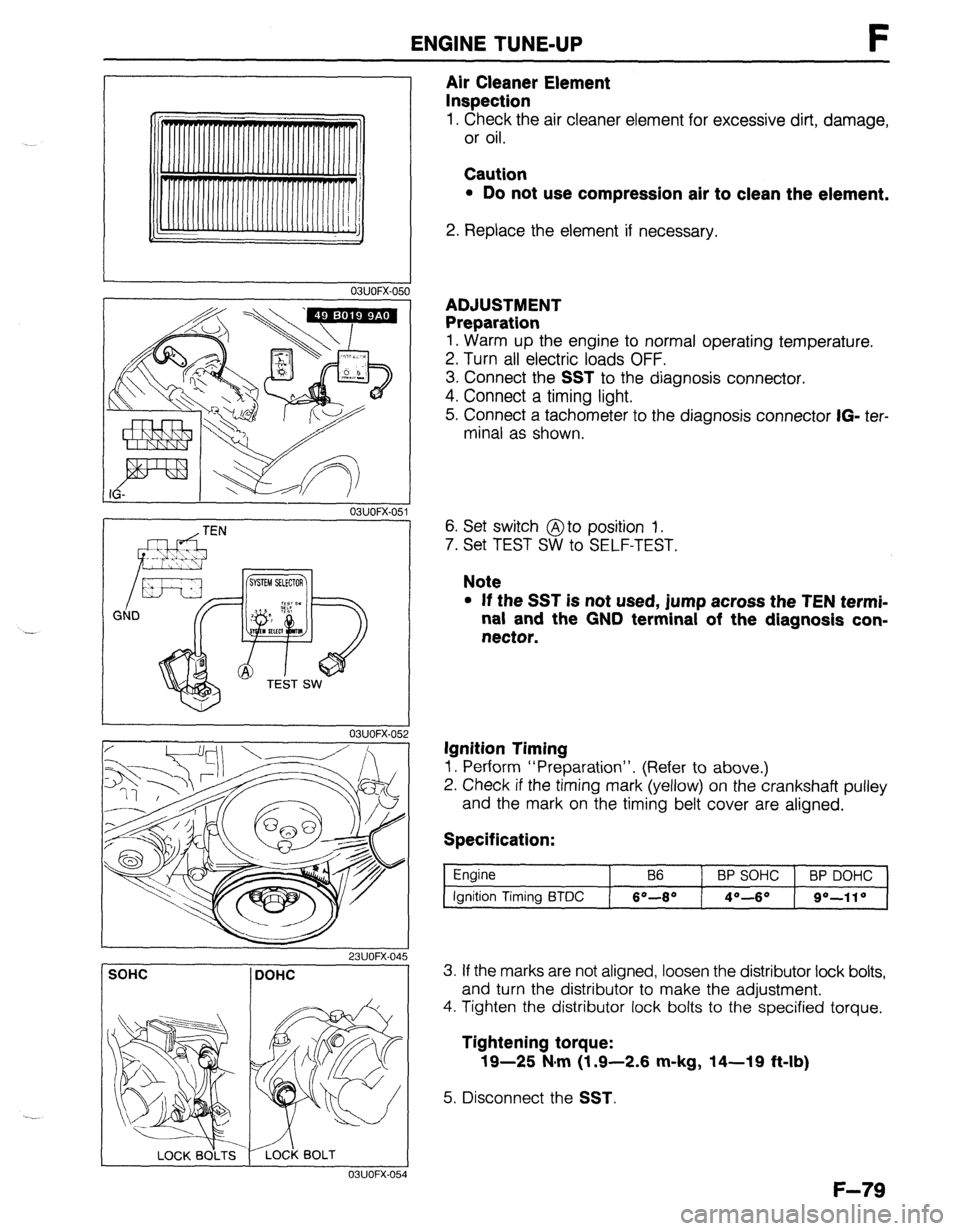

Air Cleaner Element

Inspection

1. Check the air cleaner element for excessive dirt, damage,

or oil.

Caution

l Do not use compression air to clean the element.

2. Replace the element if necessary.

ADJUSTMENT

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect a timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

1. Perform “Preparation”. (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Specification:

Engine

Ignition Timing BTDC B6 BP SOHC BP DOHC

6O-8* 4O--6O go-110

SOHC DOHC

I 03UOFX-054

3. If the marks are not aligned, loosen the distributor lock bolts,

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

F-79

Page 346 of 1164

F ENGINE TUNE-UP

23UOFX-046 Note

l When the parking brake is not applied, the idle

speed for ATX model (Canada) is approx. 800 rpm. Idle Speed

1. Perform “Preparation”. (Refer to page F-79.)

2. Apply parking brake.

3. Check that the idle speed is within specification.

Idle speed (Neutral or P range): 700-800 rpm

Caution

l Check the idle speed without the electric cooling

fan operating.

4. If not within the specification, adjust the idle by turning the

air adjusting screw.

5. Disconnect the SST.

F-80

Page 347 of 1164

ENGINE TUNE-UP F

MEMO

F-81

Page 348 of 1164

F SELF-DIAGNOSIS FUNCTION

SELF-DIAGNOSIS FUNCTION

DESCRIPTION

The engine control unit (integrated with the EC-AT control unit) has built-in Self-Diagnosis function the same

as for the previous models. When trouble occurs in the main input devices or output devices, they are indi-

cated and retrieved from the engine control unit (ECU) as service code numbers.

When inspecting for service code(s) memorized in the ECU use the Self-Diagnosis checker and system selector

(SST).

Note

l The ECU constantly checks for malfunction of the in put devices. But, the ECU checks for

malfunction of output devices only in a three second period after the ignition switch is turned

ON and the TEN terminal of the diagnosis connector is grounded.

-

-

INPUT =

SIGNALS-

-

-

- SELF-

DIAGNOSTIC

L!

I-

FUNCTION ENGINE CONTROL

UNIT

j FAIL-SAFE

FUNCTION

I

SYSTEM SELF-DIAGNOSIS

SELECTOR

CHECKER

MIL

(MALFUNCTION

INDICATOR LAMP)

Page 349 of 1164

SELF-DIAGNOSIS FUNCTION F

PREPARATION

SST

49 6019 9AO

System Selector For

diagnosis 49 HO18 9Al

Self-Diagnosis

Checker For

diagnosis

SERVICE CODE NUMBER

Inspection Procedure

1. Connect the SST to the diagnosis connector.

2. Set switch @to position 1.

3. Set TEST SW to SELF-TEST position.

23UOFX-048

03UOFX.059

I

4. Connect the SST to the System Selector and a ground

5. Set the select switch to position A.

6. Turn the ignition switch to ON.

7. Verify that 88 flashes on the digital display and the buzzer

sounds for 3 sec. after turning the ignition switch ON.

8. If 88 does not flash, check the main relay (FUEL INJ relay)

(Refer to page F-172) power supply circuit, and diagno-

sis connector wiring.

9. If 88 flashes and the buzzer sounds continuously for more

than 20 sec., check for a short circuit between the engine

control unit terminal 1 F and the diagnosis connector. Re-

place the engine control unit if necessary and perform Steps

3 and 7 again.

23UOFX-049 IO. Note any code numbers and check for the causes by refer-

ring to the check sequences shown on pages F-88

through F-103. Repair as necessary.

Note

l Cancel the code numbers by performing the after-

repair procedure following repairs.

(Refer to page F-104.)

I 23UOFX-050

F--83

Page 350 of 1164

F SELF-DIAGNOSIS FUNCTION

Troubleshooting

If a service code number is shown on the SST, check for the cause by using the chart related to the code

number shown.

Service code number

CODE LOCATION OF

NO.

MALFUNCTION OUTPUT SIGNAL PATTERN

SELF-DIAGNOSIS FAIL-SAFE

02

Ne-signal

:E nl-u No Ne-signal

-

03 G-signal

(DOHC) No G-signal Cancels 2-group

injection

06* Vehicle speed

sensor ON

OFF No input signal from Shifting performed

vehicle speed normally

sensor

08 Airflow meter ON

OFF Open or short circuit Basic fuel injection

amount fixed as for two

driving modes

(1) Idle switch ON

(2) Idle switch OFF

09 Water

thermosensor ON

OFF Maintains constant 20%

(68OF) command

10 Intake air

thermosensor Maintains constant 20°C

(68OF) command

12

Throttle sensor

“,E l--uL-l Throttle opening judged

as full stroke lockup not

provided

Atmospheric ON Maintains constant

14 pressure sensor command of sea level

(in ECU)

OFF pressure

15 Oxygen sensor

(inactivation) ON

OFF Sensor output

continues less than

0.55V 95 sec. after

engine starts

(1500 rpm) Cancels engine feedback

operation

Oxygen sensor ON Sensor output Cancels engine feedback

17

(Inversion) continues uncharged operatron

OFF 50 sec. after engine

exceeds 1500 rpm

Solenoid valve ON

25 (pressure

regulator)

OFF u 1 nnluln Open or short crrcurt

“If the marked code numbers appeor, refer to Section K

F-84