MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 371 of 1164

SELF-DIAGNOSIS FUNCTION F

SWITCH MONITOR FUNCTION

Individual switches can be inspected by the SST (Self-Diagnosis checker).

Note

l The TEN terminal of the diagnosis connector must be grounded and the ignition switch ON

(engine stopped).

l If either of the switches remain activated, the monitor lamp will be illuminated.

ECU

NEUTRAL SWITCH (MTX)

CLUTCH SWITCH (MTX)

=d-’ 1

BATTERY

INHIBITOR SWITCH (ATX)

STOPLIGHT SWITCH (MTX)

HEADLIGHT SWITCH MONITER LAMP

REAR WINDOW (SELF-DIAGNOSIS CHECKER)

DEFROSTER SWITCH

AIC SWITCH

BLOWER SWITCH

THROTTLE SENSOR asp-

- _

COOLING FAN SWITCH

03UOFX

Switch

Clutch switch

Neutral switch (MW

(M-W Self-Diagnosis Checker (Monitor lamp)

Light ON Light OFF Pedal released Pedal depressed

In gear Neutral Remark In gear

Clutch pedal released

Inhibitor switch

(ATX) L, S, D or R range

N or P range -

Throttle sensor Pedal depressed (Not fully) Pedal released/fully depressed -

Stoplight switch

Pedal depressed Pedal released -

Headlight switch

ON

OFF Headlights/parking lights: ON

Blower switch

ON

OFF Blower switch at 2nd or

above position

AIC switch

ON OFF Fan speed control at 1st po-

sition

Rear window defroster

switch ON

OFF -

Water thermoswitch Fan operating Fan not operating -

23UOFX-084

F-l 05

Page 372 of 1164

SELF-DIAGNOSIS FUNCTION

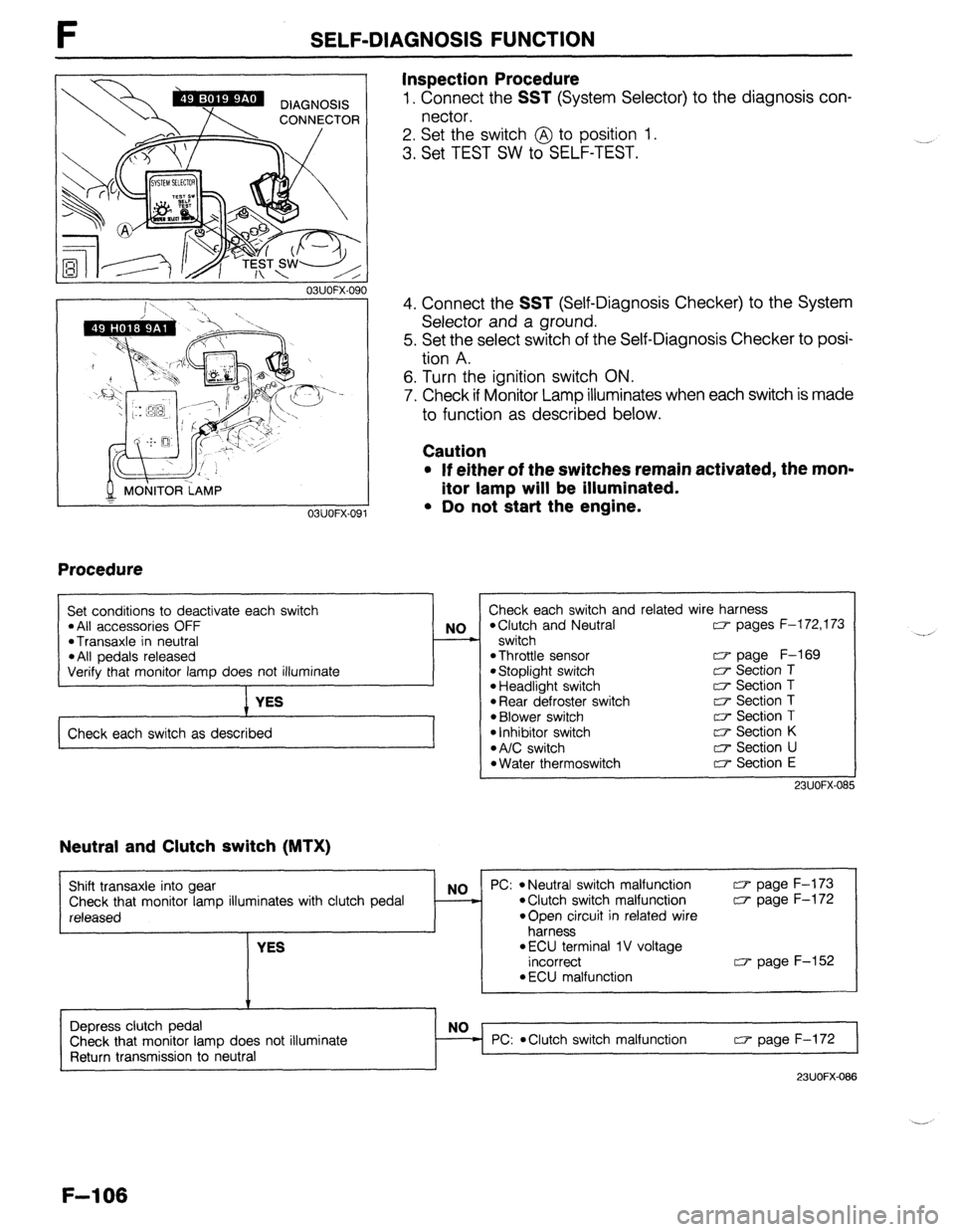

Inspection Procedure

1. Connect the SST (System Selector) to the diagnosis con-

nector.

2. Set the switch @ to position 1.

3. Set TEST SW to SELF-TEST.

03UOFX.090

MONITOR LAMP

T

03UOFX-091

Procedure

4. Connect the SST (Self-Diagnosis Checker) to the System

Selector and a ground.

5. Set the select switch of the Self-Diagnosis Checker to posi-

tion A.

6. Turn the ignition switch ON.

7. Check if Monitor Lamp illuminates when each switch is made

to function as described below.

Caution

* If either of the switches remain activated, the mon-

itor lamp will be illuminated.

l Do not start the engine.

I

I Set conditions to deactivate each switch l All accessories OFF l Transaxle in neutral l All pedals released NO

-

Verify that monitor lamp does not illuminate

YES

Check each switch as described Check each switch and related wire harness

*Clutch and Neutral CT- pages F-l 72,173

switch

*Throttle sensor w page F-169 l Stoplight switch c7 Section T l Headlight switch c7 Section T l Rear defroster switch T;P Section T l Blower switch [r+ Section T

l Inhibitor switch a Section K l A/C switch 0 Section U l Water thermoswitch c7 Section E

23UOFX-OS!

Neutral and Clutch switch (MTX)

Shift transaxle into gear

Check that monitor lamp illuminates with clutch pedal

released

YES NO PC: l Neutral switch malfunction a page F-173 l Clutch switch malfunction w page F-172

*Open circuit in related wire

harness

l ECU terminal 1 V voltage

incorrect w page F-152

l ECU malfunction

Depress clutch pedal

Check that monitor lamp does not illuminate

Return transmission to neutral PC:

*Clutch switch malfunction w page F-172

23UOFX-088

F-l 06

Page 373 of 1164

SELF-DIAGNOSIS FUNCTION

Headlight switch

Turn headlight switch ON

Check that monitor lamp illuminates

YES

Headlight switch OK

Turn headlight switch OFF NO

PC: l Headlight switch malfunction v Section T

*Open circuit in wire harness

from headlight switch to ECU

l ECU terminal 1 U (MTX) 1 H

(ATX) voltage incorrect CT page F-152

l ECU malfunction

23UOFX-087

Rear window defroster switch

Turn rear window defroster switch ON

Check that monitor lamp illuminates

YES

Rear defroster switch OK

Turn rear window defroster switch OFF NO

_ PC: *Rear window defroster switch

malfunction c7 Section T

*Open circuit in wire harness

from rear window defroster

switch to ECU

l ECU terminal 1 T (MTX) 1 J (ATX)

voltage incorrect

u page F-152

l ECU malfunction

23UOFX-088

Inhibitor switch (ATX)

Shift transaxle into L, S, D, or P range

Check that monitor lamp illuminates

YES

Inhibitor switch OK

Shift into P or N range PC: l Inhibitor switch malfunction

*Open or short circuit in related

23UOFX-089

F-l 07

Page 374 of 1164

SELF-DIAGNOSIS FUNCTION

Throttle sensor

Depress accelerator pedal (not fully) and check that

monitor lamp illuminates

YES NO

PC: *Throttle sensor malfunction CT page F-169

*Short circuit in wire harness

from throttle sensor to ECU

*ECU terminal 1 N (MTX) 1T

(ATX) voltage incorrect CT page F-150

l ECU malfunction

Depress acceleration pedal fully and check that monitor

No : PC: *Throttle sensor malfunction w page F-169

lamp does not illuminate *Open circuit in wire harness

from throttle sensor to ECU

YES *ECU terminal 2L (MTX) or 21

(ATX) voltage incorrect a page F-154

Throttle sensor OK

Release accelerator pedal

23UOFX-090

Stoplight switch

Depress brake pedal

Check that monitor lamp illuminates

YES

Stoplight switch OK

Release brake pedal NO

PC: *Stoplight switch malfunction w Section T

*Open circuit in wire harness

1

from stoplight switch to ECU

*ECU terminal 10 (MTX) 1Q

(ATX) voltage incorrect CT page F-l 52

l ECU malfunction

23UOFX-091

Blower switch

---

Turn blower switch to 2nd or higher position

Check that monitor lamp illuminates

YES

Blower switch OK NO

__L PC: *Blower switch malfunction

*Open circuit in wire harness

from blower switch to ECU

l ECU terminal 1 S (MTX) 1 P

(ATX) voltage incorrect

l ECU malfunction p Section T

w page F-152

23UOFX-092

F-l 08

Page 375 of 1164

INTAKE AIR SYSTEM F

INTAKE AIR SYSTEM

COMPONENT PARTS

Removal / Inspection / Installation

1, Remove in the order shown in the figure, referring to Removal Note.

2. inspect the intake air system components visually and repair or replace if necessary.

3. Install in the reverse order of removal, referring to

Installation Note.

BP DOHC

19-25 (1 .Q-2.6, 14-19)

A

7.8-11 N.m

7.6-11 N.m

160-l 10 cm-kg, 69-95 i / REPLACE

/ O-RING,

mm

RFPLACE 19-26 (1.9-2

I n

.6, 14-19)

-11 N.m

-110 cm-kg,

-95 in-lb)

(29-41 cm-kg,

25-36 in-lb)

I 7.6-l 1 N.m (60-l 10 cm-kg,

69-95 in-lb)

19-25 (1.91-2.6,

14-19)

N.m (m-kg, ft-lb)

-

23UOFX-093

1. Resonance duct

8. Throttle body

Inspect for damage

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 12

2. Air cleaner

9. Dashpot

Inspect for excessive dirt or damage Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page F-l 42

3. Air cleaner element

10. ISC valve

Inspection . . . . . . . . . . . . . page F- 79 Inspection . . . . . . . . . . . . . .

page F-l 16

4. Airflow meter

11. Dynamic chamber

Inspection . . . . . . . . . . . . . ,............,...,.. page F-l 68 Removal note . . . . . . . . . . . . . . . . . . . . . . . . . . . . page

F-l 12

5. Resonance chamber

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page F-l 12

Inspect for damage 12. Air valve

6. Air hose

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 16

Inspect for damage 13. Intake manifold bracket

7. Accelerator cable 14. intake manifold

Inspection I Adjustment . . . . . . . . . . . . . page F-l 14 Installation

note . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 13

F-l 09

Page 376 of 1164

F

BP SOHC

INTAKE AIR SYSTEM

IQ-25 (1.9-2.6, 14-19)

.6-6.5 N.m

6-66 cm-kg,

m IQ-25 (1.9-2.6, 14-19)

IQ-26 (Id--2.v4-19) -Bu 1

.6-11 N.m

O-110 cm-kg, 69-95 in-lb)

N.m (m-kg, ft-lb)

23UOFX-0 94

1. Resonance duct 8. Throttle body

Inspect for damage Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 12

2. Air cleaner 9. Dashpot

Inspect for excessive dirt or damage Inspection ,.,..,.......,................... page F-l 42

3. Air cleaner element 10. ISC valve

inspection ..,........,..................... page F- 79 inspection ,.,..,.........................I. page F-l 16

4. Airflow meter 11. Dynamic chamber

Inspection ..,..,.....,.......,.......,..... page F-l 68 Removal note ..,.......,................. page F-l 12

5. Resonance chamber 12. Air valve

Inspect for damage Inspection ,..., ,.... ..,..,................. page F-l 16

6. Air hose 13. Intake manifold bracket

Inspect for damage 14. Intake manifold .___

7. Accelerator cable Installation note . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 13

Inspection / Adjustment. . . . . . . . . page F-l 14

F-110

Page 377 of 1164

INTAKE AIR SYSTEM F

B6

4.6-6.6 N.m (46-66 cm-kg, 40-67 in-lb)

19-25 (1.9-2.6, 14-19)

GASKET, REPLACE

?.6--ll N.m

IO-110 cm-kg,

19-95 In-lb)

7.6-11 k.m KY

- CASKET, REPLACE (60-I 10 cm-kg,

69-95 in-lb)

\I

I 19-z (1.9-2.6, 14-19) V

N.m (m-kg, ft-It

23UOFX-0

1. Resonance duct 8. Throttle body

Inspect for damage Inspection ,,,.,.,,“,,,.,................... page F-l 12

2. Air cleaner 9. Dashpot

Inspect for excessive dirt or damage Inspection ..,...........,.................. page F-l 42

3. Air cleaner element 10. ISC valve

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F- 79 Inspection . . . . , . . . . . . . . . . . . . . . . . . . . . . . page F-l 16

4. Airflow meter 11. Dynamic chamber

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 68 Removal note. . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 12

5. Resonance chamber 12. Air valve

Inspect for damage Inspection . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 16

6. Air hose 13. Intake manifold bracket

Inspect for damage 14. Intake manifold

7. Accelerator cable Installation note . . . . . . . . . . . . . . . . . . . . . . . . . page F-l 13

inspection I Adjustment .,........... page F-l 14

F-III

Page 378 of 1164

F INTAKE AIR SYSTEM

1 03UOFX.103

OSUOFX-I 04

1

F-112

I 03UOFX.I 05

OSUOFX-10

OSUOFX-10

THROTTLE BODY

Inspection

1. Check the throttle body for wear and deposits.

2. Check if the throttle valve moves smoothly when the throt-

tle lever is moved from fully closed to fully open.

3. Replace the throttle body if necessary.

Caution

l Do not remove the thin seal coating from the throt-

tle valves or bore.

DYNAMIC CHAMBER

Removal Note

BP DOHC

l Raise the vehicle to remove the four bolts shown in the

figure.

BP SOHC

l Raise the vehicle to remove the five bolts shown in the figure.

B6

l Raise the vehicle to remove the three bolts shown in the

figure.

Inspection (BP DOHC)

1. Check the shutter valve for wear and deposits.

2. Check if the shutter valve is fully open and moves smooth-

ly from fully open to fully closed.

Page 379 of 1164

INTAKE AIR SYSTEM F

I 23UOFX-096

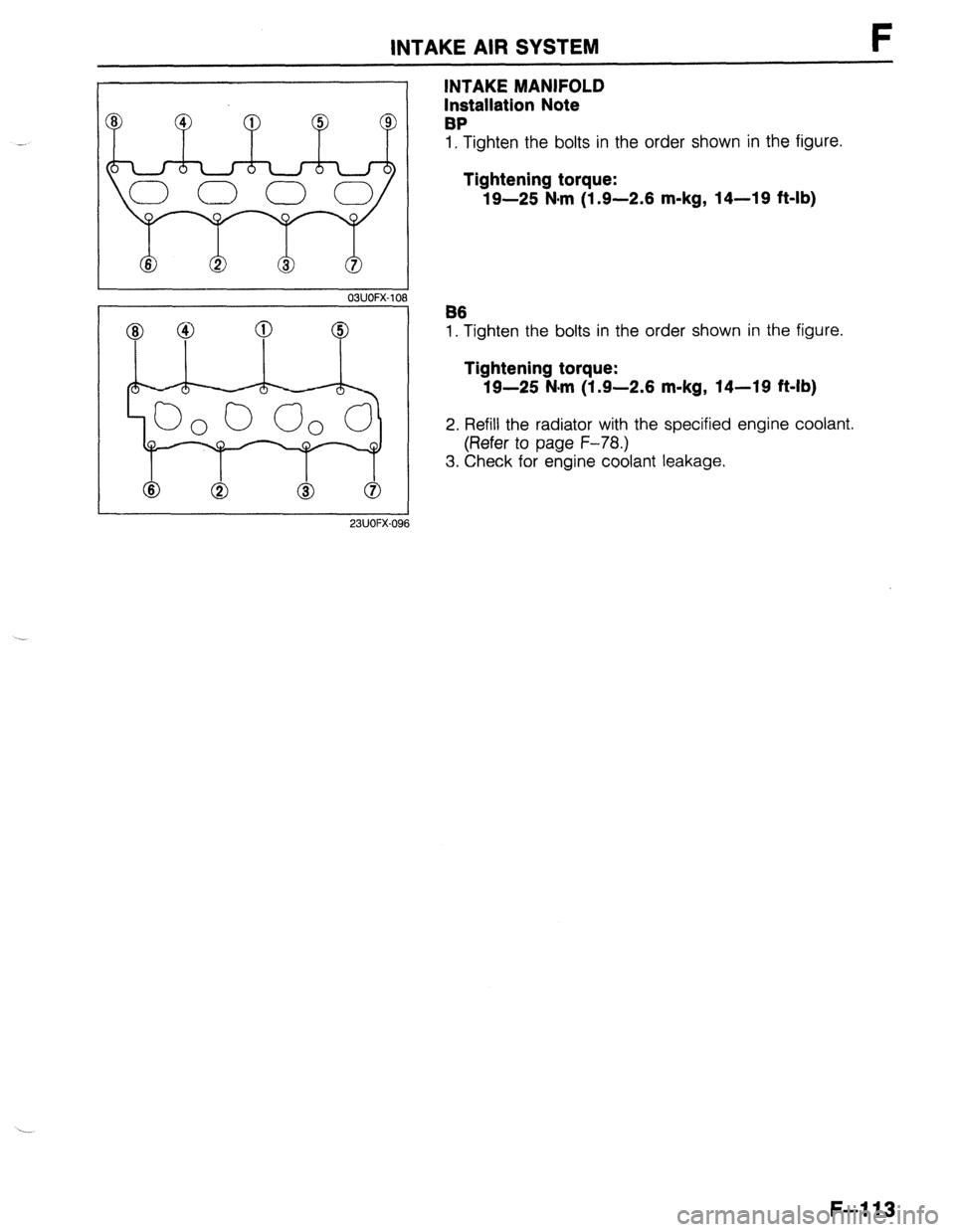

INTAKE MANIFOLD

Installation Note

BP

1, Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

B6

1. Tighten the bolts in the order shown in the figure.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

2. Refill the radiator with the specified engine coolant.

(Refer to page F-78.)

3. Check for engine coolant leakage.

F-113

Page 380 of 1164

F INTAKE AIR SYSTEM

ACCELERATOR PEDAL

Removal / Installation

1. Remove in the order shown in the figure.

2. Install in the reverse order of removal.

CLIP, REPLACE

N.m (cm-kg, in-lb)

23UOFX-OF

1. Accelerator cable 3. Clip

Inspection / Adjustment . . . . . . . . . . . . . page F-l 14 4. Return spring

2. Retainer 5. Accelerator pedal

23UOFX-OE

F-114

ACCELERATOR CABLE

Inspection I Adjustment

1. Depress the accelerator pedal fully. Check if the throttle valve

is fully opened.

2. Inspect the play of the accelerator cable.

Play: 1 .O-3.0mm (0.04-0.12 in)

3. Loosen the nuts @to adjust the play if necessary. ._ ,