MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 401 of 1164

PRESSUREREGULATORCONTROLSYSTEM F

03UOFX-17

*

03UOFX-14!

OSUOFX-17

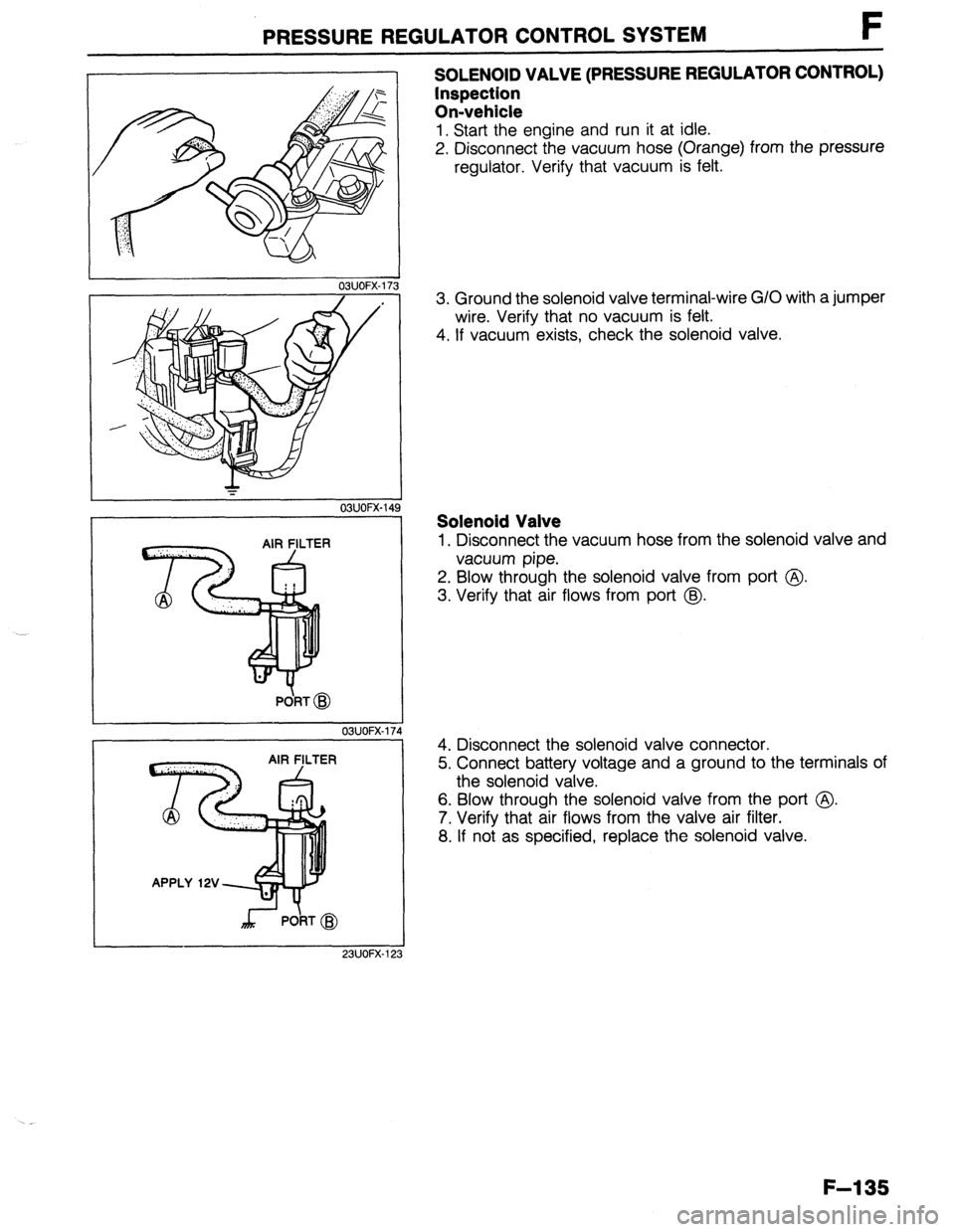

SOLENOID VALVE (PRESSURE REGULATOR CONTROL)

Inspection

On-vehicle

1. Start the engine and run it at idle.

2. Disconnect the vacuum hose (Orange) from the pressure

regulator. Verify that vacuum is felt.

3. Ground the solenoid valve terminal-wire G/O with a jumper

wire. Verify that no vacuum is felt.

4. If vacuum exists, check the solenoid valve.

Solenoid Valve

1. Disconnect the vacuum hose from the solenoid valve and

vacuum pipe.

2. Blow through the solenoid valve from port @

3. Verify that air flows from port @.

4. Disconnect the solenoid valve connector.

5. Connect battery voltage and a ground to the terminals of

the solenoid valve.

6. Blow through the solenoid valve from the port @.

7. Verify that air flows from the valve air filter.

8. If not as specified, replace the solenoid valve.

F-l 35

Page 402 of 1164

F EXHAUST SYSTEM

EXHAUSTSYSTEM

COMPONENT PARTS

Removal / Inspection / Installation

1. Remove in the order shown in the figure.

2. Check the exhaust component parts and repair or replace if necessary.

3. Install in the reverse order of removal.

29149

(3.0-5.0, 22-36) .

^ _ ^.S_

T,

nrrwCE

O-55 (4.1-5.6, 30-41)

N.m (m-kg, ft-lb

23UOFX-1

1, Main silencer

Inspect for deterioration and restriction

2. Pre-silencer

Inspect for deterioration and restriction

3. Catalytic converter

Inspect for deterioration and restriction 4. Front pipe assembly

Inspect for deterioration and restriction

5. Exhaust manifold

Inspect for deterioration and cracks

6. Exhaust manifold insulator

7. Oxygen sensor

Inspection . . . . . . . ..*...................... page F-171 --

‘Y’

F-l 36

Page 403 of 1164

NTROLSYSTEM F

STRUCTURAL VIEW

To reduce CO, HC, and NOx emissions, the following systerns are employed

1. Positive crankcase ventilation (PCV) system

2. Evaporative emission control system

3. Catalytic converter

SEPPRATOR

ECK-AND-CUT

CHARCOAL CANISTER

Page 404 of 1164

F POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

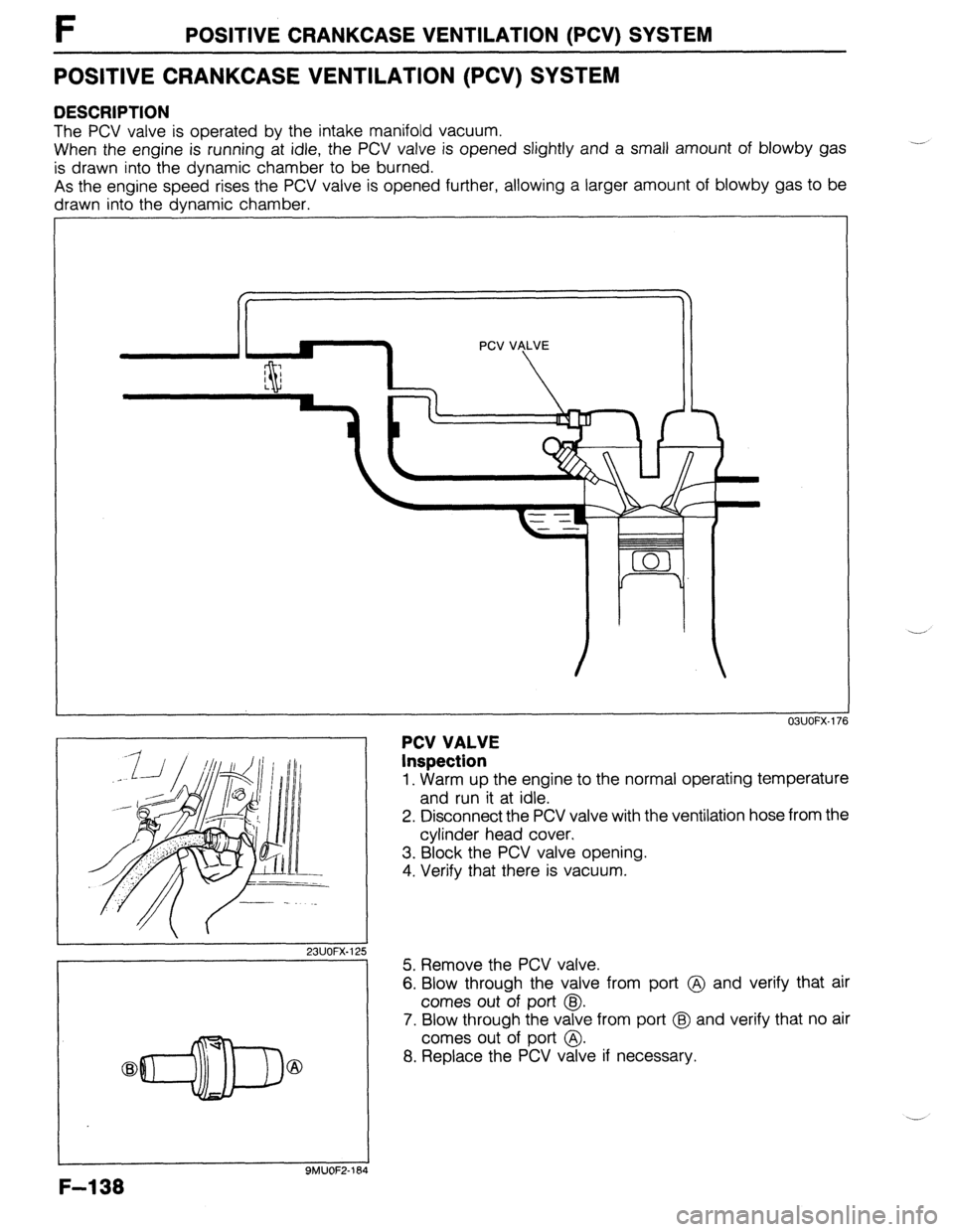

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

DESCRIPTION

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blowby gas

is drawn into the dynamic chamber to be burned.

As the engine speed rises the PCV valve is opened further, allowing a larger amount of blowby gas to be

drawn into the dynamic chamber.

23UOFX.1; !5

-7

F-l 38

9MUOF2-164

PCV VALVE

Inspection

OBUOFX-176

1. Warm up the engine to the normal operating temperature

and run it at idle.

2. Disconnect the PCV valve with the ventilation hose from the

cylinder head cover,

3. Block the PCV valve opening.

4. Verify that there is vacuum.

5. Remove the PCV valve.

6. Blow through the valve from port @ and verify that air

comes out of port @I.

7. Blow through the valve from port @ and verify that no air

comes out of port @.

8. Replace the PCV valve if necessary.

Page 405 of 1164

EVAPORATIVE EMISSION CONTROL SYSTEM t

EVAPORATIVE EMISSION CONTROL SYSTEM

DESCRIPTION

/ /

ENGINE ENGINE

CONTROL CONTROL - INPUT - INPUT

UNIT UNIT

- -

SOLENOID VALVE SOLENOID VALVE k k / /

CHECK VALVE CHECK VALVE

(TWO-WAY) (TWO-WAY)

CHARCOAL CHARCOAL

CANISTER CANISTER

CHECK-AND-CUTC CHECK-AND-CUTC

VALVE VALVE

SEPARATOR SEPARATOR TO ENGINE TO ENGINE SIGNALS

The evaporative emission control system consists of the separator, the check-and-cut valve, the two-way

check valve, the charcoal canister, the purge control solenoid valve, the engine control unit (ECU), and the

input devices. The amount of evaporative fumes introduced into the engine and burned is controlled by the

solenoid valve to correspond to the engine’s operating conditions. To maintain best engine performance,

the solenoid valve is controlled by the ECU.

Operation

.._ The solenoid valve (purge control) is controlled by duty signals from the ECU to perform purging of the char-

coal canister. Purging is done when these conditions are met:

(1) After warm-up

(2) Driving in gear

(3) Accelerator pedal depressed (idle switch OFF)

(4) Oxygen sensor functioning normally

F-l 39

Page 406 of 1164

F EVAPORATIVE EMISSION CONTROL SYSTEM

03UOFX-17! 3

03UOFX-180

INSTALLATION DIRECTION

F-l 40

I

23UOFX-126

03UOFX-18

OSUOFX-l&

SYSTEM OPERATION

1 Warm up the engine to normal operating temperature and

run it at idle.

2. Disconnect the vacuum hose from the solenoid valve as

shown in the figure, and verify that no vacuum is felt at the

solenoid valve. -.

3. If not as specified, check the solenoid valve.

SOLENOID VALVE (PURGE CONTROL)

Inspection

1. Disconnect the vacuum hoses from the solenoid valve.

2. Verify that no air flows through the valve.

3. Disconnect the solenoid valve connector and supply bat-

tery voltage as shown in the figure.

4. Verify that air flows through the valve.

5. If not as specified, replace the solenoid valve.

SEPARATOR

Inspection

1. Remove the left side trim.

2. Remove the separator.

3. Visually check the separator for damage. Replace it if

necessary.

CHECK VALVE (TWO-WAY)

Inspection

1. Remove the valve.

2. Check the operation of the valve with a vacuum pump.

Apply approx. 37 mmHg (1.46 inHg)

vacuum at port A Airflow

Apply approx. 44 mmHg (1.73 inHg)

vacuum at port B Airflow

Page 407 of 1164

EVAPORATIVE EMISSION CONTROL SYSTEM F

-l CHECK-AND-CUT VALVE

Inspection

1. Remove the check-and-cut valve.

2. Connect a pressure gauge to the passage connected to

the fuel tank.

3. Blow through the valve from port A and verify that the valve

opens at 6.36-6.34

kPa (0.065-0.065 kg/cm2,

0.92-l 2.09 psi).

4. Remove the pressure gauge and connect it to the passage

to atmosphere.

5. Blow through the valve from port B and verifyjhat the valve

opens at

0.96-4.91 kPa (0.01-0.05 kg/cmL, 0.14-0.71

psi). 1 9MUOF2-194

Note

l The test must be performed with the valve held

horizontally. Otherwise, the ball in the valve will

move out of position and close the passage.

CHARCOAL CANISTER

Inspection

1. Visually check for damage and replace the charcoal canis-

ter if necessary.

F-141

Page 408 of 1164

F DECELERATION CONTROL SYSTEM

DECELERATION CONTROL SYSTEM

DESCRIPTION

The dashpot is used to prevent the throttle valve from suddenly closing

03UOFX-185

1

DASHPOT

Inspection

1. Open the throttle valve fully. Push the dashpot rod with a

finger and verify that it goes into the dashpot slowly.

2. Release the rod and check that it comes out quickly.

3. Replace the dashpot if not as specified.

,,

OBUOFX-18

4. Warm up the engine and run it at idle.

5. Connect a tachometer to the diagnosis connector IG-

terminal and increase engine speed to 4,000 rpm.

6. Slowly decrease the engine speed and check that the le-

ver touches the dashpot rod at the specified speed.

Specification:

l B6 ..**.............,....,.............. Approx. 3,000 rpm

l BP SOHC . ..*..................*.... Approx. 2,700 rpm

l BP DOHC . . . . . . . . . . . . . . . . . . . . ...“... Approx. 3,500 rpm

7. If not as specified, loosen the locknut and turn the dashpot

to adjust.

F-l 42

Page 409 of 1164

FUEL CUT CONTROL SYSTEM F

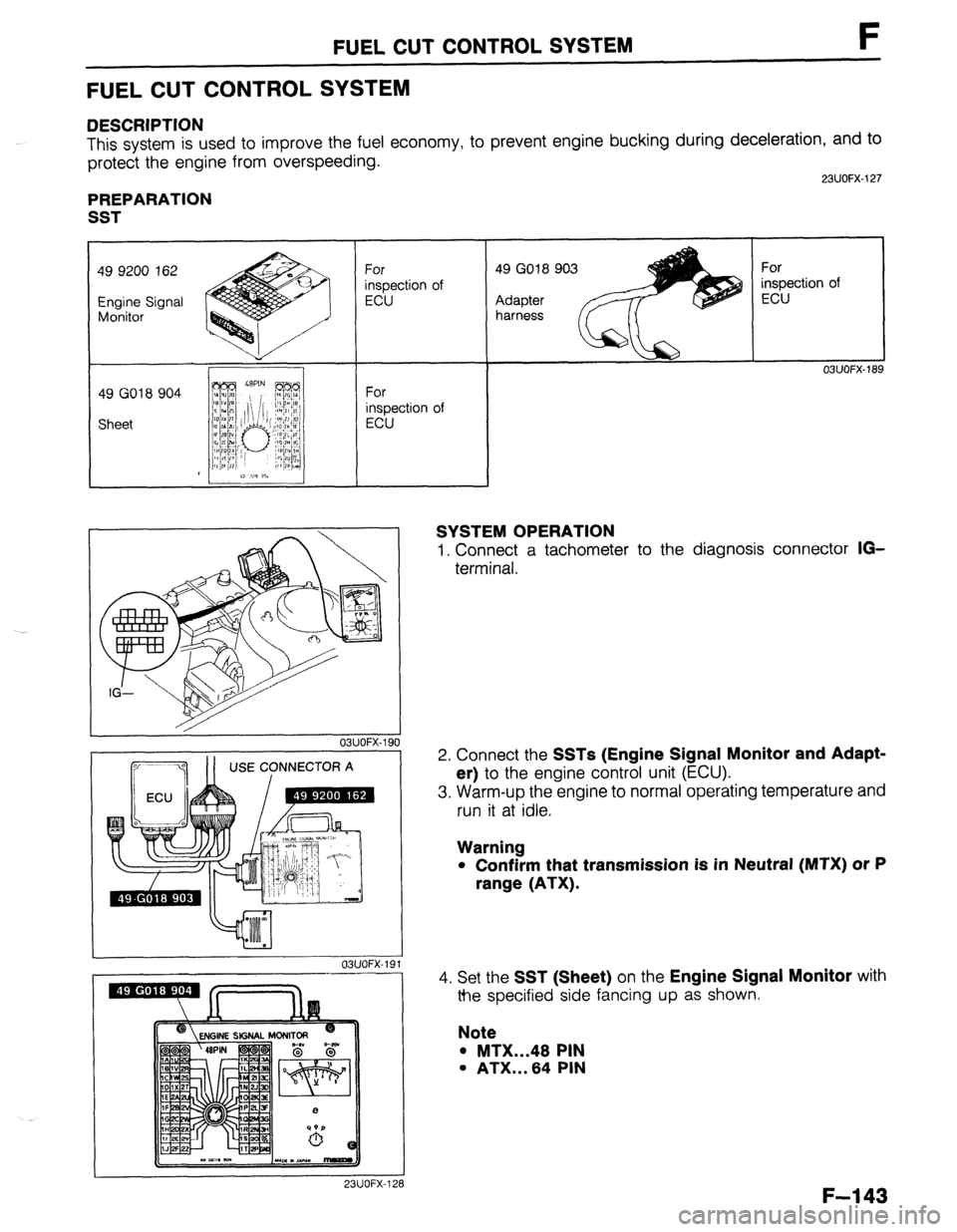

FUEL CUT CONTROL SYSTEM

DESCRIPTION

This system is used to improve the fuel economy, to prevent engine bucking during deceleration, and to

protect the engine from overspeeding.

23UOFX-127

PREPARATION

SST

r

49 9200 162

03UOFX.191

l7=---T II USE CPNNECTOR A

03UOFX-19

SYSTEM OPERATION

1. Connect a tachometer to the diagnosis connector IG-

terminal.

2. Connect the

SSTs (Engine Signal Monitor and Adapt-

er)

to the engine control unit (ECU).

3. Warm-up the engine to normal operating temperature and

run it at idle.

Warning

l Confirm that transmission is in Neutral (MTX) or P

range (ATX).

4.

Set the SST (Sheet) on the Engine Signal Monitor with

the specified side fancing up as shown.

Note

l MTX...48 PIN

l ATX...64 PIN

I 23UOFX-128

F-l 43

Page 410 of 1164

F FUEL

23UOFX-12:

0-6V

23UOFX- 131

to the terminal 2U or 2V (MTX), 3U or 3V (ATX)

hat the green and red lamps flash alternately.

nd No,3.....ECU terminal 2U (MTX)

3U (ATX)

. . . ..ECU terminal 2V (MTX)

3V (ATX)

6. Increase the engine speed to 4,000 rpm and then suddenly

release the throttle.

7. Verify that the red indicator lamp illuminates while the en-

gine speed is above approx.

1,900 rpm on deceleration.

t aced maximum rpm over 3 sec.

8. Increase the engine speed and verify that the maximum rpm

does not exceed specification.

.

.

. ..“.*..1”*“.-.“.....*......*...

Approx. 7,300 rpm

. . ..I......m....“.....*........m Approx. 6,300 rpm

F-l 44