MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1011 of 1146

528-l

L’ SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

CONTENTSM52AA-B

GENERAL INFORMATION

................................ComponentLocation

........................................

Configurati0.nDiagrams....................................Construction

Diagram........................................Introduction

........................................................SRS Circuit Diagram

......................................../idSRSConnector Construction............................SRS Schematic

................................................Warning/Caution

Labels....................................

SPECIFICATIONS................................................ServiceSpecification

........................................SRS MAINTENANCE AND

POST-COLLISION DIAGNOSIS........................Post-collisionDiagnosis

....................................Maintenance

....................................................

SRS SERVICE PRECAUTIONS........................Test Equipment To Be Used

For Troubleshooting

........................................

TROUBLESHOOTING........................................DiagnosticSequence

........................................SRS Diagnostic Procedures

-Initial Steps

....................................................

2

13

7

3

2

11

9

6

4

15

15

49

54

49

14

16

17

18

17

INDIVIDUAL COMPONENT

SERVICE. . . . . . . . . . . . . .._................................56AIR BAG MODULE AND CLOCK

SPRING

._..........._......................._.........._............... 62

AIR BAG MODULE DISPOSAL

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69Air Bag Remote Deployment Devices

. . . . . . . . . . . .69Deployed Air Bag Module Disposal

Procedures . .

.._..........._....................................... 72

Undeployed Air Bag Module Disposal

. . . . . . . . . .69

FRONT IMPACT SENSORS ._....: _._..._..................56

SRS DIAGNOSIS UNIT (SDU) . . . . . . .._...................59

CAUTIONlCarefully read and observe the information in the SRS SERVICE PRECAUTIONS (P.52B-14) prior to any service.l For information concerning troubleshooting or maintenance, always observe the procedures in the

Troubleshooting

(P.52B-17) or the SRS Maintenance and Post-collision Diagnosis (P.52B-49) sections,_respectively.lIf any SRS components are removed or replaced in connection with any service procedures, be sure to follow

the procedures in the INDIVIDUAL COMPONENT SERVICE section (P.52B-56) for the components involved.l In case of any questions about the SRS, call the regional Tech Line at l-800-446-6064.

Page 1012 of 1146

52B-2SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General informationGENERAL INFORMATION

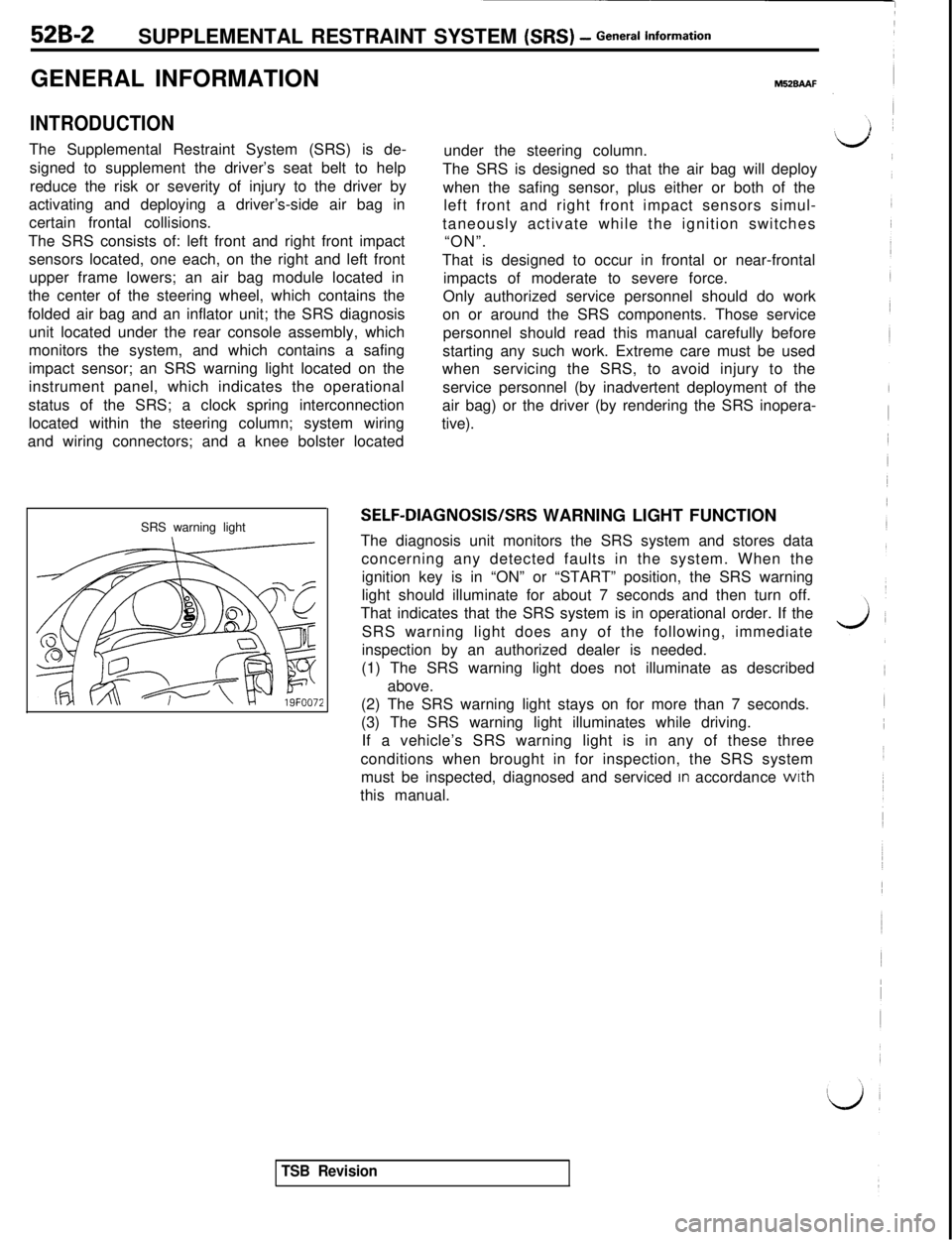

INTRODUCTIONThe Supplemental Restraint System (SRS) is de-

signed to supplement the driver’s seat belt to help

reduce the risk or severity of injury to the driver by

activating and deploying a driver’s-side air bag in

certain frontal collisions.

The SRS consists of: left front and right front impact

sensors located, one each, on the right and left front

upper frame lowers; an air bag module located in

the center of the steering wheel, which contains the

folded air bag and an inflator unit; the SRS diagnosis

unit located under the rear console assembly, which

monitors the system, and which contains a safing

impact sensor; an SRS warning light located on the

instrument panel, which indicates the operational

status of the SRS; a clock spring interconnection

located within the steering column; system wiring

and wiring connectors; and a knee bolster located

SRS warning light

M52BAAFunder the steering column.

The SRS is designed so that the air bag will deploy

when the safing sensor, plus either or both of the

left front and right front impact sensors simul-

taneously activate while the ignition switches

“ON”.

That is designed to occur in frontal or near-frontal

impacts of moderate to severe force.

Only authorized service personnel should do work

on or around the SRS components. Those service

personnel should read this manual carefully before

starting any such work. Extreme care must be used

whenservicing the SRS, to avoid injury to the

service personnel (by inadvertent deployment of the

air bag) or the driver (by rendering the SRS inopera-

tive).

SELF-DIAGNOSIS/SRS WARNING LIGHT FUNCTION

The diagnosis unit monitors the SRS system and stores data

concerning any detected faults in the system. When the

ignition key is in “ON” or “START” position, the SRS warning

light should illuminate for about 7 seconds and then turn off.

That indicates that the SRS system is in operational order. If the

SRS warning light does any of the following, immediate

inspection by an authorized dealer is needed.

(1) The SRS warning light does not illuminate as described

above.

(2) The SRS warning light stays on for more than 7 seconds.

(3) The SRS warning light illuminates while driving.

If a vehicle’s SRS warning light is in any of these three

conditions when brought in for inspection, the SRS system

must be inspected, diagnosed and serviced

In accordance wrth

this manual.

TSB Revision

Page 1013 of 1146

c

LJ

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General information52B-3

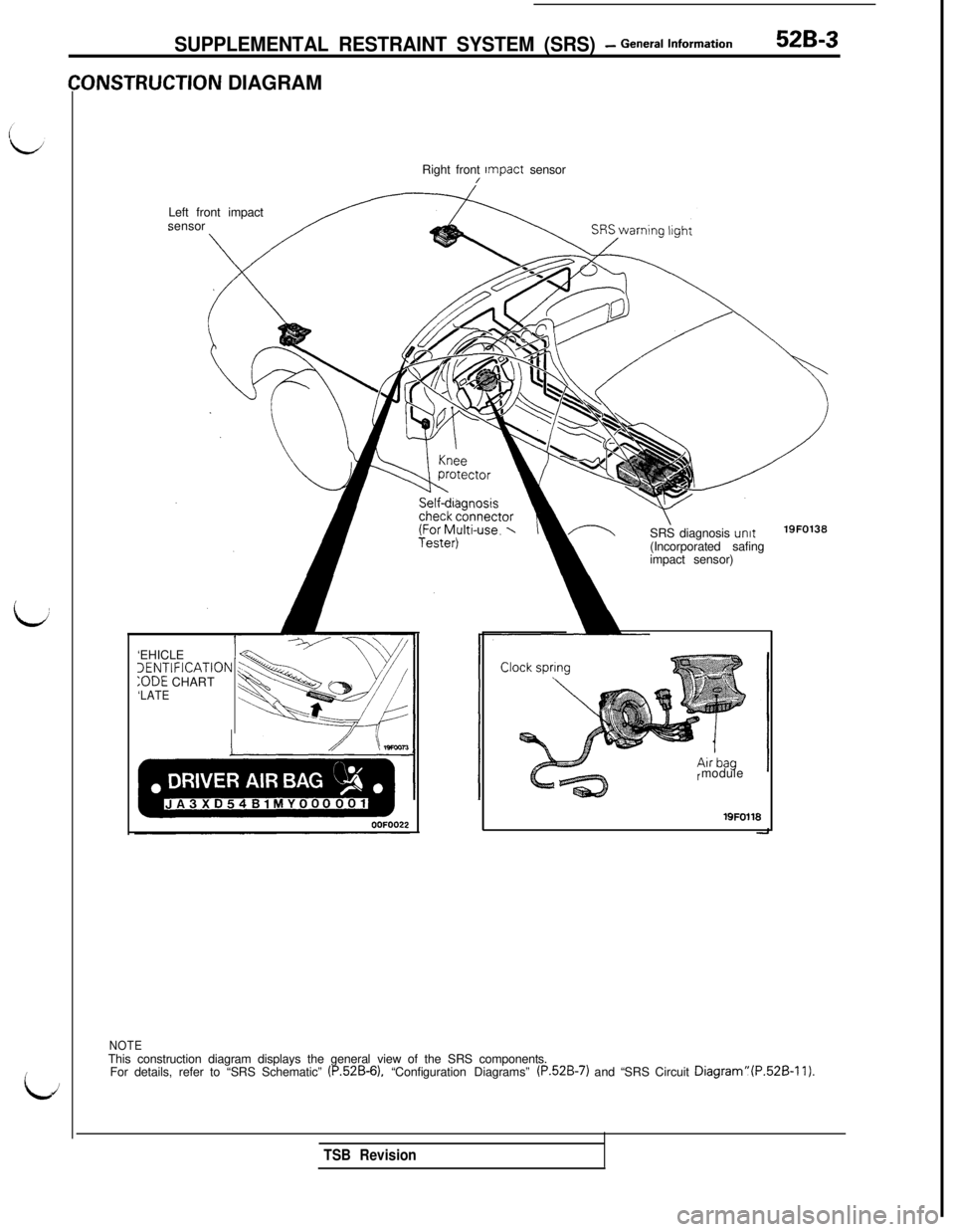

ONSTRUCTION DIAGRAM

Right front Impact sensor

/Left front impact

sensor

SRS diagnosis

unit(Incorporated safing

impact sensor)19FO138‘EHICLE

1~ENTIFICATION:ODE CHART

‘LATEmodulelQFO118

NOTEThis construction diagram displays the general view of the SRS components.

For details, refer to “SRS Schematic”

(P.52B-6). “Configuration Diagrams” (P.52B-7) and “SRS Circuit Diagram”(P.52B-11).

TSB Revision

Page 1014 of 1146

52B-4SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General lnform=*ion

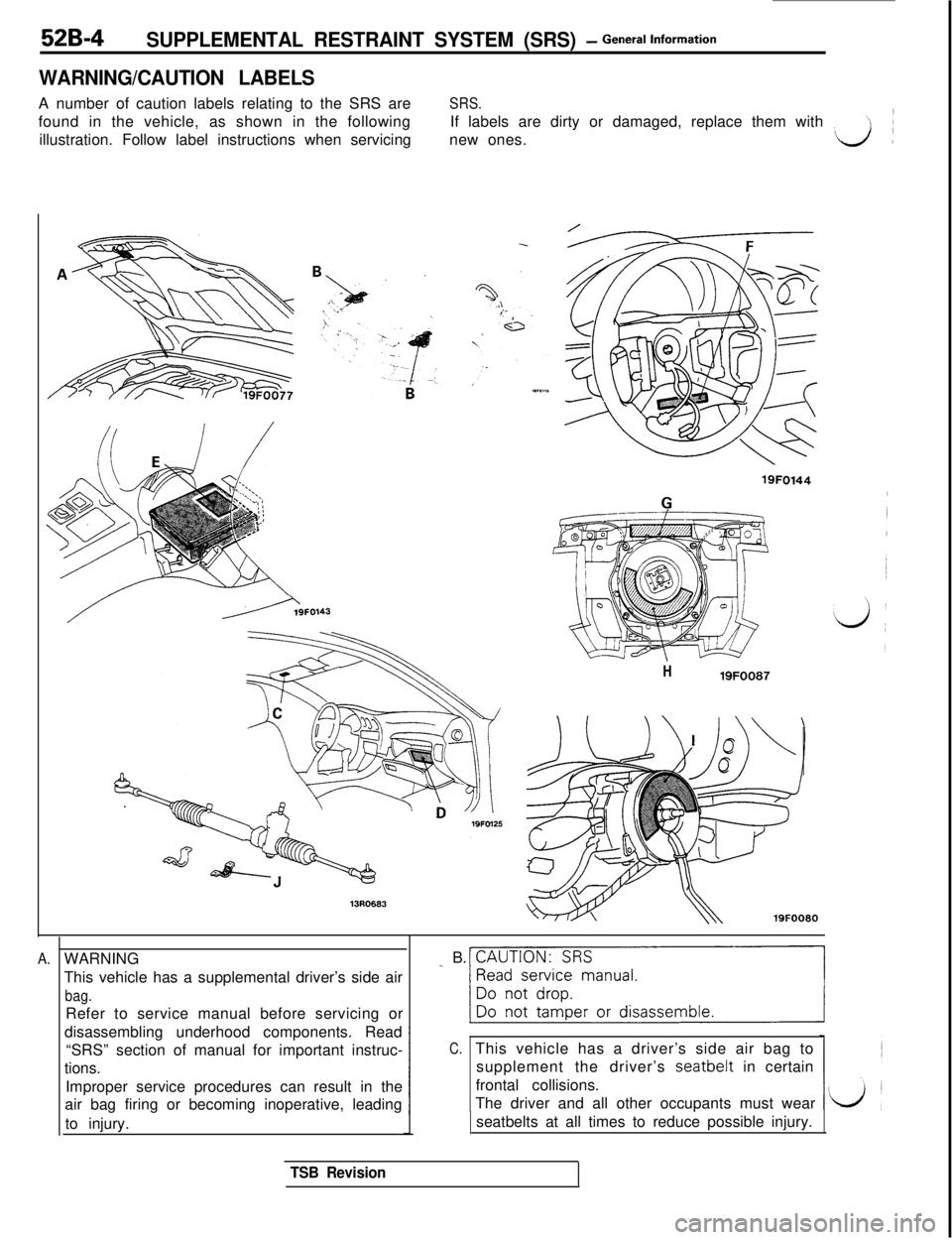

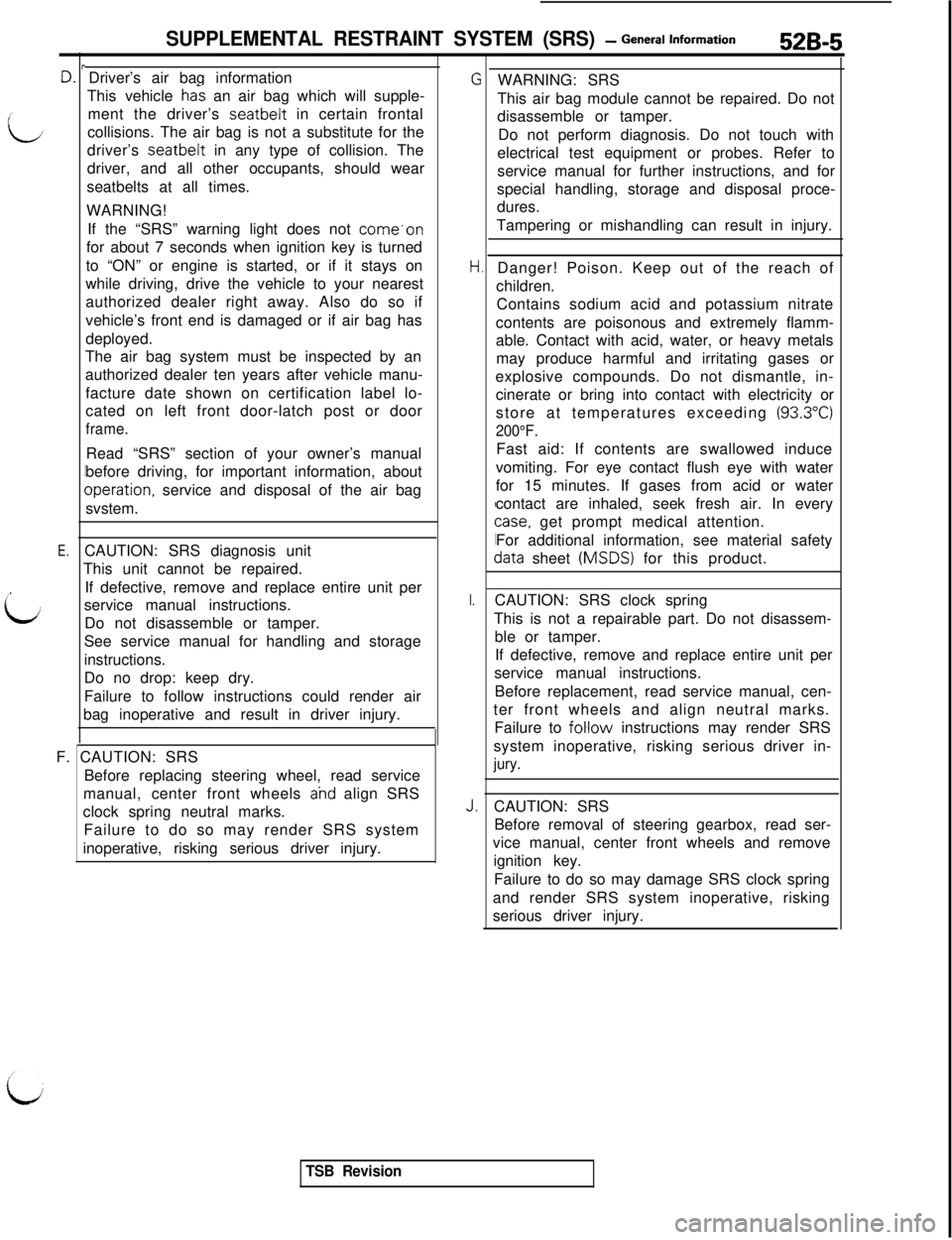

WARNING/CAUTION LABELSA number of caution labels relating to the SRS are

SRS.found in the vehicle, as shown in the followingIf labels are dirty or damaged, replace them with

illustration. Follow label instructions when servicingnew ones.

//----?9FO143

A.

H19FOO87

19FOO80WARNING

This vehicle has a supplemental driver’s side air

bag.Refer to service manual before servicing or

disassembling underhood components. Read

“SRS” section of manual for important instruc-

tions.

Improper service procedures can result in the

air bag firing or becoming inoperative, leading

to injury.

_ B. CAUTION: SRS

~1

C.This vehicle has a driver’s side air bag to

supplement the driver’s

seatbelt in certain

frontal collisions.

The driver and all other occupants must wear

seatbelts at all times to reduce possible injury.

TSB Revision

Page 1015 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General lnform=*ion52B-5

r1.c

L

E.

,

iiCAUTION: SRS diagnosis unit

This unit cannot be repaired.

If defective, remove and replace entire unit per

service manual instructions.

Do not disassemble or tamper.

See service manual for handling and storage

instructions.Driver’s air bag information

This vehicle

ha% an air bag which will supple-

ment the driver’s seatbelt in certain frontal

collisions. The air bag is not a substitute for the

driver’s seatbelt in any type of collision. The

driver, and all other occupants, should wear

seatbelts at all times.

WARNING!

If the “SRS” warning light does not come.on

for about 7 seconds when ignition key is turned

to “ON” or engine is started, or if it stays on

while driving, drive the vehicle to your nearest

authorized dealer right away. Also do so if

vehicle’s front end is damaged or if air bag has

deployed.

The air bag system must be inspected by an

authorized dealer ten years after vehicle manu-

facture date shown on certification label lo-

cated on left front door-latch post or door

frame.Read “SRS” section of your owner’s manual

before driving, for important information, about

Dperation, service and disposal of the air bag

svstem.

Do no drop: keep dry.

Failure to follow instructions could render air

bag inoperative and result in driver injury.

F. CAUTION: SRS

Before replacing steering wheel, read service

manual, center front wheels

ahd align SRS

clock spring neutral marks.

Failure to do so may render SRS system

inoperative, risking serious driver injury.

I.

J.WARNING: SRS

This air bag module cannot be repaired. Do not

disassemble or tamper.

Do not perform diagnosis. Do not touch with

electrical test equipment or probes. Refer to

service manual for further instructions, and for

special handling, storage and disposal proce-

dures.

Tampering or mishandling can result in injury.

Danger! Poison. Keep out of the reach of

children.

Contains sodium acid and potassium nitrate

contents are poisonous and extremely flamm-

able. Contact with acid, water, or heavy metals

may produce harmful and irritating gases or

explosive compounds. Do not dismantle, in-

cinerate or bring into contact with electricity or

store at temperatures exceeding

(93.3”C)

200°F.Fast aid: If contents are swallowed induce

vomiting. For eye contact flush eye with water

for 15 minutes. If gases from acid or water

contact are inhaled, seek fresh air. In every

case, get prompt medical attention.

For additional information, see material safety

data sheet (MSDS) for this product.

CAUTION: SRS clock spring

This is not a repairable part. Do not disassem-

ble or tamper.

If defective, remove and replace entire unit per

service manual instructions.

Before replacement, read service manual, cen-

ter front wheels and align neutral marks.

Failure to

foHow instructions may render SRS

system inoperative, risking serious driver in-

jury.CAUTION: SRS

Before removal of steering gearbox, read ser-

vice manual, center front wheels and remove

ignition key.

Failure to do so may damage SRS clock spring

and render SRS system inoperative, risking

serious driver injury.

TSB Revision

Page 1016 of 1146

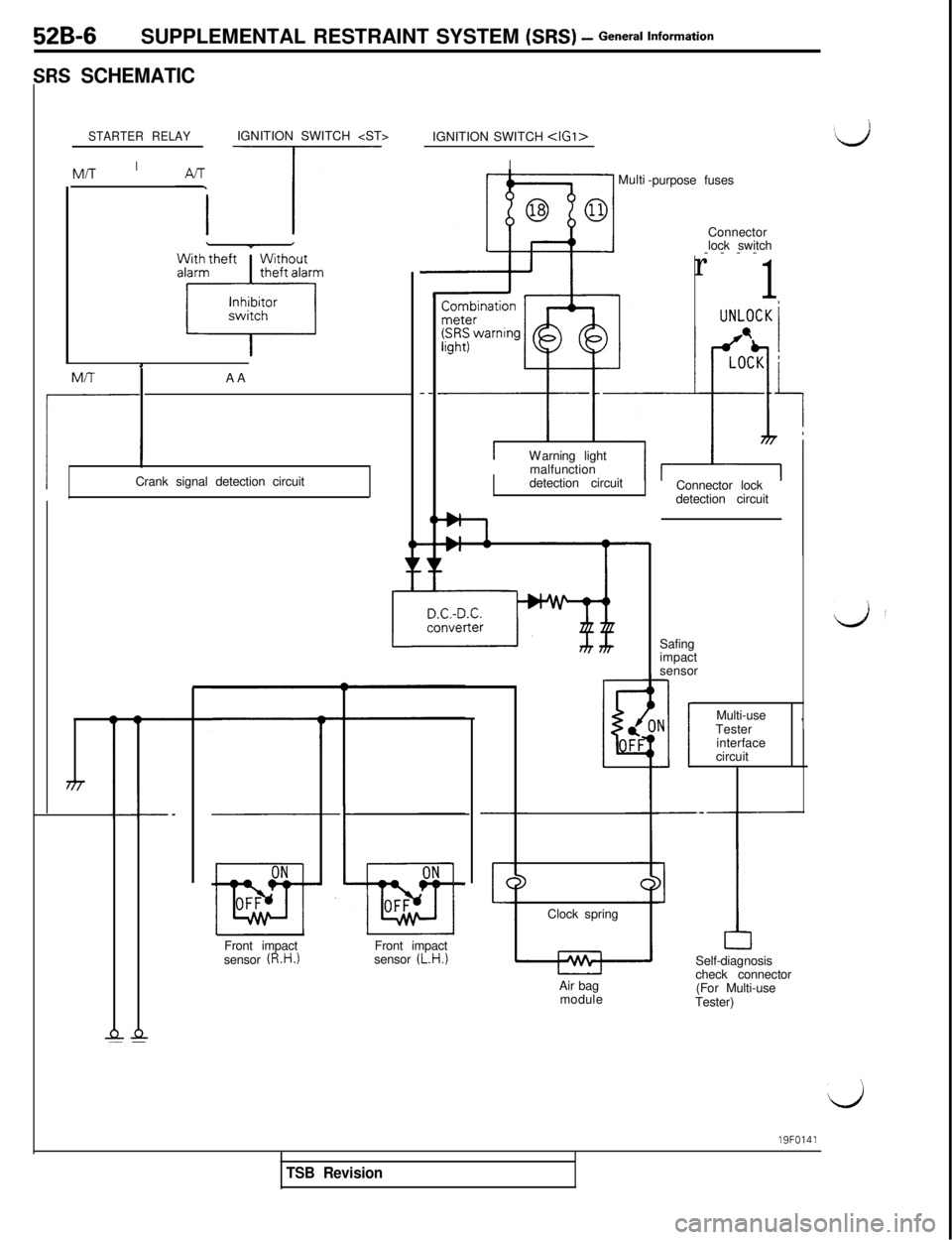

52B-6SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General Information

;RS SCHEMATIC

STARTER RELAYIGNITION SWITCH

I

‘dIGNITION SWITCH

IMulti

-purpose fuses

Connector

lock switch

----

r

1

UNLOCKiM/T -AA

IWarning light

malfunction

detection circuitICrank signal detection circuit

Connector lock

detection circuit

Safing

impact

sensor

1

N

i-Multi-use ,

Tester

interface

circuit

Self-diagnosis

check connector

(For Multi-use

Tester)

19FO141Front impact

sensor

(L.H.)Clock spring

Front impact

sensor (R.H.)IP-l-Air bag

module

TSB Revision

Page 1017 of 1146

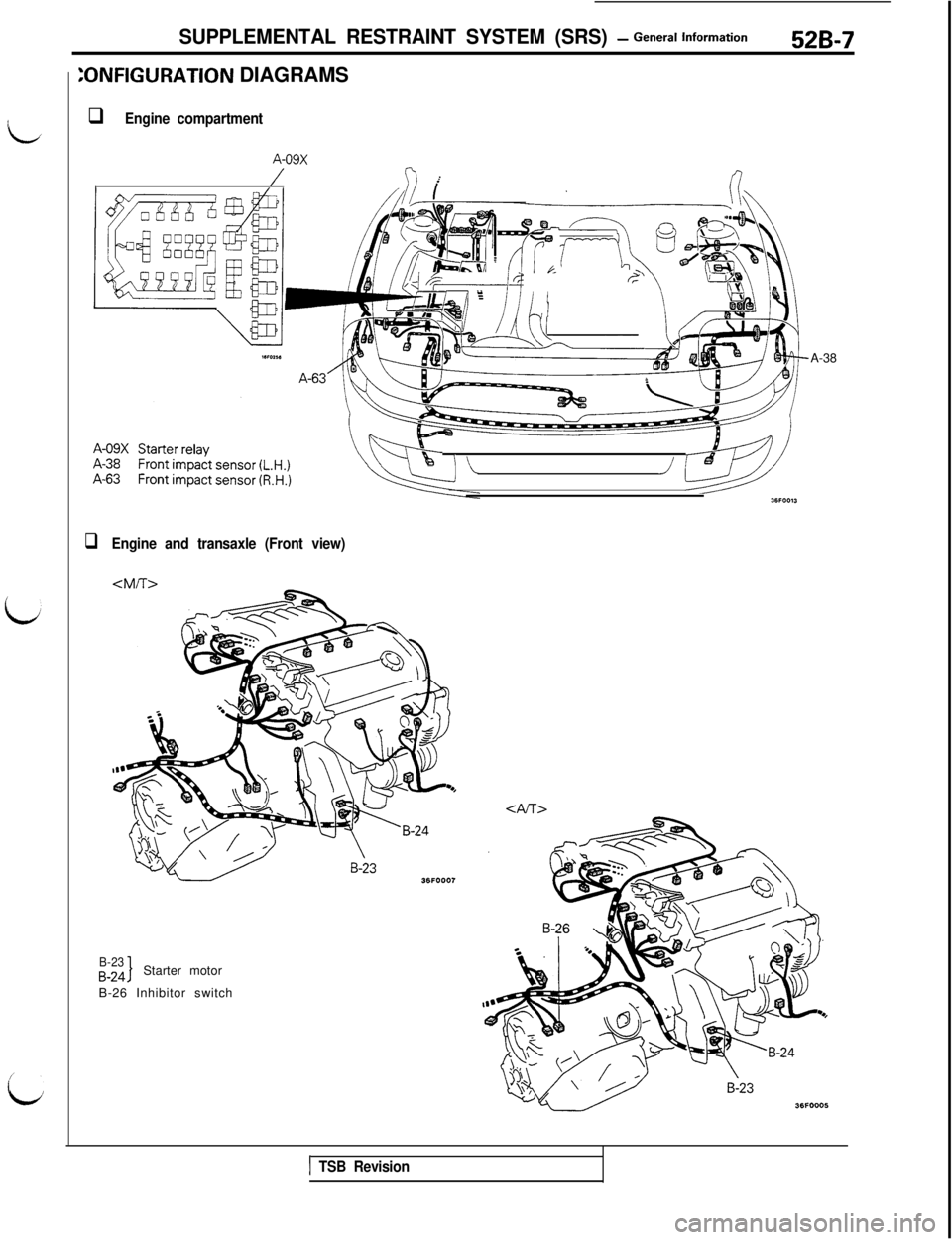

i

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General Information526-7

:ONFIGURATION DIAGRAMS

q Engine compartmentA-09X

/

+m*,.16,IIfc’ \=is\ IL\\

\

\iw I \B/f---TJwdD

’ L&/Y&!!

3BFOO13

qEngine and transaxle (Front view)

B-23B-24Starter motor

B-26 Inhibitor switchA-38

1 TSB Revision

Page 1018 of 1146

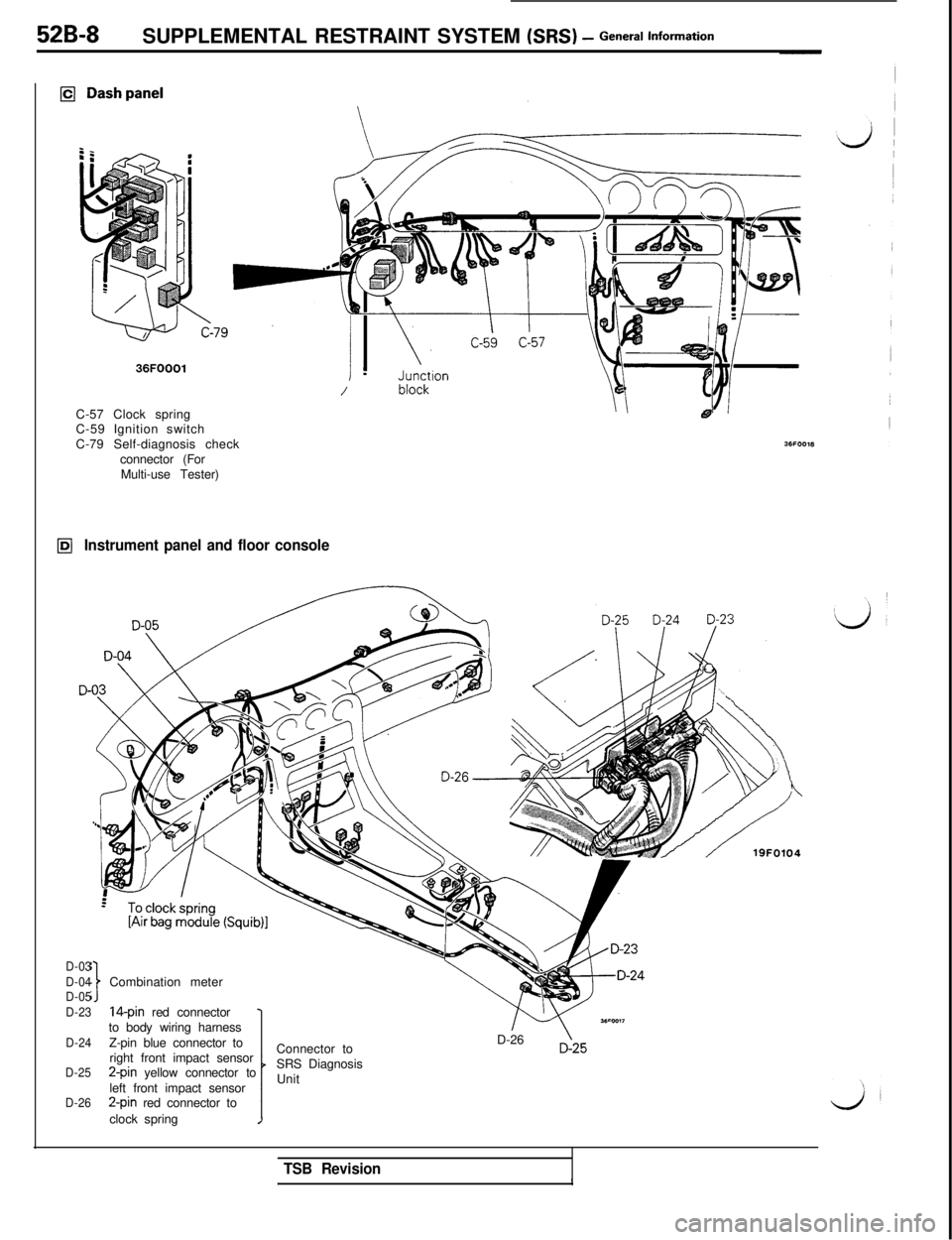

52B-8SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General Information

36FOOOlJ/C-57 Clock spring

C-59 Ignition switch

C-79 Self-diagnosis check

connector (For

Multi-use Tester)

IbJInstrument panel and floor console

D-

D-03

D-04Combination meter

D-05

D-2314-pin red connector

to body wiring harness

D-24Z-pin blue connector to

right front impact sensor

D-252-pin yellow connector to

left front impact sensor

D-262-pin red connector to

clock springConnector to

SRS Diagnosis

UnitD-26225

TSB Revision,1

Page 1019 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General Information52B-9.ock sprinq

\ Secondary lock lever

13R0721Harness side

connectorPrimary lock

/(Improperly fitted state)SRS diagnosis

unit side connector

Forced down13RO664Secondarv

lock lever’

projection

(Properly fitted state)

Secondary

lock spring

u13RO685

Prll

13R068t

ITSB I

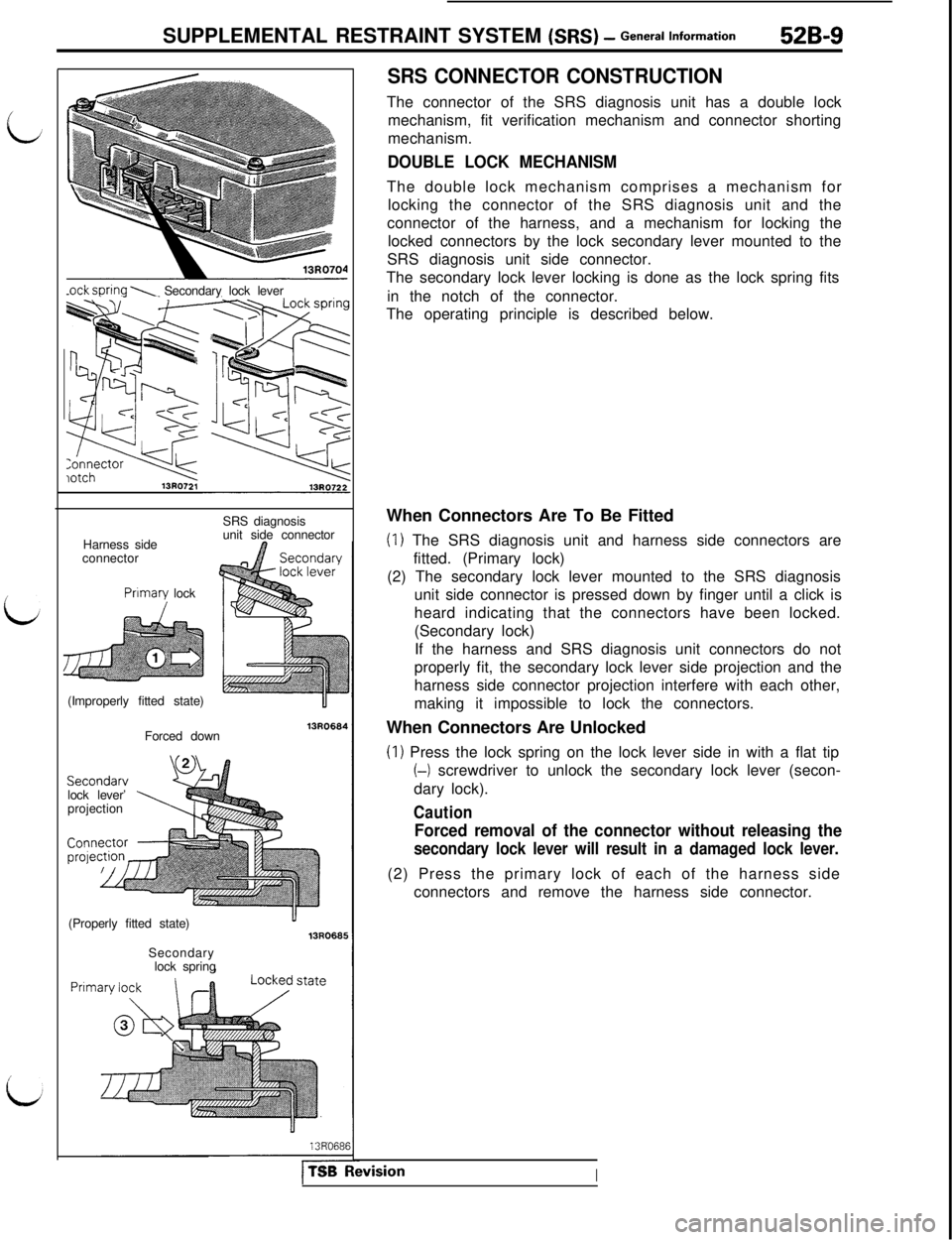

SRS CONNECTOR CONSTRUCTIONThe connector of the SRS diagnosis unit has a double lock

mechanism, fit verification mechanism and connector shorting

mechanism.

DOUBLE LOCK MECHANISMThe double lock mechanism comprises a mechanism for

locking the connector of the SRS diagnosis unit and the

connector of the harness, and a mechanism for locking the

locked connectors by the lock secondary lever mounted to the

SRS diagnosis unit side connector.

The secondary lock lever locking is done as the lock spring fits

in the notch of the connector.

The operating principle is described below.

When Connectors Are To Be Fitted

(I) The SRS diagnosis unit and harness side connectors are

fitted. (Primary lock)

(2) The secondary lock lever mounted to the SRS diagnosis

unit side connector is pressed down by finger until a click is

heard indicating that the connectors have been locked.

(Secondary lock)

If the harness and SRS diagnosis unit connectors do not

properly fit, the secondary lock lever side projection and the

harness side connector projection interfere with each other,

making it impossible to lock the connectors.

When Connectors Are Unlocked

(1) Press the lock spring on the lock lever side in with a flat tip

(--) screwdriver to unlock the secondary lock lever (secon-

dary lock).

Caution

Forced removal of the connector without releasing the

secondary lock lever will result in a damaged lock lever.(2) Press the primary lock of each of the harness side

connectors and remove the harness side connector.

FvisionI

Page 1020 of 1146

52B-10SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - General InformationI

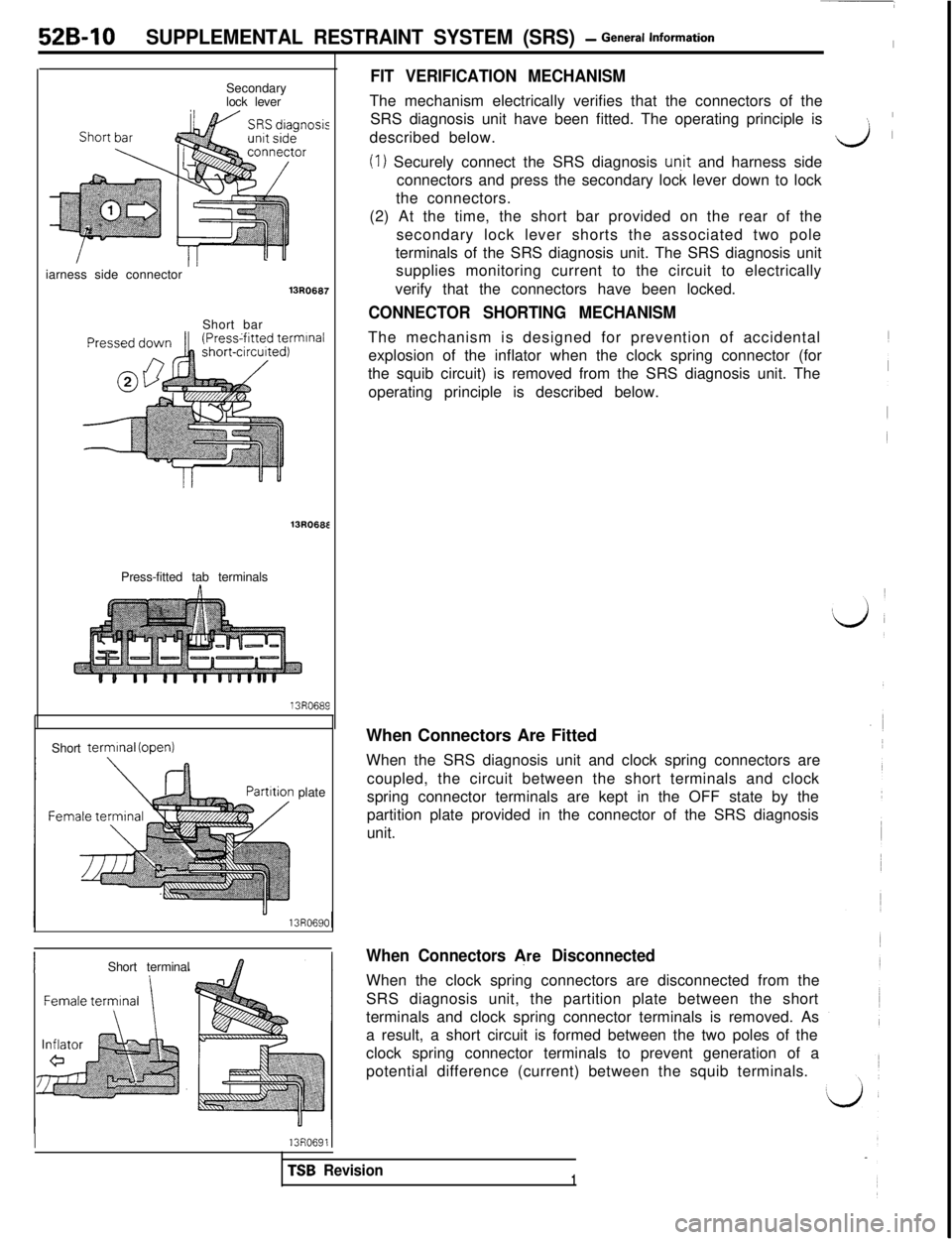

FIT VERIFICATION MECHANISMSecondary

lock leverThe mechanism electrically verifies that the connectors of the

SRS diagnosis unit have been fitted. The operating principle is

:described below.

d

(

(1) Securely connect the SRS diagnosis un.it and harness side

connectors and press the secondary lock lever down to lock

the connectors.

sisiarness side connector

13R0687Short bar

nlnal13R068E

Press-fitted tab terminals

13R0689Short

terminal (open)

plate

IShort terminal

I13R06911(2) At the time, the short bar provided on the rear of the

secondary lock lever shorts the associated two pole

terminals of the SRS diagnosis unit. The SRS diagnosis unit

supplies monitoring current to the circuit to electrically

verify that the connectors have been locked.

CONNECTOR SHORTING MECHANISMThe mechanism is designed for prevention of accidental

explosion of the inflator when the clock spring connector (for

the squib circuit) is removed from the SRS diagnosis unit. The

operating principle is described below.

When Connectors Are Fitted

When the SRS diagnosis unit and clock spring connectors are

coupled, the circuit between the short terminals and clock

spring connector terminals are kept in the OFF state by the

partition plate provided in the connector of the SRS diagnosis

unit.

When Connectors &e DisconnectedWhen the clock spring connectors are disconnected from the

SRS diagnosis unit, the partition plate between the short

terminals and clock spring connector terminals is removed. As

a result, a short circuit is formed between the two poles of the

clock spring connector terminals to prevent generation of a

potential difference (current) between the squib terminals.

TSB Revision1