MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 221 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

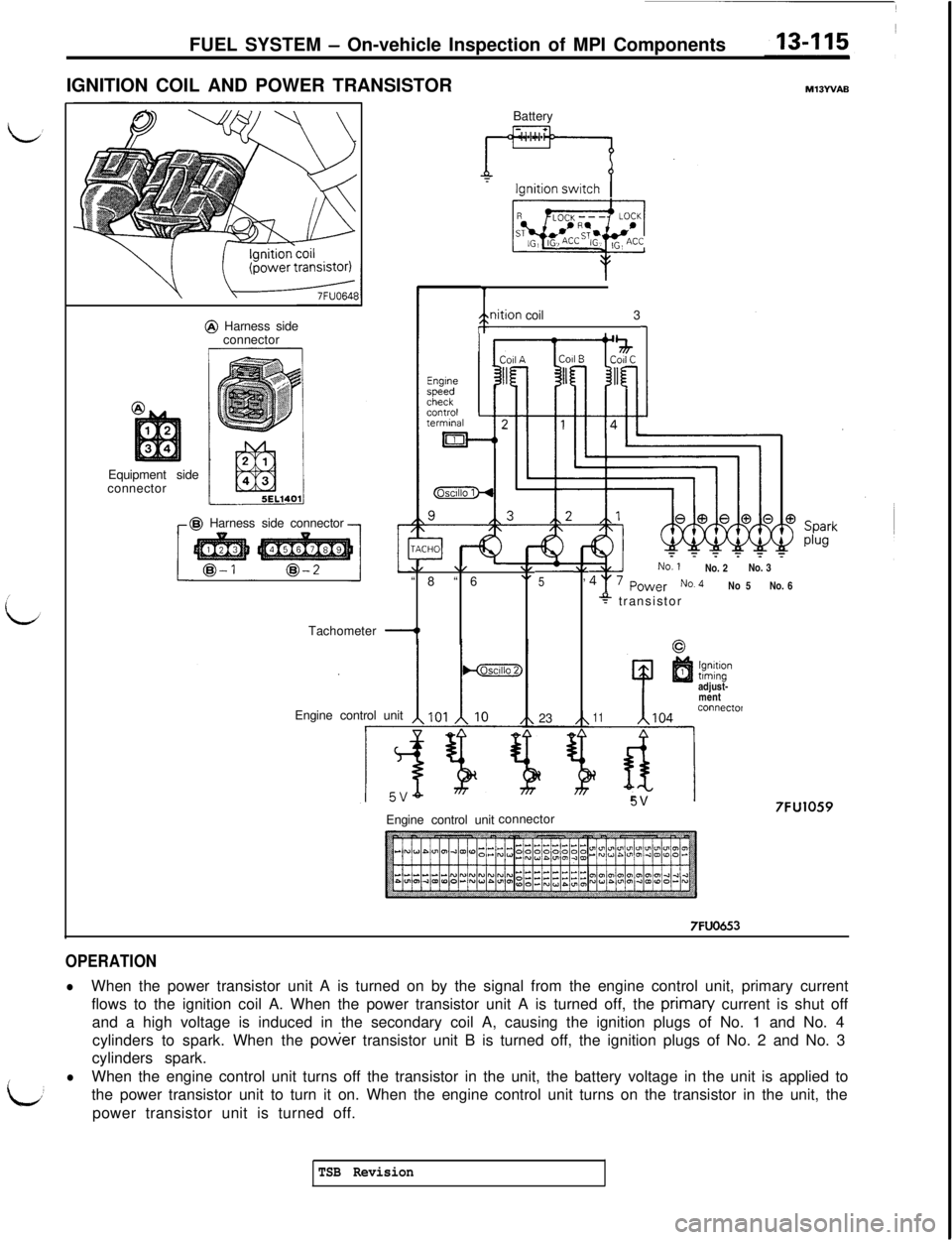

IGNITION COIL AND POWER TRANSISTOR

MlBYVABEquipment side

connector@ Harness side

connector@ Harness side connector

Tachometer

-1Battery

/gnition coil1 3

Engine control unit

\/\/\IAL“8 “6.,,523No. 2No. 3

No 5No. 6

* transistor

5Y

lgnltlontamingadjust-

mentconnectof

11104

d

w5V

7FU1059Engine control unitconnector

7FUO453

OPERATION

lWhen the power transistor unit A is turned on by the signal from the engine control unit, primary current

flows to the ignition coil A. When the power transistor unit A is turned off, the primaty current is shut off

and a high voltage is induced in the secondary coil A, causing the ignition plugs of No. 1 and No. 4

cylinders to spark. When the

power transistor unit B is turned off, the ignition plugs of No. 2 and No. 3

cylinders spark.

L

lWhen the engine control unit turns off the transistor in the unit, the battery voltage in the unit is applied to

the power transistor unit to turn it on. When the engine control unit turns on the transistor in the unit, the

power transistor unit is turned off.

TSB Revision

Page 222 of 1146

13-116FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

(d

FunctionItem No. Data displayCheck condition

Engine state

Standard valueData reading 44

Ignitionadvancel Engine: Warming up

750 rpm (Idle)7 - 23”BTDCl Timing light: Set (settiming light to check2,000 rpm30 - 40”BTDC

‘

Function

Data listItem No.Data displayCheckTerminalStandard value

condition

condition

36Continuity present or

not present betweenl Engine:

IdlingIgnition timing ad-ON

ignition timing adjustmentjustment terminal isterminal and groundgrounded

Ignition timing ad-OFFjustment terminal is

disconnected from

ground

Function

Actuator testItem No.

DriveCheck conditionNormal condition

17Set to ignition timingl Engine: idling5”BTDCadjustment model Timing light: set\

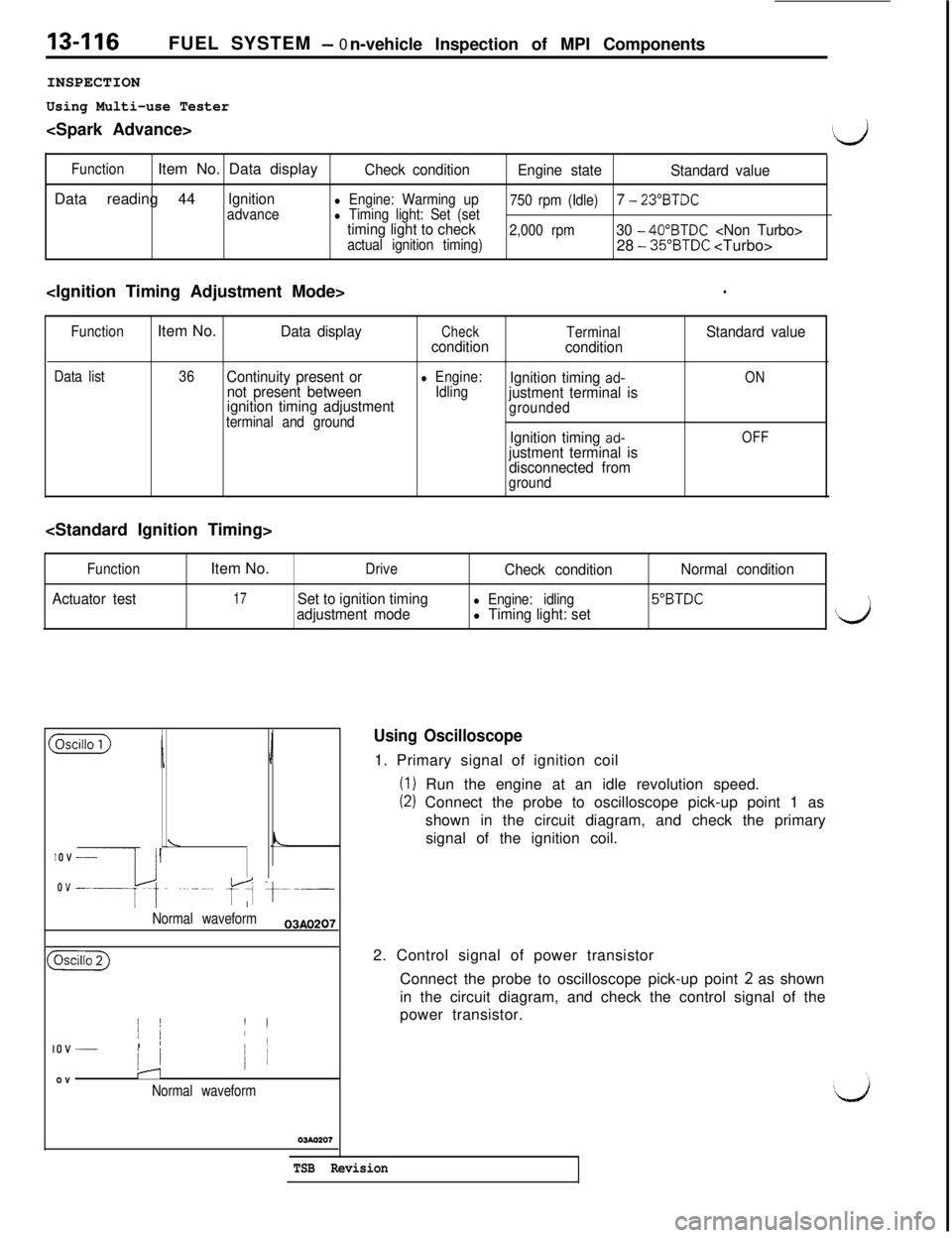

($Gizi)

IJ

\LIOV _

ovep~,. ..~_~.~ fA t---.-

I

Normal waveform03AO207

(

j /’ II

IOV _I ’/

/ 1ovIJ

Normal waveform

Using Oscilloscope1. Primary signal of ignition coil

(I) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

Connect the probe to oscilloscope pick-up point

2 as shown

in the circuit diagram, and check the control signal of the

power transistor.

TSB Revision

Page 223 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-117

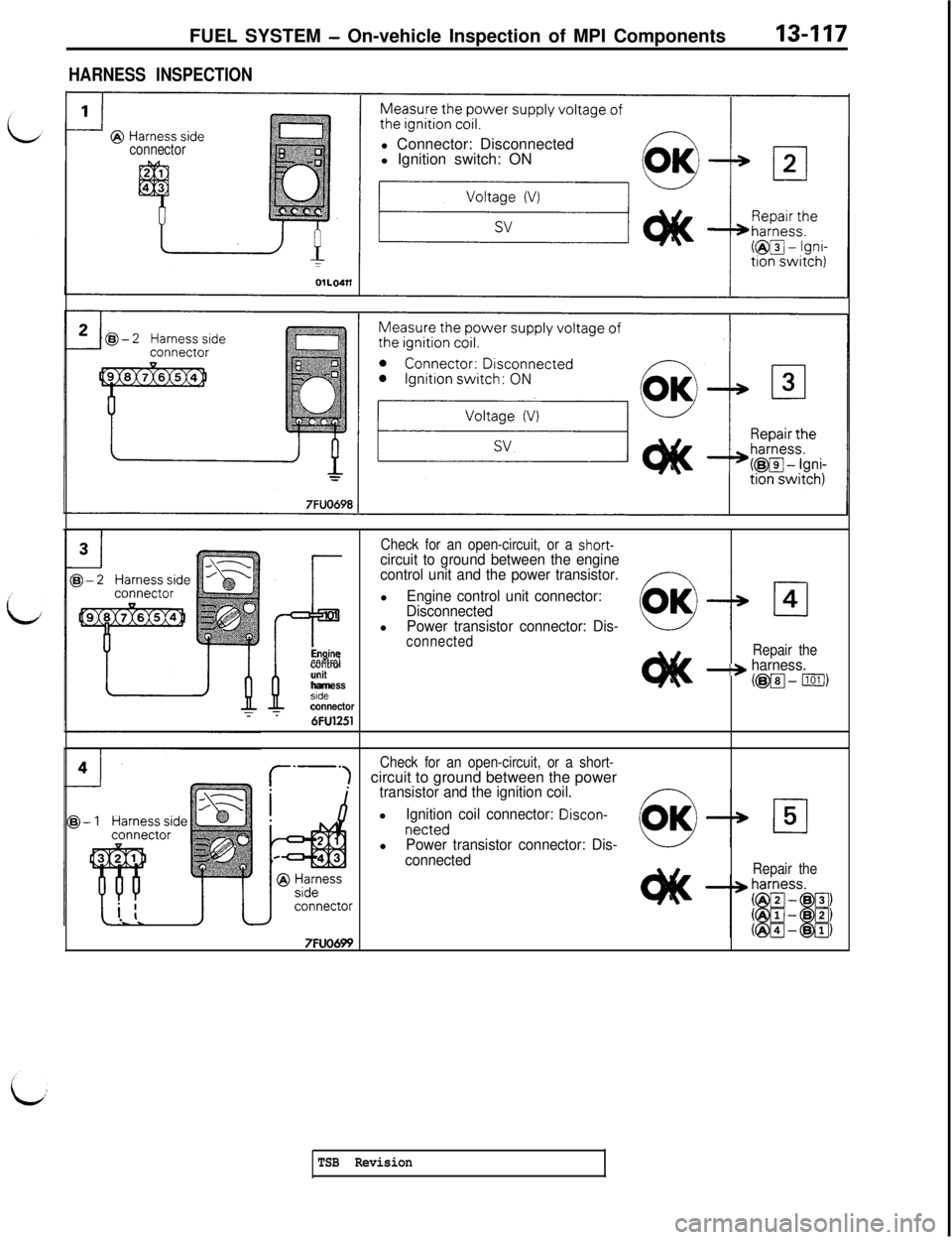

HARNESS INSPECTION

connectorl Connector: Disconnected

l Ignition switch: ON

Check for an open-circuit, or a short-

P

circuit to ground between the engine

control unit and the power transistor.l

Engine control unit connector:

Disconnectedl

Power transistor connector: Dis-connectedEngineRepair thecontrolunit-+ harness.harness(@@J-1101/)stdeconnector

T6FU1251

Check for an open-circuit, or a short-circuit to ground between the power

transistor and the ignition coil.l

Ignition coil connector: Discon-netted

l

Power transistor connector: Dis-

connected

Repair the

7FUO699

TSB Revision

Page 224 of 1146

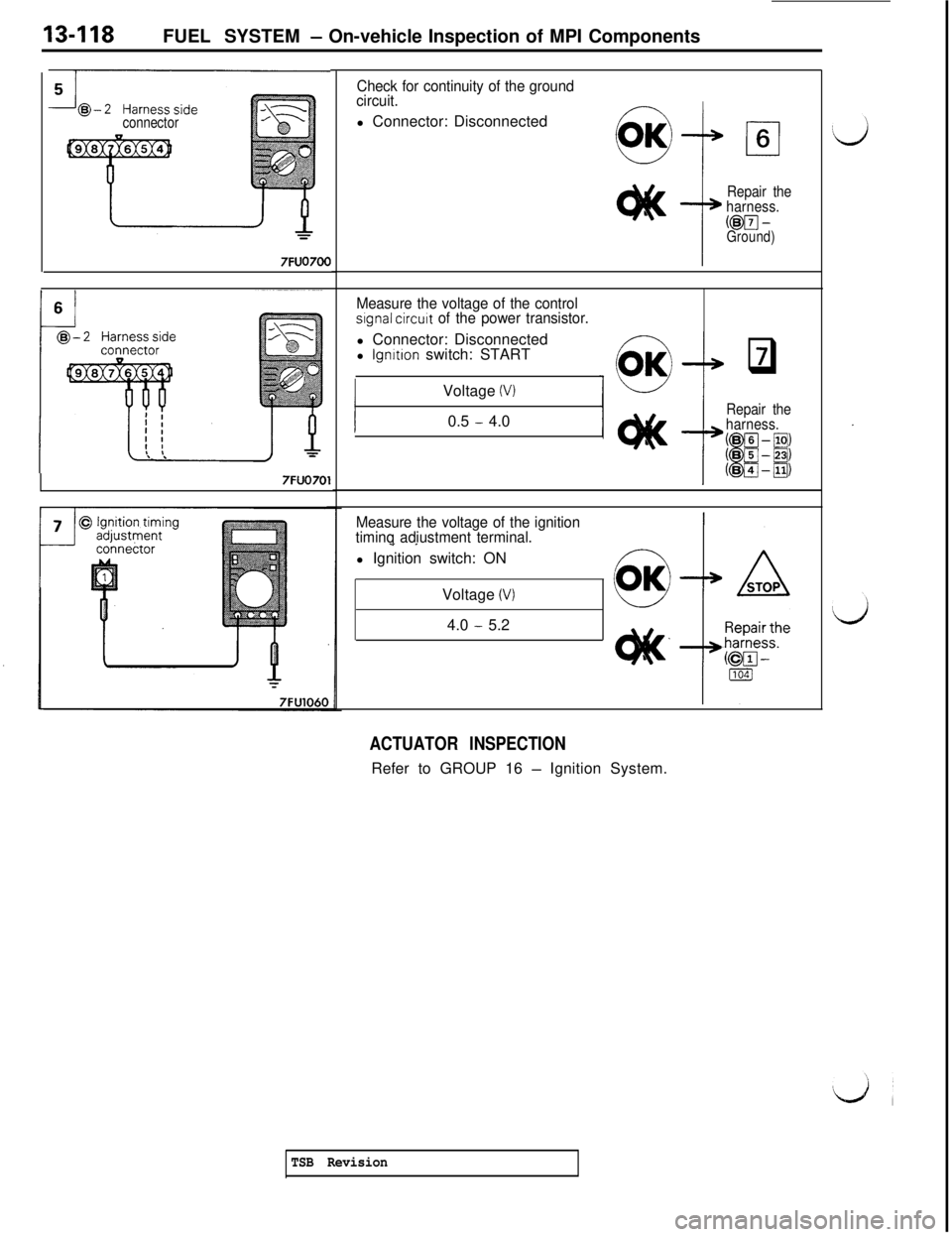

13-118FUEL SYSTEM- On-vehicle Inspection of MPI Components

connector

7FUO700

7FUO701

Check for continuity of the ground

circuit.

(1Il Connector: Disconnected

Repair the

harness.@pJ

-Ground)

Measure the voltage of the controlslgnal circuit of the power transistor.l Connector: Disconnected

l

lgnrtion switch: START

Voltage

(VI0.5

- 4.0

f

q7

Repair the

harness.

Measure the voltage of the ignition

timinq adiustment terminal.

- _l Ignition switch: ON

Voltage

(V)4.0

- 5.2

ACTUATOR INSPECTIONRefer to GROUP 16

- Ignition System.

TSB Revision

Page 225 of 1146

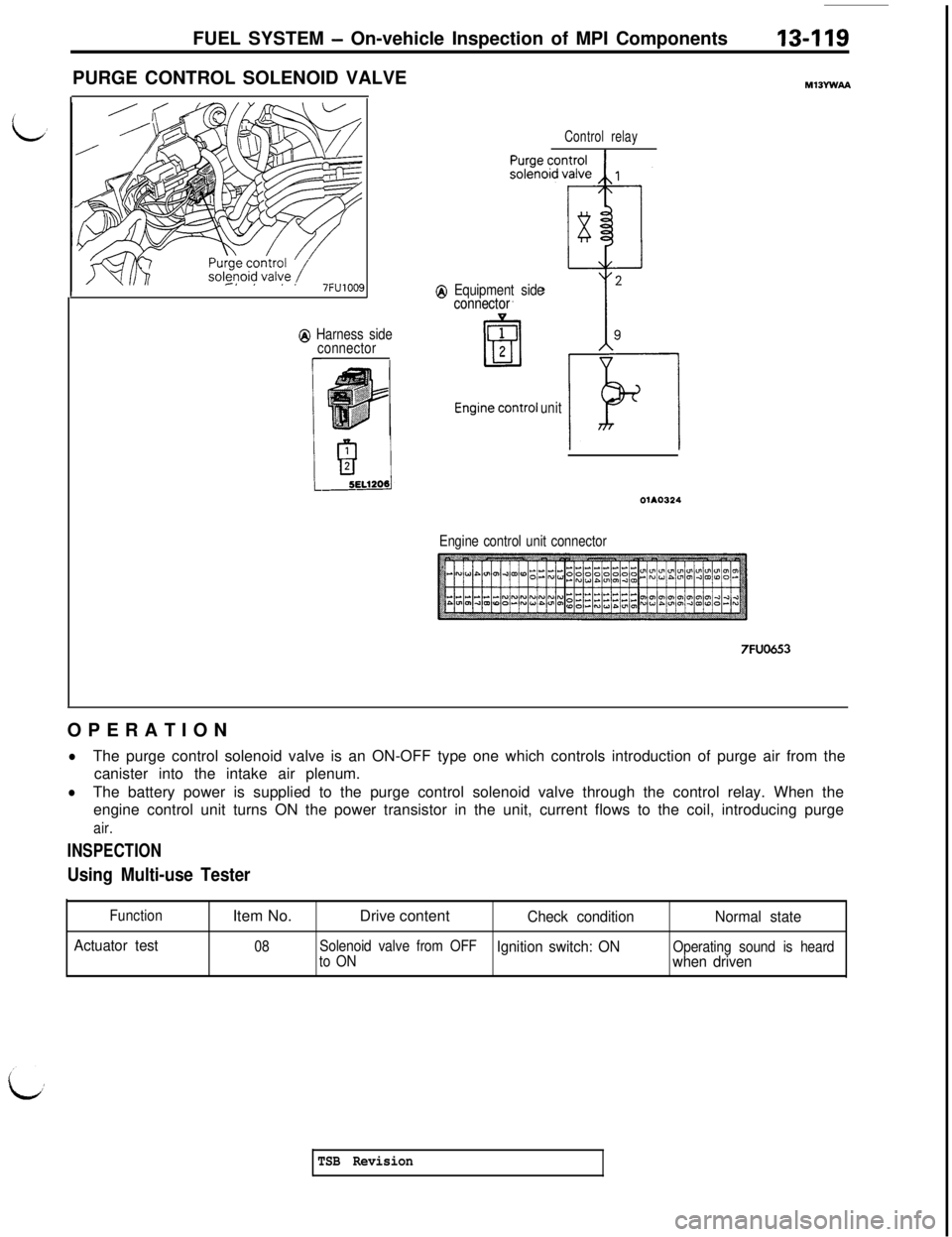

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-119PURGE CONTROL SOLENOID VALVE

Q Harness side

connector

I

Control relay

@ Equipment side

connector connector

unit

OlAO324

Engine control unit connector

7FUO653OPERATION

lThe purge control solenoid valve is an ON-OFF type one which controls introduction of purge air from the

canister into the intake air plenum.

lThe battery power is supplied to the purge control solenoid valve through the control relay. When the

engine control unit turns ON the power transistor in the unit, current flows to the coil, introducing purge

air.

INSPECTION

Using Multi-use Tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

08Solenoid valve from OFFIgnition switch: ONOperating sound is heard

to ONwhen driven

TSB Revision

Page 226 of 1146

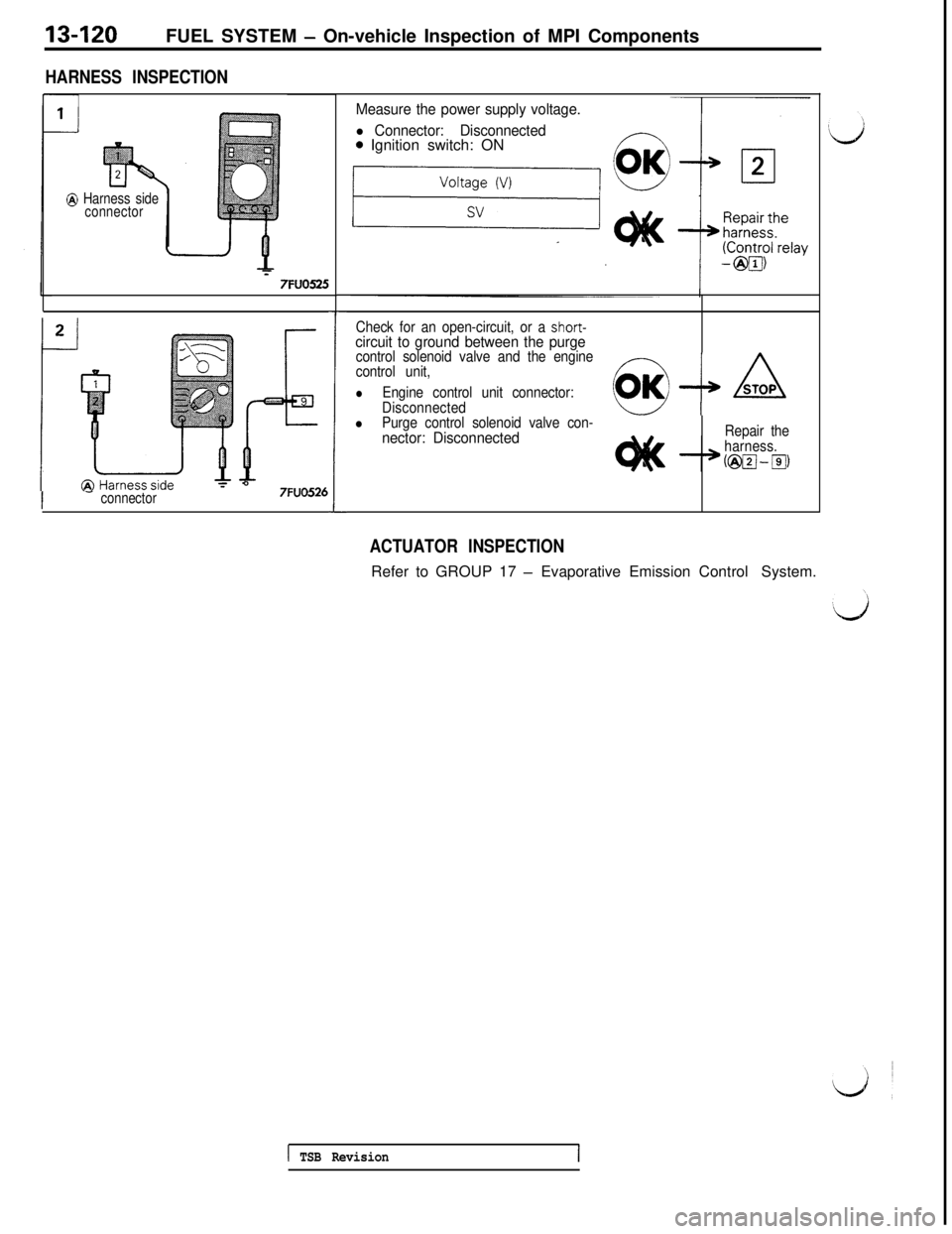

13-120FUEL SYSTEM - On-vehicle Inspection of MPI Components

HARNESS INSPECTION

@ Harness side

connector

T7FUO525

I -connector57FUO526

1

Measure the power supply voltage.

l Connector: Disconnected0 Ignition switch: ON

Check for an open-circuit, or a short-circuit to ground between the purgecontrol solenoid valve and the engine

control unit,

lEngine control unit connector:

Disconnected@-+A

lPurge control solenoid valve con-nector: DisconnectedRepair the

harness.

ACTUATOR INSPECTIONRefer to GROUP 17

- Evaporative Emission Control System.

1 TSB Revision1

Page 227 of 1146

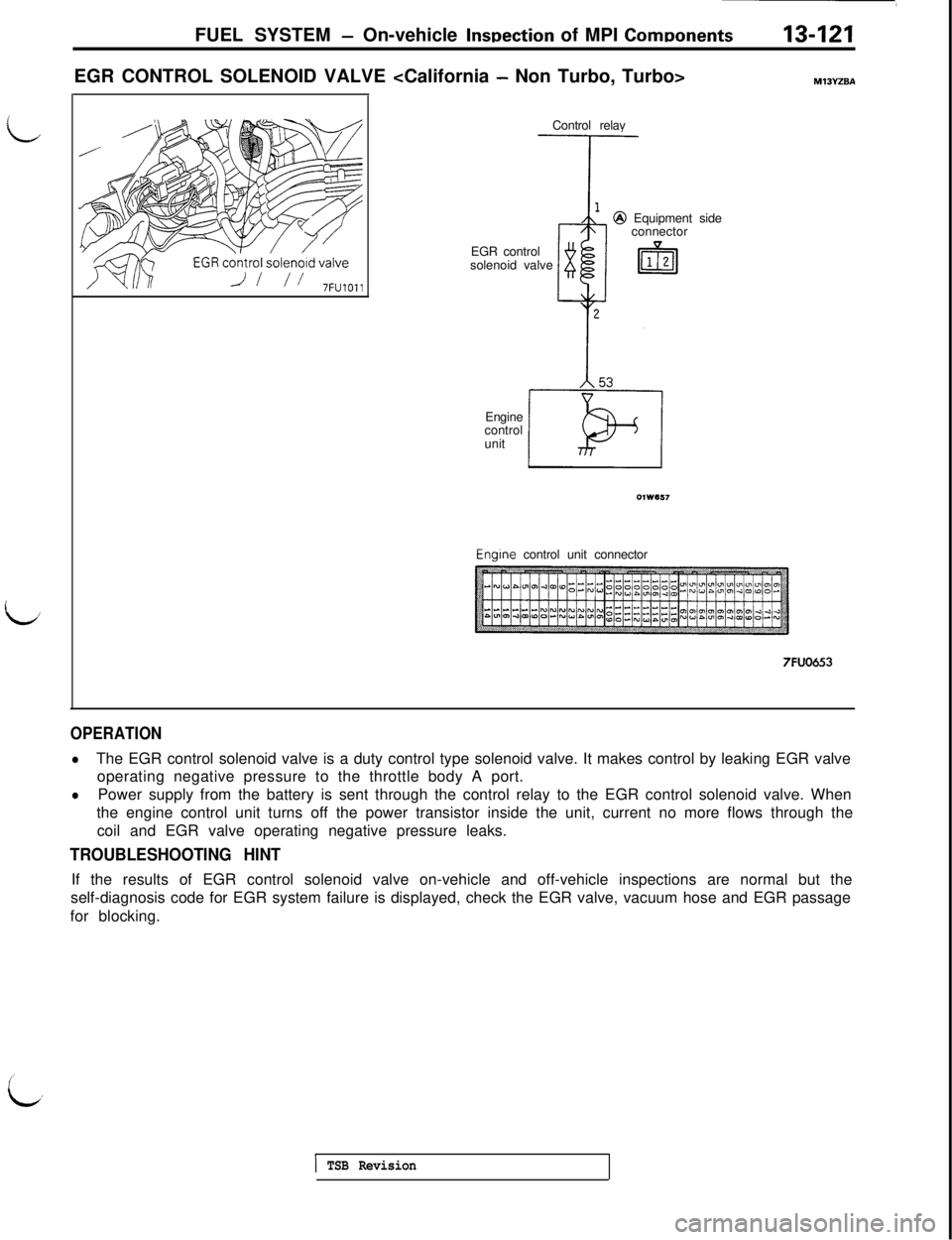

FUEL SYSTEM - On-vehicle lnwection of MPI ComDonents13-121

LEGR CONTROL SOLENOID VALVE

EGR control

solenoid valve@ Equipment side

connector

Engine

control

unitEngine control unit connector

7FUO653

OPERATION

lThe EGR control solenoid valve is a duty control type solenoid valve. It makes control by leaking EGR valve

operating negative pressure to the throttle body A port.

lPower supply from the battery is sent through the control relay to the EGR control solenoid valve. When

the engine control unit turns off the power transistor inside the unit, current no more flows through the

coil and EGR valve operating negative pressure leaks.

TROUBLESHOOTING HINTIf the results of EGR control solenoid valve on-vehicle and off-vehicle inspections are normal but the

self-diagnosis code for EGR system failure is displayed, check the EGR valve, vacuum hose and EGR passage

for blocking.

c.

1 TSB Revision

Page 228 of 1146

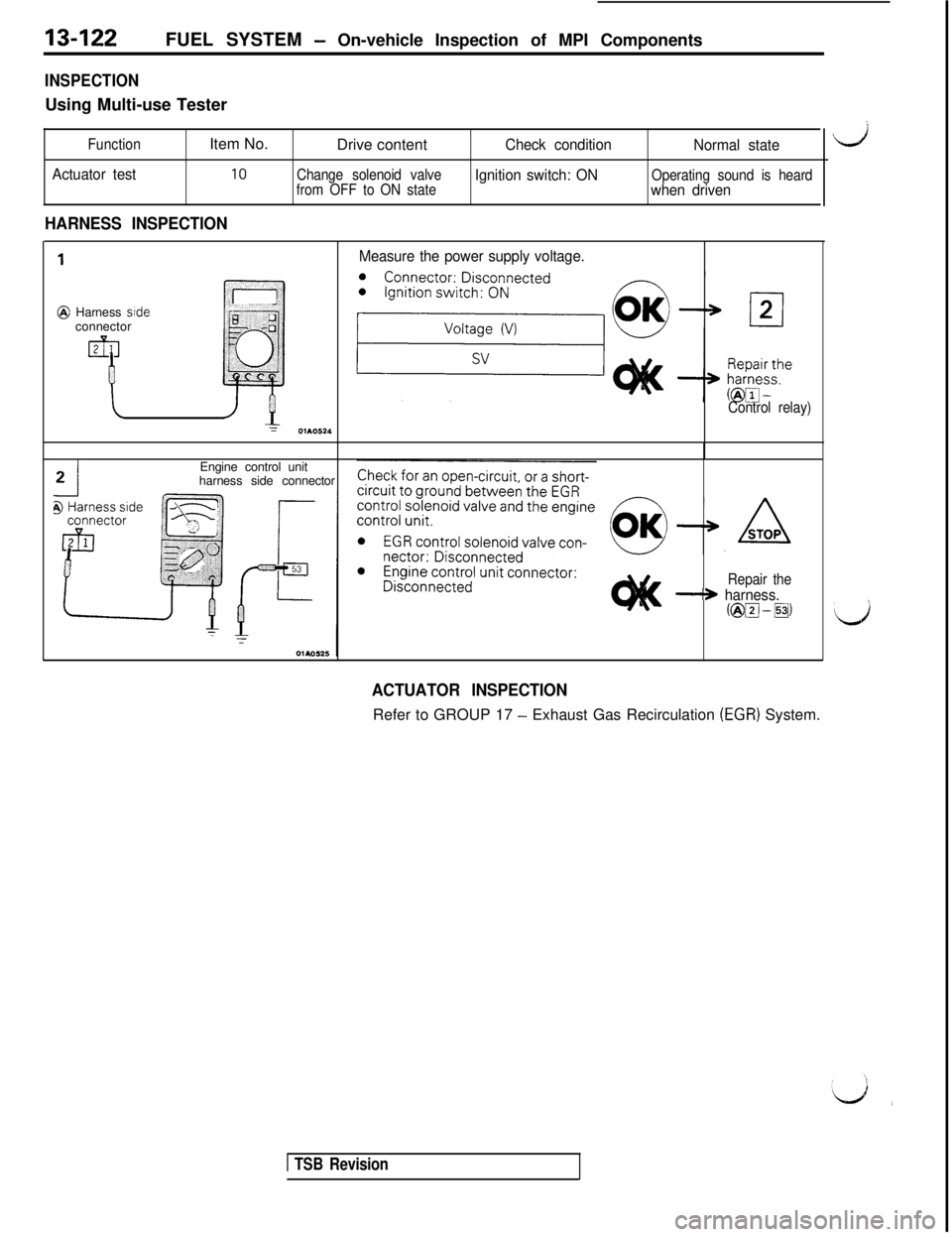

13-122FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use Tester

Function

Actuator testItem No.

Drive content

Check condition

Normal state

10Change solenoid valve

from OFF to ON stateIgnition switch: ONOperating sound is heardwhen driven

HARNESS INSPECTION

1

@ Harness side

connector

Measure the power supply voltage.

Y01105*4Engine control unit

harness side connector

Control relay)

Repair the

-S harness.C@vJ-~)

d

Ls

ACTUATOR INSPECTIONRefer to GROUP 17

- Exhaust Gas Recirculation (EGR) System.

1 TSB Revision

Page 229 of 1146

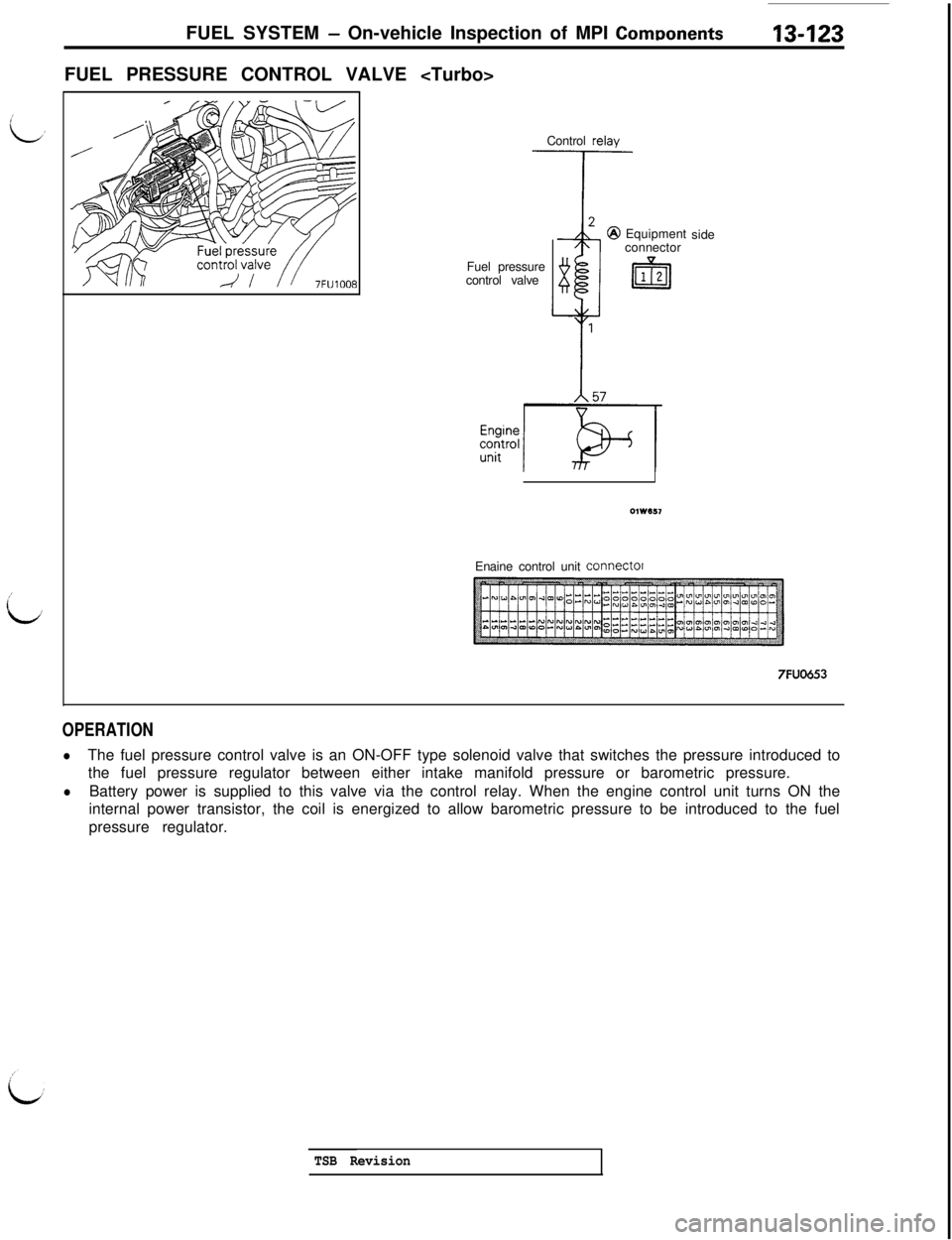

FUEL SYSTEM - On-vehicle Inspection of MPI ComDonents13-123FUEL PRESSURE CONTROL VALVE

Control relay

Fuel pressure

control valveEquipment

connectorside

Enaine control unit

connector

7FUO653

OPERATION

lThe fuel pressure control valve is an ON-OFF type solenoid valve that switches the pressure introduced to

the fuel pressure regulator between either intake manifold pressure or barometric pressure.

lBattery power is supplied to this valve via the control relay. When the engine control unit turns ON the

internal power transistor, the coil is energized to allow barometric pressure to be introduced to the fuel

pressure regulator.

TSB Revision

Page 230 of 1146

13-124FUEL SYSTEM -On-vehicle Inspection of MPI Components

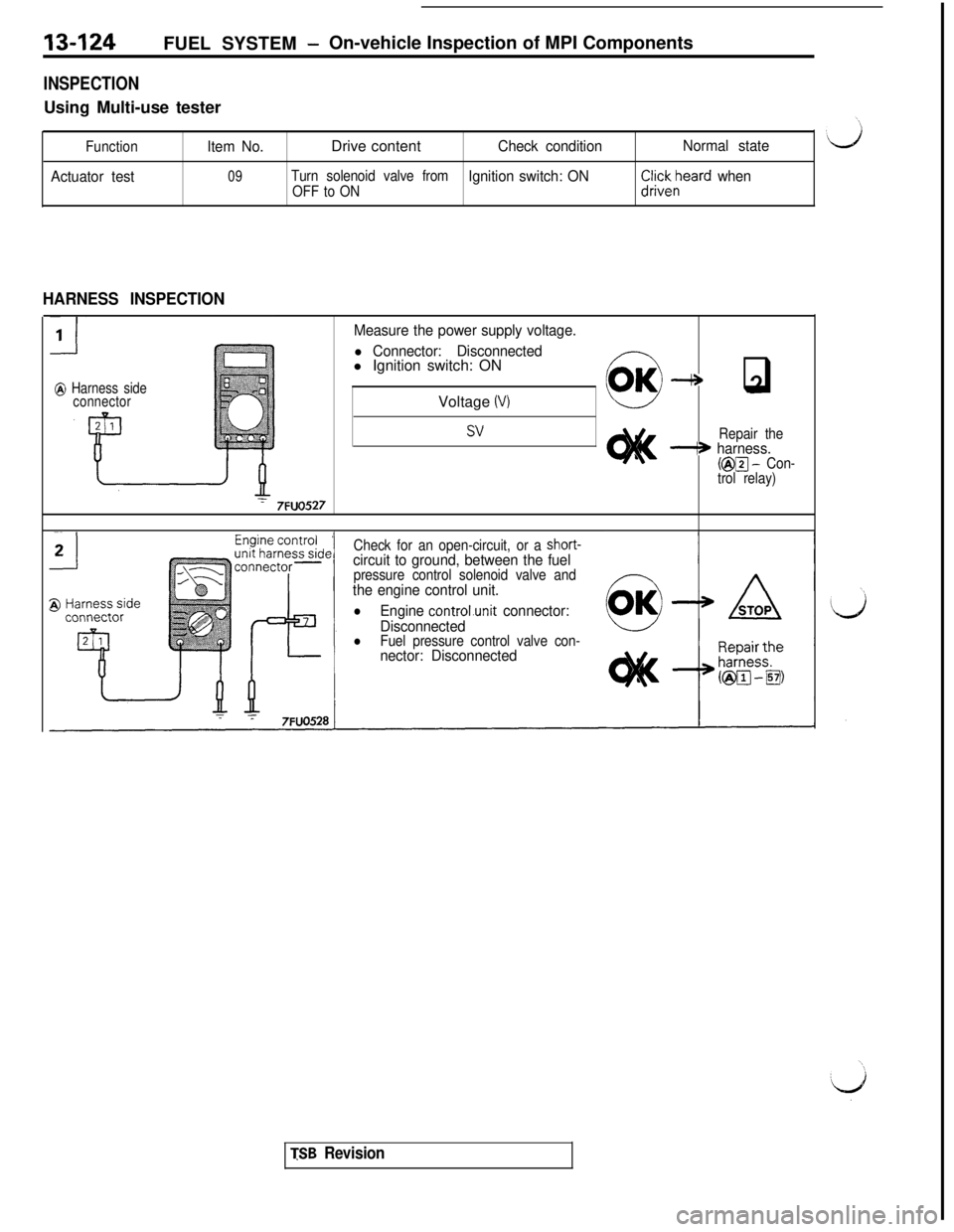

INSPECTIONUsing Multi-use tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

09Turn solenoid valve fromIgnition switch: ONOFF to ONr%;reard when

HARNESS INSPECTION

@ Harness side

connector

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

Voltage

(V)2-* q

SVRepair thei* harness.(@m - Con-

trol relay)

7FUO527

Check for an open-circuit, or a short-circuit to ground, between the fuelpressure control solenoid valve andthe engine control unit.

lEngine controLunit connector:

Disconnected

lFuel pressure control valve con-nector: Disconnected

TSB Revision