MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 201 of 1146

FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components13-95

TROUBLESHOOTING HINTSHint 1: Poor cleaning of exhaust gas will result if the oxygen sensor fails.

Hint 2:If the oxygen sensor check has resulted normal but the sensor output voltage is out of specification,

troubles of parts related to air fuel ratio control system are suspected.

[Examples]

(1) Faulty injector

(2) Air leaking into the intake manifold through gasket gap, etc.

(3) Faulty air flow sensor, intake air temperature sensor, barometric pressure sensor,’ engine

Data readingcoolant temperature sensor

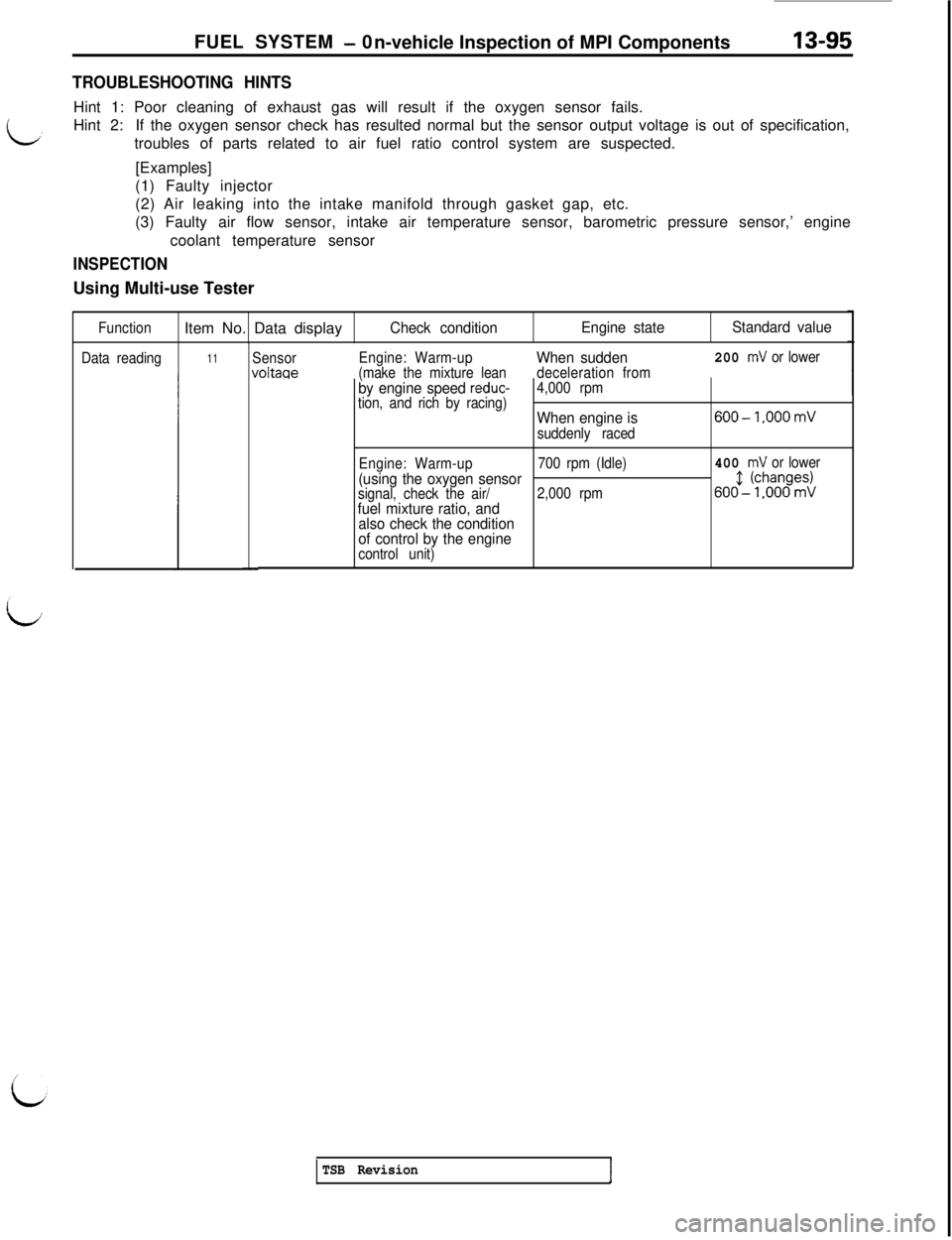

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionEngine stateStandard value

11SensorvoltaceEngine: Warm-upWhen sudden200 mV or lower

(make the mixture leandeceleration from

L

by engine speed reduc-4,000 rpm

tion, and rich by racing)

When engine is600-1,000 mV

suddenly raced

Engine: Warm-up700 rpm (Idle)

400 mV or lower

(using the oxygen sensorsignal, check the air/2,000 rpm,,,5-‘$-$-;3

fuel mixture ratio, and

also check the condition

of control by the engine

control unit)

TSB Revision

Page 202 of 1146

13-96FUEL SYSTEM - 0n-vehicle Inspection of MPI Components

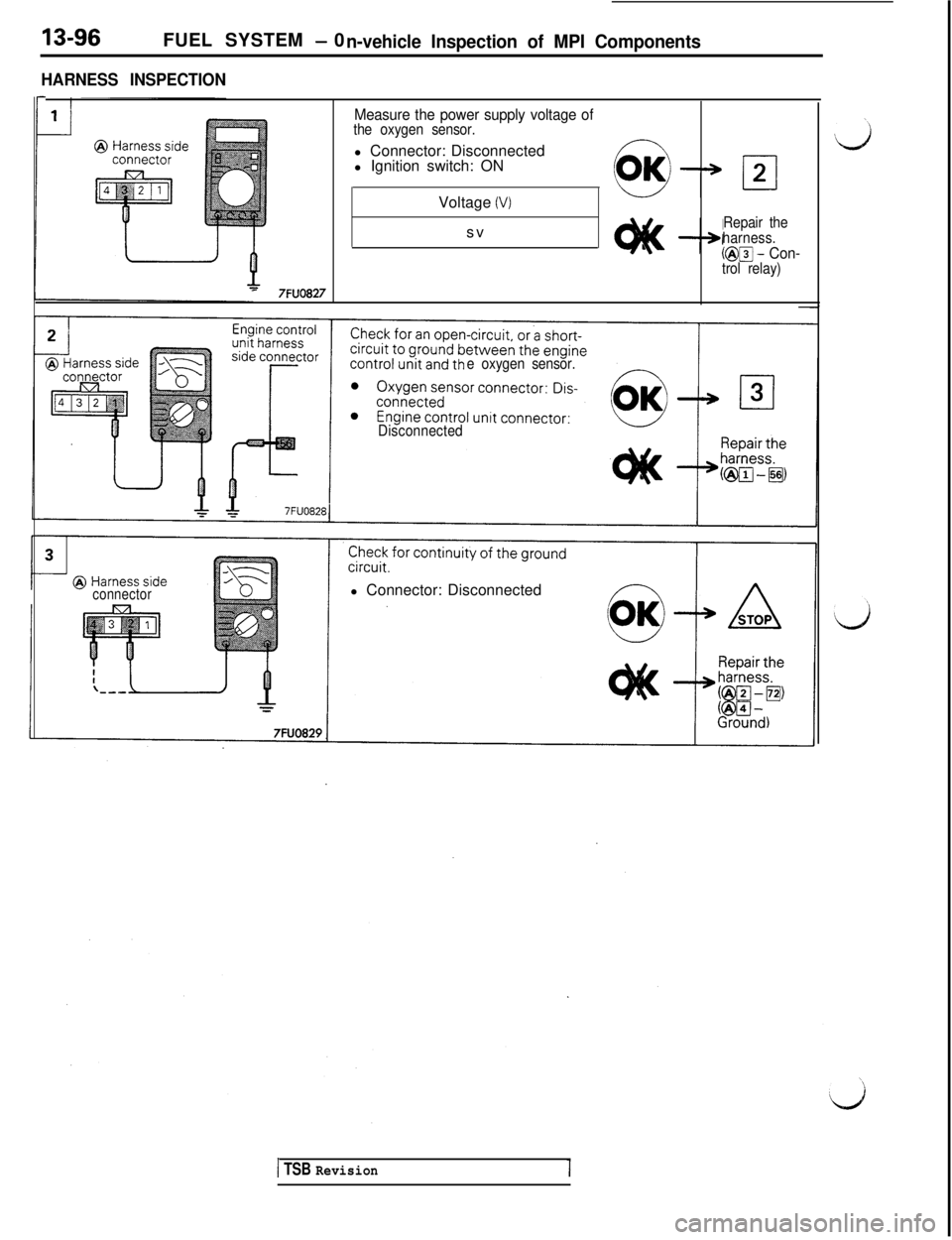

HARNESS INSPECTION

rMeasure the power supply voltage ofthe oxygen sensor.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)sv

Repair the

harness.

(@m - Con-trol relay)

- 7FUO827

e oxygen sensor.

Disconnected

connectorl Connector: Disconnected

1 TSB Revision

Page 203 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI ComDonents13-97

,

7FU1014

7FUlOl5

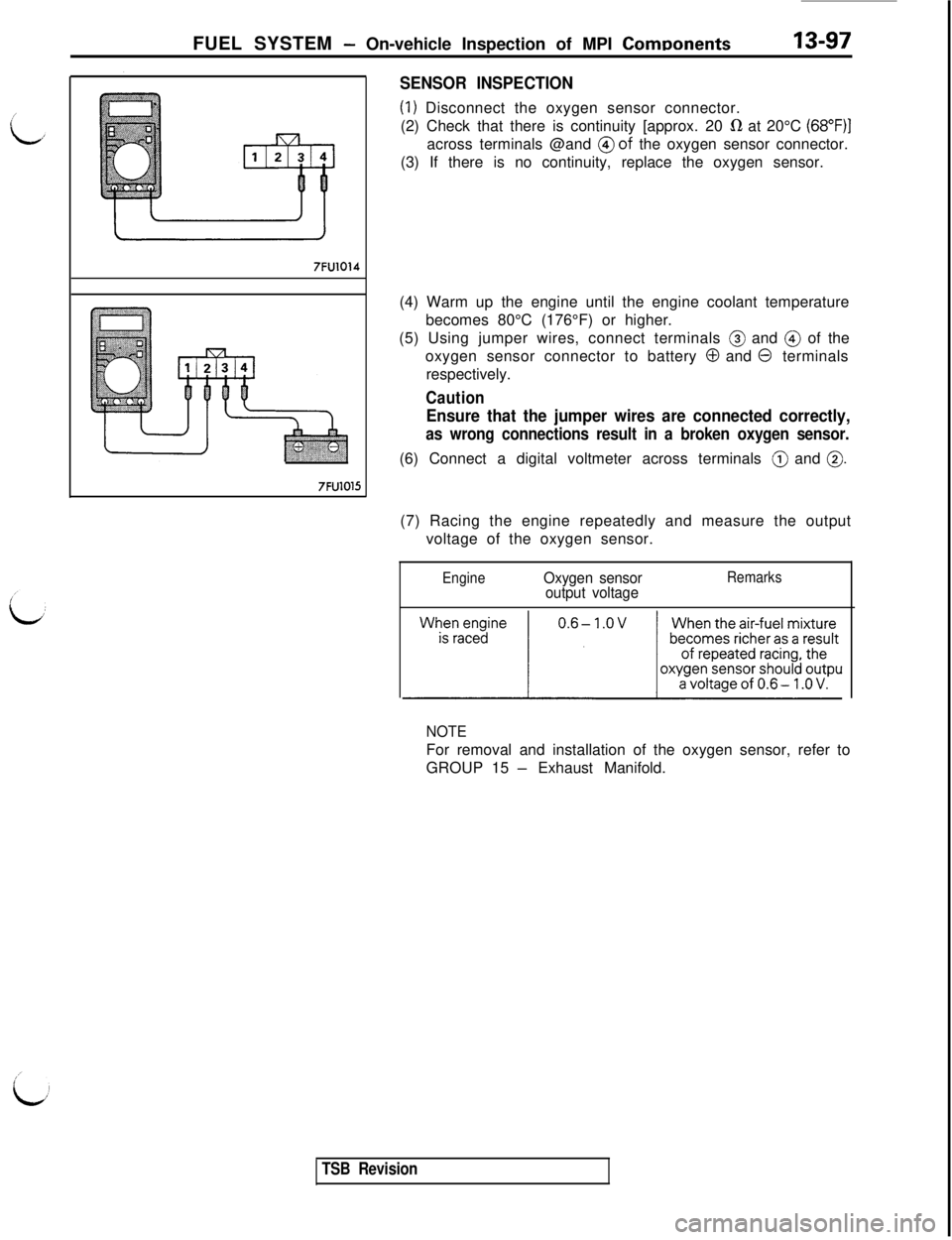

SENSOR INSPECTION

(1) Disconnect the oxygen sensor connector.

(2) Check that there is continuity [approx. 20

IR at 20°C (68”F)jacross terminals @and

@of the oxygen sensor connector.

(3) If there is no continuity, replace the oxygen sensor.

(4) Warm up the engine until the engine coolant temperature

becomes 80°C (176°F) or higher.

(5) Using jumper wires, connect terminals @ and @ of the

oxygen sensor connector to battery

0 and 0 terminals

respectively.

Caution

Ensure that the jumper wires are connected correctly,

as wrong connections result in a broken oxygen sensor.(6) Connect a digital voltmeter across terminals @ and

0.(7) Racing the engine repeatedly and measure the output

voltage of the oxygen sensor.

EngineOxygen sensor

output voltageRemarks

NOTEFor removal and installation of the oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

TSB Revision

Page 204 of 1146

FUEL SYSTEM - 0

n-vehicleInspection of MPI Components

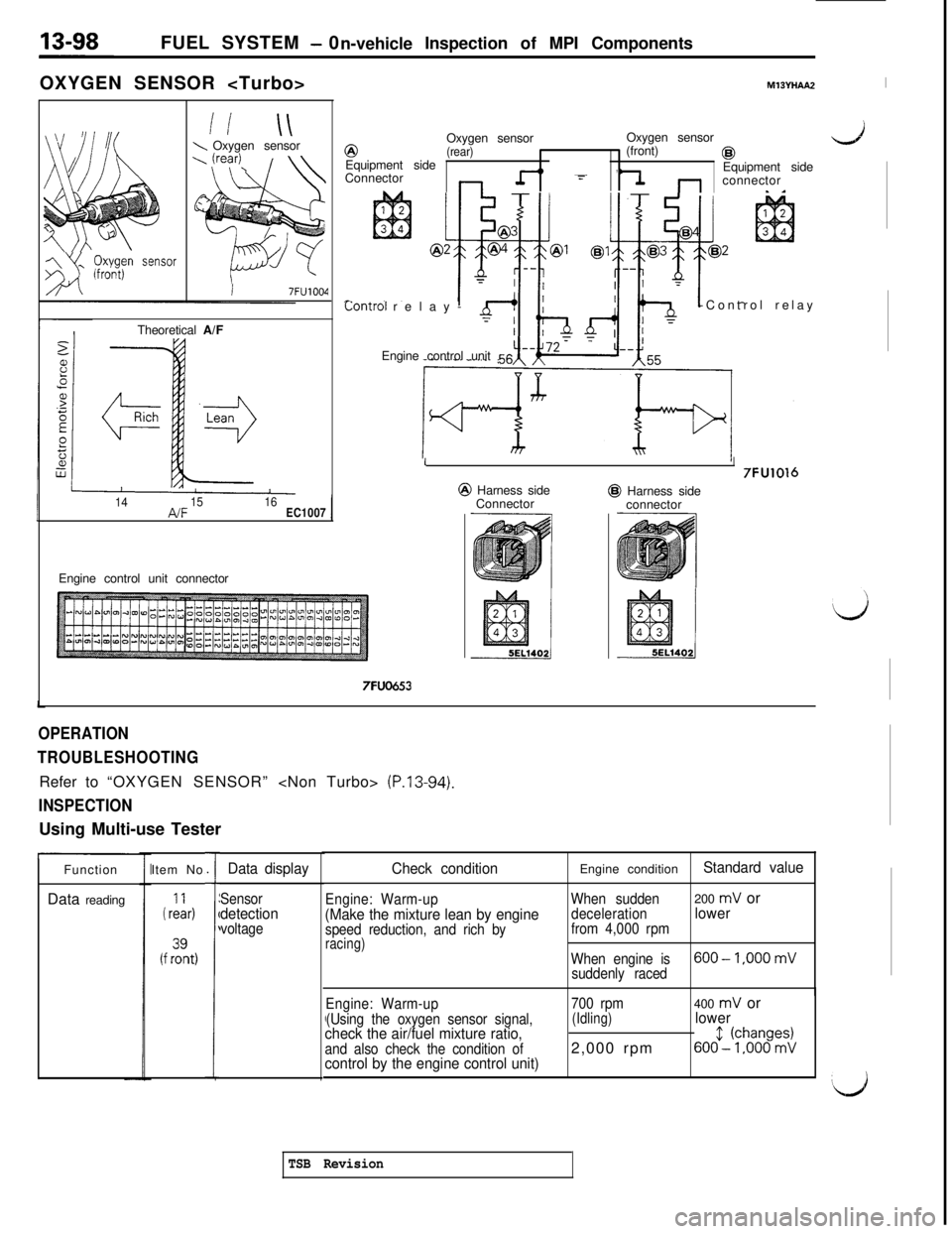

OXYGEN SENSOR

M13YHAA2I

2

2-J

_ Fr;;syn m-wr

li \\\Oxygen sensor

I7FU1004Theoretical A/F@Oxygen sensor

(rear)Oxygen sensor

Equipment side(front)@,ConnectorEquipment side:connectorf-l -1

Lonrrol relay--Control relay

Engine control unit 56

141516PJFEC1007Engine control unit connector

7FUO453

I

I7FU1016@ Harness side@ Harness side

Connector

connector

OPERATION

TROUBLESHOOTINGRefer to “OXYGEN SENSOR”

(P.13-94).

INSPECTIONUsing Multi-use Tester

Function

Data readingItem No.

i rL&

(f fzt,

,

1

Data display

Sensordetectionvoltage

Check condition

Engine: Warm-up(Make the mixture lean by enginespeed reduction, and rich byracing)Engine condition

Standard value

When sudden200 mV or

decelerationlowerfrom 4,000 rpm

When engine is

600-1.000 mV

suddenly raced

./

Engine: Warm-up

(Using the oxygen sensor signal,

check the air/fuel mixture ratio,and also check the condition ofcontrol by the engine control unit)

700 rpm(Idling)2,000 rpm400 mV orlower

6()(f--(~jbaono9~;

‘d

TSB Revision

Page 205 of 1146

1

FUEL SYSTEM- On-vehicle InsDection of MPI ComDonents13-99

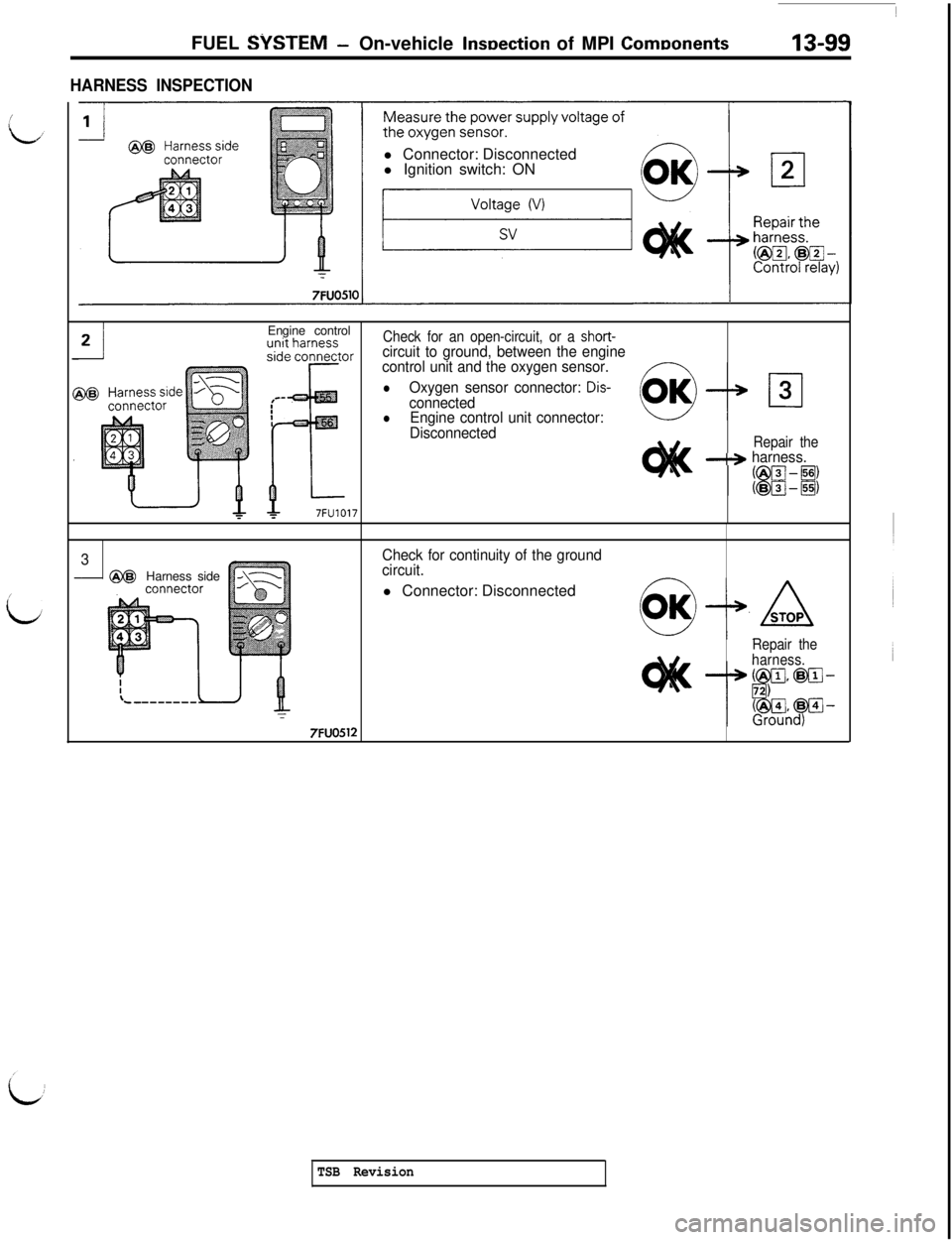

HARNESS INSPECTIONl Connector: Disconnected

l Ignition switch: ON

Engine control

Check for an open-circuit, or a short-circuit to ground, between the engine

control unit and the oxygen sensor.

lOxygen sensor connector: Dis-connectedlEngine control unit connector:

Disconnected

Repair the-+ harness.

3Check for continuity of the ground

- @@

Harness sidecircuit.l Connector: Disconnected

Repair the

harness.

7FUO512

TSB Revision

Page 206 of 1146

13-100FUEL SYSTEM - 0

n-vehicleInspection of MPI Components

SENSOR INSPECTION

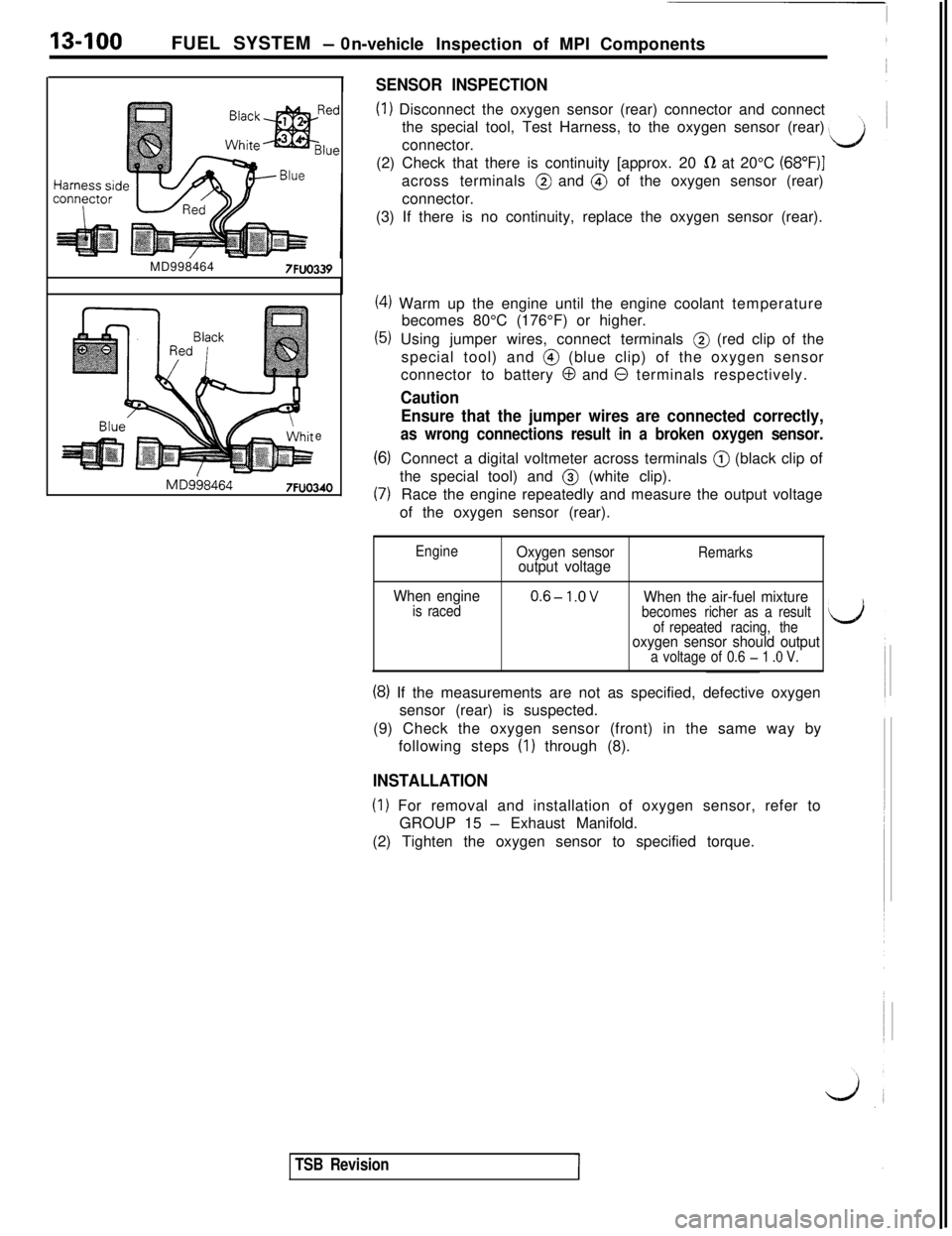

(1) Disconnect the oxygen sensor (rear) connector and connect

the special tool, Test Harness, to the oxygen sensor (rear)

connector.

MD998464

7FUO339

e

MD9584647FUO340(2) Check that there is continuity [approx. 20

R at 20°C (68”F)Iacross terminals @ and @ of the oxygen sensor (rear)

connector.

(3) If there is no continuity, replace the oxygen sensor (rear).

(4) Warm up the engine until the engine coolant temperature

becomes 80°C (176°F) or higher.

(5) Using jumper wires, connect terminals @ (red clip of the

special tool) and @ (blue clip) of the oxygen sensor

connector to battery

0 and 0 terminals respectively.

Caution

Ensure that the jumper wires are connected correctly,

as wrong connections result in a broken oxygen sensor.

(6)Connect a digital voltmeter across terminals @ (black clip of

(7)the special tool) and @ (white clip).

Race the engine repeatedly and measure the output voltage

of the oxygen sensor (rear).

EngineOxygen sensor

output voltageRemarks

When engineis raced0.6-l.OVWhen the air-fuel mixturebecomes richer as a result

of repeated racing, the

oxygen sensor should outputa voltage of 0.6 - 1 .O V.

(8) If the measurements are not as specified, defective oxygen

sensor (rear) is suspected.

(9) Check the oxygen sensor (front) in the same way by

following steps

(I) through (8).

INSTALLATION

(1) For removal and installation of oxygen sensor, refer to

GROUP 15

- Exhaust Manifold.

(2) Tighten the oxygen sensor to specified torque.

TSB Revision

Page 207 of 1146

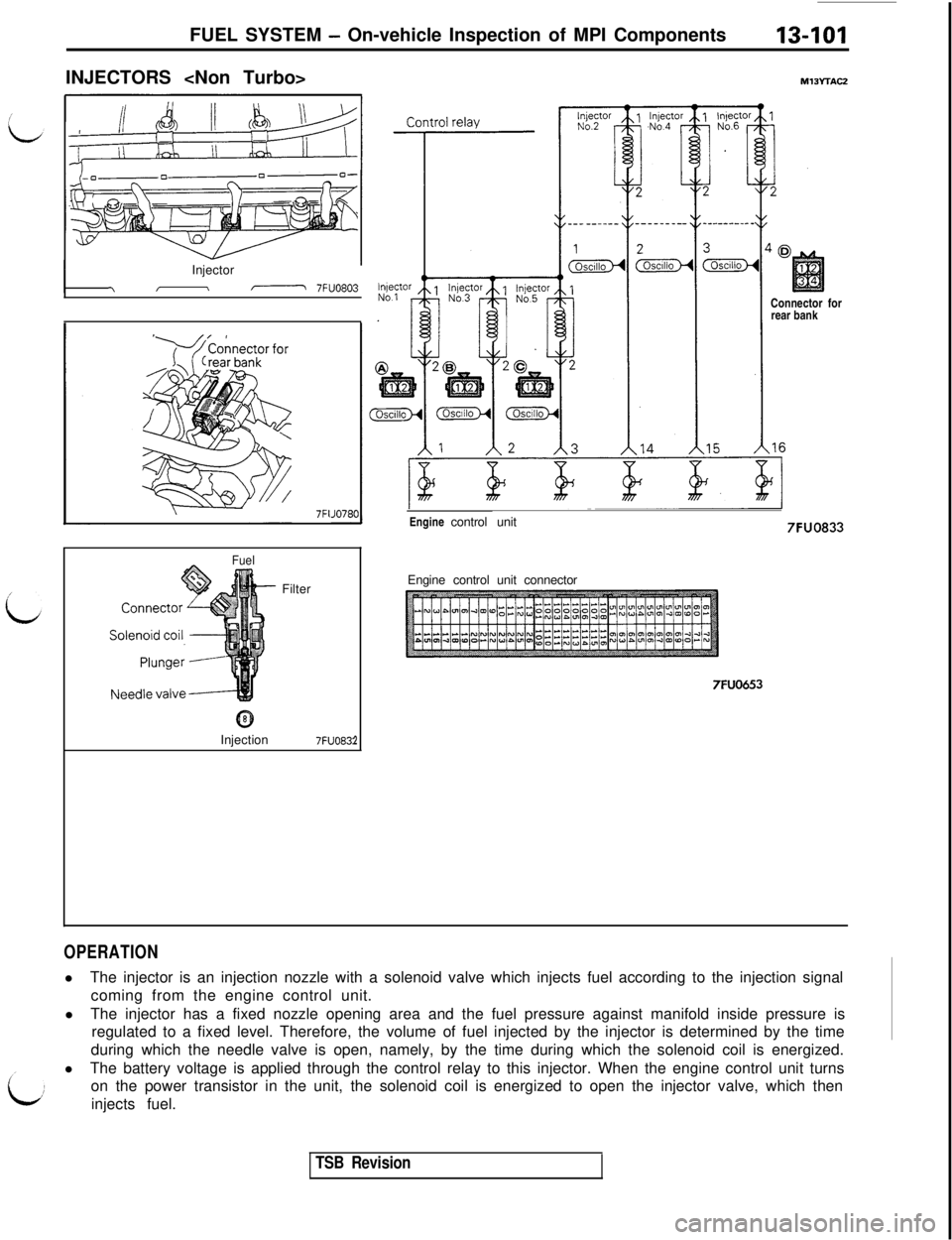

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-101INJECTORS

M13YTAC2

IInjectorII\- 7FUO803

7FI

FuelFilter

@Injection

7FUO83:2Connector for

rear bank

Engine control unit7FUO833

Engine control unit connector

7FUO653

OPERATIONlThe injector is an injection nozzle with a solenoid valve which injects fuel according to the injection signal

coming from the engine control unit.

lThe injector has a fixed nozzle opening area and the fuel pressure against manifold inside pressure is

regulated to a fixed level. Therefore, the volume of fuel injected by the injector is determined by the time

during which the needle valve is open, namely, by the time during which the solenoid coil is energized.

lThe battery voltage is applied through the control relay to this injector. When the engine control unit turns

on the power transistor in the unit, the solenoid coil is energized to open the injector valve, which then

injects fuel.

TSB Revision

Page 208 of 1146

13-102FUEL SYSTEM - On-vehicle Inspection of MPI Components

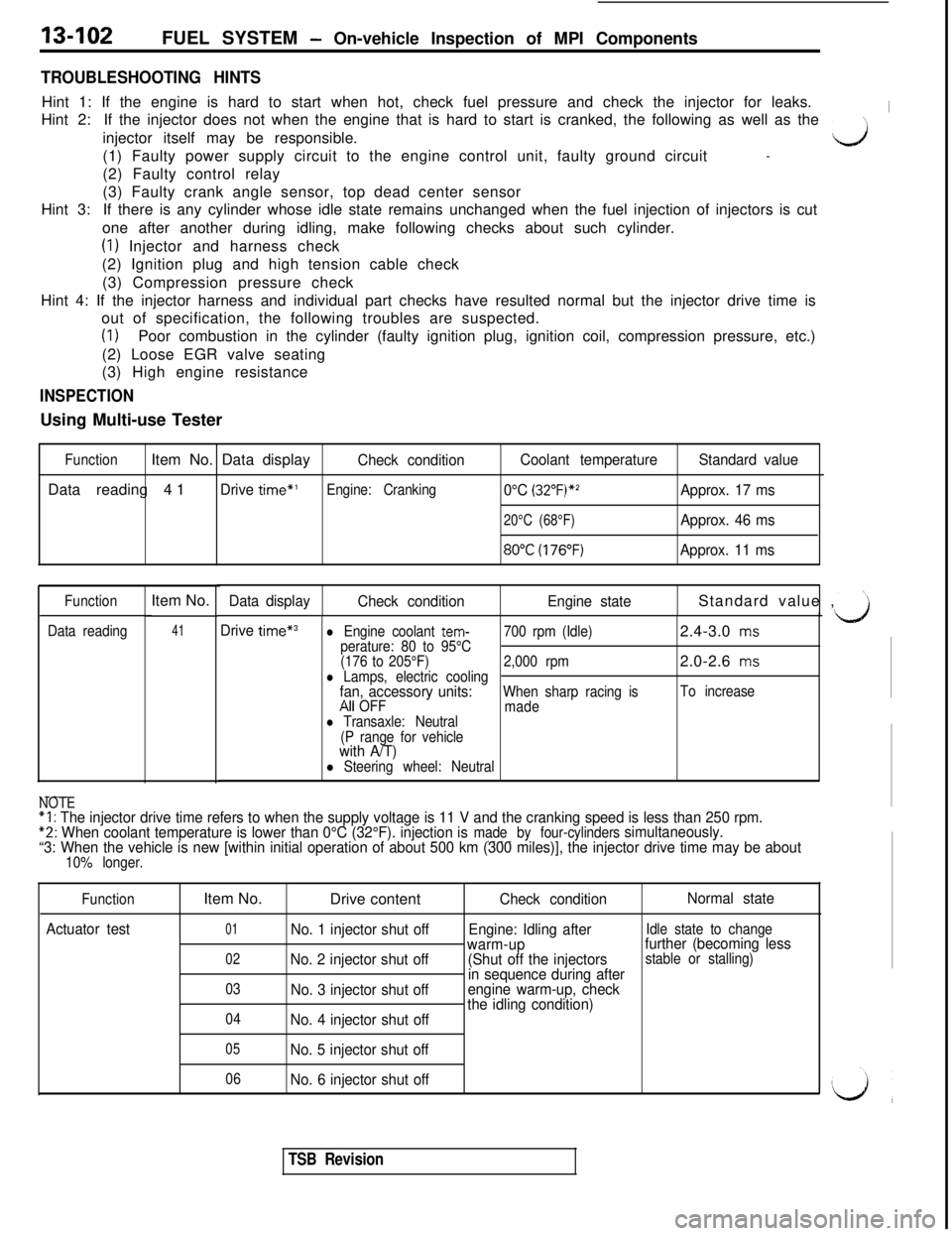

TROUBLESHOOTING HINTSHint 1: If the engine is hard to start when hot, check fuel pressure and check the injector for leaks.

Hint 2:If the injector does not when the engine that is hard to start is cranked, the following as well as the

Iinjector itself may be responsible.

(1) Faulty power supply circuit to the engine control unit, faulty ground circuit

\-J

-(2) Faulty control relay

Hint 3:(3) Faulty crank angle sensor, top dead center sensor

If there is any cylinder whose idle state remains unchanged when the fuel injection of injectors is cut

one after another during idling, make following checks about such cylinder.

(1) Injector and harness check

(2) Ignition plug and high tension cable check

(3) Compression pressure check

Hint 4: If the injector harness and individual part checks have resulted normal but the injector drive time is

out of specification, the following troubles are suspected.

(1)Poor combustion in the cylinder (faulty ignition plug, ignition coil, compression pressure, etc.)

(2) Loose EGR valve seating

(3) High engine resistance

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck conditionCoolant temperatureStandard valueData reading 41

Drive time”’Engine: Cranking0°C (32”F)*zApprox. 17 ms

20°C (68°F)Approx. 46 ms

8O"C(176"F)Approx. 11 ms

Function

Data readingItem No.Data display

41Drive time*3l Engine coolant tem-perature: 80 to 95°C700 rpm (Idle)2.4-3.0 ms

(176 to 205°F)2,000 rpm2.0-2.6

msl Lamps, electric coolingfan, accessory units:When sharp racing isTo increaseAll OFF

madel Transaxle: Neutral

(P range for vehicle

with A/T)l Steering wheel: Neutral

Check conditionEngine stateStandard value ,

.---NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.*2: When coolant temperature is lower than 0°C (32°F). injection ismade by four-cylinders.---simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive content

Check conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to change

02No. 2 injector shut offwarm-up

(Shut off the injectorsfurther (becoming less

in sequence during afterstable or stalling)

03

No. 3 injector shut offengine warm-up, check

04No. 4 injector shut offthe idling condition)

05No. 5 injector shut off

06No. 6 injector shut off

TSB Revision

Page 209 of 1146

FUEL SYSTEM- Ori-vehicle lnwection of MPI ComDonents13403

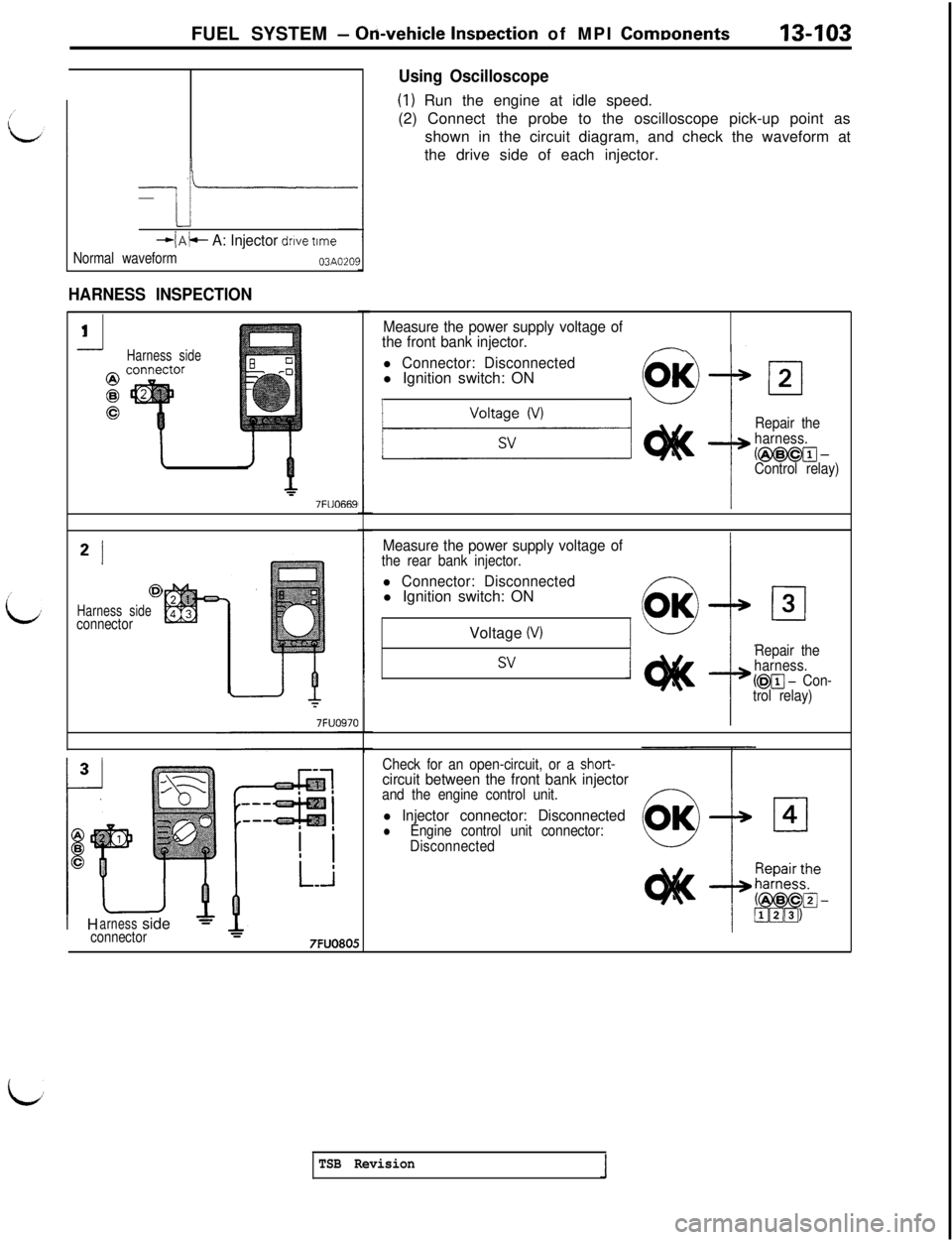

+/A+ A: Injector drive time

Normal waveform03A0201

HARNESS INSPECTION

--J1

Harness side

7FlJO669

* I

@

Harness side

connector

1 HarnessJPside =connector7FUO805

Using Oscilloscope

(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.

Measure the power supply voltage of

the front bank injector.

-

l Connector: Disconnectedl Ignition switch: ON

1

Repair the

harness.

(m-Control relay)

Measure the power supply voltage ofthe rear bank injector.

l Connector: Disconnectedl Ignition switch: ON

Voltage

(VI

svRepair the

harness.

(m - Con-

trol relay)

Check for an open-circuit, or a

short-circuit between the front bank injectorand the engine control unit.

l Injector connector: DisconnectedlEngine control unit connector:

Disconnected

id

TSB Revision

Page 210 of 1146

13-104FUEL SYSTEM - On-vehicle Inspection of MPI Components

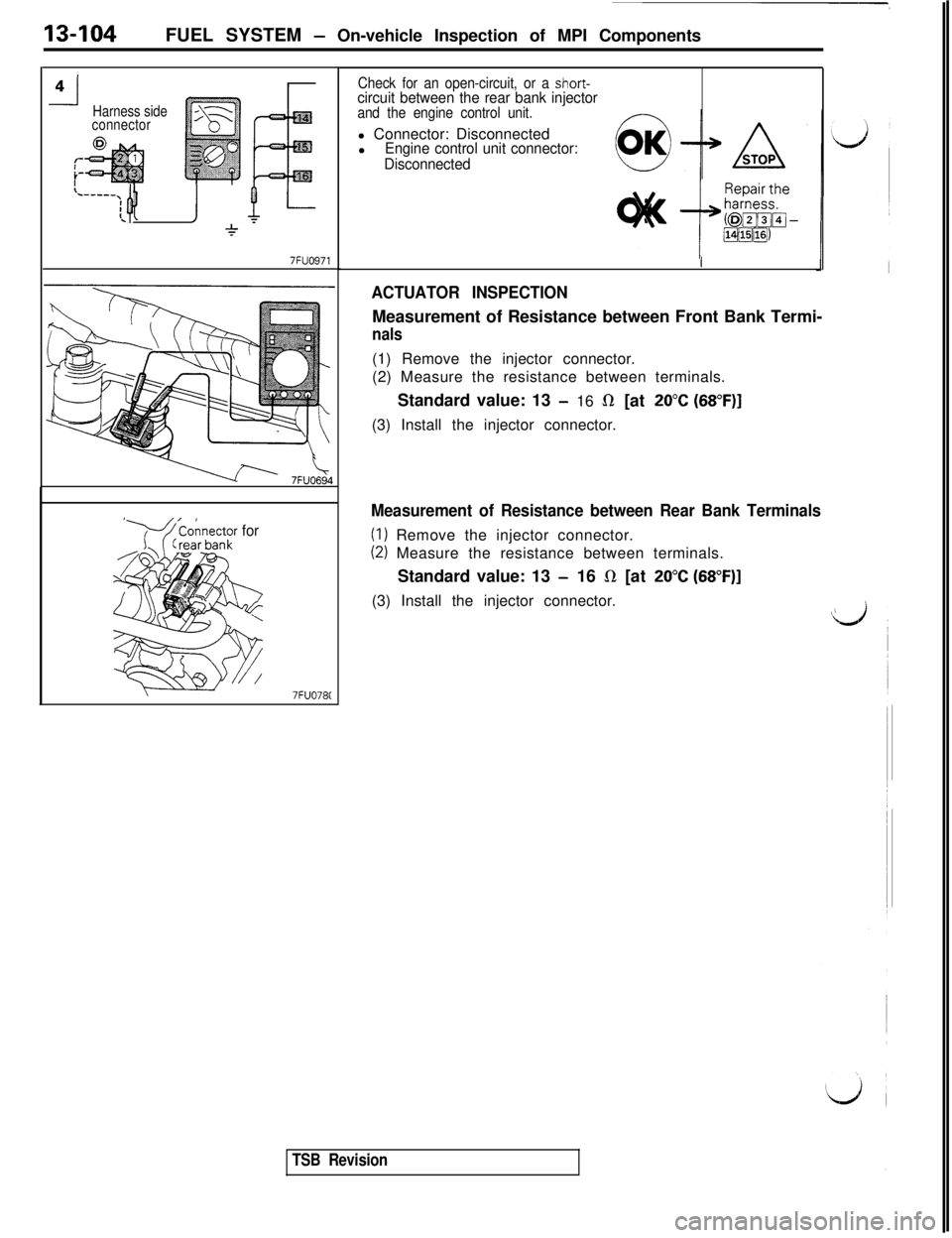

-l4Harness side

connector

L----.[ Q1J

7FUO971

‘Y-4 ’onnector for

7FUO78C

Check for an open-circuit, or a short-circuit between the rear bank injectorand the engine control unit.l Connector: Disconnected

l

Engine control unit connector:

Disconnected

I

ACTUATOR INSPECTIONMeasurement of Resistance between Front Bank Termi-

nals(1) Remove the injector connector.

(2) Measure the resistance between terminals.

Standard value: 13

- 16 il [at 20°C (68”F)](3) Install the injector connector.

Measurement of Resistance between Rear Bank Terminals

(I) Remove the injector connector.

(2) Measure the resistance between terminals.

Standard value: 13

- 16 Q [at 20°C (68”F)](3) Install the injector connector.

\

TSB Revision