MITSUBISHI 3000GT 1991 Service Manual

3000GT 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57085/w960_57085-0.png

MITSUBISHI 3000GT 1991 Service Manual

Trending: tow bar, fuse diagram, fuse chart, clock setting, radiator, fuel additives, wheel bolts

Page 231 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-125

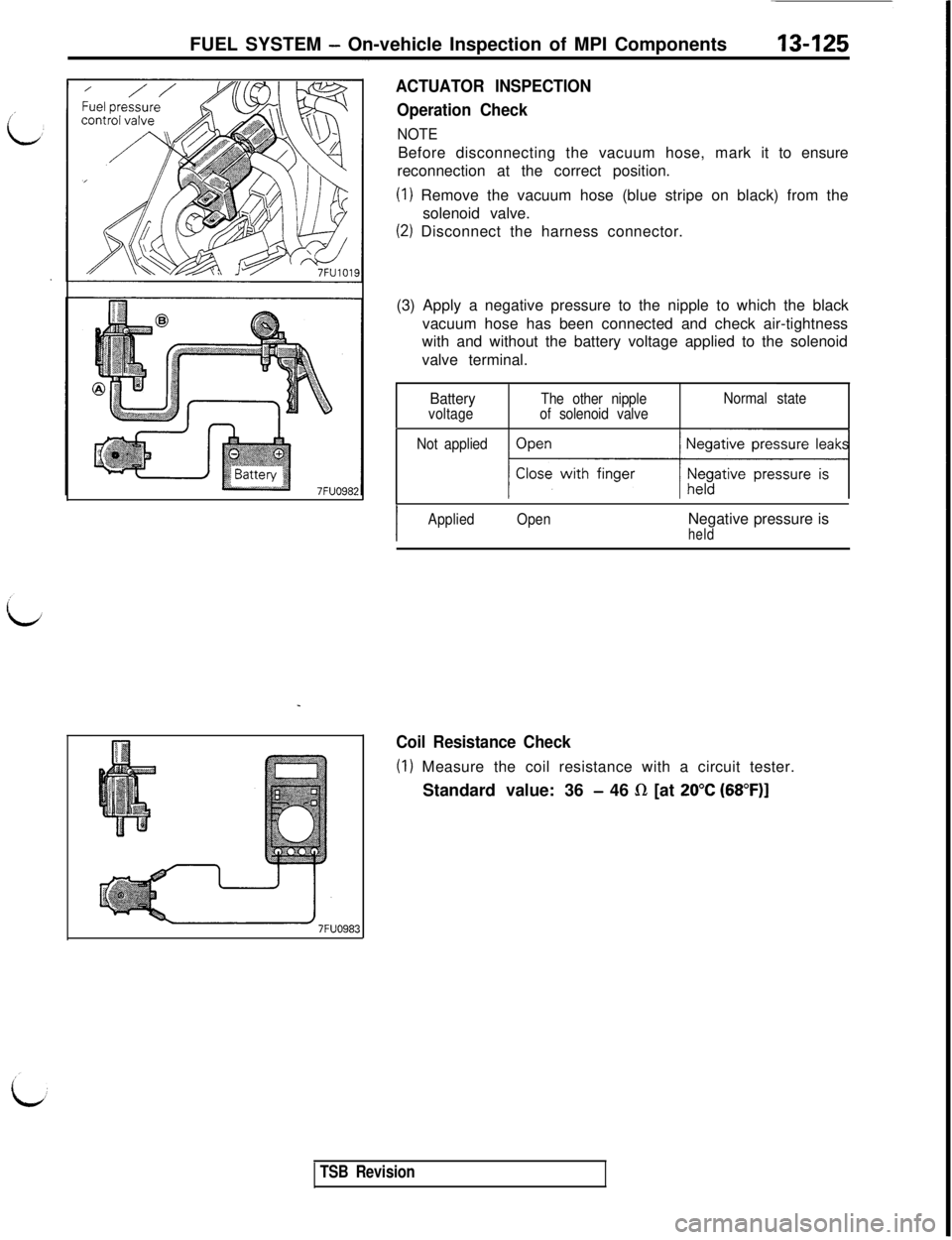

ACTUATOR INSPECTION

Operation Check

NOTEBefore disconnecting the vacuum hose, mark it to ensure

reconnection at the correct position.

(1) Remove the vacuum hose (blue stripe on black) from the

solenoid valve.

(2) Disconnect the harness connector.

(3) Apply a negative pressure to the nipple to which the black

vacuum hose has been connected and check air-tightness

with and without the battery voltage applied to the solenoid

valve terminal.

BatteryvoltageThe other nipple

of solenoid valveNormal state

Not applied

qj

I

AppliedOpenNegative pressure isheld

Coil Resistance Check

(I) Measure the coil resistance with a circuit tester.

Standard value: 36

- 46 R [at 20°C (68”F)]

TSB Revision

Page 232 of 1146

13-126FUEL SYSTEM - On-vehicle Inspection of MPI Components

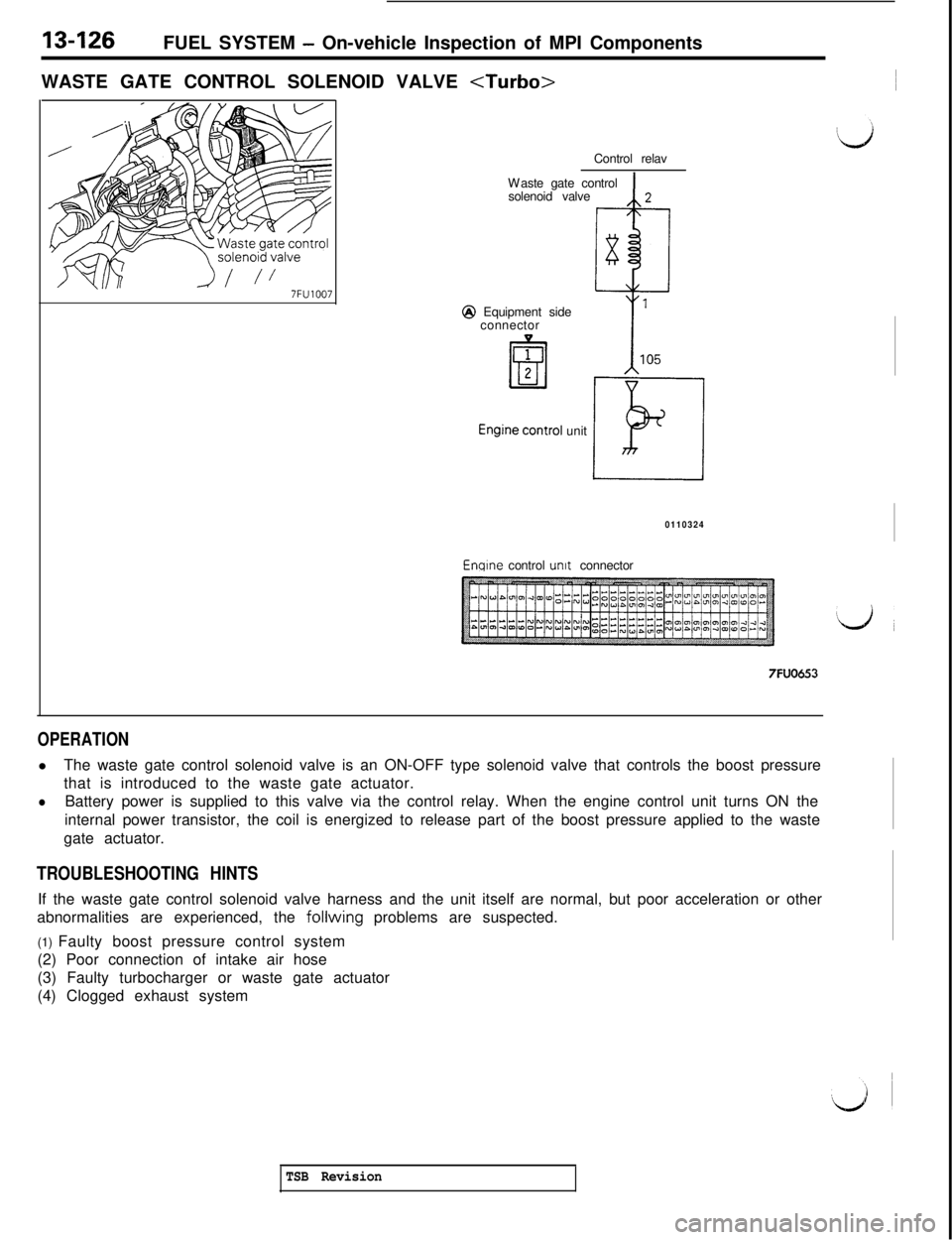

WASTE GATE CONTROL SOLENOID VALVE

7FU1007Control relav

Waste gate control

solenoid valve

Q Equipment side

connector

unit

0110324Enqlne control unit connector

7FUO653

OPERATIONlThe waste gate control solenoid valve is an ON-OFF type solenoid valve that controls the boost pressure

that is introduced to the waste gate actuator.

lBattery power is supplied to this valve via the control relay. When the engine control unit turns ON the

internal power transistor, the coil is energized to release part of the boost pressure applied to the waste

gate actuator.

TROUBLESHOOTING HINTSIf the waste gate control solenoid valve harness and the unit itself are normal, but poor acceleration or other

abnormalities are experienced, the

follwing problems are suspected.

(1) Faulty boost pressure control system

(2) Poor connection of intake air hose

(3) Faulty turbocharger or waste gate actuator

(4) Clogged exhaust system

TSB Revision

Page 233 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components'13-127

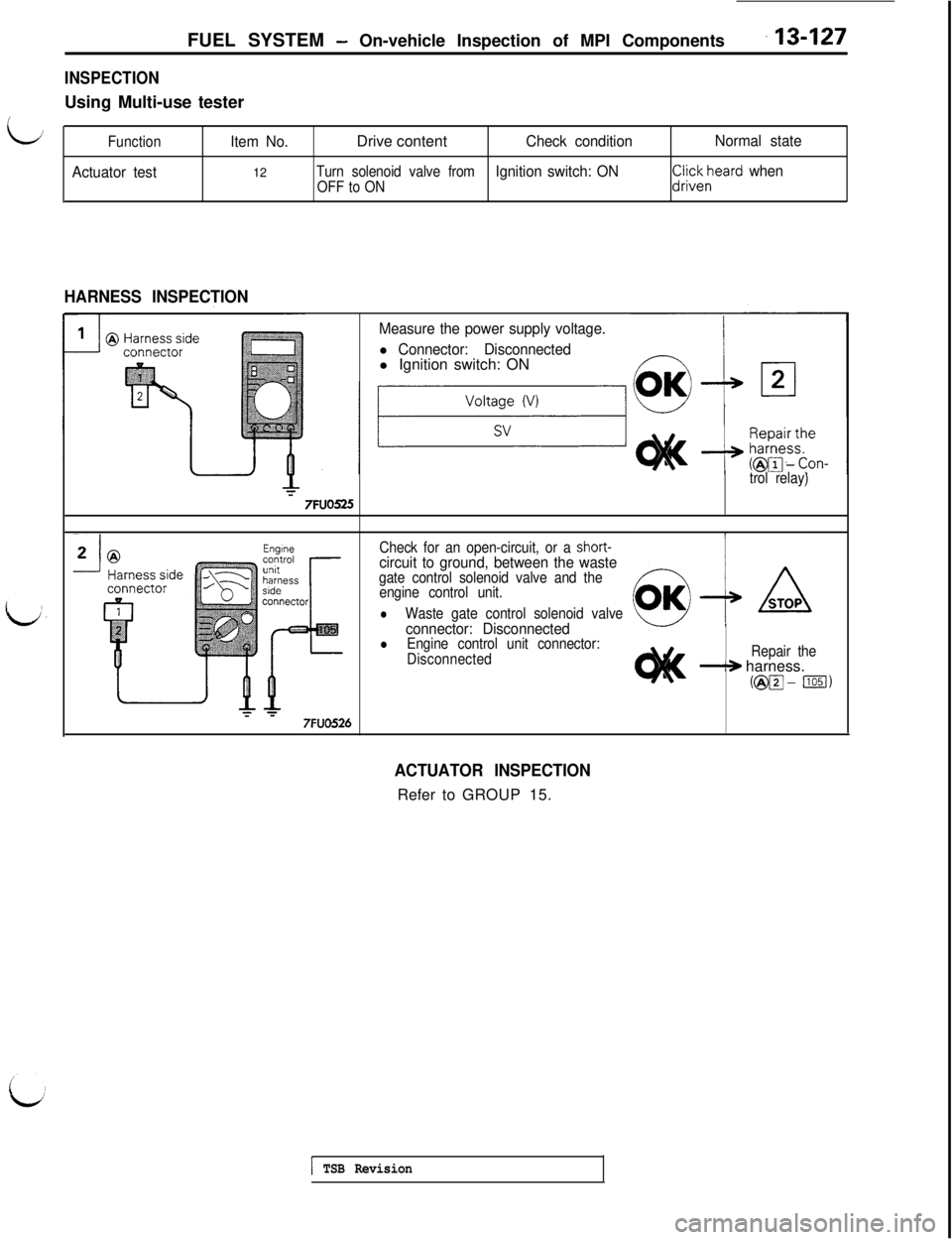

INSPECTIONUsing Multi-use tester

LFunctionItem No.Drive contentCheck conditionNormal state

Actuator test12

Turn solenoid valve fromIgnition switch: ONOFF to ON

CliZli~,“eard when

HARNESS INSPECTION

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

trol relay)

7FUO525

Check for an open-circuit, or a short-circuit to ground, between the wastegate control solenoid valve and the

engine control unit.

lWaste gate control solenoid valveconnector: DisconnectedlEngine control unit connector:

DisconnectedRepair the

-+ harness.

(@m- ml)

7FUO526

ACTUATOR INSPECTIONRefer to GROUP 15.

1 TSB Revision

Page 234 of 1146

13-128FUEL SYSTEM - On-vehicle Inspection of MPI Components

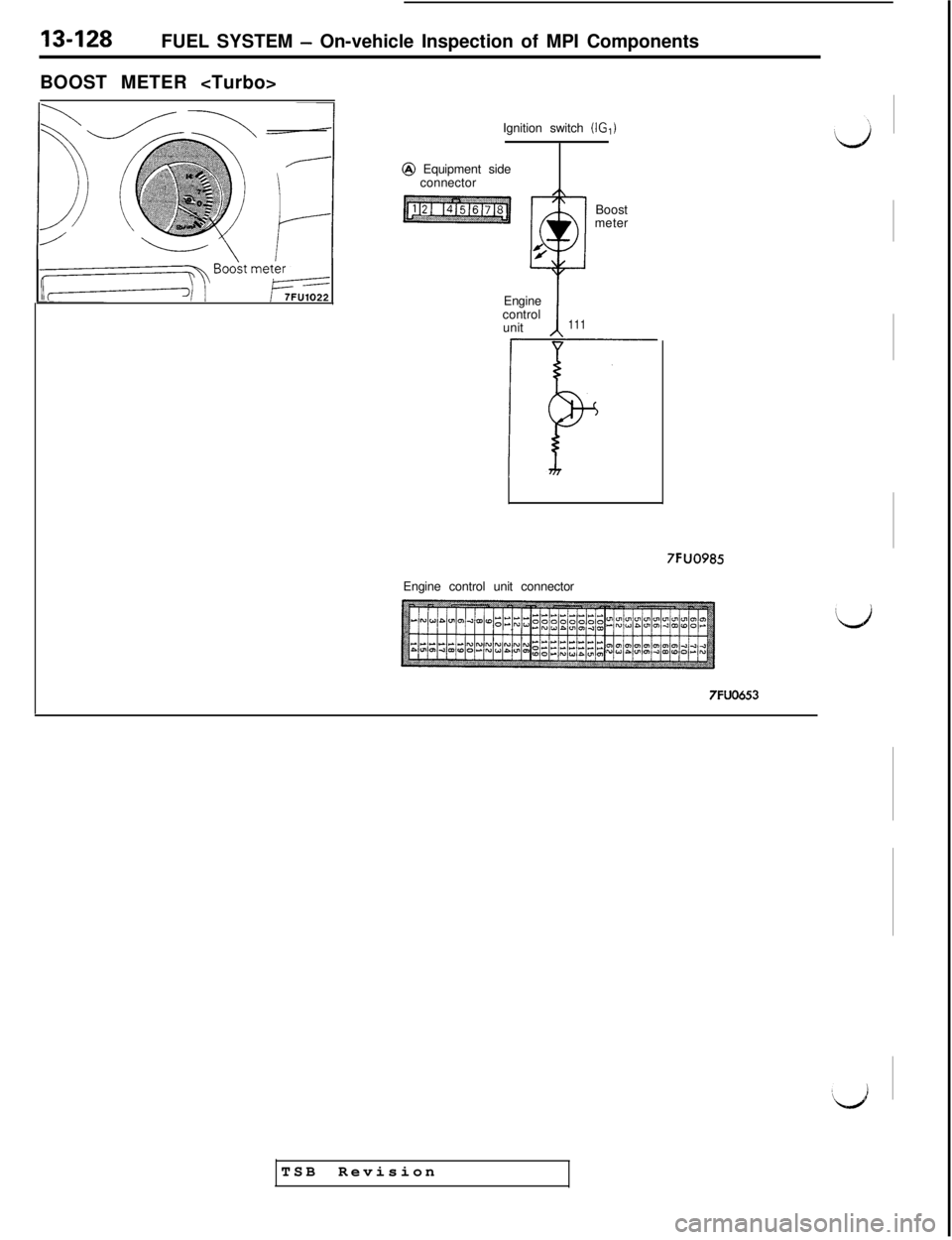

BOOST METER

Ignition switch

(IG,)@ Equipment side

connector

Boost

meter

Engine

control

unit

111

i-F7FUO985

Engine control unit connector

TSB Revision

Page 235 of 1146

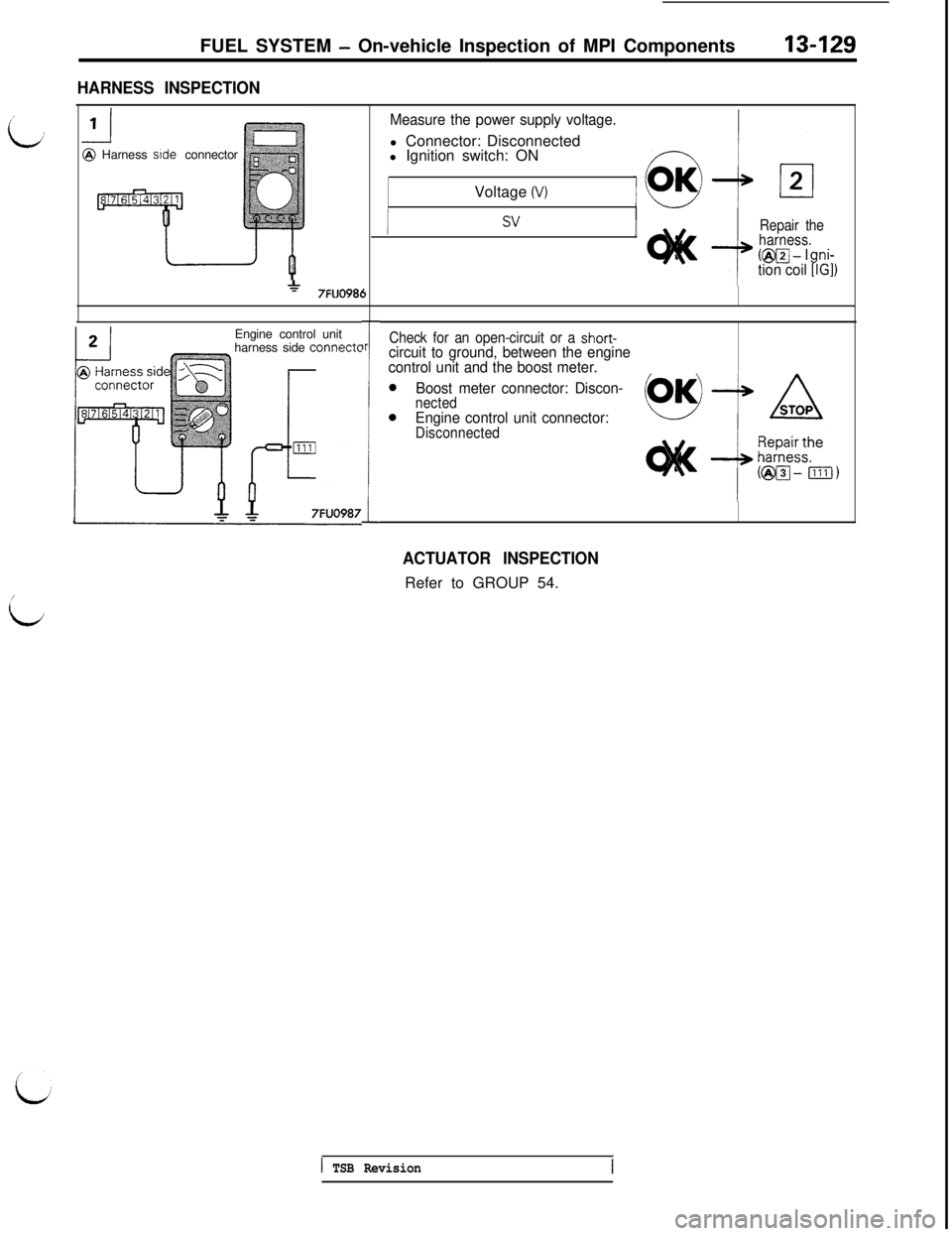

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-129

i

HARNESS INSPECTION@ Harness side connector

*7FUO986Engine control unit

harness side

connect0r

1

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)

svRepair the

harness.

(@I@-- Ini-tion coil9IG])

Check for an open-circuit or a short-circuit to ground, between the engine

control unit and the boost meter.

Boost meter connector: Discon-

nectedEngine control unit connector:Disconnected

ACTUATOR INSPECTIONRefer to GROUP 54.

1 TSB Revision

Page 236 of 1146

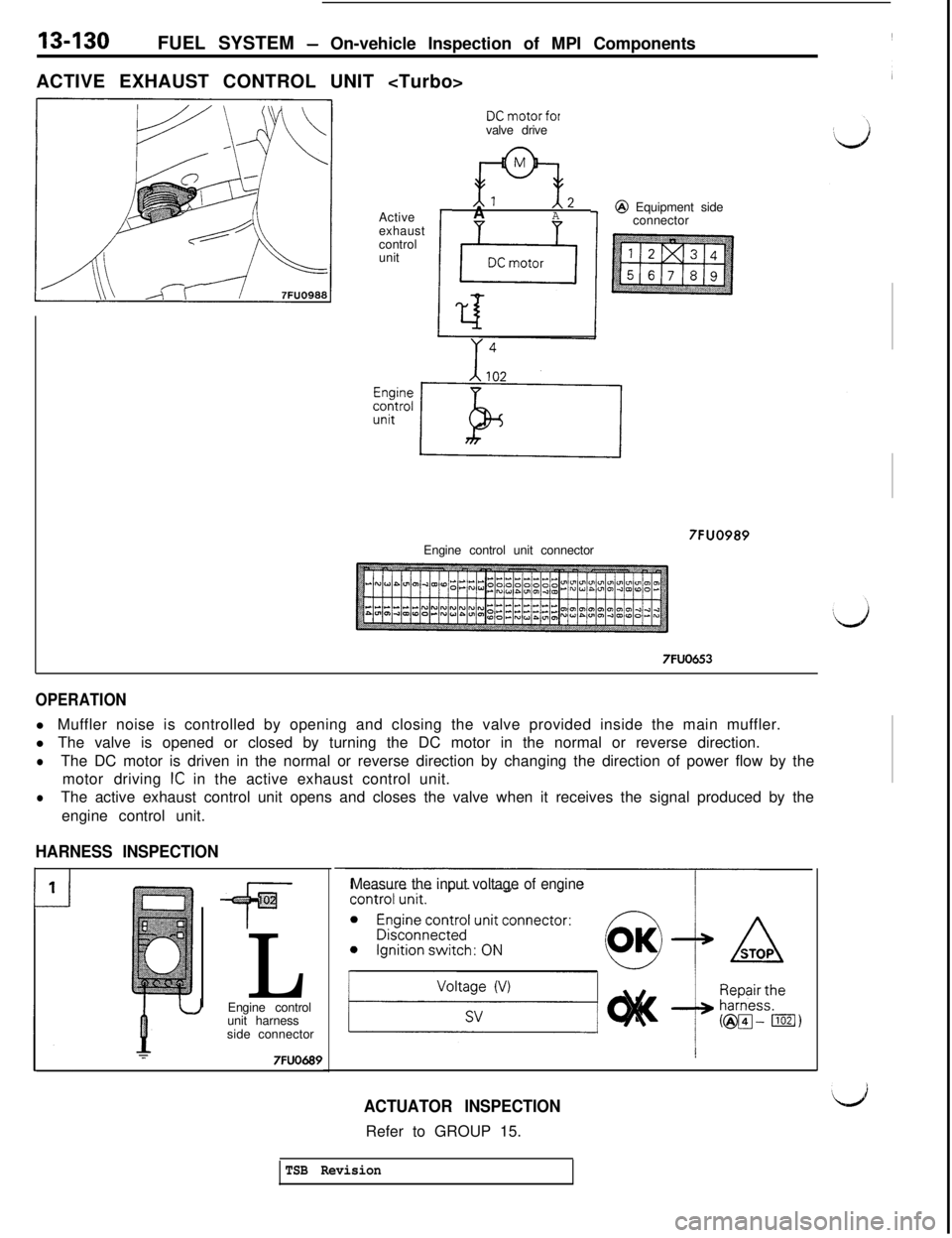

13-130FUEL SYSTEM - On-vehicle Inspection of MPI Components

ACTIVE EXHAUST CONTROL UNIT

Active

exhaust

control

unit

I

DCmotorforvalve drive

Al 12AA@ Equipment side

connector

Engine control unit connector

7FUO989

7FUO653

OPERATIONl Muffler noise is controlled by opening and closing the valve provided inside the main muffler.

l The valve is opened or closed by turning the DC motor in the normal or reverse direction.

lThe DC motor is driven in the normal or reverse direction by changing the direction of power flow by the

motor driving

IC in the active exhaust control unit.

lThe active exhaust control unit opens and closes the valve when it receives the signal produced by the

engine control unit.

HARNESS INSPECTION

0

FL

I’ JEngine control

unit harness

side connector

7FUO689I

Measure the input voltage of engine

ACTUATOR INSPECTIONRefer to GROUP 15.

TSB Revision

Page 237 of 1146

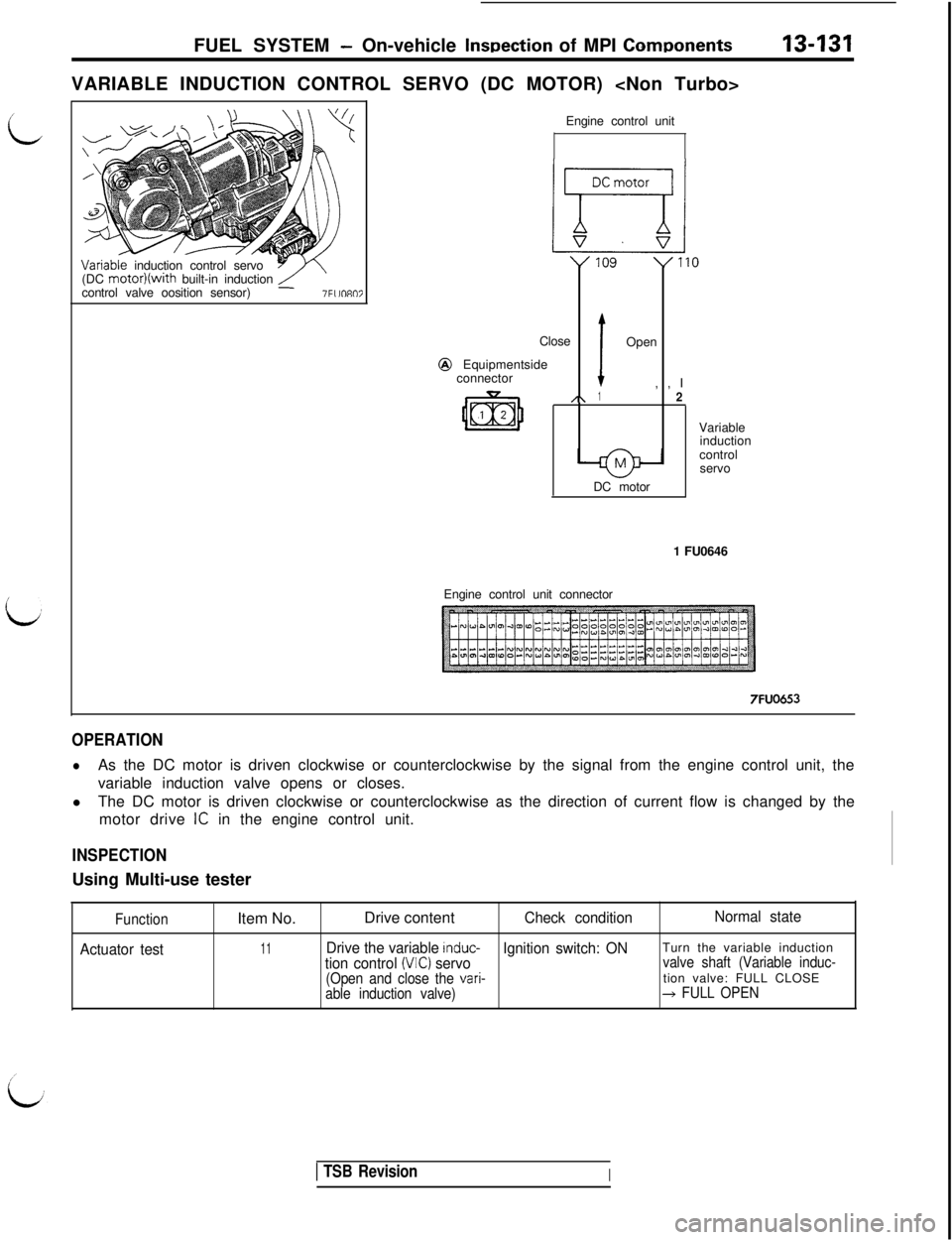

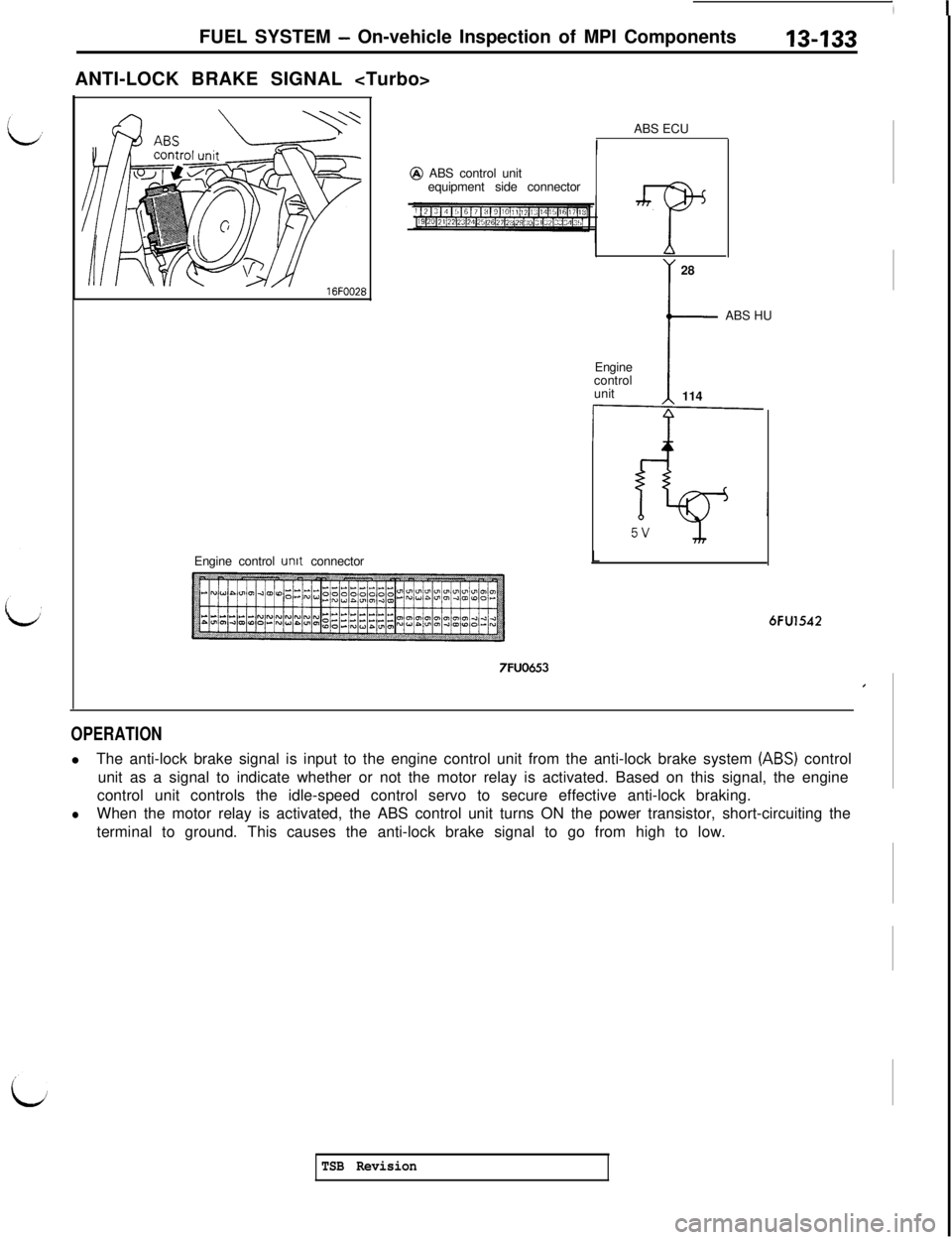

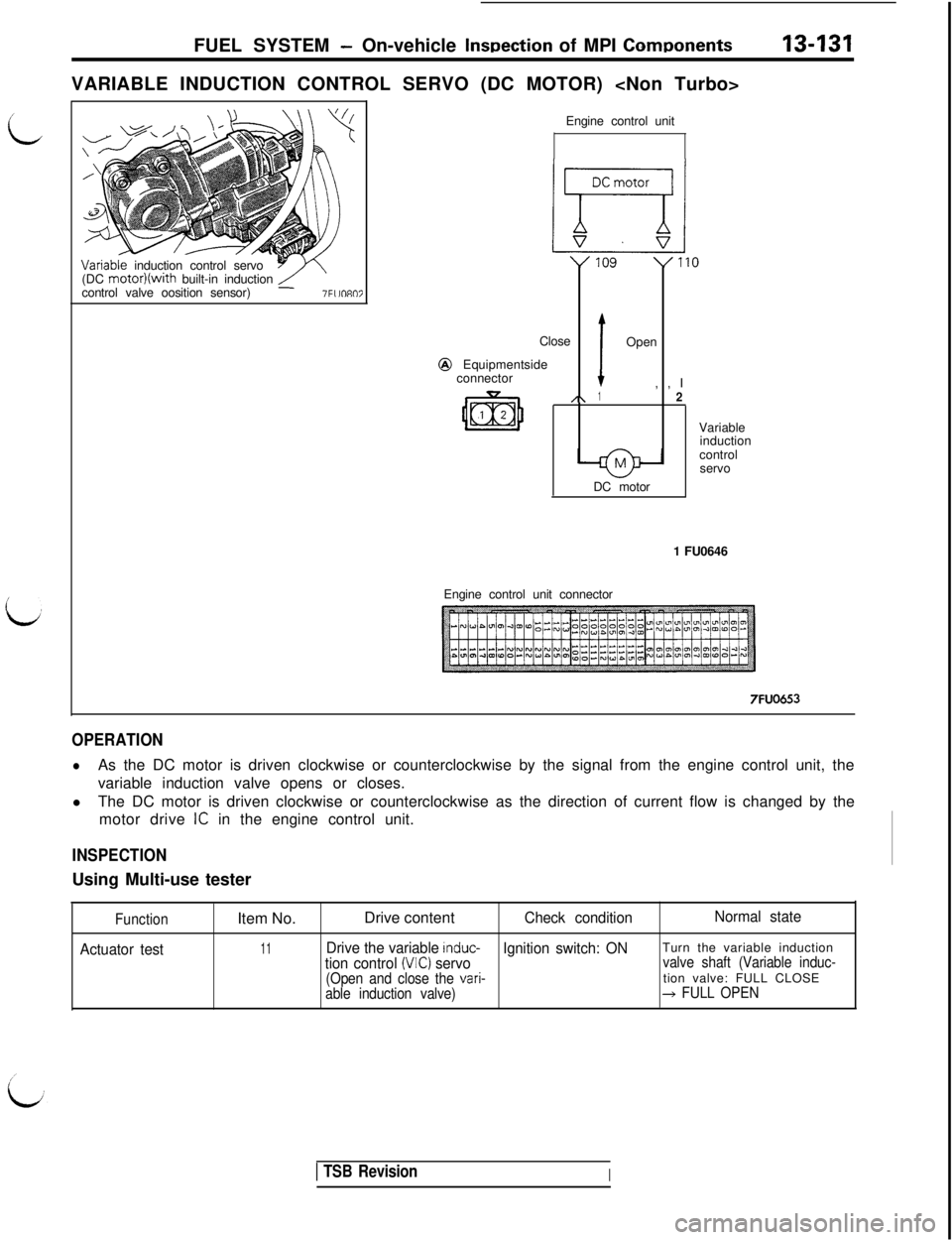

FUEL SYSTEM - On-vehicle lnwection of MPI ComDonents13-131

iVARIABLE INDUCTION CONTROL SERVO (DC MOTOR) Variable induction control servo

Y(DC motor)(with built-in induction/-control valve oosition sensor)-7Fllfl807Engine control unit

Close

connector

,\ IOpen@ Equipmentside1,,I2DC motorVariable

induction

control

servo

1 FU0646

Engine control unit connector

7FUO653

OPERATION

lAs the DC motor is driven clockwise or counterclockwise by the signal from the engine control unit, the

variable induction valve opens or closes.

lThe DC motor is driven clockwise or counterclockwise as the direction of current flow is changed by the

motor drive

IC in the engine control unit.

INSPECTIONUsing Multi-use tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

11Drive the variable induc-Ignition switch: ONTurn the variable inductiontion control (MC) servovalve shaft (Variable induc-

(Open and close the

vari-tion valve: FULL CLOSEable induction valve)+ FULL OPEN

1 TSB RevisionI

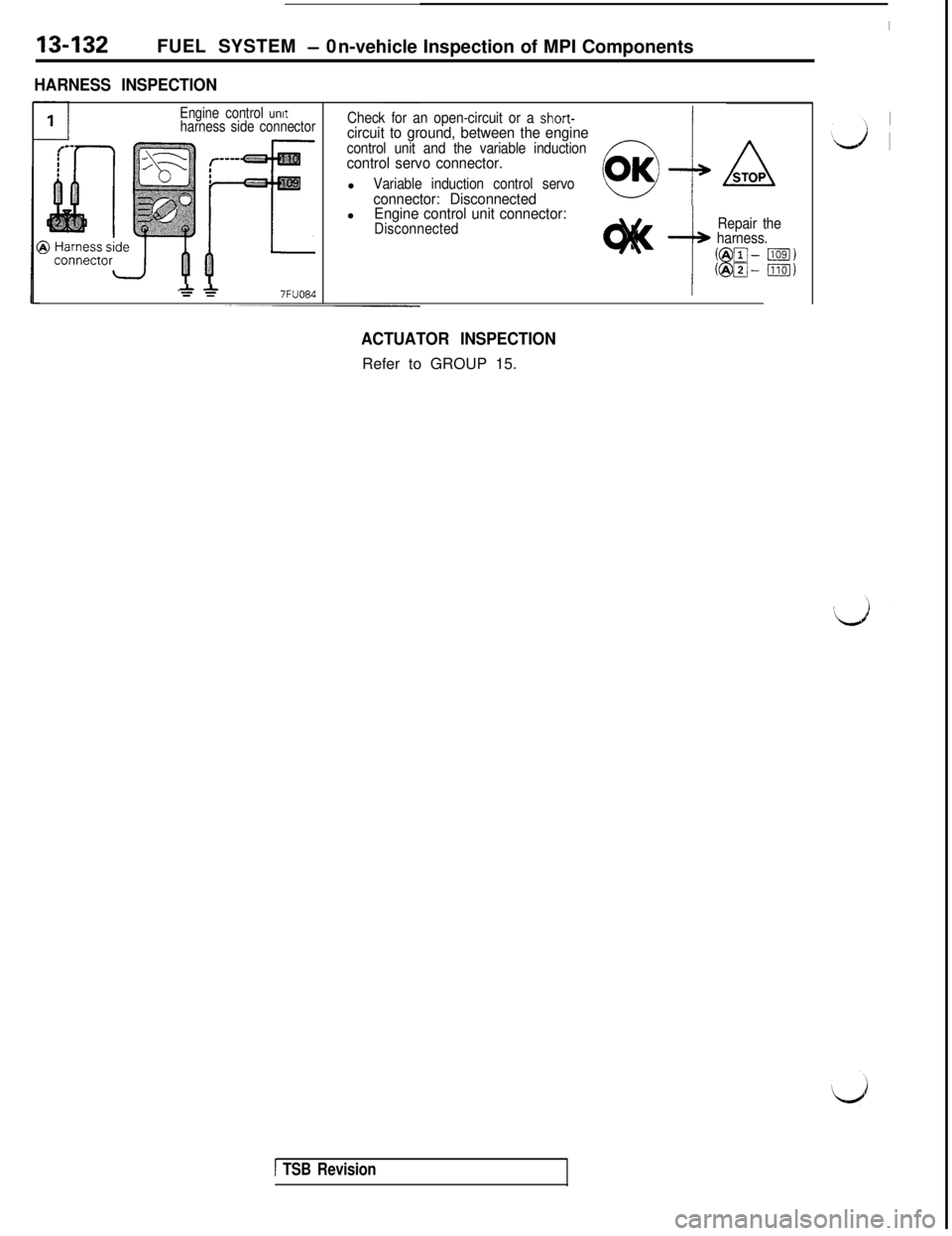

Page 238 of 1146

13-132

IFUEL SYSTEM

- 0

n-vehicle Inspection of MPI Components

HARNESS INSPECTION

Engine control unitharness side connectorCheck for an open-circuit or a short-circuit to ground, between the enginecontrol unit and the variable inductioncontrol servo connector.l

Variable induction control servoconnector: DisconnectedlEngine control unit connector:Disconnected

t

Repair the

harness.

*A7FUO84

ACTUATOR INSPECTIONRefer to GROUP 15.

1 TSB Revision

Page 239 of 1146

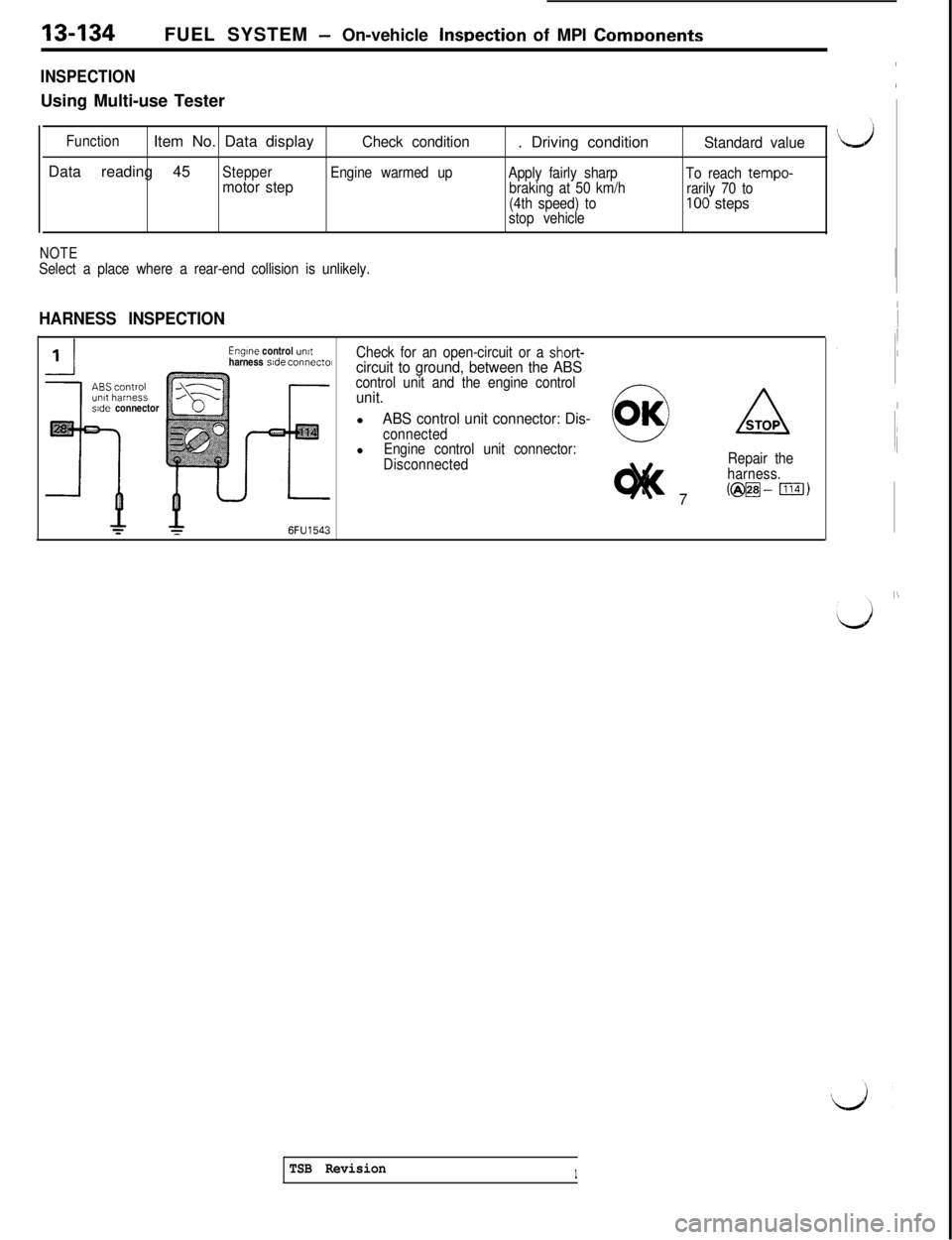

FUEL SYSTEM - On-vehicle Inspection of MPI Components

ANTI-LOCK BRAKE SIGNAL

Engine control

unit connectorABS ECU@ ABS control unit

equipment side connector

A28

tABS HU

Engine

control

unit

114

/L6FU1542

7FUO653,

OPERATIONlThe anti-lock brake signal is input to the engine control unit from the anti-lock brake system

(ABS) control

unit as a signal to indicate whether or not the motor relay is activated. Based on this signal, the engine

control unit controls the idle-speed control servo to secure effective anti-lock braking.

lWhen the motor relay is activated, the ABS control unit turns ON the power transistor, short-circuiting the

terminal to ground. This causes the anti-lock brake signal to go from high to low.

TSB Revision

Page 240 of 1146

13-134FUEL SYSTEM - On-vehicle InsDection of MPI ComDonents

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data displayCheck condition. Driving conditionStandard valueData reading 45

Stepper

Engine warmed up

Apply fairly sharp

To reach tempo-motor stepbraking at 50 km/h

rarily 70 to

(4th speed) to100 stepsstop vehicle

NOTESelect a place where a rear-end collision is unlikely.

HARNESS INSPECTION

side connector

Engine control umtharness side connecm

6FU1543

Check for an open-circuit or a short-circuit to ground, between the ABScontrol unit and the engine controlunit.l

ABS control unit connector: Dis-connectedlEngine control unit connector:

Disconnected7Repair the

harness.

(@m-ml)

I

I

I

I

IiI

I

~,

I\

TSB Revision1

Trending: roof rack, service reset, oil, key battery, washer fluid, open gas tank, brake fluid