MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 191 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-85 1

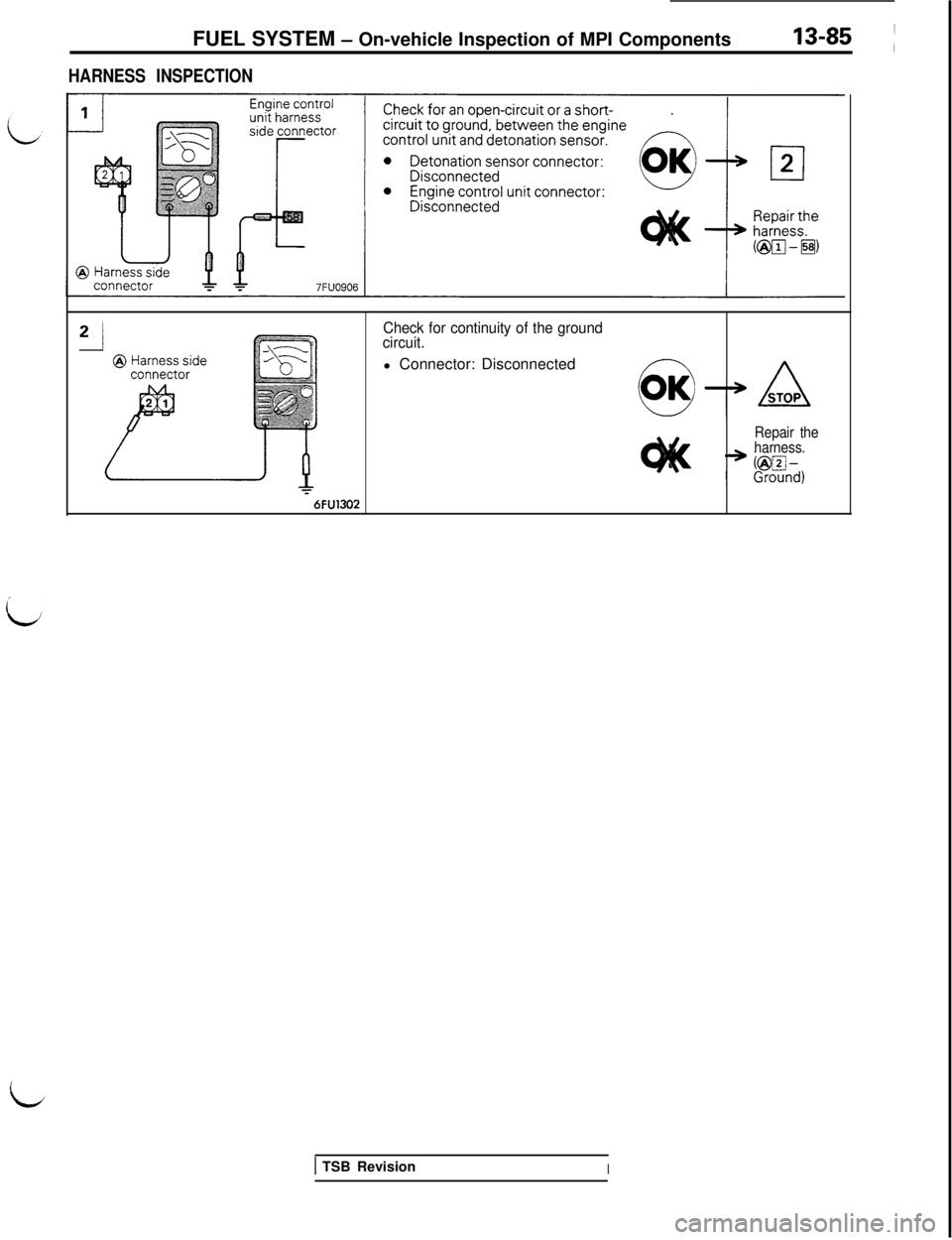

HARNESS INSPECTION

Check for continuity of the ground

circuit.l Connector: Disconnected

Repair the

harness.

76FU1302

1 TSB RevisionI

id

Page 192 of 1146

13-86FUEL SYSTEM - On-vehicle Inspection of MPI Components

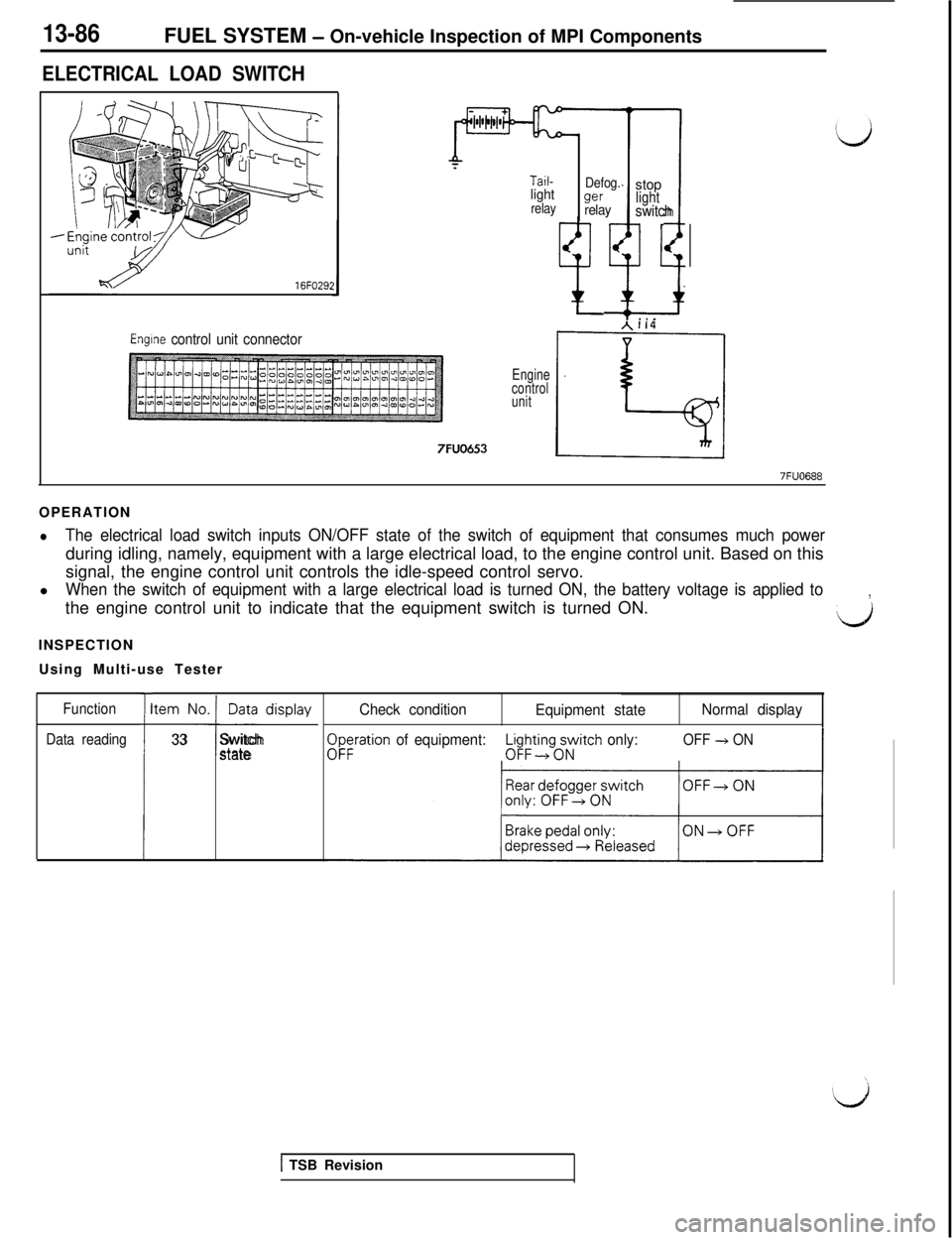

ELECTRICAL LOAD SWITCH16FO29;

Tail-lightrelayDefog.wrelaystoplight

t;1

switch

ti* . .

Engine control unit connector

Engine

control

unit7FUO653

7FUO688OPERATION

lThe electrical load switch inputs ON/OFF state of the switch of equipment that consumes much powerduring idling, namely, equipment with a large electrical load, to the engine control unit. Based on this

signal, the engine control unit controls the idle-speed control servo.

l

When the switch of equipment with a large electrical load is turned ON, the battery voltage is applied tothe engine control unit to indicate that the equipment switch is turned ON.,

LJINSPECTION

Using Multi-use Tester

Function

Data reading

I

tem No. Data display

-I-

33Switchstate

Check condition

Equipment stateNormal display

$;ration of equipment:L$ing;Atch only:OFF + ON-3

1 TSB Revision

Page 193 of 1146

FUEL SYSTEM - On-vehicle InsDection of MPI ComDonents

/

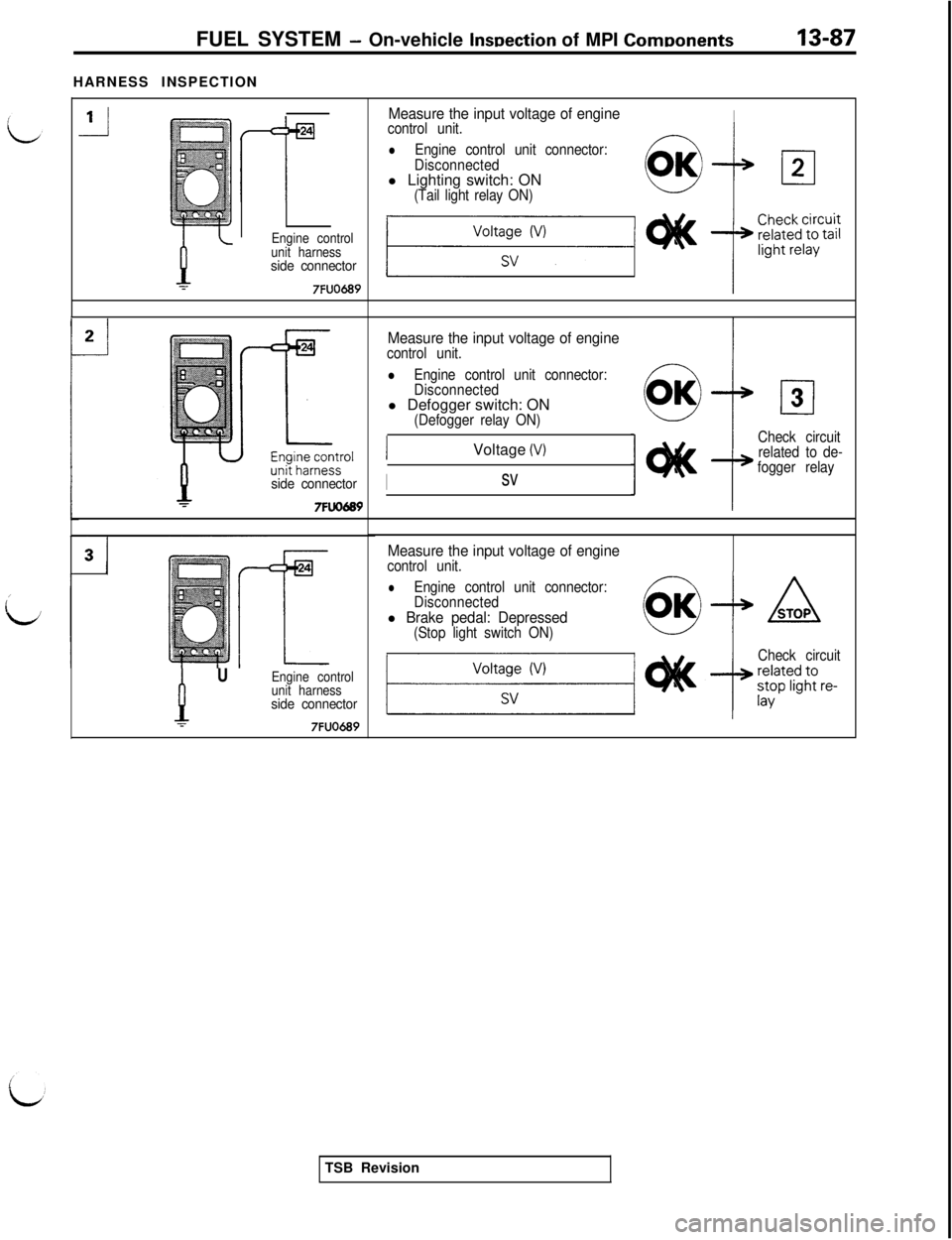

idHARNESS INSPECTION

Engine control

unit harness

side connector7FUO689

side connector7FuO689

PU

Engine control

unit harness

side connectorT7FUO689

Measure the input voltage of engineIcontrol unit.

lEngine control unit connector:

Disconnectedl Lighting switch: ON

(Tail light relay ON)

Measure the input voltage of enginecontrol unit.

lEngine control unit connector:

Disconnectedl Defogger switch: ON

(Defogger relay ON)Voltage

(V)

Isv

cl3

Check circuit

related to de-

fogger relay

Measure the input voltage of enginecontrol unit.

lEngine control unit connector:

Disconnected

l Brake pedal: Depressed(Stop light switch ON)

Check circuitTSB Revision

Page 194 of 1146

13-88FUEL SYSTEM - On-vehicle Inspection of MPI Components

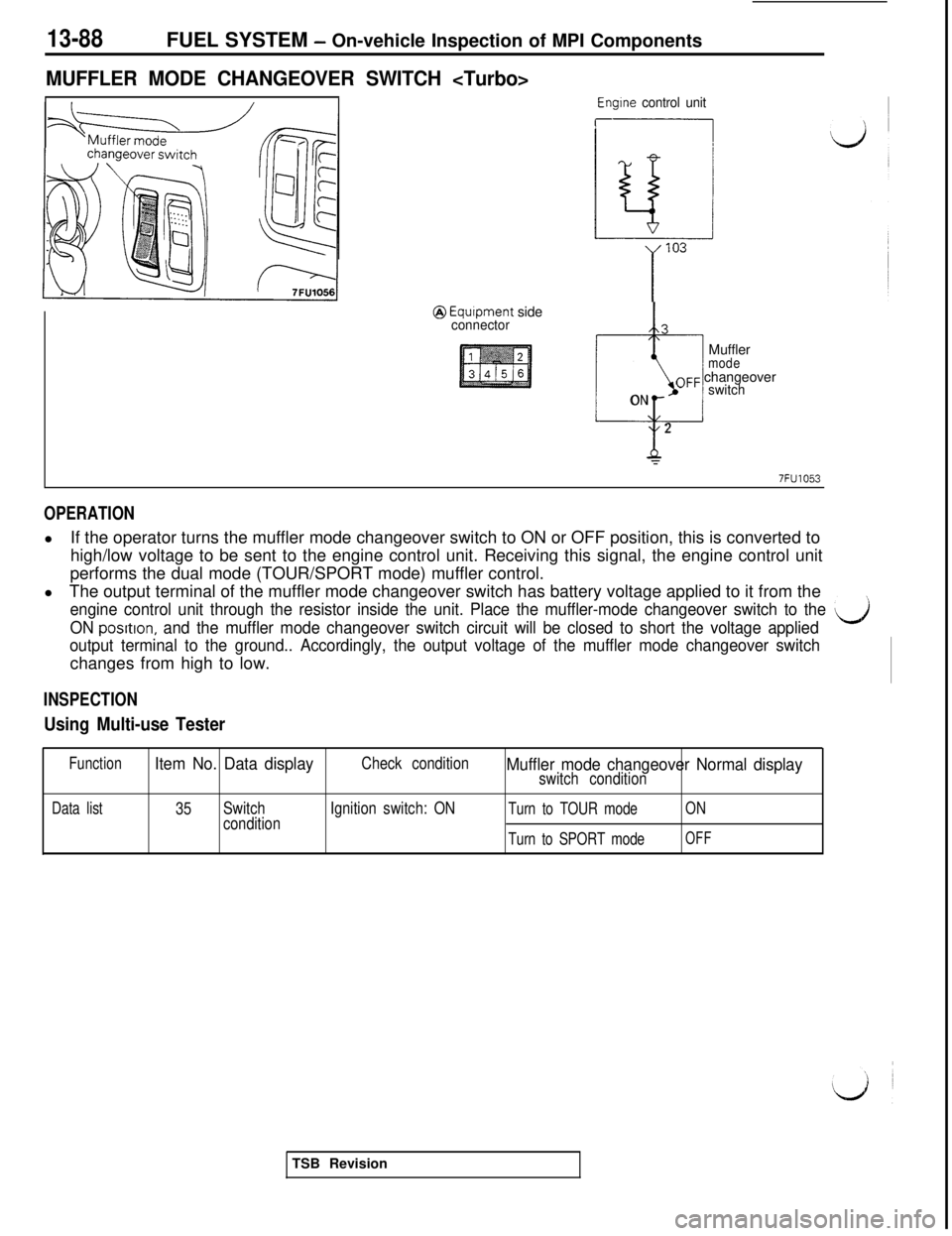

MUFFLER MODE CHANGEOVER SWITCH

Engine control unit

r

@ Equipment sideconnector3

-Muffler

modeOFF changeover

ONswitch

2

r

7FU1053

OPERATIONlIf the operator turns the muffler mode changeover switch to ON or OFF position, this is converted to

high/low voltage to be sent to the engine control unit. Receiving this signal, the engine control unit

performs the dual mode (TOUR/SPORT mode) muffler control.

lThe output terminal of the muffler mode changeover switch has battery voltage applied to it from the

engine control unit through the resistor inside the unit. Place the muffler-mode changeover switch to the ‘LJj

ON posrtton, and the muffler mode changeover switch circuit will be closed to short the voltage applied

output terminal to the ground.. Accordingly, the output voltage of the muffler mode changeover switchchanges from high to low.

INSPECTION

Using Multi-use Tester

FunctionItem No. Data displayCheck conditionMuffler mode changeover Normal displayswitch condition

Data list35Switch

conditionIgnition switch: ONTurn to TOUR mode

Turn to SPORT modeON

OFFTSB Revision

Page 195 of 1146

FUEL SYSTEM - 0n-vehicleInspection of MPI Components13-89 ~

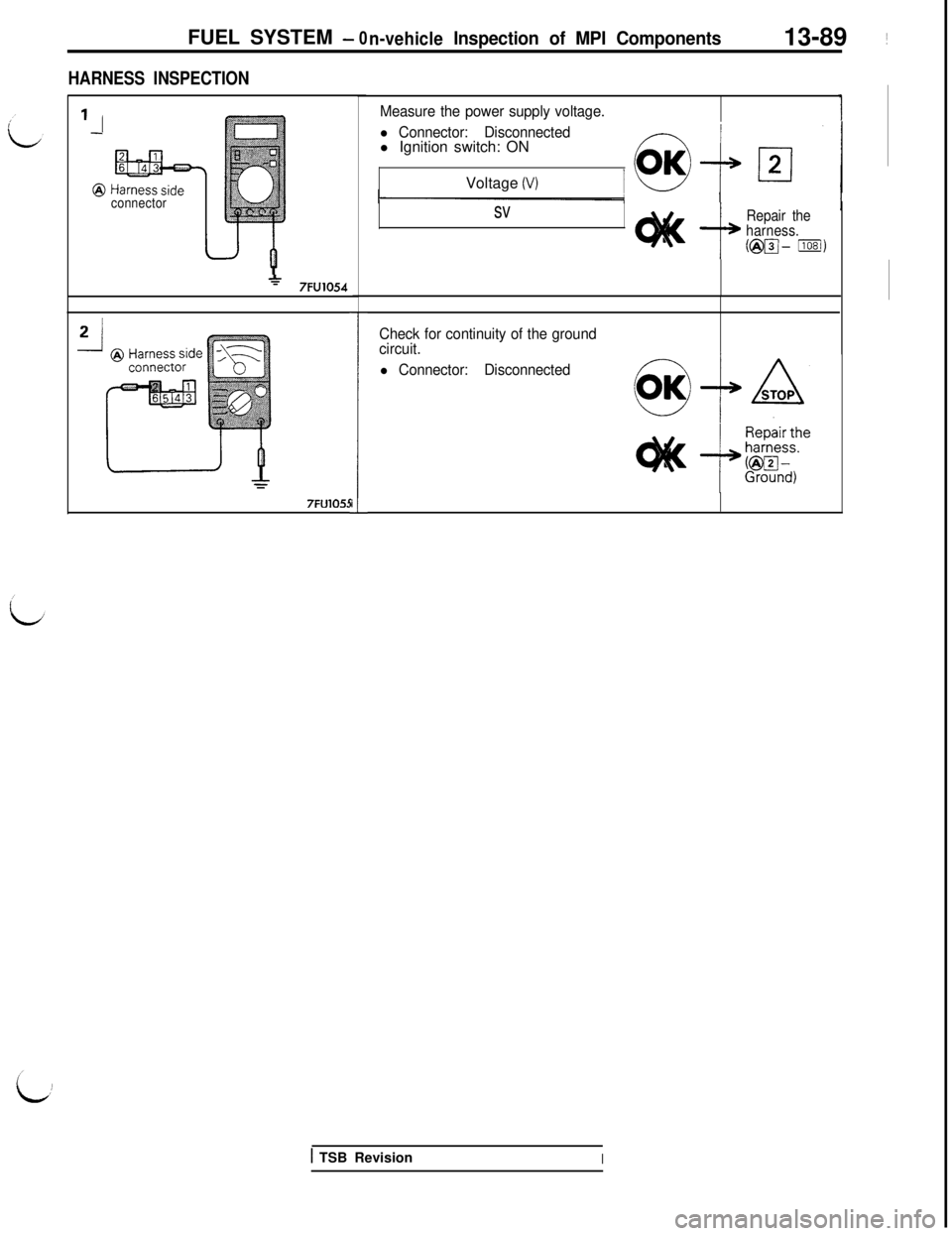

HARNESS INSPECTION

1

connector

*7FU10547FU105:

ii

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

Voltage

(V)

sv

i+

Repair the

harness.

@pJ- Ilosi)

Check for continuity of the ground

circuit.

l Connector: Disconnected

1 TSB RevisionI

Page 196 of 1146

13-90FUEL SYSTEM - On-vehicle Inspection of MPI Components

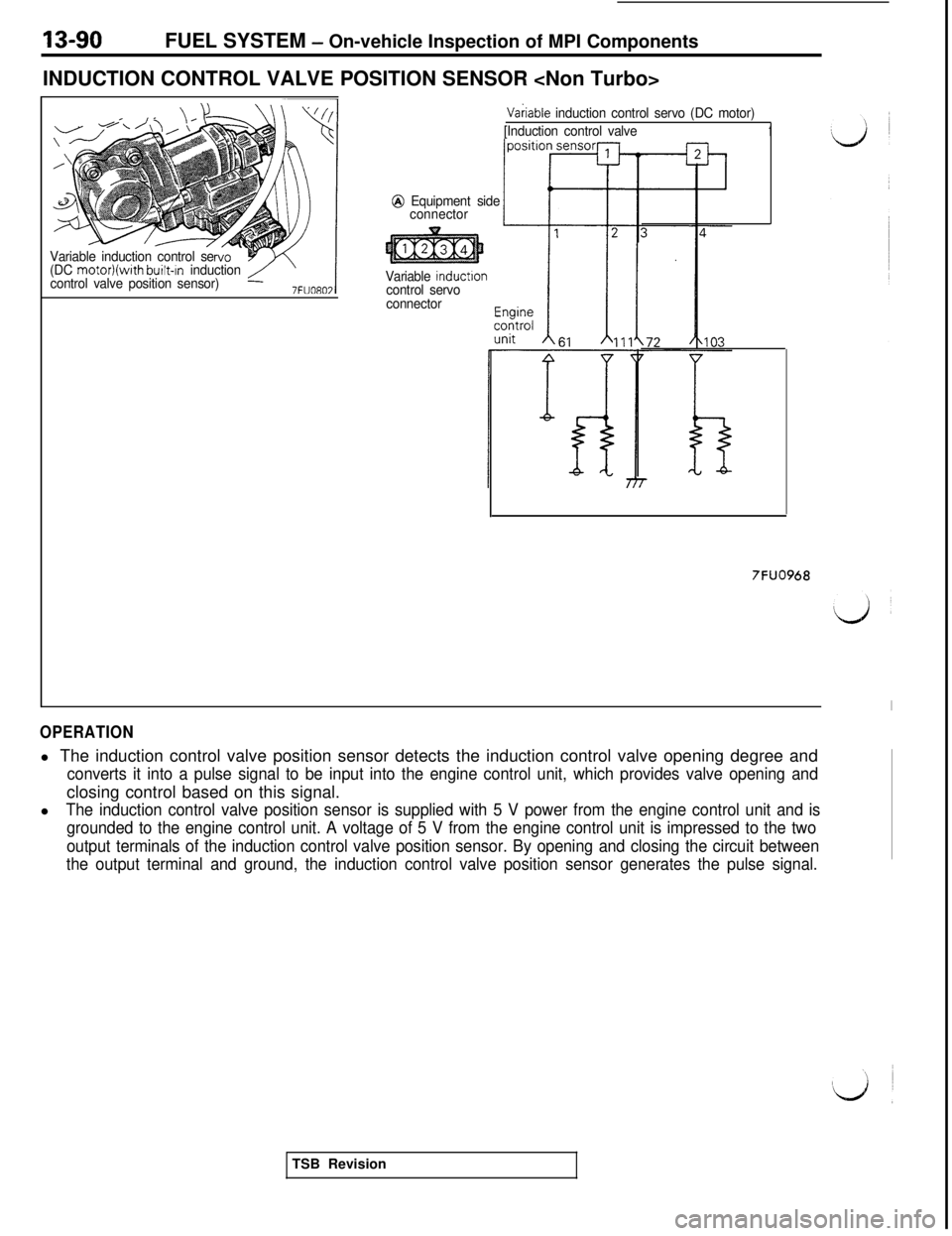

INDUCTION CONTROL VALVE POSITION SENSOR

Variable induction control se

(DC motor)(with built-In induction

control valve position sensor)

Vakiable induction control servo (DC motor)

[Induction control valve

1

@ Equipment side

connector

Variable

inductloncontrol servo

connector

7FUO968

OPERATIONl The induction control valve position sensor detects the induction control valve opening degree and

converts it into a pulse signal to be input into the engine control unit, which provides valve opening andclosing control based on this signal.

l

The induction control valve position sensor is supplied with 5 V power from the engine control unit and is

grounded to the engine control unit. A voltage of 5 V from the engine control unit is impressed to the two

output terminals of the induction control valve position sensor. By opening and closing the circuit between

the output terminal and ground, the induction control valve position sensor generates the pulse signal.TSB Revision

Page 197 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-91

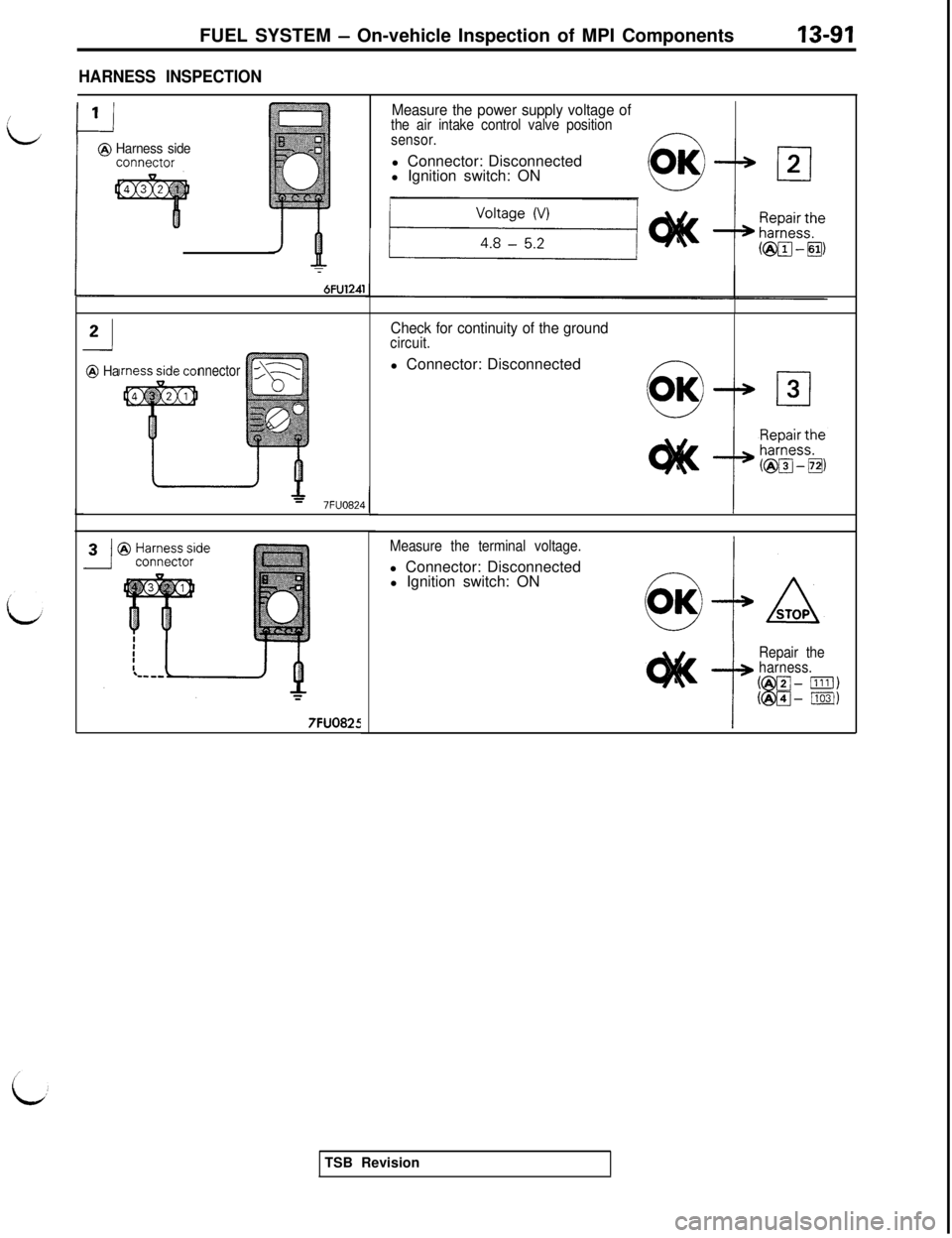

HARNESS INSPECTION

i‘@ Harness side

:

7

6FU1241

Measure the power supply voltage ofthe air intake control valve position

sensor.l Connector: Disconnected

l Ignition switch: ON

@ Hannector

=7FUO824

7FUO825

Check for continuity of the groundcircuit.l Connector: Disconnected

f---Y -

Measure the terminal voltage.l Connector: Disconnected

l Ignition switch: ON

T

Repair the

harness.TSB Revision

Page 198 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

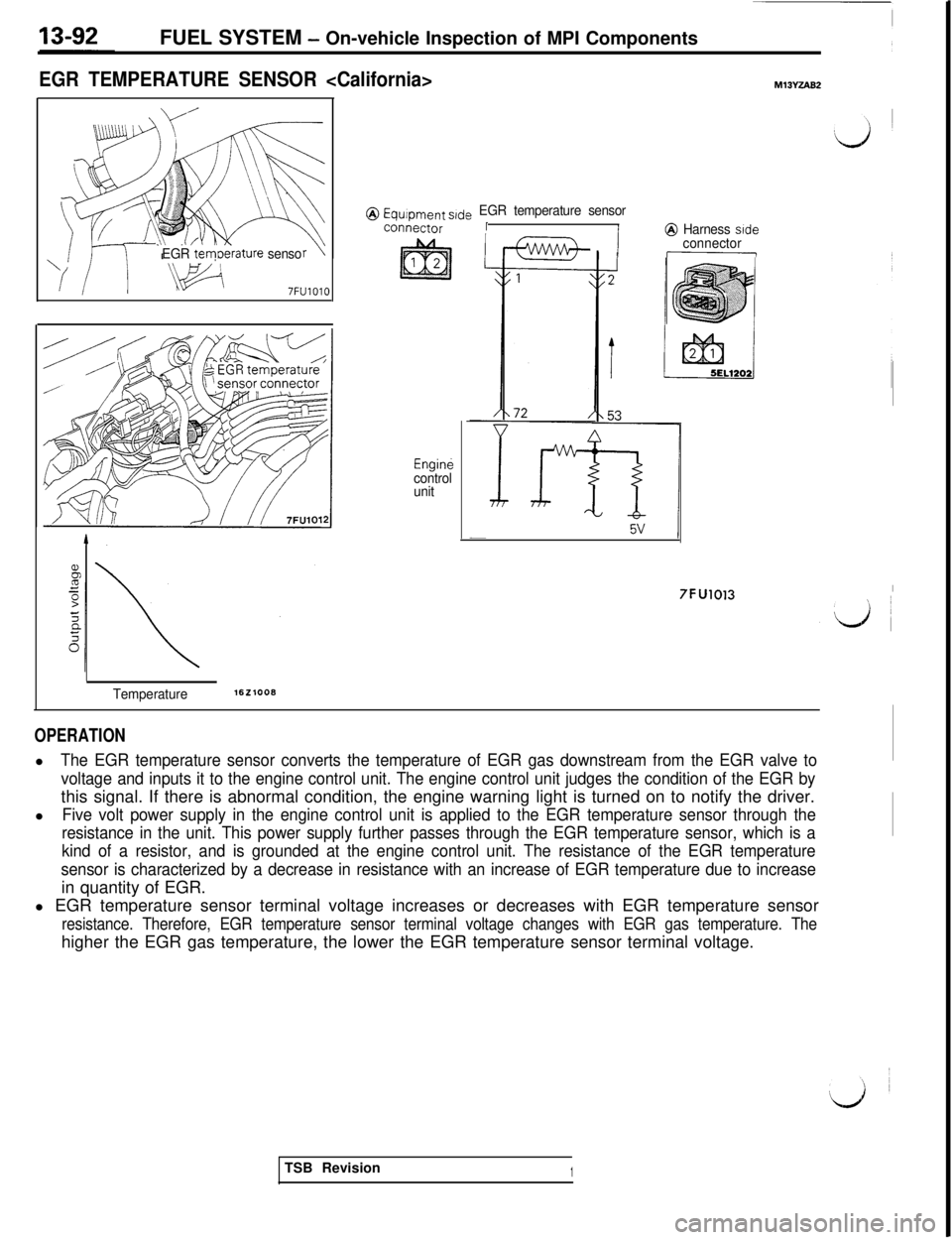

EGR TEMPERATURE SENSOR

EGR tem0erature senso

7FUlOlO

@ Equipment s,de EGR temperature sensor

connectorII@ Harness side

Enginecontrol

unit

I Iconnector

7FU1013I

Temperature1621008

OPERATIONl

The EGR temperature sensor converts the temperature of EGR gas downstream from the EGR valve to

voltage and inputs it to the engine control unit. The engine control unit judges the condition of the EGR bythis signal. If there is abnormal condition, the engine warning light is turned on to notify the driver.

l

Five volt power supply in the engine control unit is applied to the EGR temperature sensor through the

resistance in the unit. This power supply further passes through the EGR temperature sensor, which is a

kind of a resistor, and is grounded at the engine control unit. The resistance of the EGR temperature

sensor is characterized by a decrease in resistance with an increase of EGR temperature due to increasein quantity of EGR.

l EGR temperature sensor terminal voltage increases or decreases with EGR temperature sensor

resistance. Therefore, EGR temperature sensor terminal voltage changes with EGR gas temperature. Thehigher the EGR gas temperature, the lower the EGR temperature sensor terminal voltage.

TSB Revision

1

Page 199 of 1146

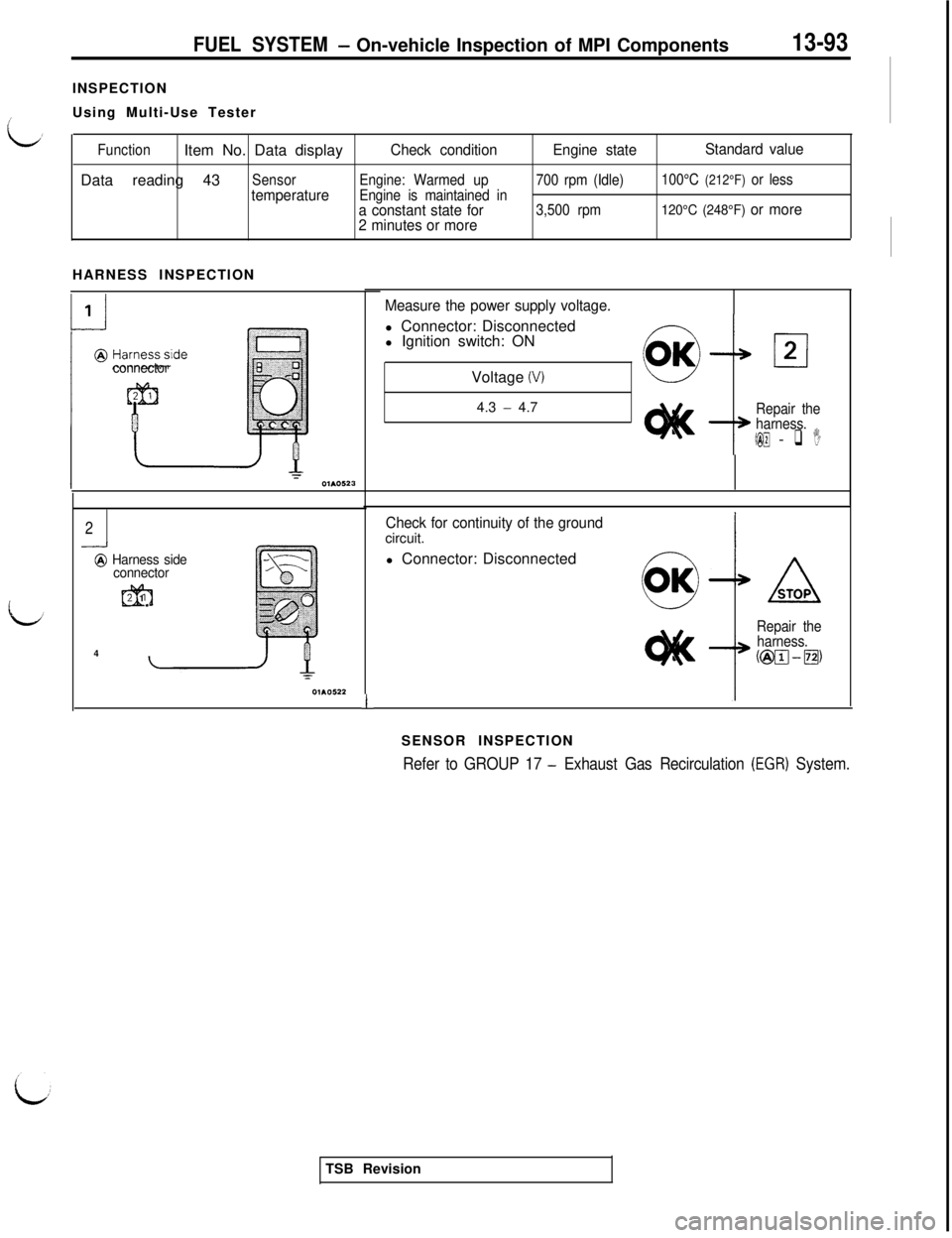

FUEL SYSTEM- On-vehicle Inspection of MPI Components13-93INSPECTION

Using Multi-Use Tester

FunctionItem No. Data displayCheck conditionEngine stateStandard valueData reading 43

SensorEngine: Warmed up700 rpm (Idle)100°C (212°F) or less

temperatureEngine is maintained in-

a constant state for3,500 rpm120°C (248°F) or more

2 minutes or moreHARNESS INSPECTION

connector

2-..-I

@ Harness side

connector

m2 1

4

1

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)4.3

- 4.7Repair the

harness.

(@I@ - q I

Check for continuity of the groundcircuit.

l Connector: Disconnected

I

Repair the

harness.@@J-m,

SENSOR INSPECTION

Refer to GROUP 17 - Exhaust Gas Recirculation (EGR) System.TSB Revision

Page 200 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components

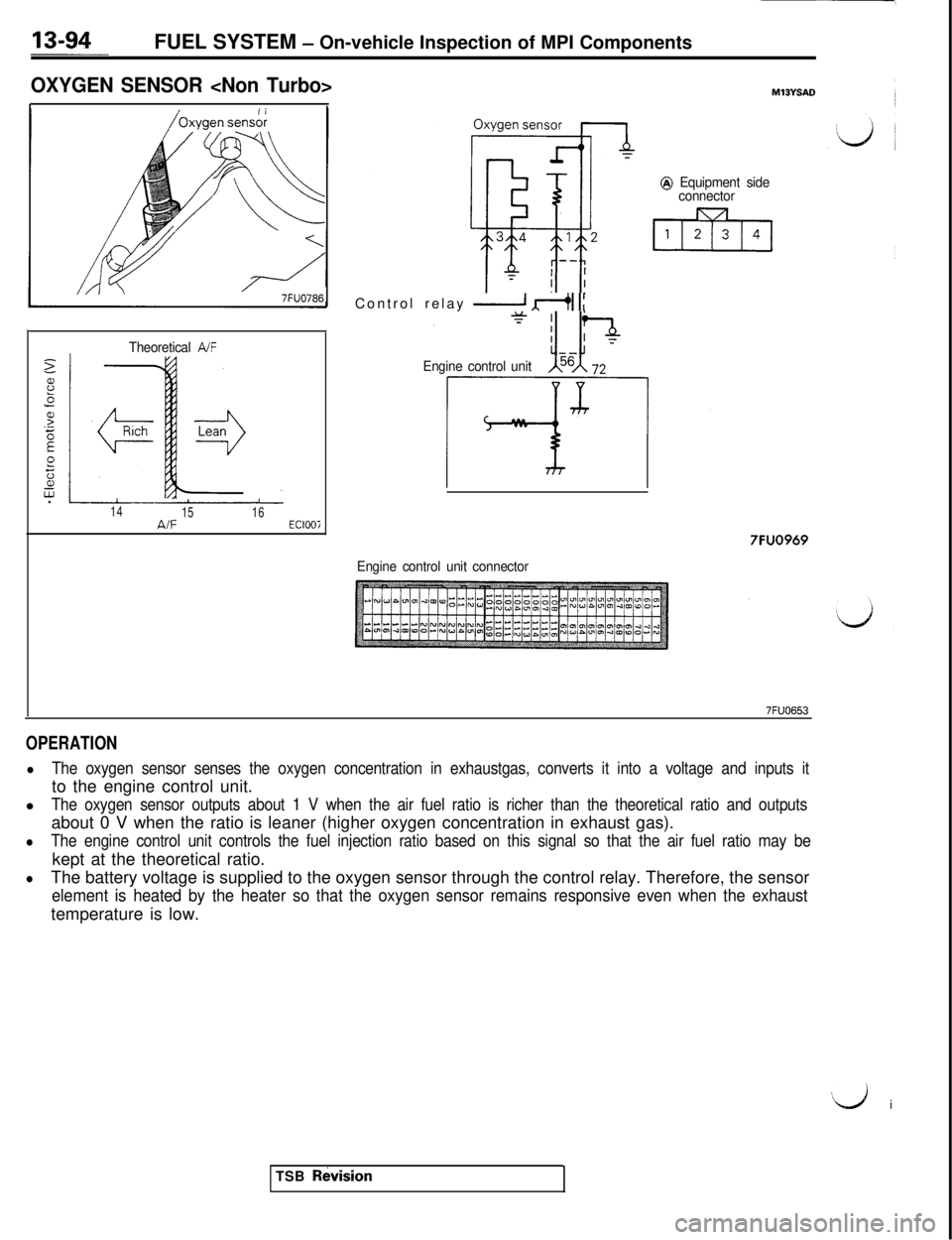

OXYGEN SENSOR

7FUO786

Theoretical A/F

14

1516A/FEClOOiControl relay

2 dI 1:

Engine control unit

@ Equipment side

connector

7FUO969

Engine control unit connector

7FUO653

OPERATION

lThe oxygen sensor senses the oxygen concentration in exhaustgas, converts it into a voltage and inputs itto the engine control unit.

l

The oxygen sensor outputs about 1 V when the air fuel ratio is richer than the theoretical ratio and outputsabout 0 V when the ratio is leaner (higher oxygen concentration in exhaust gas).

lThe engine control unit controls the fuel injection ratio based on this signal so that the air fuel ratio may bekept at the theoretical ratio.

lThe battery voltage is supplied to the oxygen sensor through the control relay. Therefore, the sensor

element is heated by the heater so that the oxygen sensor remains responsive even when the exhausttemperature is low.

‘d i

TSB

RtkisionI