MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 361 of 1146

CLUTCH - Specifications / Troubleshooting21-3

LUBRICANTS

Items

Contact surface of release bearing and fulcrum of

clutch release forkSpecified lubricants

MITSUBISHI genuine grease

Part No.0101 011 or equivalent

Inner surface of clutch release bearing

Inner surface of clutch disc spline

Contact portion of release fork to release cylinder push rod

Clutch fluid

Inner surface of clutch release cylinder and outer

circumference of piston and cup

Inner surface of clutch master cylinder and outer

circumference of piston assembly

Conforming to DOT3

SEALANTM21CE. -

Items

Thread part fittingSpecified sealant

3M ADT Part No. 8660 or equivalent

TROUBLESHOOTINGtvl21EAAM

Symptom

Clutch slips

Gear shifting

failureProbable cause

Clutch pedal play too small

Excessive wear of clutch disc facing

Hardened clutch disc facing or oil on facing

Clutch release fork not operating smoothly

Settled or damaged diaphragm spring

Clogged hydraulic system

Poorly adjusted clutch booster push rod

Clutch pedal play too large

Large clutch disc distortion or runout

Worn clutch cover assembly

Worn or corroded clutch disc splines

Separated clutch disc facing

Worn clutch release bearing

Damaged pressure plate or flywheel

Leaky or clogged hydraulic system or air

trapped in hydraulic system

Poorly adjusted clutch booster push rod

Remedy

Adjust

Replace

Replace

Repair or replace

Replace

Repair or replace

Adjust

Adjust

Replace

Replace

Replace

Replace

Replace

Replace

Repair or replace

AdjustTSB Revision

Page 362 of 1146

21-4CLUTCH - Troubleshooting

Clutchrelease forknot operating

efective clutchbooster

1 TSB Revision

Page 363 of 1146

CLUTCH - Service Adjustment Procedures21-5

Clutch pedal height

08YO41

auto-cruise control

\ \ 0Cl;tchswitch

\ \08F0010

Clutch pedal stroke

Lock nut

08F005414110052

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTMENTMZlFAAP

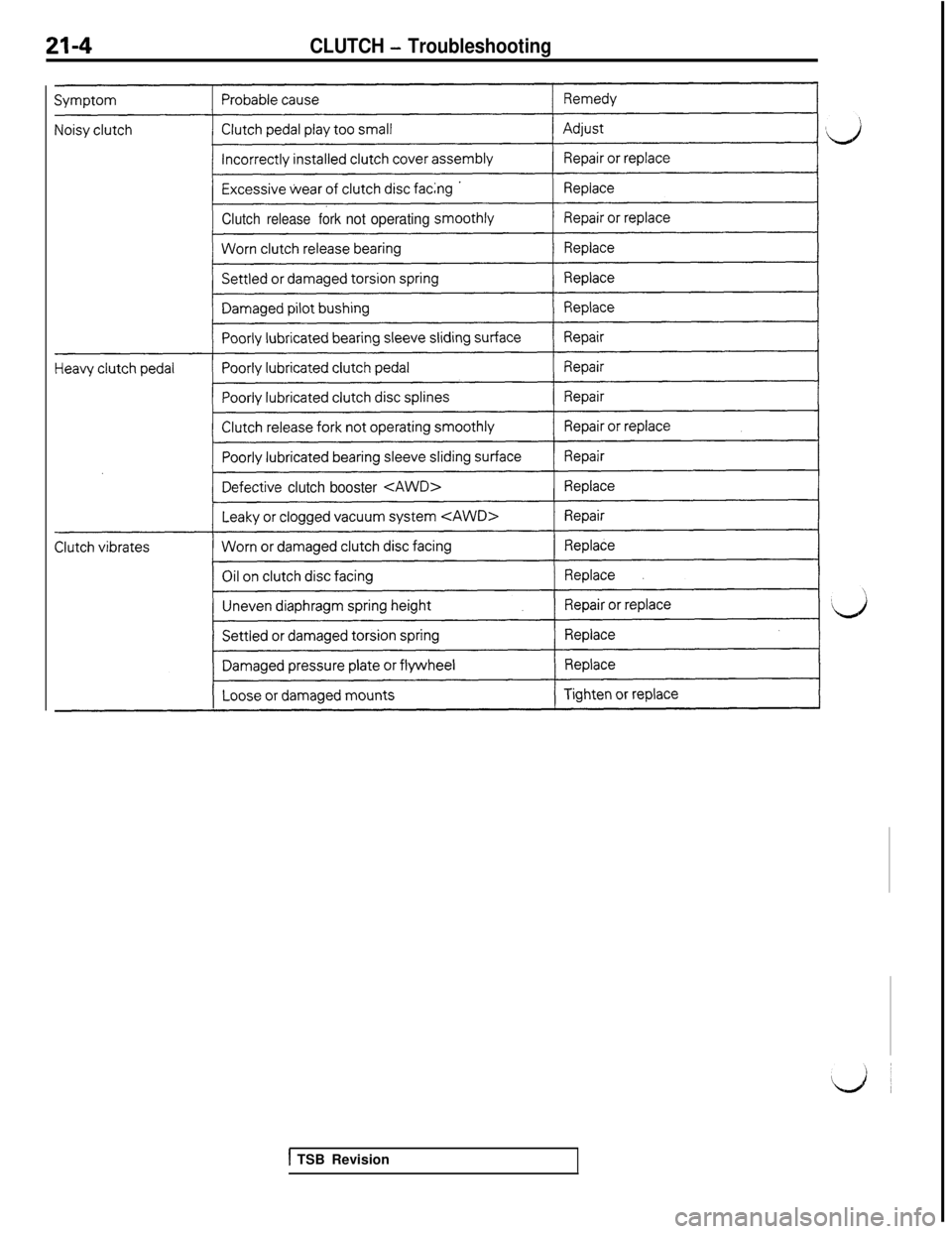

1.Measure the clutch pedal height (from the face of the pedal

pad to the firewall).

Standard value: 177

- 182 mm (6.97 - 7.17 in.)

If the clutch pedal height is not within the standard value

range, adjust as follows:

For vehicles without auto-cruise control system, turn and

adjust the bolt so that the pedal height is the standard

value, and then secure by tightening the lock nut to the

specified torque.

Vehicles with auto-cruise control system, disconnect the

clutch switch connector and turn the switch for standard

clutch pedal height. Tighten the lock nut to the specified

torque.

Specified torque: 13 Nm (9

ft.lbs.)

NOTEWhen the pedal height is lower than the standard value,

loosen the bolt or clutch switch, and then turn the push rod

to make the adjustment. After making the adjustment,

tighten the bolt or clutch switch to reach the pedal stopper,

and then lock with the lock nut.

2. Measure the clutch pedal stroke.

Standard value: 160 mm (6.29 in.) or more

If the clutch pedal stroke deviates from the standard value,

turn the push rod to adjust the stroke.

3. Return the clutch pedal gradually from its full-stroke

position to measure amount of the return made by the

pedal

u,ntil the interlock switch makes an operating sound.

Standard value: 10

- 15 mm (.394 - .591 in.)

If the amount of pedal return deviates from the standard

value, adjust it by loosening the lock nut and turning the

interlock switch.

TSB Revision

Page 364 of 1146

21-6CLUTCH - Service Adjustment Procedures

08YO4Z

Distance between the clutch pedaland the firewall when the clutchis disengaged

08NOOl C

Good

c1‘14UOO61

When engine is

stoppedNo good

\)‘14UOO6:

When engine isstarted

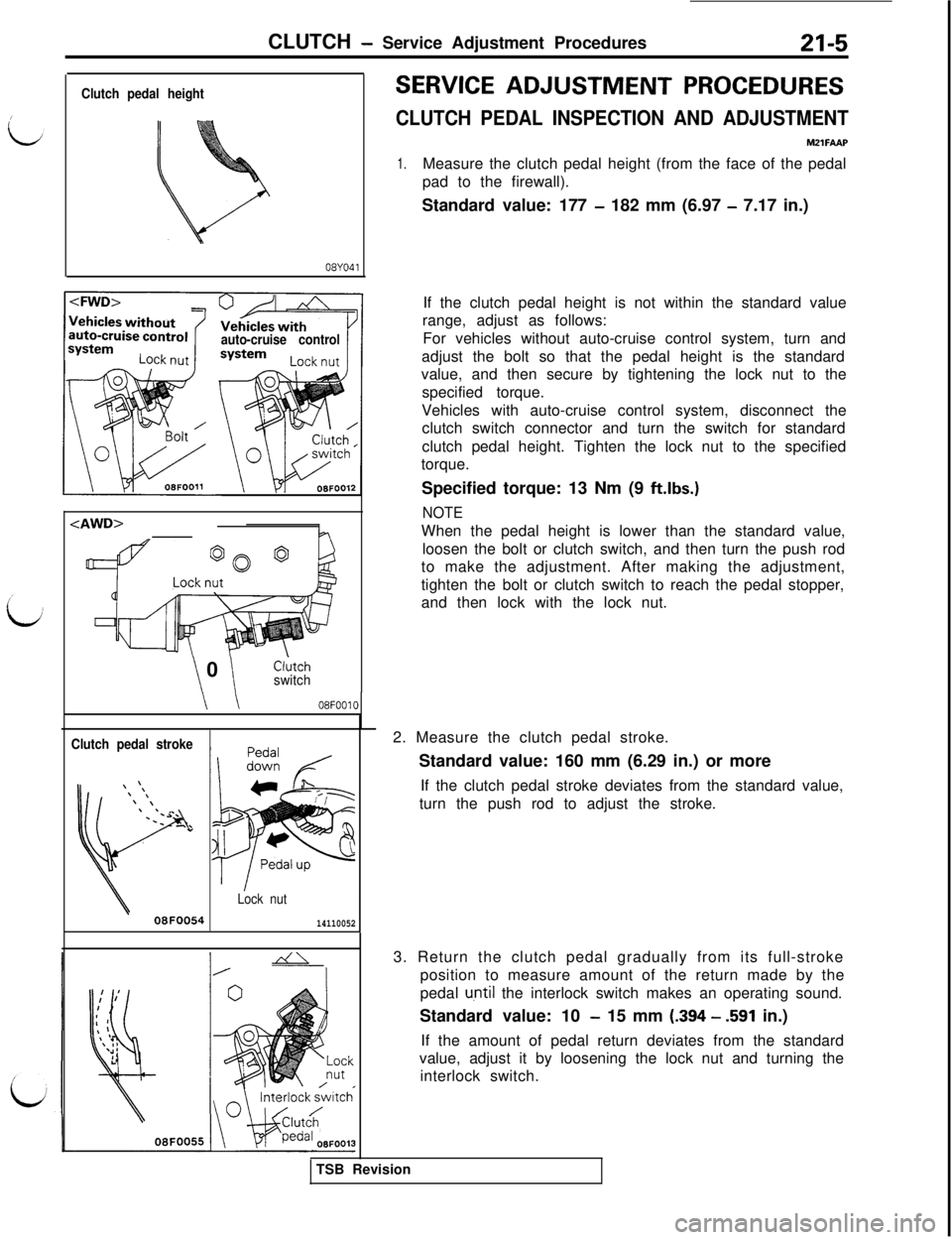

14UOO604. Measure pedal play. In the case of AWD vehicles, depress~

the pedal 2 or 3 times to eliminate booster negative

pressure with the engine stopped and then push the pedal

with a finger to measure the play.

LJClutch pedal play (including play of clevis pin)

Standard value: 6

- 13 mm (.24 - 51 in.)

2

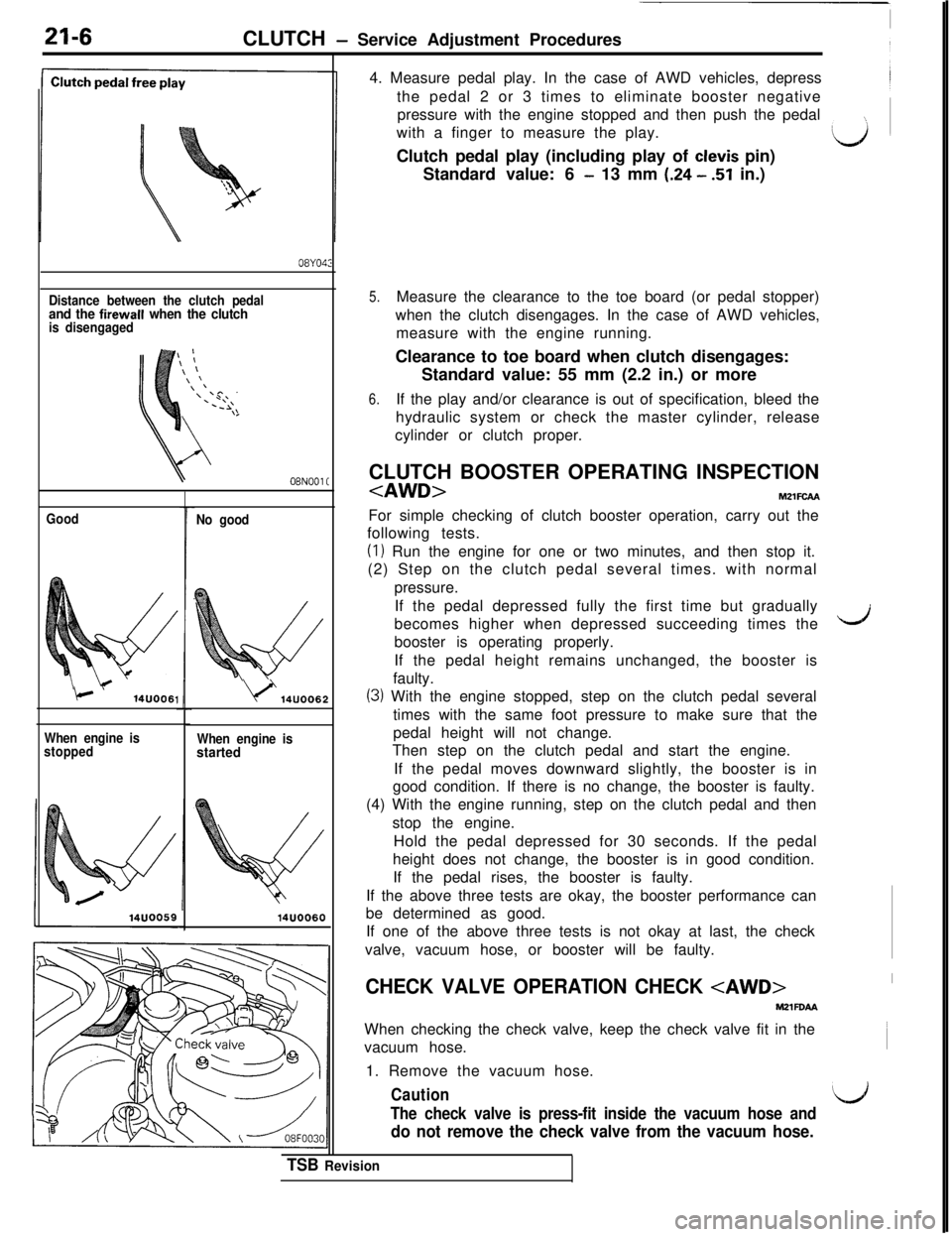

CHECK VALVE OPERATION CHECK

MZlFOAAWhen checking the check valve, keep the check valve fit in the

vacuum hose.

1. Remove the vacuum hose.

CautionL’The check valve is press-fit inside the vacuum hose and

do not remove the check valve from the vacuum hose.

5.Measure the clearance to the toe board (or pedal stopper)

when the clutch disengages. In the case of AWD vehicles,

measure with the engine running.

Clearance to toe board when clutch disengages:

Standard value: 55 mm (2.2 in.) or more

6.If the play and/or clearance is out of specification, bleed the

hydraulic system or check the master cylinder, release

cylinder or clutch proper.

CLUTCH BOOSTER OPERATING INSPECTION

following tests.

(I) Run the engine for one or two minutes, and then stop it.

(2) Step on the clutch pedal several times. with normal

pressure.

If the pedal depressed fully the first time but gradually

becomes higher when depressed succeeding times the

dbooster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.

(3) With the engine stopped, step on the clutch pedal several

times with the same foot pressure to make sure that the

pedal height will not change.

Then step on the clutch pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the clutch pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance can

be determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

TSB Revision

Page 365 of 1146

CLUTCH- Service Adiustment Procedures

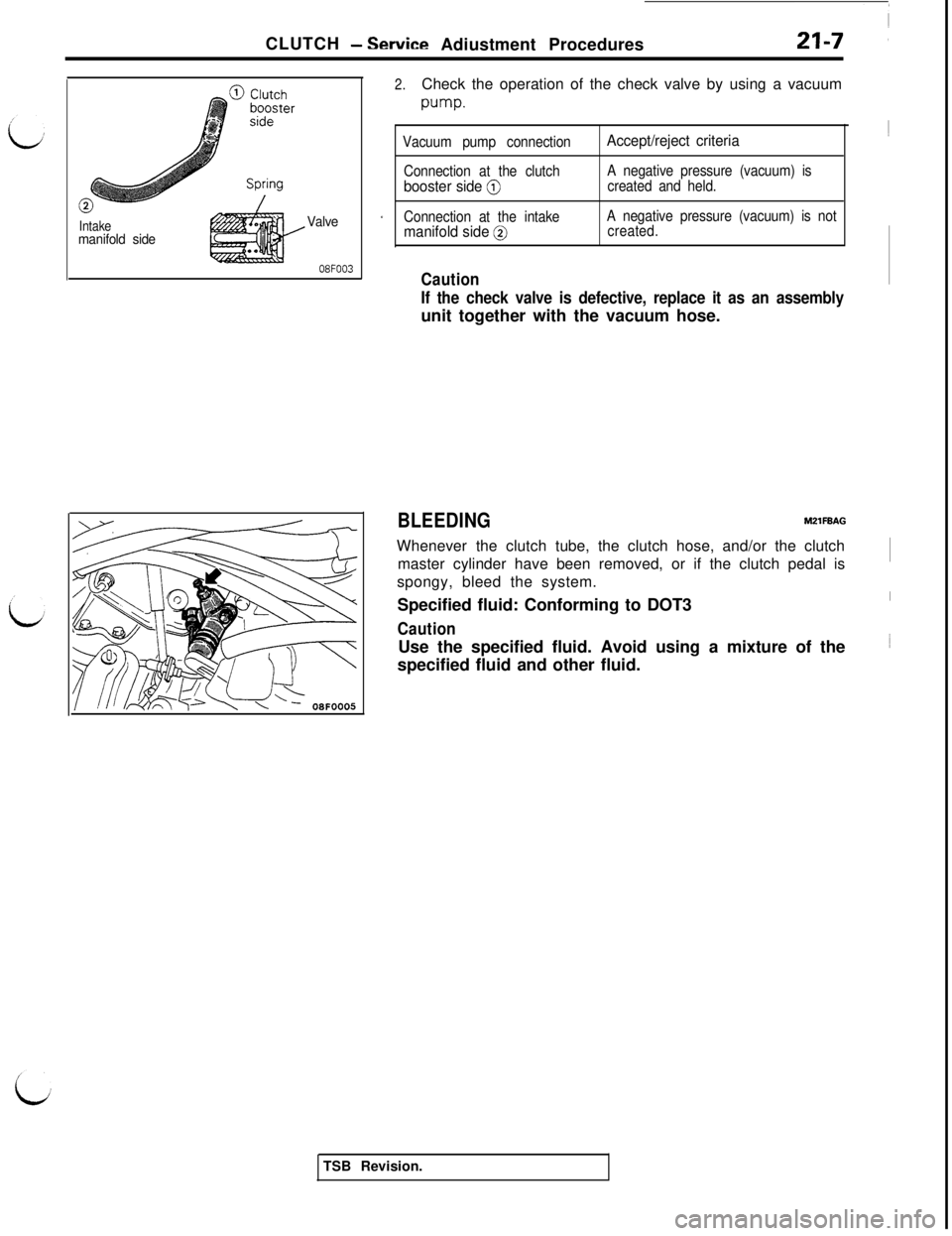

Intakemanifold sideValve

08FOO3

2.Check the operation of the check valve by using a vacuum

w-w.

Vacuum pump connectionAccept/reject criteria~

Connection at the clutchbooster side @

A negative pressure (vacuum) is

created and held.

rConnection at the intakemanifold side @

A negative pressure (vacuum) is not

created.

Caution

If the check valve is defective, replace it as an assemblyunit together with the vacuum hose.

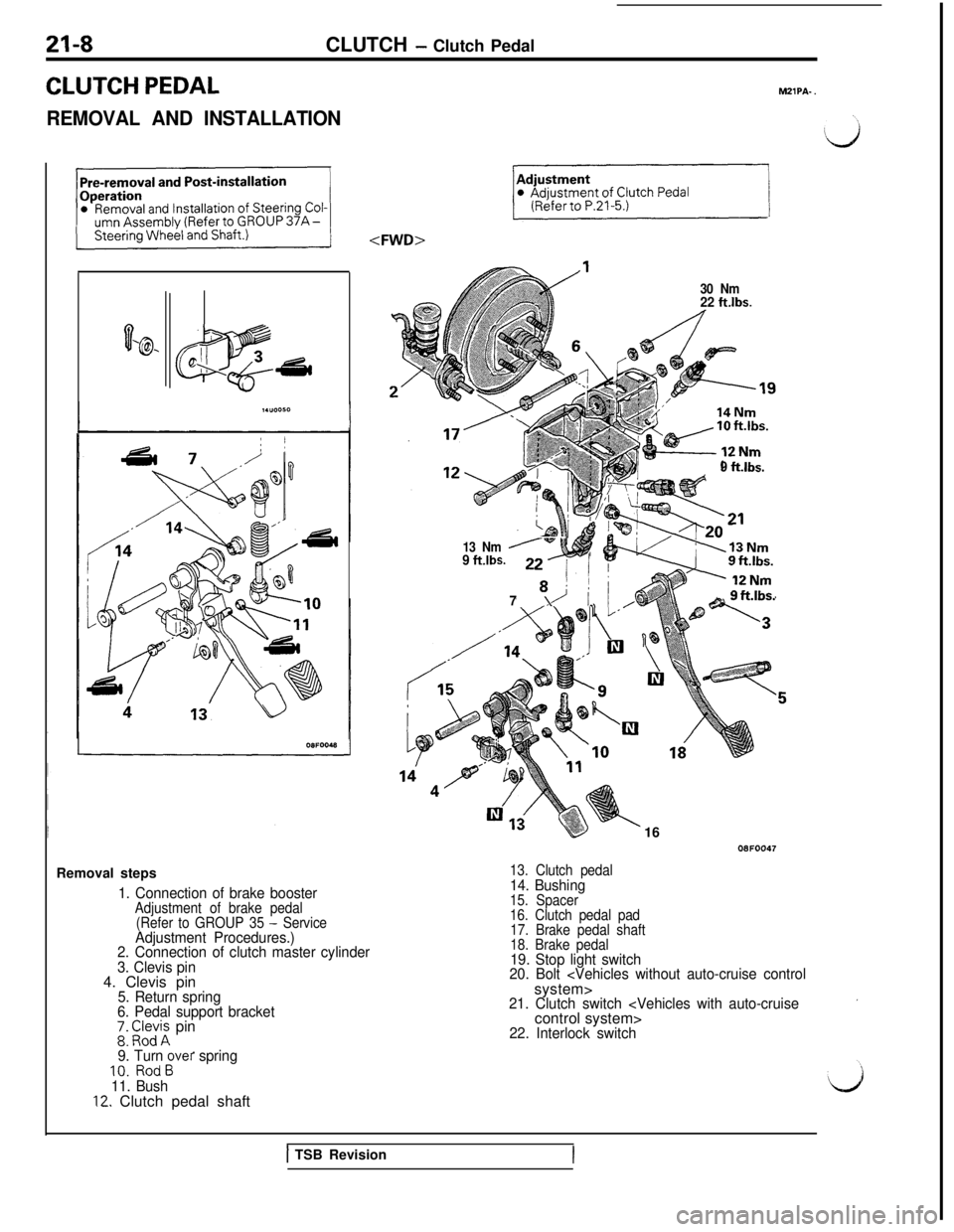

BLEEDINGMZlFBAGWhenever the clutch tube, the clutch hose, and/or the clutch

master cylinder have been removed, or if the clutch pedal is~

spongy, bleed the system.

Specified fluid: Conforming to DOT3

CautionUse the specified fluid. Avoid using a mixture of the

specified fluid and other fluid.

TSB Revision.

Page 366 of 1146

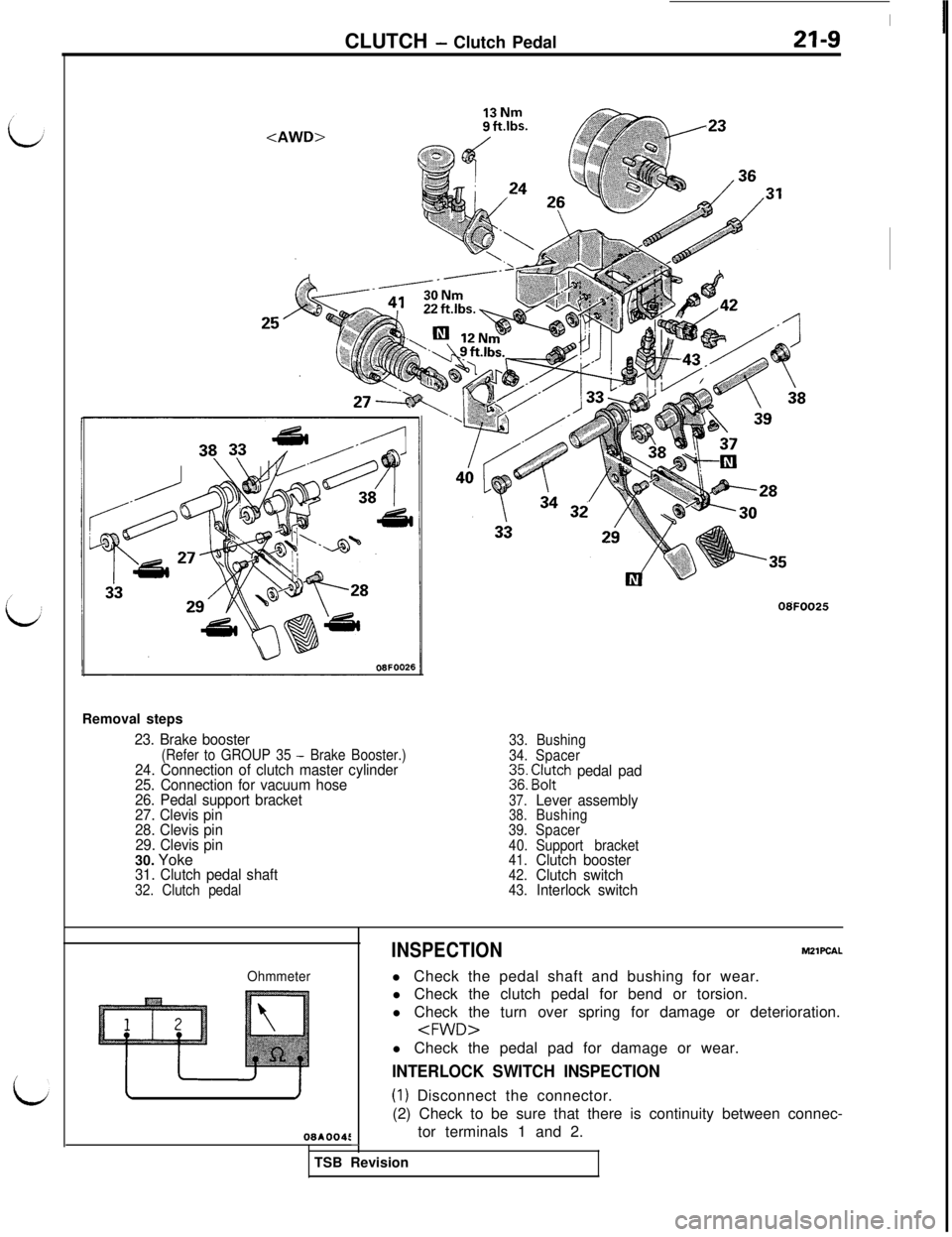

21-8CLUTCH - Clutch Pedal

CLUTCH PEDAL

REMOVAL AND INSTALLATIONMZlPA-

.

0‘@- D.,

a

;

IGsdRemoval steps

1. Connection of brake boosterAdjustment of brake pedal

(Refer to GROUP 35 - ServiceAdjustment Procedures.)

2. Connection of clutch master cylinder

3. Clevis pin4. Clevis pin

5. Return spring

6. Pedal support bracket

;: EIe;i; pin

9. Turn over spring10. RodB

11. Bush

12. Clutch pedal shaft

30 Nm22 ftlbs.

9 ft.lbs.

13 Nm

9 ft.lbs.Gw+,

8 !!

79 I_a 9ft.lbs.

k1608FOO47

13. Clutch pedal14. Bushing15. Spacer

16. Clutch pedal pad

17. Brake pedal shaft

18. Brake pedal

19. Stop light switch

20. Bolt

21. Clutch switch

22. Interlock switch

1 TSB Revision

Page 367 of 1146

IICLUTCH - Clutch Pedal

23. Brake booster(Refer to GROUP 35 - Brake Booster.)24. Connection of clutch master cylinder

25. Connection for vacuum hose

26. Pedal support bracket

27. Clevis pin

28. Clevis pin

29. Clevis pin30. Yoke

31. Clutch pedal shaft32. Clutch pedal08FOO25

33.Bushing

34.Spacer

$ E$ch pedal pad

37.Lever assembly38.Bushing

39.Spacer

40.Support bracket

41.

Clutch booster42.Clutch switch43.Interlock switch

Ohmmeter

08AOO4L

INSPECTIONMZlPCAL

l Check the pedal shaft and bushing for wear.

l Check the clutch pedal for bend or torsion.

l Check the turn over spring for damage or deterioration.

INTERLOCK SWITCH INSPECTION

(1) Disconnect the connector.

(2) Check to be sure that there is continuity between connec-

tor terminals 1 and 2.

-TSB Revision

Page 368 of 1146

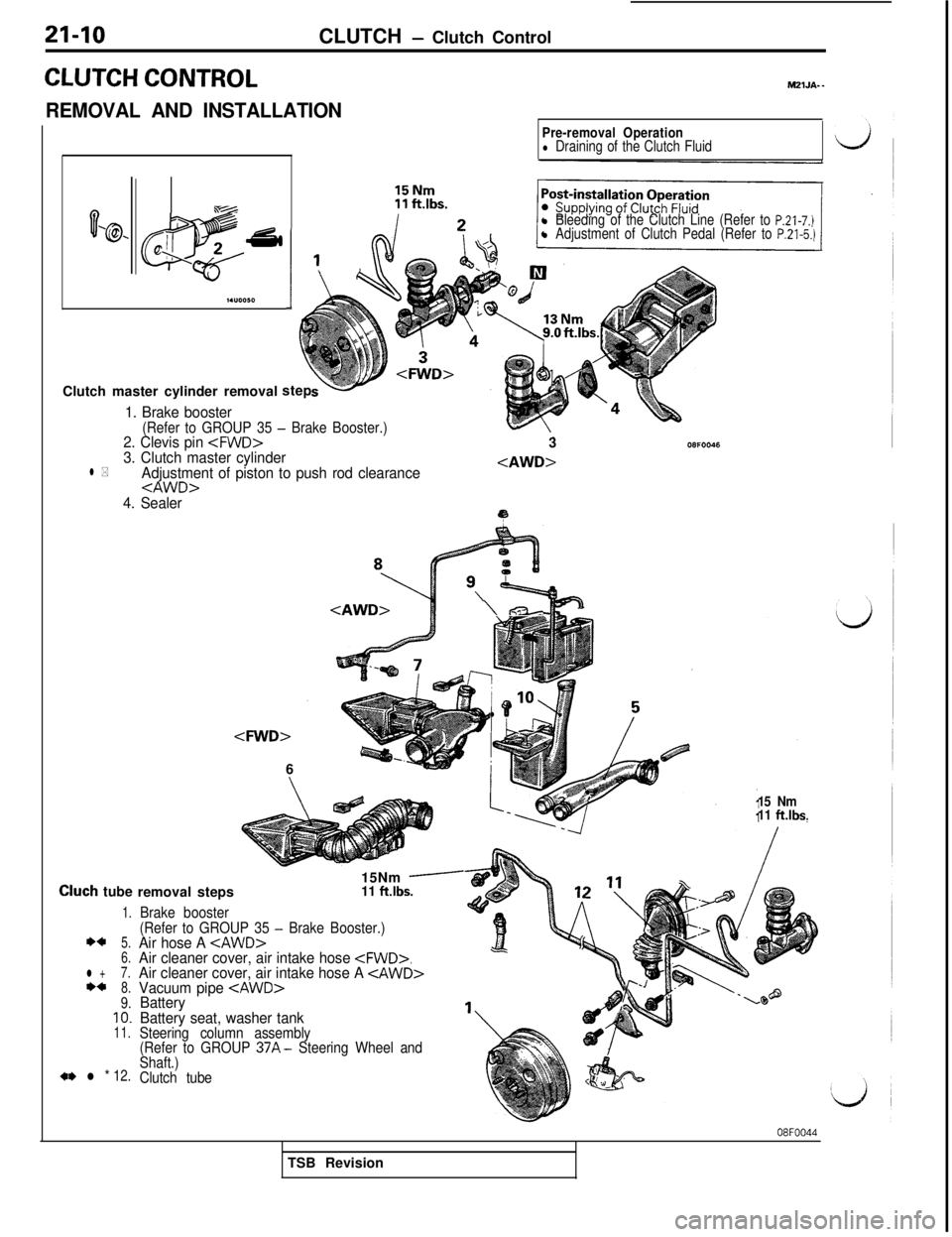

a-10CLUTCH - Clutch Control

CLUTCH CONTROL

REMOVAL AND INSTALLATIONMZlJA-

-

03% J 2’ti

m

I.“0050I

Pre-removal Operationl Draining of the Clutch Fluid

l Bleeding of the Clutch Line (Refer to P.21-7.)l Adjustment of Clutch Pedal (Refer to P.21-5.)Clutch master cylinder removalstep

1. Brake booster(Refer to GROUP 35 - Brake Booster.)2. Clevis pin

4. Sealer3

9

Cluch tube

1.

**5.

6.

l +7.**8.9.IO.11.

a* l * 12.

removal steps

Brake booster15Nm

-11 ft.lbs.

(Refer to GROUP 35

- Brake Booster.)Air hose A

Battery seat, washer tank

Steering column assembly

(Refer to GROUP 37A- Steering Wheel and

Shaft.)

Clutch tube15 Nm

11

ft.lbs.

08FOO44TSB Revision

Page 369 of 1146

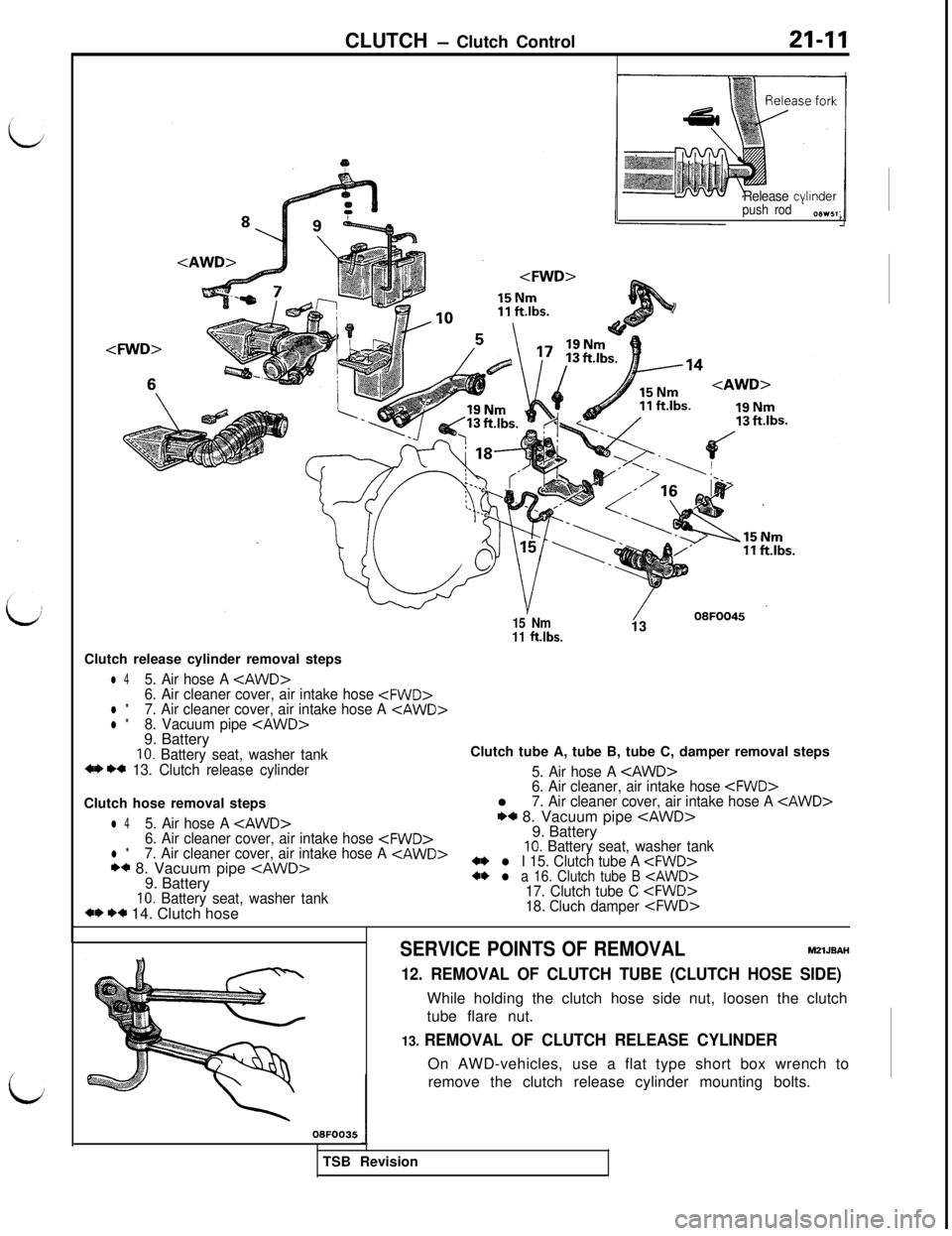

Release cylinder

push rod

txw51:

15 Nm

11 ftlbs.1308FOO45

Clutch release cylinder removal steps

l 45. Air hose A

10. Battery seat, washer tankClutch tube A, tube B, tube C, damper removal steps+* *+ 13. Clutch release cylinder

5. Air hose A

Clutch hose removal steps

6. Air cleaner, air intake hose

l 45. Air hose A

6. Air cleaner cover, air intake hose

** 8. Vacuum pipe

9. Battery+* l a 16. Clutch tube B cAWD>

10. Battery seat, washer tank17. Clutch tube C

- Clutch Control21-11

13. REMOVAL OF CLUTCH RELEASE CYLINDEROn AWD-vehicles, use a flat type short box wrench to

remove the clutch release cylinder mounting bolts.

08FOO351TSB Revision

SERVICE POINTS OF REMOVALM2lJBAH

12. REMOVAL OF CLUTCH TUBE (CLUTCH HOSE SIDE)While holding the clutch hose side nut, loosen the clutch

tube flare nut.

Page 370 of 1146

21-12CLUTCH - Clutch ControlOBFOOBf

!J

03FOOE

- Air intake hose B05FOO23

Air Intake

hose C

aAir intake hose A

Air hose CAir hose AI

05FOOZE

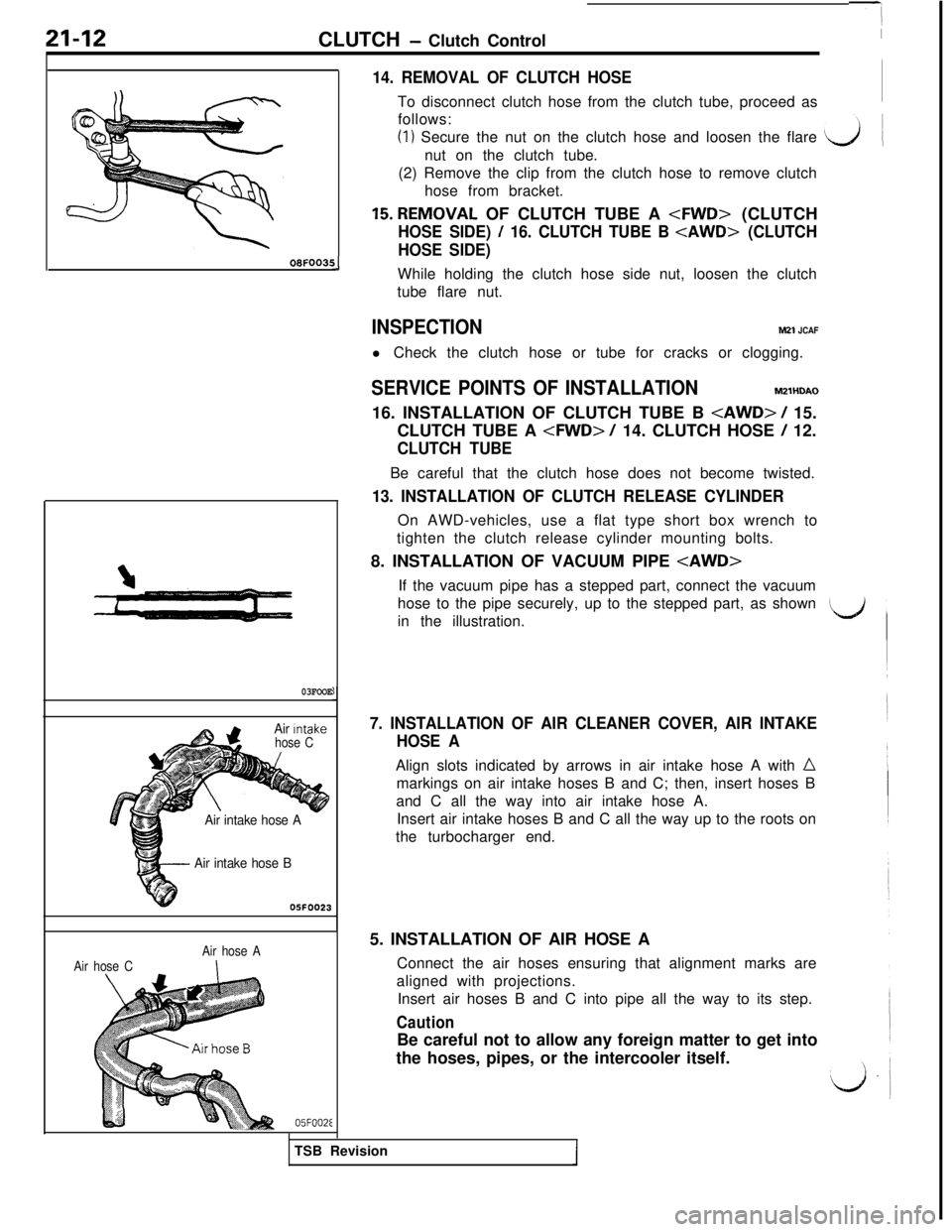

14. REMOVAL OF CLUTCH HOSETo disconnect clutch hose from the clutch tube, proceed as

follows:

(I) Secure the nut on the clutch hose and loosen the flare

nut on the clutch tube.

(2) Remove the clip from the clutch hose to remove clutch

hose from bracket.

15.REMOVAL OF CLUTCH TUBE A

HOSE SIDE) / 16. CLUTCH TUBE B

HOSE SIDE)While holding the clutch hose side nut, loosen the clutch

tube flare nut.

INSPECTIONM21 JCAFl Check the clutch hose or tube for cracks or clogging.

SERVICE POINTS OF INSTALLATIONM2lHDAO

16. INSTALLATION OF CLUTCH TUBE B

CLUTCH TUBE A

CLUTCH TUBEBe careful that the clutch hose does not become twisted.

13. INSTALLATION OF CLUTCH RELEASE CYLINDEROn AWD-vehicles, use a flat type short box wrench to

tighten the clutch release cylinder mounting bolts.

8. INSTALLATION OF VACUUM PIPE

hose to the pipe securely, up to the stepped part, as shown

in the illustration.

7. INSTALLATION OF AIR CLEANER COVER, AIR INTAKE

HOSE AAlign slots indicated by arrows in air intake hose A with

nmarkings on air intake hoses B and C; then, insert hoses B

and C all the way into air intake hose A.

Insert air intake hoses B and C all the way up to the roots on

the turbocharger end.

5. INSTALLATION OF AIR HOSE A

Connect the air hoses ensuring that alignment marks are

aligned with projections.

Insert air hoses B and C into pipe all the way to its step.

CautionBe careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

TSB Revision