MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 391 of 1146

MANUAL TRANSAXLE

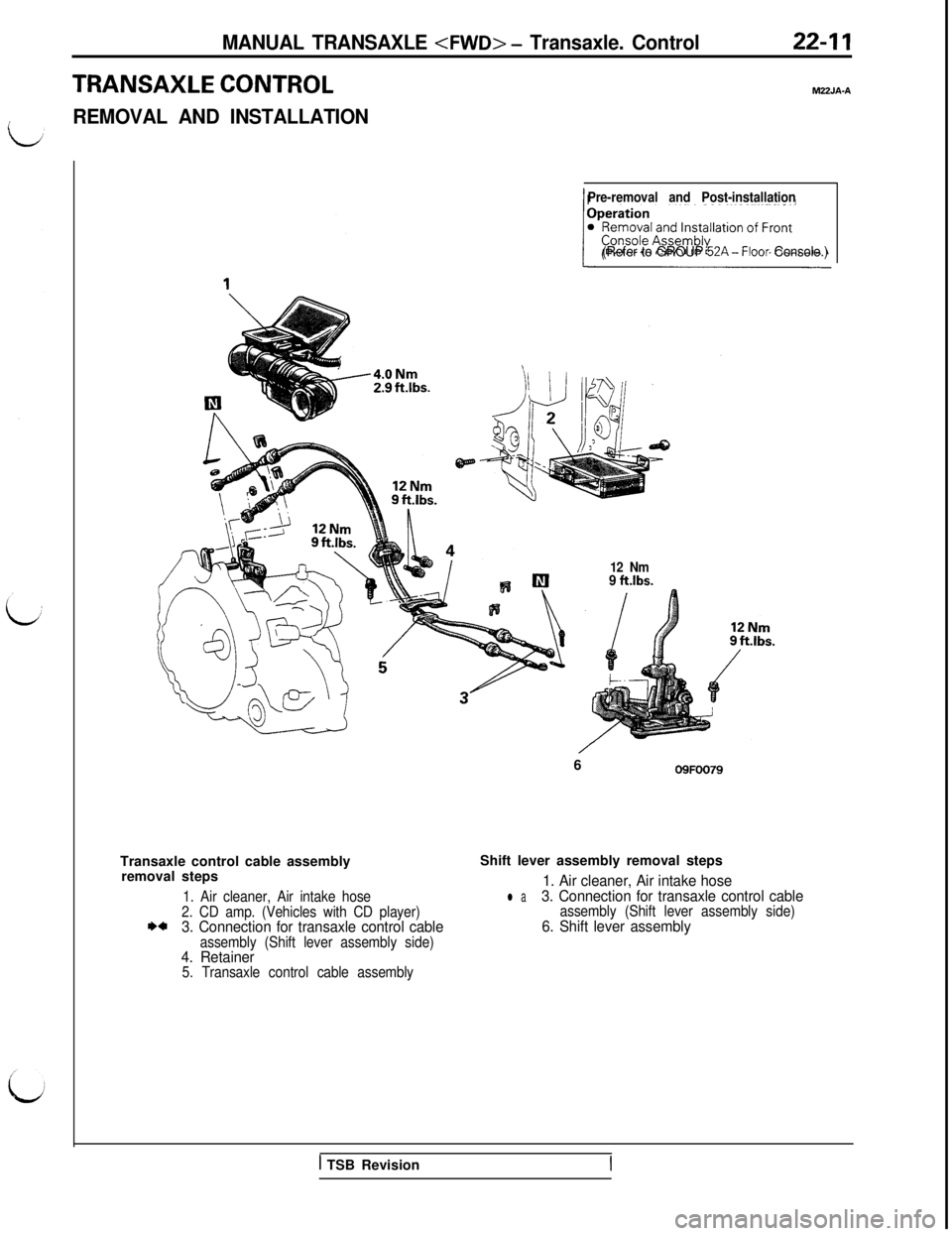

TRANSAXLE CONTROLM22JA-A

IREMOVAL AND INSTALLATION

Pre-removal and Post-installation

(Refer to GROUP 52A-Floor Console.)Transaxle control cable assembly

removal steps

1. Air cleaner, Air intake hose

2. CD amp. (Vehicles with CD player)

I)*3. Connection for transaxle control cableassembly (Shift lever assembly side)4. Retainer5. Transaxle control cable assembly12 Nm

9 ft.lbs.

/6

09FOO79Shift lever assembly removal steps

1. Air cleaner, Air intake hose

l a3. Connection for transaxle control cableassembly (Shift lever assembly side)6. Shift lever assembly

1 TSB Revision

Page 392 of 1146

22-12MANUAL TRANSAXLE

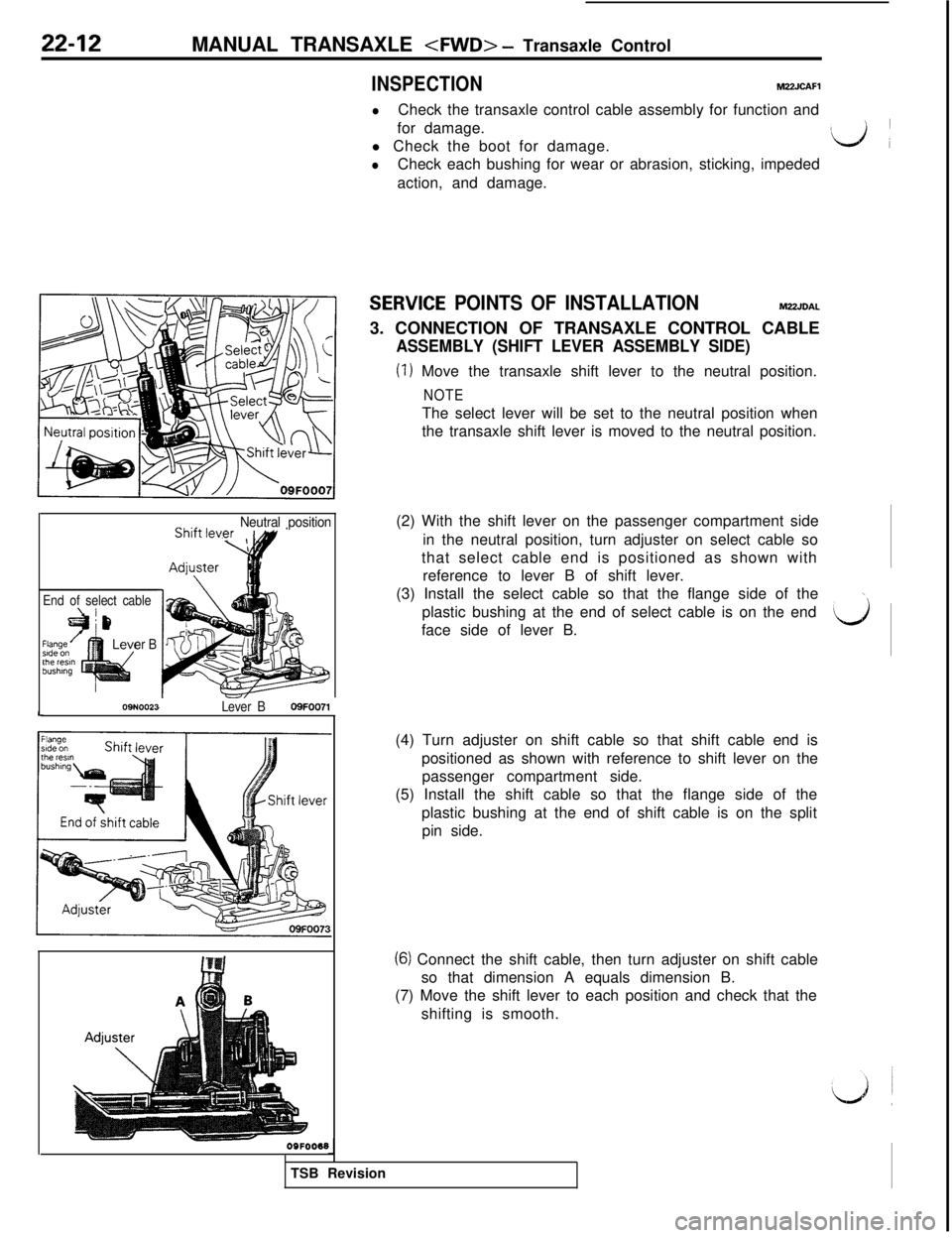

INSPECTIONM22JCAFl

lCheck the transaxle control cable assembly for function and

for damage.

l Check the boot for damage.

IlJ 1

lCheck each bushing for wear or abrasion, sticking, impeded

action, and damage.

0910023Lever B09FOO71

End of select cable

er B

Neutral position

OSFOOo8

SERVlCE POINTS OF INSTALLATIONMUJDAL

3. CONNECTION OF TRANSAXLE CONTROL CABLE

ASSEMBLY (SHIFT LEVER ASSEMBLY SIDE)

(I) Move the transaxle shift lever to the neutral position.

NOTEThe select lever will be set to the neutral position when

the transaxle shift lever is moved to the neutral position.

(2) With the shift lever on the passenger compartment side

in the neutral position, turn adjuster on select cable so

that select cable end is positioned as shown with

reference to lever B of shift lever.

(3) Install the select cable so that the flange side of the

\plastic bushing at the end of select cable is on the end

face side of lever B.

d(4) Turn adjuster on shift cable so that shift cable end is

positioned as shown with reference to shift lever on the

passenger compartment side.

(5) Install the shift cable so that the flange side of the

plastic bushing at the end of shift cable is on the split

pin side.

(6) Connect the shift cable, then turn adjuster on shift cable

so that dimension A equals dimension B.

(7) Move the shift lever to each position and check that the

shifting is smooth.

TSB Revision

Page 393 of 1146

MANUAL TRANSAXLE

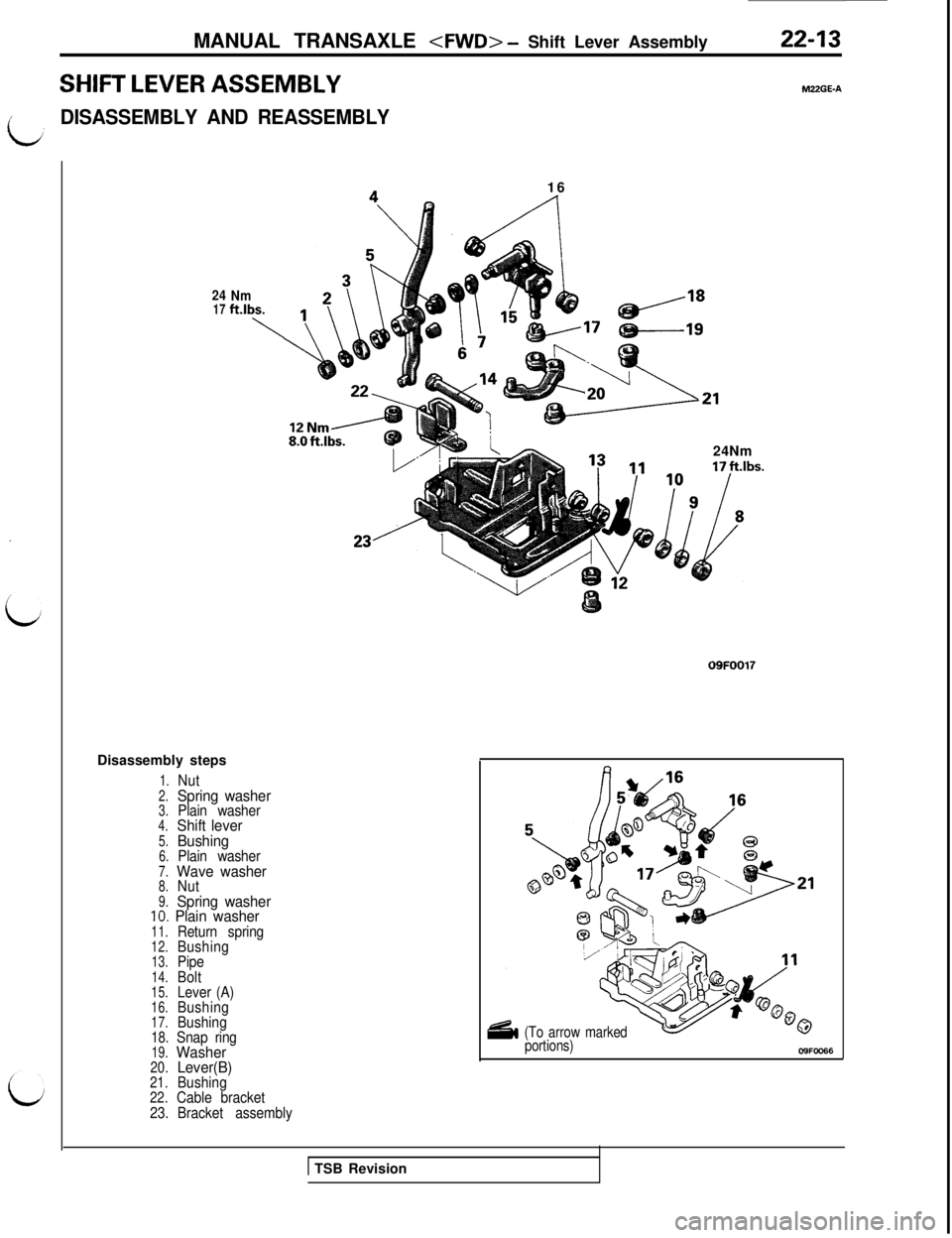

SHIFT LEVER ASSEMBLY

iDISASSEMBLY AND REASSEMBLY

2417Nmftlbs.

\Disassembly steps

1.Nut2.Spring washer3.Plain washer4.Shift lever5.Bushing6.Plain washer7.Wave washer8.Nut9.Spring washerIO. Plain washer11.Return spring12.Bushing13.Pipe14.Bolt15.Lever (A)16.Bushing17.Bushing18.Snap ring19.Washer20.Lever(B)21.Bushing22.Cable bracket

23.Bracket assembly16

24Nm

09FOO17

M22GE-A

(To arrow marked

portions)

OS%=0066

1 TSB Revision

Page 394 of 1146

22-14MANUAL TRANSAXLE

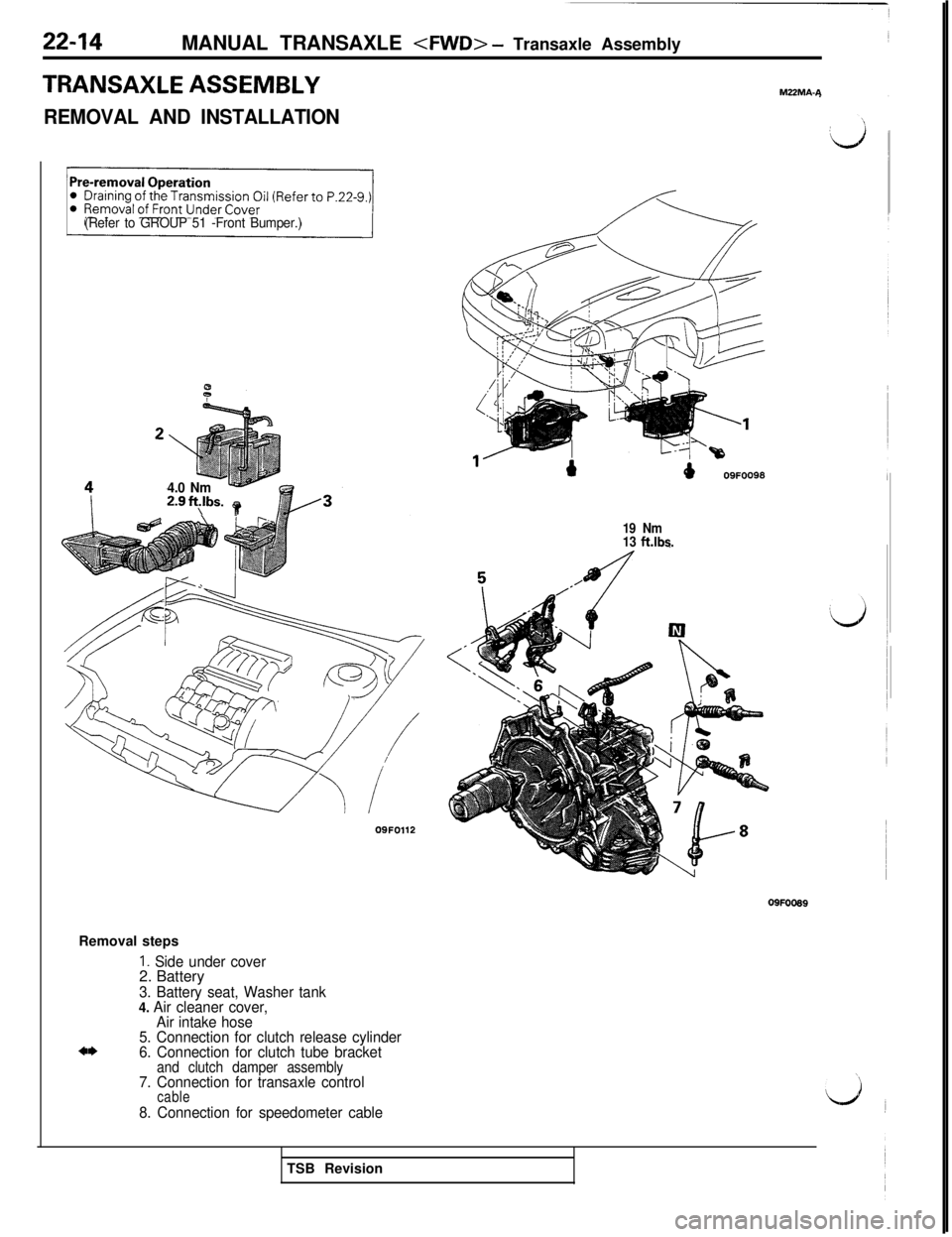

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

(Refer to GROUP 51 -Front Bumper.)

4.0 Nm2.9ft$bs. t09FO112

19 Nm

13 ft.lbs.M22MA-A

Removal steps

1. Side under cover2. Battery

3. Battery seat, Washer tank

4. Air cleaner cover,

Air intake hose

5. Connection for clutch release cylinder

6. Connection for clutch tube bracket

and clutch damper assembly7. Connection for transaxle controlcable

8. Connection for speedometer cable09FOO89

TSB Revision

Page 395 of 1146

MANUAL TRANSAXLE

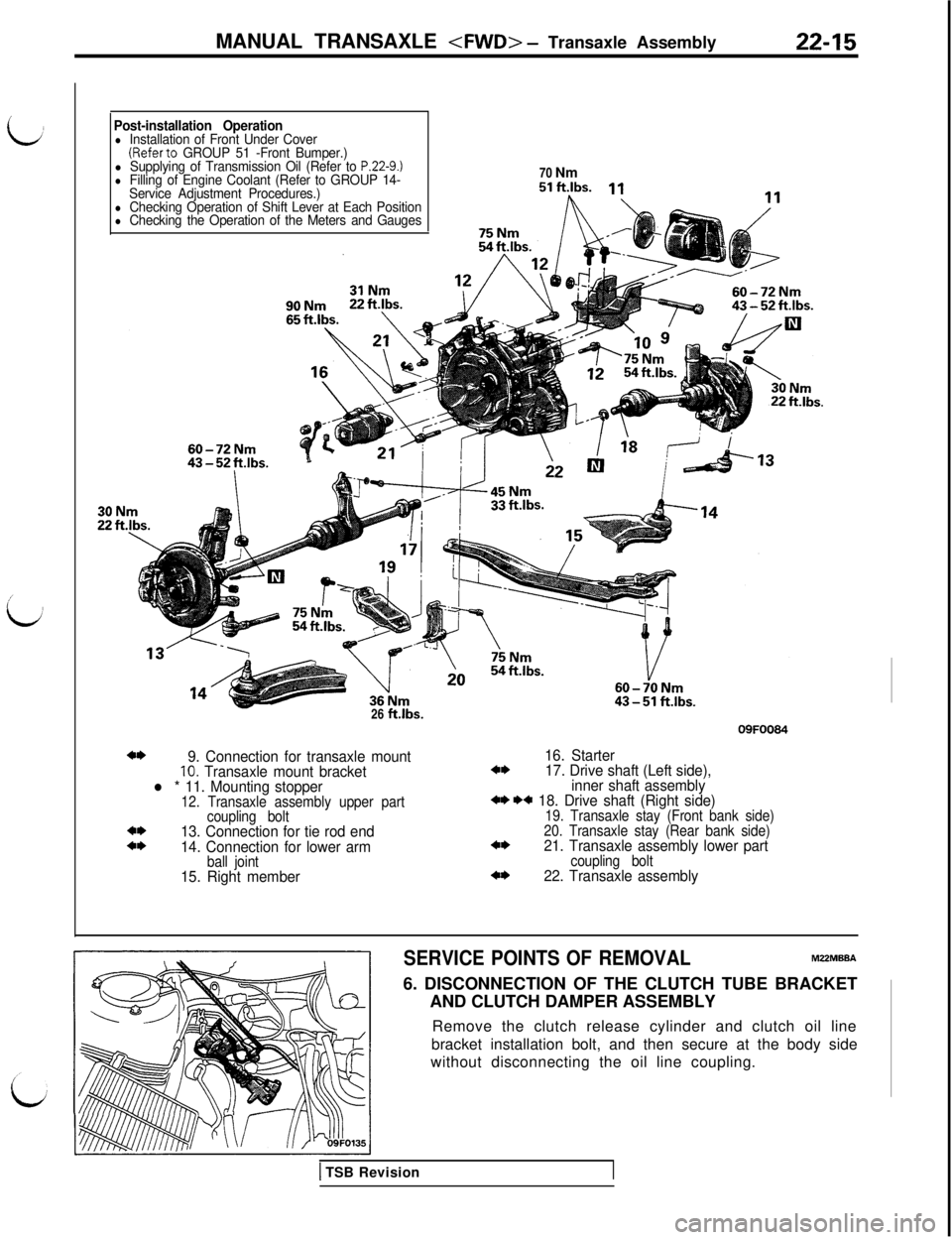

idPost-installation Operationl Installation of Front Under Cover(Referto GROUP 51 -Front Bumper.)l Supplying of Transmission Oil (Refer to P.22-9.)l Filling of Engine Coolant (Refer to GROUP 14-

Service Adjustment Procedures.)70 Nm

l Checking Operation of Shift Lever at Each Positionl Checking the Operation of the Meters and Gauges26

ft.lbs.09FOO84

4*9. Connection for transaxle mount16. Starter10. Transaxle mount bracket4*17. Drive shaft (Left side),

l * 11. Mounting stopperinner shaft assembly12. Transaxle assembly upper part+* ** 18. Drive shaft (Right side)

coupling bolt19. Transaxle stay (Front bank side)4*13. Connection for tie rod end20. Transaxle stay (Rear bank side)4*14. Connection for lower arm4*21. Transaxle assembly lower part

ball jointcoupling bolt15. Right member4*22. Transaxle assembly

SERVICE POINTS OF REMOVALMZZMBBA6. DISCONNECTION OF THE CLUTCH TUBE BRACKET

AND CLUTCH DAMPER ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the body side

without disconnecting the oil line coupling.

1 TSB Revision

Page 396 of 1146

22-16MANUAL TRANSAXLE

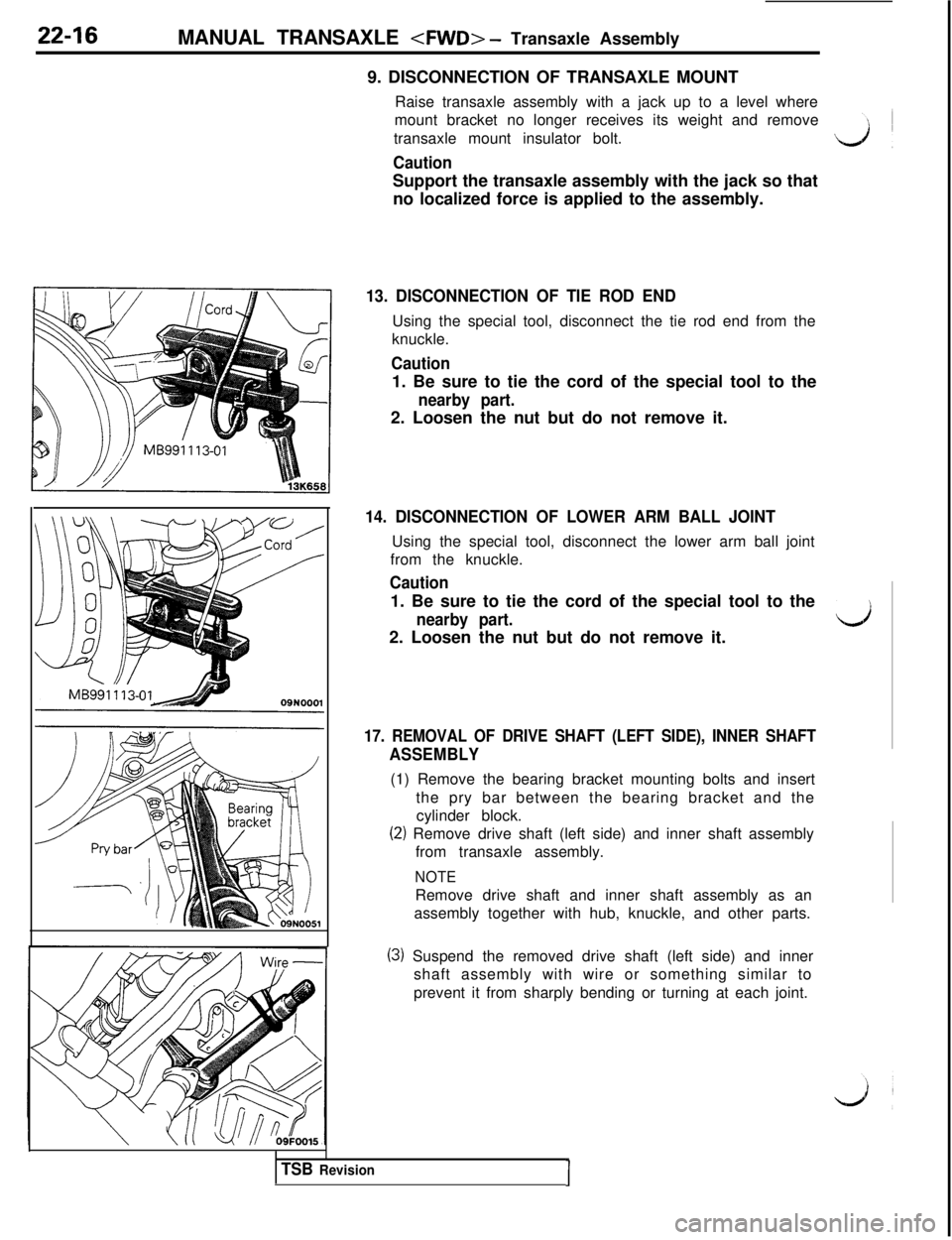

9. DISCONNECTION OF TRANSAXLE MOUNT

Raise transaxle assembly with a jack up to a level where

mount bracket no longer receives its weight and remove

transaxle mount insulator bolt.

CautionSupport the transaxle assembly with the jack so that

no localized force is applied to the assembly.

13. DISCONNECTION OF TIE ROD ENDUsing the special tool, disconnect the tie rod end from the

knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.2. Loosen the nut but do not remove it.

14. DISCONNECTION OF LOWER ARM BALL JOINTUsing the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution1. Be sure to tie the cord of the special tool to the

nearby part.2. Loosen the nut but do not remove it.

17. REMOVAL OF DRIVE SHAFT (LEFT SIDE), INNER SHAFT

ASSEMBLY(1) Remove the bearing bracket mounting bolts and insert

the pry bar between the bearing bracket and the

cylinder block.

(2) Remove drive shaft (left side) and inner shaft assembly

from transaxle assembly.

NOTERemove drive shaft and inner shaft assembly as an

assembly together with hub, knuckle, and other parts.

(3) Suspend the removed drive shaft (left side) and inner

shaft assembly with wire or something similar to

prevent it from sharply bending or turning at each joint.

TSB RevisionI

Page 397 of 1146

MANUAL TRANSAXLE

Transaxmount

bracket

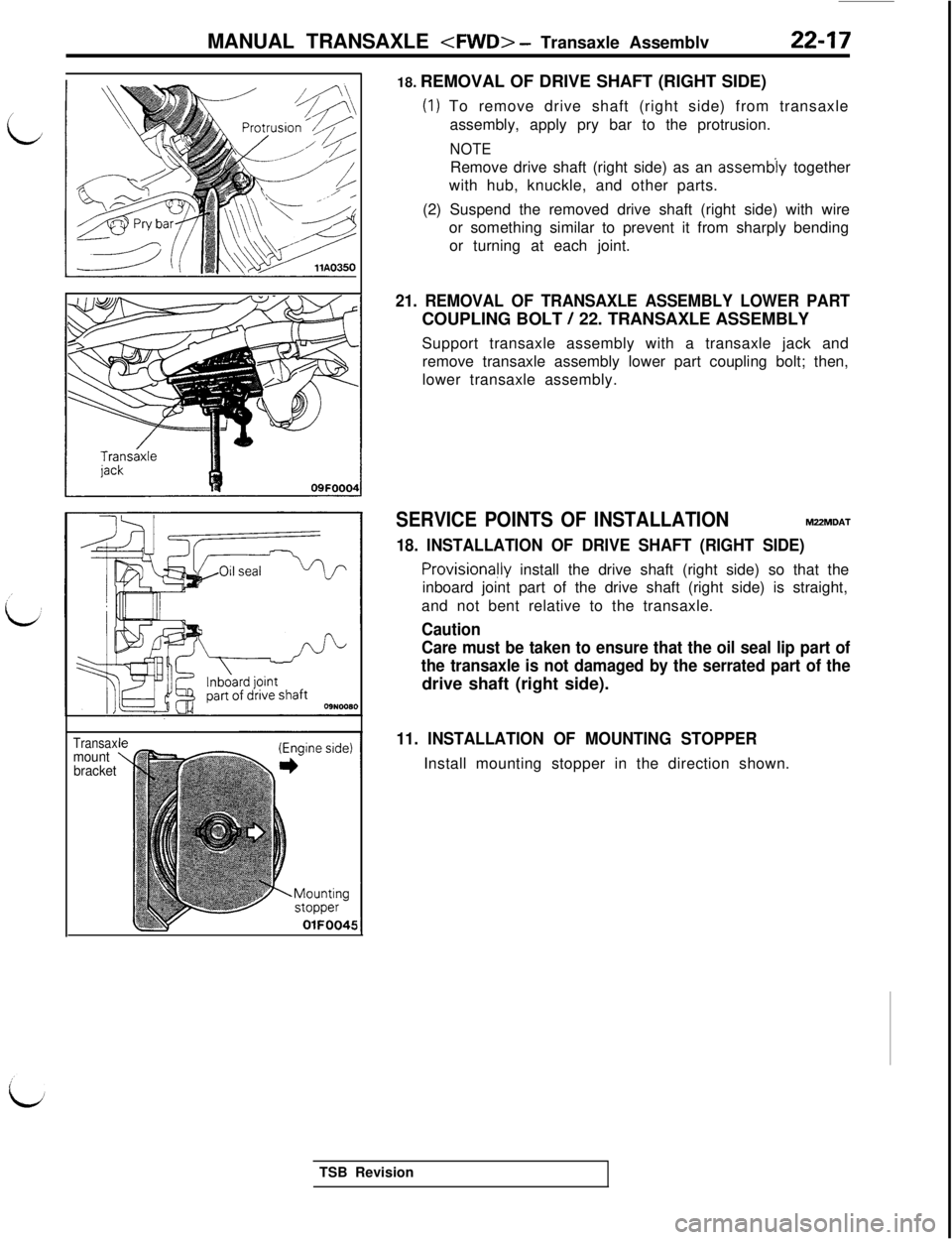

OlFOO4518. REMOVAL OF DRIVE SHAFT (RIGHT SIDE)

(1) To remove drive shaft (right side) from transaxle

assembly, apply pry bar to the protrusion.

NOTERemove drive shaft (right side) as an

assemb’ly together

with hub, knuckle, and other parts.

(2) Suspend the removed drive shaft (right side) with wire

or something similar to prevent it from sharply bending

or turning at each joint.

21. REMOVAL OF TRANSAXLE ASSEMBLY LOWER PARTCOUPLING BOLT

/ 22. TRANSAXLE ASSEMBLY

Support transaxle assembly with a transaxle jack and

remove transaxle assembly lower part coupling bolt; then,

lower transaxle assembly.

SERVICE POINTS OF INSTALLATIONM2ZMDAT

18. INSTALLATION OF DRIVE SHAFT (RIGHT SIDE)

ProvisionaHy install the drive shaft (right side) so that the

inboard joint part of the drive shaft (right side) is straight,

and not bent relative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip part of

the transaxle is not damaged by the serrated part of thedrive shaft (right side).

11. INSTALLATION OF MOUNTING STOPPERInstall mounting stopper in the direction shown.

TSB Revision

Page 398 of 1146

22-18MANUAL TRANSAXLE

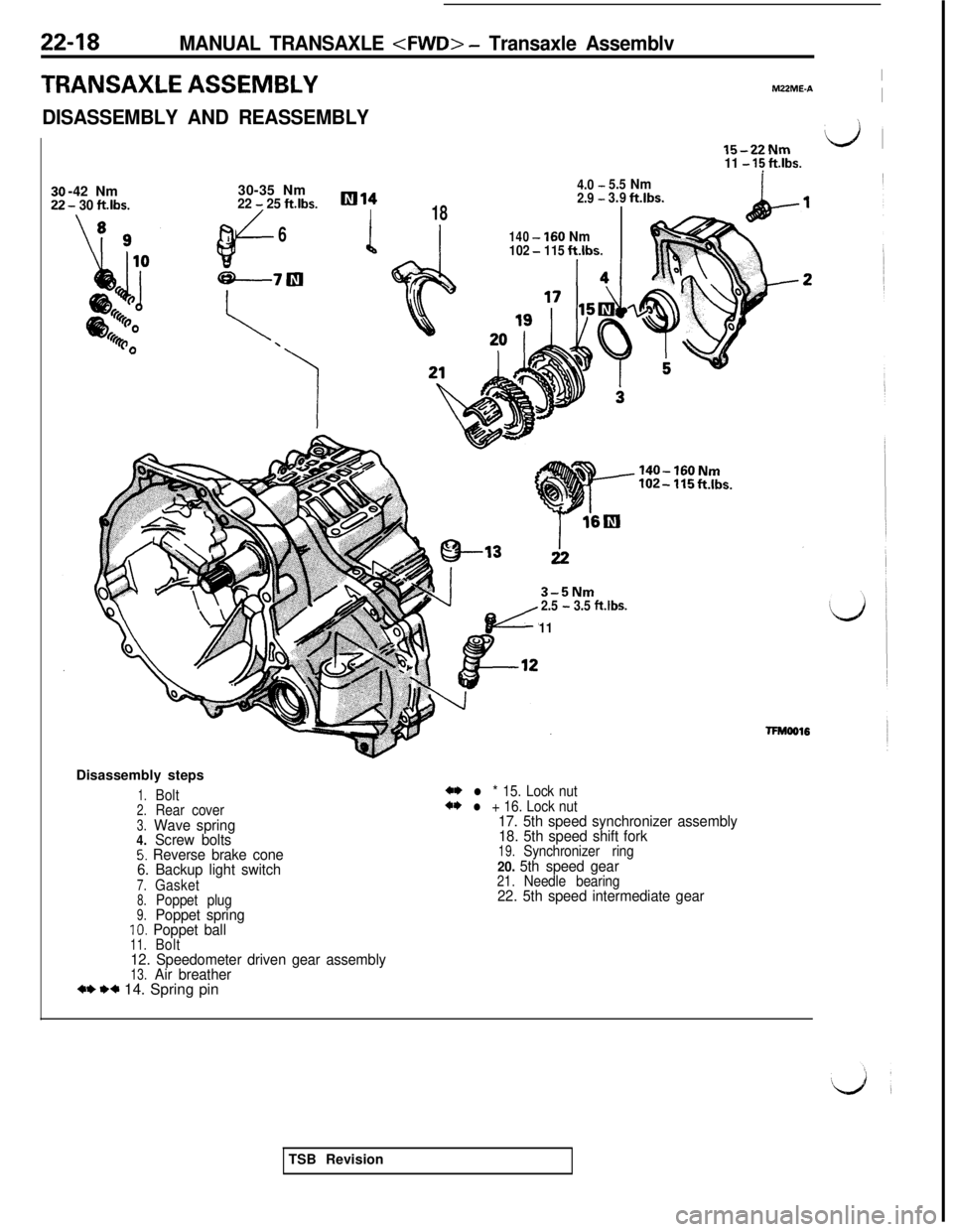

TRANSAXLE ASSEMBLYIM22ME.A

I

DISASSEMBLY AND REASSEMBLY

l5-22Nmdl

11 - 15 ftlbs.

-42 Nm

- 30 ftlbs.30-35 Nm

4.0 -5.5Nm

22

- 25 ft.lbs.lIll42.9 -3.9ftlbs.

/I18

J6140-160Nm1102-115ftlbs.

3-5Nm2.5 - 3.5 ftlbs.

11Disassembly steps

1.Bolt2.Rear cover3.Wave spring4.Screw bolts5. Reverse brake cone

6. Backup light switch

7.Gasket8.Poppet plug9.Poppet springIO. Poppet ball11.Bolt12. Speedometer driven gear assembly13.Air breather+* +* 14. Spring pin

*+ l * 15. Lock nut*+ l + 16. Lock nut17. 5th speed synchronizer assembly

18. 5th speed shift fork

19.Synchronizer ring20. 5th speed gear21.Needle bearing22. 5th speed intermediate gearTSB Revision

Page 399 of 1146

MANUAL TRANSAXLE

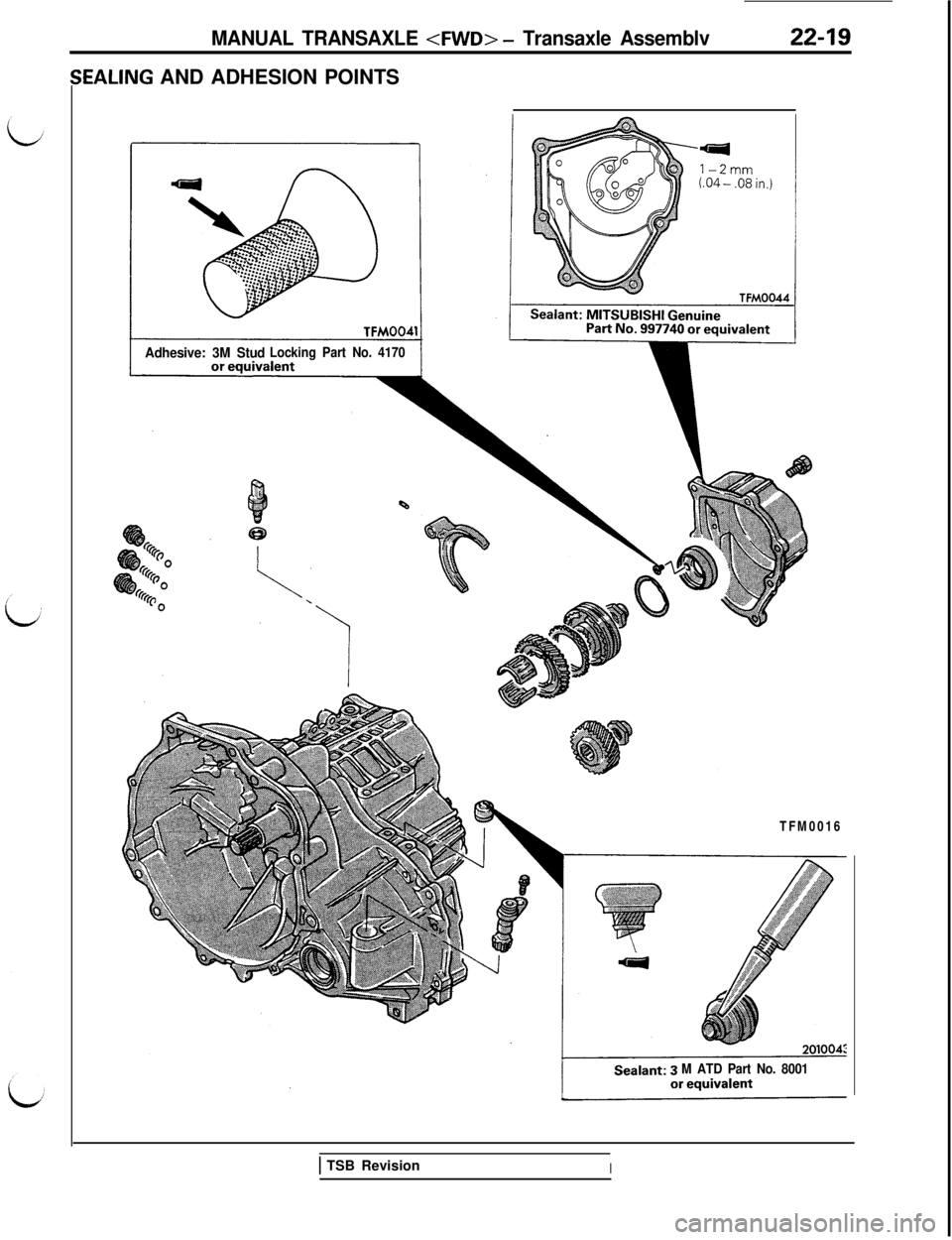

;EALING AND ADHESION POINTS

Adhesive: 3M StudLocking Part No. 4170TFM0016

M ATD Part No. 8001

1 TSB RevisionI

Page 400 of 1146

22-20MANUAL TRANSAXLE

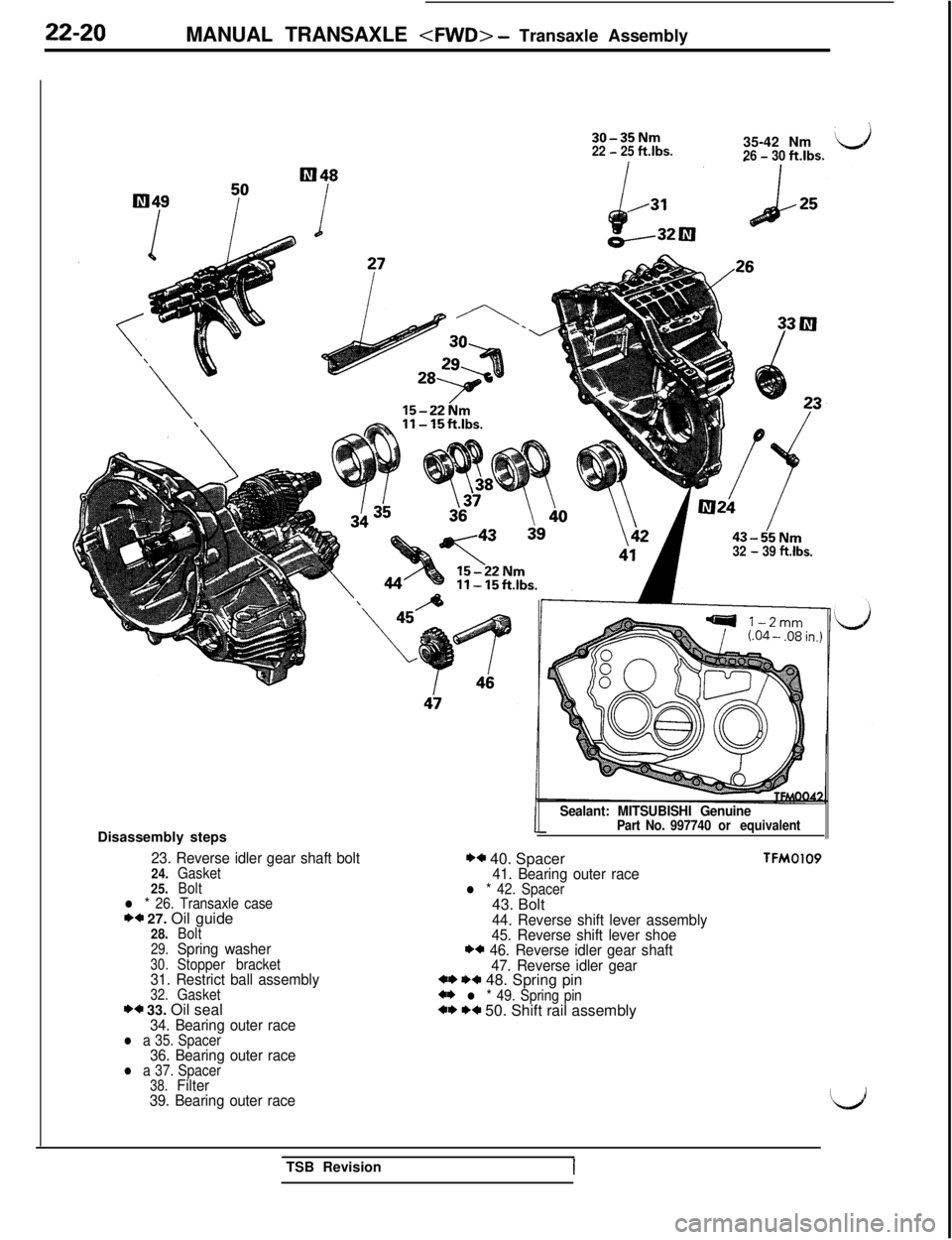

30-35Nm22 - 25ftlbs.35-42 Nm26 - 30ft.lbs.

43-55Nm32 - 39 ft.lbs.Disassembly steps

23. Reverse idler gear shaft bolt24.Gasket

25.Bolt

l * 26. Transaxle caseI)* 27. Oil guide28.Bolt29.Spring washer30.Stopper bracket31. Restrict ball assembly32.Gasket** 33. Oil seal34. Bearing outer racel a 35. Spacer36. Bearing outer racel a 37. Spacer38.Filter

39. Bearing outer raceSealant: MITSUBISHI Genuine

Part No. 997740 or equivalent

** 40. Spacer41. Bearing outer racel * 42. Spacer43. Bolt

44. Reverse shift lever assembly

45. Reverse shift lever shoe

** 46. Reverse idler gear shaft

47. Reverse idler gear

*I) I)+ 48. Spring pin*I) l * 49. Spring pin*,I) I)* 50. Shift rail assembly

TFMOlO9TSB Revision