MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 571 of 1146

PROPELLER SHAFT - Propeller Shaft25-7Mating marks

1ONOOOL

1 ON0003Mating marks

(commercially available)

\lOS520 'lOY507

SERVICE POINTS OF DISASSEMBLYM25GFAO

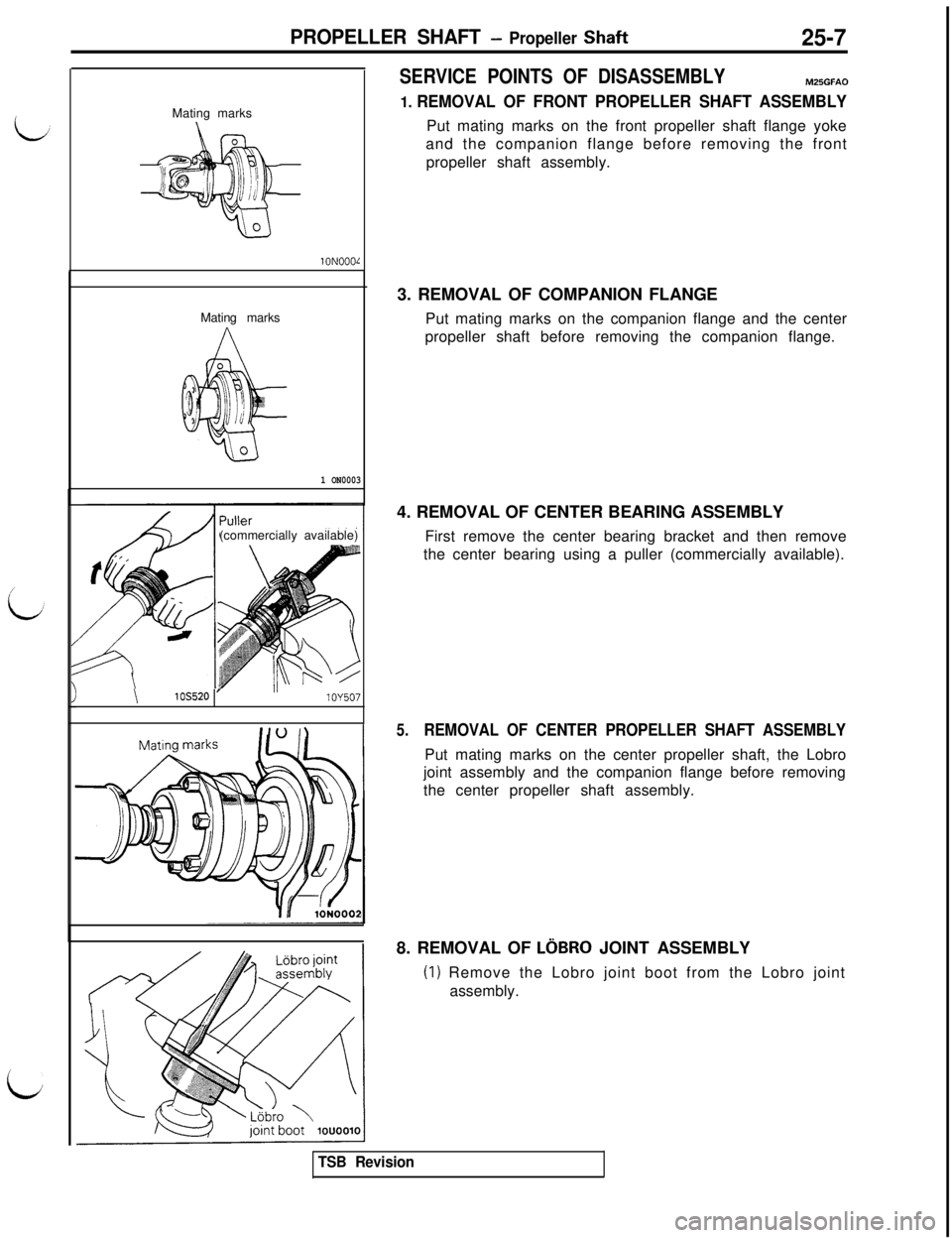

1. REMOVAL OF FRONT PROPELLER SHAFT ASSEMBLYPut mating marks on the front propeller shaft flange yoke

and the companion flange before removing the front

propeller shaft assembly.

3. REMOVAL OF COMPANION FLANGE

Put mating marks on the companion flange and the center

propeller shaft before removing the companion flange.

4. REMOVAL OF CENTER BEARING ASSEMBLY

First remove the center bearing bracket and then remove

the center bearing using a puller (commercially available).

5.REMOVAL OF CENTER PROPELLER SHAFT ASSEMBLYPut mating marks on the center propeller shaft, the Lobro

joint assembly and the companion flange before removing

the center propeller shaft assembly.

8. REMOVAL OF

LOBRO JOINT ASSEMBLY

(1) Remove the Lobro joint boot from the Lobro joint

assembly.

TSB Revision

Page 572 of 1146

25-8PROPELLER SHAFT - Propeller Shaft1 Mating marks

I,A ^.IOuter raceICageInner race

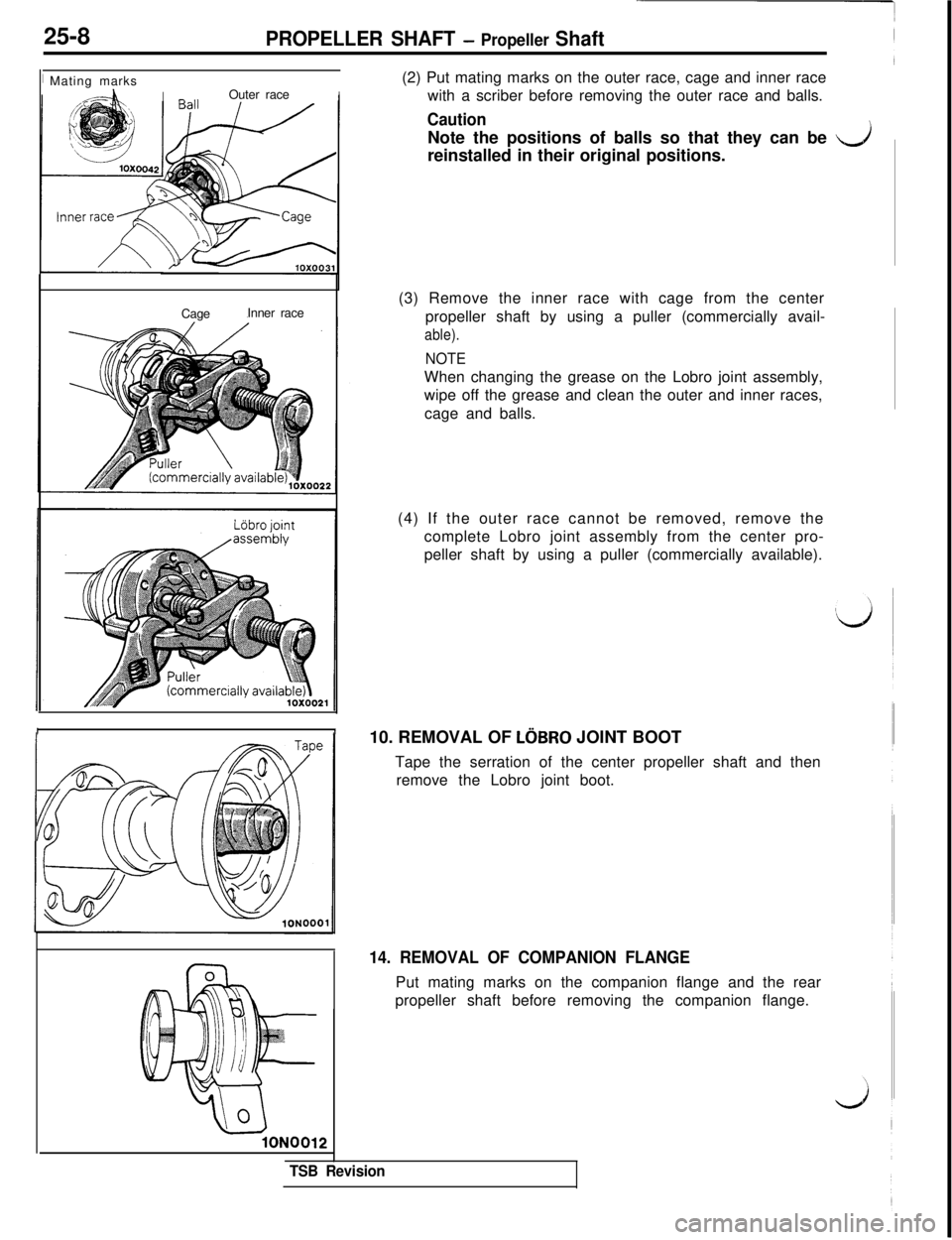

IIlON0012(2) Put mating marks on the outer race, cage and inner race

with a scriber before removing the outer race and balls.

CautionNote the positions of balls so that they can be

dreinstalled in their original positions.

(3) Remove the inner race with cage from the center

propeller shaft by using a puller (commercially avail-

able).

NOTEWhen changing the grease on the Lobro joint assembly,

wipe off the grease and clean the outer and inner races,

cage and balls.

(4) If the outer race cannot be removed, remove the

complete Lobro joint assembly from the center pro-

peller shaft by using a puller (commercially available).

10. REMOVAL OF

LOBRO JOINT BOOT

Tape the serration of the center propeller shaft and then

remove the Lobro joint boot.

14. REMOVAL OF COMPANION FLANGEPut mating marks on the companion flange and the rear

propeller shaft before removing the companion flange.

TSB Revision

Page 573 of 1146

PROPELLER SHAFT - Propeller Shaft25-9

L;Puller

[commercially available)

Companion flange

Rubber mountSelfnut-lockir

lON0007

e

lONO10X0018

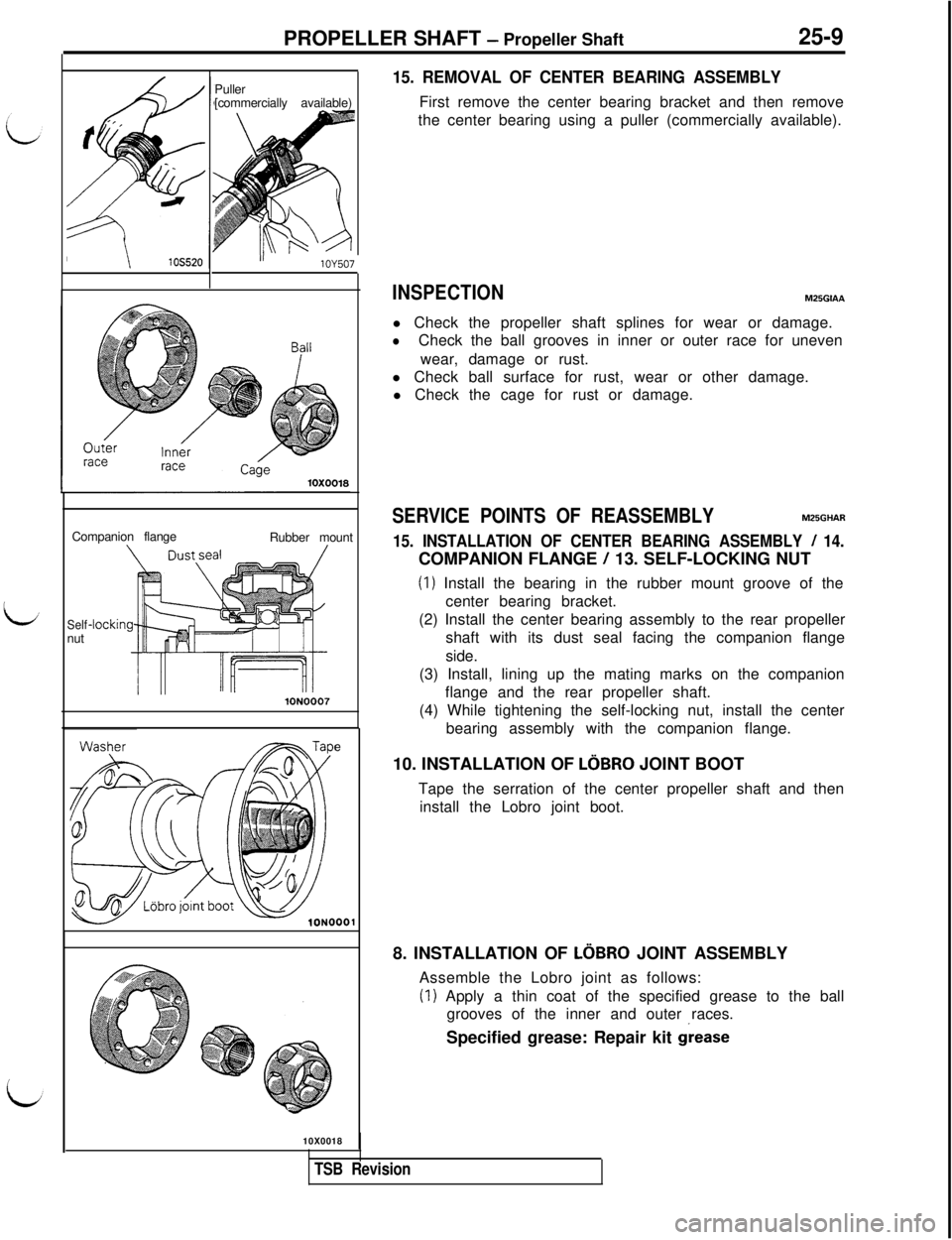

15. REMOVAL OF CENTER BEARING ASSEMBLYFirst remove the center bearing bracket and then remove

the center bearing using a puller (commercially available).

INSPECTIONM25GIAAl Check the propeller shaft splines for wear or damage.

lCheck the ball grooves in inner or outer race for uneven

wear, damage or rust.

l Check ball surface for rust, wear or other damage.

l Check the cage for rust or damage.

SERVICE POINTS OF REASSEMBLYM25GHA.R

15. INSTALLATION OF CENTER BEARING ASSEMBLY

/ 14.COMPANION FLANGE

/ 13. SELF-LOCKING NUT

(1) Install the bearing in the rubber mount groove of the

center bearing bracket.

(2) Install the center bearing assembly to the rear propeller

shaft with its dust seal facing the companion flange

side.

(3) Install, lining up the mating marks on the companion

flange and the rear propeller shaft.

(4) While tightening the self-locking nut, install the center

bearing assembly with the companion flange.

10. INSTALLATION OF

LOBRO JOINT BOOT

Tape the serration of the center propeller shaft and then

install the Lobro joint boot.

8. INSTALLATION OF

LOBRO JOINT ASSEMBLY

Assemble the Lobro joint as follows:

(I) Apply a thin coat of the specified grease to the ball

grooves of the inner and outer races.

Specified grease: Repair kit

giease

TSB Revision

Page 574 of 1146

25-10

PROPELLER SkIAFT - ProDeller Shaft

Iinner race

Recessed end

of inner race

Chamfered end

of cage

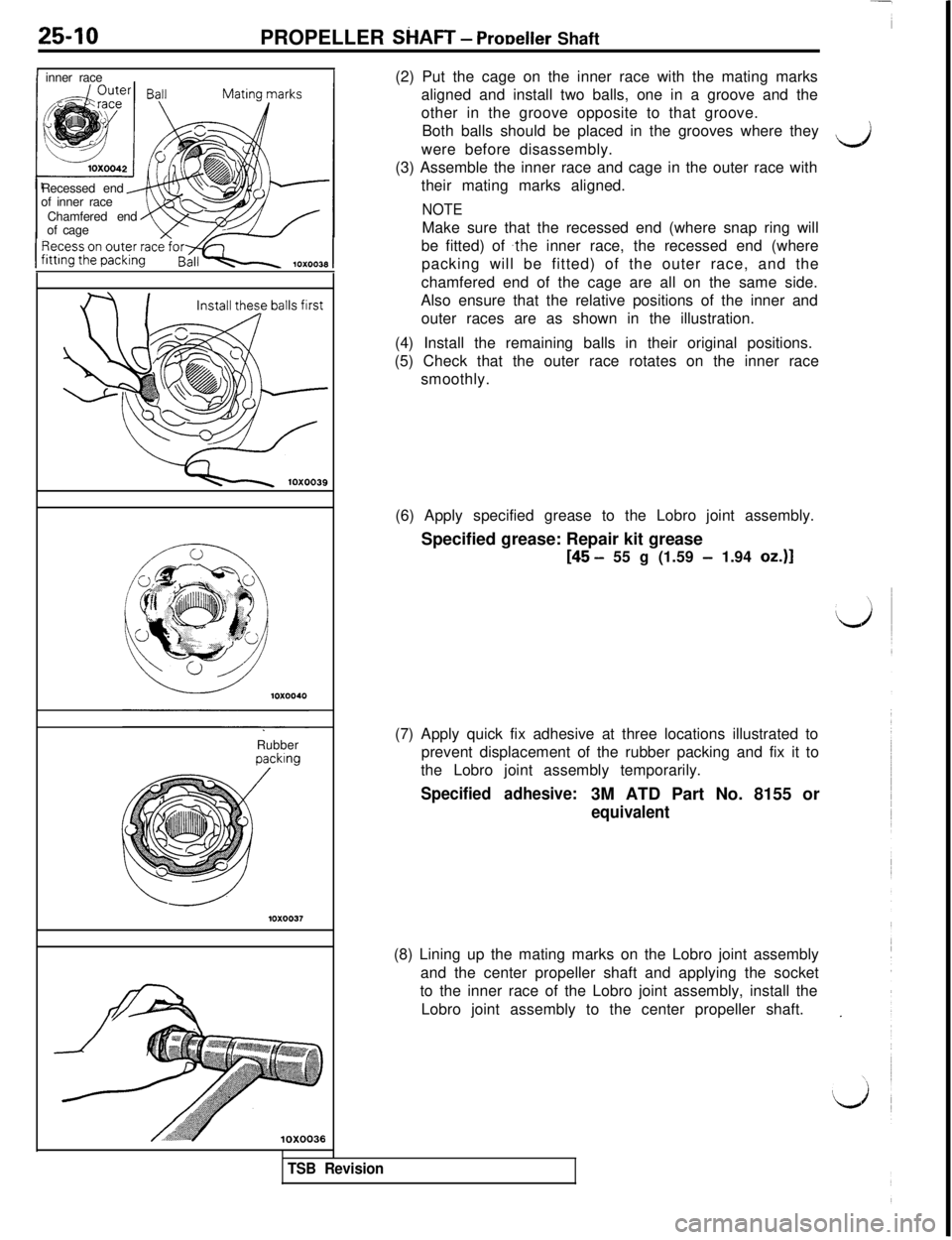

Rubberking(2) Put the cage on the inner race with the mating marks

aligned and install two balls, one in a groove and the

other in the groove opposite to that groove.

Both balls should be placed in the grooves where they

were before disassembly.

d(3) Assemble the inner race and cage in the outer race with

their mating marks aligned.

NOTEMake sure that the recessed end (where snap ring will

be fitted) of

,the inner race, the recessed end (where

packing will be fitted) of the outer race, and the

chamfered end of the cage are all on the same side.

Also ensure that the relative positions of the inner and

outer races are as shown in the illustration.

(4) Install the remaining balls in their original positions.

(5) Check that the outer race rotates on the inner race

smoothly.

(6) Apply specified grease to the Lobro joint assembly.

Specified grease: Repair kit grease

[45 - 55 g (1.59 - 1.94 oz.)]

(7) Apply quick fix adhesive at three locations illustrated to

prevent displacement of the rubber packing and fix it to

the Lobro joint assembly temporarily.

Specified adhesive:3M ATD Part No. 8155 or

equivalent(8) Lining up the mating marks on the Lobro joint assembly

and the center propeller shaft and applying the socket

to the inner race of the Lobro joint assembly, install the

Lobro joint assembly to the center propeller shaft.

TSB Revision

Page 575 of 1146

PROPELLER SHAFT - Propeller Shaft25-11

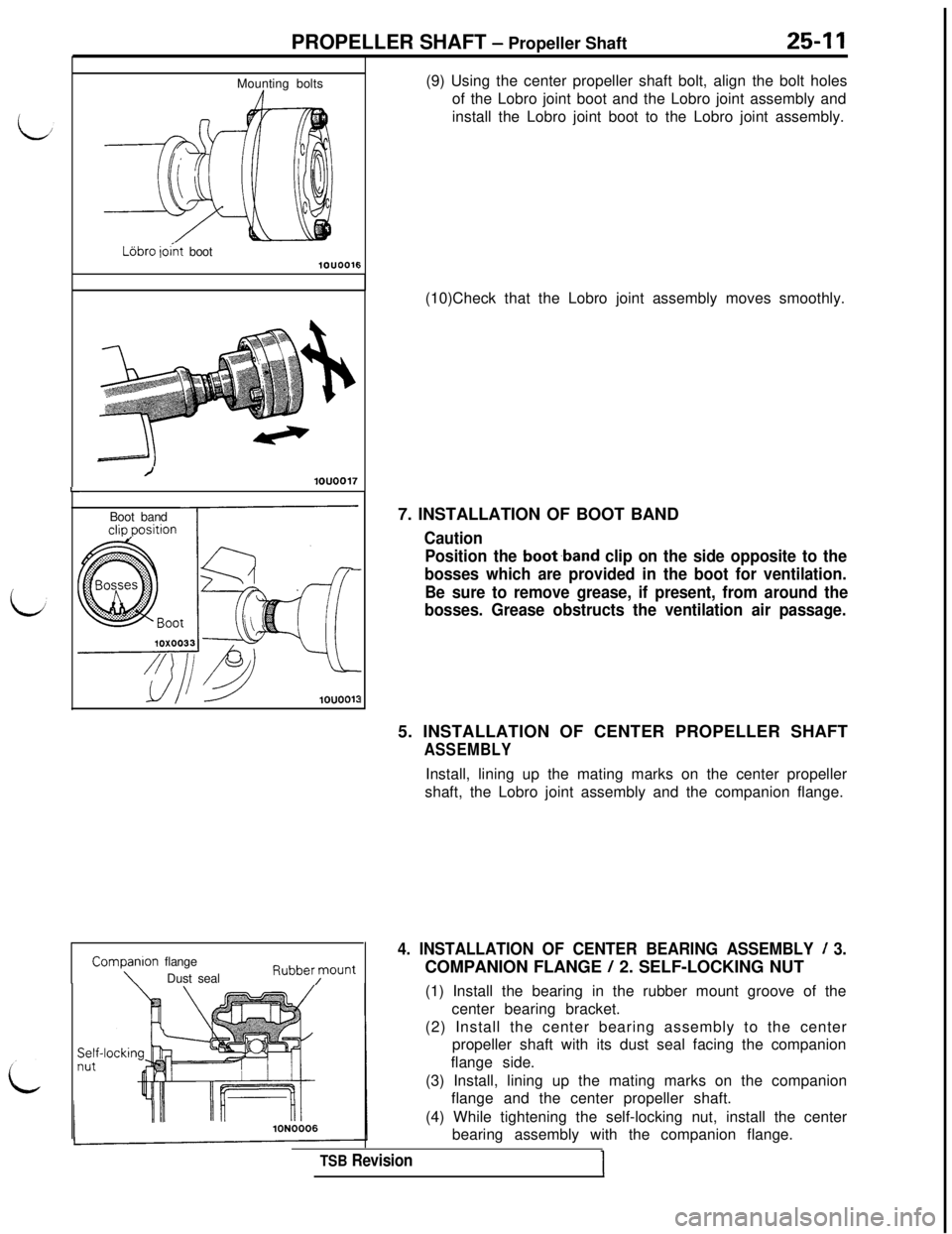

LMounting boltsL6bro

ioht boot1ouooll

/1ouoo17

5(9) Using the center propeller shaft bolt, align the bolt holes

of the Lobro joint boot and the Lobro joint assembly and

install the Lobro joint boot to the Lobro joint assembly.

(10)Check that the Lobro joint assembly moves smoothly.clio Dosition

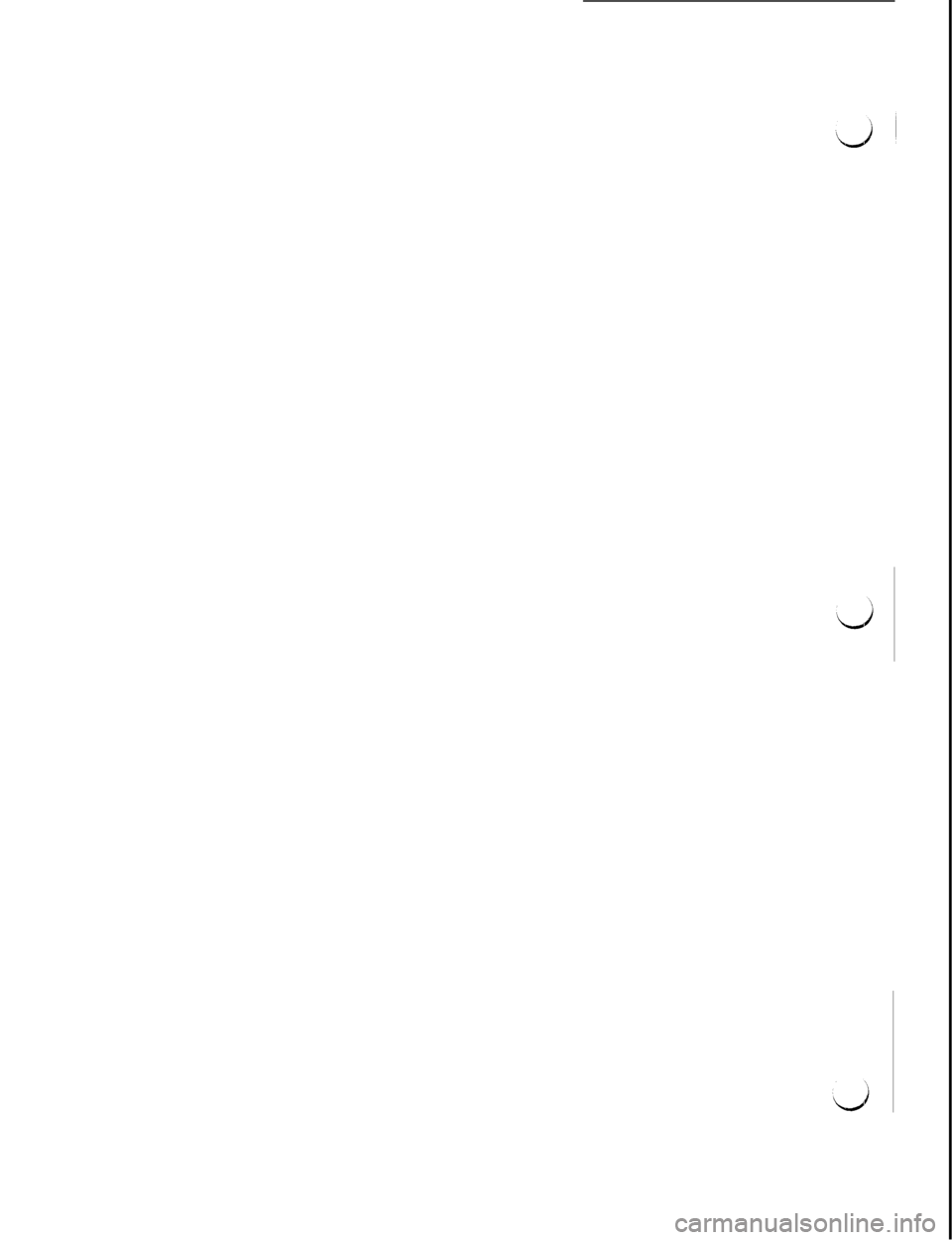

7Boot band

1ouoo13

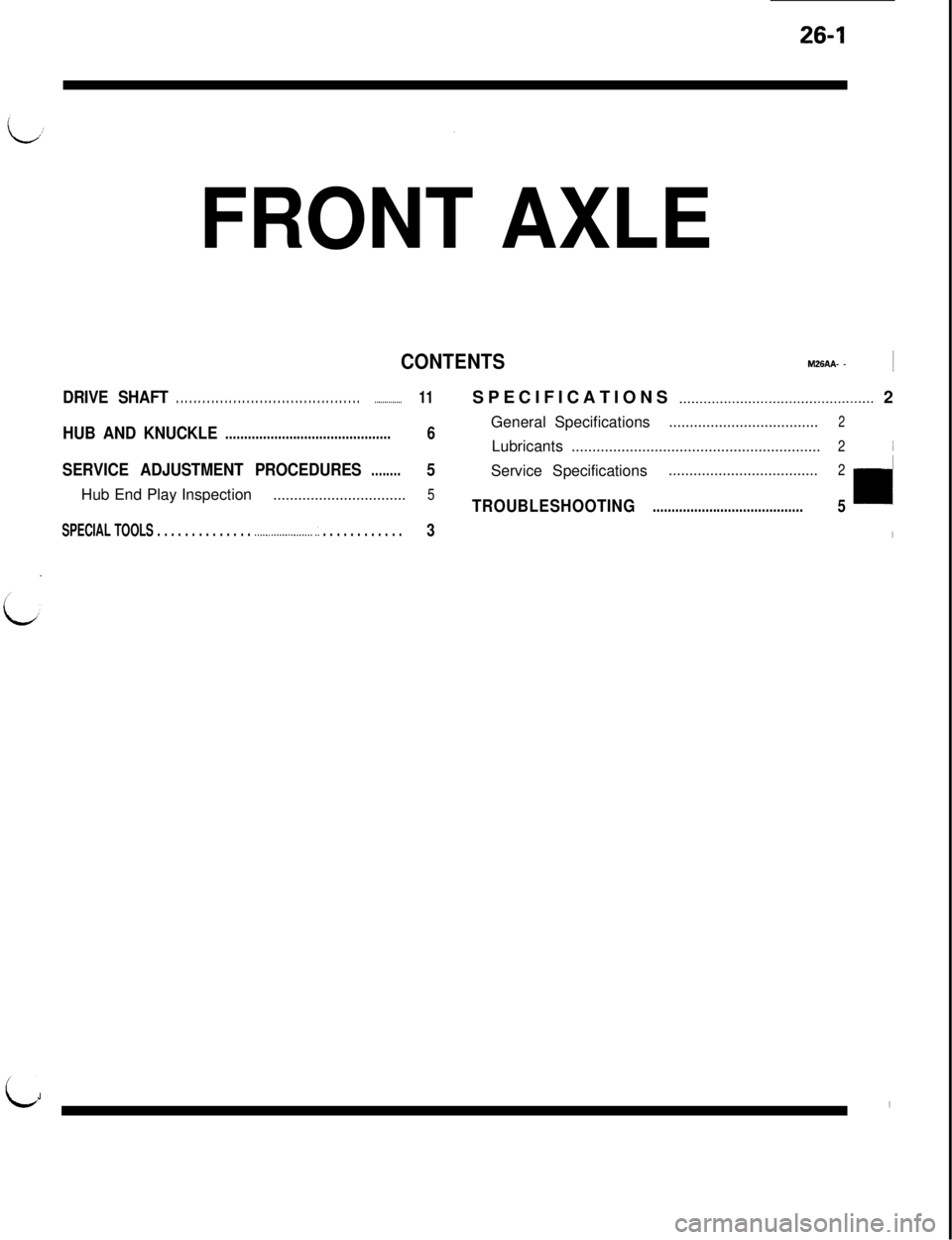

Companion flange

\Dust sealRubber/mount

I7. INSTALLATION OF BOOT BAND

Caution

Position the

boot,band clip on the side opposite to the

bosses which are provided in the boot for ventilation.

Be sure to remove grease, if present, from around the

bosses. Grease obstructs the ventilation air passage.5. INSTALLATION OF CENTER PROPELLER SHAFT

ASSEMBLYInstall, lining up the mating marks on the center propeller

shaft, the Lobro joint assembly and the companion flange.

4. INSTALLATION OF CENTER BEARING ASSEMBLY / 3.COMPANION FLANGE

/ 2. SELF-LOCKING NUT

(1) Install the bearing in the rubber mount groove of the

center bearing bracket.

(2) Install the center bearing assembly to the center

propeller shaft with its dust seal facing the companion

flange side.

(3) Install, lining up the mating marks on the companion

flange and the center propeller shaft.

(4) While tightening the self-locking nut, install the center

bearing assembly with the companion flange.

TSB Revision

Page 576 of 1146

Page 577 of 1146

26-1

FRONT AXLE

CONTENTSM26AA- -i

DRIVE SHAFT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...........11SPECIFICATIONS _..._........................................... 2

HUB AND KNUCKLEGeneral Specifications....................................2............................................6Lubricants............................................................2i

SERVICE ADJUSTMENT PROCEDURES........5Service Specifications....................................2Hub End Play Inspection

................................5TROUBLESHOOTING........................................5

SPECIAL TOOLS . . . . . . . . . . . . . . .._.................. .: . . . . . . . . . . . .3I

iJI

Page 578 of 1146

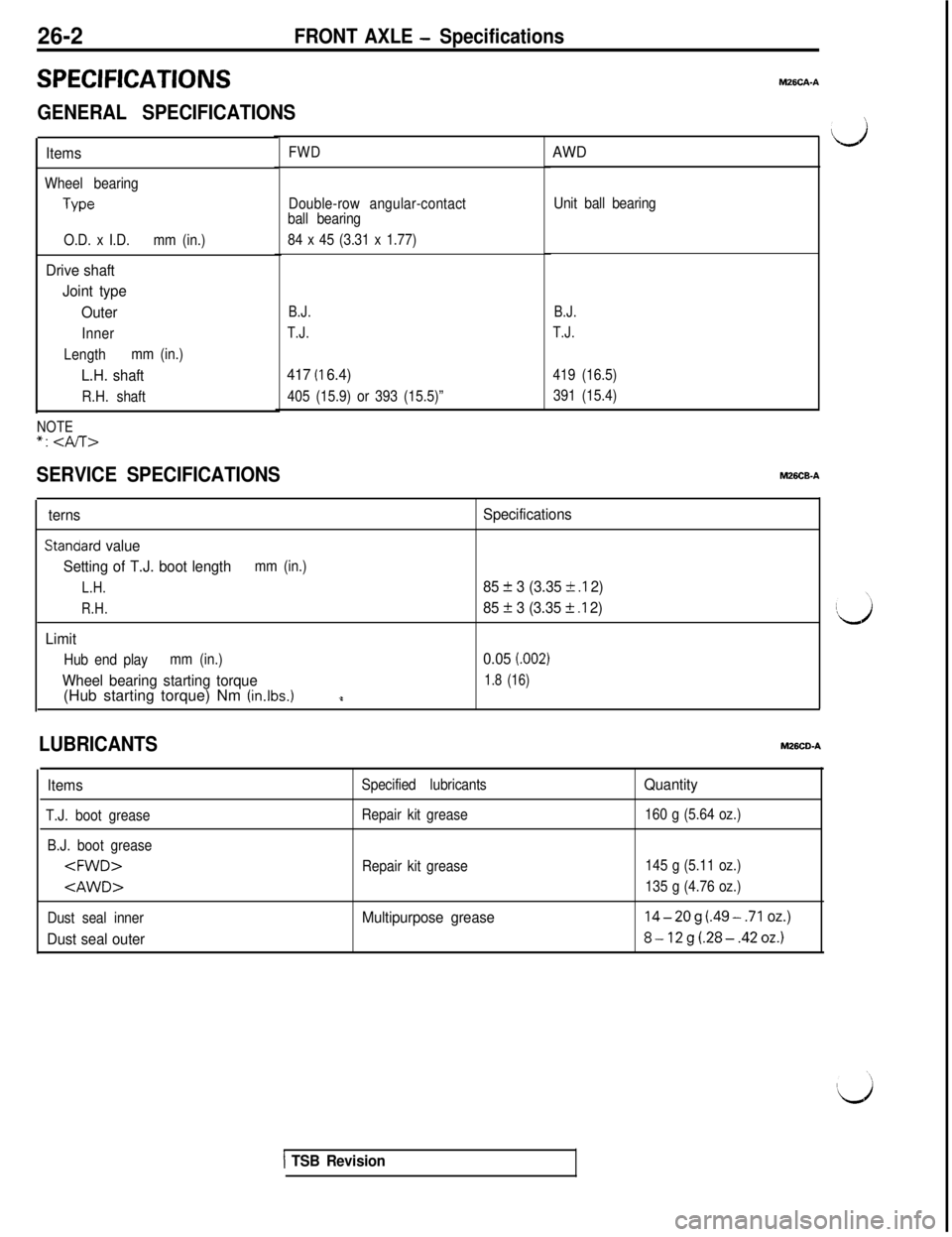

26-2FRONT AXLE - Specifications

SERVICE SPECIFICATIONS

FWD

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items

Wheel bearing

TypeDouble-row angular-contact

ball bearing

O.D. x I.D.mm (in.)

Drive shaft

Joint type

Outer

Inner

Lengthmm (in.)

L.H. shaft

R.H. shaft84 x 45 (3.31 x 1.77)

B.J.

T.J.

417 (I 6.4)

405 (15.9) or 393 (15.5)”

NOTE“1

AWD

Unit ball bearing

B.J.

T.J.

419 (16.5)

391 (15.4)

M26CB-A

terns

standard value

Setting of T.J. boot length

mm (in.)

L.H.

R.H.

Limit

Hub end playmm (in.)

Wheel bearing starting torque(Hub starting torque) Nm (in.lbs.)

Specifications

85

f 3 (3.35 k .I 2)

85

+ 3 (3.35 +- .I 2)

0.05

(.002)

1.8 (16)

LUBRICANTSM26CO-A

Items

T.J. boot grease

B.J. boot grease

Dust seal inner

Dust seal outer

Specified lubricants

Repair kit grease

Repair kit grease

Multipurpose greaseQuantity

160 g (5.64 oz.)

145 g (5.11 oz.)

135 g (4.76 oz.)

14-2og (.49-.71 oz.)

8-12g(.28-.42oz.)

1 TSB Revision

Page 579 of 1146

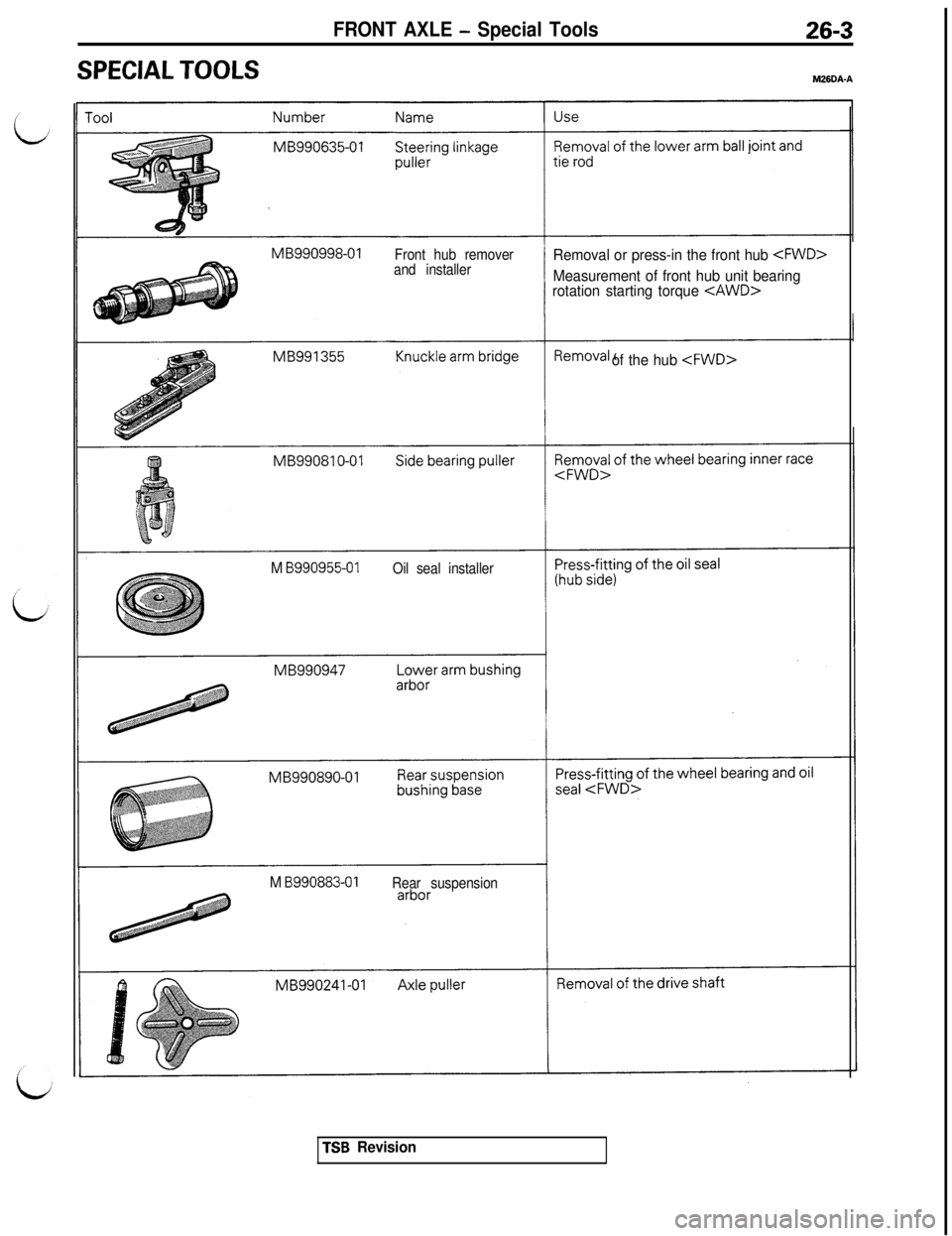

SPECIAL TOOLS

FRONT AXLE - Special Tools26-3M26DA-A

MB990998-01

Front hub remover

and installerRemoval or press-in the front hub

Measurement of front hub unit bearing

rotation starting torque

of the hub

M B990955-01Oil seal installer

MB990890-01

M B990883-01Rear suspension

TSB Revision

Page 580 of 1146

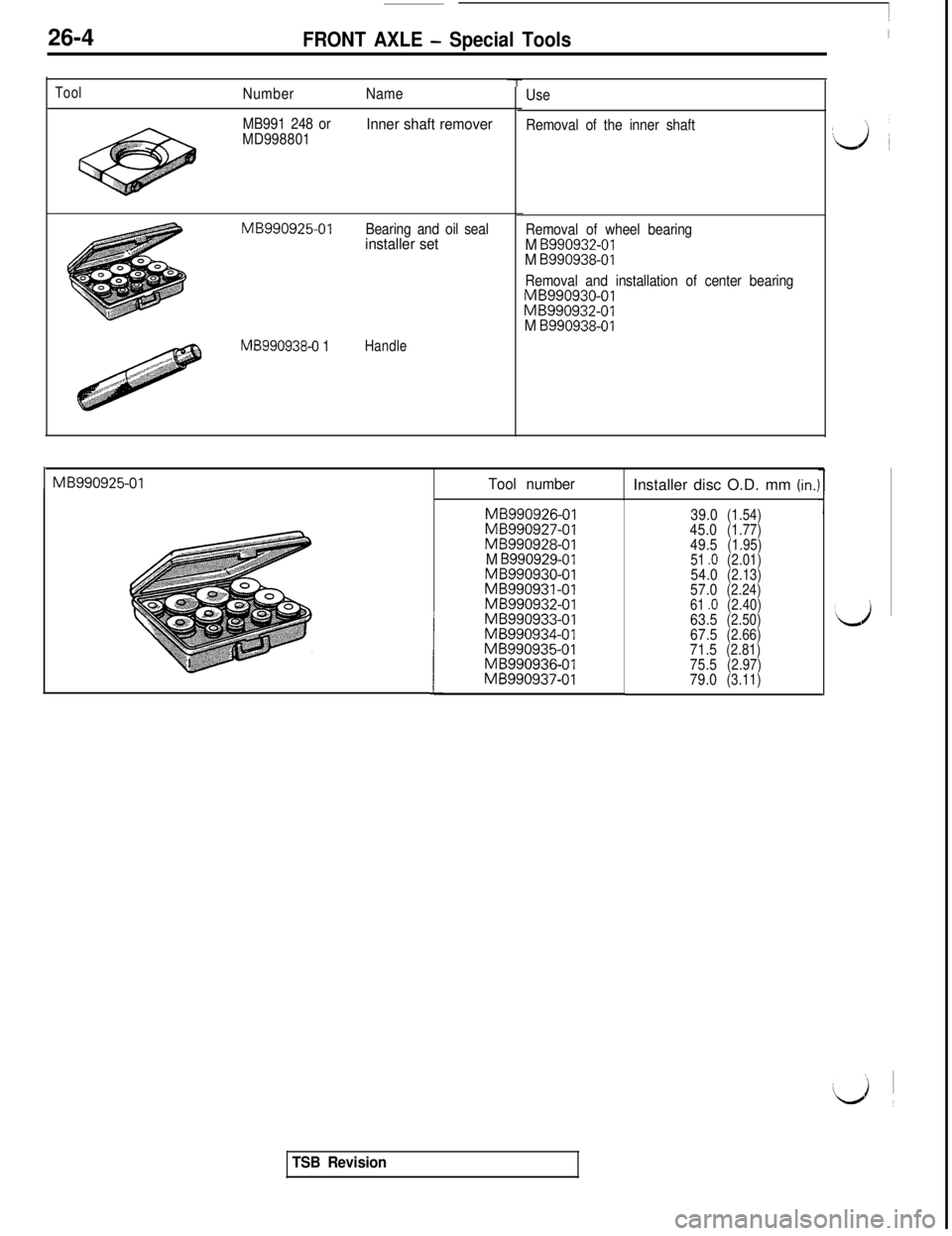

26-4FRONT AXLE - Special Tools

ToolNumberName

MB991 248 or

MD998801

Inner shaft remover

MB990925-01

Bearing and oil sealinstaller set

MB990938-0 1Handle

7Use

Removal of the inner shaft

Removal of wheel bearing

M 8990932-01M B990938-01

Removal and installation of center bearingMB990930-01MB990932-01M 8990938-01

MB990925-01Tool numberInstaller disc O.D. mm (in.:

I

MB990926-01MB990927-01MB990928-01M B990929-01MB990930-01MB990931-01MB990932-01MB990933-01MB990934-01MB990935-01MB990936-01MB990937-0139.0

(1.54)45.0(1.77)49.5(1.95)

51 .o(2.01)54.0(2.13)57.0(2.24)

61 .O(2.40)63.5(2.50)67.5(2.66)71.5(2.81)75.5(2.97)79.0(3.11)

TSB Revision