MITSUBISHI DIAMANTE 1900 Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 221 of 408

.

6-18 CHASSIS ELECTRICAL

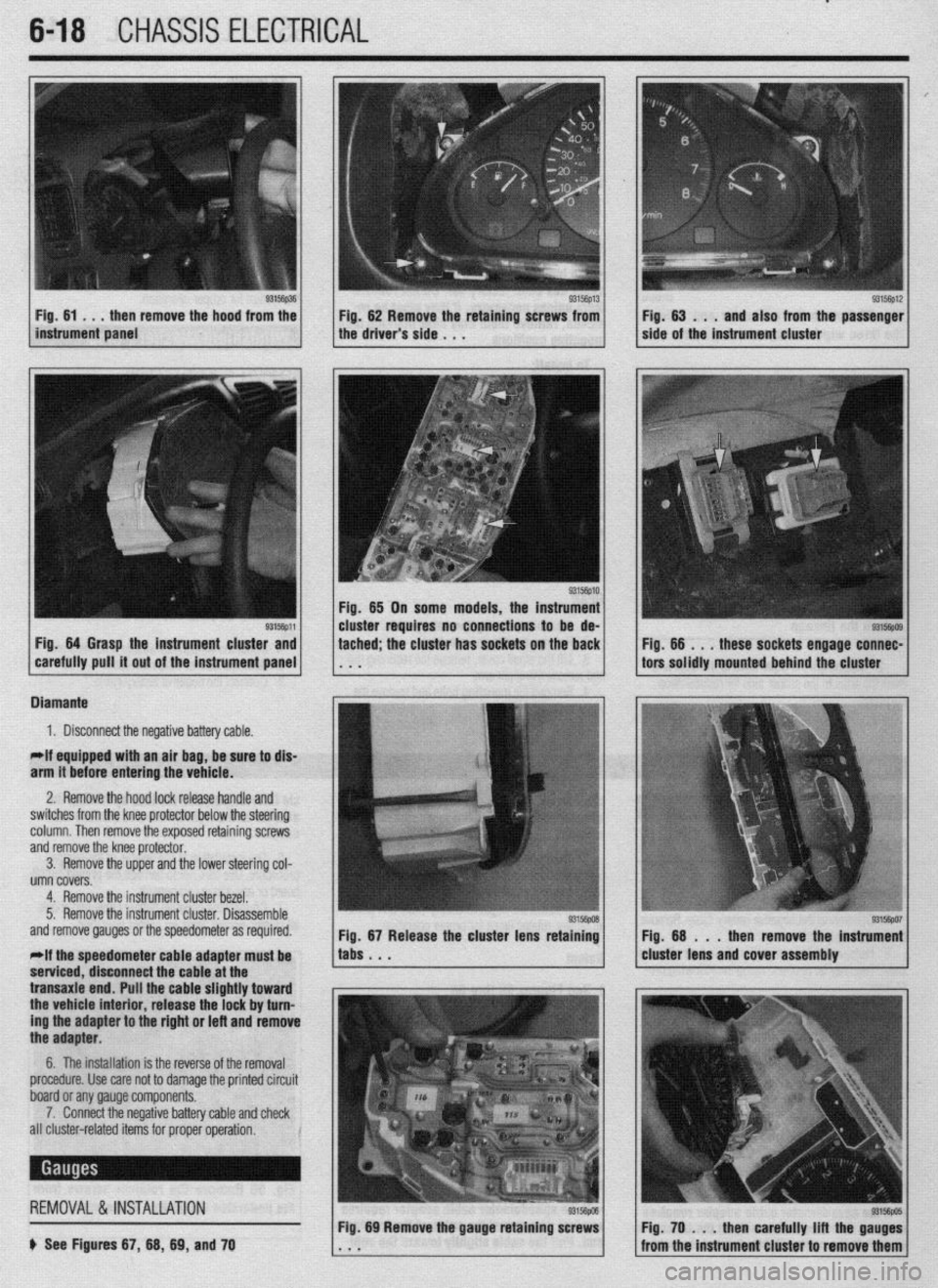

Fig. 64 Grasp the instrument cluster and

carefully pull it out of the instrument panel tached; the cluster has sockets on the back Fig. 66 . , .

these sockets engage connec-

tors solidly mounted behind the cluster

Diamante

1. Disconnect the negative battery cable.

*If equipped with an air bag, be sure to dis-

arm it before entering the vehicle.

2. Remove the hood lock release handle and

switches from the knee protector below the steering

column. Then remove the exposed retaining screws

and remove the knee protector.

3. Remove the upper and the lower steering col-

umn covers.

4. Remove the instrument cluster bezel.

5. Remove the instrument cluster. Disassemble

and remove gauges or the speedometer as required.

*If the speedometer cable adapter must be

serviced. disconnect the cable at the

transaxle end. Pull the cable slightly toward

the vehicle interior, release the lock by turn-

ing the adapter to the right or left and remove

the adapter.

6. The installation is the reverse of the removal

procedure. Use care not to damage the printed circuit

board or any gauge components,

7. Connect the negative battery cable and check

all cluster-related items for proper operation.

REMOVAL &INSTALLATION

I

b See Figures 67, 66, 69, and 70

83156pD6 Fig. 69 Remove the gauge retaining screws Fig. 70 . . . then carefully lift the gauges

from the instrument cluster to remove them

Page 222 of 408

CHASSIS ELECTRICAL 6-19

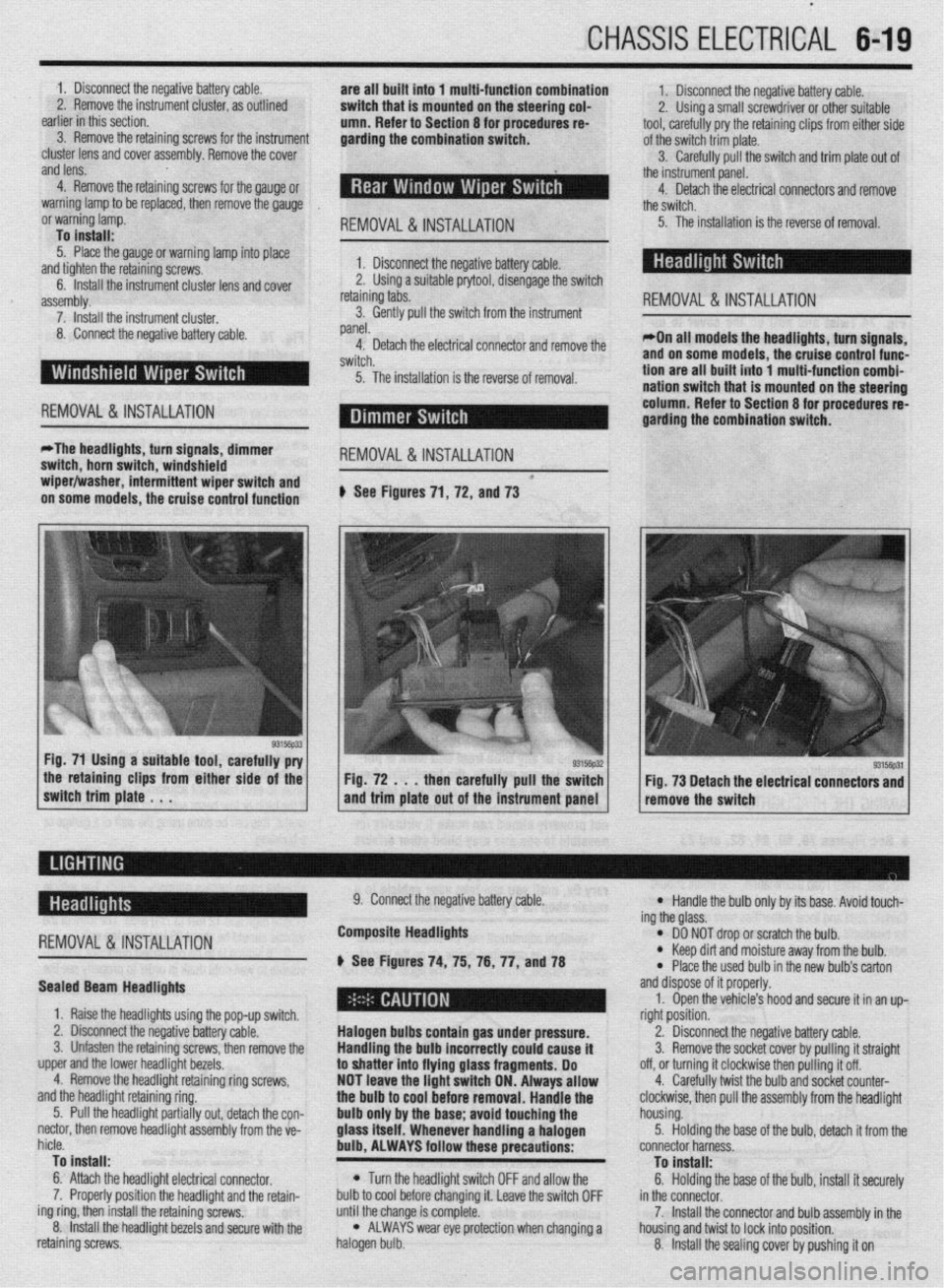

1. Disconnect the negative battery cable.

are all built into 1 multi-function combination

2. Remove the instrument cluster, as outlined 1. Disconnect the negative battery cable.

earlier in this section. switch that is mounted on the steering col-

2. Using a small screwdriver or other suitable

umn. Refer to Section 8 for procedures re-

3. Remove the retaining screws for the instrument tool, carefully pry the retaining clips from either side

garding the combination switch.

cluster lens and cover assembly. Remove the cover of the switch trim plate.

3.

and lens. Carefully pull the switch and trim plate out of

,

4. Remove the retaining screws for the gauge or the instrument panel.

4. Detach the electrical connectors and remove

warning lamp to be replaced, then remove the gauge

the switch.

or warning lamp.

REMOVAL&INSTALLATION : 5. The installation is the reverse of removal.

To install:

5. Place the gauge or warning lamp into place

and tighten the retaining screws. 1. Disconnect the negative battery cable.

6. Install the instrument cluster lens and cover 2. Using a suitable prytool, disengage the switch

assembly. retaining tabs.

REMOVAL &INSTALLATION 7. Install the instrument cluster. 3. Gently pull the switch from the instrument

8. Connect the negative battery cable. panel.

4. Detach the electrical connector and remove the *On all models the headlights, turn signals,

switch. and on some models, the cruise control func-

5. The installation is the reverse of removal. tion are all built into 1 multi-function combi-

nation switch that is mounted on the steerinq

REMOVAL &INSTALLATION column. Refer to Section 8 for procedures 6

garding the combination switch.

*The headlights, turn signals, dimmer

switch, horn switch, windshield

REMOVAL &INSTALLATION

wiper/washer, intermittent wiper switch and *

on some models, the cruise control function # See Figures 71, 72, and 73

the retaining clips from either side of the

switch trim plate . . . Fig. 72 . . . then carefully pull the switch

and trim plate out of the instrument panel Fig. 73 Detach the electrical connectors and

remove the switch

-

REMOVAL &INSTALLATION

Sealed Beam Headlights

1. Raise the headlights using the pop-up switch.

2. Disconnect the negative battery cable.

3. Unfasten the retaining screws, then remove the

upper and the lower headlight bezels.

4. Remove the headlight retaining ring screws,

and the headlight retaining ring.

5. Pull the headlight partially out, detach the con-

nectar, then remove headlight assembly from the ve-

hicle.

To install:

6. Attach the headlight electrical connector.

7. Properly position the headlight and the retain-

ing ring, then install the retaining screws.

8. Install the headlight bezels and secure with the

retaining screws. 9. Connect the negative battery cable.

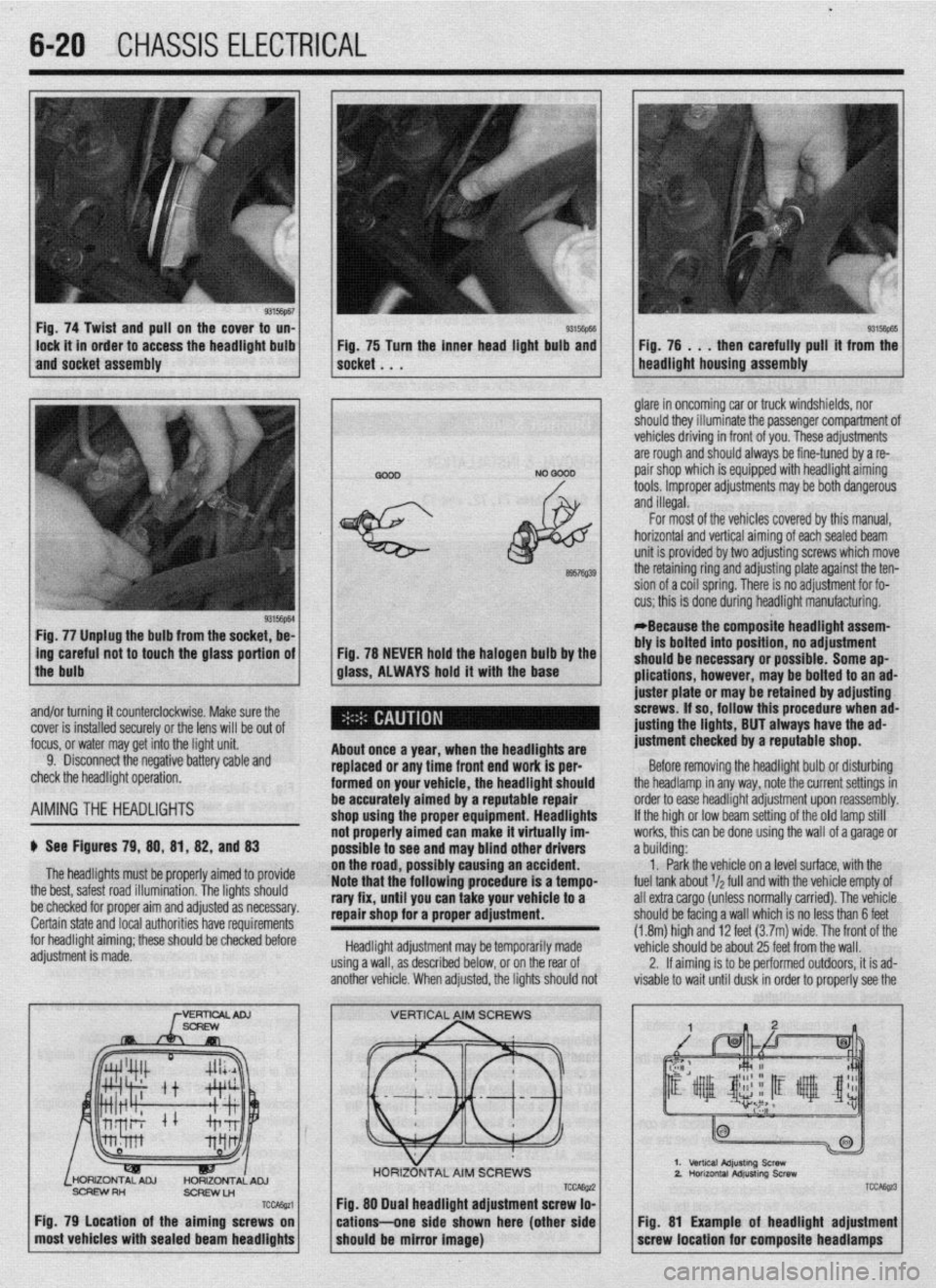

Composite Headlights

6 See Figures 74, 75, 76, 77, anU78

Halogen bulbs contain gas under pressure.

Handling the

bulb incorrectly could cause it

to shatter into flying glass fragments. Do

NOT leave the light switch ON. Always allow

the bulb to cool before removal. Handle the

bulb only by the base; avoid touching the

glass itself. Whenever handling a halogen

bulb, ALWAYS follow these precautions:

l Turn the headlight switch OFF and allow the

bulb to cool before changing it. Leave the switch OFF

until the change is complete.

l ALWAYS wear eye protection when changing a

halogen bulb.

l Handle the bulb only by its base. Avoid touch-

ing the glass.

l DO NOT drop or scratch the bulb. l Keep dirt and moisture away from the bulb.

* Place the used bulb in the new bulb’s carton

and dispose of it properly.

1. Open the vehicle’s hood and secure it in an up-

right position.

2. Disconnect the negative battery cable.

3. Remove the socket cover by pulling it straight

off, or turning it clockwise then pulling it off.

4. Carefully twist the bulb and socket counter-

clockwise, then pull the assembly from the headlight

housing.

5. Holding the base of the bulb, detach it from the

connector harness.

To install:

6. Holding the base of the bulb, install it securely

in the connector.

7. Install the connector and bulb assembly in the

housing and twist to lock into position.

8. Install the sealing cover by pushing it on

Page 223 of 408

.

6-20 CHASSIS ELECTRICAL

Fig. 74 Twist and pull on the cover to un-

lock it in order to access the headlight bulb

and socket assembly 93Mm Fig, 75 Turn the inner head light bulb and then carefully pull’ it from the

NO 0000 . glare in oncoming car or truck windshields, nor

should they illuminate the passenger compartment of

vehicles driving in front of you. These adjustments

are rough and should always be fine-tuned by a re-

pair shop which is equipped with headlight aiming

tools. Improper adjustments may be both dangerous

and illegal.

Fig. 77 Unplug the bulb from the socket, be-

L

ing careful not to touch the glass portion of

the bulb

I

6957Q39

Fig. 78 NEVER hold the halogen bulb by the

glass, ALWAYS hold it with the base

,

About once a year, when the headllgftts are

replaced or any time front end work is per-

formed on your vehicle, the headlight should

be accurately aimed by a reputable repair

shop uslng the proper equipment. Headlights

not properly aimed can make it virtually im-

possible to see ar Id may blind other drivers

ibly causing an accident.

Note that the’following procedure is a tempo-

rary fix, until you can take your vehicle to a

repair shop for a proper adjustment.

Headlight adjustment may be temporarily made

using a wall, as described below, or on the rear of

another vehicle. When adjusted, the lights should not For most of the vehicles covered by this manual,

horizontal and vertical aiming of eachsealed beam

unit is provided by two adjusting screws which move

the retaining ring and adjusting plate against the ten-

sion of a coil spring. There is no adjustment for fo-

cus; this is done during headlight manufacturing.

*Because the composite headlight assem-

bly is bolted into position, no adjustment

should be necessary or possible. Some ap-

plications, however, may be bolted to an ad-

juster plate or may be retained by adjusting

screws. If so, follow this procedure when ad-

@sting the lights, BUT always have the ad-

justment checked by a reputable shop.

Before removing the headlight bulb or disturbing

the headlamp in any way, note the current settings in

order to ease headlight adjustment upon reassembly.

If the high or low beam setting of the old lamp still

works, this can be done using the wall of a garage or

a building:

1. Park the vehicle on a level surface, with the

fuel tank about r/a full and with the vehicle empty of

all extra cargo (unless normally carried). The vehicle

should be facing a wall which is no less than 6 feet

(1.8m) high and 12 feet (3.7m) wide. The front of the

vehicle should be about 25 feet from the wall.

2. If aiming is to be performed outdoors, it is ad-

visable to wait until dusk in order to properly see the

% and/or turning it counterclockwise. Make sure the

cover is installed securely or the lens will be out of

focus, or water may get into the light unit.

9. Disconnect the negative battery cable and

check the headlight operation.

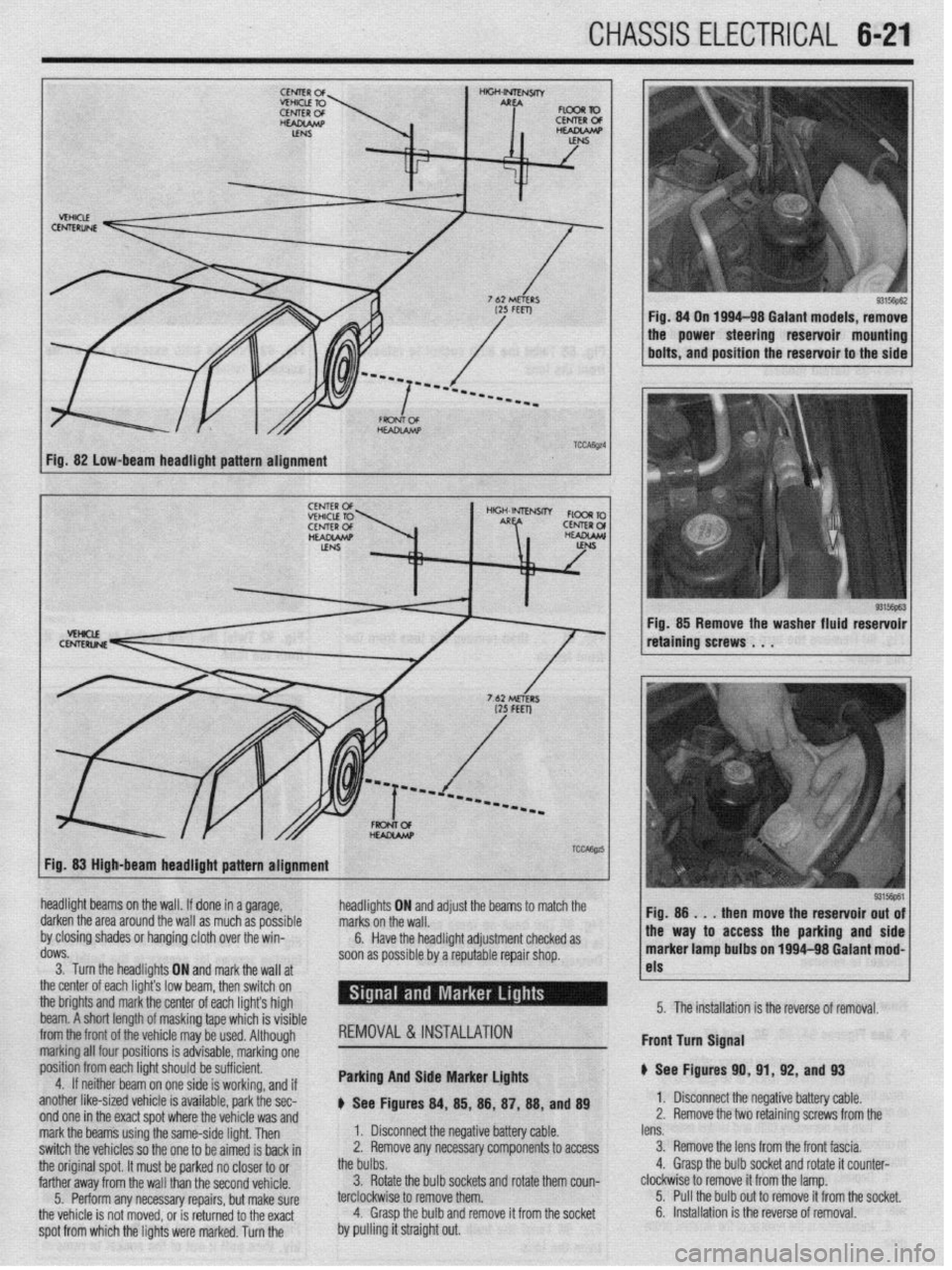

AIMINGTHE HEADLIGHTS

$ See Figures 79, 88, 81, 82, and 83

The headlights must be proper’ ’ ’ ’

the best, safest road illumination. ’ ’

ly armea IO provrae

The lights should

:.__1__1 __ - -___-_-. on the road, POSSI

be checked for proper aim and adfusreu as IlweSYdly. Certain state and local authorities have requirements

for headlight aiming; these should be checked before

adjustment is made.

SCFEWRH

ScFlEwLn

TCcAssa

Fig. 79 Location of the aiming screws on

most vehicles with sealed beam headlights

TCCAE@ Fig. 88 Dual headlight adjustment screw lo-

cations--one side shown here (other side

should be mirror image)

2.

TCC&z3

Fig. 81 Example of headlight adjustment

screw location for composite headlamps

Page 224 of 408

CHASSIS ELECTRICAL 6-21

Fig. 82 low-beam headlight pattern alignment

93156pE.3 Fig. 85 Remove the washer fluid reservoir

retaining screws . . .

Fig. 83 High-beam headlight pattern alignment

headlight beams on the wall. If done in a garage,

darken the area around the wall as much as possible

by closing shades or hanging cloth over the win-

dows.

3. Turn the headlights ON and markthe wall at

the center of each light’s low br ram, then switch on

the brights and mark the center of each lights high

beam. A short length of maskin g tape which is visible

from the front of the

whir+ ma . ._..._._ . .._ y be used. Although

marking all four po:

sitions is advisable, marking one

position from each

light should be sufficient.

4. If neithar he; ~. __

Irn on one side is working, and if

another like-sized vehicle is available, park the sec-

nnri nm in the wart cnnt whrw the whirlo um md

headli! jhts ON and adjust the beams to marcn me

I. Disconnect the negative battery cable. marks on the wall.

2. Remove any necessary components to access 6.

the bulbs. Have the headlight adjustment checked as

soon as possible by a reputable repair shop.

3. Rotate the bulb sockets and rotate them coun-

terclockwise to remove them.

4. Grasp the bulb and remove it from the socket REMOVAL&INSTALLATION

Parking And Side Marker Lights

p See Figures 84, 85, 88, 87, 88, and 89 !ss the parking and side

1~ nn loo4-98 Galant mod-

I

1 I-

5315@61

lens. 1 Fio. 8

then move the reservoir out of

3. Remove the lens from the front fascia.

4. Grasp the bulb socket and rotate it counter- marker lamp bult, _.. ._“~-

clockwise to remove it from the lamp.

5. Pull the bulb out to remove it from the socket. 5. The installation is the reverse of removal.

6. Installation is the reverse of removal. Front turn Signal

p See Figures 91

1. Disconnect tl

2. Remove the t 0, 91, 92, and 93

I(? n,-.nn+:.m b.Hnn, nnL.L

z Ill7yau”e “allcly ul”IC. 10 retainino screws from the

spot from which the lights were marked. Turn the . ..I_ WIIY I.8 %,I” V”UVL”fdYI T.II”IU Lll” “VlllUlY ,.UU U,,” mark the beams using the same-side light. Then

switch the vehicles so the one to be aimed is back in

the original spot. It must be parked no closer to or

farther away from the wall than the second vehicle.

5. Perform any necessary repairs, but make sure

the vehicle is not moved, or is returned to the exact

by pulling it straight out.

Page 225 of 408

6-22 CHASSIS ELECTRICAL

b

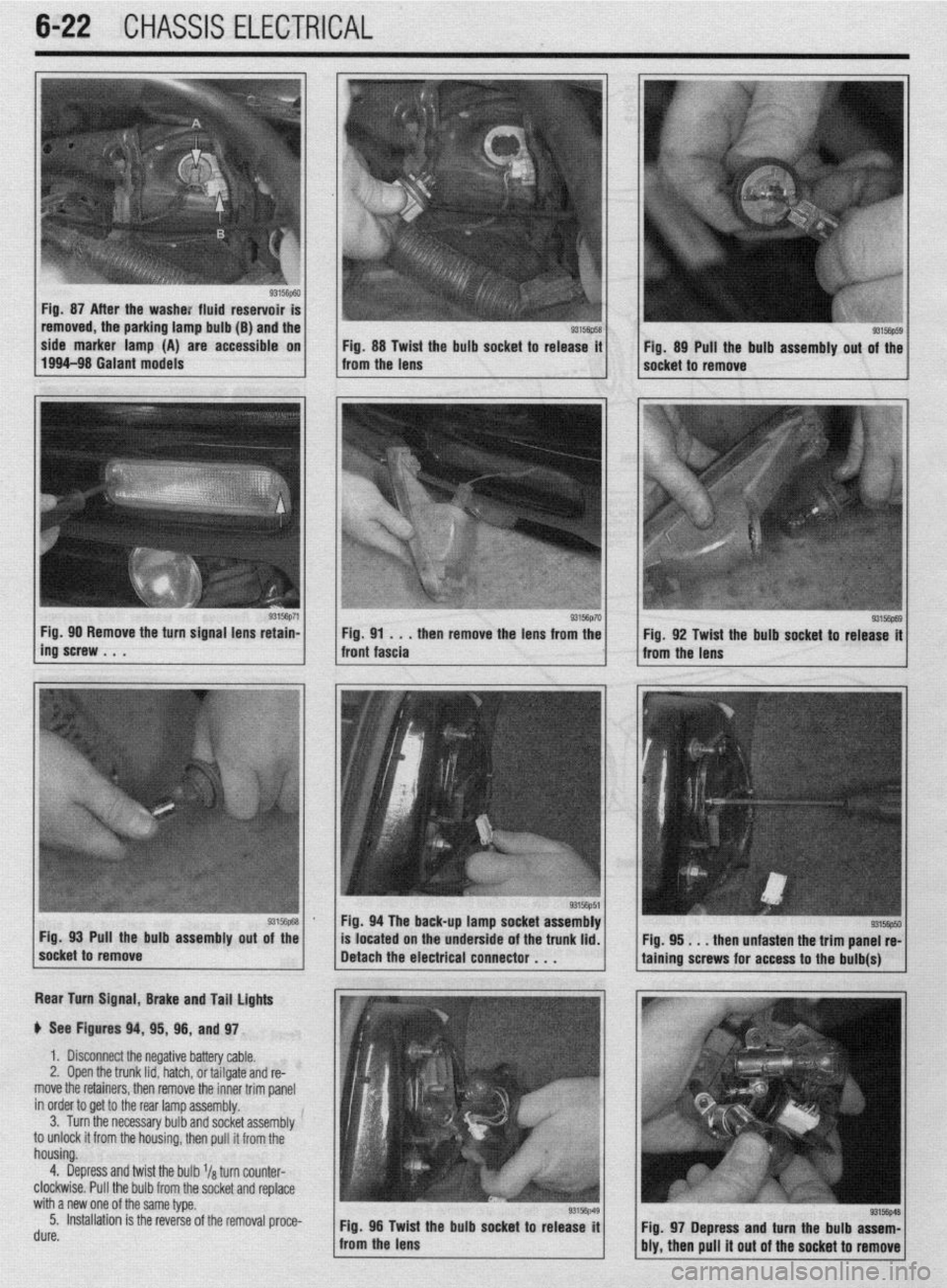

Fig. 87 After the washe: fluid reservoir

removed, the parking lamp bulb (B) and the

side marker lamp (A) are accessible on

Fig. 88 Twist the bulb socket to release it

1994-98 Galant models

from the lens Fig. 89 Pull the bulb assembly out of the

socket to remove

g3156p71 / Fig 90 Remove the turn signal lens retain-

ing’screw . . . . then remove the lens from the

Rear Turn Signal, Brake and Tail lights

p See Figures 94, 95, 96, and 97.

1. Disconnect the negative battery cable.

2, Open the trunk lid, hatch, or tailgate and re-

move the retainers, then remove the inner trim panel

in order to get to the rear lamp assembly.

3. Turn the necessary bulb and socket assembly

to unlock it from the housing, then pull it from the

housing.

4. Depress and twist the bulb l/a turn counter-

clockwise. Pull the bulb from the socket and replace

with a new one of the same type.

5. Installation is the reverse of the removal proce-

rl. ._^

UUIt?. Fig. 96 Twid

: the bulb socket to release it

from the lens

93156p69 Fig. 92 Twist the bulb socket to release it

from the lens

I

Fig. 94 The back-up lamp socket assembly

Pull the bulb assembly

out of the

located on the underside of the trunk lid.

. . . then unfasten the trim panel re-

Fig. 97 Depress and turn the bulb assem-

bly, then pull it out of the socket to remove

Page 226 of 408

![MITSUBISHI DIAMANTE 1900 Repair Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] MITSUBISHI DIAMANTE 1900 Repair Manual CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y]](/img/19/57096/w960_57096-225.png)

CHASSIS ELECTRlCiL 6-23

93156P57 Fig. 98 The back-up lamp socket assembly Fig. 99 Twist the bulb socket to release the

is located on the underside of the trunk lid locking tabs from the lens *1W5y] Fig 100 Pull the bulb assembly straight out

of the socket to remove it

Back-up light

u See Figures 98, 99, and 100

1 I Disconnect the negative battery cable.

2. Open the trunk lid.

3. If equipped, remove the trim on the underside

of the trunk lid.

4. Turn the socket counterclockwise ‘14 of a turn

to release it from the lens.

5. Pull the bulb out to remove it from the socket,

6. The installation is the reverse of removal.

7. Connect the negative battery cable.

8. Verify the operation of the lamp.

Side Marker light

# See Figures 101, lOi, 103, and 104 I. Remove the two retaining screws from the 2. Open the trunk lid and detach the electrical

lens. connector from the lamp assembly.

2. Remove the lens from the rear fascia. 3. Remove the retaining screw holding the lamp

’ 3. Grasp the bulb socket and rotate it counter- assembly.

clockwise to remove it from the lamp. 4. Lower the lamp assembly from the lamp lens.

4. Pull the bulb out to remove it from the’socket. 5. Rotate the bulb clockwise while pushing it

5. Installation is the reverse of removal. gently inward to remove it from the socket.

6. The installation is the reverse of removal. .

High-mount Brake light

199fH6 MIllAGE, 1990-93 GALANT, AND

799446 GALANT 7992-96 DlAMANTE

p See Figures 105, 106, 107, 108, and 109 1, Disconnect the negative battery cable.

2. On the Mirage and Galant, remove the square

1. Disconnect the negative battery cable.

*The lamp assembly is accessible from the

trunk underneath the package shelf. retainer clips or bolts from the high-mount brake

light cover and remove the cover.

3. On the Diamante, press gently inward on the

sides of the liaht cover and remove it from the lamp.

1 taining screw . ~ . 93156p73 1 Fig 101 Remove the side marker light re-

93156p75 1 / ;;x,;;:,sdhen puii the lens awaG;:: 1 1 fror;l the iens Fig 103 Twist the bulb socket to release it

Fig. 104 Pull the bulb assembly straight out

of the socket to remove Fig. 105 Detach the high-mount brake

light electrical connector Fig. 106 Remove the lamp retaining screws

. a *

Page 227 of 408

.

6-24 CHASSIS ELECTRICAL

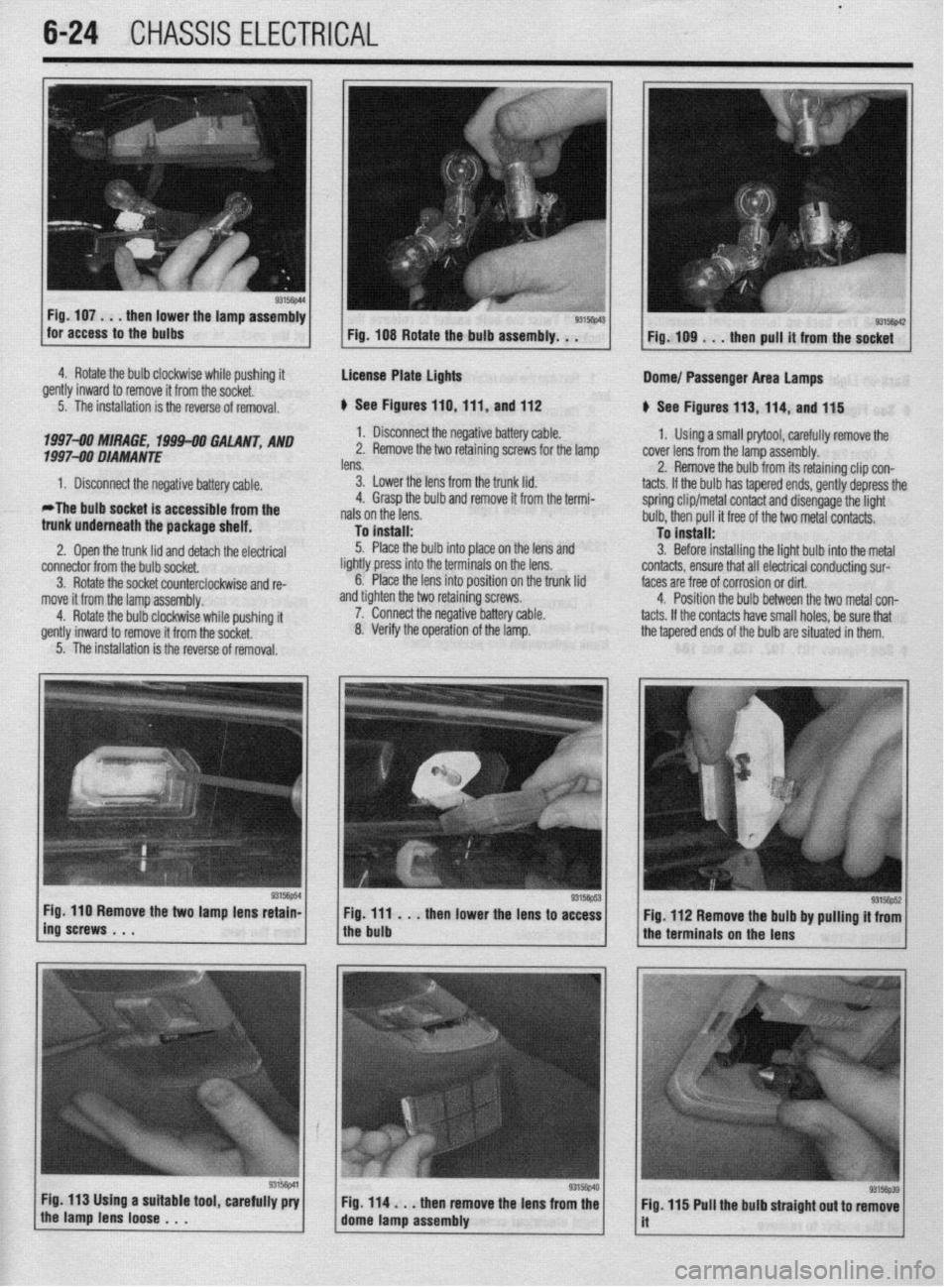

Fig. 107

. . . then lower the lamp assembly

for access to the bulbs

4. Rotate the bulb clockwise while pushing it

.,

gently inward to remove it from the socket.

5. The installation is the reverse of removal.

1997-00 MIRAGE, 1994-00 GALANT, AND

f 997-90 DIAMANTE

1. Disconnect the negative battery cable.

*The bulb socket is accessible from the

trunk underneath the package shelf.

2. Ooen the trunk lid

and detach the elwtrical connector from the bulb socket,

3. Rotate the socket counterclockwise and re-

move it from the lamp assembly.

4. Rotate the bulb clockwise while pushing

it gently inward to remove it from the socket. Fig. 108 Rotate the bulb assembly. . .

License Plate lights

p See Figures 110,111, and 112

1. Disconnect the negative battery cable.

2. Remove the two retaining screws for the lamp

lens.

3. Lower the lens from the trunk lid.

4. Grasp the bulb and remove it from the termi-

nals on the lens.

To install:

5. Place the bulb into place on the lens and

lightly press into the terminals on the lens.

6. Place the lens into position on the trunk lid

and tighten the two retaining screws.

7. Connect the negative battery cable.

8. Verify the operation of the lamp. Dome/ Passenger Area lamps

p See Figures 113, 114, and 115

1, Using a small prytool, carefully remove the

cover lens from the lamp assembly.

2. Remove the bulb from its retaining clip con-

tacts. If the bulb has tapered ends, gently depress the

spring clip/metal contact and disengage the light

bulb, then pull it free of the two metal contacts.

To install:

3. Before installing the light bulb into the metal

contacts, ensure that all electrical conducting sur-

faces are free of corrosion or dirt.

4. Position the bulb between the two metal con-

tacts. If the contacts have small holes, be sure that

the tapered ends of the bulb are situated in them.

5. The installation is the reverse of removal.

Fig. 110 Remove the two lamp lens retain-

ing screws . . . Fig. ill . . .

then lower the lens to access

the bulb Fig. 112 Remove the bulb by pulling it from

the terminals on the lens

Page 228 of 408

CHASSIS ELECTRICAL 6-25

ove the socket from ig. 118 Pull the bulb straight out to remove

6. Install the cover lens until its retaining tabs are

properly engaged. ’

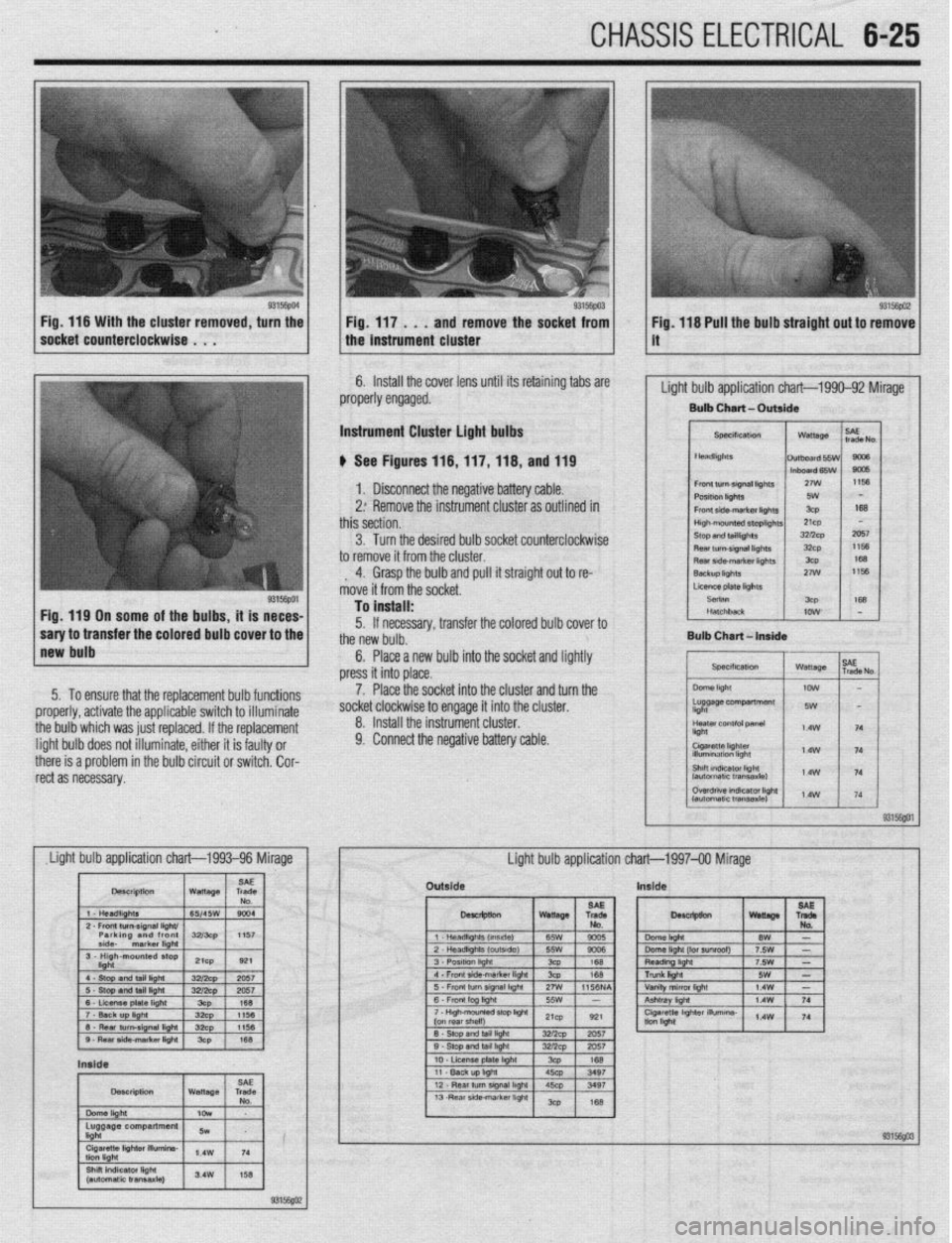

Light bulb application chart-1990-92 Mirage

Bulb Chart - Outaide

Instrument Cluster light bulbs

b See Figures 116,llf,ll8, and 119

1. Disconnect the negative battery cable.

2: Remove the instrument cluster as outlined in

this section.

3. Turn the desired bulb socket counterclockwise

to remove it from the cluster.

, 4. Grasp the bulb and pull it straight out to re-

move it from the socket.

I 1 Lmelatel~hls

Fig. 119 On some of the bulbs, it is neces-

1 ;;tbqrlrnsferthe colore ’ ’ ” . .’ ’

1 EL&

!a OUID cover IO me

Bulb Chart-In

*__. . __.

, , JvR,,Is~,,o~

press i+ in+n n,app

II llll” ~“UVV.

To install:

5. If necessary, transfer the colored bulb cover to

the new bulb.

6. Place a new bulb into the socket and lightly

Place the socket into the cluster and turn the

,“. II pithpr it ic faldtv nr 9. Connect the negative battery cable.

I

Outside Inside

Page 229 of 408

6-26 CHASSIS ELECTRICAL

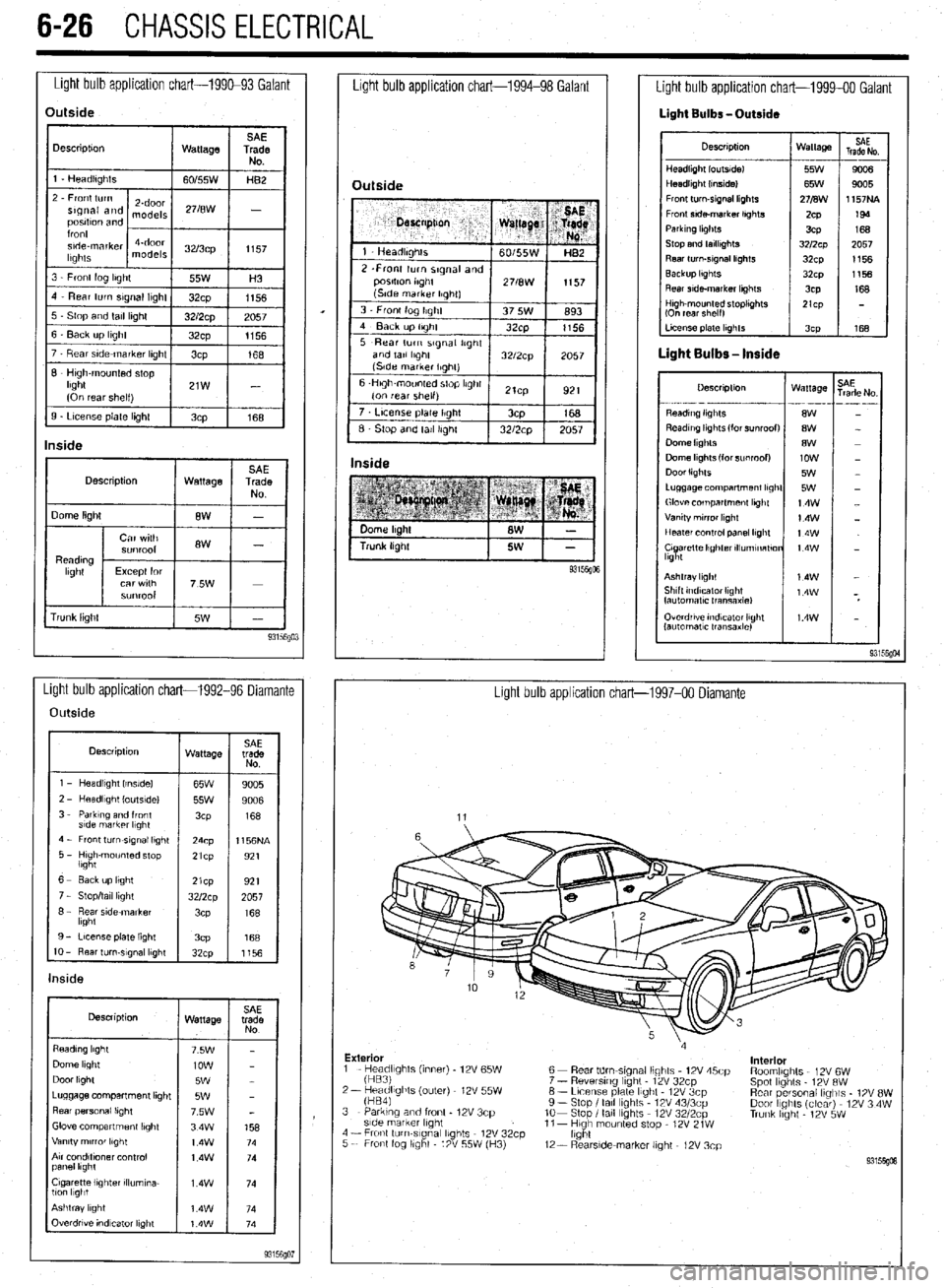

Light bulb application chart-199&93 Galant

Light bulb application chart-1994-98 Galant

Description

1 Wattage 1

rrunk lrght Overdrwe rndvzator light

lautomatlc transaxle)

Light bulb application chart-1992-96 Diamante

Light bulb application chart-1997-00 Diamante

Outside

Description

wattage SAE

trade

NO

1 - Headlrght Irnslde)

65W

9005

l----if

2 - HeadlIght loutsldel

55w 9006

3 - Parktng and front

3cP 168

s!de markrr l,ght

4 - Front turn-srgnal light

24cp 1156NA

5 - Hugh-mounted stop

lbght 21cp

921

1 6- Eackuplrght

I 1921 21cp

7 - Stop/tall light

8 - Rear side marker

lkght

9 - License plate light

3cP 168

IO - Rear turn-slgnal lkght

32cp

1156

Description

Wattage

Dome light

Door light

Luggage compartment lrght

Rear personal lrght

Glove compartment lbght

Vanity mrrror lkght

Arr condltfoner control

panel lkght

Cigarette lighter rllumrna-

llcm l1gbt

Outside

7 t License plate Ilght / 3cp

168

6 Stop and tall Irghl 1 32/2cp 1 2057 I

Inside

Light bulb application chart-1999-00 Galant

Light Bulbs -Outside

Descrrptron Wattage

HeadlIght loutsldel 55W

Headlight (Inside1 65W

Front turn-srgnal lkghts 271B\1\1

Fronr srde-marker lrghts

ZCP

Parkrng hghts

3CP

Stop and tarllrghts 3212~~

Rear turn-srgnal lrghts

32cp

Backup lkghts

32~x1

Rear srde-marker lkghts

3CP SAE

Trade No

---

90a

9005

1157NA

199

168

2057

1156

1156

168

LI- 168

Descrrptron Wattage

- . ..-- -- --_ .---

8W

8W

8W

low

5W

5W

14w

14W

t4w

t4w

Ashtray light

Shtft tndrcaror Ilght

fautomatlc Iransaxlel

Exterior

interior

1 - He;;;fghts (inner) - 12V 65W

2- keadlights (outer) 12V 55W

fHB41 6 - Rear tdm-stgnal lights 12V 45cp

7 - Reversrng light - 12V 32cp

6 - Lrcense plate light 12V 3cp

9 - Stop I tall lights 12V 43/3cp

lo- Stop I tall Ibghts 12V 3212~~

11- Hugh mounted stop - 12V 21W

light RoomlIghts 12V 6W

Spot lights 12V RW

Rear personal lrglils - 1% 8W

Door IIghts (clear) 12V 3 4W

Trunk hght - 12V 5W 3 - Parking and front - 12V 3cp

side marker lrght

4 - Fronl turn-slgnal lights 12V 32cp

5 - Front fog llghl 12V 55W (H3)

12- RearsIde-marker light - 12V 3cp

Page 230 of 408

CHASSIS ELECTRICAL 6-27

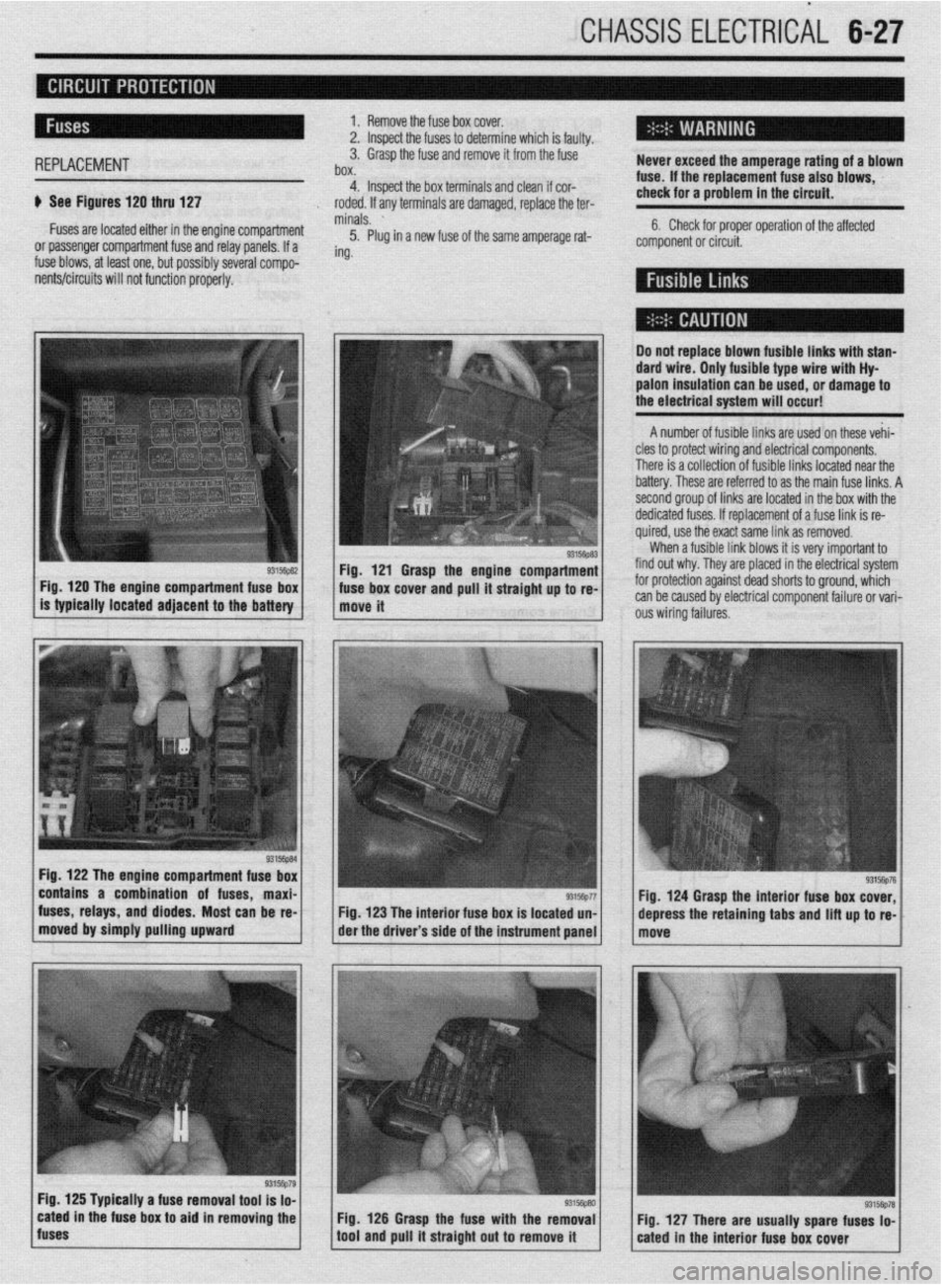

1. Remove the fuse box cover.

2. lnsoect the fuses to determine which is faulty.

REPLACEMENT 3. Grasp the fuse and remove it from the fuse

box. Never exceed the amperage rating of a blown

4. Inspect the box terminals and clean if cor- fuse. If the replacement fuse also blows,

It See Figures 120 thru 127 check for a problem in the circuit.

roded. If any terminals are damaged, replace the ter-

Fuses are located either in the engine Compartment minals. ’

5. Plug in a new fuse of the same amperage rat- 6. Check for proper operation of the affected

or passenger compartment fuse and relay panels. If a component or circuit.

fuse blows, at least one, but possibly several compo- ing.

ients/circuits will not function properly.

Fig, 120 The engine compartment fuse box

is typically located adjacent to the

battery

Fig. 122 The engine compartment fuse box

contains a combination of fuses, maxi-

fuses, relays, and diodes. Most can be re-

moved by simply pulling upward

I Do not replace blown fusible links with stan-

dard wire. Only fusible type wire with Hy

palon insulation can be

used, or damage to

the electrical system will occur!

A number of fusible links are used on these vehi-

cles to protect wiring and electrical components.

There is a collection of fusible links located near the

battery. These are referred to as the main fuse links. A

second group of links are located in the box with the

dedicated fuses. If replacement of a fuse link is re-

quired, use the exact same link as removed.

When a fusible link blows it is very important to

Fig. 121 Grasp the engine compartment find out why. They are placed in the electrical system

. ’ ‘“‘,+“” 1 ous wiring failures. fuse box cover and pull It straight up to re- for protection against dead shorts to ground, which

move it can be caused by electrical component failure or vari-

Fig. 123 The interior fuse box is located un-

der the driver’s side of the instrument panel

Fig. 125 Typically a fuse removal tool is lo-

cated in the fuse box to aid in removing the

fuses Fig. 126 Grasp the fuse with the removal

tool and pull it straight out to remove it Fig. 124 Grasp the interior fuse box cover,

depress the retaining

tabs and lift up to re-