MITSUBISHI DIAMANTE 1900 Owner's Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 21 of 408

l-22 GENERALINFORMATIONAND MAINTENANCE

tears. If the boot is damaged, it should be replaced

trode is to the block’s cooling passages) the cooler it

your driving is long distance, high speed travel, use a

immediately. Please refer to Section 7 for procedures.

will operate. A plug that absorbs little heat and re-

colder plug; if most of your driving is stop and go,

mains too cool will quickly accumulate deposits of

use a hotter plug. Original equipment plugs are gen-

oil and carbon since it is not hot enough to burn

erally a good compromise between the 2 styles and

them off. This leads to plug fouling and consequently

most people never have the need to change their

to misfiring. A plug that absorbs too much heat will

plugs from the factory-recommended heat range.

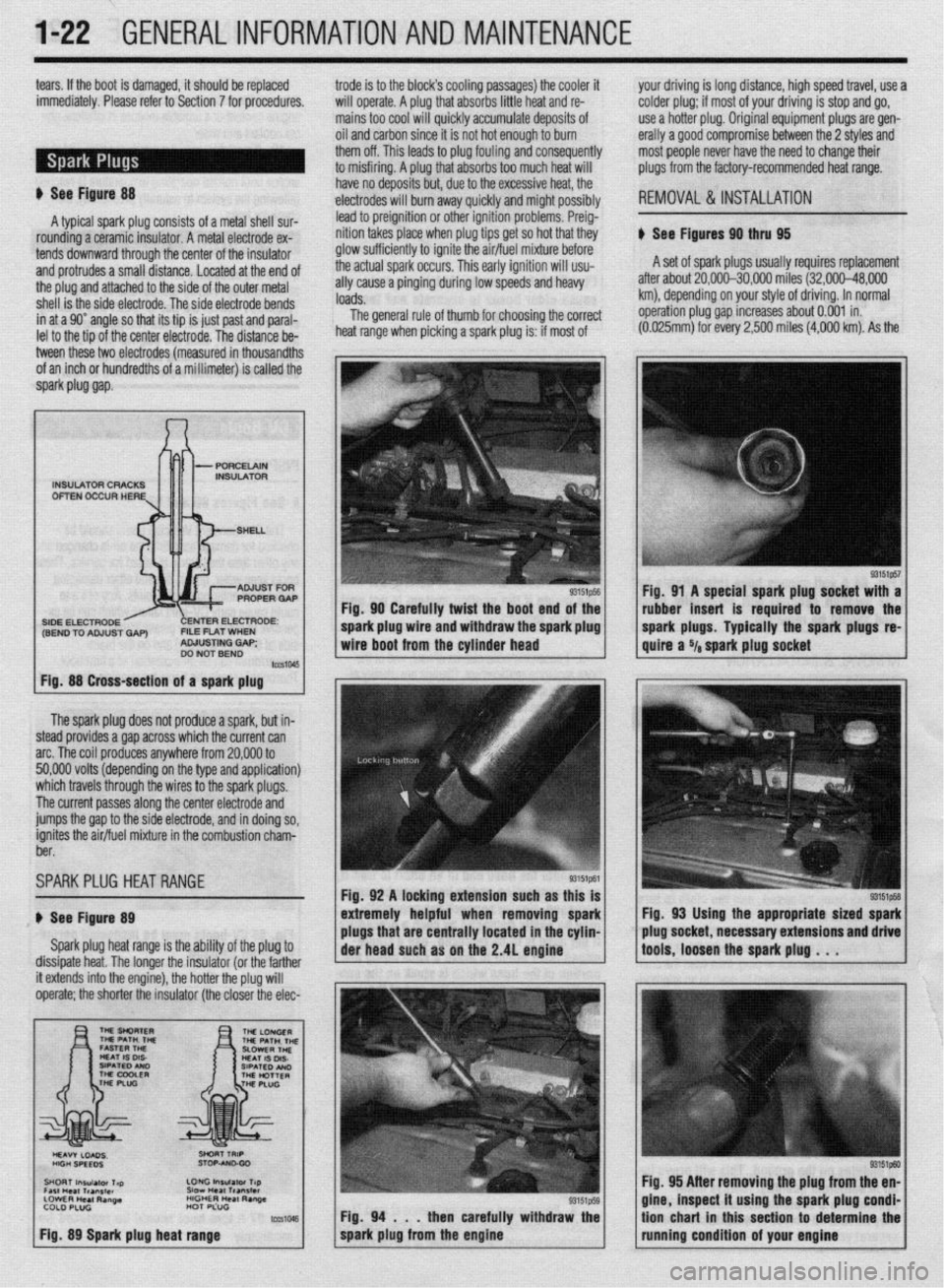

ti See Figure 88 have no deposits but, due to the excessive heat, the

,electrodes will burn away quickly and might possibly

REMOVAL &INSTALLATION

A typical spark plug consists of a metal shell sur- lead to preignition or other ignition problems. Preig-

rounding a ceramic insulator. A metal electrode ex- nition takes place when plug tips get so hot that they

ti See Figures 90 thru 95

tends downward through the center of the insulator glow sufficiently to ignite the air/fuel mixture before

and protrudes a small distance. Located at the end of the actual spark occurs. This early ignition will usu- A set of spark plugs usually requires replacement

the plug and attached to the side of the outer metal ally cause a pinging during low speeds and heavy after about 20,000-30,000 miles (32,000-48,000

shell is the side electrode. The side electrode bends loads. km), depending on your style of driving. In normal

in at a 90” angle so that its tip is just past and paral- The general rule of thumb for choosing the correct operation plug gap increases about 0.001 in.

lel to the tio of the center electrode. The distance be- heat range when picking a spark plug is: if most of (0.025mrn) for every 2,500 miles

(4,000 km). As the

tween these two electrodes (measured in thousandths

of an inch or hundredths of a millimeter) is called the

spark piug gap.

The spark plug does not produce a spark, but in-

steed provides a gap across which the current can

arc. The coil produces anywhere from 20,000 to

50,000 volts (depending on the type and application)

which travels through the wires to the spark plugs.

The current passes along the center electrode and

jumps the gap to the side electrode, and in doing so,

ignites the air/fuel mixture in the combustion charn-

ber.

SPARKPLUG HEATRANGE

ti See Figure 89

Spark plug heat range is the ability of the plug to

dissipate heat. The longer the insulator (or the farther

INSULATOR CRACKS

OFTEN OCCUR HERE

SIDE ELECTRODE ENTER ELECTRODE:

(SEND TO ADJUST GAP) FILE FLAT WHEN

ADJUSTING GAP;

DO NOT BEND

Fig. 88 Cross-section of a spark plug

it extends into the engine), the hotter the plug will

operate; the shorter the insulator (the closer the elec- Fig. 90 Carefully twist the boot end of the

I

spark plug wire and withdraw the spark plug

wire boot from the cylinder head

Fig. 92 A locking extension such as this is

extremely helpful when removing spark

plugs that are centrally located in the cyhn-

Fig. 94 . . .

then carefully withdraw the

spark plug from the engine Fig. 91 A special spark plug socket with a

rubber insert is required to remove the

spark plugs. Typically the spark plugs

re-

quire a Ya spark plug socket

Fig, 93 Using the appropriate sized spark

plug socket, necessary extensions and drive

tools, loosen the spark plug . . .

93151ptxl Fig. 95 After removing the plug from the en-

gine, inspect it using the spark plug condi-

tion chart in this section to determine the

running condition of your engine

Page 22 of 408

t

GENERALINFORMATIONAND MAINTENANCE l-23

gap increases, the plug’s voltage requirement also in-

creases. It requires a greater voltage to jump the the spark plug counterclockwise to loosen and re-

move the spark plug from the bore.

wider gap and about &o to three times as much volt-

age to fire the plug at high speeds than at idle. The

improved air/fuel ratio control of modern fuel injec-

tion combined with the higher voltage output of mod- Be sure not to use a flexible extension on the place. The click may be felt or heard, then gently pull

ern ignition systems will often allow an engine to run socket. Use of a flexible extension may allow back on the boot to assure proper contact.

.___. . _

significantly longer on a set of standard spark plugs, a shear force to be agptf’ ea to me plug.

A 12. On the 3.OL fSOHC and DOHC) and 3.5L en-

LL_ _I___ -u I_ IL-

but keep in mind that efficiency will drop as the gap shear force could break tne pug on III me

tion 3 for the installation procedure.

widens (along with fuel economy and power). cylinder head, leading to costly and frustrat-

13. If equipped, install the center cover.

When you’re removing spark plugs, work on one ing repairs.

at a time. Don’t start by removing the plug wires all at

once, because, unless you number them, they may To install:

INSPECTION & GAPPING

11. Apply a small amount of silicone dielectric

compound to the end of the spark plug lead or inside

the spark plug boot to prevent sticking, then install

the boot to the spark plug and push until it clicks into

gines, install the upper intake manifold. Refer to Sec-

,,Y” ..1111 uy”’ 1 the neaative bat&v cable and if become mixed up. Take a minute before you begin

and number the wrrpc with +sne

1. Disconnect. ~~.~

--..-., -..-.-, -..-

thevehicle has been run recently, allow the engine to

thoroughly cool.

2. If equipped, remove the center cover.

3. On the 3.OL (SOHC and DOHC) and 3.5L en-

gines, the upper intake manifold must be removed to

access the rear spark plugs. Refer to Section 3 for the

removal procedure.

4. Carefully twist the spark plug wire boot to

loosen it, then pull upward and remove the boot from

the plug. Be sure to pull on the boot and not on the

wire, otherwise the connector located inside the boot

may become separated.

5. Using compressed air, blow any water or de-

bris from the spark plug well to assure that no harm-

ful contaminants are allowed to enter the combustion

chamber when the spark plug is removed. If com-

pressed air is not available, use a raa or a brush to must be replaced.

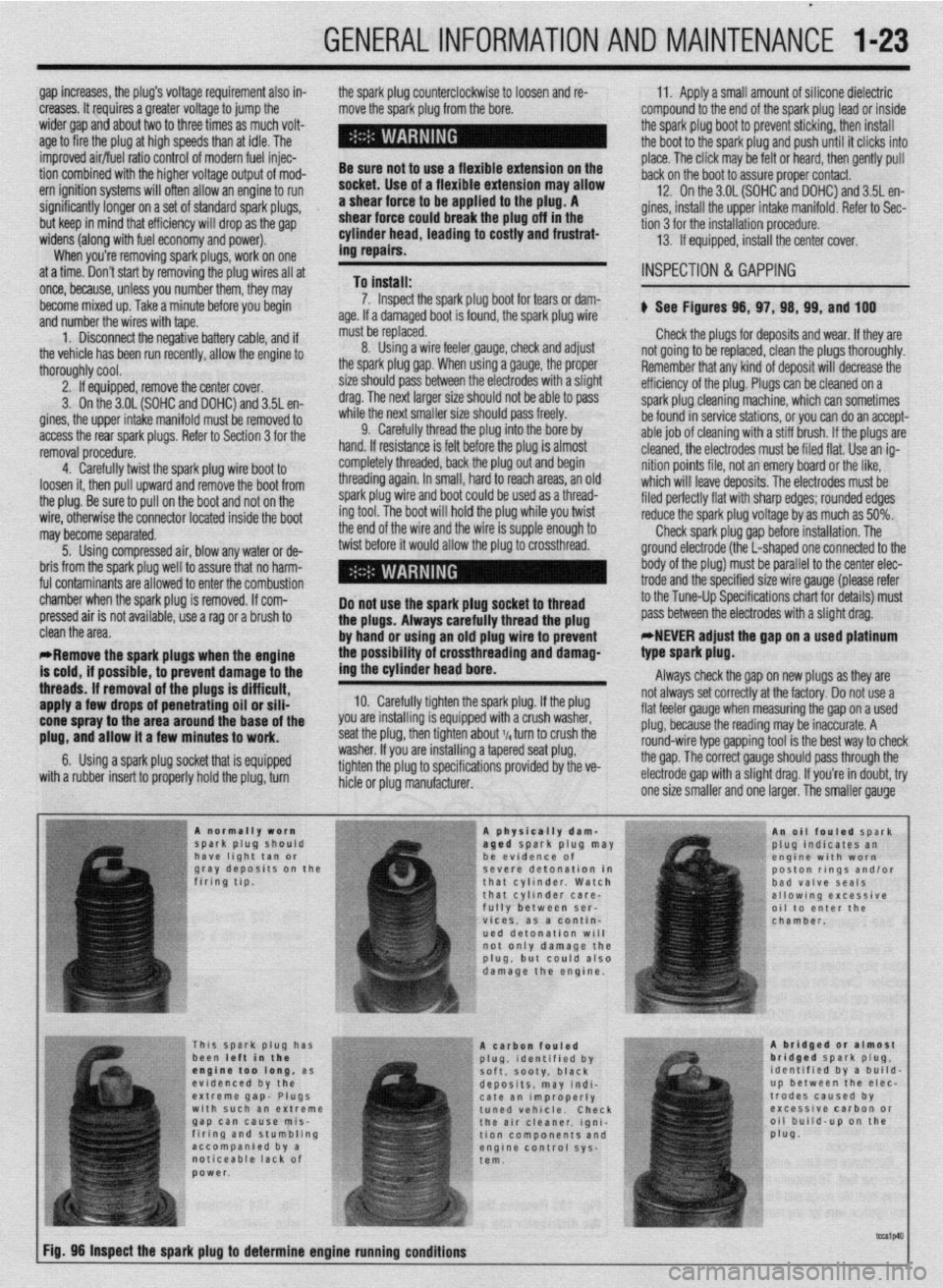

Check the plugs for deposits and wear, If they are 7. Inspect the spark plug boot for tears or dam-

age. If.a damaged boot is found, the spark plug wire

8. Using a wire feelergauge, check and adjust

the spark plug gap. When using a gauge, the proper

size should pass between the electrodes with a slight

drag. The next larger size should not be able to pass

while the next smaller size should pass freely.

9. Carefully thread the plug into the bore by

hand. If resistance is felt before the plug is almost

completely threaded, back the plug out and begin

threading again. In small, hard to reach areas, an old

spark plug wire and boot could be used as a thread-

ing tool. The boot will hold the plug while you twist

the end of the wire and the wire is supple enough to

twist before it would allow the plug to crossthread.

Do not use the spark plug sock?

l -- K-rrA tha nhme Alwmm rarntdlv thw GL I” IlllGa”

the possibility of crossthreading and damag- lad the plug

. ..Y f..“YY. rn”Y,‘““mY*“.‘, .I**” by hand or using an old plug wire to prevent

ing the cylinder head bore.

10. Carefully tighten the spark plug. If the plug

you are installing is equipped with a crush washer,

seat the plug, then tighten about I/, turn to crush the

washer. If you are installing a tapered seat plug,

tighten the plug to specifications provided by the ve-

hicle or plug manufacturer. b See Figures 98, 97, 98, 99, and 100

not going to be replaced, clean the plugs thoroughly.

Remember that any kind of deposit will decrease the

efficiency of the plug. Plugs can be cleaned on a

spark plug cleaning machine, which can sometimes

be found in service stations, or you can do an accept-

able job of cleaning with a stiff brush. If the plugs are’

cleaned, the electrodes must be filed flat. Use an ig-

nition points file, not an emery board or the like,

which will leave deposits. The electrodes must be

filed perfectly flat with sharp edges; rounded edges

reduce the spark plug voltage by as much as 50%.

Check spark plug gap before installation. The

ground electrode (the L-shaped one connected to the

body of the plug) must be parallel to the center elec-

trode and the specified size wire gauge (please refer

to the Tune-Up Specifications chart for details) must

pass between the electrodes with a slight drag:

*,NEVER adjust the gap on a used platinum

. clean the area.

*Remove the spark plugs when the engine

is cold, if possible, to prevent damage to the

threads. If removal of the plugs is difficult,

apply a few drops of penetrating oil or sili-

cone spray to the area around the base of the

plug, and allow it a few minutes to work.

6. Using a spark plug socket that is equipped

with a rubber insert to properly hold the plug, turn type spark plug.

Always check the gap on new plugs as they are

not always set correctly at the factory. Do not use a

flat feeler gauge when measuring the gap on a used

plug, because the reading may be inaccurate. A

round-wire type gapping tool is the best way to check

the gap. The correct gauge should pass through the

electrode gap with a slight drag. If you’re in doubt, try

one size smaller and one laraer. The smaller aauqe

Page 23 of 408

l-24 GENERALINFORMATIONAND MAINTENANCE

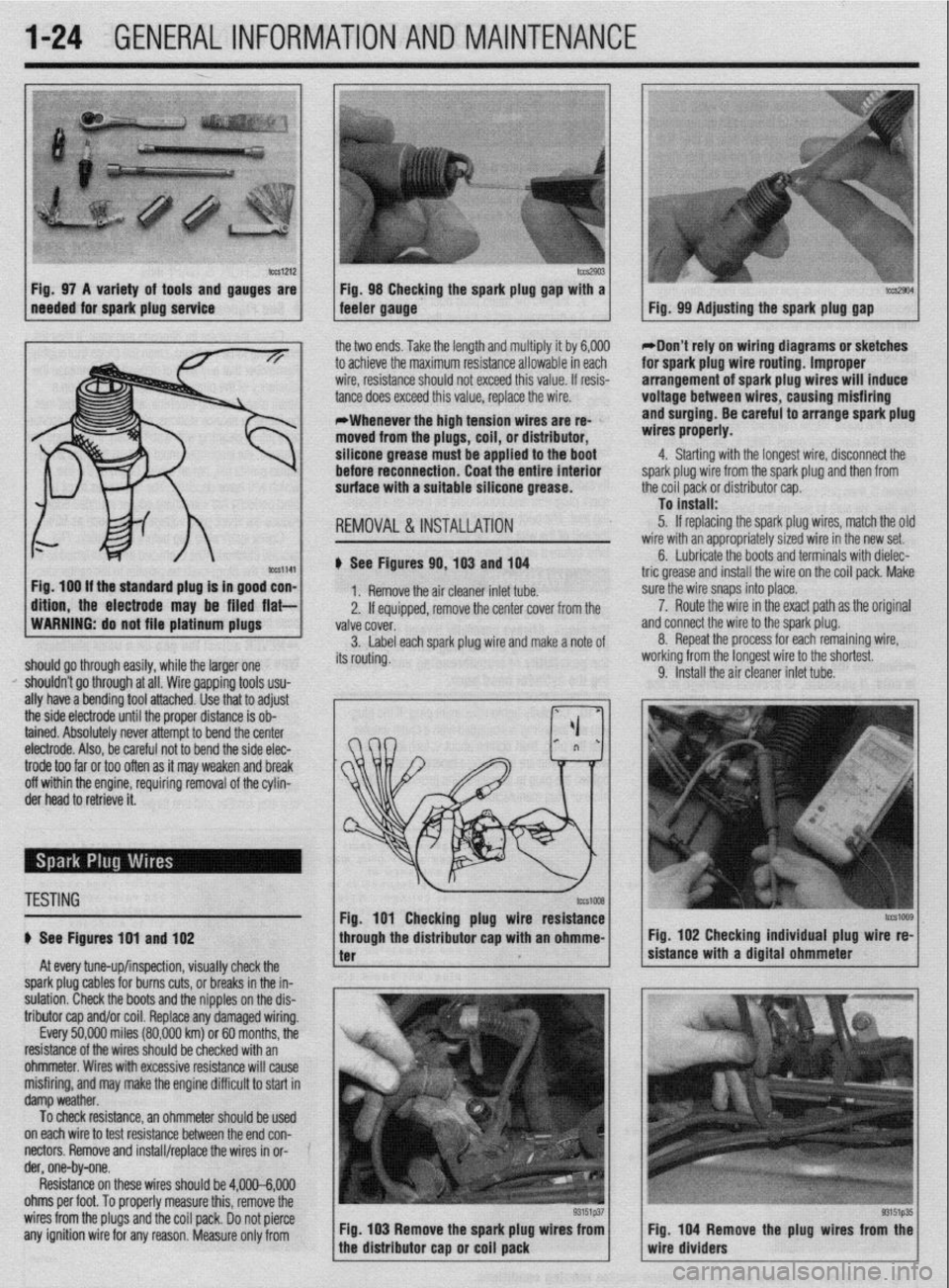

b%slZl2 Fig. 97 A variety of tools and gauges are

needed for spark plug service tm2903 Fig. 98 Checking the spark plug @au with a tccs2904 feeler gauge. - Fig. 99 Adjusting the spark plug gap

ig. 100 If the standard plug Is in good con-

ftlon, the electrode may be filed flat- the two ends. Take the length and multiply it by 6,000

to achieve the maximum resistance allowable in each

wire, resistance should not exceed this value. If resis-

tance does exceed this value, replace the wire.

*Whenever the high tension wires are re- ’

moved from the plugs, coil, or distributor,

silicone grease must be applied to the boot

before reconnection. Coat the entire Interior

surface with a suitable silicone grease.

REMOVAL &INSTALLATION

# See Figures 90,103 and 104

1. Remove the air cleaner inlet tube.

2. If eouiooed, remove the center cover from the

WARNING: do not file platinum plugs

valve covei.

3. Label each spark plug wire and make a note of

should go through easily, while the larger one its routing.

I’ shouldn’t go through at all. Wire gapping tools usu-

ally have a bending tool attached. Use that to adjust

the side electrode until the proper distance is ob-

tained. Absolutely never attempt to bend the center

electrode. Also, be careful not to bend the side elec- *Don’t rely on wiring diagrams or sketches

for spark plug wire routing. Improper

arrangement of spark plug wires will induce

voltage between wires, causing misfiring

and surging. Be careful to arrange spark plug

wires properly.

4. Starting with the longest wire, disconnect the

spark plug wire from the spark plug and then from

the coil pack or distributor cap.

To install:

5. If replacing the spark plug wires, match the olc

wire with an appropriately sized wire in the new set.

6. Lubricate the boots and terminals with dielec-

tric grease and install the wire on the coil pack. Make

sure the wire snaps into place.

a 7. Route the wire in the exact path as the original

nd connect the wire to the spark plug.

8. Repeat the process for each remaining wire,

iorking from the longest wire to the shortest.

9. Install the air cleaner inlet tube.

trode too far or too often as it may weaken and break

off within the engine, requiring removal of the cylin-

der head to retrieve it.

TESTING

# See Figures 191 and 102

At every tune-up/inspection, visually check the

spark plug cables for burns cuts, or breaks in the in-

sulation. Check the boots and the nipples on the dis-

tributor cap and/or coil. Replace any damaged wiring.

Every 50,000 miles (80,000 km) or 60 months, the

resistance of the wires should be checked with an

ohmmeter. Wires with excessive resistance will cause

misfiring, and may make the engine difficult to start in

damp weather.

To check resistance, an ohmmeter should be used ’

on each wire to test resistance between the end con-

nectors. Remove and install/replace the wires in or- ’

der, one-by-one.

Resistance on these wires should be 4,000-6,000

ohms per foot. To properly measure this, remove the

wires from the plugs and the coil pack. Do not pierce

any ignition wire for any reason. Measure only from Fig. 103 Remove the spark plug wires from

tcG1009 Fig. 102 Checking individual plug wire re-

sistance with a digital ohmmeter

Fig. 104 Remove the plug wires from the

wire dividers

Page 24 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-25

osen the distributor cap retain-

Fig. 106. . . then remove the cap from the

distributor

Fig. 107 Grasp the rotor and pull it straight

off of the distributor shaft

REMOVAL &INSTALLATION

1. Disconnect the negative battery cable.

*Depending on the reason for removing the

distributor cap, it may make more sense to Fig. 108 The rotor must be aligned correctly

to the distributor shaft before installation

other physical damage. Make sure the distributor

cap’s center button is free of damage. Check the cap

terminals for dirt or corrosion. Always check the rotor

blade and spring closely for damage. Replace any

comoonents where damaae is found.

smmE

ALGNME

LOCATOR

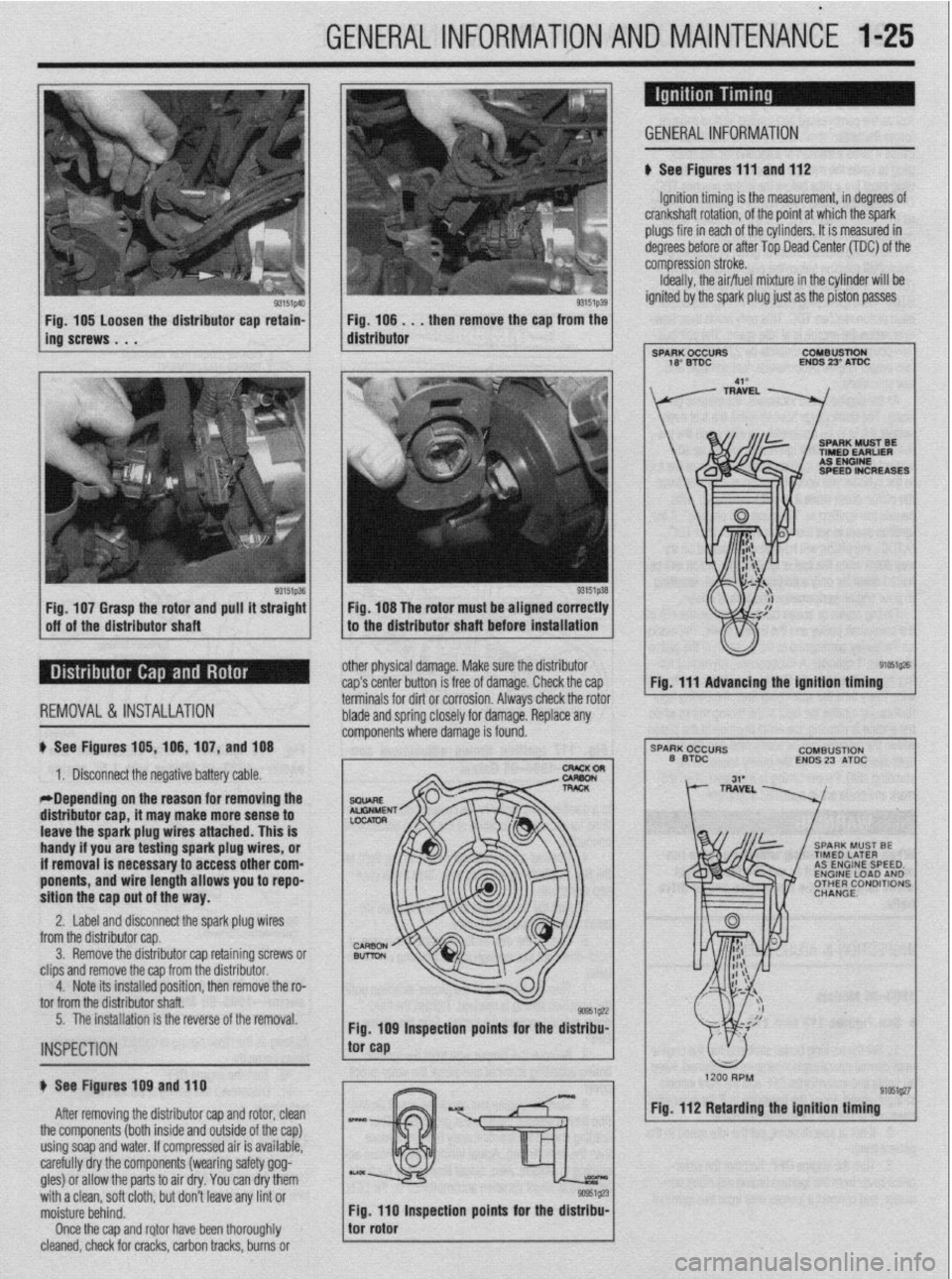

b See Figures 105,106,107, and 108 GENERAL INFORMATION

b See Figures 111 and 112

Ignition timing is the measurement, in degrees of

crankshaft rotation, of the point at which the spark

plugs fire in each of the cylinders. It is measured in

degrees before or after Top Dead Center (TDC) of the

compression stroke.

Ideally, the air/fuel mixture in the cylinder will be

ignited by the spark plug just as the piston passes

I 1 COMBUSTION

ENDS 23’ ATDC

SPEED INCREASES

9ir&1$?6

Fig. 111 Advancing the ignition timing

’

CCURS

COMBUSTION

DC

ENDS 23 ATDC

3. Remove the distributor cap retaining screws or

clips and remove the cap from the distributor.

4. Note its installed position, then remove the ro-

tor from the distributor shaft. leave the spark plug wires attached. This is

handy if you are testing spark plug wires, or

if removal is necessary to access other com-

ponents, and wire length allows you to repo-

sition the cap out of the way.

2. Label and disconnect the spark plug wires

from the distributor cao.

5. The installation is the reverse of the removal.

INSPECTION

u See Figures 109 and 110

9mg27

After removing the distributor cap and rotor, clean

the components (both inside and outside of the cap)

using soap and water. If compressed air is available,

carefully dry the components (wearing safety gog-

gles) or allow the parts to air dry. You can dry them

with a clean, soft cloth, but don’t leave any lint or

moisture behind.

Once the cap and rotor have been thoroughly Inspection points for the dis Fig. 112 Retarding the tgnttion timing

cleaned, check for cracks, carbon tracks, burns or

Page 25 of 408

.

1-26 GENERALINFORMATIONAND MAINTENANCE

TDC of the compression stroke. If this happens, the

piston WIII be at the beginning of the power stroke

just as the compressed and ignited air/fuel mixture

forces the piston down and turns the crankshaft. Be-

cause it takes a fraction of a second for the spark

plug to ignite the mixture in the cylinder, the spark

plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be completely ignited

as the piston passes TDC and the full power of the

explosion will not be used by the engine.

The timing measurement is given in degrees of

crankshaft rotation before the piston reaches TDC

(BTDC). If the setting for the ignition timing is 10”

BTDC, each spark plug must fire 10 degrees before

each piston reaches TDC. This only holds true, how-

ever, when the engine is at idle speed. The combus-

tion process must be complete by 23”ATDC to main-

tain proper engine performance, fuel mileage, and

low emissions.

As the engine speed increases, the pistons go

faster. The spark plugs have to ignite the fuel even

sooner if it IS to be completely ignited when the pis-

ton reaches TDC. If the ignition is set too far ad-

vanced (BTDC), the ignition and expansion of the fuel

in the cylinder wtll occur too soon and tend to force

the piston down while it is still traveling up. Thus

causes pre ignition or “knockmg and pinging”. If the

ignition spark is set too far retarded, or after TDC

(ATDC), the piston will have already started on its

way down when the fuel is ignited. The piston will be

forced down for only a portion of its travel, resulting

in poor engine performance and lack of power.

Timing marks or scales can be found on the rim of

the crankshaft pulley and the timing cover. The marks

on the pulley correspond to the posrtion of the piston

in the No. 1 cylinder. A stroboscopic (dynamic) tim-

ing light is hooked onto the No. 1 cylinder spark plug

wrre. Every time the spark plug fires, the timing light

flashes. By aiming the light at the timing marks while

the engine is running, the exact position of the piston

within the cylinder can be easily read (the flash of

light makes the mark on the pulley appear to be

standing still). Proper timing is indicated when the

mark and scale are in specified alignment.

When checking timing with the engine run-

ning, take care not to get the timing light

wires tangled in the tan blades and/or drive

belts.

INSPECTION &ADJUSTMENT

1990-96 Models

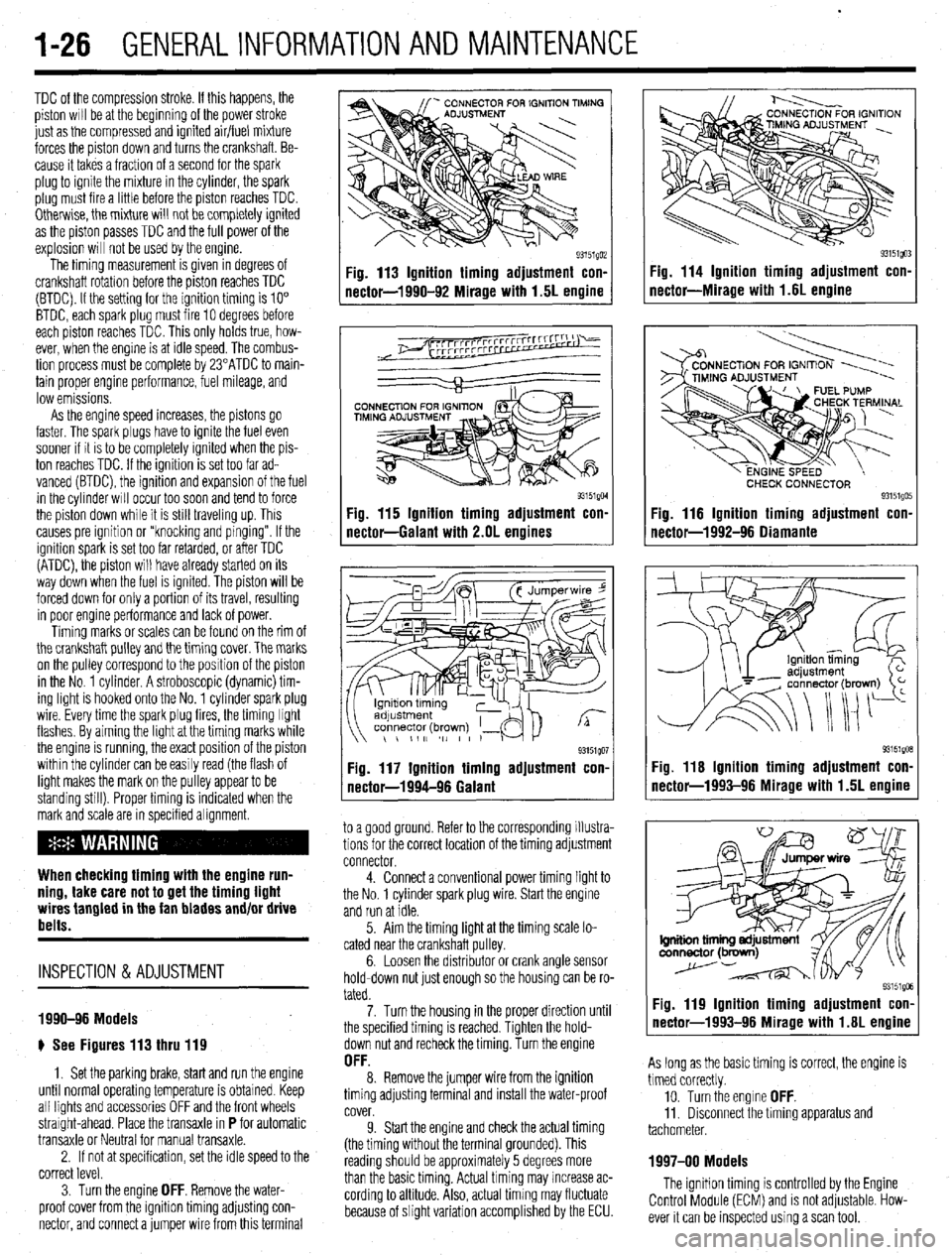

e See Figures 113 thru 119

1. Set the parking brake, start and run the engine

until normal operating temperature is obtained. Keep

all lights and accessories OFF and the front wheels

straight-ahead. Place the transaxle in

P for automatic

transaxle or Neutral for manual transaxle.

2. If not at specification, set the idle speed to the

correct level.

3. Turn the engine

OFF. Remove the water-

proof cover from the igmtion timing adjusting con-

nector, and connect a jumper wire from this terminal

Fig. 113 Ignition timing adjustment con-

nector-1990-92 Mirage with 1.5L engine

93151QM Fig. 115 Ignition timing adjustment con-

nectar-Galant with 2.OL engines

93151QO1 Fig. 117 Ignition timing adjustment con.

nectar-1994-96 Galant

to a good ground. Refer to the corresponding illustra-

tions for the correct location of the timing adjustment

connector.

4. Connect a conventional power timing light to

the No. 1 cylinder spark plug wire. Start the engine

and run at idle.

5. Aim the timing light at the timing scale lo-

cated near the crankshaft pulley.

6. Loosen the distributor or crank angle sensor

hold-down nut just enough so the housing can be ro-

tated.

7. Turn the housing in the proper direction until

the specified timing is reached. Tighten the hold-

down nut and recheck the timing. Turn the engine

OFF. 8. Remove the jumper wire from the ignition

timing adjusting terminal and install the water-proof

cover.

9. Start the engine and check the actual timing

(the timing without the terminal grounded). This

reading should be approximately 5 degrees more

than the basic timing. Actual timing may increase ac-

cording to altitude. Also, actual timing may fluctuate

because of slight variation accomplished by the ECU.

Fig. 114 Ignition timing adjustment con-

nectar-Miracle with 1.6L enaine

CHECK CONNECTOR 93151QO! Fig. 116 Ignition timing adjustment con.

nectar-1992-96 Oiamante

93151gOB Fig. 116 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.5L engine

Fig. 119 Ignition timing adjustment con-

nector-1993-96 Mirage with 1.6L engine

As long as the basic timing is correct, the engine is

timed correctly.

10. Turn the engine

OFF. 11. Disconnect the timing apparatus and

tachometer.

1997-00 Models

The ignition timing is controlled by the Engine

Control Module (ECM) and is not adjustable. How-

ever it can be inspected using a scan tool.

Page 26 of 408

GENERALINFORMATIONAND MAlNTENANdE I-27

ADJUSTMENT

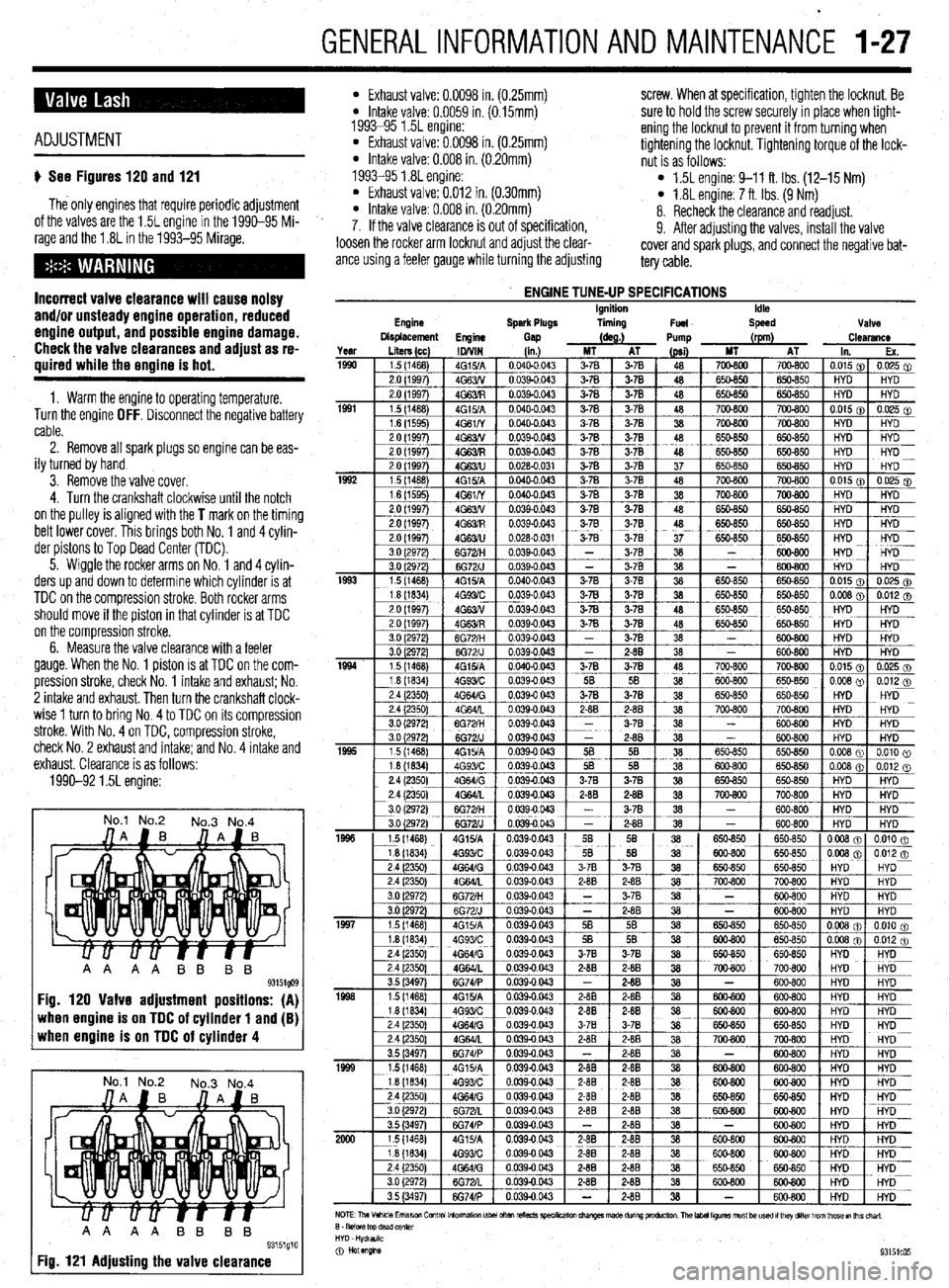

u See Figures 120 and 121

The only engines that require periodic adjustment

of the valves are the 1.5L engine in the 1990-95 Mi-

rage and the 1.8L in the 1993-95 Mirage.

Incorrect valve clearance will cause noisy

and/or unsteady engine operation, reduced

engine output, and possible engine damage.

Check the valve clearances and adjust as re-

quired while the engine is hot.

1. Warm the engine to operating temperature.

Turn the engine OFF. Disconnect the negative battery

cable.

2. Remove all spark plugs so engine can be eas-

ily turned by hand

3. Remove the valve cover.

4. Turn the crankshaft clockwise until the notch

on the pulley is aligned with the

T mark on the timing

belt lower cover. This brings both No. 1 and 4 cylin-

der pistons to Top Dead Center (TDC).

5. Wiggle the rocker arms on No. 1 and 4 cylin-

ders up and down to determine which cylinder is at

TDC on the compression stroke. Both rocker arms

should move if the piston in that cylinder is at TDC

on the compression stroke.

6. Measure the valve clearance with a feeler

gauge. When the No. 1 piston is at TDC on the com-

pression stroke, check No. 1 intake and

exhaust; No.

2 intake and exhaust. Then turn the crankshaft clock-

wise 1 turn to bring No. 4 to TDC on its compression

stroke. With No. 4 on TDC, compression stroke,

check No. 2 exhaust and intake; and No. 4 intake and

exhaust. Clearance is as follows:

1990-92 1.5L engine:

No.1 No.2

No.3 No.4

when engine is on TDC of cylinder 1 and (B) when engine is on TDC of cylinder 4

No.1 No.2

No.3 No.4

AA AA BB BB

93151g10 Fig. 121 Adjusting the valve clearance

l Exhaust valve: 0.0098 in. (0.25mm) screw. When at specification, tighten the locknut. Be l Intake valve: 0.0059 in. (0.15mm)

1993-95 1.5L engine: sure to hold the screw securely in place when tight-

l Exhaust valve: 0.0098 in. (0.25mm) ening the locknut to prevent it from turning when

* Intake valve: 0.008 in. (0.20mm) tightening the locknut. Tightening torque of the lock-

nut is as follows:

1993-95 1.8L engine:

l Exhaust valve: 0.012 in. (0.30mm) l 1.5L engine: 9-11 ft. Ibs. (12-15 Nm)

l Intake valve: 0.008 in. (0.20mm) l 1.8L engine: 7 ft. Ibs. (9 Nm)

8. Recheck the clearance and readjust.

7. If the valve clearance is out of specification,

9. After adjusting the valves, install the valve

loosen the rocker arm locknut and adjust the clear-

ante using a feeler gauge while turning the adjusting cover and spark plugs, and connect the negative bat-

tery cable.

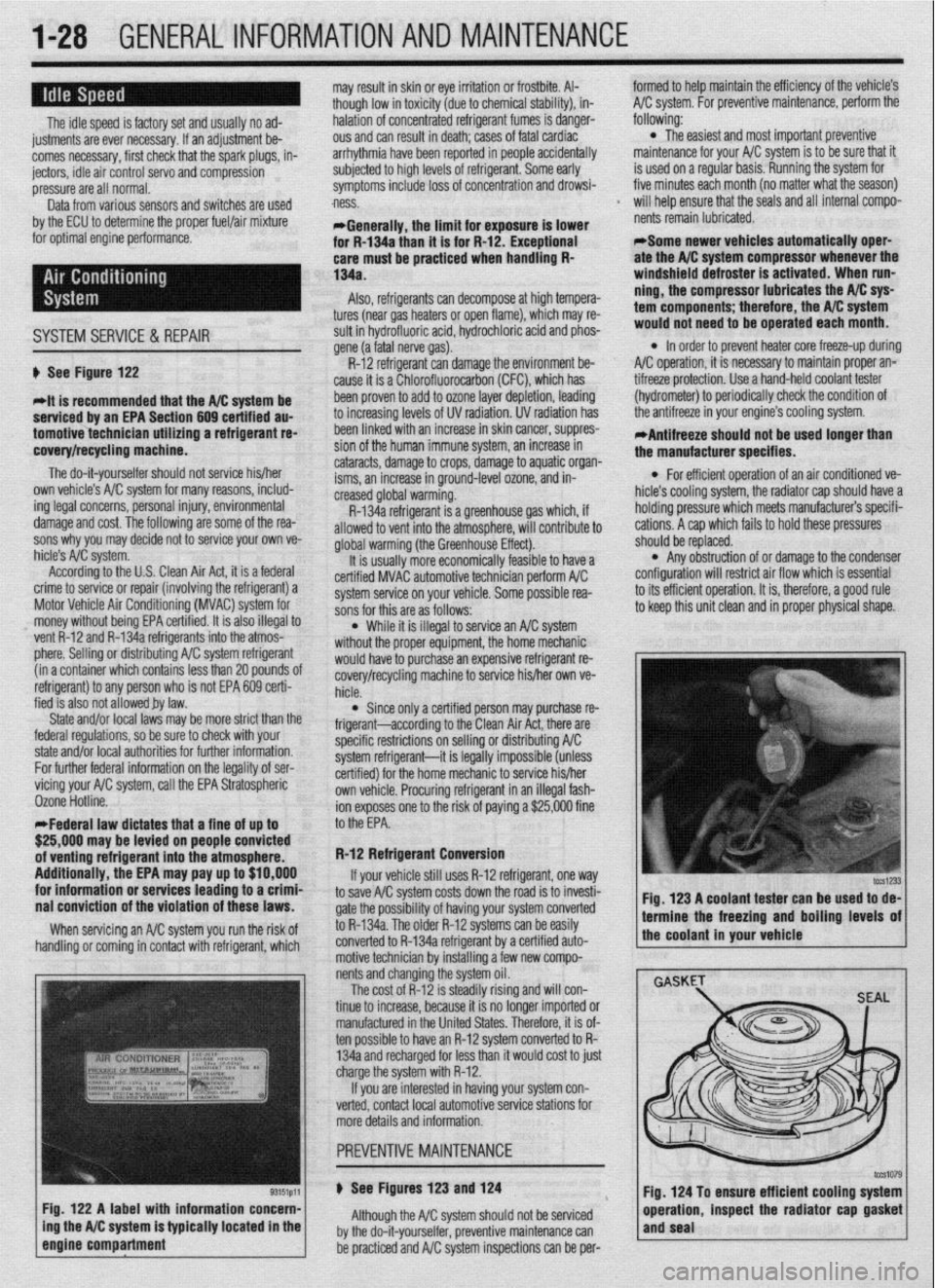

Engine

ENGINE TUNE-UP SPECIFICATIONS Ignition

Spark Plugs liming

Fuel Idle

Speed Valve

Displacement

Engine

Gap (as.) Pump (rpm)

Clearance

Page 27 of 408

l-28 GENERALINFORMATIONAND MAINTENANCE

may result in skin or eye irritation or frostbite. Al- formed to help maintain the efficiency of the vehicle’s

though low in toxicity (due to chemical stability), in- A/C system. For preventive maintenance, perform the

The idle speed is factory set and usually no ad- halation of concentrated refrigerant fumes is danger- following:

justments are ever necessary. If an adjustment be- ous and can result in death; cases of fatal cardiac

l The easiest and most important preventive

comes necessary, first check that the spark plugs, in- arrhythmia have been reported in people accidentally maintenance for your A/C system is to be sure that it

jectors, idle air control servo and compression subjected to high levels of refrigerant. Some early is used on a regular basis. Running the system for

pressure are all normal. symptoms include loss of concentration and drowsi- five minutes each month (no matter what the season)

Data from various sensors and switches are used ness. + will help ensure that the seals and all internal compo-

by the ECU to determine the proper fuel/air mixture

for optimal engine performance. cGeneraiiy, the limit for exposure is lower nents remain lubricated.

for R-134a than it is for R-12. Exceptional *Some newer vehicles automatically oper-

care must be practiced when handling R- ate the A/C system compressor whenever the

134a. windshield defroster is activated. When run-

Also, refrigerants can decompose at high tempera- ning, the compressor lubricates the A/C sys

tures (near gas heaters or open flame), which may re- tern components; therefore, the A/C system

SYSTEM SERVICE& REPAIR suit in hydrofluoric acid, hydrochloric acid and phos- would not need to be operated each month.

gene (a fatal nerve gas). * In order to prevent heater core freeze-up during

R-12 refrigerant can damage the environment be- A/C operation, it is necessary to maintain proper an-

cause it is a Chlorofluorocarbon (CFC), which has tifreeze protection. Use a hand-held coolant tester

been proven to add to ozone layer depletion, leading (hydrometer) to periodically check the condition of

to increasing levels of UV radiation. UV radiation has the antifreeze in your engine’s cooling system.

been linked with an increase in skin cancer, suppres-

sion of the human immune system, an increase in *Antifreeze should not be used longer than

cataracts, damage to crops, damage to aquatic organ- the manufacturer specifies.

isms, an increase in ground-level ozone, and in- . For efficient operation of an air conditioned ve-

creased global warming. hicle’s cooling system, the radiator cap should have a

R-134a refrigerant is a greenhouse gas which, if holding pressure which meets manufacturers specifi-

allowed to vent into the atmosphere, will contribute to cations. A cap which fails to hold these pressures

global warming (the Greenhouse Effect). should be replaced.

It is usually more economically feasible to have a

l Any obstruction of or damage to the condenser

certified MVAC automotive technician perform A/C configuration will restrict air flow which is essential

system service on your vehicle. Some possible rea- to its efficient operation. It is, therefore, a good rule

sons for this are as follows: to keep this unit clean and in proper physical shape.

l While it is illegal to service an A/C system

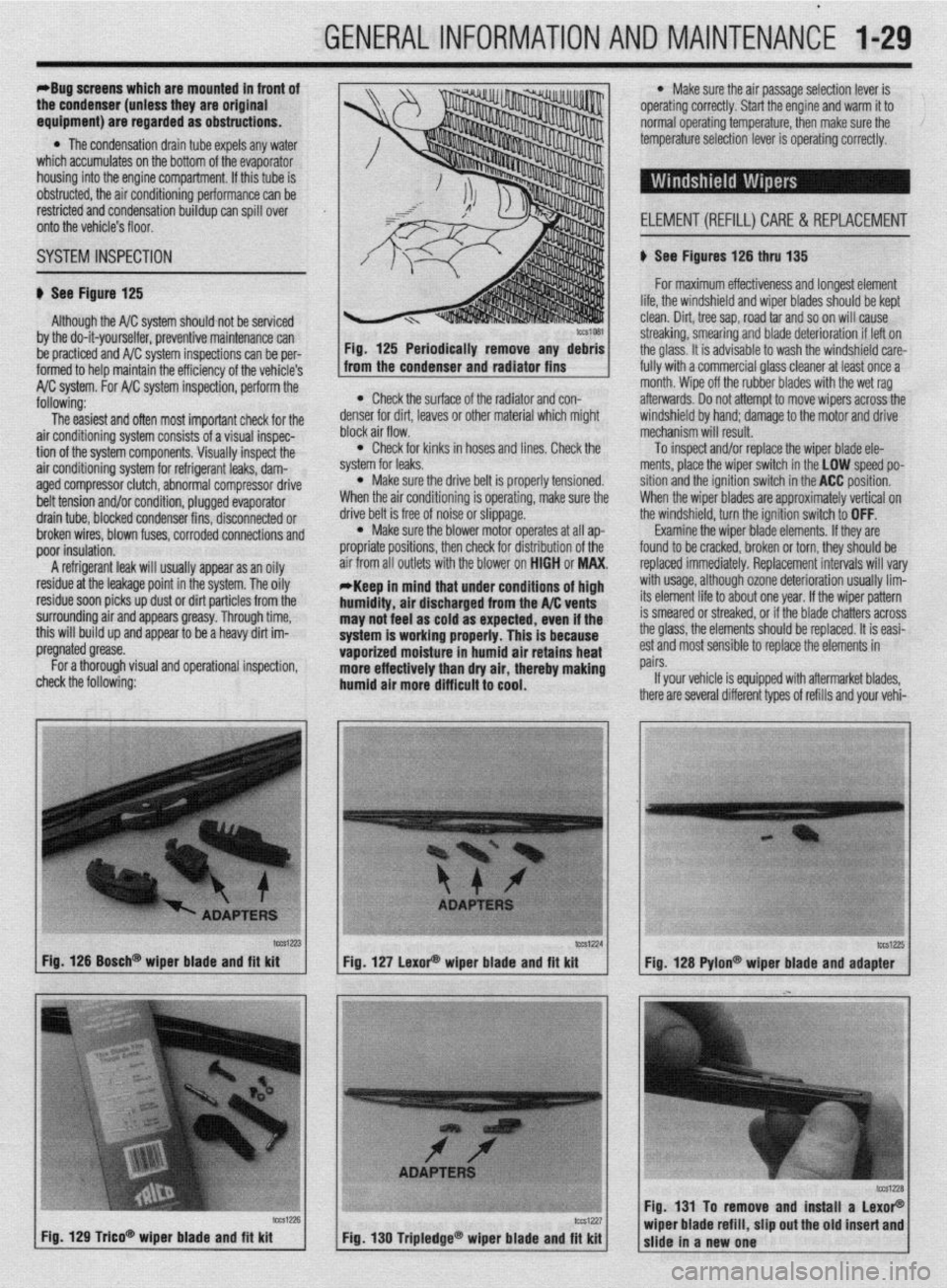

without the proper equipment, the home mechanic ti See Figure 122

*it is recommended that the A/C svstem be

serviced by an EPA Section 609 cehified au-

tomotivetechnicfan utilizing a refrigerant re-

covery/recycling machfne.

The do-it-yourselfer should not service his/her

own vehicle’s A/C system for many reasons, includ-

ing legal concerns, personal injury, environmental

damage and cost. The following are some of the rea-

sons why you may decide not to service your own ve-

hicle’s A/C system.

According to the U.S. Clean Air Act, it is a federal

crime to service or repair (involving the refrigerant) a

Motor Vehicle Air Conditioning (MVAC) system for

money without being EPA certified. It is also illegal to

vent R-12 and R-134a refrigerants into the atmos-

phere. Selling or distributing A/C system refrigerant

(in a container which contains less than 20 pounds oi

refrigerant) to any person who is not EPA 609 certi-

fied is also not allowed by law.

State and/or local laws may be more strict than the

federal regulations, so be sure to check with your

state and/or local authorities for further information.

For further federal information on the legality of ser-

vicing your AK system, call the EPA Stratospheric

Ozone Hotline.

*Federal law dictates that a fine of up to

$25,000 may be levied on people convicted

of venting refrigerant into the atmosphere.

Additionally, the EPA may pay up to $10,000

for information or services leading to a crimf

nai conviction of the violation of these laws.

When servicing an A/C system you run the risk of

handling or coming in contact with refrigerant, which

Fig. 122 A label with information concern-

ing the A/C system is typically located in the

engine compartment

f would haveto purchase an expensive refrigerant re-

covery/recycling machine to service his/her own ve-

hicle.

l Since only a certified person may purchase re-

frigerant-according to the Clean Air Act, there are

specific restrictions on selling or distributing A/C

system refrigerant-it is legally impossible (unless

certified) for the home mechanic to service his/her

own vehicle. Procuring refrigerant in an illegal fash-

ion exposes one to the risk of paying a $25,000 fine

to the EPA.

R-12 Refrigerant Conversion

If your vehicle still uses R-12 refrigerant, one

way to save A/C system costs down the road is to invesh-

gate the possibility of having your system converted

to R-134a. The older R-12 systems can be easily

converted to R-134a refrigerant by a certified auto-

motive technician by installing a few new compo-

nents and changing the system oil.

The cost of R-12 is steadily rising and will con-

tinue to increase, because it is no longer imported or

manufactured in the United States. Therefore, it is of-

ten possible to have an R-12 system converted to R-

134a and recharged for less than it would cost to just

charge the system with R-12.

If you are interested in having your system con-

verted, contact local automotive service stations for

more details and information.

u See Figures 123 and 124

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per- Fig. 123 A coolant tester can be used to de-

1 termine the freezing and boiling levels of

the coolant in your vehicle

Fig. 124 To ensure efficient cooling system

operation, inspect the radiator cap gasket

and seal

Page 28 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-29

i

*Bug screens which are mounted in front of

the condenser (unless they are original

equipment) are regarded as obstructtons.

l The condensation drain tube expels any water

which accumulates on the bottom of the evaporator

housing into the engine compartment. If this tube is

obstructed, the air conditioning performance can be

restricted and condensation buildup can spill over

onto the vehicle’s floor.

l Make sure the air passage selection lever is

operating correctly. Start the engine and warm it to

normal operating temperature, then make sure the

temperature selection lever is operating correctly.

-w

~1 ELEMENT(REFILL)CARE& REPLACEMENT

SYSTEM INSPECTION

b See Figure 125 b See Figures 126 thru 135

For maximum effectiveness and longest element

Although the A/C system should not be serviced

by the do-it-yourselfer, preventive maintenance can

be practiced and A/C system inspections can be per-

formed to help maintain the efficiency of the vehicle’s

A/C system. For A/C system inspection, perform the

following:

The easiest and often most important check for the

air conditioning system consists of a visual inspec-

tion of the system components. Visually inspect the

air conditioning system for refrigerant leaks, dam-

aged compressor clutch, abnormal compressor drive

belt tension and/or condition, plugged evaporator

drain tube, blocked condenser fins, disconnected or

broken wires, blown fuses, corroded connections and

poor insulation.

A refrigerant leak will usually appear as an oily

residue at the leakage point in the system. The oily

residue soon picks up dust or dirt particles from the

surrounding air and appears greasy. Through time,

this will build up and appear to be a heavy dirt im-

pregnated grease.

For a thorough visual and operational inspection,

check the following: * Check the surface of the radiator and con-

denser for dirt, leaves or other material which might

block air flow.

l Check for kinks in hoses and lines. Check the

system for leaks.

l Make sure the drive belt is properly tensioned.

When the air conditioning is operating, make sure the

drive belt is free of noise or slippage.

l Make sure the blower motor operates at all ap-

propriate positions, then check for distribution of the

air from all outlets with the blower on HIGH or MAX.

*Keep in mind that under conditions of high

humidity, air discharged from the A/C vents

may not feel as cold as expected, even if the

system is working properly. This is because

vaporized moisture in humid air retains heat

more effectively than dry air, thereby making

humid air more difficult to cool.

lifp thp winrkhi&i nnri winor hlarlP~ shmM hP kmt . ..“. .I.” . . * ““I.. “.” I..” ...r”* “.“““” “, ,““,” “” ,~“r~ clean. Dirt, tree sap, road tar and so on will cause

streaking, smearing and blade deterioration if left on

the glass. It is advisable to wash the windshield care-

fully with a commercial glass cleaner at least once a

month. Wipe off the rubber blades with the wet rag

afterwards. Do not attempt to move wipers across the

windshield by hand; damage to the motor and drive

mechanism will result.

To inspect and/or replace the wiper blade ele-

ments, place the wiper switch in the LOW speed po-

sition and the ignition switch in the ACC position.

When the wiper blades are approximately vertical on

the windshield, turn the ignition switch to OFF.

Examine the wiper blade elements. If they are

found to be cracked, broken or torn, they should be

replaced immediately. Replacement intervals will vary

with usage, although ozone deterioration usually lim-

its element life to about one year. If the wiper pattern

is smeared or streaked, or if the blade chatters across

the glass, the elements should be replaced. It is easi-

est and most sensible to replace the elements in

pairs.

If your vehicle is equipped with aftermarket blades,

there are several different types of refills and your vehi-

tcca-23 Fig. 126 Bosch@ wiper blade and fft kit

Fig. 129 T&o* wioer blade and fit kit tCS1224

lW1Z?5 Fig. 127 LexoP wiper blade and fit kit

Fig. 128 Pylon@ wiper blade and adapter

Fig. 131 To remove and install a LexoP

Fig, 130 Tripledge@ wiper blade and fit kit wiper blade refill, slip out the old insert and

slide in a new one

Page 29 of 408

.

l-30 GENERAL'INFORMATIONAND MAINTENANCE

n Pylon@ inserts, the clip

be removed prior to siidi then the insert can be re

After installing the replacement

strip and pull up while twisting counterclockwise.

The backing strip will snap out of the retaining tab.

Do this for the remaining tabs until the refill is free of

the blade. The length of these refills is molded into

the end and they should be replaced with identical

types. cate the front end is out of alignment or that the tires

are out of balance.

TIRE ROTATION

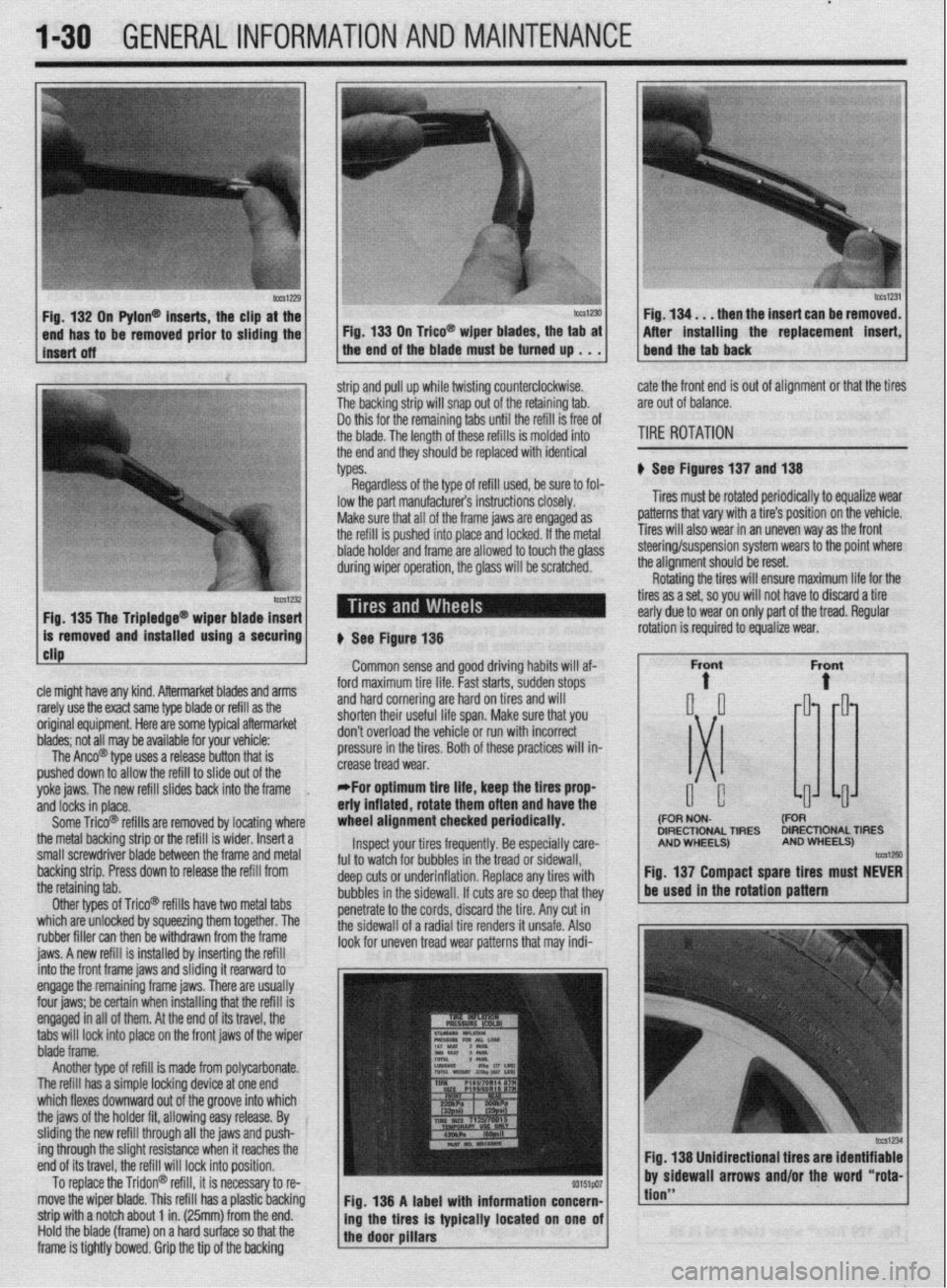

# See Figures 137 and 138

Tires must be rotated periodically to equalize wear

patterns that vary with a tire’s position on the vehicle.

Tires will also wear in an uneven way as the front

1 Fin 1% Tha Trinlarlna@

cle might have any kind. Aftermarket blades and arms

rarely use the exact same type blade or refill as the

original equipment. Here are some typiel aftermarket

blades; not all may be available for your vehicle:

The Anco@ type uses a release button that is

pushed down to allow the refill to slide out of the

yoke jaws. The new refill slides back into the frame

,

and locks in place.

Some Trico@ refills are removed by locating where

the metal backing strip or the refill is wider. Insert a

small screwdriver blade between the frame and metal

backing strip. Press down to release the refill from

the retaining tab.

Other types of Trico@’ refills have two metal tabs

which are unlocked by squeezing them together. The

rubber filler can then be withdrawn from the frame

iaws. A new refill is installed bv insertina the refill lowed to touch the olass steering/suspension system wears to the point where

the alianment should be reset.

# See Figure 138

Common sense and good driving habits will af-

ford maximum tire life. Fast starts, sudden stops

and hard cornering are hard on tires and will

shorten their useful life span. Make sure that you

don’t overload the vehicle or run with incorrect

pressure in the tires. Both of these practices will in-

crease tread wear.

*For optimum tire life, keep the fires prop

eriy inflated, rotate them often and have the

wheel alignment checked periodically.

Inspect your tires frequently. Be especially care-

ful to watch for bubbles in the tread or sidewall,

deep cuts or underinflation. Replace any tires with

bubbles in the sidewall. If cuts are so deep that they

penetrate to the cords, discard the tire. Any cut in

the sidewall of a radial tire renders it unsafe. Also

look for uneven tread wear patterns that may indi- Rotating the tires will ensure maximum life for the

tires as a set, so you will not have to discard a tire

early due to wear on only part of the tread. Regular

DIRECTIONAL TIRES DIRECTIONAL TIRES

jnto the front frame jaws and &ding it rearward to

engage the remaining frame jaws. There are usually

four jaws; be certain when installing that the refill is

engaged in all of them. At the end of its travel, the

tabs will lock into place on the front jaws of the wiper

blade frame.

Another type of refill is made from polycarbonate.

The refill has a simple locking device at one end

which flexes downward out of the groove into which

the jaws of the holder fit, allowing easy release. By

sliding the new refill through all the jaws and push-

ing through the slight resistance when it reaches the

end of its travel, the refill will lock into position.

To replace the Tridon@ refill, it is necessary to re-

move the wiper blade. This refill has a plastic backing

strip with a notch about 1 in. (25mm) from the end.

Hold the blade (frame) on a hard surface so that the

frame is tightly bowed. Grip the tip of the backing Fig. 138 A label with information concern-

ing the tires is typically located on one of

the door pillars

tion”

Page 30 of 408

GENERALINFORMATIONAND MAlNTENANdE 1-31

When rotating “unidirectional tires,” make sure

that they always roll in the same direction. This

means that a tire used on the left side of the vehicle

must not be switched to the right side and vice-versa.

Such tires should only be rotated front-to-rear or

rear-to-front, while always remaining on the same

side of the vehicle. These tires are marked on the

sidewall as to the direction of rotation; observe the

marks when reinstalling the tire(s).

Some styled or “mag” wheels may have different

offsets front to rear. In these cases, the rear wheels

must not be used up front and vice-versa. Further-

more, if these wheels are equipped with unidirectional

tires, they cannot be rotated unless the tire is re-

mounted for the proper direction of rotation.

*The compact or space-saver spare is

strictly for emergency use. it must never be

included in the tire rotation or placed on the

vehicle for everyday use. check the installed tire for any sign of interference

with the body or suspension while the vehicle is stop-

ping, turning sharply or heavily loaded.

Snow Tires

Good radial tires can produce a big advantage in

slippery weather, but in snow, a street radial tire does

not have sufficient tread to provide traction and con-

trol. The small grooves of a street tire quickly pack

with snow and the tire behaves like a billiard ball on a

marble floor, The more open, chunky tread of a snow

tire will self-clean as the tire turns, providing much

better grip on snowy surfaces.

To satisfy municipalities requiring snow tires dur-

ing weather emergencies, most snow tires carry either

an M + S designation after the tire size stamped on

the sidewall, or the designation “all-season.” In gen-

eral, no change in tire size is necessary when buying

snow tires.

Most manufacturers stronqlv recommend the use styled wheels, see if inexpensive steel

wheels are available, Although the look of

the vehicle will change, the expensive

wheels will be protected from salt, curb hits

and pothole damage.

TIRESTORAGE

If they are mounted on wheels, store the tires at

proper inflation pressure. All tires should be kept in a

cool, dry place. If they are stored in the garage or

basement, do not let them stand on a concrete floor;

set them on strips of wood, a mat or a large stack of

newspaper. Keeping them away from direct moisture

is of paramount importance. Tires should not be

stored upright, but in a flat position.

INFLATION & INSPECTION

b See Figures 140 thru 147

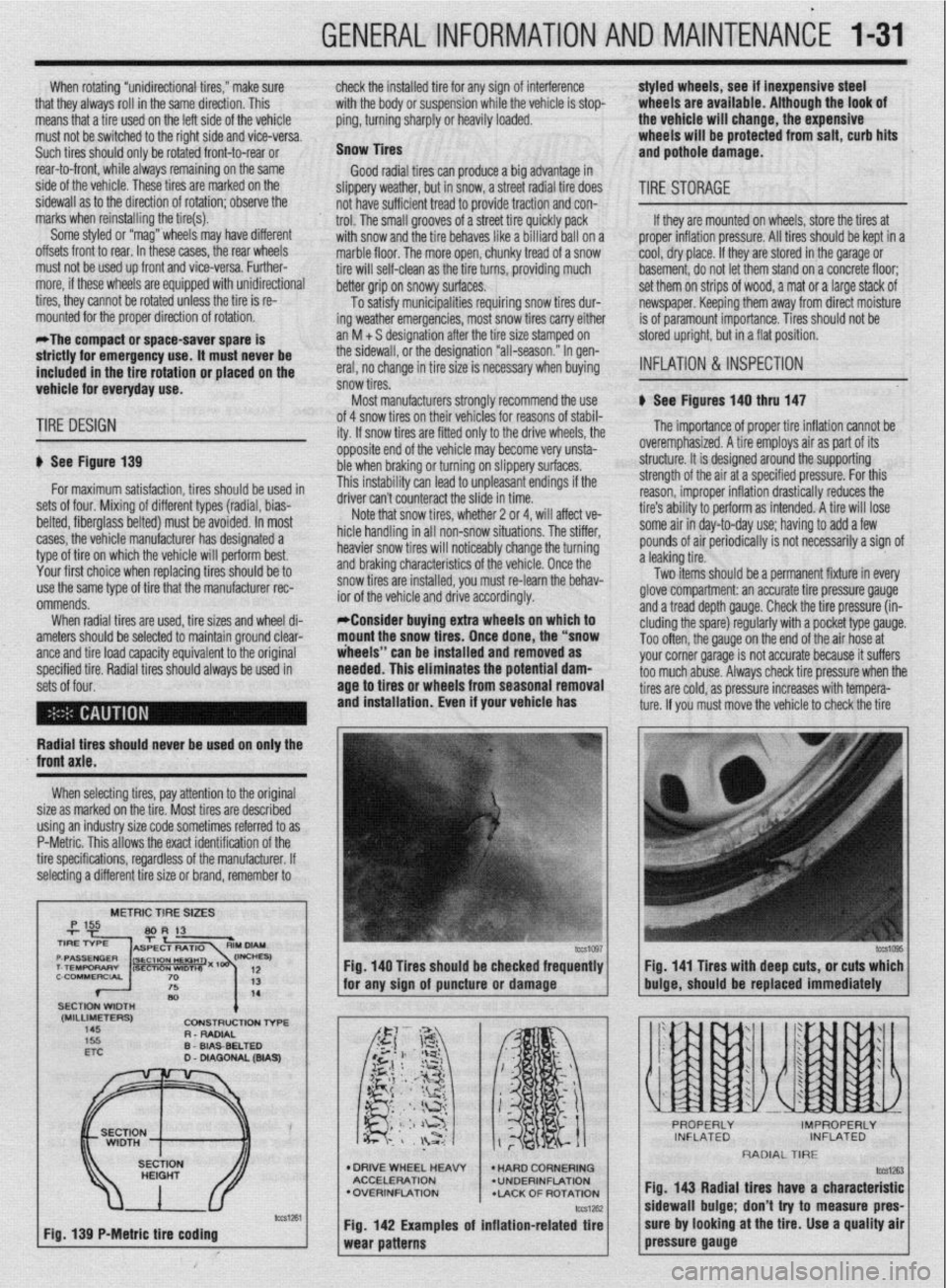

TIRE DESIGN

p See Figure 139

for maximum satisfaction, tires should be used in

sets of four. Mixing of different types (radial, bias-

belted, fiberglass belted) must be avoided. In most

cases, the vehicle manufacturer has designated a

type of tire on which the vehicle will perform best.

Your first choice when replacing tires should be to

use the same type of tire that the manufacturer rec-

ommends.

When radial tires are used, tire sizes and wheel di-

ameters should be selected to maintain ground clear-

ante and tire load caoacitv eauivalent to the oriainal

specified tire. Radial tiresshould always be used in

sets of four. of 4 snow tires on their

lehicies for reasons of stabil-

ity. If snow tires are fitter

1 only to the drive wheels, the

opposite end of the vehil cle may become very unsta-

ble when braking or turn

ring on slippery surfaces.

This instability can lead to unpleasant endings if the

A*:,,“- r-..l, ^_.. ..& ^_^^, &I.

UIIVU MII I LUUII~~MLL iue slide in time.

Note that snow tires, whether 2 or 4, will affect ve-

hicle handling in all non-snow situations. The stiffer,

heavier snow tires will noticeably change the turning

and braking characteristics of the vehicle. Once the

snow tires are installed, you must re-learn the behav-

ior of the vehicle and drive accordingly.

*Consider buying extra wheels on which to

mount the snow tires. Once done, the “snow

iheeis” can be installed and removed as

needed. This eliminates the potential

dam- age to tires or wheels from seasonal removal

and installation. Even if your vehicle has

lb The importance of proper tire inflation cannot be

overemphasized. A tire employs air as part of its

structure. It is designed around the supporting

strength of the air at a specified pressure. For this

reason, improper inflation drastically reduces the

tire’s ability to perform as intended. A tire will lose

some air in day-to-day use; having to add a few

pounds of air periodically is not necessarily a sign of

a leaking tire.

Two items should be a permanent fixture in every

glove compartment: an accurate tire pressure gauge

and a tread depth gauge. Check the tire pressure (in-

eluding the spare) regularly with a pocket type gauge.

Too often, the gauge on the end of the air hose at

vnr rr corner narane is not accurate because it suffers

~rs check tire oressure when the

Radial tires should never be used on only the

XI I._.

‘-’ --“‘“’ J s too much abuse. Alwa!

tires are cold, as pressure increases with tempera-

ture. If you must move the vehicle to check the tire

front axle.

When selecting tires, pay attention to the original

size as marked on the tire. Most tires are described

using an industry size code sometimes referred to as

P-Metric. This allows the exact identification of the

tire specifications, regardless of the manufacturer. If

selecting a different tire size or brand, remember to

METRIC TIRE SIZES

(MILLIMETERS)

145 CDNStRUCtlDN l-6-E

R - RADIAL

D

WA9

Fig. 139 P-Metric tire coding Fig. 140 Tires should be checked frequently

I I Fig. 141 Tires with deep cuts, or cuts which

for any sion of auncture or damaoe

buioe, should be replaced immediately

l DRIVE WHEEL HEAW

ACCELERATION

l OVERINFLATION

*LACK OF ROTATION

Fig. 142 Examples of inflation-related tire

RADIAL TIRE

fig. 143 Radial tires have a characteristic

sidewall bulge; don’t try to measure pres-

sure by looking at the tire. Use a quality air

pressure gauge