MITSUBISHI DIAMANTE 1900 Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 301 of 408

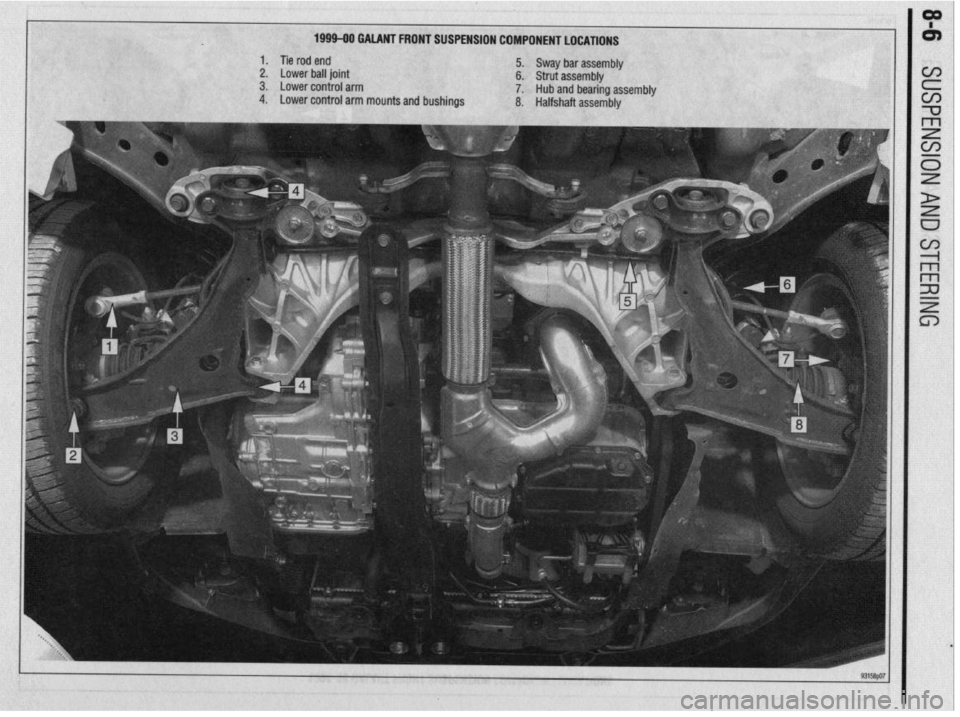

1999-90 GAIANT FRONT SUSPENSION COMPONENT LOCATIONS

1. Tie rod end

5. Sway bar assembly

2. Lower ball joint 6. Strut assembly

3. Lower control arm

7. Hub and bearing assembly

4. Lower control arm mounts and bushings

8. Halfshaft assembly

Page 302 of 408

SUSPENSION AND STEERING 8-7

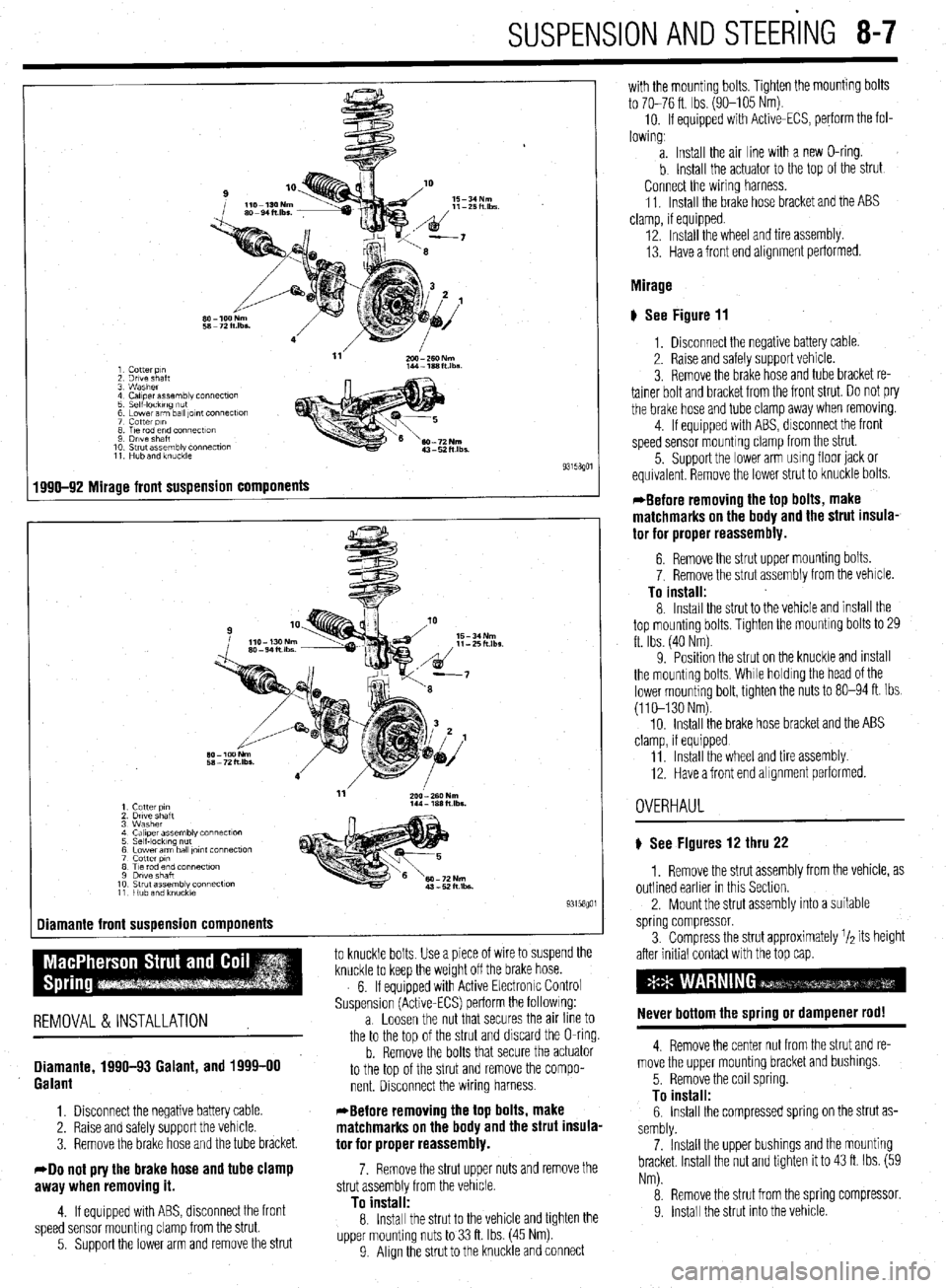

1 Cotter p,n

2 Drive shaft

3 Washer

4 Caliper assembly connecf~on

5 Self-IockIng ““f

6 Lower arm ball ,Ol”f Connectlo”

7 cotter PI”

8 T,e rod end connectton

9 Drive Shaft

10 Strut assembly connection

11 Hub and knuckle

1990-92 Mirage front suspension components

-

1 Cutter PI”

2 Drtve shaft

3 Washer

4 Ca,,perassembly connect~o”

5 Self-locking nut

6 Lower arm ball ,o,nt connection

7 cotter PI”

8 Tie rod end connection

9 Dwe shaft

10 Strut assembly connection

11 Hub and knuckie

Diamante front suspension components

1

to knuckle bolts Use a piece of wire to suspend the

knuckle to keep the weight off the brake hose.

6. If equipped with Active Electronrc Control

Suspension (Active-ECS) perform the followrng:

REMOVAL &INSTALLATION a. Loosen the nut that secures the an line to

the to the too of the strut and discard the O-ring.

Diamante, 1990-93 Galant, and 1999-00

Galant

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle.

3. Remove the brake hose and the tube bracket.

40 not pry the brake hose and tube clamp

awav when removino it.

b. Remove the bolts that secure the actuator

to the top of the strut and remove the compo-

nent. Disconnect the wiring harness.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

7. Remove the strut upper nuts and remove the

strut assemblv from the vehicle.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm and remove the strut

To instalf: 8. Install the strut to the vehicle and tighten the

upper mounting nuts to 33 ft. Ibs. (45 Nm)

9 Align the strut to the knuckle and connect with the mounting bolts. Tighten the mounting bolts

to 70-76 ft. Ibs. (90-105 Nm).

10. If equipped with Active-ECS, perform the fol-

lowing,

a. Install the air line with a new O-ring.

b Install the actuator to the top of the strut

Connect the wiring harness.

11. Install the brake hose bracket and the ABS

clamp, if equipped.

12. Install the wheel and tire assembly.

13. Have a front end alignment performed.

Mirage

# See Figure 11

1, Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Remove the brake hose and tube bracket re-

tainer bolt and bracket from the front strut. Do not pry

the brake hose and tube clamp away when removrng.

4. If equipped with ABS, disconnect the front

speed sensor mounting clamp from the strut.

5. Support the lower arm usmg floor jack or

equivalent Remove the lower strut to knuckle bolts.

*Before removing the top bolts, make

matchmarks on the body and the strut insula-

tor for proper reassembly.

6. Remove the strut upper mounting bolts.

7. Remove the strut assembly from the vehicle.

To install: 8. Install the strut to the vehicle and install the

top mounting bolts, Tighten the mountrng bolts to 29

ft. Ibs. (40 Nm)

9. Position the strut on the knuckle and mstall

the mounting bolts, While holdrng the head of the

lower mounting bolt, tighten the nuts to 80-94 ft. Ibs.

(110-130 Nm).

10. Install the brake hose bracket and the ABS

clamp, if equipped

11 Install the wheel and tire assembly

12. Have a front end alignment performed.

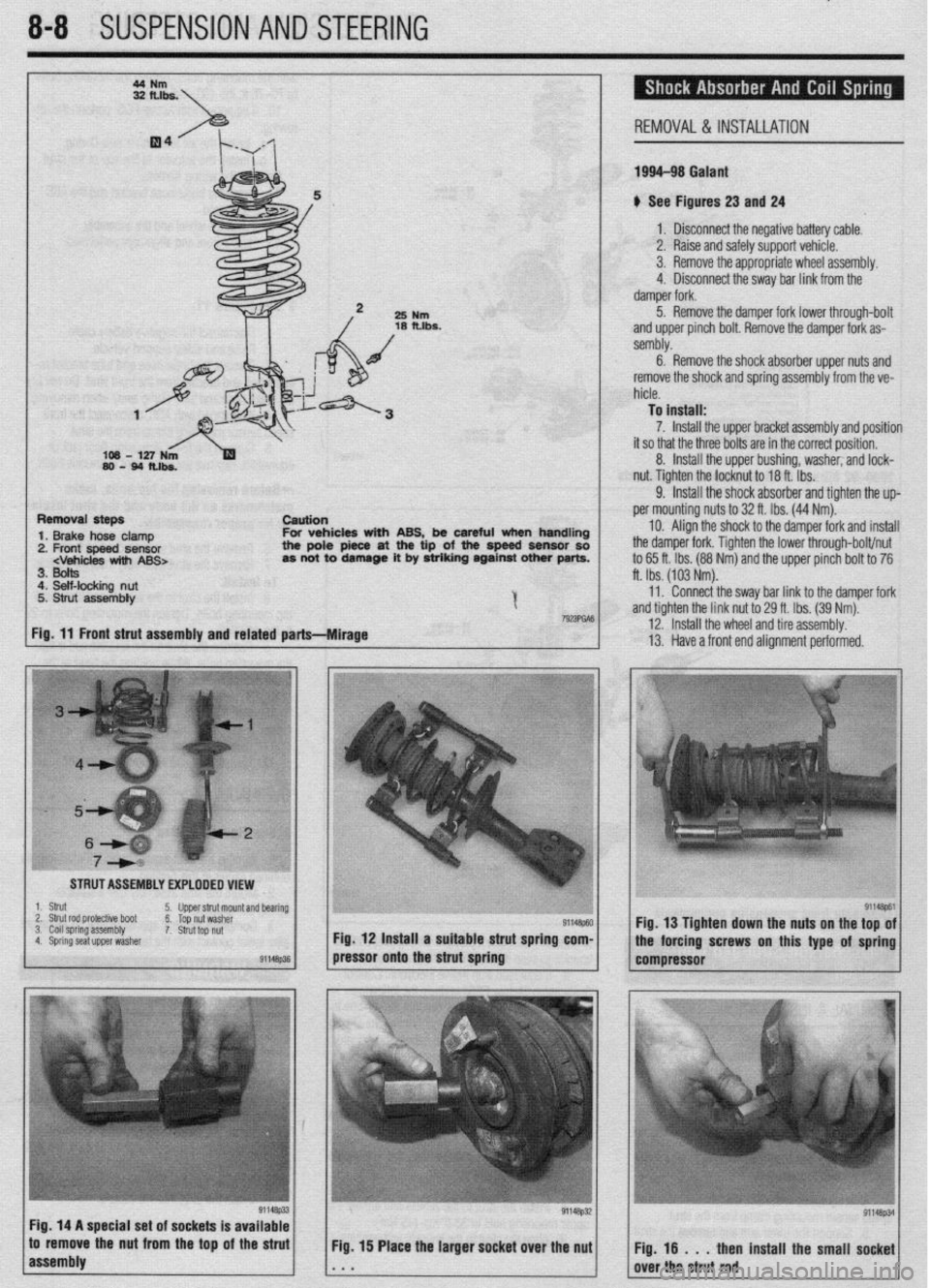

OVERHAUL

) See Figures 12 thru 22

1. Remove the strut assembly from the vehicle, as

outlined earlier in this Section.

2. Mount the strut assembly into a suitable

spring compressor.

3. Compress the strut approximately r/a its height

after initial contact with the top cap.

Never bottom the spring or dampener rod!

4. Remove the center nut from the strut and re-

move the upper mounting bracket and bushings.

5. Remove the coil spring.

To install: 6. Install the compressed spring on the strut as-

sembly.

7. Install the upper bushings and the mounting

bracket Install the nut and tighten it to 43 ft. Ibs. (59

Nm).

8. Remove the strut from the spring compressor.

9. Install the strut into the vehrcle

Page 303 of 408

8-8 SUSPENSION AND STEERING

REMOVAL &INSTALLATION

199443 Galant

u See Figures 23 and 24

1 a Disconnect the neaative batterv cable.

I 3. Remove the appronnate wheel assembly.

25

Nm

18 fths.

I 2. Raise and safelv su~oort vehicle.

I I ,I 4. Disconnect the sway bar link from the

oamper rork.

5. Remove the damper fork lower through-bolt

and upper pinch bolt. Remove the damper fork as-

sembly.

6. Remove the shock absorber upper nuts and

remove the shock and spring assembly from the ve-

hicle.

To install:

7. Install the upper bracket assembly and position

it so that the three bolts are in the correct position.

8. Install the upper bushing, washer, and lock-

nut. Tighten the locknut to 18 ft.-lbs.

9. Install the shock absorber and tighten the up-

Removal steps

csution

1. Brake hose clamp For vehicles with ABS, be careful when handling

2. Front speed sensor the pole piece at the tip of the spaed sensor so

3. Bolts

4. Self-locking nut

5. Strut assembly

I

7wmA6

Fig. 11 Front strut assembly and related parts---Mirage ft. Ibs. (103 Nm).

11. Connect the sway bar link to the damoer fork per mounting nuts to 32 ft. Ibs. (44 Nm).

IO. Align the shock to the damper fork and install

the damper fork. Tighten the lower through-bolt/nut

to 65 ft. Ibs. (88 Nm) and the upper pinch bolt to 76

and tighten the link nut tb 29 ft. Ibs. (39 Nm):

12. Install the wheel and tire assembly.

13. Have a front end alignment performed.

I STRUT ASSEMBLY EXPLODED VIEW

I ,-

:-, : ;i

,\,.^ -_ I~.’ :“:;rL~~<

-_ cy -.:;;yp;:,

91146p?Jl Fig. 12 Install a suitable strut spring com-

91146p61 Fig. 13 Tighten down the nuts on the top of

the forcing screws on this type of spring

pressor onto the strut spring

compressor

Fig. 14 A special set of sockets Is available

to remove the nut from the top of the strut

Fig. 15 Place the larger socket over the nut

1 ;ir ;;ostrut;;; install the small soi8oet

Page 304 of 408

SUSPENSION AND STEER'ING 8-9

ile loosening the larger socket (strut then remove the top nut from

91148ps4 1 Fig. 29 Remove the strut mount and bear-

ins assembly 1 Fig. 21 Remove the upper spring seat 1

washer

91148PS7

Fig. 19 . t , and remove the washer under-

neath

Fig. 22 Remove the coil spring assembly

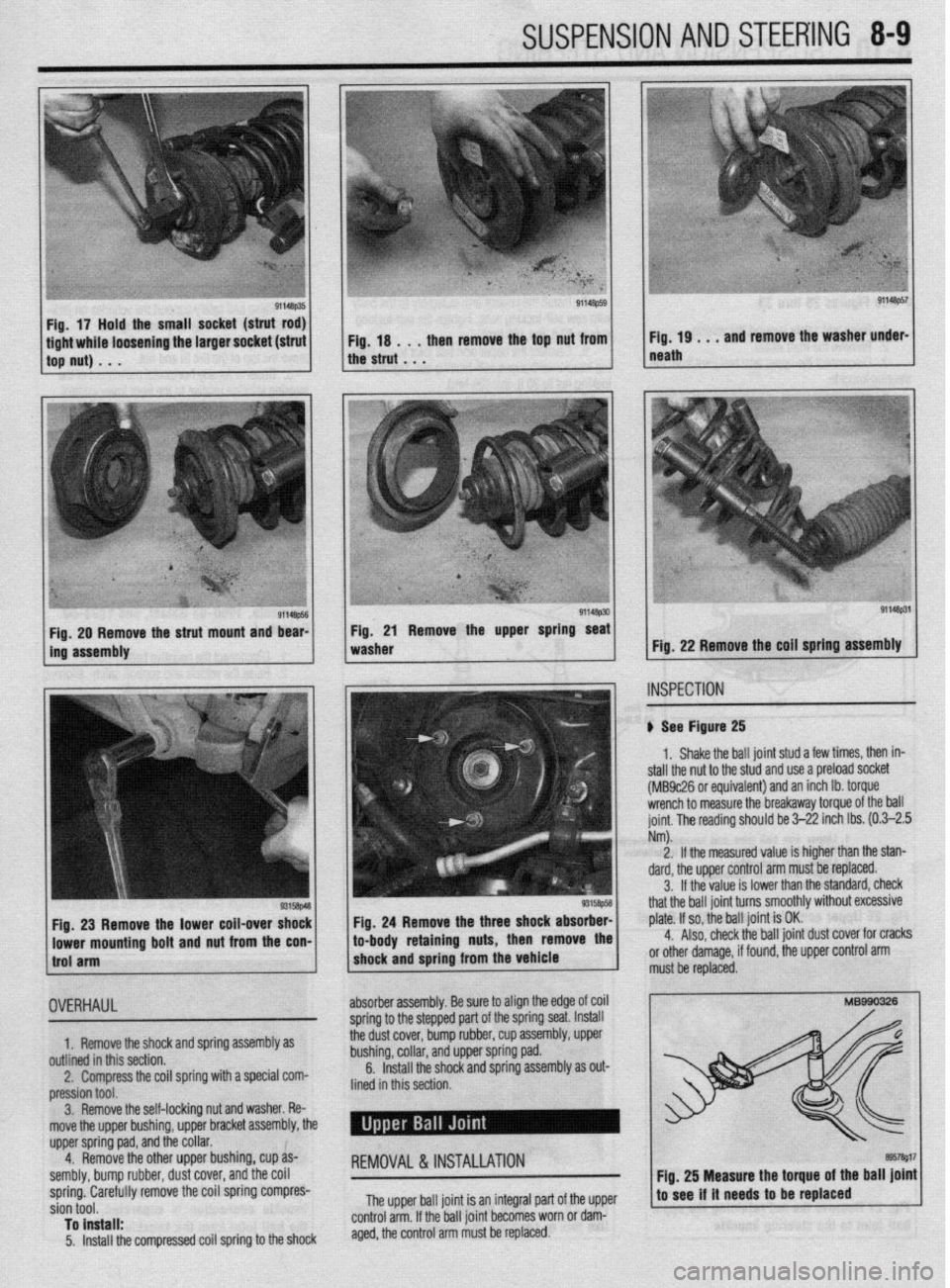

INSPECTION

’ ) See Figure 25

Fig. 23

Remove the lower coil-over shock

lowar mounting bolt

and nut from the con- 1.

Shake the ball joint stud a few times, then in-

stall the nut to the stud and use a preload socket

(MB9c26 or equivalent) and an inch lb. torque

wrench to measure the breakaway torque of the ball

joint. The reading should be 3-22 inch Ibs. (0.3-2.5

Nm).

2.

If the measured value is higher than the stan-

dard, the upper control arm must be replaced.

3.

If the value is lower than the standard, check

that the ball joint turns smoothly without excessive

Fig. 24 Remove the three shock absorber- plate. If so, the ball joint is OK. to-body retaining nuts, the 4.

Also, check the ball joint dust cover for cracks

or other damage, if found, the upper control arm

must be replaced.

1.

outlin

OVERHAUL

Remove the shock and spring assembly as

ed in this section.

Compress the coil spring with a special com-

ion tool.

Remove the self-locking nut and washer. Re-

the upper bushing, upper bracket assembly, the

sorina oad. and the collar. absorber assembly. Be sure to align the edge of coil

sorina to the steoaed Dart of the spring Seat. laSk3ll assembly, upper

nad

2.

press

3.

move

upper

4. dem&e the other upper bushing, cup as-

sembly, bump rubber, dust I cover, and the coil

spring. Carefully remove the coil spring compres-

sion tool.

To install:

5. Install the compressed coil spring to the shock

REMOVAL &INSTALLATION

Thp lwwr hall inint is an inkoral oart of the umer

6e d&cover, d;mp iubber, cup

bushing, collar, and upper spring r--.

6. Install the shock and spring assembly as out-

lined in this section.

Fig. 25 Measure the toruue of the ball joint

to see if it needs to be t&laced

..*., “rf.l’ “m.. ,-.,.. .--.. . ...-=.- r-. . .rr

control arm. If the ball joint becomes worn or dam-

aged, the control arm must be replaced.

Page 305 of 408

‘. . ^ .s ”

840 SUSPENSION ANY ik%iiiG

6. Remove thethrough-bolts that attach the up-

per arm to the shafts , . , ,

Except 199

REMOVAL&INSTALLATION

M-98 Galant

These vehicles use a strut type front suspension,

No uooer control arm is used.

1994-98 Galant

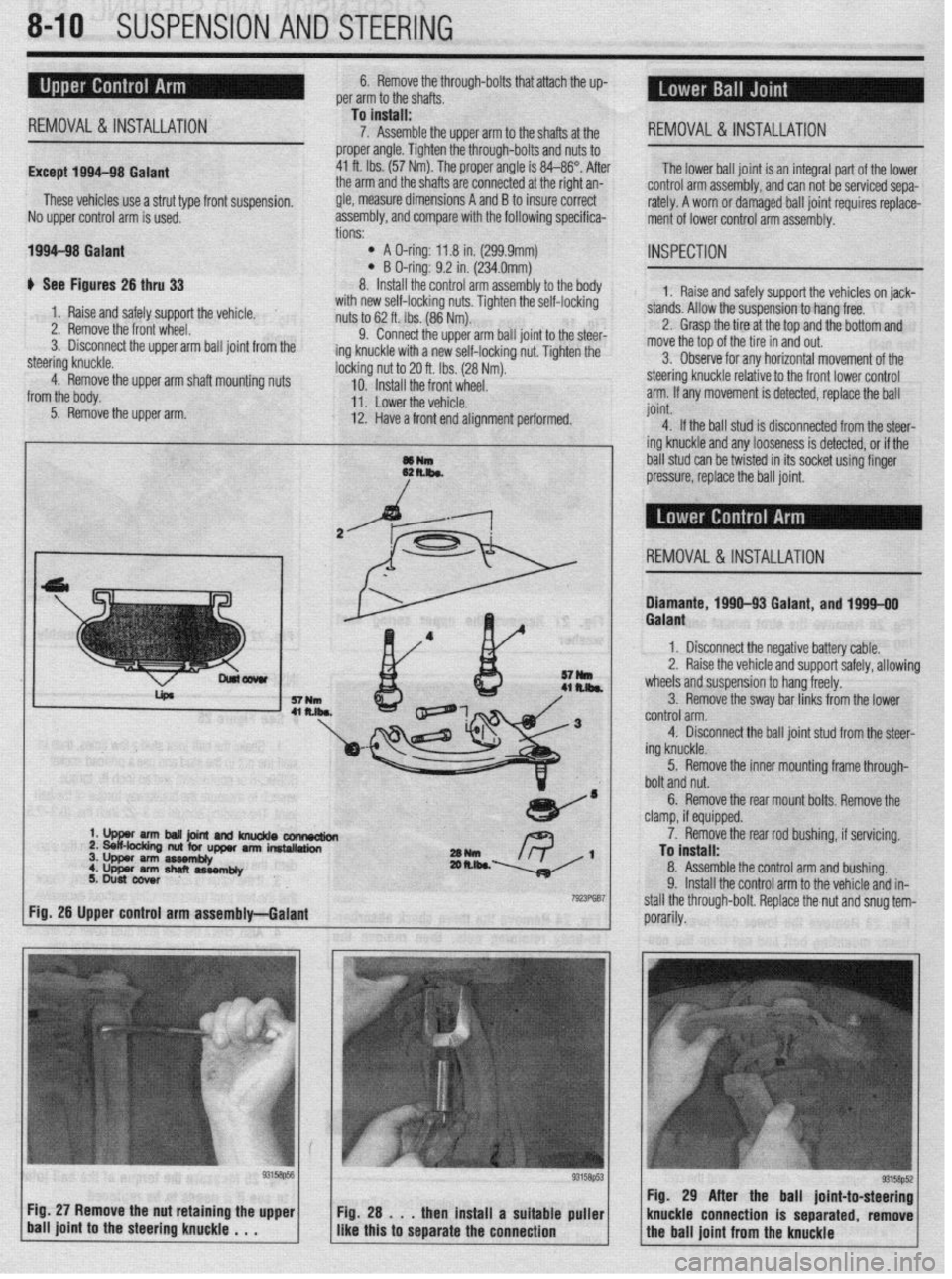

# See Figures 26 thru 33 tions: -

l A O-ring: 11.8 in. (299.9mm) l B O-ring: 9.2 in. (234.0mm)

8. Install the control arm ass

To install:

7. Assemble the upper arm to the shafts at the

proper angle. Tighten the through-bolts and nuts to

41 ft. Ibs. (57 Nm). The proper angle is 84-86”. After

the arm and the shafts are connected at the right an-

gle, measure dimensions A and B to insure correct

assembly, and comoare with the following specifica- REMOVAL& INSTALLATION

The lower ball joint is an integral part of the lower

control arm assembly, and can not be serviced sepa-

rately. A worn or damaged ball joint requires replace-

ment of lower control arm assembly.

embly to the body

_ IL_ --at I-., ..-

INSPECTION

1. Raise and safely support the vehicles on jack-

with new self-locking nuts. Tighten one sea-rockrng

nuts to 62 ft. Ibs. (86 Nm).

9. Connect the upper arm ball joint to the steer-

ing knuckle with a new self-locking nut. Tighten the

locking ^_ ~. I- -

10.

11 . L”WCl LI It: “Cl Illx.

12. Have

a front end alinnmen

nut to 20 ft. Ibs. (28 Nm). ve for any horizontal movement of the

Install the front wheel. steering knuckle relative to the front lower control

I ml.,,.* ,I.+. .,^l.:^l^ arm. If any movement is detected, replace the ball

t performed. joint.

---g -

4. If the ball stud is disconnected from the steer-

ing knuckle and any looseness is detected, or if the

~~ k hall dir! ran ho twiatm-l in itr cnrlmt II&WI finnnr ““.I VLVV “Yll YY L..l”L”” #II IIU UY”I\“L u.l,,,y ““y”’

/ pressure, replace the ball joint, stands. Allow the suspension to hang free.

2. Grasp the tire at the top and the bottom and

move the tar

3. Obser 1. Raise and safely support the vehicle.

2. Remove the front wheel.

3. Disconnect the upper arm ball joint from the

steering knuckle.

4. Remove the upper arm shaft mounting nuts

from the body.

5. Remove the upper arm.

d REMOVAL &INSTALLATION

rck ,-.-.

Diamante, 1990-93 Galant, and 1994-00

3. Remove the sway bar links from the lower

..^^l-^l ^--

titJIILIlJI alIll. 4. Disconnect the bail joint stud from the steer-

ing knuckle.

5. Remove the inner mounting frame through-

bolt and nut.

6. Remove the rear mount bolts. Remove the

clamp, if equipped.

‘YUN

- ,-. R \_ 1 2m.lk~ -

7923Fw7

7. Remove the rear rod bushing, if servicing.

To install:

8. Assemble the control arm and bushing.

9. Install the control arm to the vehicle and in-

stall the through-bolt. Replace the,nut and snua tem-

porarily. - 1 Fig. 26 Upper control arm assembly-Galant

Fig. 27 Remove the nut retaining the upper

1 ball joint to the steering knuckle , . . Fig. 29 A

Fig. 28 . , . then install a suitable puller

I I knuckle COI

like this to separate the connection Galant

1, Disconnect the negative battery cable.

2. Raise the vehicle and support safely, allowing

wheels and suspension to hang freely.

Page 306 of 408

SUSPENSION AND STEERING 8-11

-*i-

7928685

g3’w5 Fig, 30 Remove the nuts retaining the up-

per control arm to the body . . . I$ ;A, -;h$re~ove the upper co;:; 1 Fig 32 Correct angle of control arm and

shaftsGa,ant

ench to remove the

retain-

1. Connect the ball joint stud to the knuckle.

In-

Nm).

12. Install the sway bar and links.

13.

Lower the vehicle to the floor for the final

tightening of the frame mount through-bolt.

14.

Once the full weight of the vehicle is on the

floor, tighten the frame mount through-bolt nuts to

75-90 ft. Ibs. (102-122 Nm).

15. Connect the negative battery cable.

16. Check the wheel alignment and adjust if nec-

essary

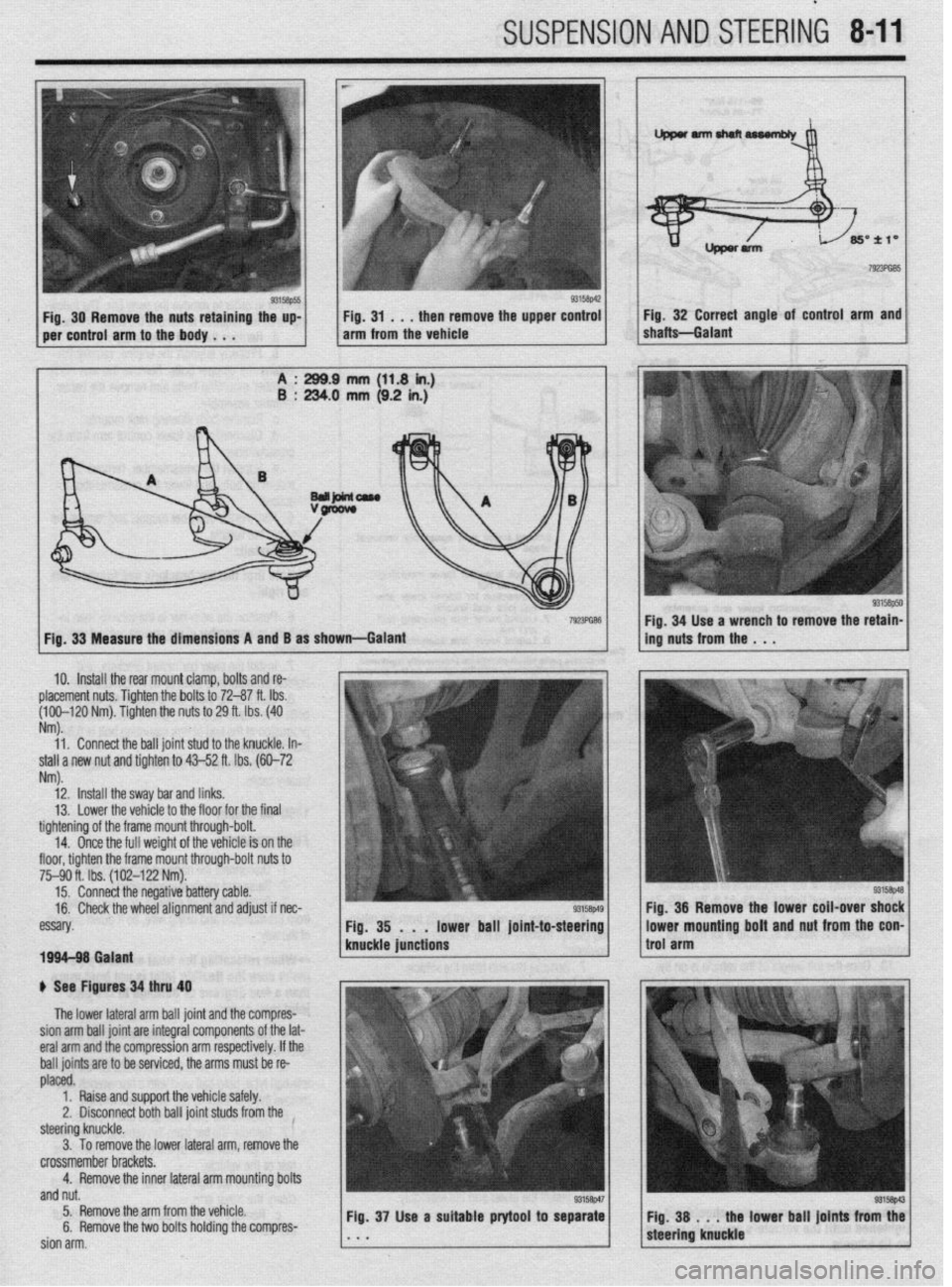

1994-98 Galant

) See Figures 34 thru 40

The lower lateral arm ball joint and the compres-

sion arm ball joint are integral components of the lat-

eral arm and the compression arm respectively. If the

ball joints are to be serviced, the arms must be re-

placed.

1.

Raise and support the vehicle safely.

2, Disconnect both ball joint studs from the

steering knuckle.

3. To remove the lower lateral arm, remove the

crossmember brackets.

4. Remove the inner lateral arm mounting bolts

and nut.

5.

Remove the arm from the vehicle.

6. Remove the two bolts holding the compres-

sion arm. Fig. 37 Use

a suitable prytool to separate

the lower ball

joints from the

Page 307 of 408

8-12 SUSPENSION AND STEERING

Compression lower an assembly

removal steps Lateral lower arm assembly removal

Hcps

1. Connection for compression lower

arm ball joint and knuckle

2. Compressron lower arm mounting

bolt

3. Compression lower arm assembly 4. stay

5. ~mdtsoorber lower mounting

6. Connection for lateral lower arm

ball joint and knuckle

7. Metal lower arm mounting bolt

end nut

6. Lateral low% arm assemblv

CSUtlOll

l : Indicates parts wfdch should k temporarily tightened,

and then fully tightened with fhe vehicle on the ground

in the unladen wndluon.

93158p62 :ig. 39 Remove the lower control arm-to-body mounting bolts, then remove the arm from the

rehicle

8. Assemole me control arms and bushmgs. 7. Remove the compression arm,

^. To install:

Y. Install the lateral control arm to the vehicle

and install the inner mounting bolts. Install a new nut

and snug temporarily. -. .*.. a.

10. Install the compression arm to the vehicle.

* 11. Connect the ball joint studs to the knuckle.

Install new nuts and tighten to 43-51 ft. Ibs (59-71

Nm).

12. Lower the vehicle to the floor for the final

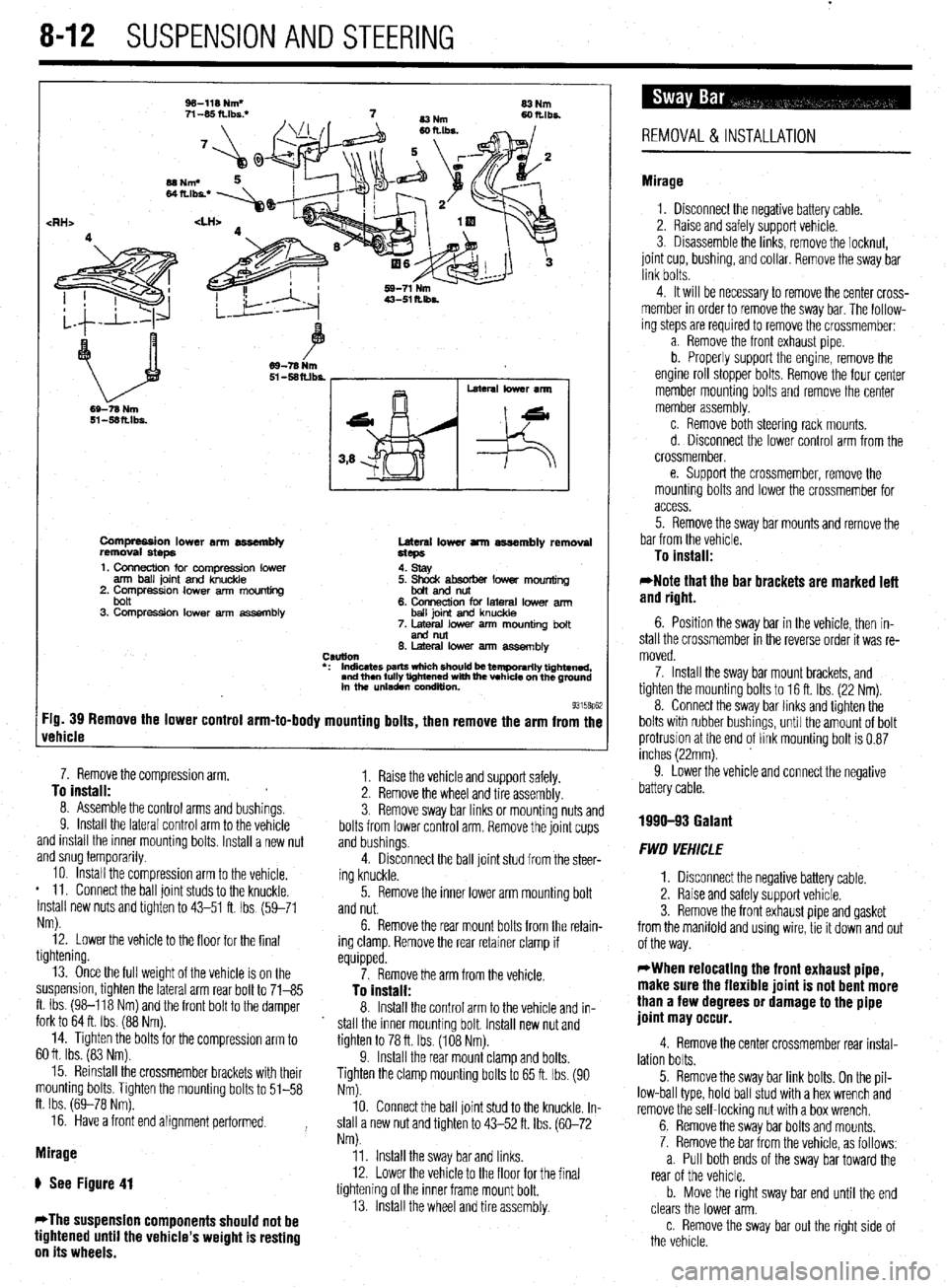

tightening. 3. Remove sway bar links or mounting nuts and

bolts from lower control arm. Remove the joint cups 1.

and bushings.

4. Raise the vehicle and support safely.

Disconnect the ball joint stud from the steer-

ing knuckle. 2. Remove the wheel and tire assembly

13. Once the full weight of the vehicle is on the

suspension, tighten the lateral arm rear bolt to 71-85

ft. Ibs. (98-118 Nm) and the front bolt to the damper

fork to 64 ft. Ibs. (88 Nm).

14. Tighten the bolts for the compresslon arm to

60 ft. Ibs. (83 Nm).

15. Reinstall the crossmember brackets with their

mounting bolts. Tighten the mounting bolts to 51-58

ft. Ibs. (69-78 Nm).

16. Have a front end alignment performed.

Mirage

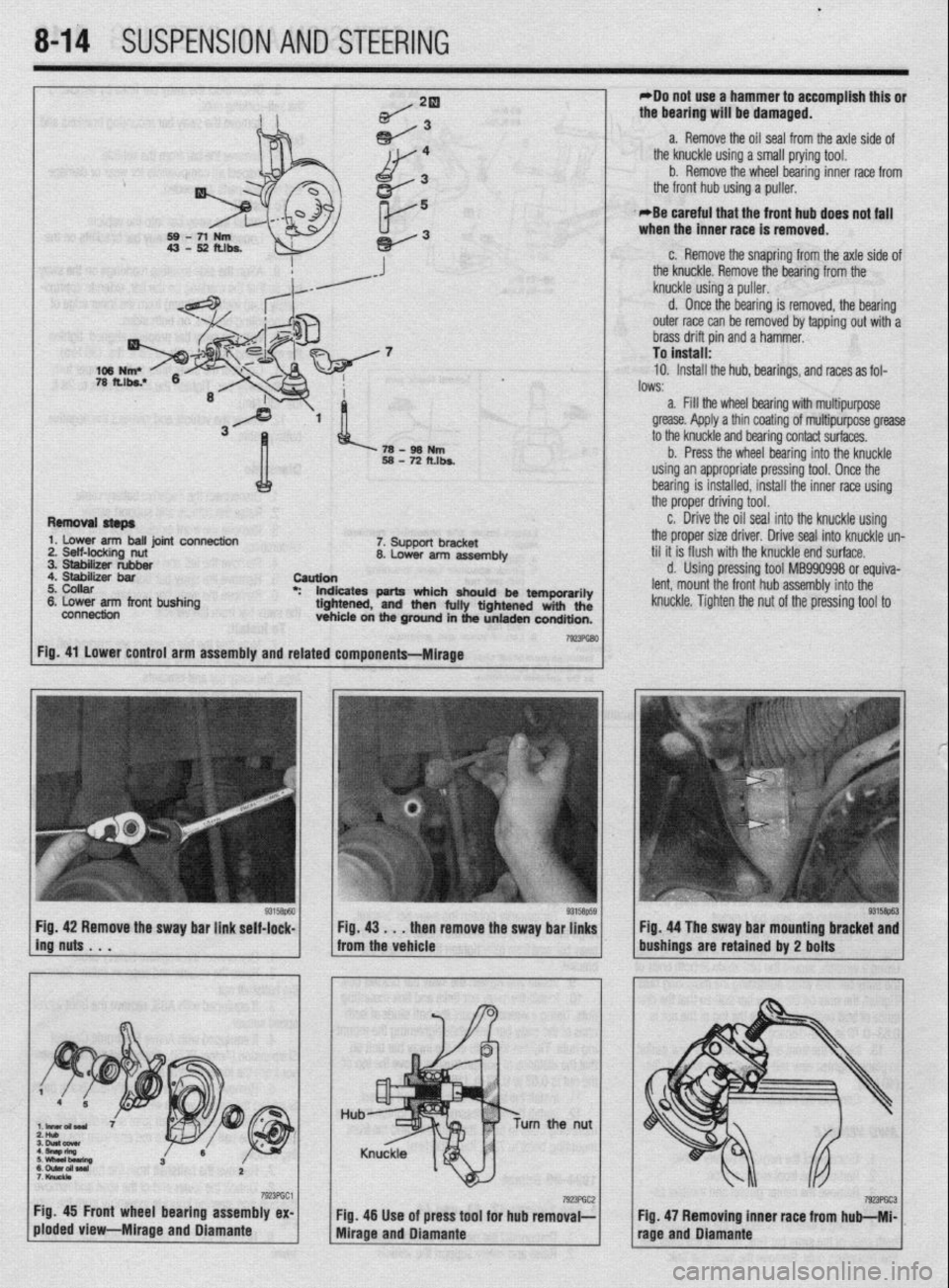

ti See Figure 41

*The suspension components should not be

tightened until the vehicle’s weight is resting

on its wheels. 5. Remove the inner lower arm mounting bolt

and nut.

6. Remove the rear mount bolts from the retain-

ing clamp. Remove the rear retainer clamp if

equipped.

7. Remove the arm from the vehicle.

To install:

8. Install the control arm to the vehicle and in-

stall the inner mounting bolt. Install new nut and

tighten to 78 ft. Ibs. (108 Nm).

9. Install the rear mount clamp and bolts.

Tighten the clamp mounting bolts to 65 ft. Ibs. (90

Nm).

10. Connect the ball joint stud to the knuckle. In-

stall a new nut and tighten to 43-52 ft. Ibs. (60-72

Nm).

11. Install the sway bar and links.

12. Lower the vehicle to the floor for the final

tightening of the inner frame mount bolt.

13. Install the wheel and tire assembly.

REMOVAL&INSTALLATION

Mirage

1. Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Disassemble the links, remove the locknut,

joint cup, bushing, and collar. Remove the sway bar

link bolts.

4. It will be necessary to remove the center cross-

member in order to remove the sway bar. The follow-

ing steps are required to remove the crossmember:

a. Remove the front exhaust pipe

b. Properly support the engine, remove the

engine roll stopper bolts. Remove the four center

member mounting bolts and remove the center

member assembly.

c. Remove both steering rack mounts.

d. Disconnect the lower control arm from the

crossmember,

e. Support the crossmember, remove the

mounting bolts and lower the crossmember for

access.

5. Remove the sway bar mounts and remove the

bar from the vehicle.

To install:

*Note that the bar brackets are marked left

and right.

6. Position the sway bar in the vehicle, then in-

stall the crossmember in the reverse order it was re-

moved.

7. Install the sway bar mount brackets, and

tighten the mounting bolts to 16 ft. Ibs. (22 Nm).

8. Connect the sway bar links and tighten the

bolts with rubber bushings, until the amount of bolt

protrusion at the end of link mounting bolt is 0.87

inches (22mm).

9. Lower the vehicle and connect the negative

battery cable.

1990-93 Galant

FWD VEHICLE

1. Disconnect the negative battery cable.

2. Raise and safely support vehicle.

3. Remove the front exhaust pipe and gasket

from the manifold and using wire, tie it down and out

of the way.

WWhen relocating the front exhaust pipe,

make sure the flexible joint is not bent more

than a few degrees or damage to the pipe

joint may occur.

4. Remove the center crossmember rear instal-

lation bolts.

5. Remove the sway bar link bolts. On the pil-

low-ball type, hold ball stud with a hex wrench and

remove the self-locking nut with a box wrench.

6. Remove the sway bar bolts and mounts.

7. Remove the bar from the vehicle, as follows:

a. Pull both ends of the sway bar toward the

rear of the vehicle.

b. Move the right sway bar end until the end

clears the lower arm.

c. Remove the sway bar out the right side of

the vehicle.

Page 308 of 408

SUSPENSION AND STEERING 8-13

W-118 Nm*

71-W ft.lbs: 83Nm

69-78 Nm

Compression lower arm assembly

removal steps

1. Connection for compression lower

arm ball joint and knuckle

2. Comoression lower arm mouniina Lateral lower tmn assembly removal

steps

4. stay

bon ’ 3. Compression lower arm assembly 6. CMlnection for lateral lower arm

ball joint and knuckle

7. lateral lower arm mounting boll

andnllt

0. hleral lower am7 assembly

CWtlOtl

l : Indicates parts which should be temporarily tightened,

and then fully tightened with the vehicle on the ground

in the unladen condition

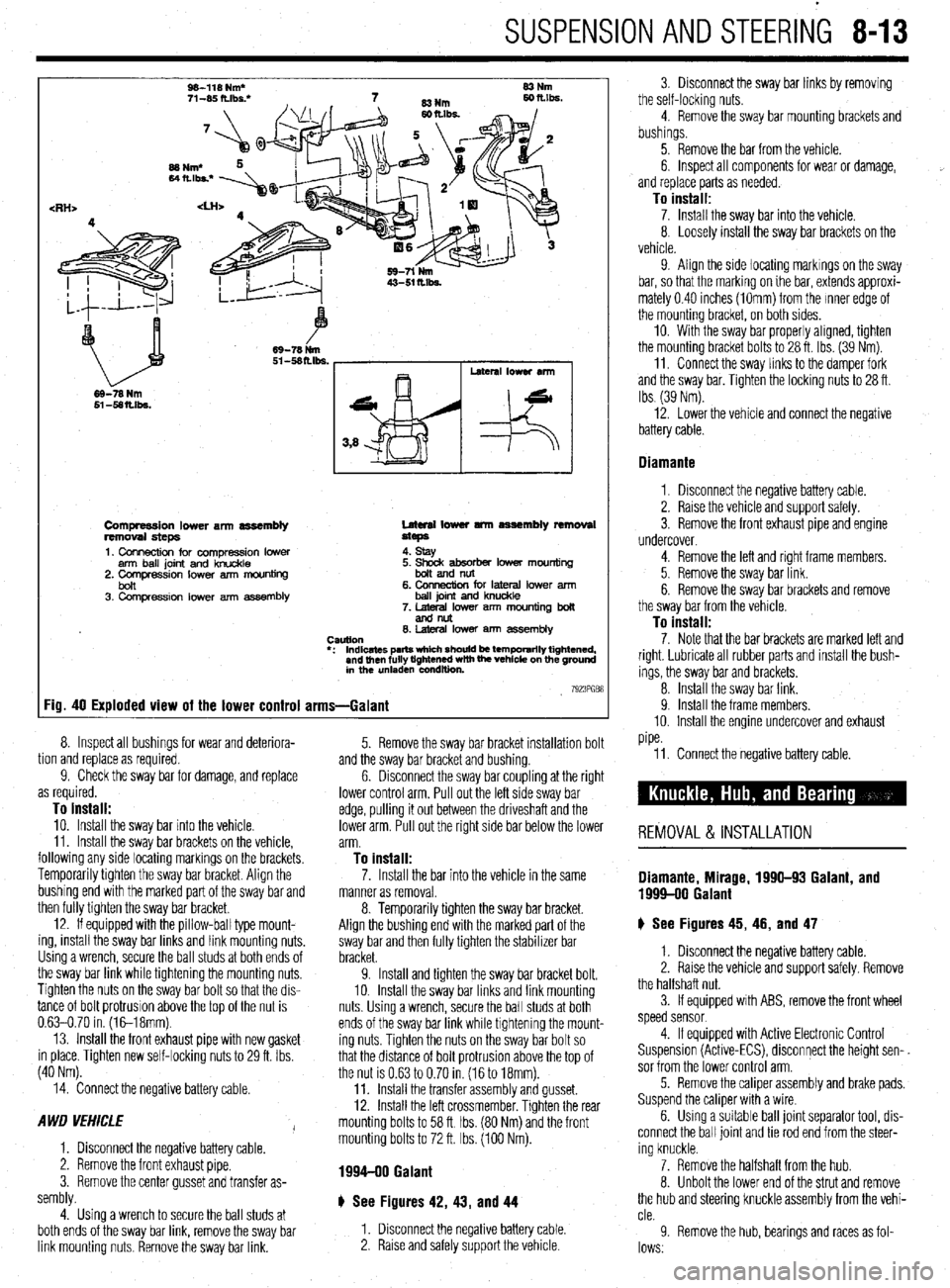

7923PGB8 Fig. 40 Exploded view of the lower control arms-Galant

tion and replace as required. 8.

9. Inspect all bushings for wear and deteriora-

Check the sway bar for damage, and replace

as required.

To install: 10. Install the sway bar into the vehicle.

11. Install the sway bar brackets on the vehicle,

following any side locating markings on the brackets.

Temporarily tighten the sway bar bracket. Align the

bushing end with the marked part of the sway bar and

then fully tighten the sway bar bracket.

12. If equipped with the pillow-ball type mount-

ing, install the sway bar links and link mounting nuts.

Using a wrench, secure the ball studs at both ends of

the sway bar link while tightening the mounting nuts.

Tighten the nuts on the sway bar bolt so that the dis-

tance of bolt protrusion above the top of the nut is

0.63-0.70 in. (1&18mm).

13. Install the front exhaust pipe with new gasket

in place. Tighten new self-locking nuts to 29 ft. Ibs.

(40 Nm). and the sway bar bracket and bushing.

6. 5. Remove the sway bar bracket installation bolt

Disconnect the sway bar coupling at the right

lower control arm. Pull out the left side sway bar

edge, pulling it out between the driveshaft and the

lower arm. Pull out the right side bar below the lower

arm.

To install:

14. Connect the negative battery cable.

A WD VEHICLE

I

1. Disconnect the negative battery cable.

2. Remove the front exhaust pipe.

3. Remove the center gusset and transfer as-

sembly.

4. Using a wrench to secure the ball studs at

both ends of the sway bar link, remove the sway bar

link mounting nuts. Remove the sway bar link. 11. Connect the negative battery cable.

REMOVAL & INSTALLATION

7. Install the bar into the vehicle in the same Diamante, Mirage, 1996-93 Galant, and manner as removal. 1999-00 Galant 8. Temporarily tighten the sway bar bracket.

Align the bushing end with the marked part of the

sway bar and then fully tighten the stabilizer bar

bracket.

9. Install and tighten the sway bar bracket bolt.

10. Install the sway bar links and link mounting

nuts Using a wrench, secure the ball studs at both

ends of the sway bar link while tightening the mount-

ing nuts. Tighten the nuts on the sway bar bolt so

that the distance of bolt protrusion above the top of

the nut is 0.63 to 0.70 in. (16 to 18mm).

11. Install the transfer assembly and gusset.

12. Install the left crossmember. Tighten the rear

mounting bolts to 58 ft Ibs. (80 Nm) and the front

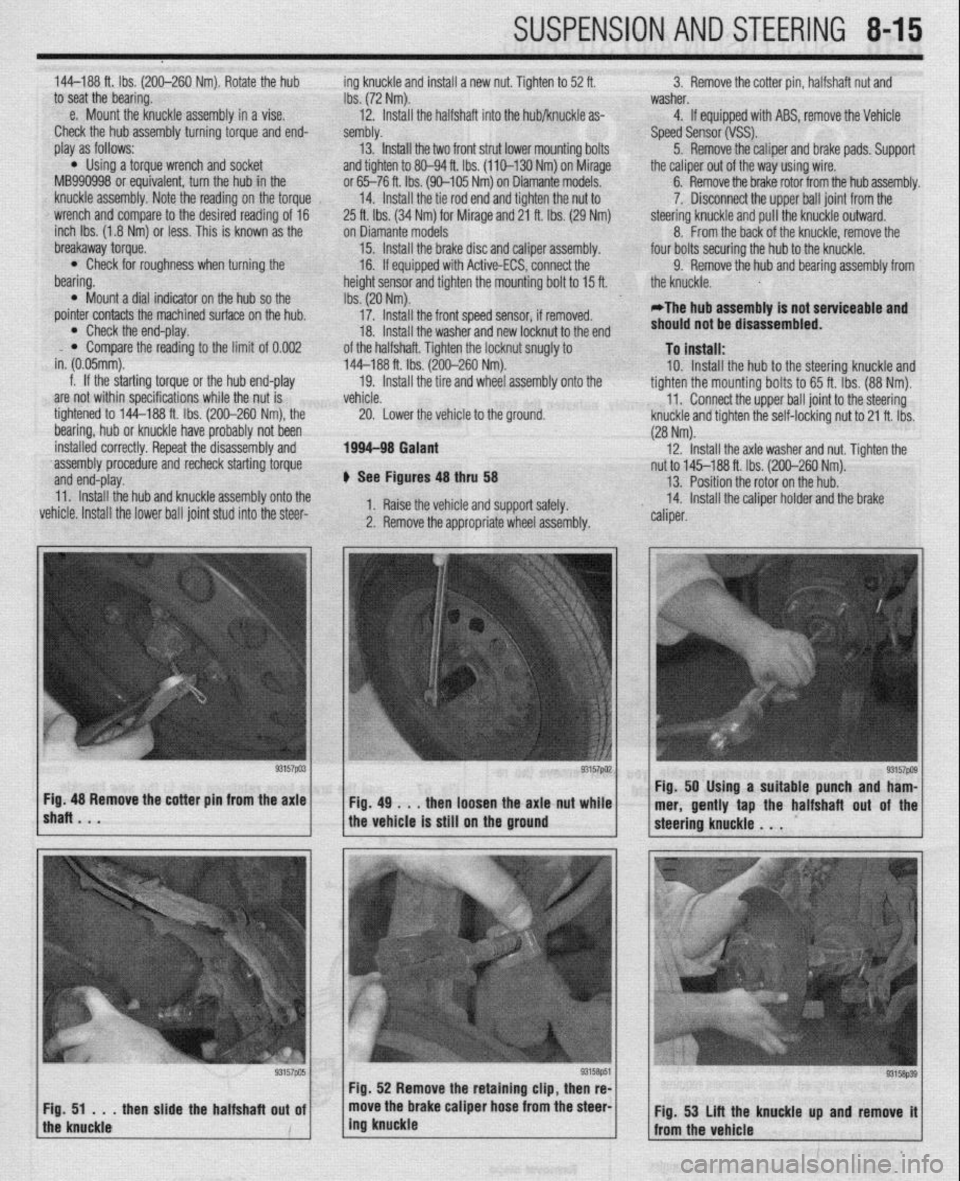

mounting bolts to 72 ft. Ibs. (100 Nm). ) See Figures 45, 46, and 47

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely. Remove

the halfshaft nut.

3. If equipped with ABS, remove the front wheel

speed sensor

1994-90 Galant

4. If equipped with Active Electronic Control

Suspension (Active-ECS), disconnect the height sen-.

sor from the lower control arm.

5. Remove the caliper assembly and brake pads.

Suspend the caliper with a wire

6. Using a suitable ball joint separator tool, dis-

connect the ball joint and tie rod end from the steer-

ing knuckle.

7. Remove the halfshaft from the hub.

8. Unbolt the lower end of the strut and remove

the hub and steering knuckle assembly from the vehi-

cle.

9 Remove the hub, bearings and races as fol-

lows.

# See Figures 42, 43, and 44

1. Disconnect the negative battery cable.

2. Raise and safely support the vehicle 3. Disconnect the sway bar links by removing

the self-locking nuts.

4. Remove the sway bar mounting brackets and

bushings.

5. Remove the bar from the vehicle.

6. Inspect all components for wear or damage,

and replace parts as needed.

To install: 7. Install the sway bar into the vehicle.

8. Loosely install the sway bar brackets on the

vehicle.

9. Align the side locating markings on the sway

bar, so that the marking on ihe bar, extends approxi-

mately 0.40 inches (1Omm) from the Inner edge of

the mounting bracket, on both sides.

10. With the sway bar properly aligned, tighten

the mounting bracket bolts to 28 ft. Ibs. (39 Nm).

11. Connect the sway links to the damper fork

and the sway bar. Tighten the locking nuts to 28 ft.

Ibs (39 Nm).

12. Lower the vehicle and connect the negative

battery cable.

Diamante

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the front exhaust pipe and engine

undercover.

4. Remove the left and right frame members.

5. Remove the sway bar link.

6. Remove the sway bar brackets and remove

the sway bar from the vehicle.

To install: 7. Note that the bar brackets are marked left and

right. Lubricate all rubber parts and install the bush-

ings, the sway bar and brackets.

8. Install the sway bar link.

9. Install the frame members.

10. Install the engine undercover and exhaust

pipe.

Page 309 of 408

.

8-14 SUSPENSION AND STEERING

*Do not use a hammer to accomplish this or

the bearing will be damaged.

a. Remove the oil seal from the axle side of

the knuckle using a small prying tool.

b. Remove the wheel bearing inner race frorr

the front hub using a puller.

. -Be careful that the front hub does not fall

when the inner race is removed.

108 N ?a fu c. Remove the snapring from the axle side 01

the knuckle. Remove the bearing from the

knuckle UI **

;rng a purrer.

d. One e the bearing is removed, the bearing

outer race can be removed by tapping out with-a

brass drift pin and a hammer.

To install:

10. Install the hub, bearings, and races as fol-

lows:

a. Fill the wheel bearing with multipurpose

grease. Apply a thin coating of multipurpose greas

+- +hn L”S?kle and bearina contact surfaces.

L” u lC N IUI b. Pre: is the wheel bearing into the knuckle

using an a #ppropriate pressing tool. Once the

bearing is

installed, install the inner race using

the proper driving tool.

c. Drivi

e the oil seal into the knuckle using

the proper size driver. Drive seal into knuckle un

til it is flush with the knuckle end surface.

d. Using pressing tool MB990998 or equiva-

lent, mount the front hub assembly into the

knuckle. Tighten the nut of the pressing tool to

:tg. 41 Lower control arm assembly and related components-Mirage Remrnml stsps

1. Lower arrn ball joint connection

2. Self-locking nut

3. Stabilizer rubber

4. Stabilizer bar

5. Collar

8. Lower arm front bushing

connection --?8-98Nm

58-72ft.b.

7. Support bracket

8. Lower arm assembly

Caution

*: lndkates parts which should be temporarily

tightened, and then fully tightensd with the

vehicle on the ground in the unladen condition.

1 ing’nuts . . . 9315Bp63

Fig 42 Remove the sway bar link self-lock- Q3158p60 1 1 :;izi . ..t$i yovy the sway ba~~~~~ 1. / . Fig 44 The sway bar mounting bracket and

bushings are retained by 2 bolts ,,,,

I I I’ r

urn the nut

7923PGC1 Fig, 45 Front wheel bearing assembly ex-

ploded View-Mirage and Diamante 7923PGC2 Fig. 46 Use of press tool for hub removal--

Mirage and Diamante 79wGc3 Fig. 47 Removing inner race from hub-Ml-

rage and Diamante

Page 310 of 408

SUSPENSION AND STEERING 845

144-188 ft. Ibs. (200-260 Nm). Rotate the hub ing knuckle and install a new nut. Tighten to 52 ft. 3. Remove the cotter pin, halfshaft nut and

to seat the bearing.

Ibs. (72 Nm). washer.

e. Mount the knuckle assembly in a vise.

12. Install the halfshaft into the hub/knuckle as- 4. If equipped with ABS, remove the Vehicle

Check the hub assembly turning torque and end- sembly.

Speed Sensor (VSS).

play as follows: 13. Install the two front strut lower mounting bolts

5. Remove the caliper and brake pads. Support

l Using a torque wrench and socket

and tighten to 80-94 ft. Ibs. (110-130 Nm) on Mirage

the caliper out of the way using wire.

MB990998 or equivalent, turn the hub in the or 65-76 ft. Ibs. (90-105 Nm) on Diamante models. 6. Remove the brake rotor from the hub assembly.

knuckle assembly. Note the reading on the torque

14. Install the tie rod end and tighten the nut to 7. Disconnect the upper ball joint from the

wrench and compare to the desired reading of 16

25 ft. lbs. (34 Nm) for Mirage and 21 ft. Ibs. (29 Nm) steering knuckle and pull the knuckle outward.

inch Ibs. (1.8 Nm) or less. This is known as the ‘on Diamante models

8. From the back of the knuckle, remove the

breakaway torque.

15. Install the brake disc and caliper assembly. ‘four bolts securing the hub to the knuckle.

l Check for roughness when turning the

16. If equipped with Active-ECS, connect the

9. Remove the hub and bearing assembly from

bearing.

height sensor and tighten the mounting bolt to 15 ft.

the knuckle.

0 Mount a dial indicator on the hub so the

Ibs. (20 Nm).

pointer contacts the machined surface on the hub.

17. Install the front speed sensor, if removed.

*The hub assembly is not serviceable and

l Check the end-play.

18. Install the washer and new locknut to the end should not be disassembled.

l Compare the reading to the limit of 0.002

in. (0.05mm). of the halfshaft. Tighten the locknut snugly to To install: 144-188 ft. Ibs. (200-260 Nm).

f. If the starting torque or the hub end-play

19. Install the tire and wheel assembly onto the 10. Install the hub to the steering knuckle and

are not within specifications while the nut is tighten the mounting bolts to 65 ft. Ibs. (88 Nm).

vehicle.

11.

tightened to 144-188 ft. Ibs. (200-260 Nm), the

Lower the vehicle to the ground. Connect the upper ball joint to the steering

20.

bearing, hub or knuckle have probably not been ‘knuckle and tighten the self-locking nut to 21 ft. Ibs.

(28 Nm).

installed correctly. Repeat the disassembly and 1994-98 Galant 12.

‘assembly procedure and recheck starting torque Install the axle washer and nut. Tighten the

and end-play. nut to 145-188 ft. Ibs. (200-260 Nm).

+ See Figures 48 thru 58 13. Position the rotor on the hub.

11. Install the hub and knuckle assembly onto the

vehicle. Install the lower ball joint stud into the steer- 1. Raise the vehicle and support safely. 14. Install the caliper holder and the brake

2. Remove the appropriate wheel assembly. ” caliper.

lshaRBmV * “57pa3~ ~Fig.4g~..thenloosehtheaxlattut~~;.~ Fig. 48 Remove the cotter pm from the axle Fig. 50 Using a suitable punch and ham-

mer, gently tap the halfshaft out of the

the vehicle is still on the ground