MITSUBISHI DIAMANTE 1900 Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 311 of 408

8116 SUSPENSION AND STEERING

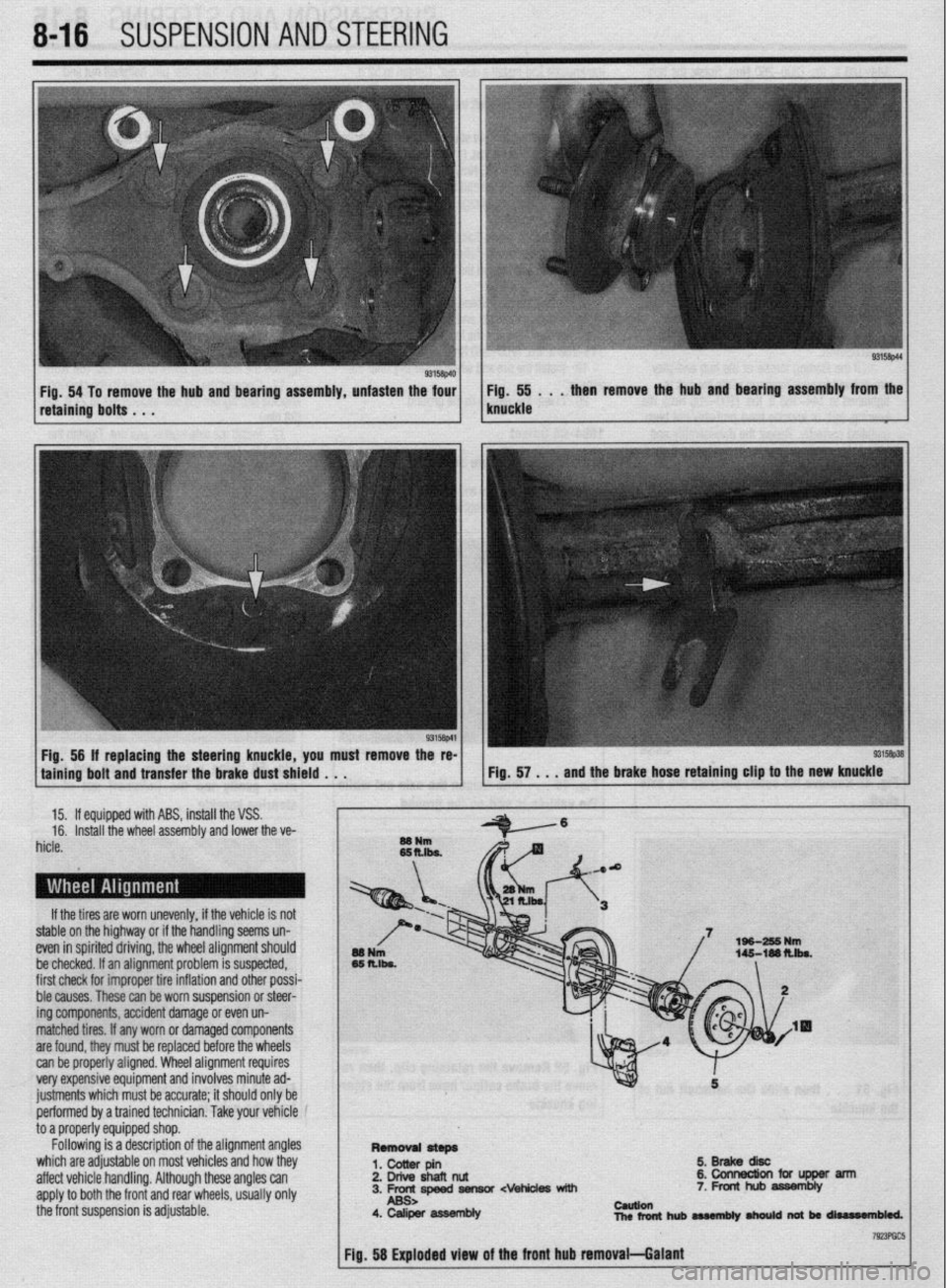

Fig. 54 To remove the hub and bearing assembly, unfasten the four Fig. 55 . . . then remove the hub and bearing assembly from the

retaining bolts . . . knuckle

Fig, 56 If replacing the steering knuckle, you must remove the re-

taining bolt and transfer the brake dust shield . . .

15. If equipped with ABS, install the VSS.

16. Install the wheel assembly and lower the ve-

hicle.

If the tires are worn unevenly, if the vehicle is not

stable on the highway or if the handling seems un-

even in spirited driving, the wheel alignment should

be checked. If an alignment problem is suspected,

first check for improper tire inflation and other possi-

ble causes. These can be worn suspension or steer-

ing components, accident damage or even un-

matched tires. If any worn or damaged components

are found, they must be replaced before the wheels

can be properly aligned. Wheel alignment requires

very expensive equipment and involves minute ad-

justments which must be accurate; it should only be

performed by a trained technician. Take your vehicle

to a properly equipped shop.

Following is a description of the alignment angles

which are adjustable on most vehicles and how they

affect vehicle handling. Although these angles can

apply to both the front and rear wheels, usually only

the front suspension is adjustable.

5.BrakediW

2. Drive shafl nut &collnectionfciflJpperarm

3. Frc-rc,speed fiensor cvehides with 7. Front hub assembly

4. Caliper asWmbly cauuen

nlcrfonthubaMmbly~natbrrliurr#n61ed.

Page 312 of 408

SUSPENSION AND STEERING 8-17

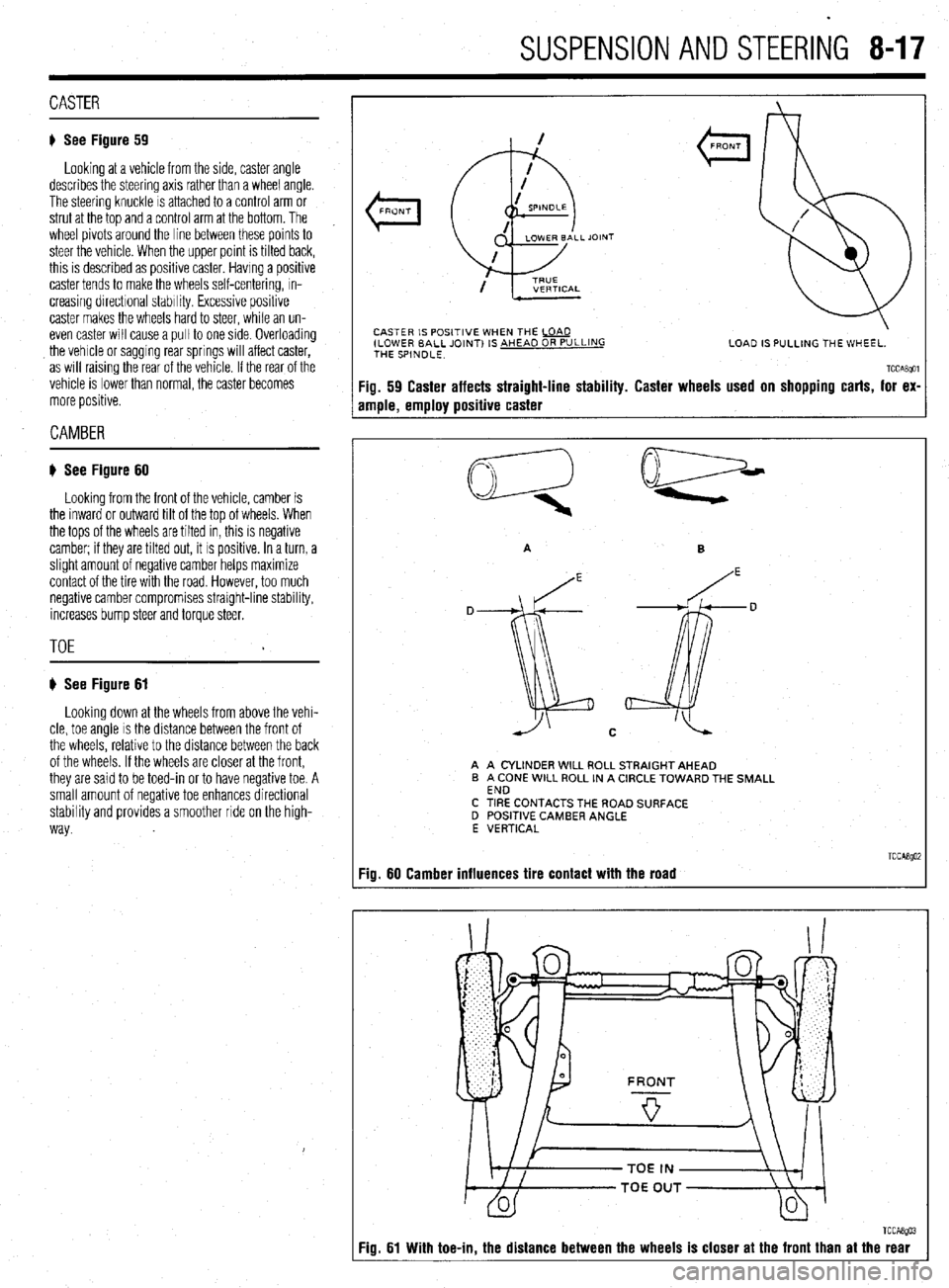

CASTER

) See Figure 59

Looking at a vehicle from the side, caster angle

describes the steering axis rather than a wheel angle.

The steering knuckle is attached to a control arm or

strut at the top and a control arm at the bottom. The

wheel pivots around the line between these points to

steer the vehicle. When the upper point is tilted back,

this is described as positive caster. Having a positive

caster tends to make the wheels self-centering, in-

creasing directional stability. Excessive positive

caster makes the wheels hard to steer, while an un-

even caster will cause a pull to one side. OVerlOading

the vehicle or sagging rear springs will affect caster,

as will raising the rear of the vehicle. If the rear of the

vehicle is lower than normal, the caster becomes

more positive.

CAMBER

# See Figure 60

Looking from the front of the vehicle, camber is

the inward or outward tilt of the top of wheels. When

the tops of the wheels are tilted in, this is negative

camber; if they are tilted out, it is positive. In a turn, a

slight amount of negative camber helps maximize

contact of the tire with the road. However, too much

negative camber compromises straight-line stability,

increases bump steer and torque steer.

TOE

) See Figure 61

Looking down at the wheels from above the vehi-

cle, toe angle is the distance between the front of

the wheels, relative to the distance between the back

of the wheels. If the wheels are closer at the front,

they are said to be toed-in or to have negative toe. A

small amount of negative toe enhances directional

stability and provides a smoother ride on the high-

way.

< FRONT

CASTER IS POSITIVE WHEN THE La

ILOWER BALL JOINT) IS AHEAD OR PULLING

THE SPINDLE. LOAD IS PULLING THE WHEEL.

TCCABgOl Fig. 59 Caster affects straight-line stability. Caster wheels used on shopping carts, for ex-

ample, employ positive caster

D

A A CYLINDER WILL ROLL STRAIGHT AHEAD

B A CONE WILL ROLL IN A CIRCLE TOWARD THE SMALL

END

C TIRE CONTACTS THE ROAD SURFACE

D POSITIVE CAMBER ANGLE

E VERTICAL

TCCABgOi :ig. 60 Camber influences tire contact with the road

Fig. 61 With toe-in, the distance between the wheels is closer at the front than at the rear

Page 313 of 408

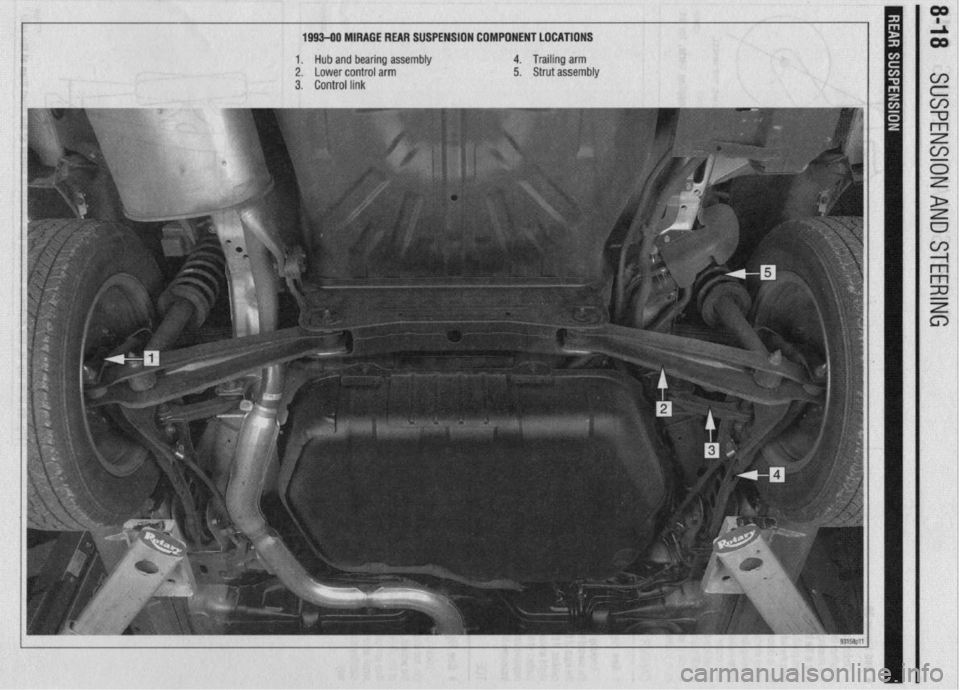

1993-90 MIRAGE REAR SUSPENSION COMPONENT LOCATIONS

1.

Hub and bearing assembly 4. Trailing arm

2. Lower control arm 5. Strut assembly

3. Control link

Page 314 of 408

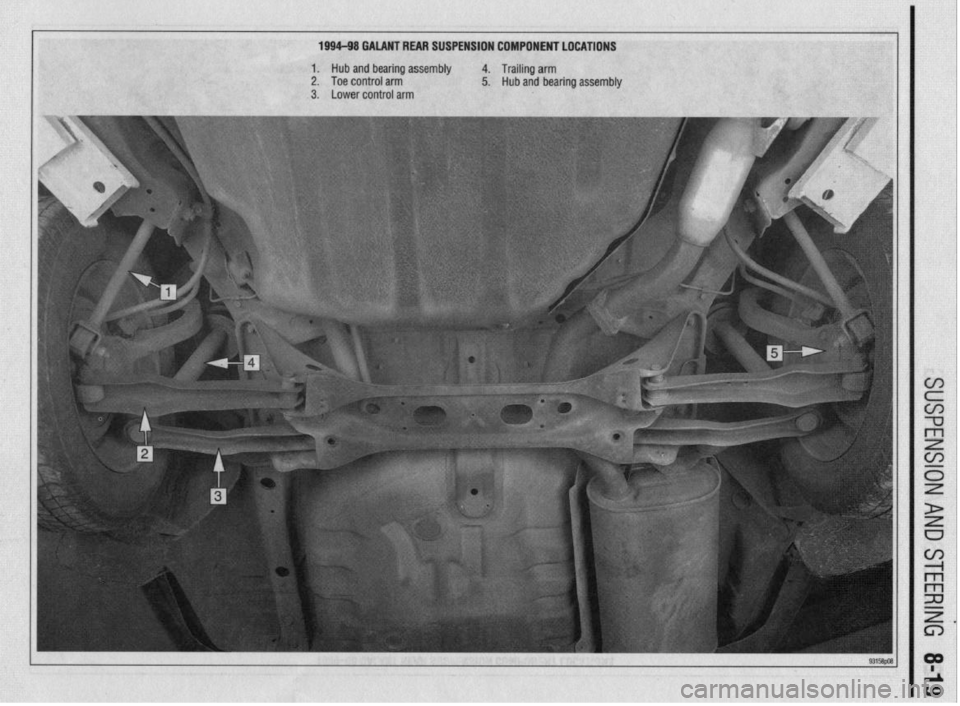

1994-98 GALANT REAR SUSPENSION COMPONENT LOCATIONS

1. Hub and bearing assembly 4. Trailing arm

2. Toe control arm 5. Hub and bearina assemblv

II

3. Lower control arm

Page 315 of 408

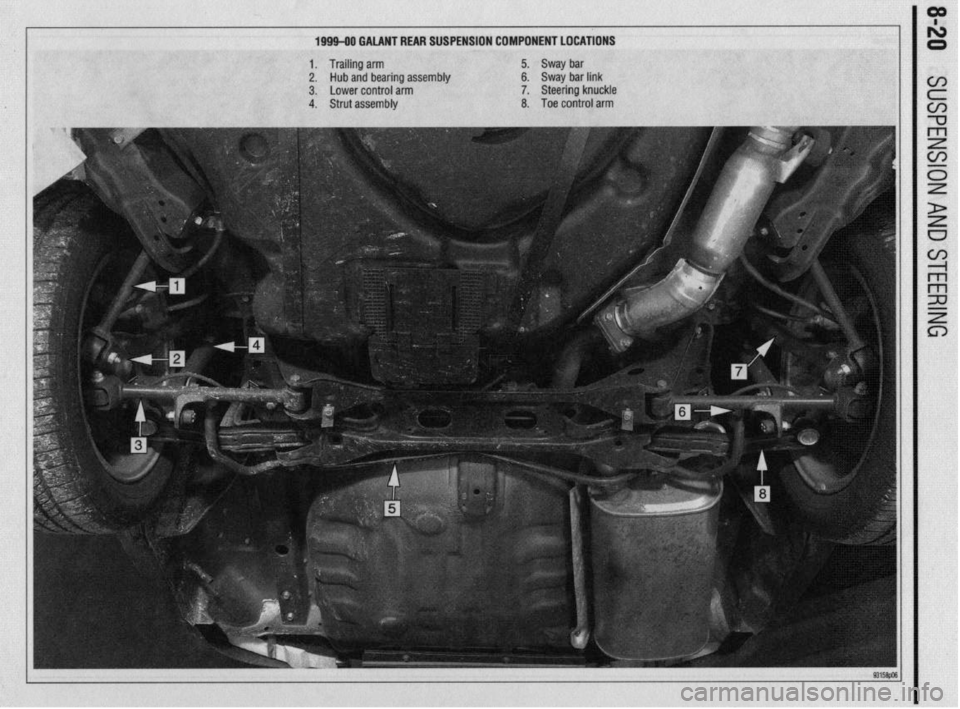

199940 GALANT REAR SUSPENSION COMPONENT LOCATIONS

1. Trailing arm

5.

Sway bar

2.

Hub and bearing assembly 6. Sway bar link

3. Lower control arm

7.

Steering knuckle

4. Strut assembly

8.

Toe control arm

Page 316 of 408

.

SUSPENSION AND STEERING 8-21

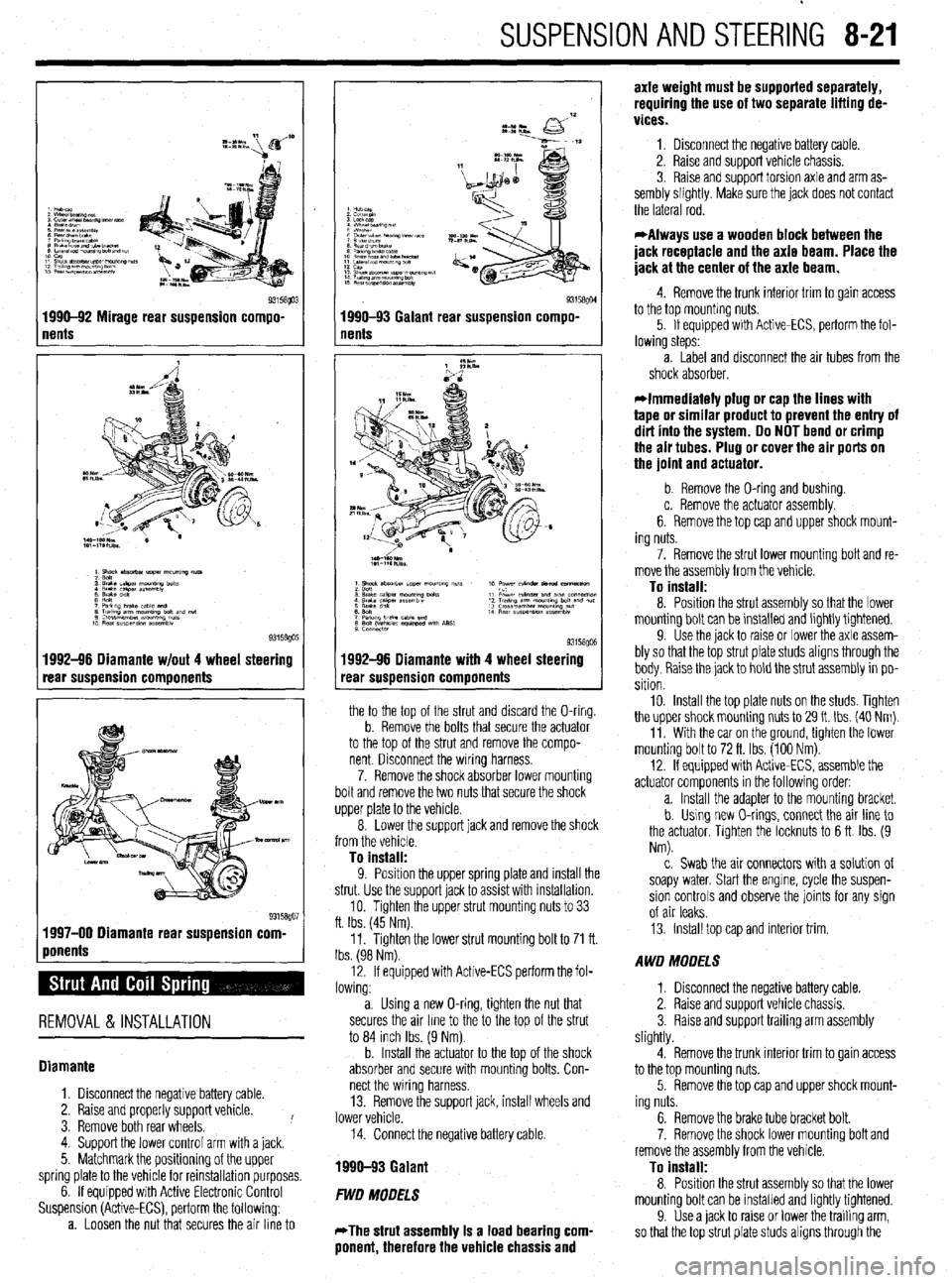

1 nents Q3158!@3 1990-92 Mirage rear suspension compo-

1992-96 Diamante w/out 4 wheel steering

rear suspension components

1 ponents %” 1997-00 Diamante rear suspension corn

REMOVAL & INSTALLATION

Diamante

1. Disconnect the negative battery cable.

2. Raise and properly support vehicle.

3. Remove both rear wheels. !

4. Support the lower control arm with a jack.

5. Matchmark the positioning of the upper

spring plate to the vehicle for reinstallation purposes.

6. If equipped with Active Electronic Control

Suspension (Active-ECS), perform the following:

a. Loosen the nut that secures the air line to

I

93158QM 1990-93 Galant rear suspension compo-

nents

1992-96 Diamante with 4 wheel steering

rear suspension components

the to the top of the strut and discard the O-ring.

b. Remove the bolts that secure the actuator

to the top of the strut and remove the compo-

nent Disconnect the wiring harness.

7. Remove the shock absorber lower mounting

bolt and remove the two nuts that secure the shock

upper plate to the vehicle.

8. Lower the support jack and remove the shock

from the vehicle.

To install:

9. Position the uooer sprina elate and install the

strut. Use the support’jack to as% with installation.

10. Tighten the upper strut mounting nuts to 33

ft. Ibs. (45 Nm).

11. Tighten the lower strut mounting bolt to 71 ft.

Ibs. (98 Nm).

12. If equipped with Active-ECS perform the fol-

lowing:

a. Using a new O-ring, tighten the nut that

secures the air line to the to the top of the strut

to 84 inch Ibs. (9 Nm).

b. Install the actuator to the top of the shock

absorber and secure with mounting bolts. Con-

nect the wiring harness.

13. Remove the support jack, install wheels and

lower vehicle.

14. Connect the negative battery cable.

1990-93 Galant

FWD MODELS

*The strut assembly Is a load bearing com-

ponent, therefore the vehicle chassis and axle weight must be supported separately,

requiring the use of two separate lifting de-

vices.

1. Disconnect the negative battery cable.

2. Raise and support vehicle chassis.

3. Raise and support torsion axle and arm as-

sembly slightly. Make sure the jack does not contact

the lateral rod.

*Always use a wooden block between the

jack receptacle and the axle beam. Place the

jack at the center of the axle beam.

4. Remove the trunk interior trim to gain access

to the top mounting nuts.

5. If equipped with Active-ECS, perform the fol-

lowing steps:

a. Label and disconnect the air tubes from the

shock absorber.

*Immediately plug or cap the lines with

tape or similar product to prevent the entry of

dirt into the system. Do NOT bend or crimp

the air tubes. Plug or cover the air ports on

the joint and actuator.

b. Remove the O-ring and bushing.

c. Remove the actuator assembly.

6. Remove the top cap and upper shock mount-

ing nuts.

7. Remove the strut lower mounting bolt and re-

move the assembly from the vehicle.

To install:

8. Position the strut assembly so that the lower

mounting bolt can be installed and lightly tightened.

9. Use the jack to raise or lower the axle assem-

bly so that the top strut plate studs aligns through the

body. Raise the jack to hold the strut assembly in po-

sition

10. Install the top plate nuts on the studs. Tighten

the upper shock mounting nuts to 29 It. Ibs. (40 Nm).

11. With the car on the ground, tighten the lower

mounting bolt to 72 ft. Ibs. (100 Nm).

12. If equipped with Active-ECS, assemble the

actuator components in the following order:

a. Install the adapter to the mounting bracket.

b. Using new O-rings, connect the air line to

the actuator, Tighten the locknuts to 6 ft Ibs. (9

Nm).

c. Swab the air connectors with a solution of

soapy water. Start the engine, cycle the suspen-

sion controls and observe the joints for any sign

of air leaks.

13. Install top cap and interior trim.

AWD MODELS

1. Disconnect the negative battery cable.

2. Raise and support vehicle chassis.

3. Raise and support trailing arm assembly

slightly.

4. Remove the trunk interior trim to gain access

to the top mounting nuts.

5. Remove the top cap and upper shock mount-

ing nuts.

6. Remove the brake tube bracket bolt.

7. Remove the shock lower mounting bolt and

remove the assembly from the vehicle.

To install:

8. Position the strut assembly so that the lower

mounting bolt can be installed and lightly tightened.

9. Use a jack to raise or lower the trailing arm,

so that the top strut plate studs aligns through the

Page 317 of 408

sembly slightly.

3. In order to gain access to the top mounting

nuts, remove the rear seat as follows:

r

I-- a. While pulling the rear seat stopper out- lb

ward, lift the lower cushion upward. Remove the

lower cushion.

b. Remove the seat back mounting bolts.

c. Lift the seat back upward and remove the

seat.

4. Remove the shock upper mounting nuts.

5. Remove the shock lower mounting bolt and

remove the assembly from the vehicle.

To install:

6. Position the shock assembly so that the

lower mounting bolt can be installed and lightly

tightened.

7. Use a jack to raise or lower the lower control

arm, so that the top shock plate studs align through

the body. Raise the jack to hold the shock assembly

in position.

8 “, In&dl the tnn nlato nl Itc: nn thp dl~rk nnri ,,,“Lu,l .,,” .“* r....” ,.“.., “.. . ..” -.I__-..” tighten the mounting nuts to 32 ft. Ibs. (44 Nm).

9. With the vehicle on the ground, tighten the

lower mounting bolt to 71 ft. Ibs. (98 Nm).

10. Install the rear seat back and cushion.

Miraae

I

1. Remove the trunk interior trim to aain access

to the top mounting nuts.

2. Remove the top cap and upper shock mount-

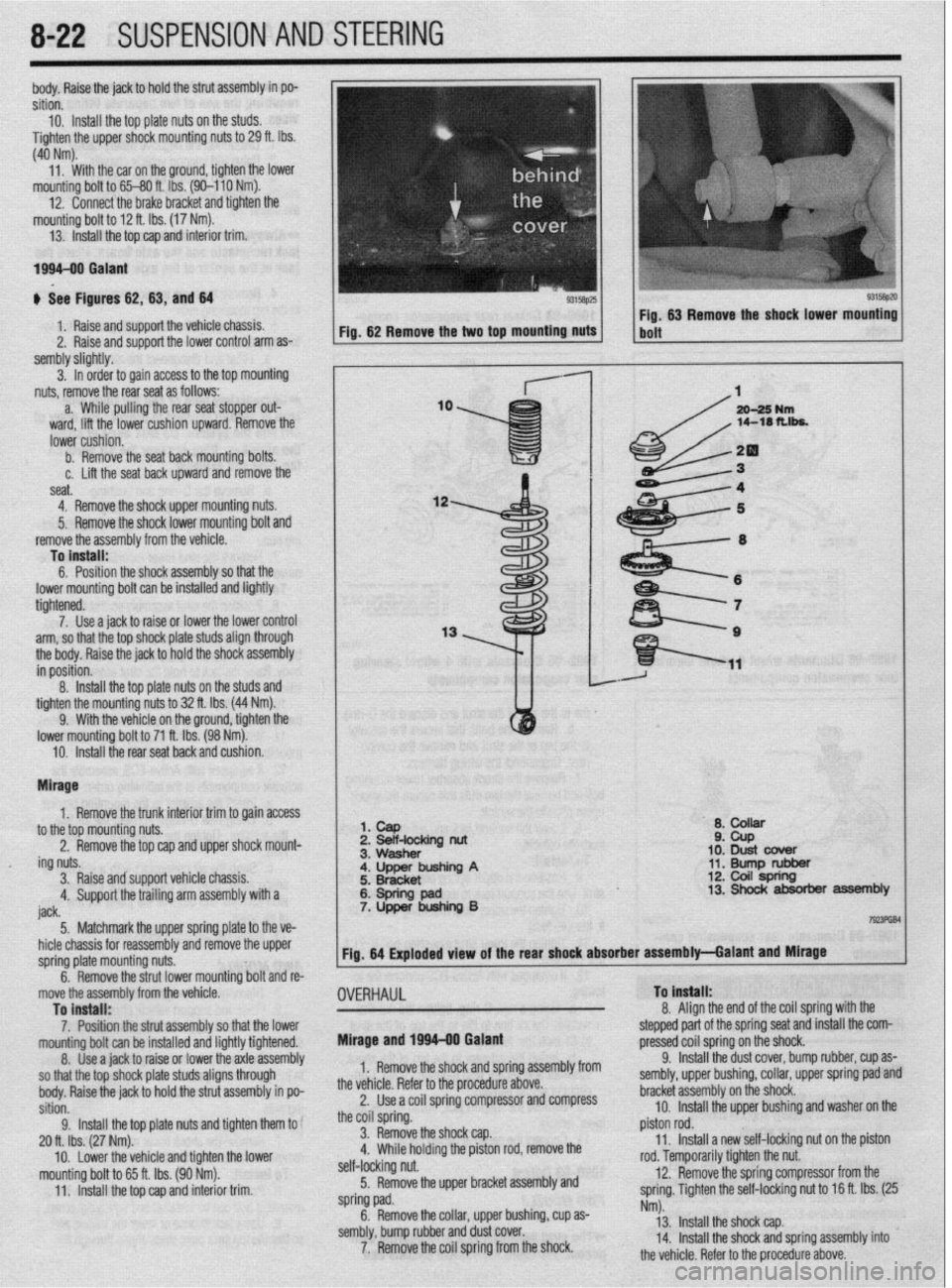

I 1. cap

2 Beif-locking nut

Q* ,A,ll)rrr ii ZPb

10: Dust cbver

11. Bump rubber 12. Coil spring

8-22 SUSPENSION AND STEERING

,

I

ing nuts.

3. Raise andsupport vehicle chassis.

4. Support the trailing arm assembly with a

iack a. ““QJ1vw

;. ~~;~~inp A

6: Spring pad 7. Upper bushing B 13. Shock absorber assembly

I----. 5 Matchmark thF! unner snrino elate to the ve-

I TmFliBl

_. .._._....._... . .._ -TT- _r

u r _.- .-

hicle chassis for reassembly and remove the upper

spring plate mounting nuts.

^ ^

. . .a .I II. I Fig. 64 Exploded view of the rear shock absorber assembly-Galant and Mirage

I

-t

Inrmg DOII ana re-

9.

OVERHAUL To Install:

o A*. .* I b. nemove tne strut lower mol

move the assembly from the vehicle

To install:

7. Position the strut assembly so that the lower

mountino bolt can be installed and liahtlv tiahtened.

8. t&e a jack to raise or lower thk &le&sembly

so that the top shock plate studs aligns through

body. Raise the jack to hold the strut assembly in po-

sition.

9. Install the top plate nuts and tighten them to

20 ft. Ibs. (27 Nm).

mounting bolt to 65 ft. Ibs. (90 Nm).

11. Install the top cap and interior trim. Mirage and 1996-00 Galant 0. ,,ngn me ena of the coil spring with the

stepped part of the spring seat and install the com-

pressed cnil snrinn nn the shock

1. Remove the shock and spring assembly from

the vehicle. Refer to the procedure above.

2. Use a coil spring compressor and compress

the coil spring.

3. Remove the shock cap.

” \w.;,n hrrh~inn +I-.- n;r+nn rnr( rnmn,rc, thn ,. .,,,,,- ,,-,-,* *J ..l” r .I._. * .-_, .-...-.- . ..-

self-locking nut.

5. Remove the upper bracket assembly and

spring pad.

6. Remove the collar, upper bushing, cup as-

sembly, bump rubber and dust cover.

7. Remove the coil spring from the shock. _.. -r,.. J _ _ _ __

9. Install the dust cover, bump rubber, cup as-

sembly, upper bushing, collar, upper spring pad and

bracket assembly on the shock.

10. Install the upper bushing and washer on the

piston rod.

11. Install a new self-locking nut on the piston

roa. temporarily tighten the nut.

12. Remove the spring compressor from the

spring. Tighten the self-locking nut to 16 ft. Ibs. (25

Nm).

13. Install the shock cap.

14. Install the shock and spring assembly into

the v&i&a Rnfnr tn the nmrd~w~ ahnrm

Page 318 of 408

SUSPENSION AND STEERING 8-23

i-l

12. Check rear wheel alignment and adjust if nec-

REMOVALANDINSTALLATION

essary.

1990-93 Galant

1. Disconnect the neoative battetv cable.

2. Raise and safely sipport vehicle.

3. Remove the tire and wheel assembly.

4. Support the rear lower control arm.

5. Remove the brake line clamp bolt.

6. Remove the nut and separate the upper ball

joint, using tool MB9f35 or equivalent, from the rear

trailing arm/steering knuckle.

*It is important to use proper method of

joint separation when reusing joint. Damage

can result from unapproved methods, result-

ing in possible joint failure.

7. Matchmark the eccentric nn the IInner instal-

8. Remove the upper arm from the vehicle.

To install:

9. Install the arm to the vehicle and install the

upper arm installation bolt. Align the matchmarks

and tighten the nut snugly only.

10. Install the upper arm ball joint to the rear

spindle assembly and install new nut. Tighten to 52

ft. Ibs. (72 Mm).

11. Install the tire and wheel assembly.

12. Lower the vehicle until the suspension sup-

ports its weight.

13. Tighten the upper arm installation bolt to 116

ft. Ibs. (160 Nmj. 1. Disconnect the negative battery cable.

- . .._...- -.. . ..- -rr-. lation bolt and remove from the control arm.

14. ‘Check the rear wheel alignment.

1994-98 Galant

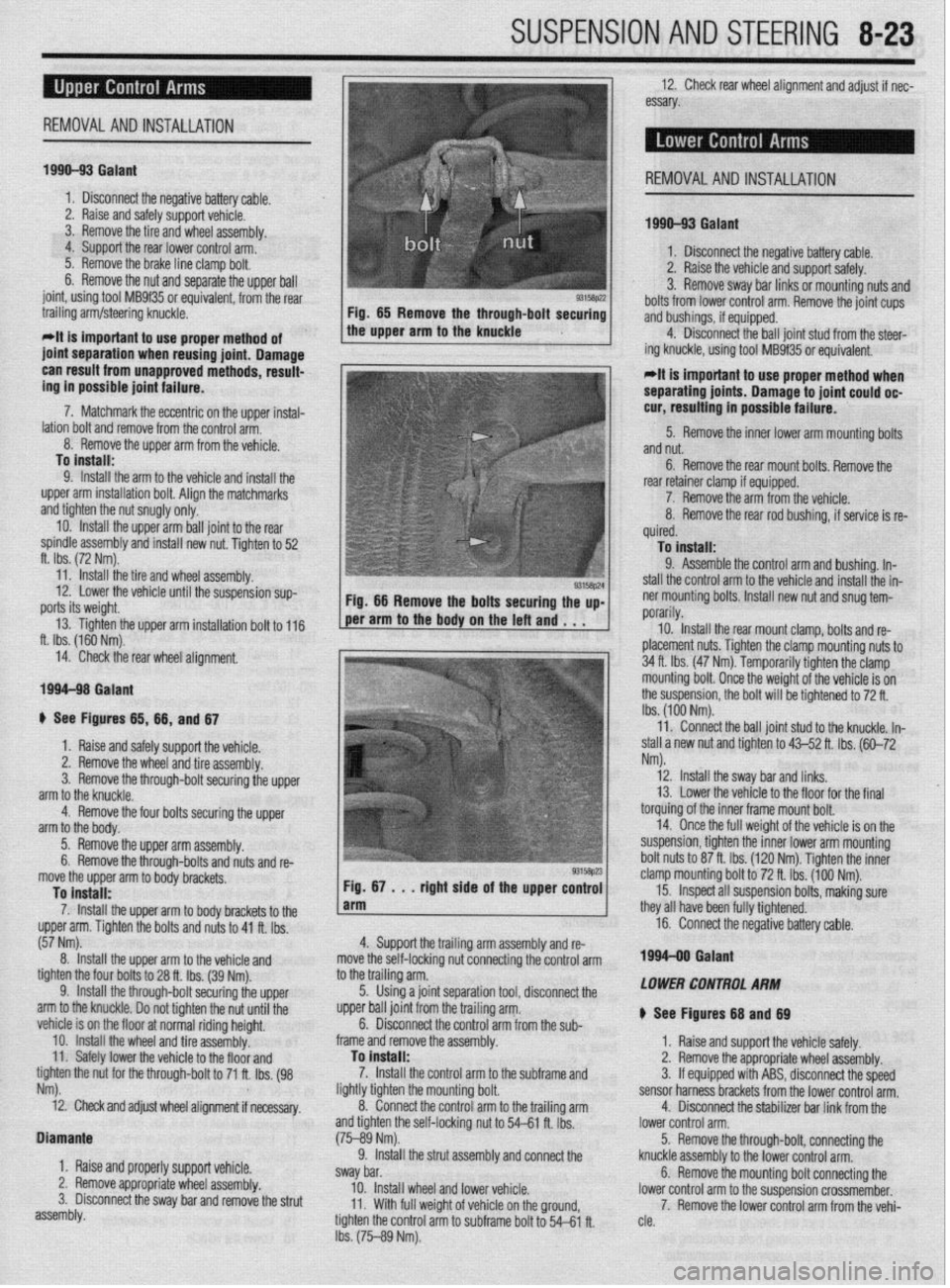

ti See Figures 65, 66, and 67 1

REMOVAL AND INSTALLATION

1990-93 Galant

2. Raise the vehicle and support safely.

!4315ap22 3. Remove sway bar links or mounting nuts and

Fig. 65 Remove the through-bolt securing bolts from lower control arm. Remove the joint cups

the upper arm to the knuckle and bushings, if equipped.

4. Disconnect the ball joint stud from the steer-

ing knuckle, using tool MB9f35 or equivalent.

*It is important to use proper method when

separating joints. Damage to joint could oc-

cur, resulting in possible failure.

5. Remove the inner lower arm mounting bolts

and nut.

6. Remove the rear mount bolts. Remove the

rear retainer clamp if equipped.

7. Remove the arm from the vehicle.

8. Remove the rear rod bushing, if service is re-

quired.

To install:

9. Assemble the control arm and bushing. In-

stall the control arm to the vehicle and install the in-

ner mounting bolts. Install new nut and snug tem-

nnrarilv md . . . 1 f.r”‘Y”‘,.

10. Install the rear mount clamp, bolts and re-

placement nuts. Tighten the clamp mounting nuts to

34 ft. Ibs. (47 Nm). Temporarily tighten the clamp

mounting bolt. Once the weight of the vehicle is on

the suspension, the bolt will be tightened to 72 ft.

Ibs. (100 Nm).

4. Support the trailing arm assembly and re-

move the Self-locking nut connecting the control arm

.* 11. Connect the ball joint stud to the knuckle. In-

stall a new nut and tighten to 43-52 ft. Ibs. (60-72

Nm).

12. Install the swav bar and links.

to tne tramng arm.

5. Using a joint separation tool, disconnect the

upper ball joint from the trailing ary.

6. Disconnect the control arm from the sub-

frame and remove the assembly.

To install:

7. Install the control arm to the subframe and

liahtlv tiahten the mounting bolt.

rol arm to the trailina arm 13. Lower the vehicle to the floor for the final

torquing of the inner frame mount bolt.

14. Once the full weight of the vehicle is on the

suspension, tighten the inner lower arm mounting

bolt nuts to 87 ft. Ibs. (120 Nm). Tighten the inner

clamp mounting bolt to 72 ft. Ibs. (100 Nm).

15. InSpet all suspension bolts, making sure

they all have been fully tightened.

16. Connect the negative battery cable.

199440 Gafant

LOWER CONTROL ARM

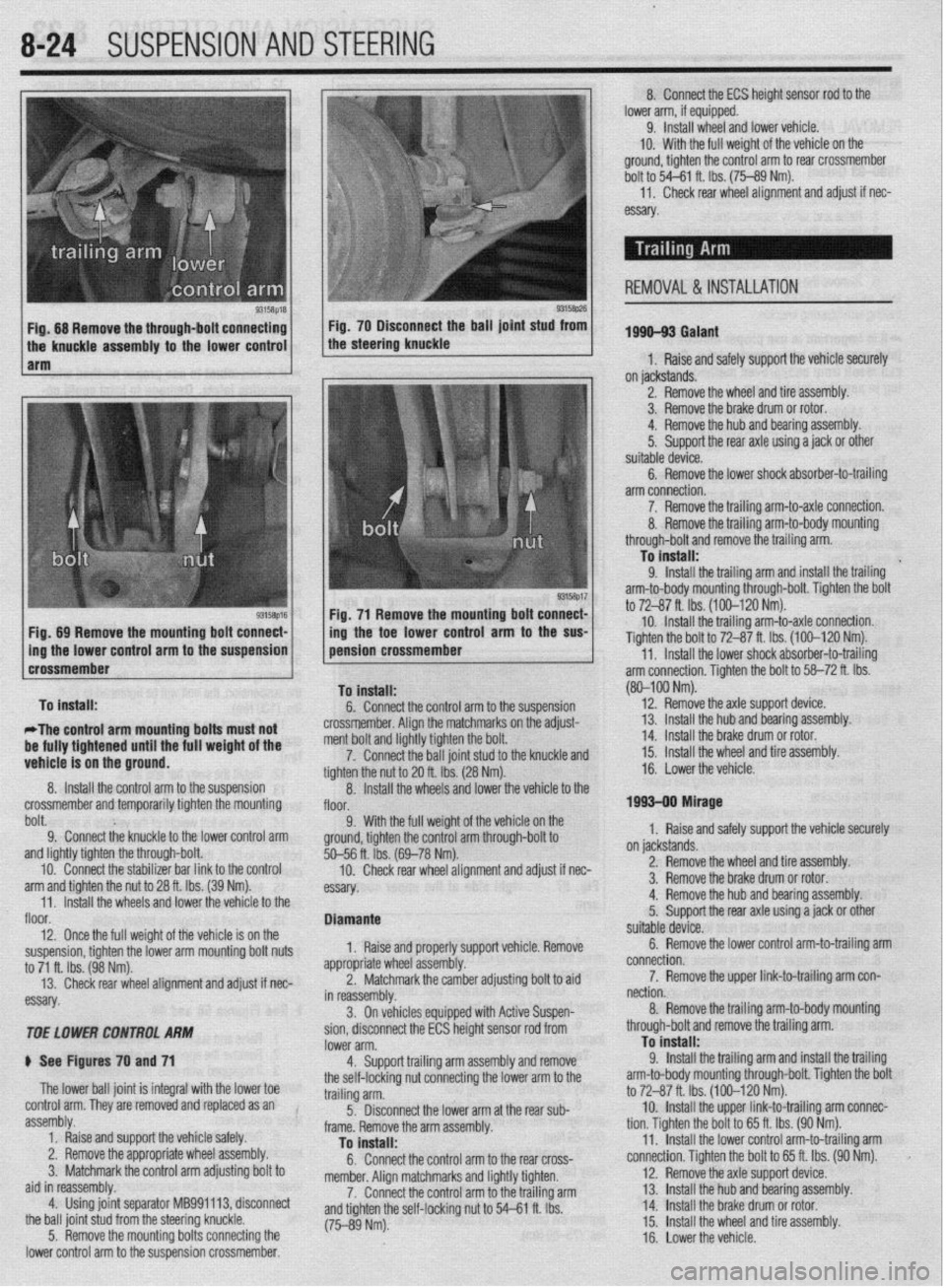

+ See Figures 68 and 69

1. Raise and support the vehicle safely.

2. Remove the appropriate wheel assembly.

3. If equipped with ABS, disconnect the speed

sensor harness brackets from the lower control arm.

4. Disconnect the stabilizer bar link from the

----“‘-‘I’

1 b Raise and safely support the vehicle.

2. Remove the wheel and tire assembly.

3. Remove the through-bolt securing the upper

arm to the knuckle.

4. Remove the four bolts securing the upper

arm to the body.

5. Remove the uooer arm assemhlv

re-

move the upper arm to body brackets,

To install:

7. Install the upper arm to body brackets to the

upper arm. Tighten the bolts and nuts to 41 ft. Ibs.

(57 Nm).

8. Install the upper arm to the vehicle and

tighten the four bolts to 28 ft. Ibs. (39 Nm). 6. Remove the through-bolts and nuts and

9. Install the through-bolt securing

vehicle is on the floor at normal ridina heiaht.

10. Install the wheel and tire assekbly:

11. Safely lower the vehicle to the floor and

tighten the nut for the through-bolt to 71 ft. Ibs. (98

Nm).

i2. Check and adjust wheel alignment if necessary. 8’. eonnectthe&i

and tighten the self-locki

(75-89 Nm). ng nut to 54-61 ft. Ibs.

connect the lower control arm.

5. Remove the through-bolt, connecting the

knuckle assembly to the lower control arm.

fi Romn\fn +hn mwntinn hnlt cnnnwtinn the 9. Install the strut assembly and

sway bar.

10. Install wheel and lower vehicle. V. IIVIII”“~ OK, ill” -...... J I”.. --....--.... J .,,” lower control arm to the suspension crossmember. Diamante

1, Raise and properly support vehicle.

2. Remove appropriate wheel assembly.

3. Disconnect the sway bar and remove the strut

assembly. 11. With full weight of vehicle on the ground,

tighten the control arm to subframe bolt to 54-61 ft.

Ibs. (75-89 Nm). 7. Remove the lower control arm from the vehi-

cle.

Page 319 of 408

8-24 SUSPENSION AND STEERING

9315t$M 93158p26 Fig. 68 Remove the through-bolt connecting Fig. 70 Disconnect the ball joint stud from

the knuckle assembly to the lower control the steering knuckle

1 arm

Fig. 71 Remove the mounting bolt connect-

Fig, 89 Remove the mounting bolt connect- /

1 ing the toe lower control arm to the SW

Dolt. 9; Connect the knuckle to the lower control arm 9. With the full weigh

ground, tighten the control

and lightly tighten the through-bolt.

10. Connect the stabilizer bar link to the control

arm and tighten the nut to 28 ft. Ibs. (39 Nm).

11. Install the wheels and lower the vehicle to the

floor.

12. Once the full weight of the vehicle is on the

suspension, tighten the lower arm mounting bolt nuts

to 71 ft. Ibs. (98 Nm).

13. Check rear wheel alignment and adjust if nec-

essary.

TOE LOWER CONTROL ARhl

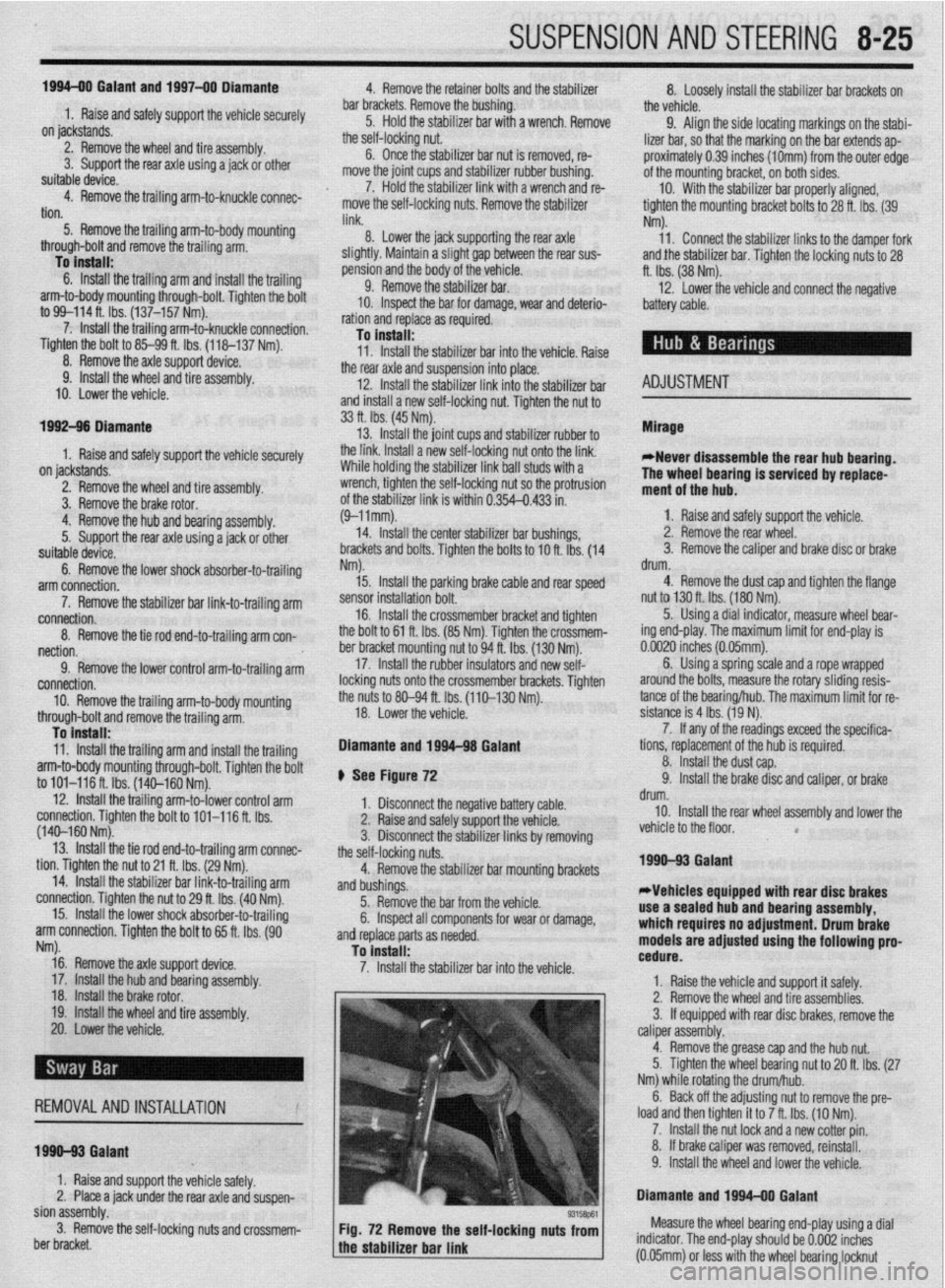

ti See Figures 70 and 71

The lower ball joint is integral with the lower toe

control arm. They are removed and replaced as an

assembly.

1. Raise and support the vehicle safely.

2. Remove the appropriate wheel assembly.

3. Matchmark the control arm adjusting bolt to

aid in reassembly.

4. Using joint separator MB991113, disconnect

the ball joint stud from the steering knuckle.

5. Remove the mounting bolts connecting the

lower control arm to the suspension crossmember. %--56 ft. ibs. (

10. Check

essay. rem an0 aajusr

II nec-

orl vehicle Remove

ldiustina bolt to aid

soen- Diamante

1, Raise and properly supp

appropriate whl

eel assembly.

2. Matchn

narkthe camber a , _

in reassembly.

3. On vehicles equipped with Active Su r

sion, disconnect the ECS height sensor rod from

lower arm.

4. Support trailing arm assembly and remove

the self-locking nut connecting the lower arm to the

trailing arm.

5. Disconnect the lower arm at the rear sub-

frame. Remove the arm assembly.

To install:

6. Connect the control arm to the rear cross-

member. Alion matchmarks and liahtlv tiohten.

7. Connect the control arm tothe trailing arm

and tighten the self-locking nut to 54-P e rho I I IL IY.J.

(75-89 Nm). 8. Connect the ECS height sensor rod to the

lower arm, if equipped.

9. Install wheel and lower vehicle.

IO. With the full weight of the vehicle on the

ground, tighten the control arm to rear crossmember

bolt to 54-61 ft. Ibs. (75-89 Nm).

11,

Check rear wheel alignment and adjust if nec-

essary

1996-93 Galant

1, Raise and safely support the vehicle securely

on jackstands.

2. Remove the wheel and tire assembly.

3. Remove the brake drum or rotor.

4. Remove the hub and bearing assembly.

5.

Support the rear axle using a jack or other

suitable device.

6. Remove the lower shock absorber-to-trailing

arm connection.

7. Remove the trailing arm-to-axle connection.

REMOVAL & INSTALLATION

(80-100 Nm).

12.

Remove the axle suooort device.

on jackstands.

2. Remove the wheel and tire assembly.

3. Remove the brake drum or rotor.

4. Remove the hub and bearing assembly.

5.

Support the rear axle using a jack or other

suitable device.

6. Remove the lower control arm-to-trailing arm

connection.

7. Remove the upper link-to-trailing arm con-

nection.

8. Remove the trailing arm-to-body mounting

through-bolt and remove the trailing arm.

To install:

9.

Install the trailing arm and install the trailing

arm-to-body mounting through-bolt. Tighten the bolt

to 72-87 ft. Ibs. (100-120 Nm).

10. Install the upper link-to-trailing arm connec-

tion. Tighten the bolt to 65 ft. Ibs. (90 Nm).

11. Install the lower control arm-to-trailing arm

connection. Tighten the bolt to 65 ft. Ibs. (90 Nm).

12. Remove the axle support device.

13. Install 1 he hub and bearing assembly.

14 Install 1

. _ .he brake drum or rotor.

15.

Install the wheel and tire assembly.

16. Lower the vehicle.

Page 320 of 408

SUSPENSION AND STEERING 8-25

1994-00 Galant and 1997-00 Diamante

4. Remove the retainer bolts and the stabilizer

..- 8, Loosely in”,“,, +I?,, r+&,il;7nr kn- h.~r.l,,d” -..

1. Raise and safely support the vehicle securely he bushing.

the vehicle.

on jackstands.

7er hnr with FI wmnph Remnun (1 Alinn th

2. Remove the wheel and tire assembly.

3. Support the rear axle using a jack or other

suitable device.

4. Remove the trailing arm-to-knuckle connec-

tion,

5. Remove the trailing arm-to-body mounting

n~~““yll-““!~ (1II” fWll”“C LllG llcllllll$j a,,,,. To install:

6. Install the trailing arm and install the trailing

arm-to-body mounting through-bolt. Tighten the bolt

to 99-114 ft. Ibs. (137-157 Nm).

7. Install the trailing arm-to-knuckle connection. Dar brackets. Hemove t

5. Hold the stabilL_. __. . . _ . .._..“... ..I . .._._

the self-locking nut.

6. Once the stabilizer bar nut is removed, re-

move the joint cups and stabilizer rubber bushing.

7. Hold the stabilizer link with a wrench and re-

move the self-locking nuts. Remove the stabilizer

link.

8. Lower the jack supporting the rear axle

in a slight gap between the rear sus-

? body of the vehicle.

! the stabilizer bar.

IL_ L__ I__ _)----- .-- .-J JAI.... slightly. Mainta

pension and thf

9. Remow

10. Inspect LIIB uar 101 uamage, wear ana aereno-

ration and replace as required.

-Fe c--a-...

1 IIIJMII UK 3La”III‘w “ill “lduKm “II

“. , ,,LY,, ,,ie side locating markings on the stabi-

lizer bar, so that the marking on the bar extends ap-

proximately 0.39 inches (1Omm) from the outer edge

of the mounting bracket, on both sides.

10. With the stabilizer bar properly aligned,

tighten the mounting bracket bolts to 28 ft. Ibs. (39

Nm).

11. Connect the stabilizer links to the damper fork

andihe stabilizer bar. Tighten the locking nuts to 28

ft. Ibs. (38 Nm).

12. Lower the vehicle and connect the negative

8.. Ia

mery came.

Tighten the bolt to 85-99 ft. Ibs. (118-137 Nm).

nemove me axle suppon

9. Install the wheel and tire

10. Lower the vehicle. aewce.

assembly.

I 0 Insran: 11, Install the stabilizer bar into the vehicle. Raise

the rear axle and suspension into place.

12. Install the stabilizer link into the stabilizer ba

Ir

ADJUSTMENT anfi indc4ll 33 ft. Ibs. (45 Nm).

13. Install the ioint __-_ _.._ __

1. Raise and safely support the vehicle securely the link. Ins’

..I.,

Mlhiln hnlrii, tall a rkW self~locking n

lll~llG llUlulng the stabi” ” ’ ’ ’

wrench, tighten the self,

of the stabilizer link is v

ihe hub and bearing assembly.

5. Support the rear axle using a jack or other

suitable device.

6. Remove the lower shock absorber-to-trailing

arm connection. ocking nut. Tighten the nut to

ClrnC 2nd ?$bilizer rubber to

ut onto the link.

nzer nnK oall studs with a

-locking nut so the protrusion

within 0.354-0.433 in.

I stabilizer bar bushings,

>+nn thn hnk In -I A u (9-llmm).

14. Install the cente

brackets and bolts. Tiqt Mirage

*Never disassemble the rear hub bearing.

The wheel bearing is serviced by replace-

ment of the hub.

1. Raise and safely support the vehicle.

2. Remove the rear wheel.

3. Remove the caliper and brake disc of brake 1992-96 biamante

on IacKsranos.

2. Remove the wheel and tire assembly

3, Remove thn hralm rntnr 4. Remove1

7. Remove the stabilizer bar link-to-trailing arm

connection.

8. Remove the tie rod end-to-trailing arm con-

nection.

9. Remove the lower control arm-to-trailing arm

connection.

10. Remove the trailing arm-to-body mounting

through-bolt and remove the trailing arm. Nm).

15. Install the parking

sensor installation bolt.

, , I oraxe cat * ale ar

member bracket and tighten

i Nm). Tighten the crossmem-

A to 94 ft. Ibs. (130 Nm). 16. Install the cross

the bolt to 61 ft. Ibs. (8!

ber bracket mounting nl

17. Install the rubbe

locking nuts onto the cro:

the nuts to 80-94 fl. Ibs. (

18. Lower the vehicle. id rear speed drum.

4. Remove the dust cab and tighten the flange ll”, *lb+ to 130 ft. Ibs. (180 Nm).

5. Using a dial indicator, measure wheel bear-

!r insulators and new seif-

ismemoer ’ brackets. Tighten

[110-130 Nm). ing end-play. The maximum limit for end-play is

o.oc-- ‘^ -- rzu mcnes (u.usmm).

arol

tanc

sisk 6. Using a spring scale and a rope wrapped

md the bolts, measure the rotary sliding resis-

e of the bearing/hub. The maximum limit for re-

mce is 4 Ibs. (19 N).

7. If any of the readings exceed the specifica-

To install:

11. Install the trailing arm and install the trailina Diamante and 1994-98 Gal&i

t tions, replacement of the hub is required.

8. Install the dust cap.

9. Install the brake disc and caliper, or brake

negative battery ( sble.

;“I,-.

I support the vbhlblG.

stabilizer links by removing

Alizer bar mounting brackets

from the vehicle.

lonents for wear or damage,

ded. drum.

10. Install the rear wheel assembly and lower the

vehicle to the floor.

*

1990-93 Galant

*Vehicles equipped with rear disc brakes

use a sealed hub and bearing assembly,

which requires no adjustment. Drum brake

models are

adjusted using the following pro- arm-to-body mounting through-bolt. Tighten the bolt

to 101-116 ft. Ibs. (140-160 Nm). ) See Figure 72

12. Install the trailing arm-to-lower control arm

1. Disconnect the I

connection. Tighten the bolt to 101-116 ft. Ibs.

(140-160 Nm). 2. Raise and safely

13. Install the tie rod end-to-trailing arm connec- 3. Disconnect the I

tion. Tighten the nut to 21 ft. Ibs. (29 Nm). the self-locking nuts.

14. Install the stabilizer bar link-to-trailing arm 4. Remove the stat

connection. Tighten the nut to 29 ft. Ibs. (40 Nm). and bushings.

15. Install the lower shock absorber-to-trailing

5. Remove the bar

arm connection. Tighten the bolt to 65 ft. Ibs. (90 6. Inspect all comr

. and replace parts as nee

Nrn).

16. Remove the axle support device.

17. Install the hub and bkaring assembly,

18. Install the brake rotor.

19. Install the wheel and tire assembly.

20. Lower the vehicle.

REMOVALANDINSTALLATION

1990-93 Gaiant

1. Raise and support the vehicle safely.

2. Place a jack under the rear axle and suspen- To install:

7 InstA the dnhili cedure. ._._ . . .._ -.--.. lzer bar into the vehicle.

1. Raise the vehicle and support it safely.

2. Remove the wheel and tire assemblies.

3. If equipped with rear disc brakes, remove the

caliper assembly.

4. Remove the grease cap and the hub nut.

5. Tighten the wheel bearing nut to 20 ft. Ibs. (27

Nm) while rotatir ” ”

6. Back off th

load and then tighten it to 7 ft. Ibs. (10 Nm).

7. Install the nut lock and a new cotter pin.

8. If brake caliper was removed, reinstall.

9. Install the wheel and lower the vehicle.

Diamante and lQQ44 Galant 10 tne mum/hub.

ie adjusting nut to remove the pre-

Sian assembly.

3. Remove the self-locking nuts and crossmem-

ber bracket.

93158P61 Fig. 72 Remove the self-locking nuts from Measure the wheel bearing end-play using a dial

the stabilizer bar link indicator. The end-play should be 0.002 inches

a (0.05mm) or less with the wheel bearing locknut