MITSUBISHI DIAMANTE 1900 Manual Online

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 81 of 408

.

3-20 ENGINEANDENGINEOVERHAUL

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the overflow hose and disconnect

the upper radiator hose.

*It is recommended that each clamp be

matchmarked to the hose. Observe the marks

and reinstall the clamps exactly when rein-

stalling the radiator.

4. If equipped with an automatic transaxle, re-

move and plug the fluid cooler hoses.

5. Unplug the electrical connector(s) from the

coolant fan motor.

6. Remove the mounting bolts, then remove the

fan and shroud assembly from the vehicle.

7. Remove the fan blade retainer nut from the

shaft on the fan motor and separate the fan from the

motor.

8. Remove the motor to shroud attaching

screws and the motor from the shroud.

To tnstall: 9. Install the motor to the shroud and secure

with the mounting bolts.

10. Install the remaining components in the re-

verse order of removal.

11. Fill the coohng system. Connect the negative

battery cable and check the cooling fan for proper op-

eration.

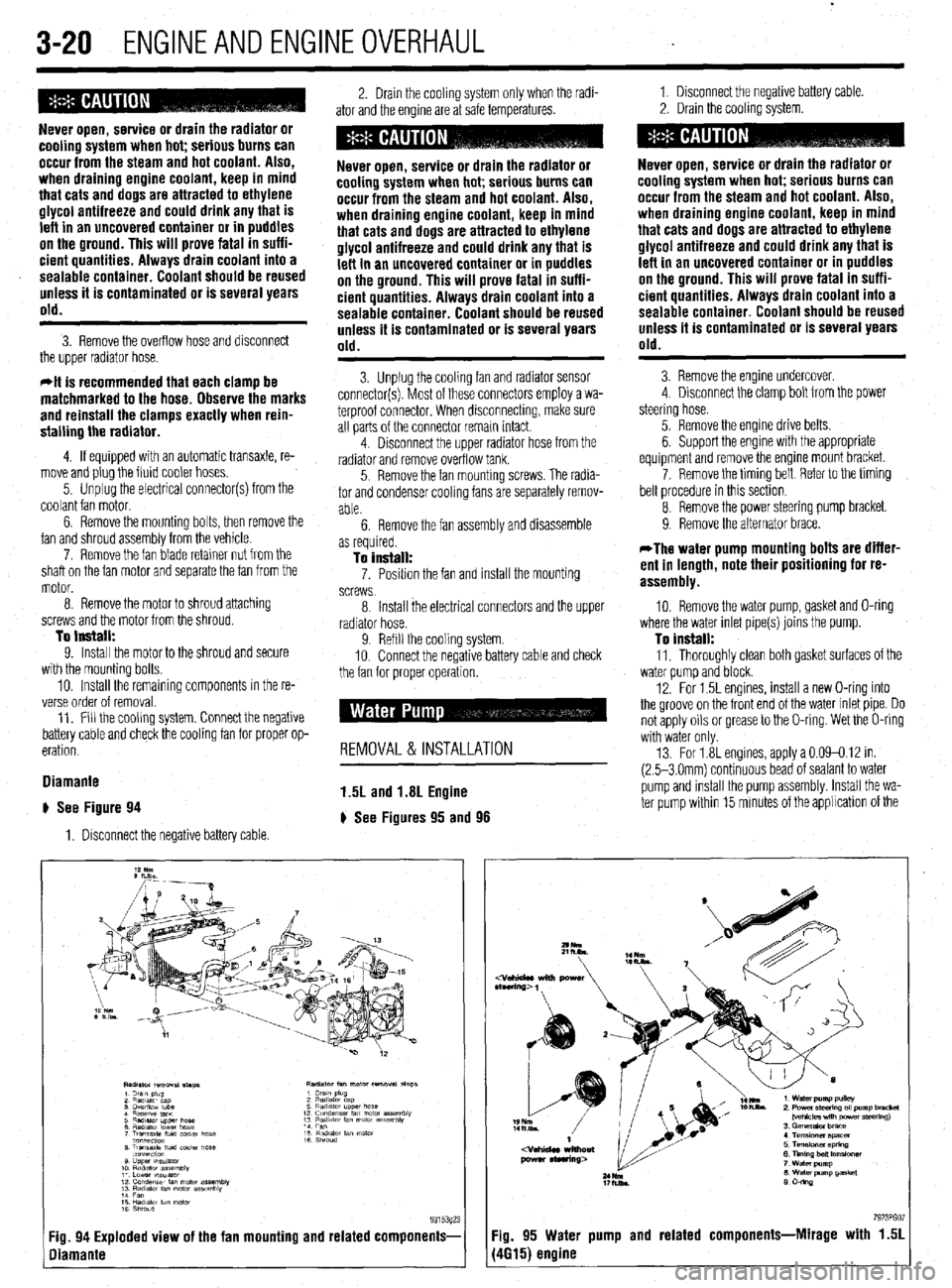

Diamante

# See Figure 94

1. Disconnect the negative battery cable 2. Drain the cooling system only when the radi-

ator and the engine are at safe temperatures. 1. Disconnect the negative battery cable

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Unplug the cooling fan and radiator sensor

connector(s). Most of these connectors employ a wa-

terproof connector. When disconnecting, make sure

all parts of the connector remain intact.

4. Disconnect the upper radiator hose from the

radiator and remove overflow tank.

5. Remove the fan mounting screws. The radia-

tor and condenser cooling fans are separately remov-

able.

6. Remove the fan assembly and disassemble

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4 Disconnect the clamp bolt from the power

steering hose.

5. Remove the engine drive belts.

6. Support the engine with the appropriate

equipment and remove the engine mount bracket.

7. Remove the timing belt Reier to the timing

belt procedure in this section

8 Remove the power steering pump bracket.

9. Remove the alternator brace.

as required.

To install: 7. Posrtion the fan and install the mounting

screws

*The water pump mounting bolts are differ-

ent in length, note their positioning for re-

assembly.

8 Install the electrical connectors and the upper

radiator hose.

9. Refill the cooling system.

IO. Connect the negative battery cable and check

the fan for orooer ooeration. 10. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install: 11, Thoroughly clean both gasket surfaces of the

water oumo and block.

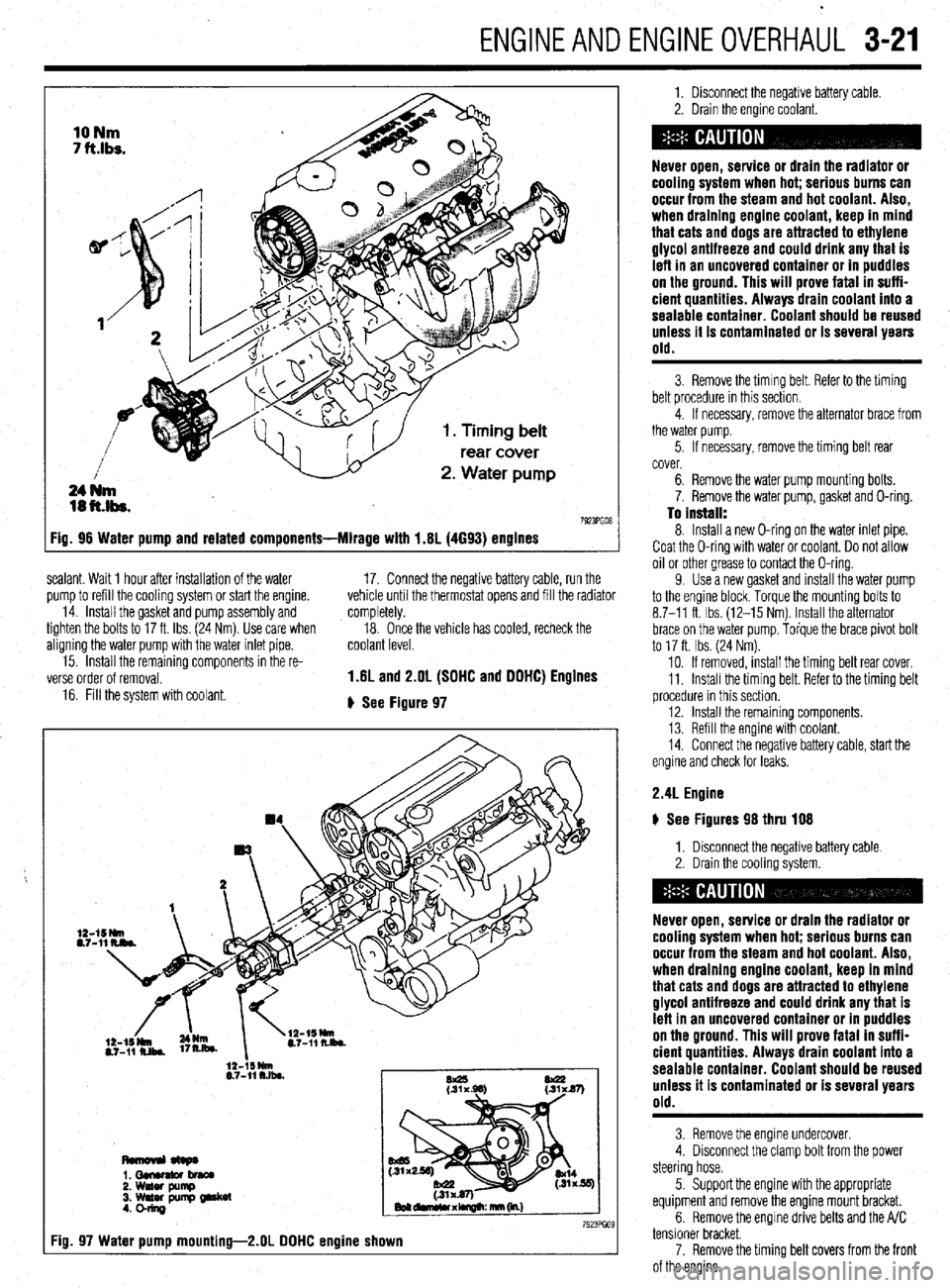

12. For 1.5L engines, install a new O-ring into

the groove on the front end of the water inlet pipe. Do

not apply oils or grease to the O-ring. Wet the O-ring

with water only

13. For 1.8L engines, apply a 0.09-0.12 in.

(2.5-3 Omm) continuous bead of sealant to water

pump and rnstall the pump assembly. Install the wa-

ter pump within 15 minutes of the applrcation of the

REMOVAL & INSTALLATION

1.5L and 1.8L Engine

) See Figures 95 and 98

7923PGO :ig. 94 Exploded view of the fan mounting and related components- Fig. 95 Water pump and related components-Mirage with 1.51

liamante (4615) engine

Page 82 of 408

ENGINEANDENGINEOVERHAUL 3-21

7923PG08

ealant. Wait 1 hour after installation of the water

pump to refill the cooling system or start the engine.

14. Install the gasket and pump assembly and

tighten the bolts to 17 ft. Ibs. (24 Nm). Use care when

aligning the water pump with the water inlet pipe.

15. Install the remaining components in the re-

verse order of removal.

16. Fill the system with coolant. 17. Connect the negative battery cable, run the

vehicle until the thermostat opens and fill the radiator

completely.

18. Once the vehicle has cooled, recheck the

coolant level.

1.6L and 2.OL (SOHC and OOHC) Engines

+ See Figure 97

Fig

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the timing belt. Refer to the timing

belt procedure in this section.

4. If necessary, remove the alternator brace from

the water pump.

5. If necessary, remove the timing belt rear

cover.

6. Remove the water pump mounting bolts.

7. Remove the water pump, gasket and O-ring.

To Install: 8. Install a new O-ring on the water inlet pipe.

Coat the O-ring with water or coolant. Do not allow

oil or other grease to contact the O-ring.

9. Use a new gasket and install the water pump

to the engine block Torque the mounting bolts to

8.7-11 ft. Ibs. (12-15 Nm). Install the alternator

brace on the water pump. Torque the brace pivot bolt

to 17 ft. Ibs. (24 Nm).

10. If removed, install the timing belt rear cover.

11. Install the timing belt. Refer to the timing belt

procedure in this section.

12. Install the remaining components.

13. Refill the engine with coolant.

14. Connect the negative battery cable, start the

engine and check for leaks.

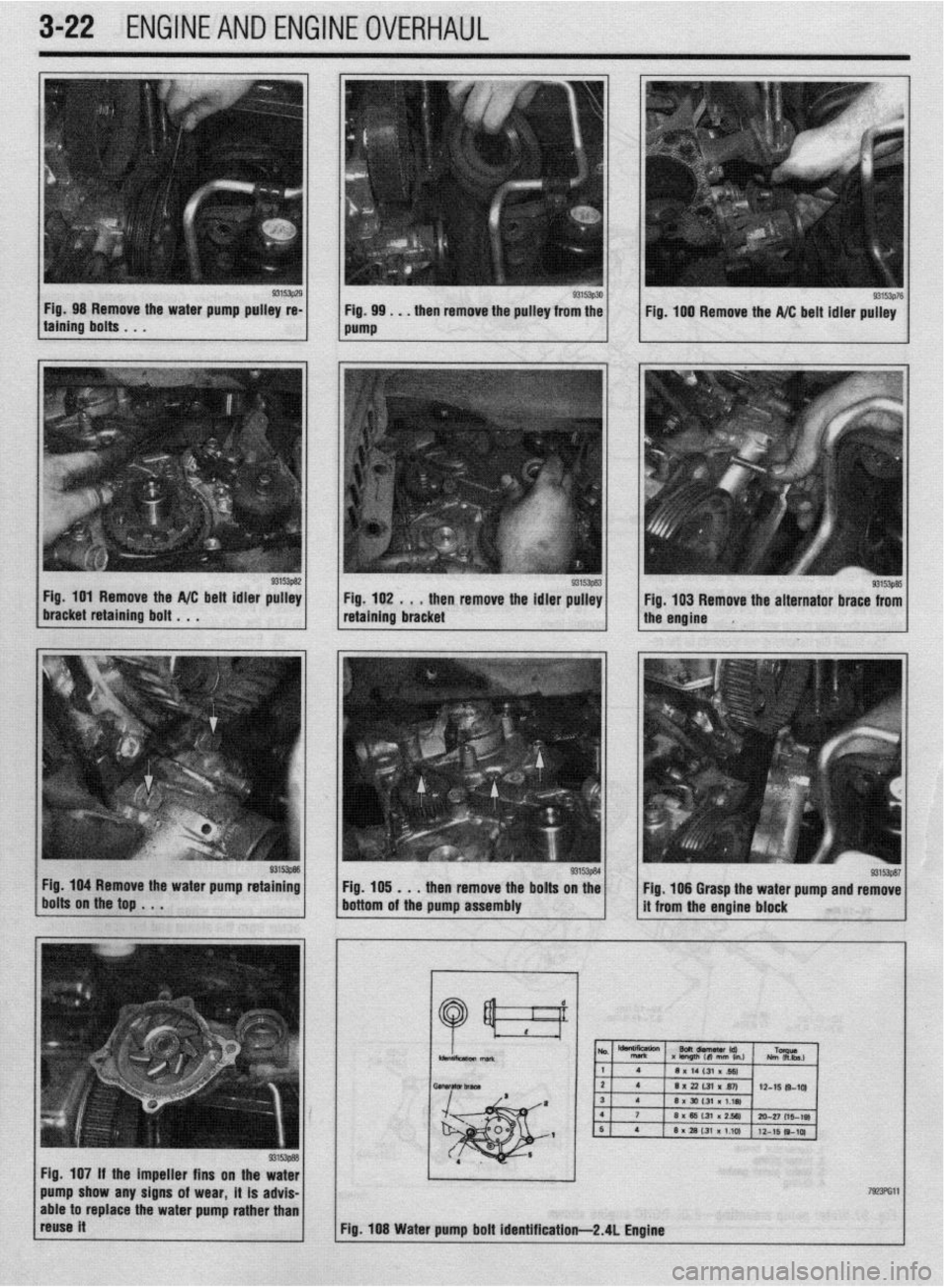

2.4L Engine

) See Figures 98 thru 108

1. Disconnect the negative battery cable

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4. Disconnect the clamp bolt from the power

steering hose.

5 Support the engine with the appropriate

equipment and remove the engine mount bracket.

6. Remove the engine drive belts and the A/C

tensioner bracket.

7. Remove the timing belt covers from the front

of the engine.

Page 83 of 408

3-22 ENGINEANDENGINEOVERHAUL

Fig. 98 Remove the wafer pump pulley re-

taining bolts ~ . .

Fig 101 Remove the A/C beit idler pulley

braEketretainingboit..., g3’a/ 93153p30 Fig. 99 . . . then remove the pulley from the

pump

931531183 Fig. 102 . . * then remove the idler pulley

retaining bracket

Fig. 104 Remove the water pump retaining

Fig. lfJ5 . . . then remove the bolts on the

bolts on the top . . .

bottom of the pump assembly

Fig. 107 if the impeller fins on the water

able to replace the water pump rather than

reuse it Fig. 100 Remove the A/C belt idler pulley

g. 103 Remove the alternator brace from

Fig. 108 Water pump bolt identification-2.41 Engine

Page 84 of 408

ENGlNEANDENGlNEOVERHAiL 3-23

8. Remove the camshaft and silent shaft timing

belts. Refer to the timing belt procedure in this sec-

tion

9. Remove the A/C belt idler pulley and pulley

bracket.

10. Remove the alternator brace,

11. Remove the water pump, gasket and O-ring

where the water inlet pipe(s) joins the pump.

To install:

12. Thoroughly clean both gasket surfaces of the

water pump and block.

13. Install a new O-ring into the groove on the

front end of the water inlet pipe and wet with clean

antifreeze only. Do not apply oils or grease to the O-

ring.

14. Using a new gasket, install the water pump

assembly. Tighten bolts with the head mark 4 to 10

ft Ibs. (14 Nm) and bolts with the head mark 7 to 18

ft. Ibs. (24 Nm).

15. Install the A/C pulley and pulley bracket,

16. Install the timing belts. Refer to the timing

belt procedure in this section.

17. Install the engine drive belts.

18. Install the engine mount bracket.

19. Install the engine undercover,

20. Fill the system with coolant.

21. Connect the negative battery cable, run the

vehicle until the thermostat opens and fill the radiator

completely.

22. Once the vehicle has cooled, recheck the

coolant level.

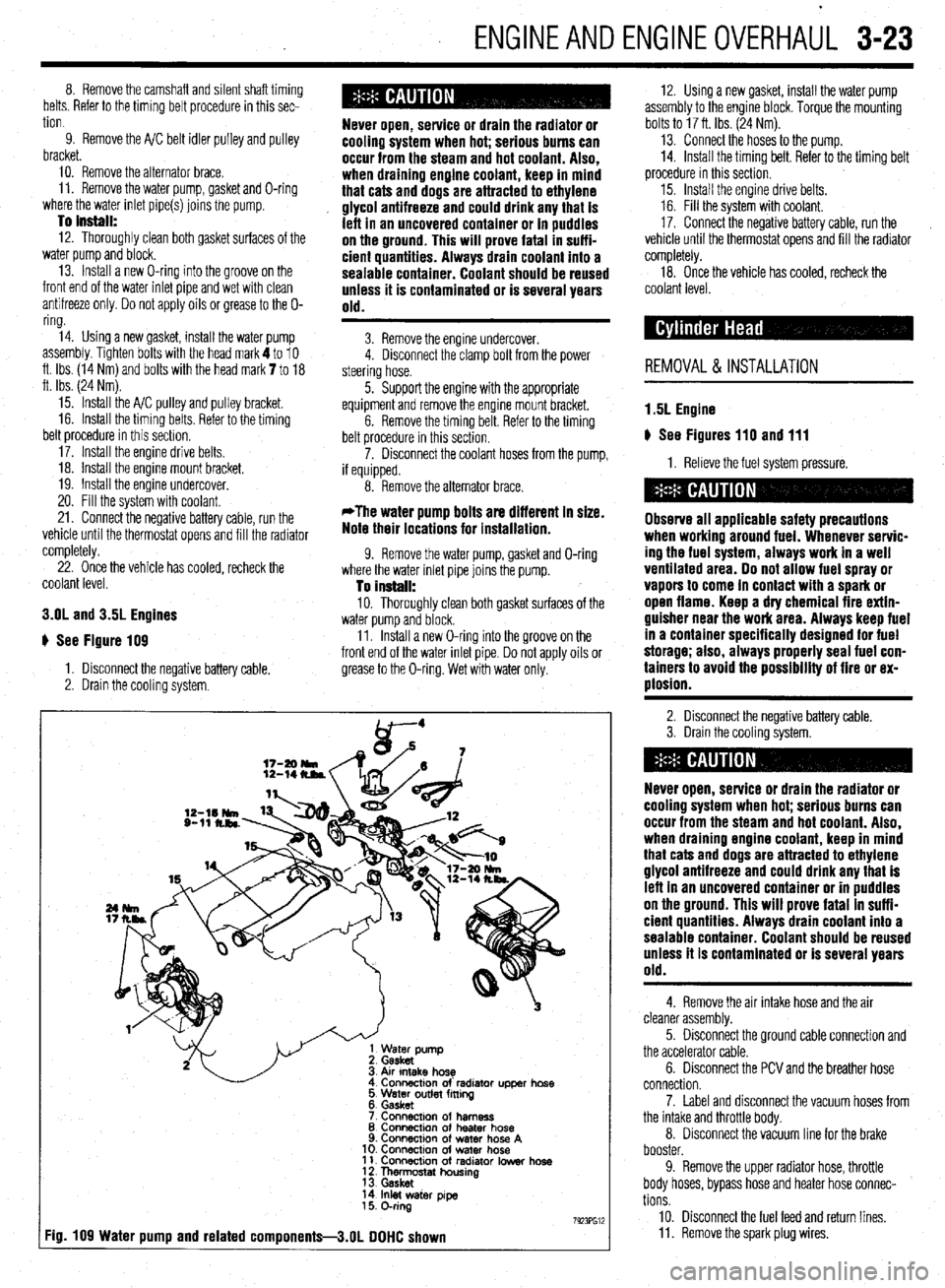

3.OL and 3.5L Engines

# See Figure 109

1. Disconnect the negative battery cable,

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the engine undercover.

4. Disconnect the clamp bolt from the power

steering hose.

5. Support the engine with the appropriate

equipment and remove the engine mount bracket.

6. Remove the timing belt. Refer to the timing

belt procedure in this section.

7. Disconnect the coolant hoses from the pump,

if equipped.

8. Remove the alternator brace.

*The water pump bolts are different in size.

Note their locations for installation.

9. Remove the water pump, gasket and O-ring

where the water inlet pipe joins the pump.

To install: 10. Thoroughly clean both gasket surfaces of the

water pump and block.

11. Install a new O-ring into the groove on the

front end of the water inlet pipe. Do not apply oils or

grease to the O-ring. Wet with water only.

Atr Intake hose

Connactlon of’ radlator upper hose

5 Water outlet fming

6. Gasket

7 Connacmn of harness

8 Connection of heater hose

9. Connection of water hose A

10. ConnectIon of water hose

11. Connection of radiator Iowar hose

1 f Thn&ostat housing

14 Inlet water pye

15 O-ring

7923Fw :ig. 109 Water pump and related components-3.01 DOHC shown

12. Using a new gasket, install the water pump

assembly to the engine block. Torque the mounting

bolts to 17 ft. Ibs. (24 Nm).

13. Connect the hoses to the pump.

14. Install the timing belt. Refer to the timing belt

procedure in this section.

15. Install the engine drive belts.

16. Fill the system with coolant.

17. Connect the negative battery cable, run the

vehicle until the thermostat opens and fill the radiator

completely.

18. Once the vehicle has cooled, recheck the

coolant level.

REMOVAL & INSTALLATION

1.5L Engine

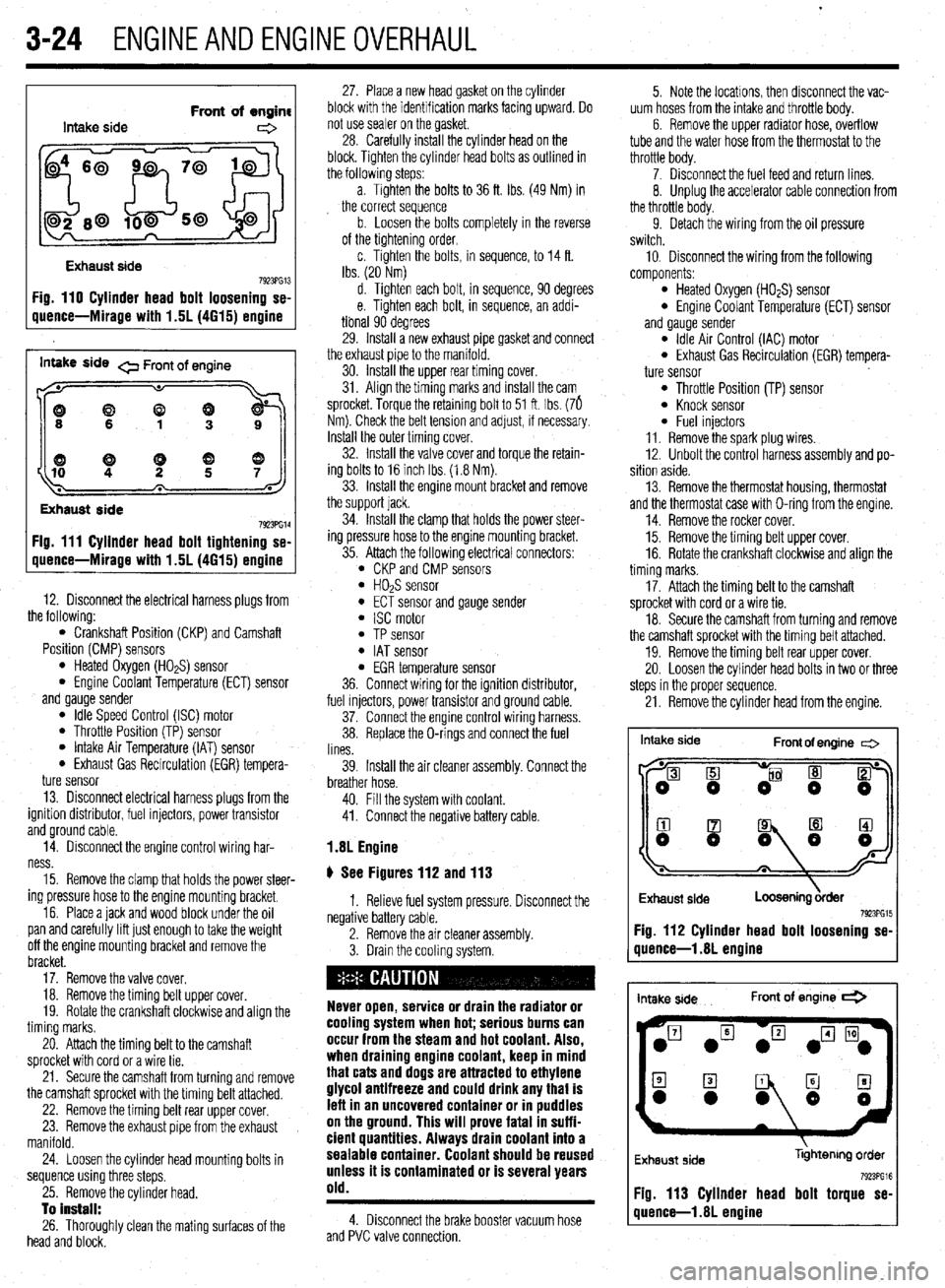

u See Figures 110 and 111

1. Relieve the fuel system pressure.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Remove the air intake hose and the air

cleaner assembly.

5. Disconnect the ground cable connection and

the accelerator cable.

6. Disconnect the PCV and the breather hose

connection.

7. Label and disconnect the vacuum hoses from

the intake and throttle body.

8. Disconnect the vacuum line for the brake

booster.

9. Remove the upper radiator hose, throttle

body hoses, bypass hose and heater hose connec-

tions

10. Disconnect the fuel feed and return lines.

11. Remove the spark plug wires.

Page 85 of 408

3-24 ENGINEANDENGINEOVERHAUL

Intake side Front of engine

e

Exhaust side

7923PG13 Fig. 110 Cylinder head bolt loosening se-

uuence-Mirage with 1.5L (4615) ermine

inwe side 0 Front of engine

((9

Exhaust side

7923PG14 Fig. 111 Cyllnder head bolt tightening se-

quence-Mirage with 1.5L (4615) engine

12. Disconnect the electrical harness plugs from

the following:

l Crankshaft Position (CKP) and Camshaft

Position (CMP) sensors

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Speed Control (ISC) motor l Throttle Position (TP) sensor l Intake Air Temperature (IAT) sensor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

13. Disconnect electrical harness plugs from the

ignition distributor, fuel injectors, power transistor

and ground cable.

14. Disconnect the engine control wiring har-

ness.

15. Remove the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

16. Place a jack and wood block under the oil

pan and carefully lift just enough to take the weight

off the engine mounting bracket and remove the

bracket.

17. Remove the valve cover.

18. Remove the timing belt upper cover.

19. Rotate the crankshaft clockwise and align the

timing marks.

20. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

21. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

22. Remove the timing belt rear upper cover.

23. Remove the exhaust pipe from the exhaust

manifold.

24. Loosen the cylinder head mounting bolts in

sequence using three steps.

25. Remove the cylinder head.

To install:

26. Thoroughly clean the mating surfaces of the

head and block. 27. Place a new head gasket on the cylinder

block with the identification marks facing upward. Do

not use sealer on the gasket.

28. Carefully install the cylinder head on the

block. Tighten the cylinder head bolts as outlined in

the followlng steps:

a. Tighten the bolts to 36 ft. Ibs. (49 Nm) in

the correct sequence

b. Loosen the bolts completely in the reverse

of the tightening order,

c. Tighten the bolts, in sequence, to 14 ft.

Ibs. (20 Nm)

d. Tighten each bolt, in sequence, 90 degrees

e. Tighten each bolt, in sequence, an addi-

tional 90 degrees

29. Install a new exhaust pipe gasket and connect

the exhaust pipe to the manifold.

30. Install the upper rear timing cover.

31. Align the timing marks and install the cam

sprocket. Torque the retaining bolt to 51 ft. Ibs. (76

Nm). Check the belt tension and adjust, if necessary.

Install the outer timing cover.

32. Install the valve cover and torque the retain-

ing bolts to 16 inch Ibs. (1.8 Nm).

33. Install the engine mount bracket and remove

the support jack.

34. Install the clamp that holds the power steer-

ing pressure hose to the engine mounting bracket.

35. Attach the following electrical connectors:

l CKP and CMP sensors l HOPS sensor l ECT sensor and gauge sender l ISC motor l TP sensor l IAT sensor l EGR temperature sensor

36. Connect wiring for the ignition distributor,

fuel injectors, power transistor and ground cable.

37. Connect the engine control wiring harness.

38. Replace the O-rings and connect the fuel

lines.

39. Install the air cleaner assembly. Connect the

breather hose.

40. Fill the system with coolant.

41. Connect the negative battery cable.

1.8L Engine

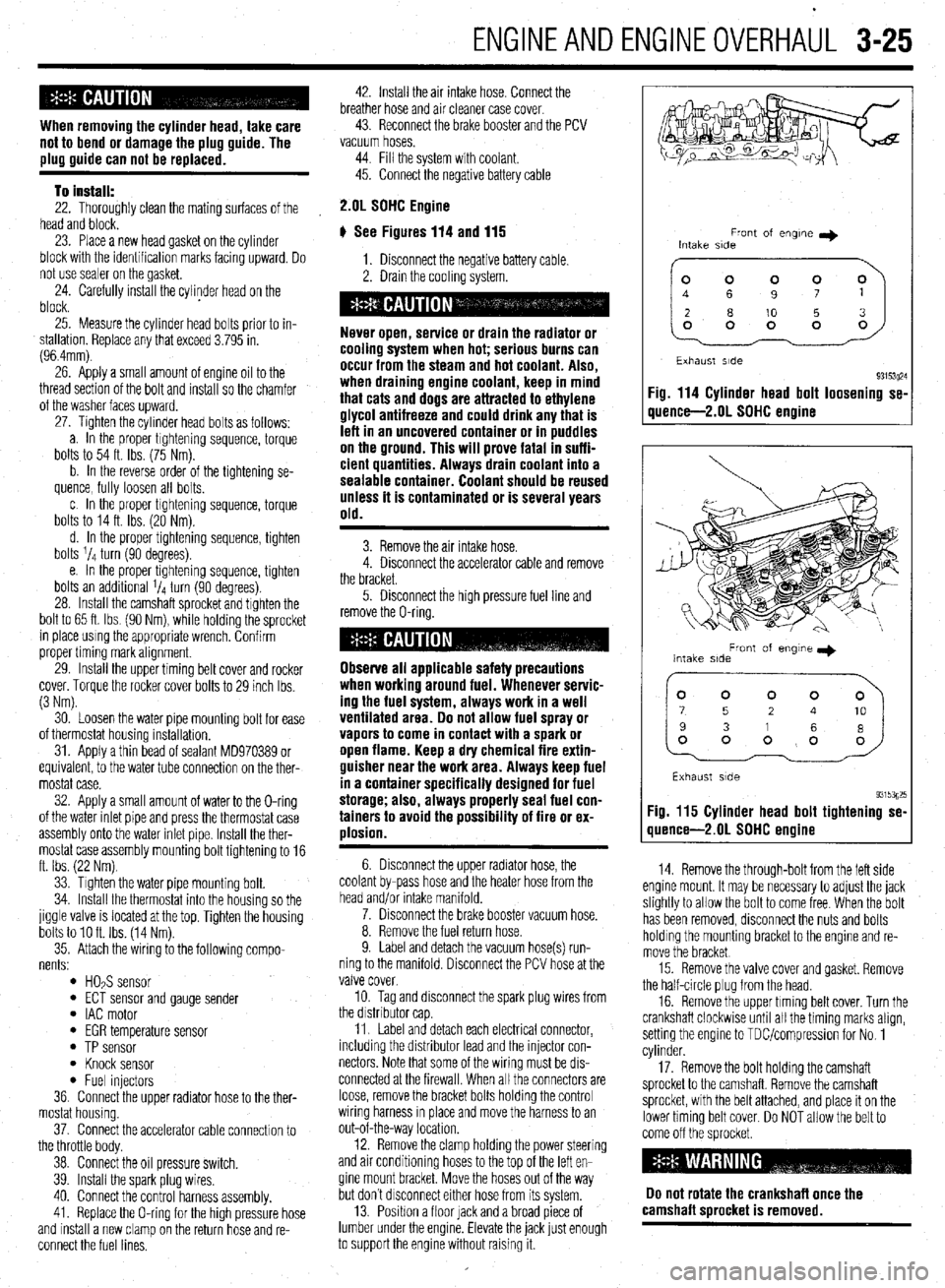

# See Figures 112 and 113

1. Relieve fuel system pressure. Disconnect the

negative battery cable.

2. Remove the air cleaner assembly.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

lefl in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the brake booster vacuum hose

and PVC valve connection. 5. Note the locations, then disconnect the vac-

uum hoses from the intake and throttle body.

6. Remove the upper radiator hose, overflow

tube and the water hose from the thermostat to the

throttle body.

7. Disconnect the fuel feed and return lines.

8. Unplug the accelerator cable connection from

the throttle body.

9. Detach the wiring from the oil pressure

switch.

10, Disconnect the wiring from the following

components:

l Heated Oxygen (HO*S) sensor l Engine Coolant Temperature (ECT) sensor

and gauge sender

l Idle Air Control (IAC) motor l Exhaust Gas Recirculation (EGR) tempera-

ture sensor

l Throttle Position (TP) sensor l Knock sensor l Fuel injectors

11. Remove the spark plug wires.

12. Unbolt the control harness assembly and po-

sition aside.

13. Remove the thermostat housing, thermostat

and the thermostat case with O-ring from the engine.

14. Remove the rocker cover.

15. Remove the timing belt upper cover.

16. Rotate the crankshaft clockwise and align the

timing marks.

17. Attach the timing belt to the camshaft

sprocket with cord or a wire tie.

18. Secure the camshaft from turning and remove

the camshaft sprocket with the timing belt attached.

19. Remove the timing belt rear upper cover.

20. Loosen the cylinder head bolts in two or three

steps in the proper sequence.

21. Remove the cylinder head from the engine.

Intake side

Front of engine c=>

I

Exhaust side

Loosening &der 7923PG15 Fig. 112 Cylinder head bolt loosening se-

quence-l .8L engine

intake side Front of engine *

Exhaust side libhtenng order

Fig. 113 Cylinder head bolt torque se-

quence-l .8L engine

Page 86 of 408

ENGINEANDENGINEOVERHAUL 3-25

When removina the cvlinder head. take care

not to bend or iamag;! the plug guide. The

plug guide can not be replaced.

To install:

22. Thoroughly clean the mating surfaces of the

head and block.

23. Place a new head gasket on the cylinder

block with the identification marks facing upward. Do

not use sealer on the gasket.

24. Carefully install the cylinder head on the

block.

25. Measure the cylinder head bolts prior to in-

stallation Replace any that exceed 3.795 in.

(96.4mm)

26. Apply a small amount of engine oil to the

thread section of the bolt and install so the chamfer

of the washer faces upward.

27. Tighten the cylinder head bolts as follows:

a. In the proper tightening sequence, torque

bolts to 54 ft. Ibs. (75 Nm).

b. In the reverse order of the tightening se-

quence, fully loosen all bolts.

c In the proper trghtening sequence, torque

bolts to 14 ft. Ibs. (20 Nm).

d. In the proper tightening sequence, tighten

bolts 1/4 turn (90 degrees).

e. In the proper tightening sequence, tighten

bolts an additional 1/4 turn (90 degrees).

28. Install the camshaft sprocket and tighten the

bolt to 65 ft. Ibs (90 Nm), while holding the sprocket

in place using the appropriate wrench. Confirm

proper timing mark alignment.

29. Install the upper timing belt cover and rocker

cover. Torque the rocker cover bolts to 29 inch Ibs.

(3 Nm).

30. Loosen the water pipe mounting bolt for ease

of thermostat housing installation.

31. Apply a thin bead of sealant MD970389 or

equivalent, to the water tube connection on the ther-

mostat case.

32. Apply a small amount of water to the O-ring

of the water inlet pipe and press the thermostat case

assembly onto the water inlet pipe. Install the ther-

mostat case assembly mounting bolt tightening to 16

ff. Ibs. (22 Nm).

l ECT sensor and gauge sender l IAC motor 33. Tighten the water pipe mounting bolt.

34. Install the thermostat into the housing so the

jiggle valve is located at the top. Tighten the housing

bolts to 10 ft. Ibs (14 Nm).

35. Attach the wiring to the following compo-

nents:

l HO& sensor

l EGR temperature sensor l TP sensor l Knock sensor l Fuel injectors

36. Connect the upper radiator hose to the ther-

mostat housing.

37. Connect the accelerator cable connection to

the throttle body.

38. Connect the oil pressure switch.

39. Install the spark plug wires,

40. Connect the control harness assembly.

41. Replace the O-ring for the high pressure hose

and install a new clamp on the return hose and re-

connect the fuel lines. 42. Install the air intake hose. Connect the

breather hose and air cleaner case cover

43. Reconnect the brake booster and the PCV

vacuum hoses.

44. Fill the system with coolant.

45. Connect the negative battery cable

2.01 SOHC Engine

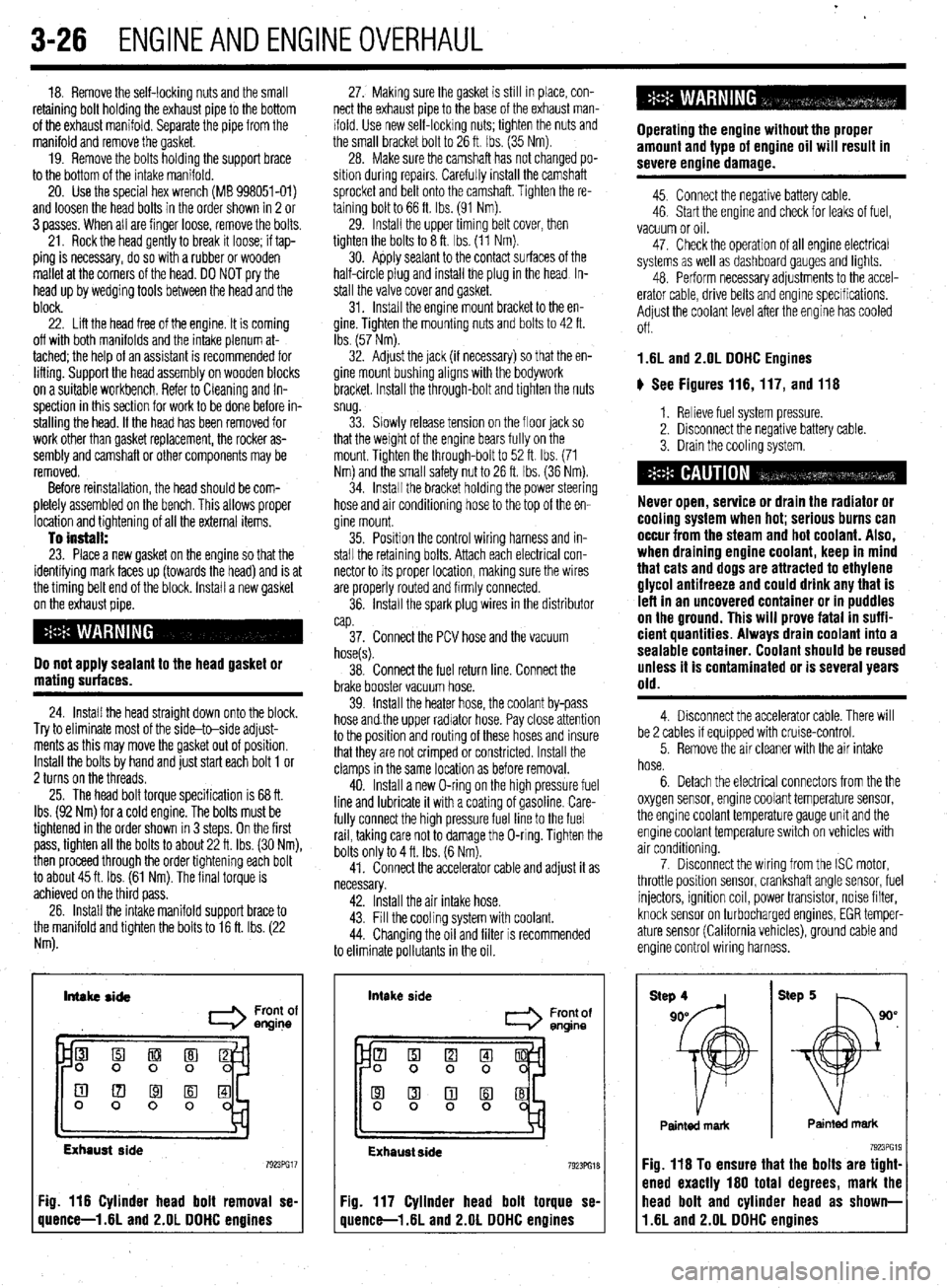

# See Figures 114 and 115

1. Disconnect the negative battery cable.

2. Drain the coolrng system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the air intake hose.

4. Disconnect the accelerator cable and remove

the bracket.

5. Disconnect the high pressure fuel line and

remove the O-ring.

Observe all applicable safety precautions

when working around fuel. Whenever servic-

ing the fuel system, always work in a well

ventilated area. Do not allow fuel spray or

vapors to come in contact with a spark or

open flame. Keep a dry chemical fire extin-

guisher near the work area. Always keep fuel

in a container specifically designed for fuel

storage; also, always properly seal fuel con-

tainers to avoid the possibility of fire or ex-

plosion.

6. Disconnect the upper radiator hose, the

coolant by-pass hose and the heater hose from the

head and/or intake manifold.

7. Disconnect the brake booster vacuum hose.

8. Remove the fuel return hose.

9. Label and detach the vacuum hose(s) run-

ning to the manifold. Disconnect the PCV hose at the

valve cover.

10. Tag and disconnect the spark plug wires from

the drstnbutor cap

11. Label and detach each electrical connector,

including the distributor lead and the injector con-

nectors Note that some of the wiring must be drs-

connected at the firewall. When all the connectors are

loose, remove the bracket bolts holding the control

wiring harness rn place and move the harness to an

out-of-the-way location.

12. Remove the clamp holding the power steering

and air conditioning hoses to the top of the left en-

gine mount bracket. Move the hoses out of the way

but don’t drsconnect either hose from its system.

13. Position a floor lack and a broad piece of

lumber under the engine. Elevate the jack lust enough

to support the engine without raising it.

Front of engne I)

Intake side

~~

Exhaust side

93153~24 Fig. 114 Cylinder head bolt loosening se-

quence-2.01 SOHC engine

Front of engme I)

Intake side

Exhaust side

93153g25 Fig. 115 Cylinder head bolt tightening se-

quence-2.01 SDHC engine

14. Remove the through-bolt from the left side

engine mount. It may be necessary to adjust the jack

slightly to allow the bolt to come free When the bolt

has been removed, disconnect the nuts and bolts

holding the mounting bracket to the engine and re-

move the bracket

15. Remove the valve cover and gasket. Remove

the half-circle plug from the head.

16. Remove the upper timing belt cover. Turn the

crankshaft clockwise until all the timing marks align,

setting the engine to TDUcompression for No. 1

cylinder.

17. Remove the bolt holding the camshaft

sprocket to the camshaft. Remove the camshaft

sprocket, with the belt attached, and place it on the

lower timing belt cover. Do NOT allow the belt to

come off the sprocket

Do not rotate the crankshaft once the

camshaft sorocket is removed.

Page 87 of 408

3-26 ENGINEANDENGINEOVERHAUL

18. Remove the self-locking nuts and the small

retaining bolt holding the exhaust pipe to the bottom

of the exhaust manifold. Separate the pipe from the

manifold and remove the gasket.

19. Remove the bolts holding the support brace

to the bottom of the intake manifold.

20. Use the special hex wrench (MB 998051-01)

and loosen the head bolts in the order shown in 2 or

3 passes. When all are finger loose, remove the bolts.

21. Rock the head gently to break it loose; if tap-

ping is necessary, do so with a rubber or wooden

mallet at the corners of the head. DO NOT pry the

head up by wedging tools between the head and the

block.

22. Lift the head free of the engine. It is coming

off with both manifolds and the intake plenum at-

tached; the help of an assistant is recommended for

lifting. Support the head assembly on wooden blocks

on a suitable workbench. Refer to Cleaning and In-

spection in this section for work to be done before in-

stalling the head. If the head has been removed for

work other than gasket replacement, the rocker as-

sembly and camshaft or other components may be

removed.

Before reinstallation, the head should be com-

pletely assembled on the bench. This allows proper

location and tightening of all the external items.

To install: 23. Place a new gasket on the engine so that the

identifying mark faces up (towards the head) and is at

the timing belt end of the block. Install a new gasket

on the exhaust pipe.

Do not apply sealant to the head gasket or

mating surfaces.

24. Install the head straight down onto the block.

Try to eliminate most of the side-to-side adjust-

ments as this may move the gasket out of position.

Install the bolts by hand and just start each bolt 1 or

2 turns on the threads.

25. The head bolt torque specification is 68 ft.

Ibs. (92 Nm) for a cold engine. The bolts must be

tightened in the order shown in 3 steps. On the first

pass, tighten all the bolts to about 22 ft. Ibs. (30 Nm),

then proceed through the order tightening each bolt

to about 45 ft. Ibs. (61 Nm). The final torque is

achieved on the third pass.

26. Install the intake manifold support brace to

the manifold and tighten the bolts to 16 ft. Ibs. (22

Nm). 27. Making sure the gasket is still in place, con-

nect the exhaust pipe to the base of the exhaust man-

ifold. Use new self-locking nuts; tighten the nuts and

the small bracket bolt to 26 ft. Ibs. (35 Nm).

28. Make sure the camshaft has not changed po-

sition during repalrs. Carefully install the camshaft

sprocket and belt onto the camshaft. Tighten the re-

taining bolt to 66 ft. Ibs. (91 Nm).

29. Install the upper timing belt cover, then

tighten the bolts to 8 ft. Ibs. (11 Nm).

30. Apply sealant to the contact surfaces of the

half-circle plug and install the plug in the head In-

stall the valve cover and gasket.

31. Install the engine mount bracket to the en-

gine. Tighten the mounting nuts and bolts to 42 ft.

Ibs. (57 Nm).

32. Adjust the jack (if necessary) so that the en-

gine mount bushing aligns with the bodywork

bracket. Install the through-bolt and tighten the nuts

snug.

33. Slowly release tension on the floor jack so

that the weight of the engine bears fully on the

mount. Tighten the through-bolt to 52 ft. Ibs. (71

Nm) and the small safety nut to 26 ft. tbs. (36 Nm).

34. Install the bracket holding the power steering

hose and air conditioning hose to the top of the en-

gine mount.

35. Position the control wiring harness and in-

stall the retaining bolts. Attach each electrical con-

nector to its proper location, making sure the wires

are properly routed and firmly connected.

36. Install the spark plug wires in the distributor

cap.

37. Connect the PCV hose and the vacuum

hose(s).

38. Connect the fuel return line. Connect the

brake booster vacuum hose.

39. Install the heater hose, the coolant by-pass

hose and.the upper radiator hose. Pay close attention

to the position and routing of these hoses and insure

that they are not crimped or constricted. Install the

clamps in the same location as before removal.

40. Install a new O-ring on the high pressure fuel

line and lubricate it with a coating of gasoline. Care-

fully connect the high pressure fuel line to the fuel

rail, taking care not to damage the O-ring. Tighten the

bolts only to 4 ft. Ibs. (6 Nm).

41. Connect the accelerator cable and adjust it as

necessary.

42. Install the air intake hose.

43. Fill the cooling system with coolant.

44. Changing the oil and filter is recommended

to eliminate pollutants in the oil.

Intake side

I Front of

engine

Exhaust side

Fig. 116 Cylinder head bolt removal se-

quence-l .6L and 2.OL DDHC engines intake

side

Front of

entine

Exhaust side 7923PG18

Fig. 117 Cylinder head bolt torque se-

quence-l .6L and 2.OL DDHC engines Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

45. Connect the negative battery cable.

46. Start the engine and check for leaks of fuel,

vacuum or oil.

47. Check the operation of all engine electrical

systems as well as dashboard gauges and lights.

48. Perform necessary adjustments to the accel-

erator cable, drive belts and engine specifications.

Adjust the coolant level after the engine has cooled

Off.

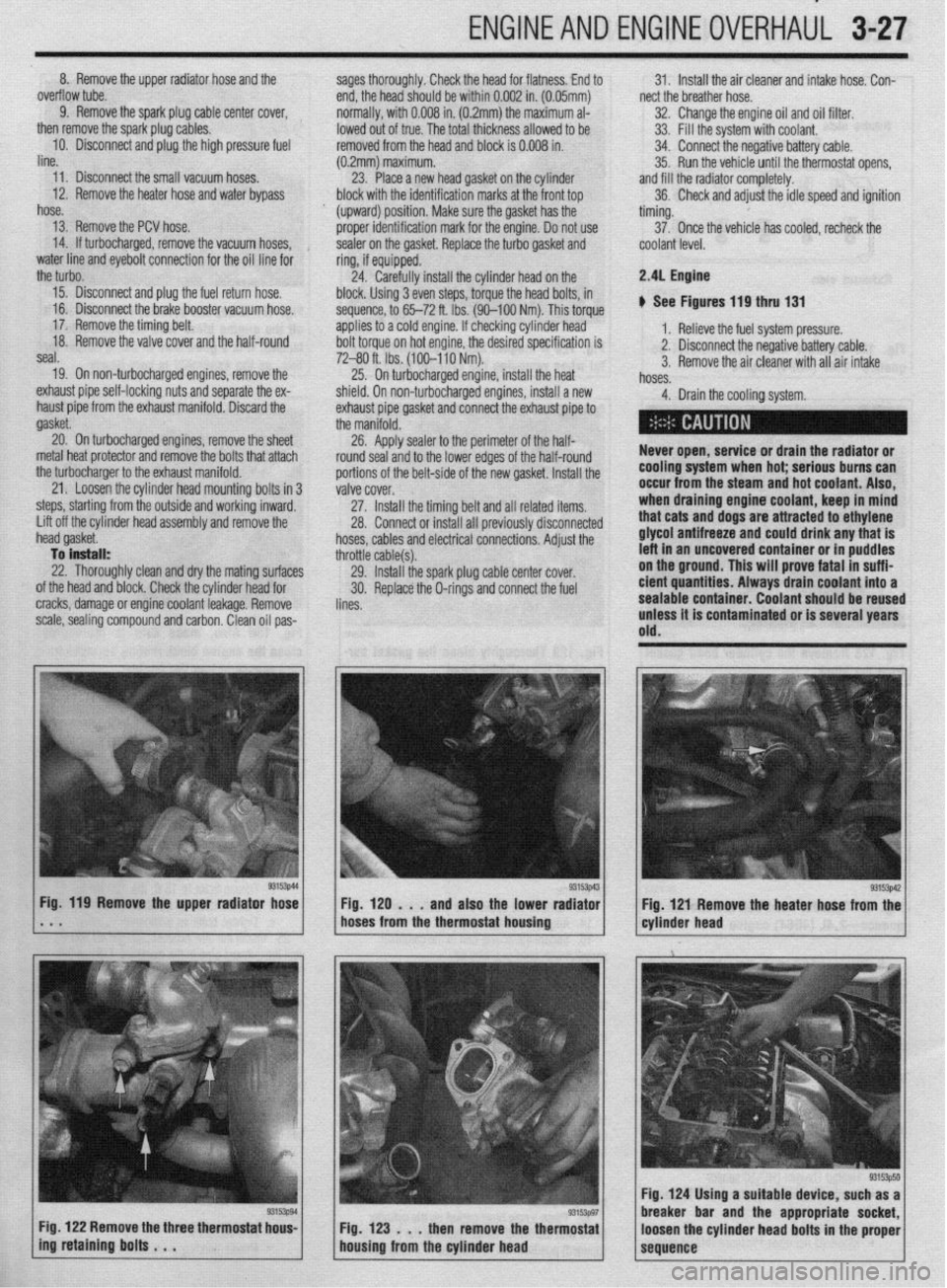

1.6L and 2.OL DDHC Engines

ti See Figures 116,117, and 116

1. Relieve fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

4. Disconnect the accelerator cable. There will

be 2 cables if equipped with cruise-control.

5. Remove the air cleaner with the air intake

hose.

6. Detach the electrical connectors from the the

oxygen sensor, engine coolant temperature sensor,

the engine coolant temperature gauge unit and the

engine coolant temperature switch on vehicles with

air conditioning.

7. Disconnect the wiring from the ISC motor,

throttle position sensor, crankshaft angle sensor, fuel

injectors, ignition coil, power transistor, noise filter,

knock sensor on turbocharged engines, EGR temper-

ature sensor (California vehicles), ground cable and

engine control wiring harness.

Painted mark Painted mark

Fig. 116 To ensure that the bolts are tight-

ened exactly 160 total degrees, mark the

11.6L and 2.OL DDHC engines head bolt and cylinder head as shown-

Page 88 of 408

ENGlNEANDENGlNEOVERHALiL 3-27

8. Remove the upper radiator hose and the

sages thoroughly. Check the head for flatness. End to 31. Install the air cleaner and intake hose. Con-

overflow tube. end, the head should be within 0.002 in. (0.05mm) nect the breather hose.

9. Remove the spark plug cable center cover,

normally, with 0.008 in. (0.2mm) the maximum al- 32. Change the engine oil and oil filter,

then remove the spark plug cables.

lowed out of true. The total thickness allowed to be 33. Fill the system with coolant.

10. Disconnect and plug the high pressure fuel

removed from the head and block is 0.008 in.

line. 34. Connect the negative battery cable.

(0.2mm) maximum. 35. Run the vehicle until the thermostat opens,

11. Disconnect the small vacuum hoses.

23. Place a new head gasket on the cylinder and fill the radiator completely.

12. Remove the heater hose and water bypass

block with the identification marks at the front top 36. Check and adjust the idle speed and ignition

hose.

(upward) position. Make sure the gasket has the timing.

13. Remove the PCV hose.

proper identification mark for the engine. Do not use 37. Once the vehicle has cooled, recheck the

14. If turbocharged, remove the vacuum hoses,

sealer on the gasket. Replace the turbo gasket and coolant level.

water line and eyebolt connection for the oil line for

ring, if equipped.

the turbo.

24. Carefully install the cylinder head on the 2.41 Engine

15. Disconnect and plug the fuel return hose. block. Using 3 even steps, torque the head bolts, in

16. Disconnect the brake booster vacuum hose.

sequence, to 65-72 ft. Ibs. (90-100 Nm). This torque b See Figures 119 thru 131

17. Remove the timing belt. applies to a cold engine. If checking cylinder head

18. Remove the valve cover and the half-round

bolt torque on hot engine, the desired specification is 1. Relieve the fuel system pressure.

seal.

7240 ft. Ibs. (100-110 Nm). 2. Disconnect the negative battery cable.

19. On non-turbocharged engines, remove the 3. Remove the air cleaner with all air intake

25. On turbocharged engine, install the heat

hoses.

exhaust pipe self-locking nuts and separate the ex-

shield. On non-turbocharged engines, install a new

haust pipe from the exhaust manifold. Discard the

exhaust pipe gasket and connect the exhaust pipe to 4. Drain the cooling system.

gasket.

the manifold.

20. On turbocharged engines, remove the sheet

26. Apply sealer to the perimeter of the half-

metal heat protector and remove the bolts that attach

round seal and to the lower edges of the half-round Never open, service or drain the radiator or

the turbocharger to the exhaust manifold.

portions of the belt-side of the new gasket. Install the cooling system when hot; serious burns can

21. Loosen the cylinder head mounting bolts in 3

valve cover. occur from the steam and hot coolant. Also,

steps, starting from the outside and working inward,

27. Install the timing belt and all related items. when draining engine coolant, keep in mind

Lift off the cylinder head assembly and remove the

28. Connect or install all previously disconnected that cats and dogs are attracted to ethylene

n head gasket.

hoses, cables and electrical connections. Adjust the glycol antifreeze and could drink any that is

To install:

throttle cable(s). left in an uncovered container or in puddles

22. Thoroughly clean and dry the mating surfaces

29. Install the spark plug cable center cover. on the ground. This will prove fatal in suffi-

of the head and block. Check the cylinder head for

30. Replace the O-rings and connect the fuel eient quantities. Always drain coolant into a

cracks, damage or engine coolant leakage. Remove

lines. sealable container. Coolant should be reused

scale, sealing compound and carbon. Clean oil pas- unless it is contaminated or is several years

old.

g3153p44 Fig. 119 Remove the upper radiator hose

* . . 1 Fig. 129 . . . and also the lower rad:gzi / cyl.der head g3153W

Fig 121 Remove the heater hose from the

hoses from the thermostat housing

Fig. 122 Remove the three thermostat hous-

Fig. 123 . . . then remove the thermostat

ing retaining bolts . . .

housing from the cylinder head

93153p50 Fig. 124 Using a suitable device, such as a

breaker bar and the appropriate socket,

loosen the cylinder head bolts in the proper

sequence

Page 89 of 408

3-28 ENGINEANDENGINEOVERHAUL

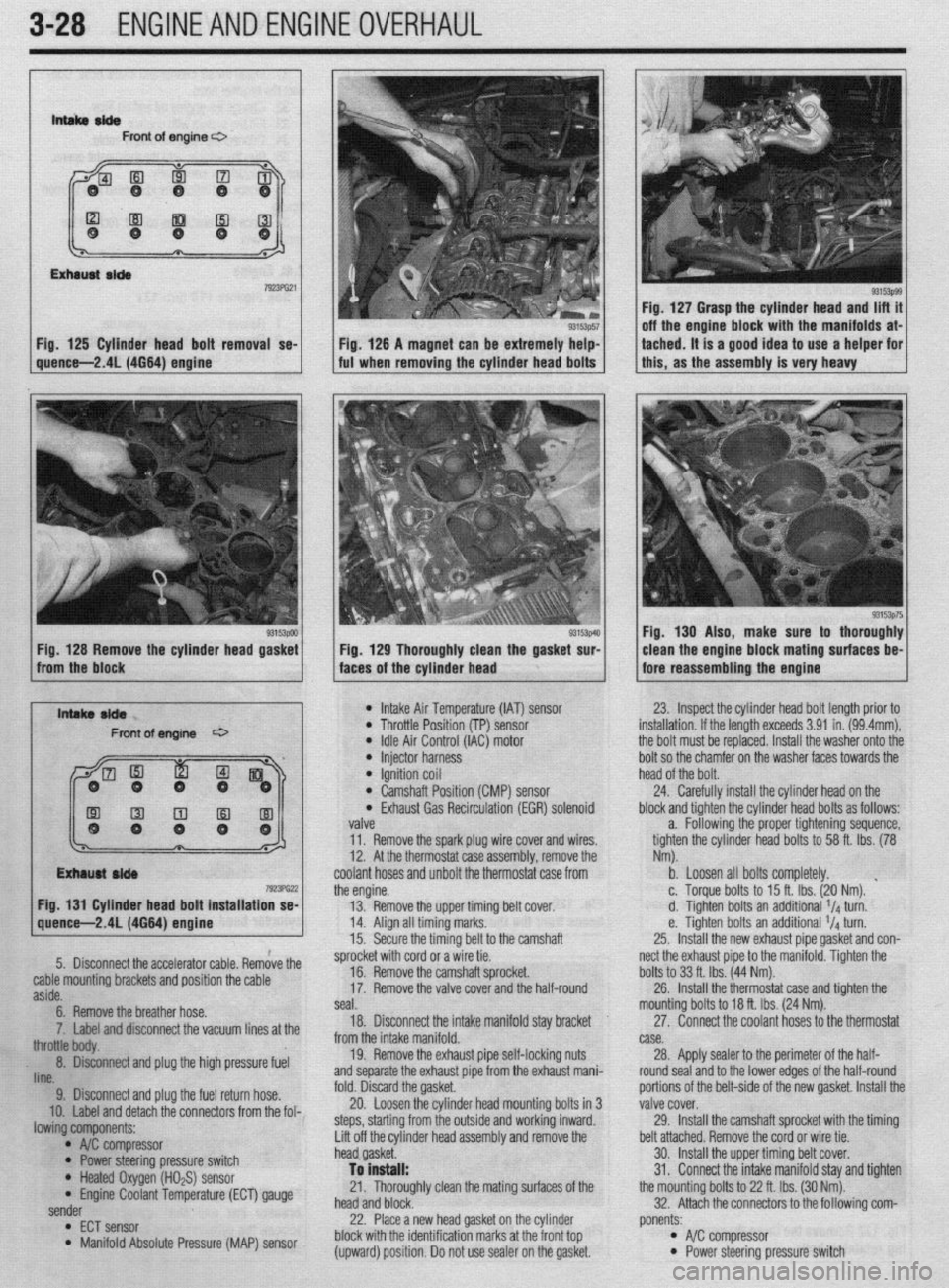

lntsltaelde Front of engine c3

Fig. 125 Cylinder head bolt removal se- Fig. 127 Grasp the cylinder head and lift it

off the engine block with the manifolds at-

ig. 126 A magnet can be extremely help- tached. It is a good idea to use a helper for

quence-2.41(4664) engine I ful when removing the cylinder head bolts 1 1 this, as the assembly is very heavy

93153pOO Fig. 128 Remove the cylinder head gasket 33153p4!3 Fig, 129 Thoroughly clean the gasket sur- Fig. 130 Also, make sure to thoroughly

clean the engine block mating surfaces be-

from the block

faces of the cylinder head fore reassembling the engine

l Intake Air Temperature (IAT) sensor l Throttle Position (TP) sensor

: /I;%;,; rZ;Z;;(lAC) motor 23. Inspect the cylinder head bolt length prior to

installation. If the length exceeds 3.91 in. (99.4mm),

the bolt must be replaced. Install the washer onto the

bolt so the chamfer on the washer faces towards the

l Ignition coil head of the bolt. l Camshaft Position (CMP) sensor 24. Carefully install the cylinder head on the l Exhaust Gas Recirculation (EGR) solenoid block and tighten the cylinder head bolts as follows:

valve a. Following the proper tightening sequence,

11. Remove the spark plug wire cover and wires. tighten the cylinder head bolts to 58 ft. Ibs. (78

12. At the thermostat case assembly, remove the Nm).

coolant hoses and unbolt the thermostat case from b. Loosen all bolts completely.

the engine. c. Torque bolts to 15 ft. Ibs. (20 Nm). ’

Fig. 131 Cylinder head bolt installation se-

13. Remove the upper timing belt cover d. Tighten bolts an additional 1/4 turn.

14. Align all timing marks. e. Tighten bolts an additional 1/4 turn.

15. Secure the timina belt to the camshaft 25. Install the new exhaust pipe aasket and con-

iliiL.-

5.

9. Disconnect and plug the fuel return hose. Disconnect the accelerator cable. Remove the

cable mounting brackets and position the cable

10. Label and detach the connectors from the fol- aside.

lowing components: 6. Remove the breather hose.

* A$ compressor

* Power steering pressure switch ‘7. Label and disconnect the vacuum lines at the

* Heated Oxygen (HO$) sensor tree body.

* Engine Coolant Temperature (ECT) gauge . 8. D&connect and plug the high pressure fuel

sender

lint3

l

ECT sensor l Manifold Absolute Pressure (MAP) sensor sprocket with cord or a wire tie.

fold. Discard the gasket, 16. Remove the camshaft sprocket.

20. Loosen the cylinder head mounting bolts in 3 17.

steps, starting from the outside and working inward. Remove the valve cover and the half-round

seal.

Lift off the cylinder head assembly and remove the 18. Disconnect the intake manifold stay bracket

head gasket.

To install: from the intake manifold.

21. Thoroughly clean the mating surfaces of the 19. Remove the exhaust pipe self-locking nuts

head and block. and separate the exhaust pipe from the exhaust mani-

22. Place a new head gasket on the cylinder

block with the identification marks at the front top

(upward) position. Do not use sealer on the gasket. nect the exhaust pipe to the manifold. Tighten the

portions of the belt-side of the new gasket. Install thr bolts to 33 ft. Ibs. (44 Nm).

valve cover. 26.

29. Install the thermostat case and tighten the

Install the camshaft sprocket with the timing mounting bolts to 18 ft. Ibs. (24 Nm).

belt attached. Remove the cord or wire tie.

30. Install the upper timing belt cover. 27. Connect the coolant hoses to the thermostat

31. Connect the intake manifold stay and tighten case.

the mounting bolts to 22 ft. Ibs. (30 Nm). 28.

32. Attach the connectors to the following com- Apply sealer to the perimeter of the half-

round seal and to the lower edges of the half-round

ponents: l A/C compressor l Power steering pressure switch

Page 90 of 408

ENGINEANDENGINEOVERHAUL 3-29

l HOzS sensor l ECT gauge sender l ECT sensor l MAP sensor l IAT sensor l TP sensor l IAC motor l injector harness l ignition coil l CMP sensor l EGR solenoid valve

33. Install the spark plug wires and cover,

34. Replace the O-rings and connect the fuel

lines.

35. Install the air cleaner and intake hose. Con-

nect the breather hose.

36. Fill the cooling system.

37. Connect the negative battery cable

3.01 DDHC Engine

ti See Figures 132 and 133

1. Relieve fuel system pressure. Disconnect the

negative battery cable.

2. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantltles. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the air intake hoses.

4. Remove air intake plenum and intake mani-

fold.

5. Remove the exhaust manifold.

6. Remove the timing belt. Refer to the timing

belt procedure in this section.

7. Remove the breather hose.

8. Remove the spark plug wire center cover and

remove the spark plug wires.

9. Remove the rocker covers.

10. Remove the intake camshaft sprockets.

11. Remove the rear timing belt cover.

12. Remove the ignition coil assembly.

13. Disconnect all water hoses from the thermo-

stat housing and remove the housing.

14. Disconnect the water inlet from the front

head.

15. Loosen the cylinder head mounting bolts in

the reverse of the torque sequence and loosen the

bolts in three steps. Lift off the cylinder head assem-

bly and remove the head gasket.

To install: 16. Thoroughly clean the sealing surfaces of the

head and block.

17. Place a new head gasket on the cylinder

block with the identification marks in the front top

(upward) position. Do not use sealer on the gasket,

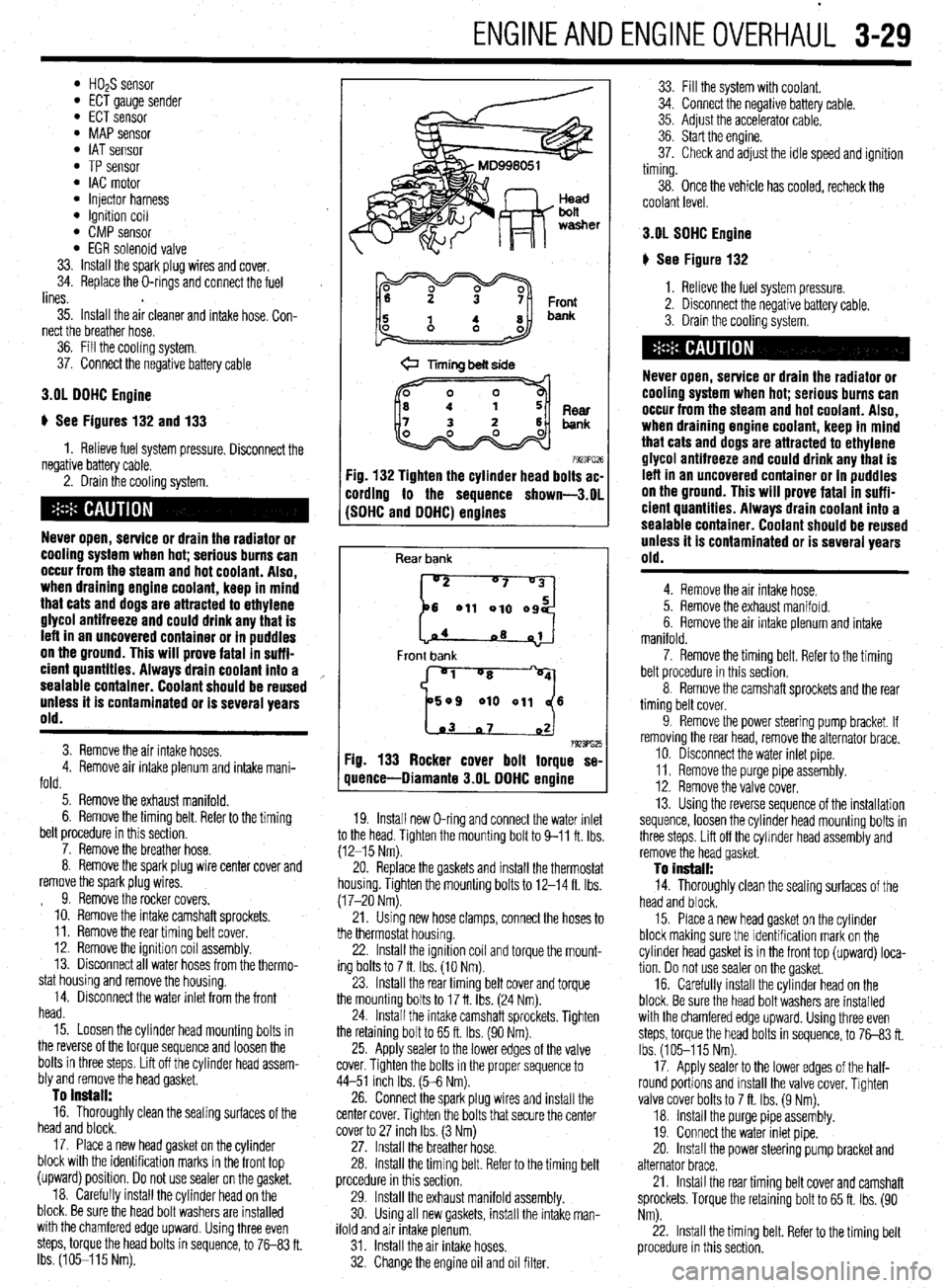

18. Carefully install the cylinder head on the

block. Be sure the head bolt washers are installed

with the chamfered edge upward. Using three even

steps, torque the head bolts in sequence, to 76-83 ft.

Ibs. (105-115 Nm).

@ Timing belt side

7923PG26 :ig. 132 Tighten the cylinder head bolts ac-

:ording to the sequence shown-3.01

SDHC and DDHC) engines

Rear bank

[::od

04

~8 01

Front bank

'1 "8

509 010 011 6

1.03 07 02 7923ffi25 Fig. 133 Rocker cover bolt torque se-

quence-Diamante 3.OL DDHC engine

19. Install new O-ring and connect the water inlet

to the head. Tighten the mounting bolt to 9-11 ft. Ibs

(12-15 Nm).

20. Replace the gaskets and install the thermostat

housing. Tighten the mounting bolts to 12-14 ft. Ibs.

(17-20 Nm).

21. Using new hose clamps, connect the hoses to

the thermostat housing.

22. Install the Ignition coil and torque the mount-

ing bolts to 7 ft. Ibs. (10 Nm).

23. Install the rear timing belt cover and torque

the mounting bolts to 17 ft. Ibs. (24 Nm).

24. Install the intake camshaft sprockets. Tighten

the retaining bolt to 65 ft. Ibs. (90 Nm).

25. Apply sealer to the lower edges of the valve

cover. Tighten the bolts in the proper sequence to

44-51 inch Ibs. (5-6 Nm).

26. Connect the spark plug wires and install the

center cover. Tighten the bolts that secure the center

cover to 27 inch Ibs. (3 Nm)

27. Install the breather hose.

28. Install the timing belt. Refer to the timing belt

procedure in this section,

29. Install the exhaust manifold assembly.

30. Using all new gaskets, install the intake man-

ifold and air intake plenum.

31. Install the air intake hoses.

32. Change the engine oil and oil filter. 33. Fill the system wrth coolant.

34. Connect the negabve battery cable.

35. Adjust the accelerator cable.

36. Start the engine.

37. Check and adjust the idle speed and ignition

timing.

38. Once the vehicle has cooled, recheck the

coolant level.

3.OL SDHC Engine

# See Figure 132

1. Relieve the fuel system pressure.

2. Disconnect the negative battery cable.

3. Drain the cooling system.

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

alvcol antifreeze and could drink any that is

Left in an uncovered container or in puddles

on the ground. This will Drove fatal in suff i-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

Unless it is Contaminated or is several years

old.

4. Remove the air intake hose.

5. Remove the exhaust manifold.

6. Remove the air intake plenum and intake

manifold.

7. Remove the timing belt. Refer to the timing

belt procedure in this section.

8. Remove the camshaft sprockets and the rear

timing belt cover.

9. Remove the power steering pump bracket. If

removing the rear head, remove the alternator brace.

10. Disconnect the water inlet pipe.

11. Remove the purge pipe assembly.

12. Remove the valve cover,

13. Using the reverse sequence of the installation

sequence, loosen the cylinder head mounting bolts in

three steps. Lift off the cylmder head assembly and

remove the head gasket.

To install: 14. Thoroughly clean the sealing surfaces of the

head and block.

15. Place a new head gasket on the cylinder

block making sure the identification mark on the

cylrnder head gasket is in the front top (upward) loca-

tion. Do not use sealer on the gasket,

16. Carefully install the cylinder head on the

block. Be sure the head bolt washers are installed

with the chamfered edge upward. Using three even

steps, torque the head bolts in sequence, to 7683 ft.

Ibs. (105-115 Nm).

17. Apply sealer to the lower edges of the half-

round portions and install the valve cover. Tighten

valve cover bolts to 7 ft. Ibs. (9 Nm).

18. Install the purge pipe assembly.

19. Connect the water inlet pipe.

20. Install the power steering pump bracket and

alternator brace.

21. Install the rear timing belt cover and camshaft

sprockets. Torque the retaining bolt to 65 ft. Ibs. (90

Nm).

22. Install the timing belt. Refer to the timing belt

procedure in this section.