MITSUBISHI DIAMANTE 1900 Owners Manual

Manufacturer: MITSUBISHI, Model Year: 1900, Model line: DIAMANTE, Model: MITSUBISHI DIAMANTE 1900Pages: 408, PDF Size: 71.03 MB

Page 91 of 408

.

3-30 ENGINEANDENGINEOVERHAUL

23. Using all new gaskets, install the intake man-

ifold, air intake plenum and exhaust manifold.

24. Install the air intake hose.

25. Fill the system with coolant.

26. Connect the negative battery cable.

27. Start the engine.

28. Check and adjust the idle speed and ignition

timing.

29. Once the vehicle has cooled, recheck the

coolant level.

3.51 Engine

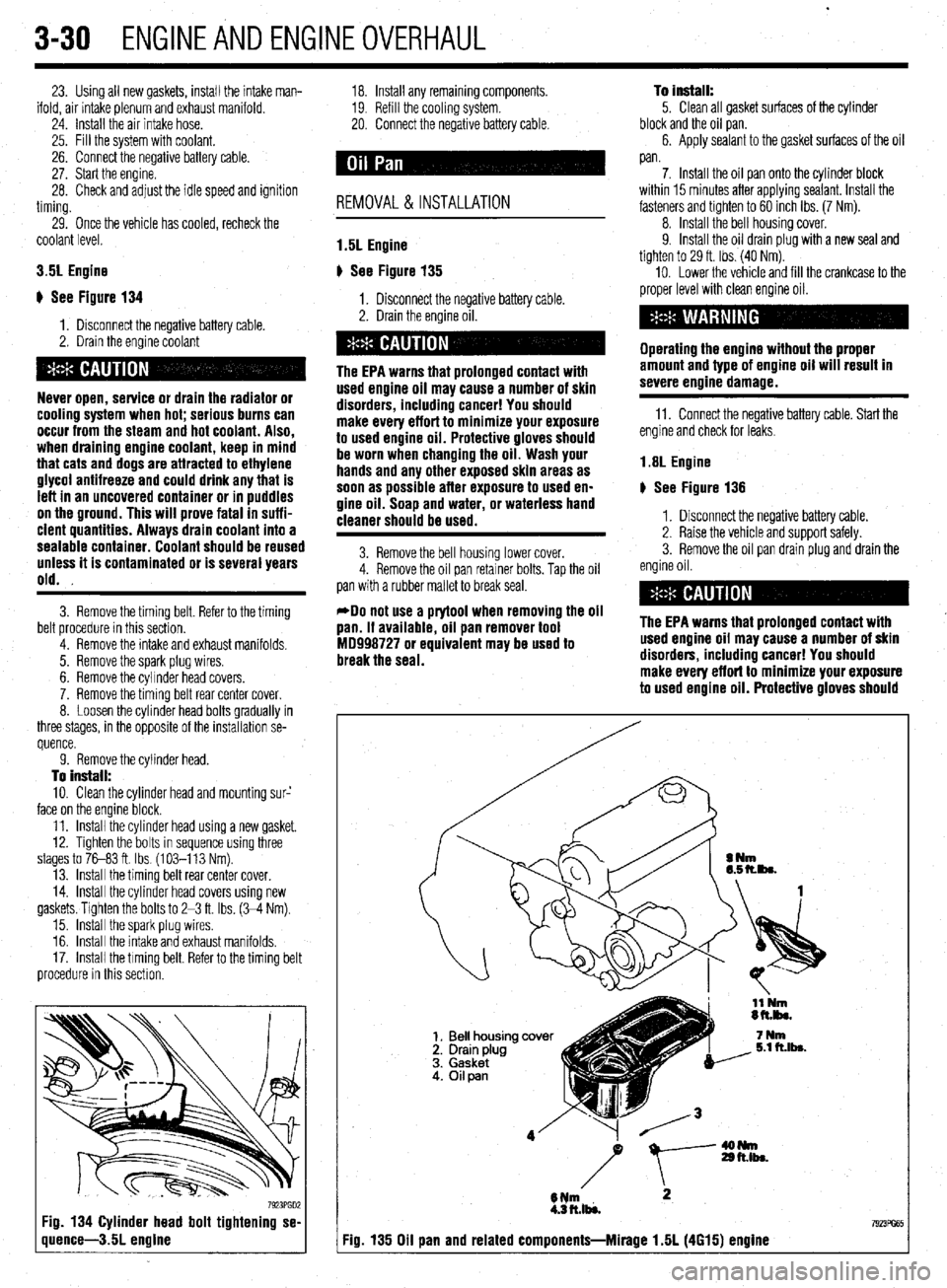

ti See Figure 134

1. Disconnect the negative battery cable.

2. Drain the engine coolant

Never open, service or drain the radiator or

cooling system when hot; serious burns can

occur from the steam and hot coolant. Also,

when draining engine coolant, keep in mind

that cats and dogs are attracted to ethylene

glycol antifreeze and could drink any that is

left in an uncovered container or in puddles

on the ground. This will prove fatal in suffi-

cient quantities. Always drain coolant into a

sealable container. Coolant should be reused

unless it is contaminated or is several years

old.

3. Remove the timing belt. Refer to the timing

belt procedure in this section.

4. Remove the intake and exhaust manifolds.

5. Remove the spark plug wires.

6. Remove the cylrnder head covers.

7. Remove the timing belt rear center cover.

8. Loosen the cylinder head bolts gradually in

three stages, in the opposite of the installation se-

quence.

9. Remove the cylinder head.

To install: 10. Clean the cylinder head and mounting sur-’

face on the engine block.

11. Install the cylinder head using a new gasket.

12. Tighten the bolts in sequence using three

stages to 76-83 ft. Ibs. (103-113 Nm).

13. Install the timing belt rear center cover.

14. Install the cylinder head covers using new

gaskets. Tighten the bolts to 2-3 ft. Ibs. (334 Nm).

15. Install the spark plug wires,

16. Install the intake and exhaust manifolds,

17. Install the timing belt. Refer to the timing belt

procedure in this section.

7923PGD2 Fig. 134 Cylinder head bolt tightening se-

quence-3.5L engine

18. Install any remaining components.

19. Refill the cooling system.

20. Connect the negative battery cable.

REMOVAL &INSTALLATION

1.5L Engine

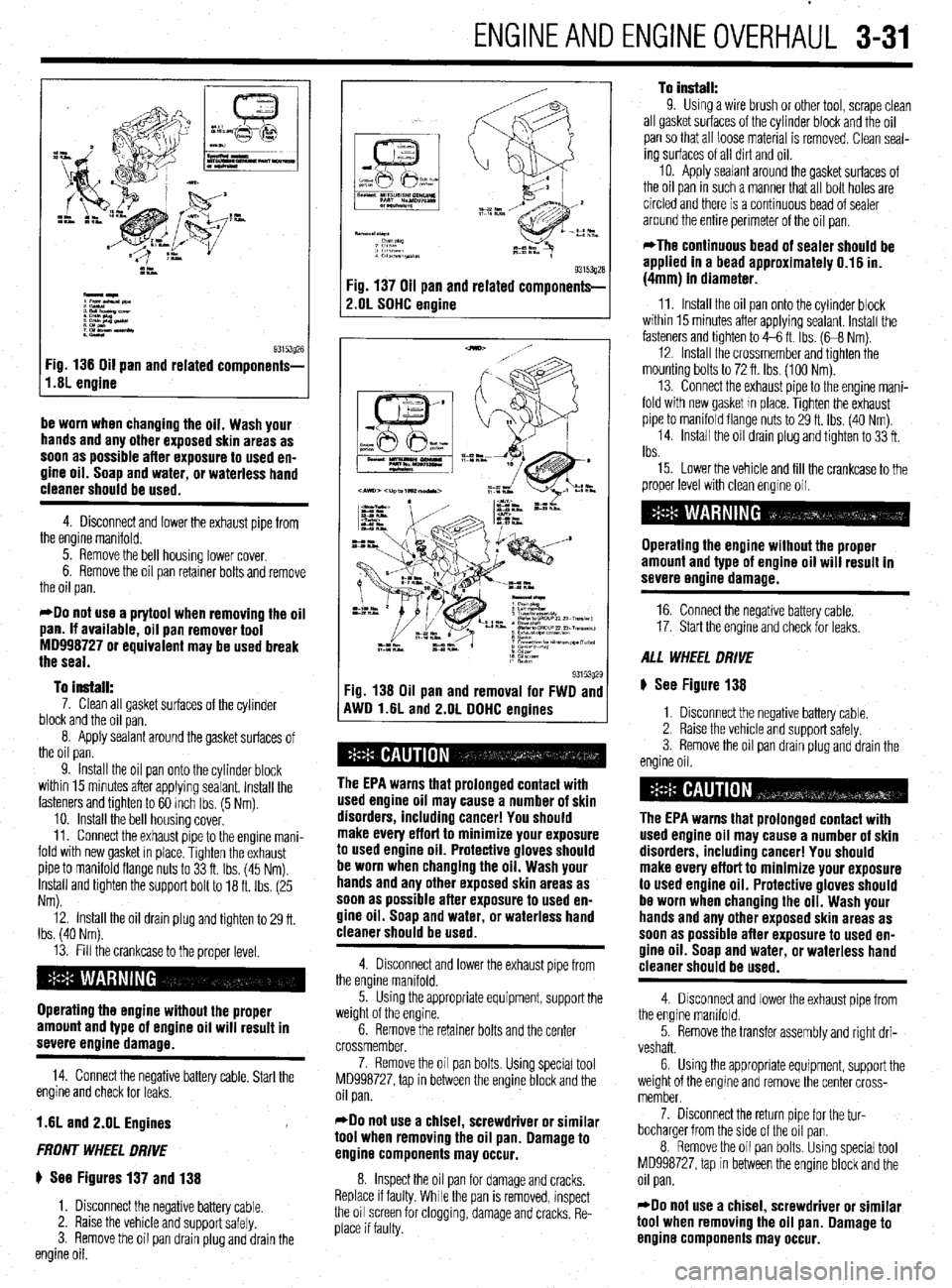

p See Figure 135

1. Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the bell housing lower cover.

4. Remove the oil pan retainer bolts. Tap the oil

pan with a rubber mallet to break seal.

*Do not use a prytool when removing the oil

pan. If available, oil pan remover tool

MD998727 or equivalent may be used to

break the seal. To install:

5. Clean all gasket surfaces of the cylinder

block and the oil pan.

6. Apply sealant to the gasket surfaces of the oil

pan.

7. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 60 inch Ibs. (7 Nm).

8. Install the bell housing cover.

9. Install the oil drain plug with a new seal and

tighten to 29 ft. Ibs. (40 Nm).

10. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

11. Connect the negative battery cable. Start the

engine and check for leaks.

1.8L Engine

# See Figure 136

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

I Fig. 135 Oil pan and related components-Mirage 1.5L (4615) engine

Page 92 of 408

ENGINEANDENGINEOVERHAUL 3-31

I,.s; engine g3i53g26

Fig 136 Oil pan and related components-

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the bell housing lower cover.

6. Remove the oil pan retainer bolts and remove

the oil pan.

*Do not use a prytool when removing the oil

pan. If available, oil pan remover tool

MD998727 or equivalent may be used break

the seal.

To install:

7. Clean all gasket surfaces of the cylinder

block and the oil pan.

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 60 inch Ibs. (5 Nm).

10. install the bell housing cover.

11. Connect the exhaust pipe to the engine mani-

fold with new gasket in place. Tighten the exhaust

pipe to manifold flange nuts to 33 ft. Ibs. (45 Nm).

Install and tighten the support bolt to 18 ft. Ibs. (25

Nm).

12. Install the oil drain plug and tighten to 29 ft.

Ibs. (40 Nm).

13. Fill the crankcase to the proper level.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable. Start the

engine and check for leaks.

1.6L and 2.OL Engines

FRONT WHEEL DRIVE

ti See Figures 137 and 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

93153gza Fig. 137 Oil pan and related components-

2.OL SOHC engine

93153g29 Fig. 138 Oil pan and removal for FWD and

AWD l.liL and 2.OL DDHC enoines

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Using the appropriate equipment, support the

weight of the engine.

6. Remove the retainer bolts and the center

crossmember,

7. Remove the oil pan bolts. Using special tool

MD998727, tap in between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

8. Inspect the oil pan for damage and cracks.

Replace if faulty. While the pan is removed, inspect

the oil screen for clogging, damage and cracks. Re-

place if faulty.

To install: 9. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

10. Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

11. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (G8 Nm).

12. Install the crossmember and tighten the

mounting bolts to 72 ft. Ibs. (100 Nm).

13. Connect the exhaust pipe to the engine mani-

fold with new gasket In place. Tighten the exhaust

pipe to manifold flange nuts to 29 ft. Ibs. (40 Nm)

14. Install the oil drain plug and tighten to 33 ft.

Ibs.

15. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

16. Connect the negative battery cable.

17. Start the engine and check for leaks.

ALL WHEEL DRIVE

ti See Figure 138

1. Disconnect the negative battery cable.

2. Raise the vehicle and support safely.

3. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Disconnect and lower the exhaust pipe from

the engine manifold.

5. Remove the transfer assembly and right dri-

veshaft.

6. Using the appropriate equipment, support the

weight of the engine and remove the center cross-

member.

7. Disconnect the return pipe for the tur-

bocharger from the side of the oil pan.

8. Remove the oil pan bolts. Using special tool

MD998727, tap In between the engine block and the

oil pan.

*Do not use a chisel, screwdriver or similar

tool when removing the oil pan. Damage to

engine components may occur.

Page 93 of 408

.

3-32 ENGINEANDENGINEOVERHAUL

9. Inspect the oil pan for damage and cracks.

Replace if faulty, While the pan is removed, inspect

the oil screen for clogging, damage and cracks, Re-

place if faulty.

To install: 10. Using a wire brush or other tool, scrape clean

all gasket surfaces of the cylinder block and the oil

pan so that all loose material is removed. Clean seal-

ing surfaces of all dirt and oil.

11, Apply sealant around the gasket surfaces of

the oil pan in such a manner that all bolt holes are

circled and there is a continuous bead of sealer

around the entire perimeter of the oil pan.

*The continuous bead of sealer should be

applied in a bead approximately 0.16 in.

(4mm) in diameter.

12. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 4-6 ft. Ibs. (68 Nm).

13. Install the oil return pipe using a new gasket,

if removed. Tighten retainers to 5-7 ft. Ibs. (7-10

Nm).

14. Install the left member and tighten the forward

retainer bolts to 72 ft. Ibs. (100 Nm). Tighten the

rearward left member bolts to 58 ft. Ibs. (80 Nm).

15. Install the transfer assembly and right drive-

shaft.

16. Connect the exhaust pipe from the engine

manifold with new gasket in place. Tighten the ex-

haust pipe to manifold flange nuts to 29 ft. Ibs. (40

Nm).

17. Install the oil drain plug and tighten to 33 ft.

Ibs.

18. Lower the vehicle and fill the crankcase to the

proper level with clean engine oil.

Operating the engine without the proper

amount and type of engine oil will result in

severe enaine damage.

19. Connect the negative battery cable. Start the

engine and check for leaks.

2.4L Engine

) See Figure 139

1, Disconnect the negative battery cable. -

,(L.. K%

2 mM_

-Ip

t 8*t.almcwr

:y&pn

::Elm

93153g30 Fig. 139 Oil pan and related components-

2.4L engine

2. Remove the oil pan drain plug and drain the

engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the oil dipstick and tube assembly.

4. Detach the Heated Oxygen (HOaS) sensor

connector.

5. Remove the front exhaust pipe from the vehi-

cle.

6. Remove the bell housing cover.

7. Remove the oil pan retainer bolts. Using spe-

cial tool MD998727 or equivalent, tap in between the

engine block and the oil pan.

*Do not use a prytool when removing the oil

pan. Damage to engine components may oc-

cur.

To install:

8. Apply sealant around the gasket surfaces of

the oil pan.

9. Install the oil pan onto the cylinder block

within 15 minutes after applying sealant. Install the

fasteners and tighten to 6 ft. Ibs. (8 Nm).

10. Install the oil drain plug and tighten to 29 ft.

Ibs. (39 Nm).

11. Install the bell housing cover, and tighten the

mounting bolts to 7 ft. Ibs. (9 Nm).

12. Install the front exhaust pipe and tighten the

bolts at the catalytic converter to 36 ft. Ibs. (49 Nm).

Tighten the nuts at the exhaust manifold to 32 ft. Ibs.

(44 Nm).

13. Reconnect the HOPS sensor connector.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

15. Connect the negative battery cable. Start the

engine and check for leaks.

3.OL Engines

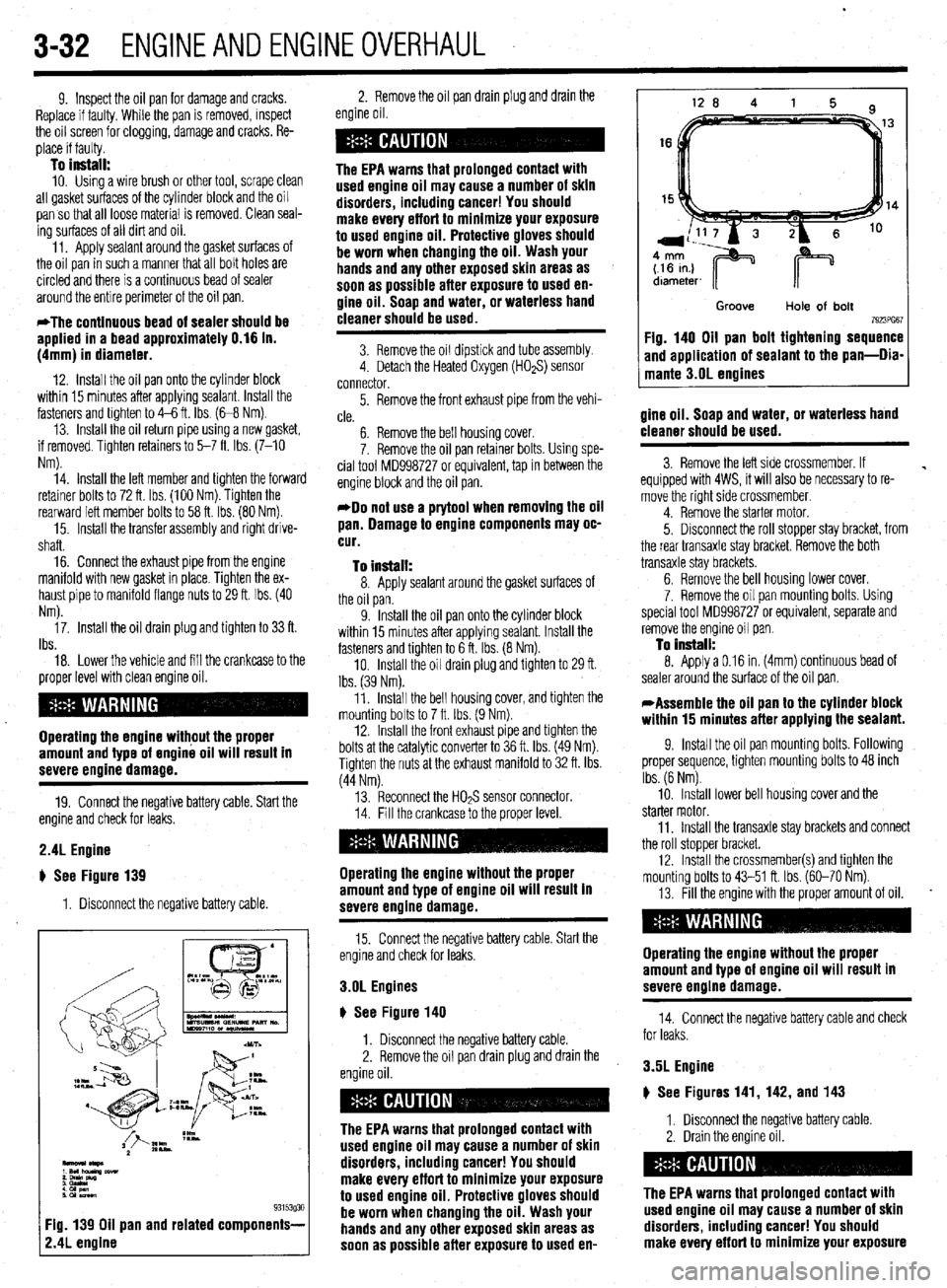

u See Figure 140

1. Disconnect the negative battery cable.

2. Remove the oil pan drain plug and drain the

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

Groove

Hole of bolt 7923PG67 Fig. 140 Oil pan bolt tightening sequence

and application of sealant to the pan-Dia-

mante 3.OL engines

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the left side crossmember. If

equipped with 4WS, it will also be necessary to re-

move the right side crossmember.

4. Remove the starter motor.

5. Disconnect the roll stopper stay bracket, from

the rear transaxle stay bracket. Remove the both

transaxle stay brackets.

6. Remove the bell housing lower cover.

7. Remove the oil pan mounting bolts. Using

special tool MD998727 or equivalent, separate and

remove the engine oil pan.

To install: 8. Apply a 0.16 in. (4mm) continuous bead of

sealer around the surface of the oil pan.

*Assemble the oil pan to the cylinder block

within 15 minutes after applying the sealant.

9. Install the oil pan mounting bolts. Following

proper sequence, tighten mounting bolts to 48 inch

Ibs. (6 Nm).

10. Install lower bell housing cover and the

starter motor.

11, Install the transaxle stay brackets and connect

the roll stopper bracket.

12. Install the crossmember and tighten the

mounting bolts to 43-51 ft. Ibs. (60-70 Nm).

13. Fill the engine with the proper amount of oil.

.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

14. Connect the negative battery cable and check

for leaks.

3.5L Engine

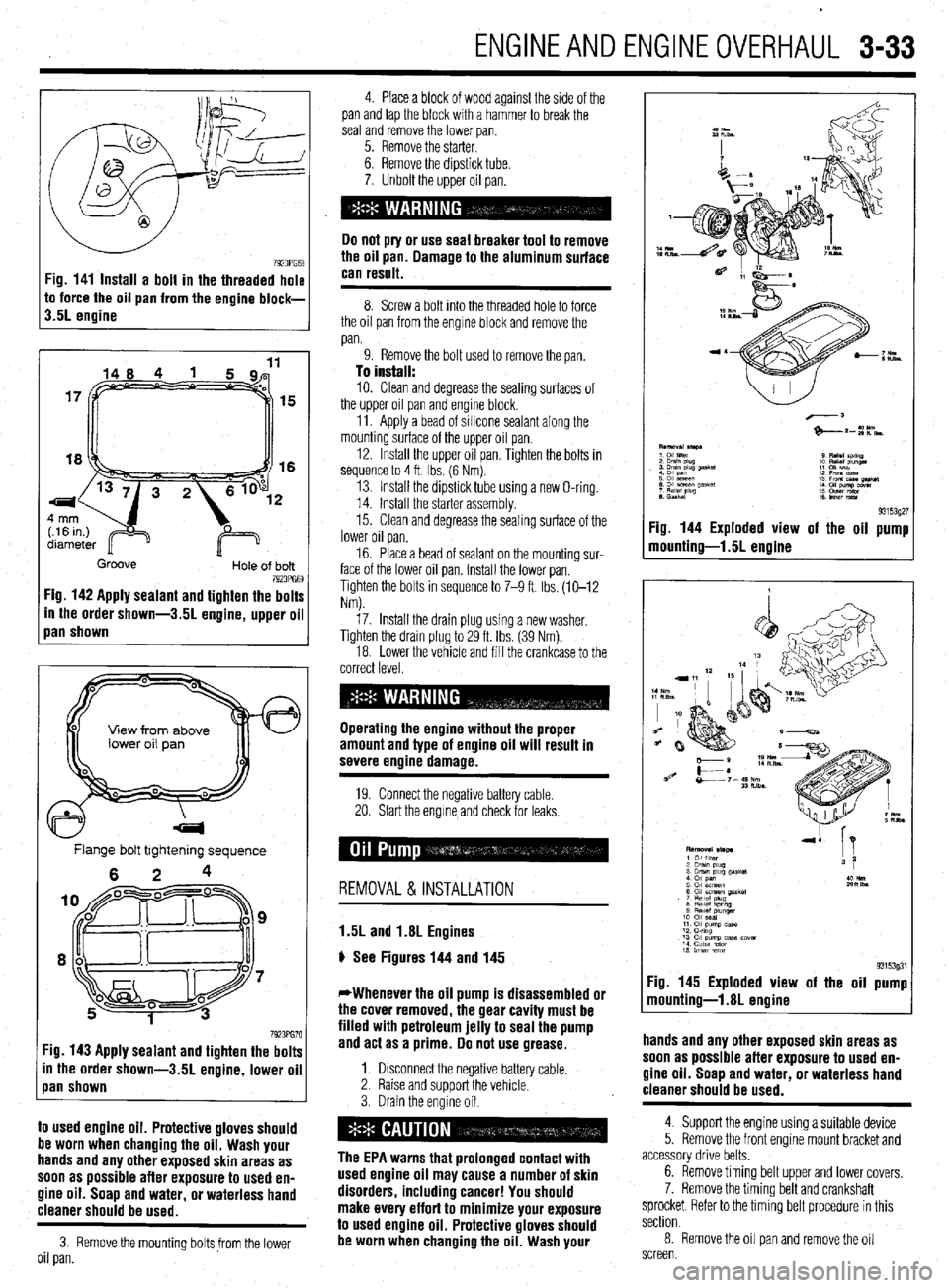

p See Figures 141, 142, and 143

1, Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, includina cancer! You should

make eve’ry effort to minimize your exposure

Page 94 of 408

ENGINEANDENGINEOVERHAUL 3-33

7923PG68 Fig. 141 Install a bolt in the threaded hole

to force the oil pan from the engine block-

3.5L engine

15

16

Groove

Hole of bolt 7923PG69 Fig. 142 Apply sealant and tighten the bolts

In the order shown-3.51 engine, upper oil

Ian shown

View from above

Flange bolt tightening sequence

6 2 4

7923PG70 :ig. 143 Apply sealant and tighten the bolts

in the order shown-3.51 engine, lower oil

pan shown

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the mounting boltsfrom the lower

oil pan. 4. Place a block of wood against the side of the

pan and tap the block with a hammer to break the

seal and remove the lower pan.

5. Remove the starter.

6. Remove the dipstick tube.

7. Unbolt the upper oil pan.

Do not pry or use seal breaker tool to remove

the oil pan. Damage to the aluminum surface

can result.

8. Screw a bolt into the threaded hole to force

the oil pan from the engine block and remove the

pan.

9. Remove the bolt used to remove the pan.

To install:

10. Clean and degrease the sealing surfaces of

the upper oil pan and engine block.

11. Apply a bead of sillcone sealant along the

mounting surface of the upper oil pan.

12. Install the upper oil pan. Tighten the bolts in

sequence to 4 ft Ibs. (6 Nm).

13. Install the dipstick tube using a new O-ring.

14. Install the starter assembly.

15. Clean and degrease the sealing surface of the

lower oil pan.

16. Place a bead of sealant on the mounting sur-

face of the lower

oil pan. Install the lower pan.

Tighten the bolts in sequence to 7-9 ft. Ibs. (10-12

Nm).

17. Install the drain plug using a new washer,

Tighten the drain plug to 29 ft. Ibs (39 Nm).

18. Lower the vehicle and fill the crankcase to the

correct level.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

19 Connect the negative battery cable.

20. Start the engrne and check for leaks,

REMOVAL & INSTALLATION

1.5L and 1.8L Engines

p See Figures 144 and 145

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. Do not use grease.

1. Drsconnect the negative battery cable.

2. Raise and support the vehicle.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

93153927 Fig. 144 Exploded view of the oil pump

mounting-l .5L engine

93153931 Fig. 145 Exploded view of the oil pump

mounting-l.81 engine

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

. . . .

cleaner snoutd be used.

4. Support the engine using a suitable device

5. Remove the front engme mount bracket and

accessory drive belts.

6. Remove timing belt upper and lower covers.

7. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section.

8. Remove the oil pan and remove the oil

screen.

Page 95 of 408

3-34 ENGINEANDENGINEOVERHAUL

9. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

10. Remove the front case assembly and oil

pump assembly.

11. Remove the oil pump cover.

12. Remove the inner and outer gears from the

front case.

To install 13. Remove all gasket material from the mating

surfaces and clean all parts.

14. Thoroughly coat both oil pump gears with

clean engine oil and install them in the correct direc-

tion of rotation.

15. Install the pump cover and tighten the bolts to

84 inch Ibs. (10 Nm).

16. Coat the relief valve and spring with clean en-

gine oil. Install them and tighten the plug to 33 ft.

Ibs. (45 Nm).

17. Install a new front crankshaft seal and coat

the lips of the seal with clean engine oil.

18. Install the front case and oil pump assembly

to the engine block using a new gasket. Tighten the

bolts to loft. Ibs. (14 Nm)

19. Install the oil screen with new gasket. Torque

the screen bolts to 14 ft. Ibs. (19 Nm).

20. Install the oil pan.

21. Install the crankshaft sprocket and timing

belt. Refer to the timing belt procedure in this sec-

tion.

22. Fill the crankcase to the proper level.

Operating the engine without the proper

amount and type of engine oil will result in

severe enoine damaae.

23. Connect the negative battery cable.

1.6L, 2.OL and 2.4L Engines

p See Figures 146, 147, 148, and 149

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. Do not use grease.

1. Disconnect the negative battery cable.

2. Rotate the engine so No. 1 cylinder is on Top

Dead Center (TDC) of its compression stroke.

3. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible afler exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4 Using the proper equipment, support the

weight of the engine Remove the front engine mount

bracket and accessory drive belts.

5 Remove timing belt upper and lower covers.

6. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section. 7. Detach the electrical connector from the oil

pressure sending unit and remove the oil pressure

sensor. Remove the oil filter and the oil filter bracket.

8. Remove the oil pan, oil screen and gasket.

9. Using special tool MD998162, remove the

plug cap in the engine front cover.

10. Remove the plug on the side of the engine

block. Insert a Phrllips screwdriver with a shank di-

ameter of 0.32 in. (8mm) into the plug hole. This will

hold the silent shaft.

11. Remove the driven gear bolt that secures the

oil pump driven gear to the silent shaft.

12. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

13. Remove the front case cover and oil pump

assembly. If necessary, the silent shaft can come out

with the cover assembly.

14. Remove the oil pump cover, located on the

back of the engine front cover. Remove the oil pump

drive and driven gears.

15. After disassembling the oil pump, clean all

components and remove gasket material from mating

surfaces.

16. Assemble the oil pump gears into the front

case and rotate it to ensure smooth rotation and no

looseness. Be sure there is no ridge wear on the con-

tact surface between the front case and the gear sur-

face of the oil pump front cover.

To install 17. Align the timing mark on the oil pump drive

gear with that on the driven gear and install them into

the engine front case. Apply engine 011 to the gears.

18. Install the oil pump cover and tighten the re-

tainer bolts to 13 ft. Ibs. (18 Nm).

19. Using the appropriate driver, install a new

crankshaft seal into the front case.

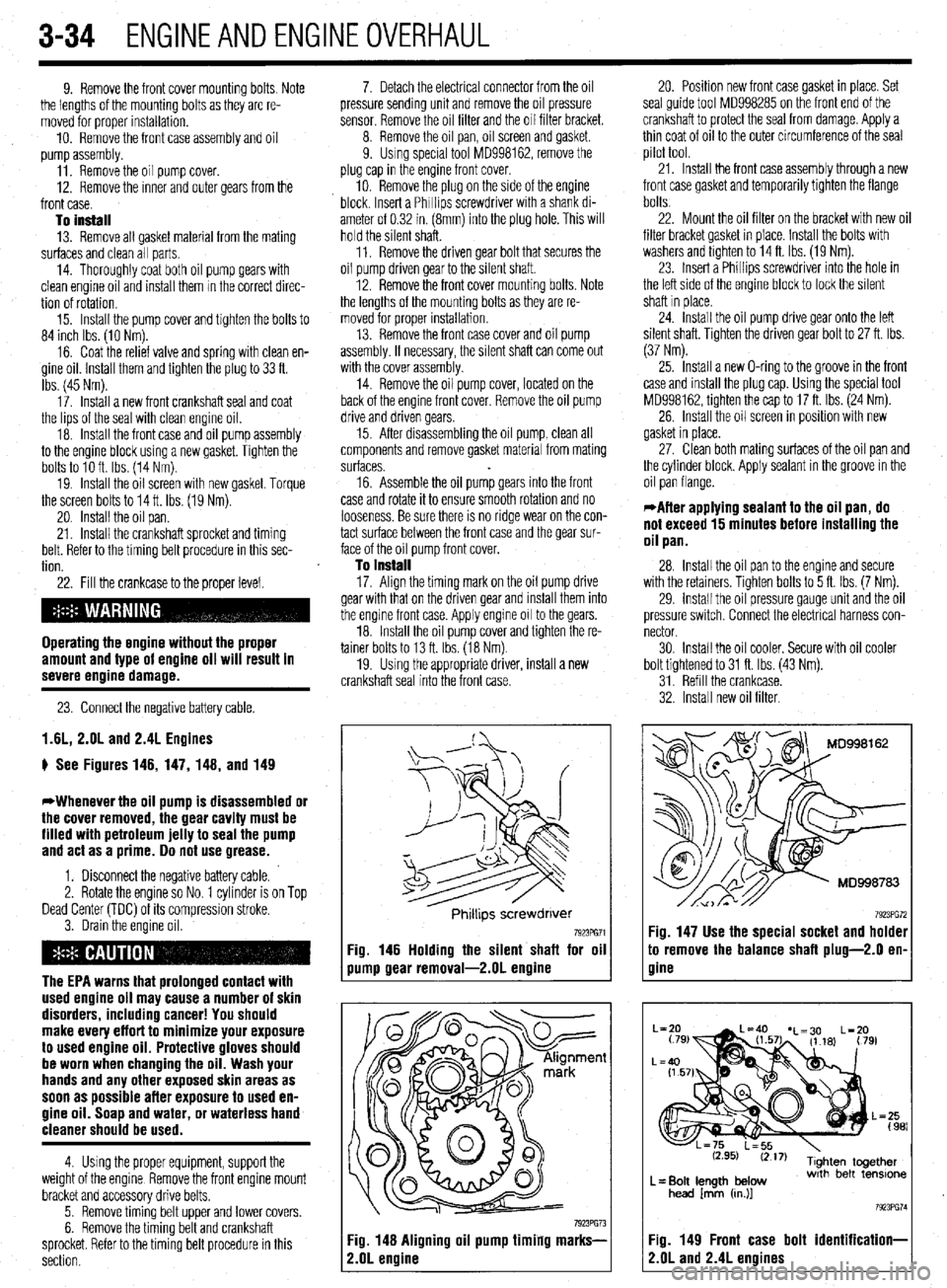

Phrllips screwdrrver

7923PG71 Fig. 146 Holding the silent shaft for oil

pump gear removal-2.01 engine

7923PG73 Fig. 148 Aligning oil pump timing marks-

2.OL ermine

20. Position new front case gasket in place. Set

seal guide tool MD998285 on the front end of the

crankshaft to protect the seal from damage. Apply a

thin coat of oil to the outer circumference of the seal

pilot tool.

21. Install the front case assembly through a new

front case gasket and temporarily tighten the flange

bolts.

22. Mount the oil filter on the bracket with new oil

filter bracket gasket in place. Install the bolts with

washers and tighten to 14 ft. Ibs. (19 Nm).

23. Insert a Phillips screwdriver into the hole in

the left side of the engine block to lock the silent

shaft in place.

24. Install the oil pump drive gear onto the left

silent shaft. Tighten the driven gear bolt to 27 ft. Ibs.

(37 Nm).

25. Install a new O-ring to the groove in the front

case and install the plug cap. Using the special tool

MD998162, tighten the cap to 17 ft. Ibs. (24 Nm).

26. Install the oil screen in position with new

gasket in place.

27. Clean both mating surfaces of the oil pan and

the cylinder block. Apply sealant In the groove in the

oil pan flange.

*After applying sealant to the oil pan, do

not exceed 15 minutes before installing the

oil pan.

28. Install the oil pan to the engine and secure

with the retainers. Tighten bolts to 5 ft. Ibs. (7 Nm).

29. install the oil pressure gauge unit and the oil

pressure switch. Connect the electrical harness con-

nector.

30. Install the oil cooler. Secure with oil cooler

bolt tightened to 31 ft. Ibs (43 Nm).

31. Refill the crankcase.

32. Install new oil filter.

7923PG72 Fig. 147 Use the special socket and holder

:o remove the balance shaft plug-2.0 en-

7ine

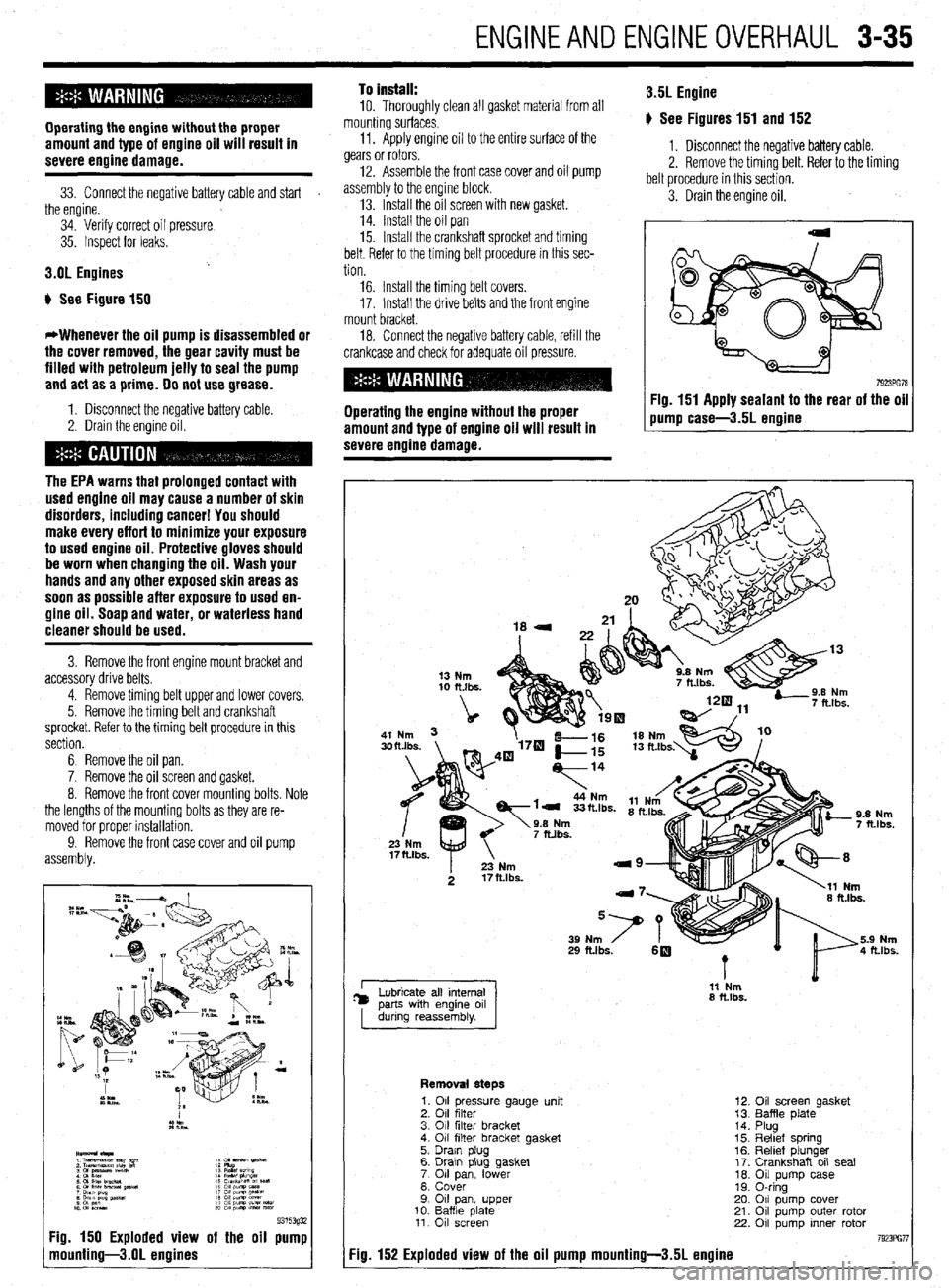

L= Bolt length below

head /mm (cn.)]

Fig. 149 Front case bolt identification-

?.OL and 2.4L engines

Page 96 of 408

ENGINEANDENGINEOVERHAUL 3-35

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage.

33. Connect the negative battery cable and start

the engine.

34. Verify correct oil pressure

35. Inspect for leaks.

3.OL Engines

b See Figure 150

*Whenever the oil pump is disassembled or

the cover removed, the gear cavity must be

filled with petroleum jelly to seal the pump

and act as a prime. 00 not use grease.

1. Disconnect the negative battery cable.

2. Drain the engine oil.

The EPA warns that prolonged contact with

used engine oil may cause a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

3. Remove the front engine mount bracket and

accessory drive belts.

4. Remove timing belt upper and lower covers.

5. Remove the timing belt and crankshaft

sprocket. Refer to the timing belt procedure in this

section.

6 Remove the oil pan.

7. Remove the oil screen and gasket.

8. Remove the front cover mounting bolts. Note

the lengths of the mounting bolts as they are re-

moved for proper installation.

9. Remove the front

assembly. and oil pump

9315393i 7g. 150 Exploded view of the oil pump

nounting-3.01 engines

To install:

10. Thoroughly clean all gasket material from all

mounting surfaces.

11. Apply engine oil to the entire surface of the

gears or rotors.

12. Assemble the front case cover and oil pump

assembly to the engine block.

13. Install the oil screen with new gasket.

14. Install the oil pan

15. Install the crankshaft sprocket and timing

belt. Refer to the timing belt procedure in this sec-

tion 3.5L Engine

p See Figures 151 and 152

1. Disconnect the negative battery cable.

2. Remove the timing belt. Refer to the timing

belt procedure in this section.

3. Drain the engine oil.

16. Install the timing belt covers.

17. Install the drive belts and the front engine

mount bracket.

18. Connect the negative battery cable, refill the

crankcase and check for adequate oil pressure.

Operating the engine without the proper

amount and type of engine oil will result in

severe engine damage. Fig. 151 Apply sealant to the rear of the oil

pump case-3.5L ermine

I 11 Nm

8 ft.lbs.

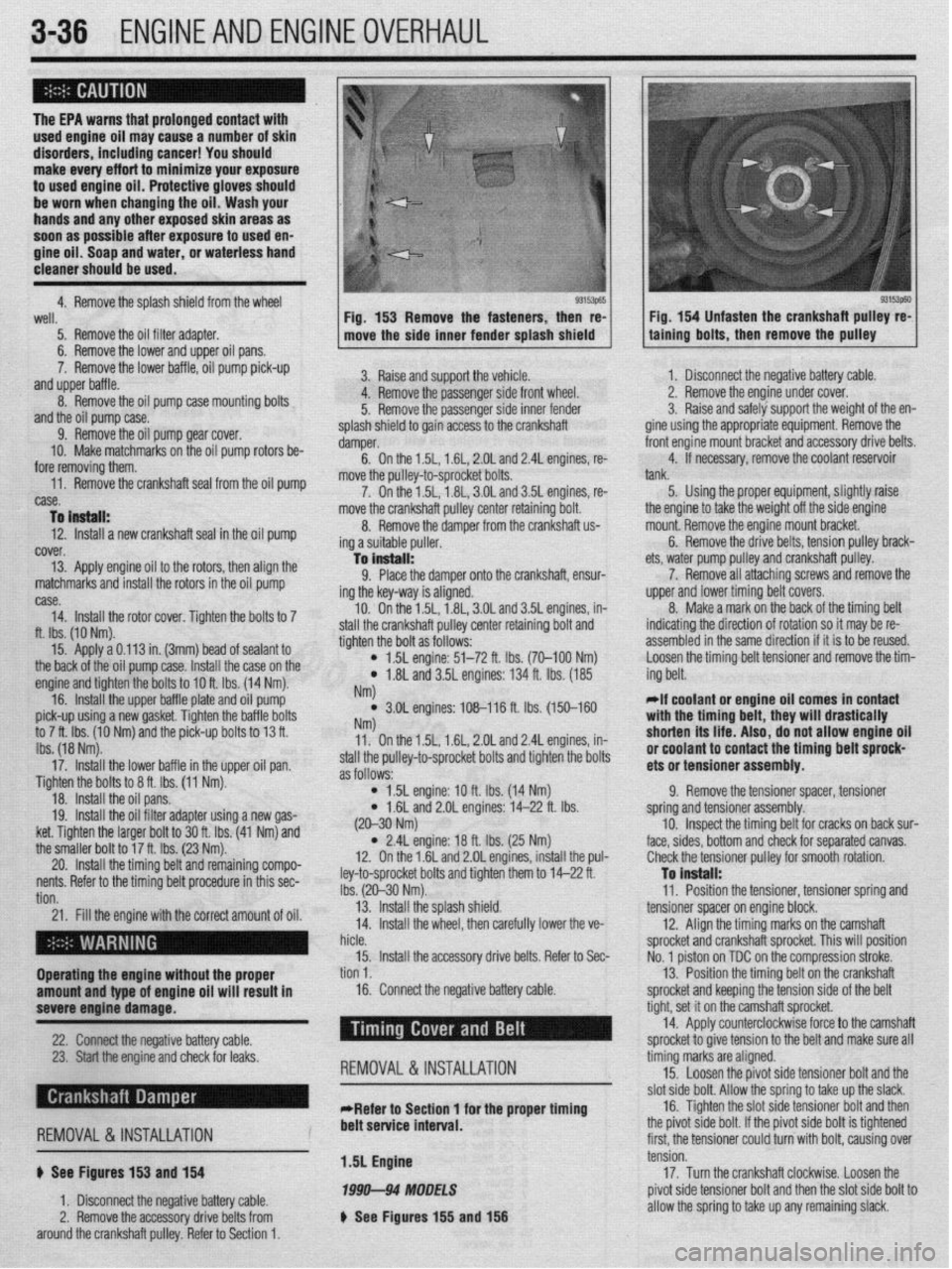

Removal steps

7g. 152 Exploded view of the oil pump mounting-3.51 engine

1. 011 pressure gauge unit

2. 011 filter

3. 011 filter bracket

4. 011 filter bracket gasket

5. Drain plug

6. Drawn plug gasket

7 011 lower pan,

8. Cover

9 011 pan, upper

10. Baffle date 11. 011 screen

12.

13.

14.

15.

16.

17.

10.

19.

20.

21.

22. Oil screen gasket

Baffle plate

Plug

Reltef spring

Relief plunger

Crankshaft oil seal

Oil pump case

0-ring

011 pump cover

011 pump outer rotor

011 pump inner rotor

Page 97 of 408

3-36 ENGINEANDENGINEOVERHAUL

The EPA warns that urolonaed contact with

used engine oil may cause”a number of skin

disorders, including cancer! You should

make every effort to minimize your exposure

to

used engine oil. Protective gloves should

be worn when changing the oil. Wash your

hands and any other exposed skin areas as

soon as possible after exposure to

used en-

gine oil. Soap and water, or waterless hand

cleaner should be used.

4. Remove the solash shield from the wheel

93153p65 93153p60 well.

5. Remove the oil filter adapter.

6. Remove the lower and upper oil pans.

7. Remove the lower baffle, oil pump pick-up

and upper baffle.

8. Remove the oil pump case mounting bolts

and the oil pump case.

9. Remove the oil pump gear cover.

10. Make matchmarks on the oil pump rotors be-

fore removing them.

,,. r.-- -IL- -.( -L.11---‘I --. IL- -.I _ --

nemove me cranksnarr sear rrom me 011 pump

case.

To instell:

12. Install a new crankshaft seal in the oil pump

cover.

13. Apply engine oil to the rotors, then align the

matchmarks and install the rotors in the oil pump Fig. 153 Remove the fasteners, then re-

move the side inner fender splash shield

3. Raise and support the vehicle.

4. Remove the passenger side front wheel.

5. Remove the passenger side inner fender

splash shield to gain access to the crankshaft

damper.

6. On the 1.5L, 1.6L, 2.OL and 2.4L engines, re-

move the oullev-to-sorocket bolts.

7. On thei .5L, i .8L, 3.OL and 3.5L engines, re-

move the crankshaft pulley center retaining bolt.

8. Remove the damper from the crankshaft us

ing a suitable puller.

-la install:

9. Place the damper onto the crankshaft, ensur-

ing the key-way is aligned.

10. On the 1.5L, 1.8L, 3.OL and 3.5L engines, in-

e crankshaft pulley center retaining bolt and

the bolt as follows: Fig. 154 Unfasten the crankshaft pulley re-

talning bolts, then remove the pulley

case.

14. Install the rotor cover. Tighten the bolts to 7

ft. Ibs. (10 Nm).

15. Apply a 0.113 in. (3mm) bead of sealant to

the back of the oil pump case. I[ -‘-‘I IL -~-- IL-

nsrall me ca

se on me engine and tighten the bolts to IOft Ihc 11 ,,, -. , .4 Nm).

16. Install the upper baffle r tlal te and oil pump

pick-up using a new gasket. Tic fhtti,, ,,lG va,,,ti ““a,., an tha hafflc, hnltc to 7 ft. Ibs. (10 Nm) and the pit k-up bolts to 13 ft.

Ibs. (18 Nm).

17. Install the lower baffle in the upper oil pan.

Tighten the bolts to 8 ft. Ibs. (11 Nm).

18. Install the oil pans.

19. Install the oil filter adapter using a new gas-

ket. Tighten the larger bolt to 30 ft. Ibs. (41 Nm) and

the smaller bolt to 1’ u ‘L- Inn ‘I--’ stall thl

tighten

4

) 1.5L engine: 51-72 ft. Ibs. (70-100 Nm)

l 1.8L and 3.5L engines: 134 ft. Ibs. (185

NM

l 3.OL engines: 108-116 ft. lbs. (150-160 NW 11. On the 1.5L, 1.6L, 2.OL and 2.4L engines, in-

stall the pulley-to-sprocket bolts and tighten the bolts

as follows:

l 1.5L engine: 10 ft. Ibs. (14 Nm)

* 1.6L and 2.OL engines: 14-22 ft. Ibs. 1. Disconnect the negative battery cable.

2. Remove the engine under cover.

3. Raise and safely support the weight of the en-

gine using the appropriate equipment. Remove the

front engine mount bracket and accessory drive belts.

4. If necessary, remove the coolant reservoir

tank.

5. Using the proper equipment, slightly raise

ets, water pump pulley

7. Remove all attr

upper and lower timin{

8. Make a mark o

indicating the directior

assembled in the same the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

6. Remove the drive belts, tension pulley brack-

and crankshaft pulley.

aching screws and remove the

J belt covers.

n the back of the timing belt

I of rotation so it may be re-

! direction if it is to be reused.

tensioner and remove the tim-

Loosen the timing belt

ing belt.

*If coolant or engine oil comes in contact

with the timing bplt thaw will r(mcti~~llv Wll L, .,,s,, n,,, u,uu.,vu,,,

shorten its life. A ,IS o, do not allow engine oil

#.I nn..lr”* In rind In,

“I IruuI(IIIL Lu Irulll&t the timing belt sprock-

ets or tensioner assembly.

9. Remove the tensioner spacer, tensioner

spring and tensioner assembly.

cracks on back sur-

;eoarated canvas.

20. Install the tilllIllY uljllOllu IclllallllllY ~ullIPV-

:

nents. Refer to the timing belt procedure in this sec-

: tion.

21. Fill the engine with the correct amount of oil.

I . (20-30 Nm)

l 2.4L engine: 18 ft. Ibs. (25 Nm)

12. On the 1.6L and 2.OL engines, install the pul-

ley-to-sprocket bolts and tighten them to 14-22 ft.

Ibs. (20-30 Nm).

13. Install the splash shield.

14. Install the wheel, then carefully lower the ve- 10. Inspect the timing belt for I

face, sides, bottom and check for ! (

Check the tensioner pulley for smooth rotation.

To install:

11. Position the tensioner, tensioner spring and

tensioner spacer on engine block.

12. Align the timing marks on the camshaft

ft sprocket. This will position

tn the comoression stroke.

I hicle.

sprocket and cranksha

15. Install the accessory drive belts. Refer to Sec-

No. 1 piston on TDC o

Operating the engine without the proper tion 1.

13. Position the timing belt on the crankshaft

amount and type of engine oil will result in 16. Connect the negative battery cable.

sprocket and keeping the tension side of the bolt

severe engine damage.

-

22. -s

Chrmxt the nenntive h;lttm cnhle --, , I” ,.-J XL.._ I -..-., --I.-.

23. Start the engine and check for leaks.

REMOVAL &INSTALLATION

tight, set it on the cam, shaft sprocket.

14. Apply counterc Yockwise force to the camshaft

snrnckd tn nive tensin In -r .__.._. ._ J..- ._ - _ to the belt and make sure all

timing marks are aligned.

15. Loosen the pivot side tensioner bolt and the

clnt

&In hnlt Allnur thn rnrinn tn tdm III-I thn slack, cl then , d I, I’ r),“I 44”” ““IL. “ll”sl LllU .y”“yj L” L”I\U Low Ul” L .-Refer to Section 1 for the proper timing 16. Tighten the slot side tensioner bolt ark

., , , , ,, ,, ,, , , , , ,, . ,, ,~

REMOVAL &INSTALLATION

6 See Figures 153 and 154

1. Disconnect the negative battery cable.

2. Remove the accessory drive belts from

around the crankshaft pulley. Refer to Section 1. belt service interval.

1.5L Engine

1999-94 MODELS

b See Figures 155 and 156 me p~vor sloe DOI~. IT me p~vor sloe OOII

IS ogntened

first, the tensioner could turn with bolt, causing over

tension.

17. Turn the crankshaft clockwise. Loosen the

pivot side tensioner bolt and then the slot side bolt to

allow the spring to take up any remaining slack.

Page 98 of 408

ENGINEANDENGINEOVERHAUL 3-37

1. Ben

2. Power4teerlna Dump 7. washer

8. Crankshaft pullet

9. Damper pulls

10. upper ccwer

11. Lowercowr

12. llmingbeil

13. crsnkshat? E#ocket 14. Flsnge

i 5. Tensbner spacer

16. Tef~kner WkW

1; Tgibnrr

19: camehan sprocket

91251ga

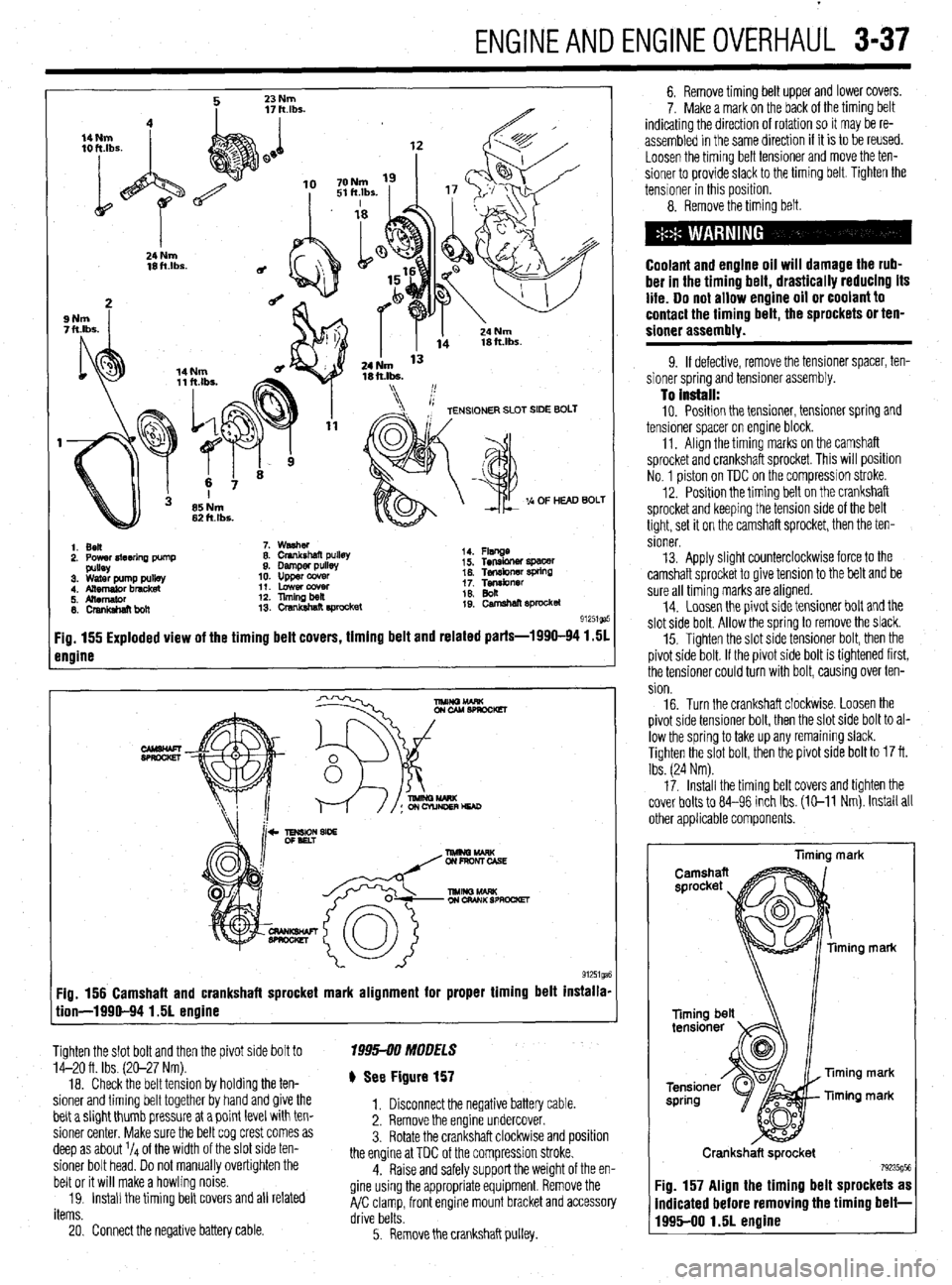

Fig. 155 Exploded view of the timing belt covers, timing belt and related parts-1990-94 1.51

engine

Fig. 156 Camshaft and crankshaft sprocket mark alignment for proper timing belt installa-

tion-1990-94 1.51 engine

Tighten the slot bolt and then the pivot side bolt to

14-20 ft. Ibs. (20-27 Nm).

18. Check the belt tension by holding the ten-

sioner and timing belt together by hand and give the

belt a slight thumb pressure at a point level with ten-

sioner center. Make sure the belt cog crest comes as

deep as about l/4 of the width of the slot side ten-

sioner bolt head. Do not manually overtighten the

belt or it will make a howling noise.

19. Install the timing belt covers and all related

items. 1995-00 MOOFLS

) See Figure 157

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. Rotate the crankshaft clockwlse and position

the engine at TDC of the compression stroke.

4. Raise and safely support the weight of the en-

gine using the appropriate equipment. Remove the

A/C clamp, front engine mount bracket and accessory

drive belts.

20. Connect the negative battery cable.

5. Remove the crankshaft pulley. 6. Remove timing belt upper and lower covers.

7. Make a mark on the back of the timing belt

indicating the direction of rotation so it may be re-

assembled in the same direction if it is to be reused.

Loosen the timing belt tensioner and move the ten-

sioner to provide slack to the timing belt. Tighten the

tensioner in this position.

8. Remove the timing belt.

Coolant and engine oil will damage the rub-

ber in the timing belt, drastically reducing its

life. Do not allow engine oil or coolant to

contact the timing belt, the sprockets or ten-

sioner assembly.

9. If defective, remove the tensioner spacer, ten-

sioner spring and tensioner assembly.

To install: 10. Position the tensioner, tensioner spring and

tensioner spacer on engine block.

11. Align the timing marks on the camshaft

sprocket and crankshaft sprocket. This will position

No. 1 piston on TDC on the compression stroke.

12. Position the timing belt on the crankshaft

sprocket and keeping the tension side of the belt

tight, set it on the camshaft sprocket, then the ten-

sioner.

13. Apply slight counterclockwise force to the

camshaft sprocket to give tension to the belt and be

sure all timing marks are aligned.

14. Loosen the pivot side tensioner bolt and the

slot side bolt. Allow the spring to remove the slack.

15. Tighten the slot side tensioner bolt, then the

pivot side bolt. If the pivot side bolt is tightened first,

the tensioner could turn with bolt, causing over ten-

sion.

16. Turn the crankshaft clockwise. Loosen the

pivot side tensioner bolt, then the slot side bolt to al-

low the spring to take up any remaining slack.

Tighten the slot bolt, then the pivot side bolt to 17 ft.

Ibs. (24 Nm).

17. Install the timing belt covers and tighten the

cover bolts to 84-96 inch Ibs. (E-11 Nm). Install all

other applicable components.

liming mark

ming mark

Timing mark

Timing mark

Crankshaft sprocket

79235g5t Fig. 157 Align the timing belt sprockets as

indicated before removing the timing belt-

1995-00 1.51 engine

Page 99 of 408

3-38 ENGINEANDENGINEOVERHAUL

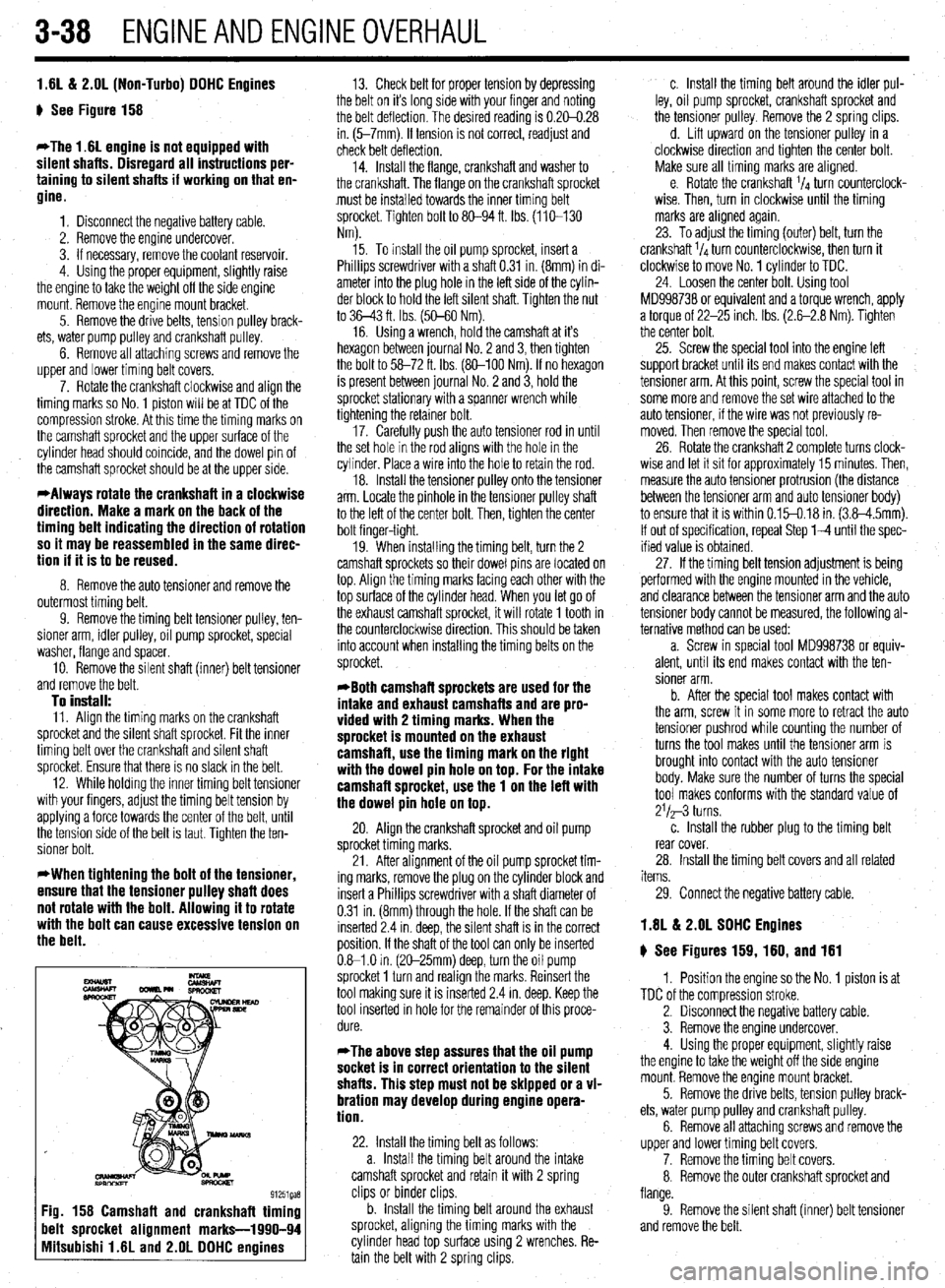

1.61&? 2.OL (Non-Turbo) DOHC Engines

g See Figure 158

*The 1.6L engine is not equipped with

silent shafts. Disregard all instructions per-

taining to silent shafts if working on that en-

gine.

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. If necessary, remove the coolant reservoir.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Rotate the crankshaft clockwise and align the

timing marks so No. 1 piston will be at TDC of the

compression stroke. At this time the timing marks on

the camshaft sprocket and the upper surface of the

cylinder head should coincide, and the dowel pin of

the camshaft sprocket should be at the upper side.

*Always rotate the crankshaft in a clockwise

direction. Make a mark on the back of the

timing belt indicating the direction of rotation

so it may be reassembled in the same direc-

tion if it is to be reused.

8. Remove the auto tensioner and remove the

outermost timing belt.

9. Remove the timing belt tensioner pulley, ten-

sioner arm, idler pulley, oil pump sprocket, special

washer, flange and spacer.

10. Remove the silent shaft (inner) belt tensioner

and remove the belt.

To install: 11. Align the timing marks on the crankshaft

sprocket and the silent shaft sprocket. Fit the inner

timing belt over the crankshaft and silent shaft

sprocket. Ensure that there is no slack in the belt.

12. While holding the inner timing belt tensioner

with your fingers, adjust the timing belt tension by

applying a force towards the center of the belt, until

the tension side of the belt is taut. Tighten the ten-

sioner bolt.

*When tightening the bolt of the tensioner,

ensure that the tensioner pulley shaft does

not rotate with the bolt. Allowing it to rotate

with the bolt can cause excessive tension on

the belt.

13. Check belt for proper tension by depressing

the belt on it’s long side with your finger and noting

the belt deflection. The desired reading is 0.20-0.28

in. (5-7mm). If tension is not correct, readjust and

check belt deflection.

14. Install the flange, crankshaft and washer to

the crankshaft. The flange on the crankshaft sprocket

must be installed towards the inner trming belt

sprocket. Tighten bolt to 80-94 ft. Ibs. (110-130

Nm).

15. To install the oil pump sprocket, insert a

Phillips screwdriver with a shaft 0.31 in. (8mm) in di-

ameter into the plug hole in the left side of the cylin-

der block to hold the left silent shaft. Tighten the nut

to 36-43 ft. Ibs. (50-60 Nm).

16. Using a wrench, hold the camshaft at it’s

hexagon between journal No. 2 and 3, then tighten

the bolt to 58-72 ft. Ibs. (80-100 Nm). If no hexagon

is present between journal No. 2 and 3, hold the

sprocket stationary with a spanner wrench while

tightening the retainer bolt.

17. Carefully push the auto tensioner rod in until

the set hole in the rod aligns with the hole in the

cylinder. Place a wire into the hole to retain the rod.

18. Install the tensioner pulley onto the tensioner

arm. Locate the pinhole in the tensioner pulley shaft

to the left of the center bolt. Then, tighten the center

bolt finger-tight.

19. When installing the timing belt, turn the 2

camshaft sprockets so their dowel pins are located on

top. Align the timing marks facing each other with the

top surface of the cylinder head. When you let go of

the exhaust camshaft sprocket, it will rotate 1 tooth in

the counterclockwise direction. This should be taken

into account when installing the timing belts on the

sprocket.

*Both camshaft sprockets are used for the

intake and exhaust camshafts and are pro-

vided with 2 timing marks. When the

sprocket is mounted on the exhaust

camshaft, use the timing mark on the right

with the dowel pin hole on top. For the intake

camshafl sprocket, use the 1 on the left with

the dowel pin hole on top.

20. Align the crankshaft sprocket and oil pump

sprocket timing marks.

21. After alignment of the oil pump sprocket tim-

ing marks, remove the plug on the cylinder block and

insert a Phillips screwdriver with a shaft diameter of

0.31 in. (8mm) through the hole. If the shaft can be

inserted 2.4 in. deep, the silent shaft is in the correct

position. If the shaft of the tool can only be inserted

0.61 .O in. (2C-25mm) deep, turn the oil pump

sprocket 1 turn and realign the marks. Reinsert the

tool making sure it is inserted 2.4 in. deep. Keep the

tool inserted in hole for the remainder of this proce-

dure.

*The above step assures that the oil pump

socket is in correct orientation to the silent

shafts. This step must not be skipped or a vi-

bration may develop during engine opera-

tion.

22. Install the timing belt as follows:

a. Install the timing belt around the intake

camshaft sprocket and retain it with 2 spring

clips or binder clips.

b. Install the timing belt around the exhaust

sprocket, aligning the timing marks with the

cylinder head top surface using 2 wrenches. Re-

tain the belt with 2 spring clips. c. Install the timing belt around the idler pul-

ley, oil pump sprocket, crankshaft sprocket and

the tensioner pulley. Remove the 2 spring clips.

d. Lift upward on the tensioner pulley in a

clockwise direction and tighten the center bolt.

Make sure all timing marks are aligned.

e. Rotate the crankshaft ‘14 turn counterclock-

wise. Then, turn in clockwise until the timing

marks are alrgned again.

23. To adjust the timing (outer) belt, turn the

crankshaft ‘14 turn counterclockwise, then turn it

clockwise to move No. 1 cylinder to TDC.

24. Loosen the center bolt. Using tool

MD998738 or equivalent and a torque wrench, apply

a torque of 22-25 inch. Ibs. (2.6-2.8 Nm). Tighten

the center bolt.

25. Screw the special tool into the engine left

support bracket until its end makes contact with the

tensioner arm. At this point, screw the special tool in

some more and remove the set wire attached to the

auto tensioner, if the wire was not previously re-

moved. Then remove the specral tool.

26. Rotate the crankshaft 2 complete turns clock-

wise and let it sit for approximately 15 minutes. Then,

measure the auto tensioner protrusion (the distance

between the tensioner arm and auto tensioner body)

to ensure that it is within 0.15-0.18 in. (3.8-4.5mm).

If out of specification, repeat Step l-4 until the spec-

ified value is obtained.

27. If the timing belt tension adjustment is being

performed with the engine mounted in the vehicle,

and clearance between the tensioner arm and the auto

tensioner body cannot be measured, the following al-

ternative method can be used:

a. Screw in special tool MD998738 or equiv-

alent, until its end makes contact with the ten-

sioner arm.

b. After the special tool makes contact with

the arm, screw it in some more to retract the auto

tensioner pushrod while counting the number of

turns the tool makes until the tensioner arm is

brought into contact with the auto tensioner

body. Make sure the number of turns the special

tool makes conforms with the standard value of

21/a-3 turns.

c. Install the rubber plug to the timing belt

rear cover.

28. Install the timing belt covers and all related

items.

29. Connect the negative battery cable.

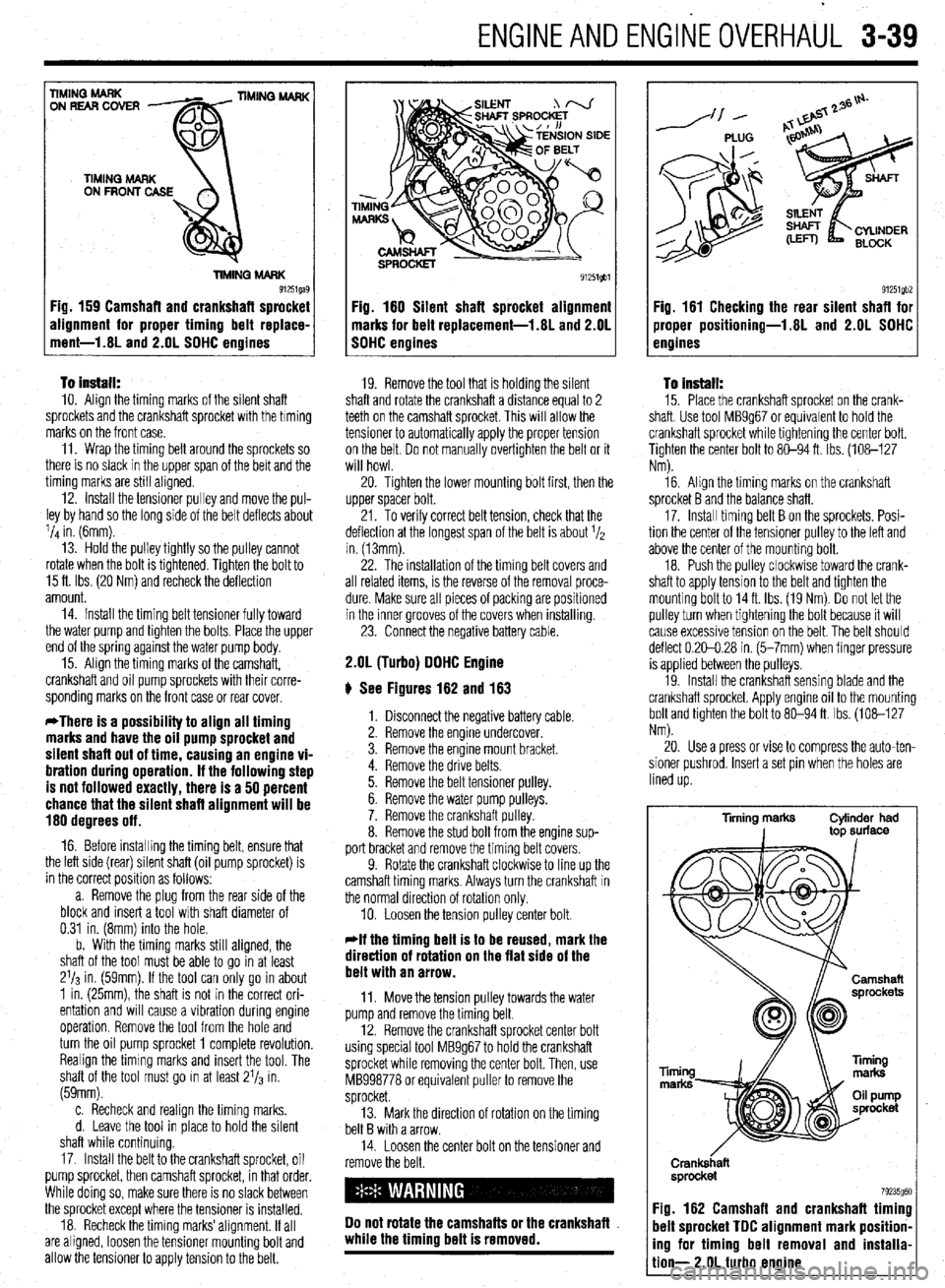

1.8L & 2.OL SOHC Engines

g See Figures 159, 160, and 161

1. Position the engine so the No. 1 piston is at

TDC of the compression stroke.

2. Disconnect the negative battery cable.

3. Remove the engine undercover.

4. Using the proper equipment, slightly raise

the engine to take the weight off the side engine

mount. Remove the engine mount bracket.

5. Remove the drive belts, tension pulley brack-

ets, water pump pulley and crankshaft pulley.

6. Remove all attaching screws and remove the

upper and lower timing belt covers.

7. Remove the timing belt covers.

8. Remove the outer crankshaft sprocket and

flange.

9. Remove the silent shaft (inner) belt tensioner

and remove the belt.

Page 100 of 408

.

ENGlNEANDENGlliEOVERHAUL 3-39

To install: IO. Align the timing marks of the silent shaft

sprockets and the crankshaft sprocket with the timing

marks on the front case.

11. Wrap the timing belt around the sprockets so

there is no slack in the upper span of the belt and the

timing marks are still aligned.

12. Install the tensioner pulley and move the pul-

ley by hand so the long side of the belt deflects about

l/d in. (6mm).

13. Hold the pulley tightly so the pulley cannot

rotate when the bolt is tightened. Tighten the bolt to

15 ft. Ibs. (20 Nm) and recheck the deflection

amount.

14. Install the timing belt tensioner fully toward

the water pump and tighten the bolts. Place the upper

end of the spring against the water pump body.

15. Align the timing marks of the camshaft,

crankshaft and oil pump sprockets with their corre-

sponding marks on the front case or rear cover.

*There is a possibility to align all timing

marks and have the oil pump sprocket and

silent shaft out of time, causing an engine vi-

bration during operation. If the following step

is not followed exactly, there is a 50 percent

chance that the silent shaft alignment will be

180 degrees off.

16. Before installing the timing belt, ensure that

the left side (rear) silent shaft (oil pump sprocket) is

in the correct position as follows:

a. Remove the plug from the rear side of the

block and insert a tool with shaft diameter of

0.31 in. (8mm) into the hole.

b. With the timing marks still aligned, the

shaft of the tool must be able to go in at least

2’13 in. (59mm). If the tool can only go in about

1 in. (25mm), the shaft is not in the correct ori-

entation and will cause a vibration during engine

operation. Remove the tool from the hole and

turn the oil pump sprocket 1 complete revolution.

Realign the timing marks and insert the tool. The

shaft of the tool must go in at least 21/3 in.

(59mm).

c. Recheck and realign the timing marks.

d. Leave the tool in place to hold the silent

shaft while continuing

17. Install the belt to the crankshaft sprocket, oil

pump sprocket, then camshaft sprocket, in that order.

While doing so, make sure there is no slack between

the sprocket except where the tensioner is installed.

18. Recheck the timing marks’alignment. If all

are aligned, loosen the tensioner mounting bolt and

allow the tensioner to apply tension to the belt.

E

91251gbl

Fig. 180 Silent shaft sprocket alignment

marks for belt replacement-l.81 and 2.OL

SOHC engines

19. Remove the tool that is holding the silent

shaft and rotate the crankshaft a distance equal to 2

teeth on the camshaft sprocket. This will allow the

tensioner to automatically apply the proper tension

on the belt. Do not manually overtighten the belt or it

will howl.

20. Tighten the lower mounting bolt first, then the

upper spacer bolt.

21. To verify correct belt tension, check that the

deflection at the longest span of the belt is about 1/2

in. (13mm).

22. The installation of the timing belt covers and

all related items, is the reverse of the removal proce-

dure. Make sure all pieces of packing are positioned

in the inner grooves of the covers when installing.

23. Connect the negative battery cable.

2.OL (Turbo) OOHC Engine

ti See Figures 162 and 163

1. Disconnect the negative battery cable.

2. Remove the engine undercover.

3. Remove the engine mount bracket.

4. Remove the drive belts.

5. Remove the belt tensioner pulley.

6. Remove the water pump pulleys.

7. Remove the crankshaft pulley.

8. Remove the stud bolt from the engine sup-

port bracket and remove the timing belt covers.

9. Rotate the crankshaft clockwise to line up the

camshaft timing marks. Always turn the crankshaft in

the normal direction of rotation only.

10. Loosen the tension pulley center bolt.

*If the timing belt is to be reused, mark the

direction of rotation on the flat side of the

belt with an arrow.

11. Move the tension pulley towards the water

pump and remove the timing belt.

12. Remove the crankshaft sprocket center bolt

using special tool MB9g67 to hold the crankshaft

sprocket while removing the center bolt. Then, use

MB998778 or equivalent puller to remove the

sprocket.

13. Mark the direction of rotation on the timing

belt B with a arrow.

14. Loosen the center bolt on the tensioner and

remove the belt.

00 not rotate the camshafts or the crankshafl

while the timing belt is removed.

/--- PLUG

91251gb2 Fig. 161 Checking the rear silent shafl for

jroper positioning-1.8L and 2.OL SOHC

Pnoines

To Install:

15. Place the crankshaft sprocket on the crank-

shaft. Use tool MB9g67 or equivalent to hold the

crankshaft sprocket while tightening the center bolt.

Tighten the center bolt to 80-94 ft. Ibs. (108-127

Nm).

16. Align the timing marks on the crankshaft

sprocket B and the balance shaft.

17. Install timing belt B on the sprockets. Posi-

tion the center of the tensioner pulley to the left and

above the center of the mounting bolt.

18. Push the pulley clockwise toward the crank-

shaft to apply tension to the belt and tighten the

mounting bolt to 14ft. Ibs. (19 Nm) Do not let the

pulley turn when tightening the bolt because it will

cause excessive tension on the belt. The belt should

deflect 0.20-0.28 in. (5-7mm) when finger pressure

is applied between the pulleys.

19. Install the crankshaft sensing blade and the

crankshaft sprocket. Apply engine oil to the mounting

bolt and tighten the bolt to 80-94 ft. Ibs. (108-127

Nm).

20. Use a press or vise to compress the auto-ten-

sioner pushrod, Insert a set pin when the holes are

lined up.

Tming marks Cylinder had

I top surface

Ti

m

Crank&aft

sprocket

79235g60 :ig. 162 Camshaft and crankshaft timing

lelt sprocket TOC alignment mark position-

ng for timing belt removal and installa-

ion- 2.OL turbo engine